Sustainable Design and Engineering: A Relationship Analysis between Digital Destructive and Non-Destructive Testing Process for Lightweight Concrete

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Cement

2.1.2. Fine Aggregate

2.1.3. Coarse Aggregate

2.1.4. Expanded Polystyrene Beads

2.2. Batching, Mixing and Preparation of Test Specimens

2.3. Testing Methodology

2.3.1. Ultrasonic Pulse Velocity Test

- L = Travel Path Length (m), T = transit (µs), V = Pulse velocity (km/s)

- µ = Poisson Ratio

- V = pulse velocity (m/s)

- ρ =Density of concrete (kg/m3)

- Ed = Dynamic modulus of elasticity (GPa)

2.3.2. Rebound Hammer Test

2.3.3. Compressive Strength Test

3. Results and Discussion

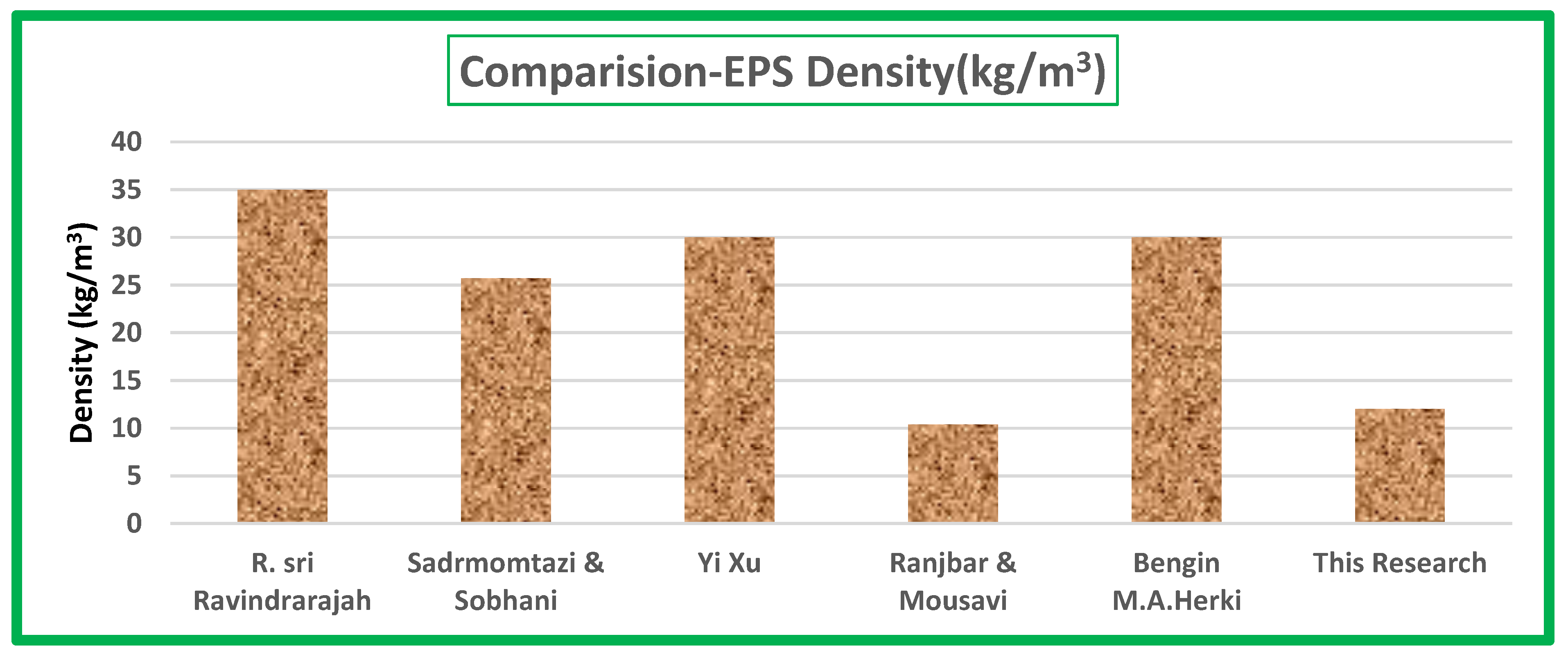

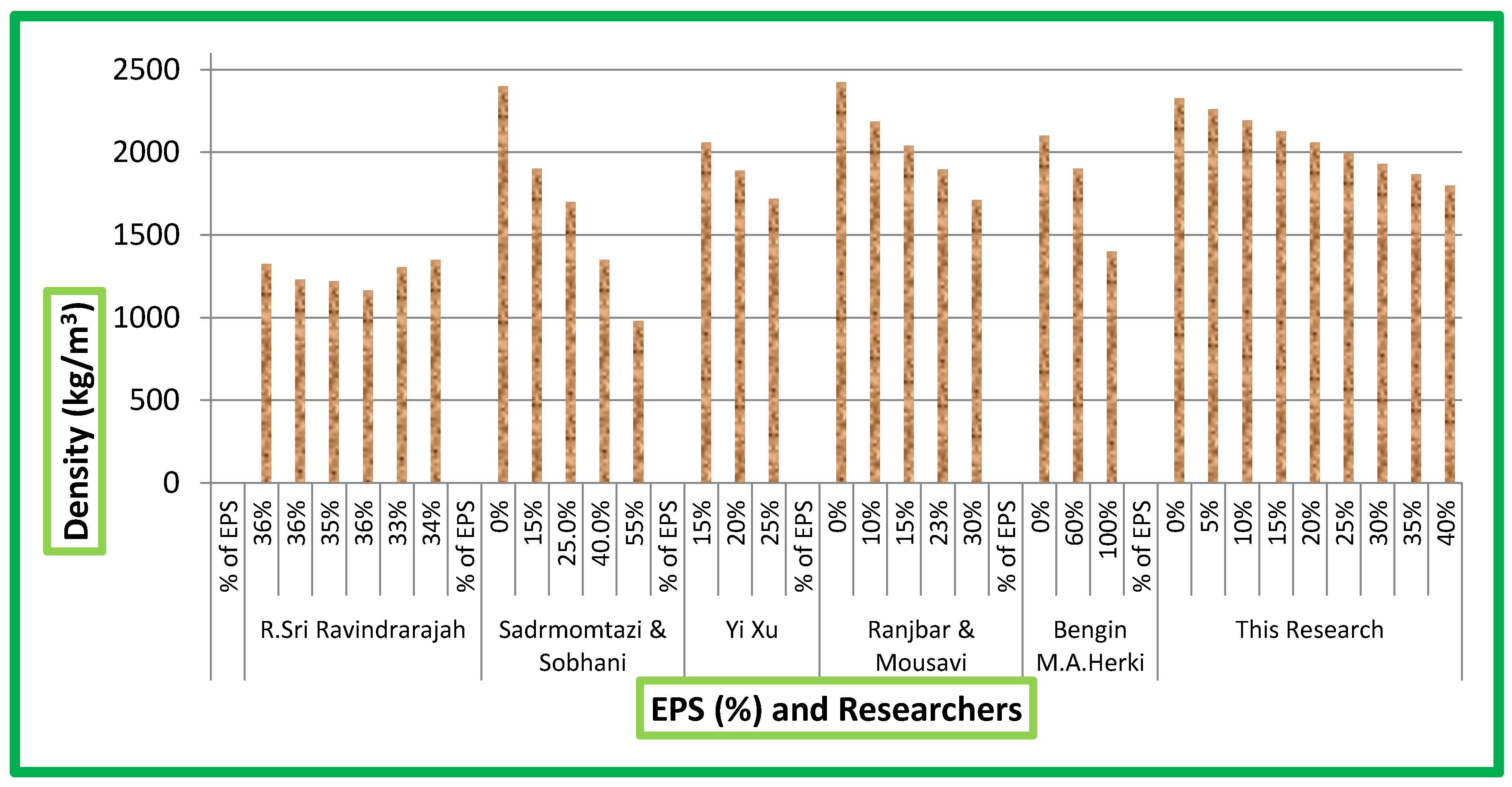

3.1. Effect of EPS Beads on Density

3.2. Effect of EPS Beads on U.P.Velocity

3.3. % Beads vs. Compressive Strength

- (1)

- The first factor may be the lack of a natural coarse aggregate in the concrete because the concrete mixes containing coarse aggregate showed a variation in strength and density.

- (2)

- The replacement of natural aggregates with EPS-beads and the resulting increase in the surface area of fine particles, which can lead to the weakening of interfacial transition zones (ITZ) between the aggregates and the cement paste.

- (3)

- It is observed that full compaction was difficult to achieve with the EPS-beads concrete mixes. Due to this entrapped air content and voids are increased as the volume of EPS-beads (%) is increased. Due to compaction reasons, strength is decreased.

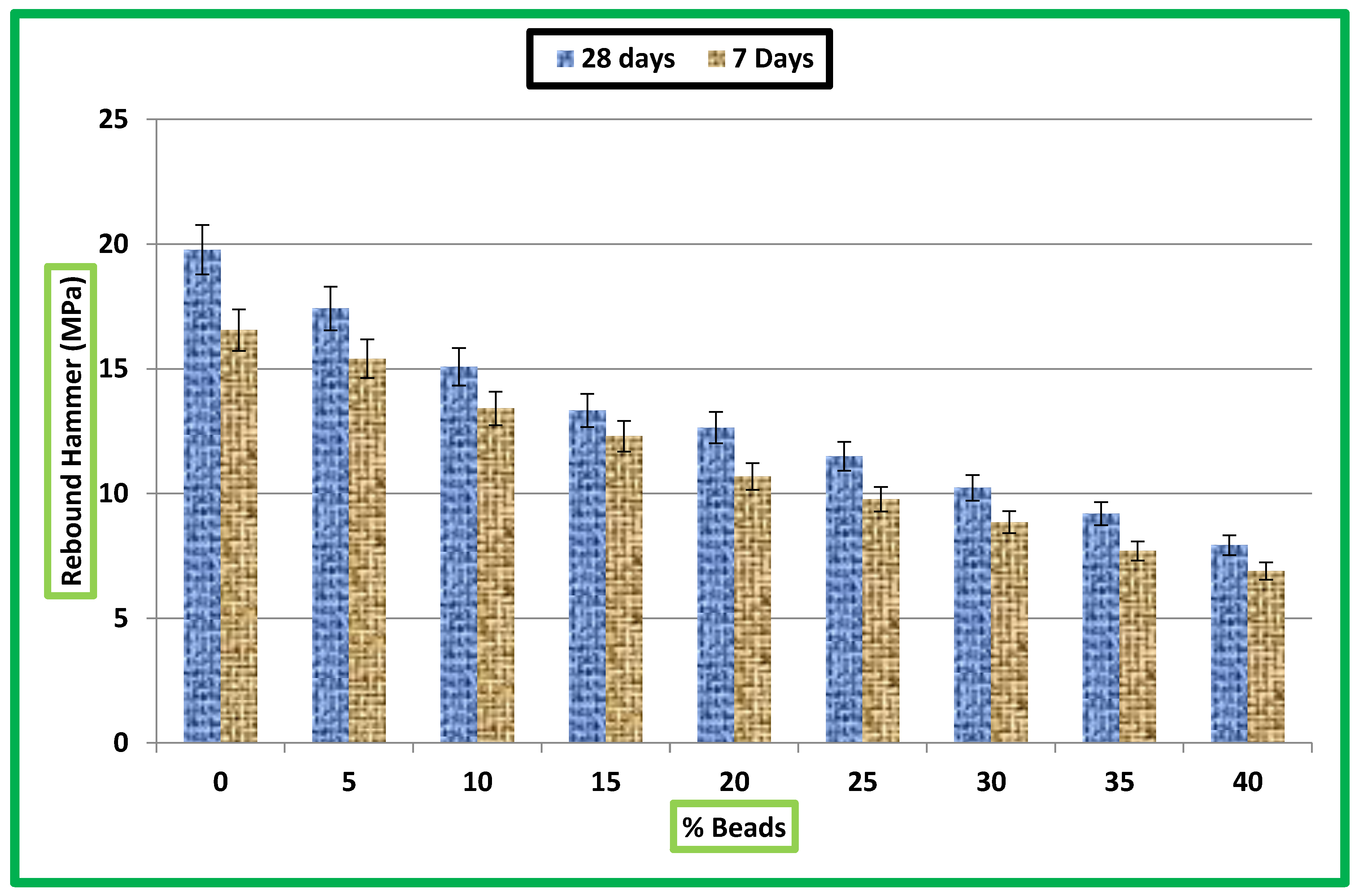

3.4. By Rebound Hammer

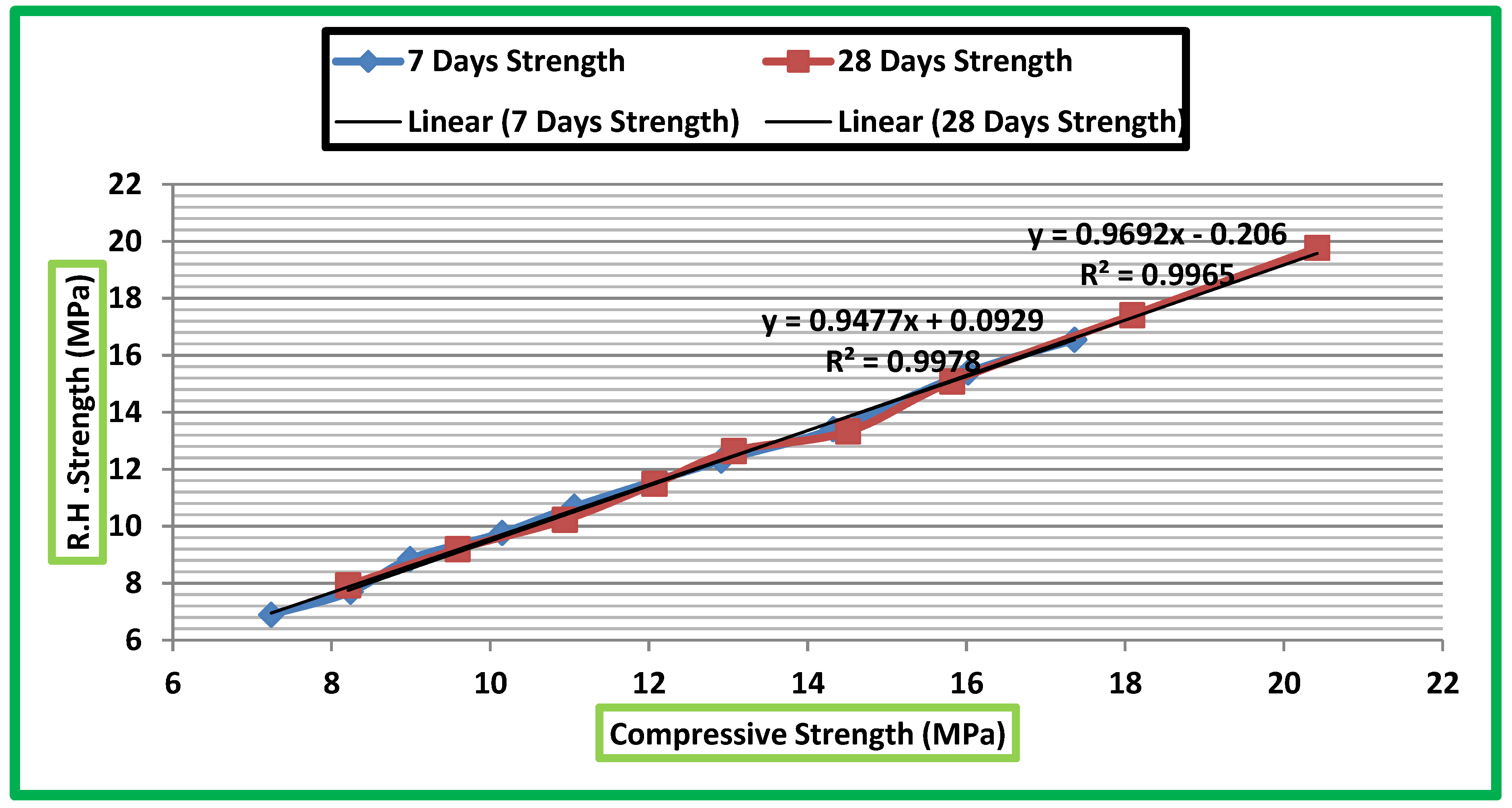

3.5. Analysis of Destructive and Non-Destructive Values

3.6. Pulse Velocity vs. Compressive Strength

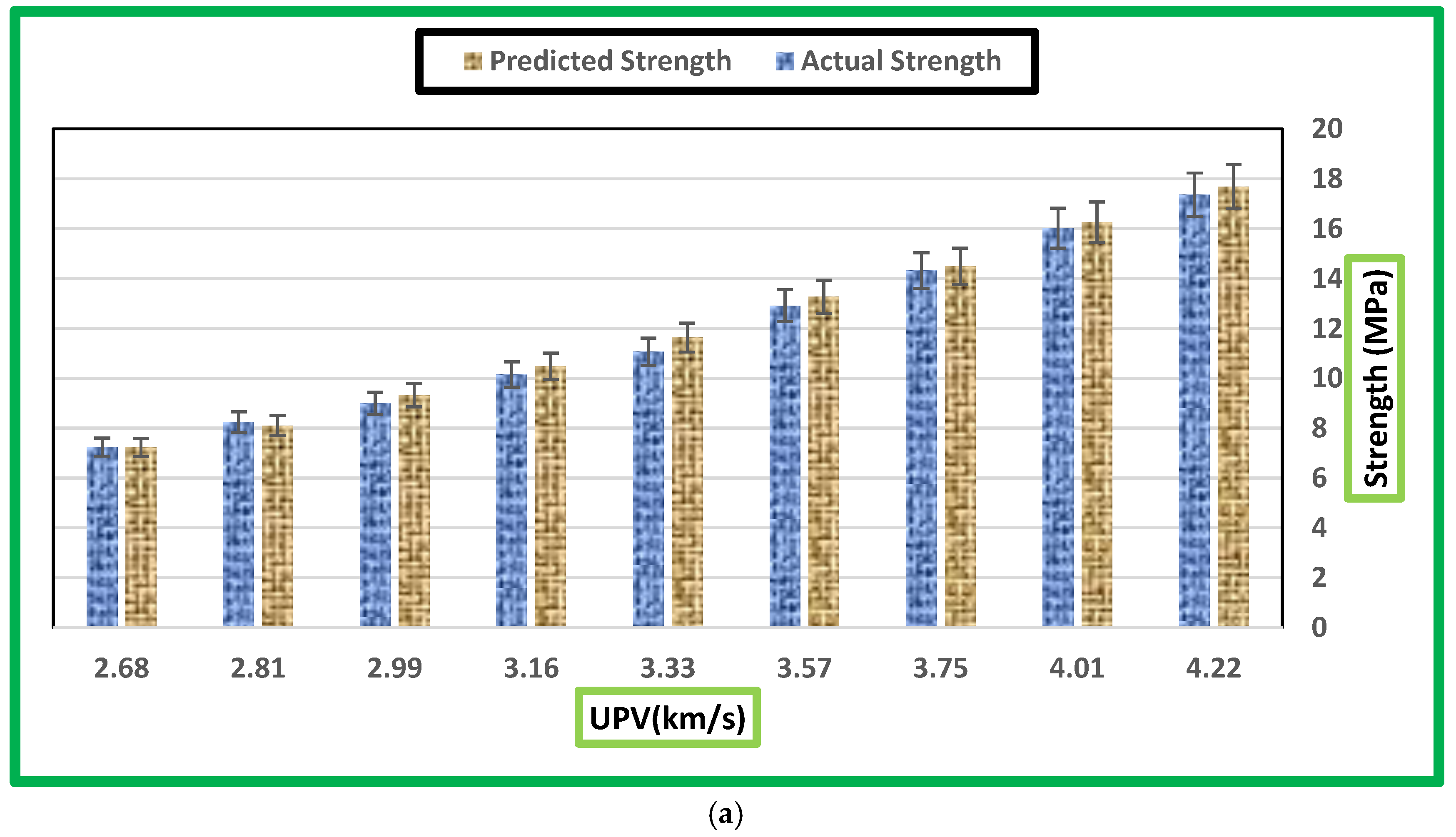

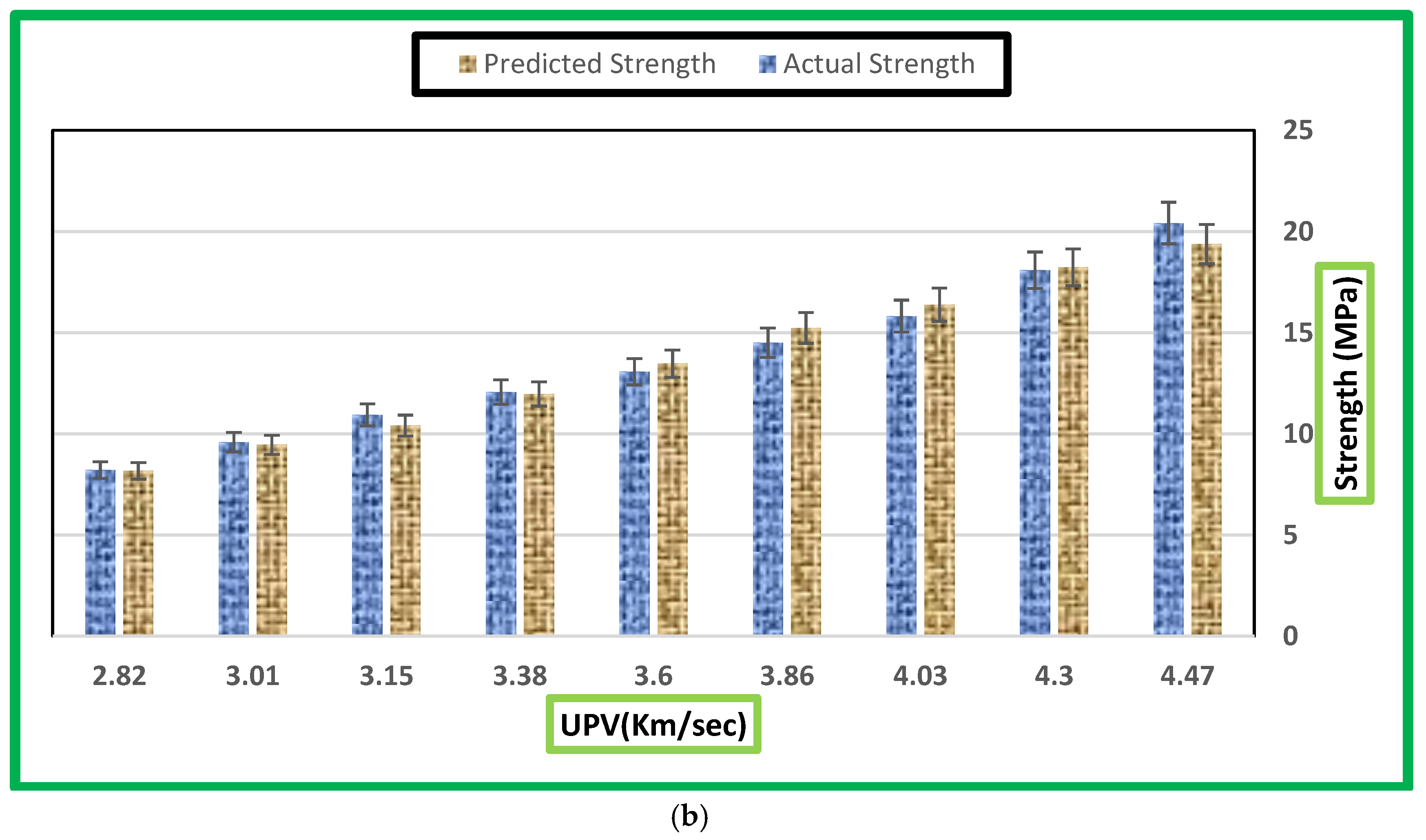

3.7. Predicted Strength from UPV Results by Regression Analysis

- x = Avg Pulse velocity (km/s)

- y = Compressive strength of concrete cylinder (MPa)

3.8. Effect of Beads vs. Dynamic Modulus of Elasticity

3.9. Effect of UPV vs. Ed

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Schackow, A.; Effting, C.; Folgueras, M.V.; Güths, S.; Mendes, G.A. Mechanical and thermal properties of lightweight concretes with vermiculite and EPS using air-entraining agent. Constr. Build. Mater. 2014, 57, 190–197. [Google Scholar] [CrossRef]

- Herki, B. Combined Effects of Densified Polystyrene and Unprocessed Fly Ash on Concrete Engineering Properties. Buildings 2017, 7, 77. [Google Scholar] [CrossRef]

- Kaplan, G.; Yaprak, H.; Memiş, S.; Alnkaa, A. Artificial Neural Network Estimation of the Effect of Varying Curing Conditions and Cement Type on Hardened Concrete Properties. Buildings 2019, 9, 10. [Google Scholar] [CrossRef]

- Kuhail, Z.; Shihada, S. Mechanical properties of polystyrene-lightweight concrete. IUG J. Nat. Stud. 2015, 11, 93–114. [Google Scholar]

- Ismail, I.; Saim, A.A.; Saleh, A.L. Properties of Hardened Concrete Bricks Containing Expanded Polystyrene Beads; Universiti Teknologi Malaysia: Johor, Malaysia, 2003. [Google Scholar]

- Xu, Y.; Jiang, L.; Xu, J.; Li, Y. Mechanical properties of expanded polystyrene lightweight aggregate concrete and brick. Constr. Build. Mater. 2012, 27, 32–38. [Google Scholar] [CrossRef]

- Ghahari, S.; Mohammadi, A.; Ramezanianpour, A. Performance assessment of natural pozzolan roller compacted concrete pavements. Case Stud. Constr. Mater. 2017, 7, 82–90. [Google Scholar] [CrossRef]

- Yasar, E.; Duran Atis, C.; Kilic, A.; Gulsen, H. Strength properties of lightweight concrete made with basaltic pumice and fly ash. Mater. Lett. 2003, 57, 2267–2270. [Google Scholar] [CrossRef]

- Alshihri, M.M.; Azmy, A.M.; El-Bisy, M.S. Neural networks for predicting compressive strength of structural light weight concrete. Constr. Build. Mater. 2009, 23, 2214–2219. [Google Scholar] [CrossRef]

- Babu, D.S.; Babu, K.G.; Tiong-Huan, W. Effect of polystyrene aggregate size on strength and moisture migration characteristics of lightweight concrete. Cem. Concr. Compos. 2006, 28, 520–527. [Google Scholar] [CrossRef]

- Chen, B.; Liu, J. Contribution of hybrid fibers on the properties of the high-strength lightweight concrete having good workability. Cem. Concr. Res. 2005, 35, 913–917. [Google Scholar] [CrossRef]

- Chia, K.S.; Zhang, M.-H. Water permeability and chloride penetrability of high-strength lightweight aggregate concrete. Cem. Concr. Res. 2002, 32, 639–645. [Google Scholar] [CrossRef]

- Kitouni, S.; Houari, H. Lightweight concrete with Algerian limestone dust. Part. II: Study on 50% and 100% replacement to normal aggregate at timely age. Cerâmica 2015, 61, 462–468. [Google Scholar]

- Tanyildizi, H. Statistical analysis for mechanical properties of polypropylene fiber reinforced lightweight concrete containing silica fume exposed to high temperature. Mater. Des. 2009, 30, 3252–3258. [Google Scholar] [CrossRef]

- Mohammed, J.H.; Hamad, A.J. Materials, properties and application review of Lightweight concrete. Tech. Rev. Fac. Eng. Univ. Zulia 2014, 37, 10–15. [Google Scholar]

- Ferrándiz-Mas, V.; García-Alcocel, E. Durability of expanded polystyrene mortars. Constr. Build. Mater. 2013, 46, 175–182. [Google Scholar] [CrossRef] [Green Version]

- Sayadi, A.A.; Tapia, J.V.; Neitzert, T.R.; Clifton, G.C. Effects of expanded polystyrene (EPS) particles on fire resistance, thermal conductivity and compressive strength of foamed concrete. Constr. Build. Mater. 2016, 112, 716–724. [Google Scholar] [CrossRef]

- Ayse, K.; Filiz, K. Properties of concrete containing waste expanded polystyrene and natural resin. Constr. Build. Mater. 2016, 105, 572–578. [Google Scholar]

- Miled, K.; Le Roy, R.; Sab, K.; Boulay, C. Compressive behavior of an idealized EPS lightweight concrete: Size effects and failure mode. Mech. Mater. 2004, 36, 1031–1046. [Google Scholar] [CrossRef]

- Liu, N.; Chen, B. Experimental study of the influence of EPS particle size on the mechanical properties of EPS lightweight concrete. Constr. Build. Mater. 2014, 68, 227–232. [Google Scholar] [CrossRef]

- Ferrándiz-Mas, V.; Bond, T.; Garcia-Alcocel, E.; Cheeseman, C.R. Lightweight mortars containing expanded polystyrene and paper sludge ash. Constr. Build. Mater. 2014, 61, 285–292. [Google Scholar] [CrossRef] [Green Version]

- Tang, W.; Lo, Y.; Nadeem, A. Mechanical and drying shrinkage properties of structural-graded polystyrene aggregate concrete. Cem. Concr. Compos. 2008, 30, 403–409. [Google Scholar] [CrossRef]

- Vakhshouri, B.; Nejadi, S. Review on the mixture design and mechanical properties of the lightweight concrete containing expanded polystyrene beads. Aust. J. Struct. Eng. 2018, 19, 1–23. [Google Scholar] [CrossRef]

- Lakshmikandhan, K.N.; Harshavardhan, B.S.; Prabakar, J.; Saibabu, S. Investigation on Wall Panel Sandwiched With Lightweight Concrete. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2017. [Google Scholar]

- Ghahari, S.; Ramezanianpour, A.M.; Ramezanianpour, A.A.; Esmaeili, M. An accelerated test method of simultaneous carbonation and chloride ion ingress: Durability of silica fume concrete in severe environments. Adv. Mater. Sci. Eng. 2016, 2016. [Google Scholar] [CrossRef]

- Hu, J.; Ren, J.; Wu, D. Dynamic Mechanical Properties of EPS Concrete Under Impact Loading. J. Shanghai Jiaotong Univ. Sci. 2019, 24, 94–100. [Google Scholar] [CrossRef]

- Khademi, F.; Akbari, M.; Jamal, S.M. Predictia Rezistentei La Compresiune A Betonului Prin Testare Upv (Ultrasonic Pulse Velocity) Si Modelare Cu Retele Neuronale Artificiale/Prediction of Concrete Compressive Strength Using Ultrasonic Pulse Velocity Test. and Artificial Neural Network Modeling. Rev. Romana Mater. 2016, 46, 343. [Google Scholar]

- Dahiru, D. Relationship between ultrasonic pulse velocity test result and concrete cube strength. ATBU J. Environ. Technol. 2016, 9, 13–25. [Google Scholar]

- Pavlik, V. Corrosion of hardened cement paste by acetic and nitric acids part I: Calculation of corrosion depth. Cem. Concr. Res. 1994, 24, 551–562. [Google Scholar] [CrossRef]

- Shetty, M. Concrete Technology; S. Chand & Company LTD.: Ram Nagar, New Delhi, 2005; pp. 420–453. [Google Scholar]

- Sanchez, K.; Tarranza, N. Reliability of rebound hammer test in concrete compressive strength estimation. Int. J. Adv. Agric. Environ. Eng. IJAAEE 2014, 1, 198–202. [Google Scholar]

- Adenot, F.; Buil, M. Modelling of the corrosion of the cement paste by deionized water. Cem. Concr. Res. 1992, 22, 489–496. [Google Scholar] [CrossRef]

- Revie, R.W. Corrosion and Corrosion Control: An Introduction to Corrosion Science and Engineering; John Wiley & Sons: Hoboken, NJ, USA, 2008. [Google Scholar]

- Azreen, M.; Pauzi, I.M.; Nasharuddin, I.; Haniza, M.M.; Akasyah, J.; Karsono, A.D.; Yen Lei, V. Prediction of concrete compression strength using ultrasonic pulse velocity. In AIP Conference Proceedings; AIP Publishing: College Park, MD, USA, 2016. [Google Scholar]

- Bertolini, L.; Elsener, B.; Pedeferri, P.; Redaelli, E.; Polder, R. Corrosion of Steel in Concrete; Wiley Online Library: Weinheim, Germany, 2013. [Google Scholar]

- American Society for Testing and Materials. ASTM C150-07 Standard Specification for Portland Cement; American Society for Testing and Materials: West Conshohocken, PA, USA, 2007. [Google Scholar]

- Demirboga, R.; Kan, A. Thermal conductivity and shrinkage properties of modified waste polystyrene aggregate concretes. Constr. Build. Mater. 2012, 35, 730–734. [Google Scholar] [CrossRef]

- Choi, N.; Ohama, Y. Development and testing of polystyrene mortars using waste EPS solution-based binders. Constr. Build. Mater. 2004, 18, 235–241. [Google Scholar] [CrossRef]

- Allahverdi, A.; Azimi, S.A.; Alibabaie, M. Development of multi-strength grade green lightweight reactive powder concrete using expanded polystyrene beads. Constr. Build. Mater. 2018, 172, 457–467. [Google Scholar] [CrossRef]

- Chen, B.; Liu, J. Properties of lightweight expanded polystyrene concrete reinforced with steel fiber. Cem. Concr. Res. 2004, 34, 1259–1263. [Google Scholar] [CrossRef]

- American Society for Testing and Materials. ASTM 578–C06 Standard Specification for Rigid, Cellular Polystyrene Thermal Insulation; American Society for Testing and Materials: West Conshohocken, PA, USA, 2006. [Google Scholar]

- Altun, F.; Kişi, Ö.; Aydin, K. Predicting the compressive strength of steel fiber added lightweight concrete using neural network. Comput. Mater. Sci. 2008, 42, 259–265. [Google Scholar] [CrossRef]

- Babu, K.G.; Babu, D.S. Behaviour of lightweight expanded polystyrene concrete containing silica fume. Cem. Concr. Res. 2003, 33, 755–762. [Google Scholar] [CrossRef]

- Ravindrarajah, R.S. Strength evaluation of high-strength concrete by ultrasonic pulse velocity method. NDT E Int. 1997, 4, 261. [Google Scholar]

- Galan, A. Estimate of concrete strength by ultrasonic pulse velocity and damping constant. J. Proc. 1967, 64, 678–684. [Google Scholar]

- Solis-Carcaño, R.; Moreno, E.I. Evaluation of concrete made with crushed limestone aggregate based on ultrasonic pulse velocity. Constr. Build. Mater. 2008, 22, 1225–1231. [Google Scholar] [CrossRef]

- Davis, A.; Ansari, F.; Gaynor, R.D.; Lozen, K.M.; Rowe, T.J.; Caratin, H.; Heidbrink, F.D.; Malhotra, V.M.; Simons, B.P.; Carino, N.J.; et al. Nondestructive Test Methods for Evaluation of Concrete in Structures; American Concrete Institute (ACI): Farmington Hills, MI, USA, 1998. [Google Scholar]

- Sansalone, M.J.; Streett, W.B. Impact-Echo. Nondestructive Evaluation of Concrete and Masonry; Bullbrier Press: Jersey Shore, PA, USA, 1997. [Google Scholar]

- Price, W.F.; Hynes, J. In-situ strength testing of high strength concrete. Mag. Concr. Res. 1996, 48, 189–197. [Google Scholar] [CrossRef]

- Nazarian, S.; Baker, M.; Crain, K. Assessing quality of concrete with wave propagation techniques. Mater. J. 1997, 94, 296–305. [Google Scholar]

- Al-Nu’man, B.S.; Aziz, B.R.; Abdulla, S.A.; Khaleel, S.E. Compressive Strength Formula for Concrete using Ultrasonic Pulse Velocity. Int. J. Eng. Trends Technol. IJETT 2015, 26, 8–13. [Google Scholar]

- American Society for Testing and Materials. ASTM C597, Standard Test Method for Pulse Velocity through Concrete; American Society for Testing and Materials: West Conshohocken, PA, USA, 2009. [Google Scholar]

- Al-Amawee, A.H.; Salman, M.M. The Ratio between Static and Dynamic Modulusof Elasticity in Normal and High. Strength Concrete. J. Eng. Sustain. Dev. 2006, 10, 163–174. [Google Scholar]

- I.E.A.E-T.C.S. No. 17. Guidebook on Non-Destructive Testing of Concrete Structures; Int. Atomic Energy Agency: Vienna, Austria, 2002. [Google Scholar]

- Jones, R.; Fącąoaru, I. Recommendations for testing concrete by the ultrasonic pulse method. Matér. Constr. 1969, 2, 275–284. [Google Scholar] [CrossRef]

- Liu, J.-C.; Sue, M.-L.; Kou, C.-H. Estimating the strength of concrete using surface rebound value and design parameters of concrete material. Tamkang J. Sci. Eng. 2009, 12, 1–7. [Google Scholar]

- Sannidha, V. Health Monitoring Of Structures. Master’s Thesis, College of Engineering, Visakhapatham, India, 2008. [Google Scholar]

- American Society for Testing and Materials. ASTM C 39-96 Standard Test. Method for Compressive Strength of Cylindrical Concrete Specimens; Annual Book of ASTM Standards; American Society for Testing and Materials: West Conshohocken, PA, USA, 1996. [Google Scholar]

- Ravindrarajah, R.S.; Tuck, A. Properties of hardened concrete containing treated expanded polystyrene beads. Cem. Concr. Compos. 1994, 16, 273–277. [Google Scholar] [CrossRef]

- Sadrmomtazi, A.; Sobhani, J.; Mirgozar, M.A.; Najimi, M. Properties of multi-strength grade EPS concrete containing silica fume and rice husk ash. Constr. Build. Mater. 2012, 35, 211–219. [Google Scholar] [CrossRef]

- Ranjbar, M.M.; Mousavi, S.Y. Strength and durability assessment of self-compacted lightweight concrete containing expanded polystyrene. Mater. Struct. 2015, 48, 1001–1011. [Google Scholar] [CrossRef]

- Bogas, J.A.; Gomes, M.G.; Gomes, A. Compressive strength evaluation of structural lightweight concrete by non-destructive ultrasonic pulse velocity method. Ultrasonics 2013, 53, 962–972. [Google Scholar] [CrossRef]

| LOI | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 | K2O | Na2O |

|---|---|---|---|---|---|---|---|---|

| 3.41 | 20.16 | 4.40 | 3.68 | 63.30 | 2.91 | 2.61 | 0.94 | 0.21 |

| Property | Result | Standard |

|---|---|---|

| Normal Consistency (%) | 30 | ASTM C-187 |

| Fineness% | 95 | ASTM C 184 |

| Initial Setting Time(mints) | 145 | ASTM C-191 |

| Final Setting Time(mints) | 220 | ASTM C-191 |

| Soundness(mm) | 1 | ASTM C-189 |

| Property | Result | Standard |

|---|---|---|

| Fineness Modulus | 2.23 | ASTM C-136 |

| Bulk Density (kg/m3) | 1527 | ASTM C-29 |

| Physical Properties | ||

|---|---|---|

| Property | Result | Standards |

| Bulk Density (kg/m3) | 1487 | ASTM C-29 |

| Aggregate Impact value (%) | 20.45 | BS812: Part 3 |

| Aggregate Crushing Value (%) | 26.50 | BS812: Part 3 |

| Los Angeles abrasion (%) | 32 | ASTM: C131 |

| Water Absorption (%) | 4.9 | ASTM C-127 |

| Physical Property | Unit | Classification | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Type XI | Type I | Type VIII | Type XII | Type X | Type II | Type IV | Type IX | Type VI | Type VII | Type V | ||

| Density, min | kg/m3 | 12 | 15 | 18 | 19 | 21 | 22 | 26 | 29 | 29 | 35 | 48 |

| Compressive Resistance at Yield, min | KPa | 35 | 69 | 90 | 104 | 104 | 104 | 173 | 173 | 276 | 414 | 690 |

| Flexural Strength, min | KPa | 70 | 173 | 208 | 276 | 276 | 276 | 345 | 345 | 414 | 517 | 690 |

| Water Absorption by Total Immersion, max | volume% | 4 | 4 | 3 | 0.3 | 0.3 | 3 | 0.3 | 2 | 0.3 | 0.3 | 0.3 |

| Mix ID | EPSB-0 | EPSB-5 | EPSB-10 | EPSB-15 | EPSB-20 | EPSB-25 | EPSB-30 | EPSB-35 | EPSB-40 | |

|---|---|---|---|---|---|---|---|---|---|---|

| W/C Ratio | 0.60 | 0.60 | 0.60 | 0.60 | 0.60 | 0.60 | 0.60 | 0.60 | 0.60 |  |

| Repl. of Beads (%) | 0 | 5 | 10 | 15 | 20 | 25 | 30 | 35 | 40 |  |

| Cement (kg/m3) | 320 | 320 | 320 | 320 | 320 | 320 | 320 | 320 | 320 |  |

| Fine Agg. (kg/m) | 680 | 680 | 680 | 680 | 680 | 680 | 680 | 680 | 680 |  |

| Coarse Agg. kg/m3) | 1326 | 1259 | 1192 | 1126 | 1059 | 995 | 926 | 862 | 795 |  |

| EPS Beads (kg/m3) | 0 | 0.53 | 1.07 | 1.6 | 2.14 | 2.67 | 3.21 | 3.74 | 4.27 |  |

| Water (kg/m3) | 192 | 192 | 192 | 192 | 192 | 192 | 192 | 192 | 192 |  |

| Mix ID | Beads | Density | Compressive Strength | Compressive Strength |

|---|---|---|---|---|

| Unit | (%) | (kg/m3) | 7 Days (MPa) | 28 Days (MPa) |

| EPSB-0 | 0 | 2326 | 17.36 | 20.42 |

| EPSB-5 | 5 | 2260 | 16.02 | 18.09 |

| EPSB-10 | 10 | 2194 | 14.32 | 15.82 |

| EPSB-15 | 15 | 2128 | 12.91 | 14.51 |

| EPSB-20 | 20 | 2060 | 11.06 | 13.07 |

| EPSB-25 | 25 | 1997 | 10.15 | 12.07 |

| EPSB-30 | 30 | 1930 | 8.99 | 10.94 |

| EPSB-35 | 35 | 1866 | 8.24 | 9.59 |

| EPSB-40 | 40 | 1800 | 7.24 | 8.21 |

| Mix ID | Beads | Density | Compressive Strength | Compressive Strength |

|---|---|---|---|---|

| Unit | (%) | (kg/m3) | 7 Days (MPa) | 28 Days (MPa) |

| EPSB-0 | 0 | 2326 | 16.55 | 19.77 |

| EPSB-5 | 5 | 2260 | 15.4 | 17.41 |

| EPSB-10 | 10 | 2194 | 13.41 | 15.08 |

| EPSB-15 | 15 | 2128 | 12.3 | 13.33 |

| EPSB-20 | 20 | 2060 | 10.69 | 12.64 |

| EPSB-25 | 25 | 1997 | 9.77 | 11.49 |

| EPSB-30 | 30 | 1930 | 8.85 | 10.23 |

| EPSB-35 | 35 | 1866 | 7.7 | 9.2 |

| EPSB-40 | 40 | 1800 | 6.9 | 7.93 |

| Mix ID | Beads | Density | % Difference | % Difference |

|---|---|---|---|---|

| Unit | (%) | (kg/m3) | 7 Days | 28 Days |

| EPSB-0 | 0 | 2326 | −4.67 | −3.18 |

| EPSB-5 | 5 | 2260 | −3.87 | −3.75 |

| EPSB-10 | 10 | 2194 | −6.35 | −4.67 |

| EPSB-15 | 15 | 2128 | −4.72 | −8.13 |

| EPSB-20 | 20 | 2060 | −3.34 | −3.28 |

| EPSB-25 | 25 | 1997 | −3.74 | −4.80 |

| EPSB-30 | 30 | 1930 | −1.55 | −6.48 |

| EPSB-35 | 35 | 1866 | −6.55 | −4.06 |

| EPSB-40 | 40 | 1800 | −4.69 | −3.41 |

| Mix ID | Beads | Avg Velocity 7 days | Predicted Strength | Destructive (C.S) | Difference |

|---|---|---|---|---|---|

| Units | (%) | km/s | 7 Days (MPa) | 7 Days (MPa) | % |

| EPSB-0 | 0 | 4.22 | 17.68 | 17.36 | 1.84 |

| EPSB-5 | 5 | 4.01 | 16.26 | 16.02 | 1.5 |

| EPSB-10 | 10 | 3.75 | 14.49 | 14.32 | 1.19 |

| EPSB-15 | 15 | 3.57 | 13.27 | 12.91 | 2.79 |

| EPSB-20 | 20 | 3.33 | 11.63 | 11.06 | 5.15 |

| EPSB-25 | 25 | 3.16 | 10.48 | 10.15 | 3.25 |

| EPSB-30 | 30 | 2.99 | 9.32 | 8.99 | 3.67 |

| EPSB-35 | 35 | 2.81 | 8.1 | 8.24 | −1.7 |

| EPSB-40 | 40 | 2.68 | 7.22 | 7.24 | −0.28 |

| Mix ID | Beads | Avg Velocity 28 days | Predicted Strength | Destructive (C.S) | Difference |

|---|---|---|---|---|---|

| Unit | (%) | km/s | 28 Days (MPa) | 28 Days (MPa) | % |

| EPSB-0 | 0 | 4.47 | 19.38 | 20.42 | −5.09 |

| EPSB-5 | 5 | 4.3 | 18.23 | 18.09 | 0.77 |

| EPSB-10 | 10 | 4.03 | 16.39 | 15.82 | 3.6 |

| EPSB-15 | 15 | 3.86 | 15.24 | 14.51 | 5.03 |

| EPSB-20 | 20 | 3.6 | 13.47 | 13.07 | 3.06 |

| EPSB-25 | 25 | 3.38 | 11.97 | 12.07 | −0.83 |

| EPSB-30 | 30 | 3.15 | 10.41 | 10.94 | −4.84 |

| EPSB-35 | 35 | 3.01 | 9.46 | 9.59 | −1.36 |

| EPSB-40 | 40 | 2.82 | 8.17 | 8.21 | −0.49 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qurashi, M.A.; Shah, S.A.R.; Farhan, M.; Taufiq, M.; Khalid, W.; Arshad, H.; Tayyab, M.; Shahzadi, G.; Waseem, M. Sustainable Design and Engineering: A Relationship Analysis between Digital Destructive and Non-Destructive Testing Process for Lightweight Concrete. Processes 2019, 7, 791. https://doi.org/10.3390/pr7110791

Qurashi MA, Shah SAR, Farhan M, Taufiq M, Khalid W, Arshad H, Tayyab M, Shahzadi G, Waseem M. Sustainable Design and Engineering: A Relationship Analysis between Digital Destructive and Non-Destructive Testing Process for Lightweight Concrete. Processes. 2019; 7(11):791. https://doi.org/10.3390/pr7110791

Chicago/Turabian StyleQurashi, Muhammad Ahmed, Syyed Adnan Raheel Shah, Muhammad Farhan, Muhammad Taufiq, Waleed Khalid, Hunain Arshad, Muhammad Tayyab, Gullnaz Shahzadi, and Muhammad Waseem. 2019. "Sustainable Design and Engineering: A Relationship Analysis between Digital Destructive and Non-Destructive Testing Process for Lightweight Concrete" Processes 7, no. 11: 791. https://doi.org/10.3390/pr7110791