Adsorption of Organic Constituents from Reverse Osmosis Concentrate in Coal Chemical Industry by Coking Coal

Abstract

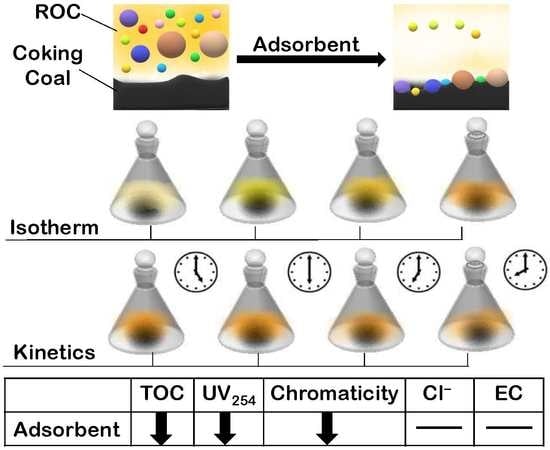

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Effect of Adsorbent Dosage

2.3. Adsorption Isotherm Experiments

2.4. Adsorption Kinetics Experiments

2.5. Analytical Methods

3. Results and Discussion

3.1. Effect of Adsorbent Dosage

3.2. Adsorption Isotherms

3.3. Adsorption Kinetics

3.4. BET Test

3.5. FTIR and XPS Analysis

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Sun, Y.X.; Gao, Y.; Hu, H.Y.; Tang, F.; Yang, Z. Characterization and biotoxicity assessment of dissolved organic matter in RO concentrate from a municipal wastewater reclamation reverse osmosis system. Chemosphere 2014, 117, 545–551. [Google Scholar] [CrossRef] [PubMed]

- Jia, S.H.; Ma, Z.; Qin, J.; Si, H.S.; Toh, C.S. Inline coagulation–ultrafiltration as the pretreatment for reverse osmosis brine treatment and recovery. Desalination 2015, 365, 242–249. [Google Scholar]

- Jiang, C.; Wang, Y.; Zhang, Z.; Xu, T. Electrodialysis of concentrated brine from RO plant to produce coarse salt and freshwater. J. Membr. Sci. 2014, 450, 323–330. [Google Scholar] [CrossRef]

- Sanmartino, J.A.; Khayet, M.; García-Payo, M.C.; El-Bakouri, H.; Riaza, A. Treatment of reverse osmosis brine by direct contact membrane distillation: Chemical pretreatment approach. Desalination 2017, 420, 79–90. [Google Scholar] [CrossRef]

- Maeng, S.K.; Khan, W.; Park, J.W.; Han, I.; Yang, H.S.; Song, K.G.; Choi, W.J.; Kim, S.; Woo, H.; Kim, H.C. Treatment of highly saline RO concentrate using Scenedesmus quadricauda for enhanced removal of refractory organic matter. Desalination 2018, 430, 128–135. [Google Scholar] [CrossRef]

- Lu, J.; Fan, L.; Roddick, F.A. Potential of BAC combined with UVC/H2O2 for reducing organic matter from highly saline reverse osmosis concentrate produced from municipal wastewater reclamation. Chemosphere 2013, 93, 683–688. [Google Scholar] [CrossRef]

- Yang, Y.; Pignatello, J.J.; Ma, J.; Mitch, W.A. Effect of matrix components on UV/H2O2 and UV/S2O82− advanced oxidation processes for trace organic degradation in reverse osmosis brines from municipal wastewater reuse facilities. Water Res. 2016, 89, 192–200. [Google Scholar] [CrossRef] [PubMed]

- Wang, W. Characterisation and removal of organic matter from a reverse osmosis concentrate by a PAC accumulative countercurrent four-stage adsorption-MF hybrid process. Sep. Purif. Technol. 2017, 189, 425–432. [Google Scholar] [CrossRef]

- Simate, G.S.; Maledi, N.; Ochieng, A.; Ndlovu, S.; Zhang, J.; Walubita, L.F. Coal-based adsorbents for water and wastewater treatment. J. Environ. Chem. Eng. 2016, 4, 2291–2312. [Google Scholar] [CrossRef]

- Karanfil, T. Role of Granular Activated Carbon Surface Chemistry on the Adsorption of Organic Compounds. 1. Priority Pollutants. Environ. Sci. Technol. 1999, 33, 3217–3224. [Google Scholar] [CrossRef]

- Zeledon-Toruno, Z.C.; Lao-Luque, C.; de las Heras, F.X.C.; Sole-Sardans, M. Removal of PAHs from water using an immature coal (leonardite). Chemosphere 2007, 67, 505–512. [Google Scholar] [CrossRef] [PubMed]

- Liu, G.Q.; Sui, J.H.; Zhang, H.; Wu, B.C.; Li, Y.Z. Adsorption mechanism of RO concentrate by peanut shell activated carbon. Environ. Chem. 2012, 31, 862–868. [Google Scholar]

- Yang, J.; Wang, J.B.; Wang, Y.H.; Zhang, F.Y. Treatment of reverse osmosis concentrate from coal chemical industry with advanced oxidation process. Chin. J. Environ. Eng. 2015, 9, 3680–3686. [Google Scholar]

- Ning, K.J.; Wang, J.F.; Xu, H.X.; Sun, X.F.; Huang, G.; Liu, G.W.; Zhou, L.M. Effects and mechanistic aspects of absorbing organic compounds by coking coal. Water Sci. Technol. J. Int. Assoc. Water Pollut. Res. 2017, 9, 76. [Google Scholar] [CrossRef] [PubMed]

- Li, P.; Ailijiang, N.; Cao, X.; Lei, T.; Liang, P.; Zhang, X.; Huang, X.; Teng, J. Pretreatment of coal gasification wastewater by adsorption using activated carbons and activated coke. Colloids Surf. A Physicochem. Eng. Asp. 2015, 482, 177–183. [Google Scholar] [CrossRef]

- Chetima, A.; Wahabou, A.; Zomegni, G.; Ntieche Rahman, A.; Bup Nde, D. Bleaching of Neutral Cotton Seed Oil Using Organic Activated Carbon in a Batch System: Kinetics and Adsorption Isotherms. Processes 2018, 6, 22. [Google Scholar] [CrossRef]

- Kyzas, G.; Christodoulou, E.; Bikiaris, D. Basic Dye Removal with Sorption onto Low-Cost Natural Textile Fibers. Processes 2018, 6, 166. [Google Scholar] [CrossRef]

- Yuliani, G.; Garnier, G.; Chaffee, A.L. Utilization of raw and dried Victorian brown coal in the adsorption of model dyes from solution. J. Water Process Eng. 2017, 15, 43–48. [Google Scholar] [CrossRef]

- Goswami, S.; Pant, H.J.; Ambade, R.N.; Paul, B.; Varshney, L.; Dash, A. Study of adsorption characteristics of Au(III) onto coal particles and their application as radiotracer in a coal gasifier. Appl. Radiat. Isotopes 2017, 122, 127–135. [Google Scholar] [CrossRef]

- Yang, X.; Yi, H.H.; Tang, X.L.; Zhao, S.Z.; Yang, Z.Y.; Ma, Y.Q.; Feng, T.C.; Cui, X.X. Behaviors and kinetics of toluene adsorption-desorption on activated carbons with varying pore structure. J. Environ. Sci. 2017, 5, 67. [Google Scholar] [CrossRef]

- Zhu, J.F.; Liu, J.Z.; Yang, Y.M.; Cheng, J.; Zhou, J.H.; Cen, K.F. Fractal characteristics of pore structures in 13 coal specimens: Relationship among fractal dimension, pore structure parameter, and slurry ability of coal. Fuel Process. Technol. 2016, 149, 256–267. [Google Scholar] [CrossRef]

- Ji, X.Q.; Yao, H.F.; Li, W. FTIR spectroscopic study on tectonically deformed coals in Hancheng mining area. J. China Coal Soc. 2016, 41, 2050–2056. [Google Scholar]

- Xu, B.; Chen, L.; Xing, B.; Li, Z.; Zhang, L.; Yi, G.; Huang, G.; Mohanty, M.K. Physicochemical properties of Hebi semi-coke from underground coal gasification and its adsorption for phenol. Process Saf. Environ. Prot. 2017, 107, 147–152. [Google Scholar] [CrossRef]

- Tao, G.; Zhang, M.X.; Ma, X.M. XPS and FTIR Spectroscopy Characterization about the Structure of Coking Coal in Xinyang. Spectrosc. Spectr. Anal. 2017, 37, 2406–2411. [Google Scholar]

- Chen, S.; Tang, L.; Tao, X.; Chen, L.; Yang, Z.; Li, L. Effect of oxidation processing on the surface properties and floatability of Meizhiyou long-flame coal. Fuel 2017, 210, 177–186. [Google Scholar] [CrossRef]

| Parameter | Specific Surface Area (m2·g−1) | Adsorption Average Pore Size (nm) | Surface Area Average Particle Size (μm) | Proximate Analysis | |||

|---|---|---|---|---|---|---|---|

| Mad (%) | Aad (%) | Vad (%) | FCad (%) | ||||

| Coal | 2.794 | 11.189 | 6.488 | 0.2 | 6.85 | 30.78 | 62.18 |

| Parameter | TOC (mg·L−1) | UV254 (Abs) | Chromaticity (mg Pt-Co L−1) | Cl− (mg·L−1) | EC (mg·L−1) |

|---|---|---|---|---|---|

| ROC | 330 | 9.32 | 1243 | 23,342.76 | 86,200 |

| Model | Freundlich | Langmuir | ||||

|---|---|---|---|---|---|---|

| parameter | KF | 1/n | R2 | qm | R2 | |

| TOC | 0.0459 | 0.933 | 0.9945 | 24.527 | 0.002 | 0.9997 |

| UV254 | 0.286 | 0.693 | 0.9748 | 1.067 | 0.450 | 0.9995 |

| Chromaticity | 1.910 | 0.644 | 0.9710 | 112.360 | 0.006 | 0.9960 |

| Pseudo-First-Order | Pseudo-Second-Order | ||||||

|---|---|---|---|---|---|---|---|

| parameter | measurements | K1 | R2 | fitted value | K2 | R2 | fitted value |

| TOC | 3.7 | 0.0096 | 0.9298 | 1.4980 | 0.0138 | 0.9997 | 3.7037 |

| UV254 | 0.668 | 0.0069 | 0.9573 | 0.6318 | 0.0868 | 0.9998 | 0.6680 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, H.; Qin, Q.; Zhang, C.; Ning, K.; Zhao, R.; Wang, P.; Deng, J.; Huang, G. Adsorption of Organic Constituents from Reverse Osmosis Concentrate in Coal Chemical Industry by Coking Coal. Processes 2019, 7, 44. https://doi.org/10.3390/pr7010044

Xu H, Qin Q, Zhang C, Ning K, Zhao R, Wang P, Deng J, Huang G. Adsorption of Organic Constituents from Reverse Osmosis Concentrate in Coal Chemical Industry by Coking Coal. Processes. 2019; 7(1):44. https://doi.org/10.3390/pr7010044

Chicago/Turabian StyleXu, Hongxiang, Qizheng Qin, Changfeng Zhang, Kejia Ning, Rong Zhao, Penghui Wang, Jiushuai Deng, and Gen Huang. 2019. "Adsorption of Organic Constituents from Reverse Osmosis Concentrate in Coal Chemical Industry by Coking Coal" Processes 7, no. 1: 44. https://doi.org/10.3390/pr7010044

APA StyleXu, H., Qin, Q., Zhang, C., Ning, K., Zhao, R., Wang, P., Deng, J., & Huang, G. (2019). Adsorption of Organic Constituents from Reverse Osmosis Concentrate in Coal Chemical Industry by Coking Coal. Processes, 7(1), 44. https://doi.org/10.3390/pr7010044