Quality Properties and Pyrolysis Characteristics of Cassava Rhizome Pellets Produced by Alternating between Pelletizing and Torrefaction

Abstract

1. Introduction

2. Experimental Procedure and Analysis

2.1. Raw Materials

2.2. Pellets of Raw Cassava Rhizome (P-RC)

2.3. Pellets of Torrefied Cassava Rhizome Followed by Pelletizing (P-TC)

2.4. Pellets of Pelletized Cassava Rhizome Followed by Torrefaction (T-CP)

2.5. Properties of P-RC, P-TC, and T-CP

2.6. Pyrolysis Characteristics

3. Result and Discussion

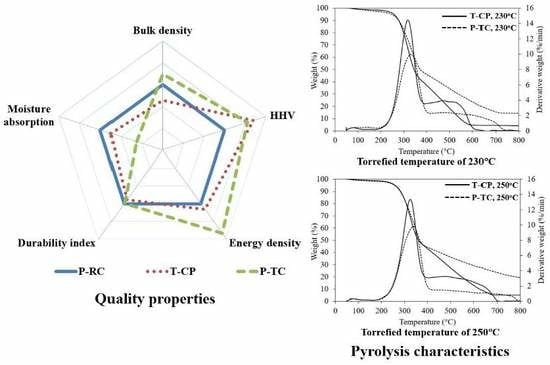

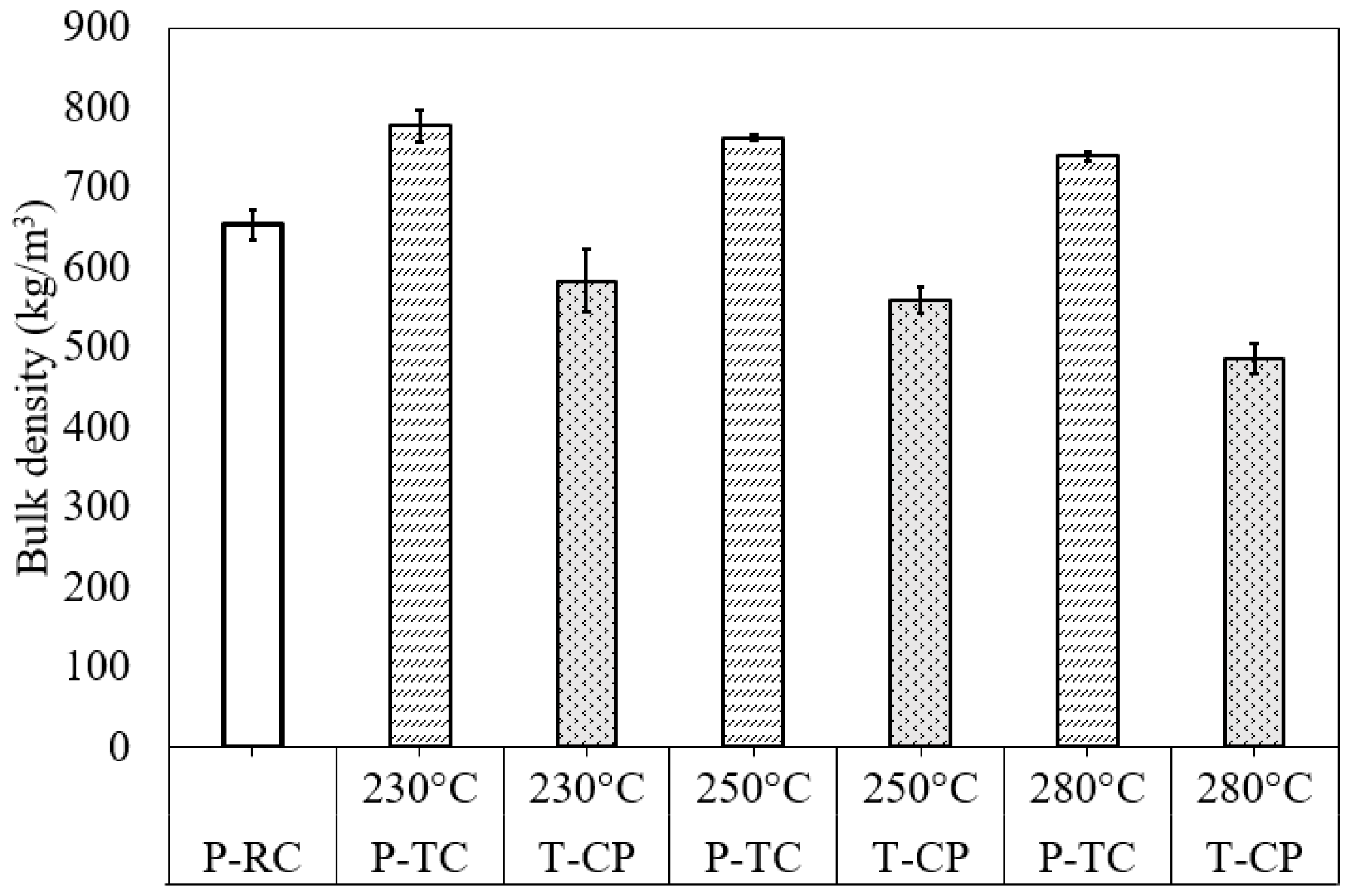

3.1. Bulk Density

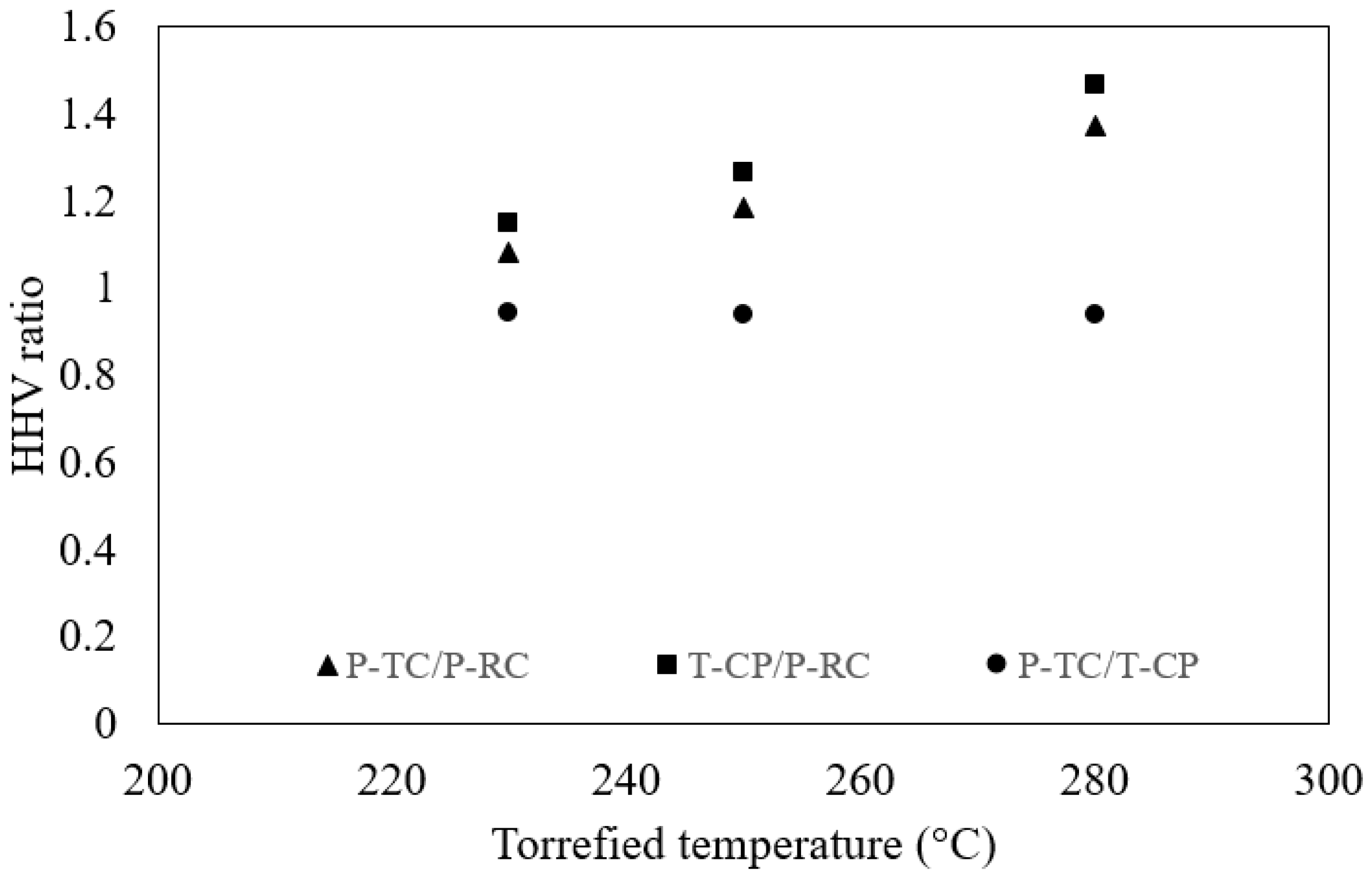

3.2. Higher Heating Value

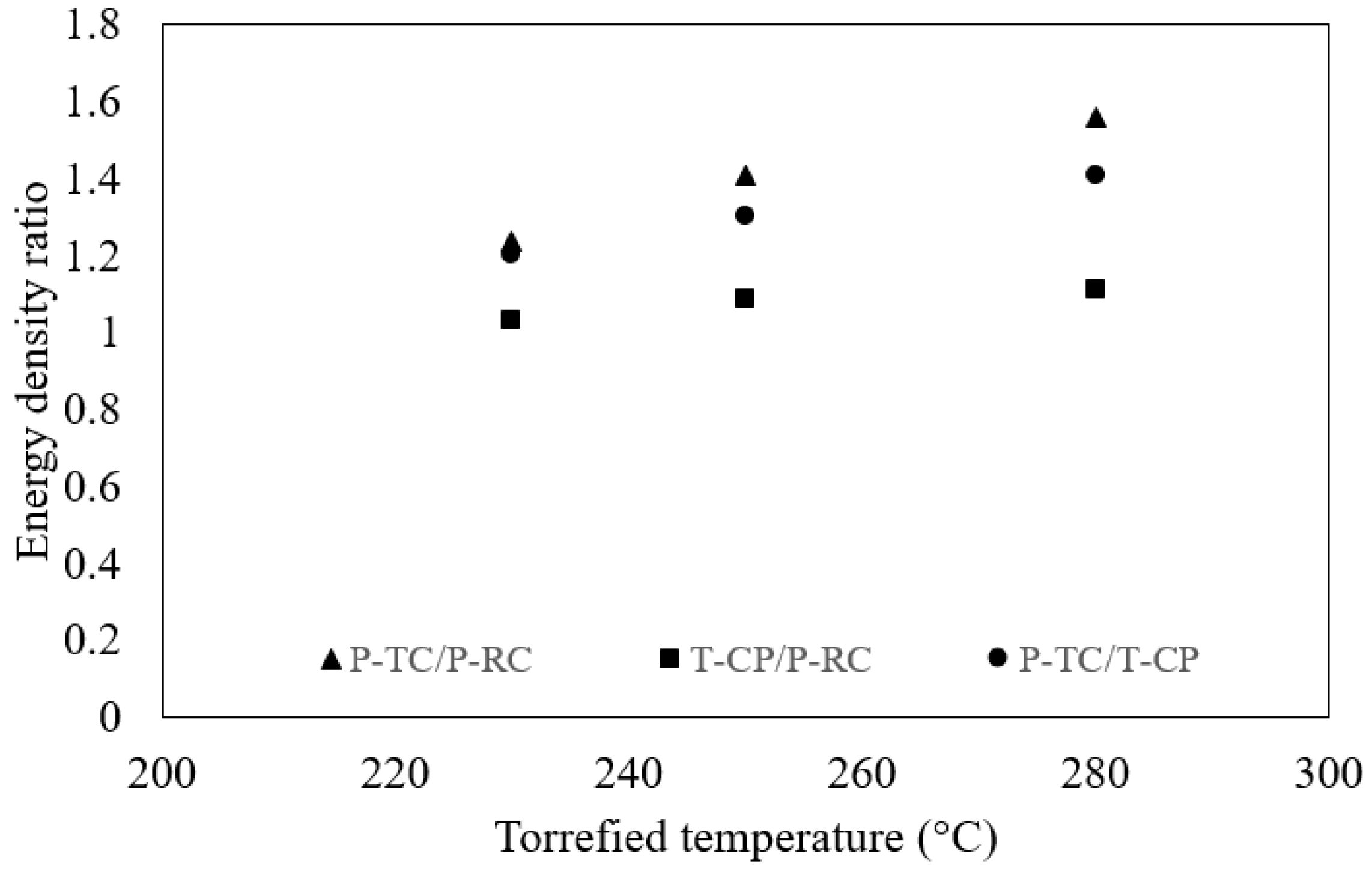

3.3. Energy Density and Durability Index

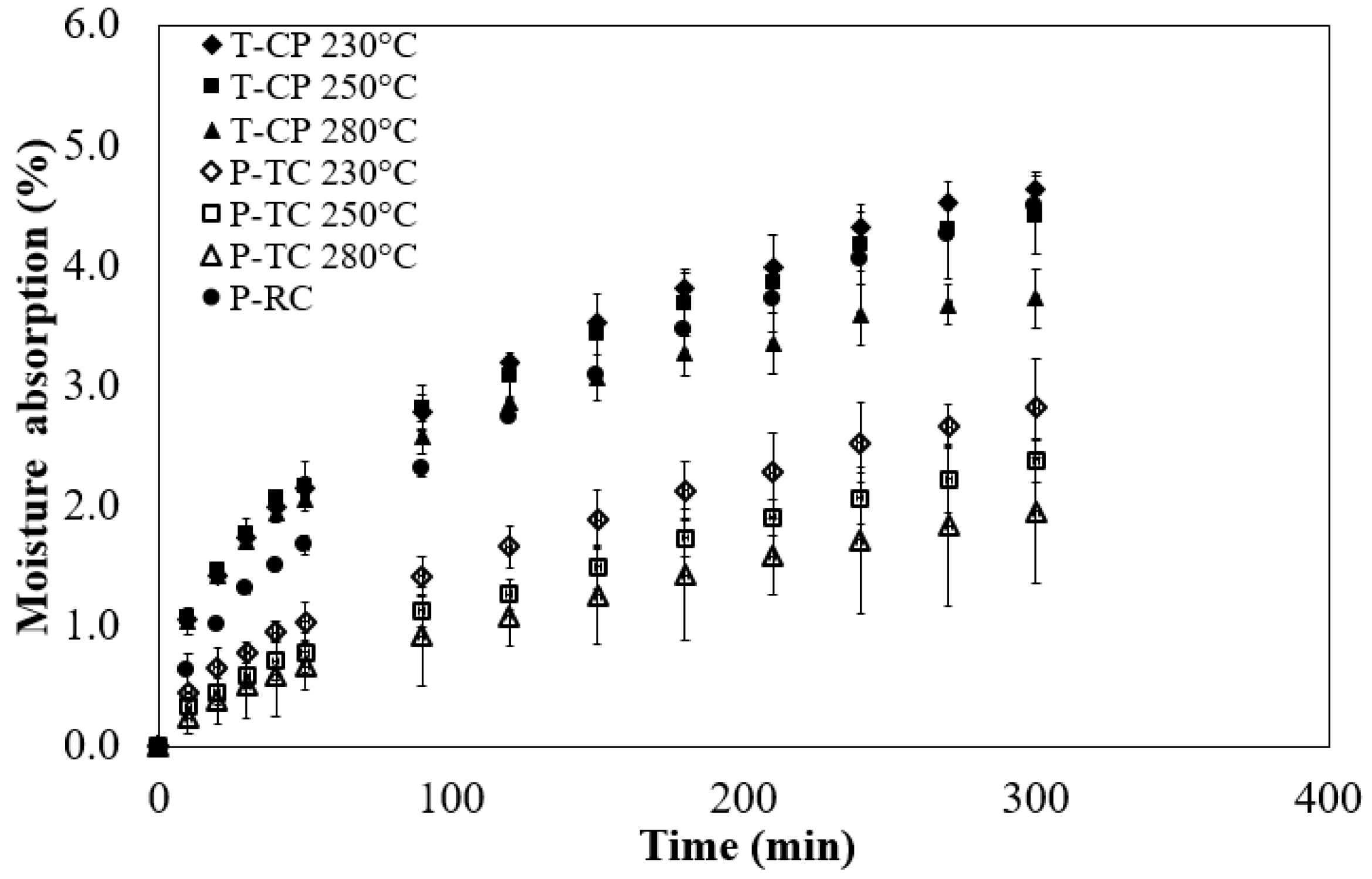

3.4. Moisture Absorption

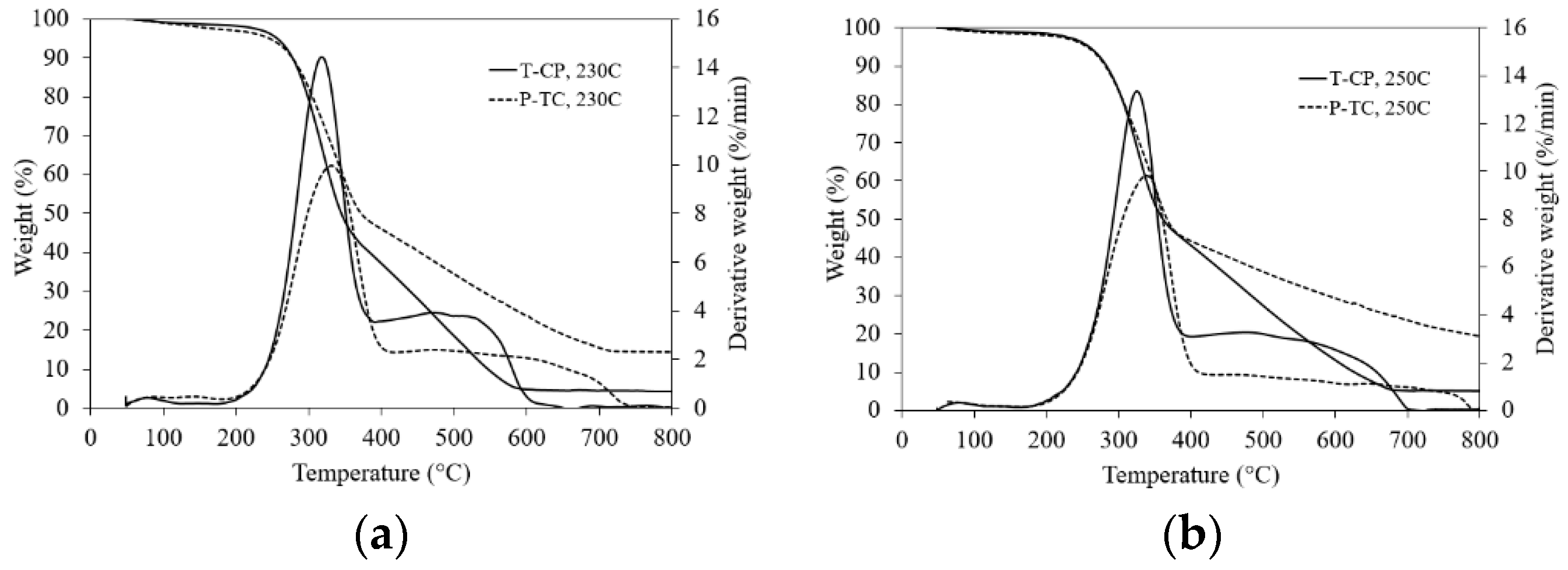

3.5. Pyrolysis Characteristics

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Crawford, N.C.; Ray, A.E.; Yancey, N.A.; Nagle, N. Evaluating the pelletization of “pure” and blended lignocellulosic biomass feedstocks. Fuel Process. Technol. 2015, 140, 46–56. [Google Scholar] [CrossRef]

- Soleimani, M.; Tabil, X.L.; Grewal, R.; Tabil, L.G. Carbohydrates as binders in biomass densification for biochemical and thermochemical processes. Fuel 2017, 193, 134–141. [Google Scholar] [CrossRef]

- Rhén, C.; Öhman, M.; Gref, R.; Wästerlund, I. Effect of raw material composition in woody biomass pellets on combustion characteristics. Biomass Bioenergy 2007, 31, 66–72. [Google Scholar] [CrossRef]

- Theerarattananoon, K.; Xu, F.; Wilson, J.; Ballard, R.; Mckinney, L.; Staggenborg, S.; Vadlani, P.; Pei, Z.J.; Wang, D. Physical properties of pellets made from sorghum stalk, corn stover, wheat straw, and big bluestem. Ind. Crop. Prod. 2011, 33, 325–332. [Google Scholar] [CrossRef]

- Zamorano, M.; Popov, V.; Rodríguez, M.L.; García-Maraver, A. A comparative study of quality properties of pelletized agricultural and forestry lopping residues. Renew. Energy 2011, 36, 3133–3140. [Google Scholar] [CrossRef]

- Gil, M.V.; Oulego, P.; Casal, M.D.; Pevida, C.; Pis, J.J.; Rubiera, F. Mechanical durability and combustion characteristics of pellets from biomass blends. Bioresour. Technol. 2010, 101, 8859–8867. [Google Scholar] [CrossRef] [PubMed]

- Nilsson, D.; Bernesson, S.; Hansson, P.-A. Pellet production from agricultural raw materials—A systems study. Biomass Bioenergy 2011, 35, 679–689. [Google Scholar] [CrossRef]

- Rudolfsson, M.; Borén, E.; Pommer, L.; Nordin, A.; Lestander, T.A. Combined effects of torrefaction and pelletization parameters on the quality of pellets produced from torrefied biomass. Appl. Energy 2017, 191, 414–424. [Google Scholar] [CrossRef]

- Prins, M.J.; Ptasinski, K.J.; Janssen, F.J.J.G. Torrefaction of wood: Part 2. Analysis of products. J. Anal. Appl. Pyrolysis 2006, 77, 35–40. [Google Scholar] [CrossRef]

- Chen, W.-H.; Hsu, H.-C.; Lu, K.-M.; Lee, W.-J.; Lin, T.-C. Thermal pretreatment of wood (Lauan) block by torrefaction and its influence on the properties of the biomass. Energy 2011, 36, 3012–3021. [Google Scholar] [CrossRef]

- Wang, G.; Luo, Y.; Deng, J.; Kuang, J.; Zhang, Y. Pretreatment of biomass by torrefaction. Chin. Sci. Bull. 2011, 56, 1442–1448. [Google Scholar] [CrossRef]

- Wannapeera, J.; Fungtammasan, B.; Worasuwannarak, N. Effects of temperature and holding time during torrefaction on the pyrolysis behaviors of woody biomass. J. Anal. Appl. Pyrolysis 2011, 92, 99–105. [Google Scholar] [CrossRef]

- Medic, D.; Darr, M.; Shah, A.; Potter, B.; Zimmerman, J. Effects of torrefaction process parameters on biomass feedstock upgrading. Fuel 2012, 91, 147–154. [Google Scholar] [CrossRef]

- Bridgeman, T.G.; Jones, J.M.; Shield, I.; Williams, P.T. Torrefaction of reed canary grass, wheat straw and willow to enhance solid fuel qualities and combustion properties. Fuel 2008, 87, 844–856. [Google Scholar] [CrossRef]

- Martín-Lara, M.A.; Ronda, A.; Zamora, M.C.; Calero, M. Torrefaction of olive tree pruning: Effect of operating conditions on solid product properties. Fuel 2017, 202, 109–117. [Google Scholar] [CrossRef]

- Bach, Q.-V.; Chen, W.-H.; Lin, S.-C.; Sheen, H.-K.; Chang, J.-S. Wet torrefaction of microalga Chlorella vulgaris ESP-31 with microwave-assisted heating. Energy Convers. Manag. 2017, 141, 163–170. [Google Scholar] [CrossRef]

- Li, H.; Liu, X.; Legros, R.; Bi, X.T.; Jim Lim, C.; Sokhansanj, S. Pelletization of torrefied sawdust and properties of torrefied pellets. Appl. Energy 2012, 93, 680–685. [Google Scholar] [CrossRef]

- Shankar Tumuluru, J.; Sokhansanj, S.; Hess, J.R.; Wright, C.T.; Boardman, R.D. A review on biomass torrefaction process and product properties for energy applications. Ind. Biotechnol. 2011, 7, 384–401. [Google Scholar] [CrossRef]

- Ghiasi, B.; Kumar, L.; Furubayashi, T.; Lim, C.J.; Bi, X.; Kim, C.S.; Sokhansanj, S. Densified biocoal from woodchips: Is it better to do torrefaction before or after densification? Appl. Energy 2014, 134, 133–142. [Google Scholar] [CrossRef]

- Lam, P.S.; Sokhansanj, S.; Bi, X.; Lim, C.J.; Melin, S. Energy Input and Quality of Pellets Made from Steam-Explode Douglas Fir (Pseudotsuga menziesii). Energy Fuel 2011, 25, 1521–1528. [Google Scholar] [CrossRef]

- Larsson, S.H.; Rudolfsson, M.; Nordwaeger, M.; Olofsson, I.; Samuelsson, R. Effects of moisture content, torrefaction temperature, and die temperature in pilot scale pelletizing of torrefied Norway spruce. Appl. Energy 2013, 102, 827–832. [Google Scholar] [CrossRef]

- Stelte, W.; Clemons, C.; Holm, J.K.; Sanadi, A.R.; Ahrenfeldt, J.; Shang, L.; Henriksen, U.B. Pelletizing properties of torrefied spruce. Biomass Bioenergy 2011, 35, 4690–4698. [Google Scholar] [CrossRef]

- Stelte, W.; Nielsen, N.P.K.; Hansen, H.O.; Dahl, J.; Shang, L.; Sanadi, A.R. Pelletizing properties of torrefied wheat straw. Biomass Bioenergy 2013, 49, 214–221. [Google Scholar] [CrossRef]

- Peng, J.; Wang, J.; Bi, X.T.; Lim, C.J.; Sokhansanj, S.; Peng, H.; Jia, D. Effects of thermal treatment on energy density and hardness of torrefied wood pellets. Fuel Process. Technol. 2015, 129, 168–173. [Google Scholar] [CrossRef]

- Shang, L.; Nielsen, N.P.K.; Dahl, J.; Stelte, W.; Ahrenfeldt, J.; Holm, J.K.; Thomsen, T.; Henriksen, U.B. Quality effects caused by torrefaction of pellets made from Scots pine. Fuel Process. Technol. 2012, 101, 23–28. [Google Scholar] [CrossRef]

- Chen, W.-H.; Zhuang, Y.-Q.; Liu, S.-H.; Juang, T.-T.; Tsai, C.-M. Product characteristics from the torrefaction of oil palm fiber pellets in inert and oxidative atmospheres. Bioresour. Technol. 2016, 199, 367–374. [Google Scholar] [CrossRef] [PubMed]

- PFI-Standard-Specification-November-2011.pdf n.d. Available online: https://www.pelletheat.org/assets/docs/pfi-standard-specification-november-2011.pdf (accessed on 6 December 2019).

- Bridgeman, T.G.; Jones, J.M.; Williams, A.; Waldron, D.J. An investigation of the grindability of two torrefied energy crops. Fuel 2010, 89, 3911–3918. [Google Scholar] [CrossRef]

- Angles, M.N.; Ferrando, F.; Farriol, X.; Salvado, J. Suitability of steam exploded residual softwood for the production of binderless panel. Effect of the pre-treatment severity and lignin addition. Biomass Bioenergy 2001, 21, 211–224. [Google Scholar] [CrossRef]

- Soponpongpipat, N.; Sittikul, D.; Comsawang, P. Prediction model of higher heating value of torrefied biomass based on the kinetics of biomass decomposition. J. Energy Inst. 2016, 89, 425–435. [Google Scholar] [CrossRef]

- Serrano, C.; Monedero, E.; Lapuerta, M.; Portero, H. Effect of moisture content, particle size, and pine addition on quality parameters of barley straw pellets. Fuel Process. Technol. 2011, 92, 699–706. [Google Scholar] [CrossRef]

- Mok, W.S.L.; Antal, M.J.; Szabo, P.; Varhegyi, G.; Zelei, B. Formation of charcoal from biomass in a sealed reactor. Ind. Eng. Chem. Res. 1992, 31, 1162–1166. [Google Scholar] [CrossRef]

- Slopiecka, K.; Bartocci, P.; Fantozzi, F. Thermogravimetric analysis and kinetic study of poplar wood. Appl. Energy 2012, 97, 491–497. [Google Scholar] [CrossRef]

- Fierro, V.; Torné-Fernández, V.; Montané, D.; Celzard, A. Study of the decomposition of kraft lignin impregnated with orthophosphoric acid. Thermochim. Acta 2005, 433, 142–148. [Google Scholar] [CrossRef]

- Urych, B. Determination of kinetic parameters of coal pyrolysis to simulate the process of underground coal gasification (UCG). J. Sustain. Min. 2014, 13, 3–9. [Google Scholar] [CrossRef]

| P-RC | P-TC | T-CP | |||||

|---|---|---|---|---|---|---|---|

| 230 °C | 250 °C | 280 °C | 230 °C | 250 °C | 280 °C | ||

| Bulk density (kg/m3) | 653.56 ±17.9 | 777.28 ±20.15 | 762.43 ±3.69 | 739.69 ± 5.76 | 583.26 ± 38.97 | 559.68 ± 15.98 | 486.3 ± 17.98 |

| Higher heating value (HHV) (MJ/kg) | 16.25 ± 0.45 | 17.56 ± 0.57 | 19.24 ± 1.16 | 22.31 ± 0.92 | 18.63 ± 1.2 | 20.54 ± 1.13 | 23.83 ± 0.99 |

| Energy density (GJ/m3) | 10.62 | 13.13 | 14.97 | 16.55 | 10.92 | 11.50 | 11.77 |

| Durability index (%) | 98.09 ± 1.02 | 97.85 ± 0.61 | 97.79 ± 0.48 | 97.24 ± 0.91 | 96.81 ± 0.36 | 96.29 ± 0.32 | 90.96 ± 0.82 |

| Char yield (%) | - | 72.89 | 65.02 | 52.96 | 83.10 | 73.62 | 55.45 |

| Maximum moisture absorption (%) | 4.49 ± 0.10 | 2.82 ± 0.41 | 2.38 ± 0.19 | 1.95 ± 0.60 | 4.64 ± 0.15 | 4.41 ± 0.33 | 3.73 ± 0.24 |

| Raw Cassava Rhizome | Torrefied Char | |||

|---|---|---|---|---|

| 230 °C | 250 °C | 280 °C | ||

| SEC for pelletizing (kW-h/kg) | 0.12 | 0.35 | 0.35 | 0.4 |

| Step 1 | Step 2 | ||||||

|---|---|---|---|---|---|---|---|

| Item | E (kJ/mol) | A (min−1) | r2 | Tsp | E (kJ/mol) | A (min-1) | r2 |

| T-CP,230 | 87.8 | 2.6 × 107 | 0.9713 | 390 | 80.8 | 4.7 × 104 | 0.8318 |

| P-TC,230 | 81.8 | 6.5 × 106 | 0.9642 | 400 | 52.3 | 2.1 × 102 | 0.7046 |

| T-CP,250 | 80.6 | 4.9 × 106 | 0.9783 | 400 | 52.2 | 2.4 × 102 | 0.8076 |

| P-TC,250 | 80.7 | 4.3 × 106 | 0.9750 | 410 | 43.6 | 3.5 × 101 | 0.7807 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Soponpongpipat, N.; Comsawang, P.; Nanetoe, S. Quality Properties and Pyrolysis Characteristics of Cassava Rhizome Pellets Produced by Alternating between Pelletizing and Torrefaction. Processes 2019, 7, 930. https://doi.org/10.3390/pr7120930

Soponpongpipat N, Comsawang P, Nanetoe S. Quality Properties and Pyrolysis Characteristics of Cassava Rhizome Pellets Produced by Alternating between Pelletizing and Torrefaction. Processes. 2019; 7(12):930. https://doi.org/10.3390/pr7120930

Chicago/Turabian StyleSoponpongpipat, Nitipong, Paisan Comsawang, and Suwat Nanetoe. 2019. "Quality Properties and Pyrolysis Characteristics of Cassava Rhizome Pellets Produced by Alternating between Pelletizing and Torrefaction" Processes 7, no. 12: 930. https://doi.org/10.3390/pr7120930

APA StyleSoponpongpipat, N., Comsawang, P., & Nanetoe, S. (2019). Quality Properties and Pyrolysis Characteristics of Cassava Rhizome Pellets Produced by Alternating between Pelletizing and Torrefaction. Processes, 7(12), 930. https://doi.org/10.3390/pr7120930