Advances in Mathematical Modeling of Gas-Phase Olefin Polymerization

Abstract

:1. Introduction

2. Mathematical Model Development for Olefin Polymerization

2.1. Advances in the Polymerization of Olefins in the Gas Phase

2.2. Overview of the Kinetic Model, and the Mass and Energy Balance for Olefin Polymerization in the Gas Phase

2.3. Numerical Methods for the Simulation of the Mathematical Model

3. A General Guideline to Implement the Mathematical Model

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| Partial rate constants | |

| A | Area (m2) |

| The cross-sectional area of the cooling jacket tube (m2) | |

| The cross-sectional area of the fluidized bed (m2) | |

| The surface area of the pipe (m2) | |

| The cross-sectional area of the pipe (m2) | |

| Alkyl Aluminum (mol/m3) | |

| Partial rate constants | |

| By-product (mol/m3) | |

| Concentration of the component i (mol/m3) | |

| Co – Catalyst (mol/m3) | |

| Heat capacity (J/Kg·K) | |

| Heat capacity of the polyolefin (J/Kg·K) | |

| Heat capacity in the cooling jacket tube (J/Kg·K) | |

| Diameter (m) | |

| Inlet diameter (m) | |

| Outer diameter (m) | |

| Dispersion coefficient (m2/s) | |

| Activation energy (J/mol) | |

| Mass flow rate (kg/s) | |

| Potential active site flow rate of a site type j injected into the reactor (mol/s) | |

| Mass flow rate in the jacket cooling tube (kg/s) | |

| The fraction of the catalyst in the polyolefin | |

| Mass fraction of the activated catalyst | |

| Mass fraction of the deactivated catalyst | |

| Mass fraction of the hydrogen | |

| Mass fraction of the monomer | |

| Fluidized bed reactor | |

| Generation of the inert rate constant (m3mol−1s−1) | |

| Height of the reactor (m) | |

| Enthalpy of the reactor (J/kg) | |

| Bubble to emulsion heat transfer coefficient (W/m3K) | |

| Bubble to cloud heat transfer coefficient (W/m3K) | |

| Cloud to emulsion heat transfer coefficient (W/m3K) | |

| Enthalpy of the inlet feedstock into the reactor (J/kg) | |

| Hydrogen (mol/m3) | |

| Wall heat transfer coefficient (W/m2K) | |

| Horizontal-stirred bed reactor | |

| Initiators (mol/m3) | |

| Pre-exponential reaction rate constant (s−1 or m3mol−1s−1) | |

| Reaction rate constant | |

| Activation rate constant for active site type j (m3mol−1s−1) | |

| Catalyst activation by hydrogen rate constant for a site type j (s−1) | |

| Catalyst activation by monomer rate constant for a site type j (s−1) | |

| Spontaneous site activation rate constant for active site type j (s−1) | |

| Site activation by alkyl aluminum rate constant for active site type j (s−1) | |

| Site activation by hydrogen rate constant for a site type j (s−1) | |

| Site activation by monomer rate constant for a site type j (s−1) | |

| Hydrogen abstraction rate constant (m3mol−1s−1) | |

| Hydrogen abstraction without a vinyl group rate constant (m3mol−1s−1) | |

| Hydrogen abstraction with a vinyl group rate constant (m3mol−1s−1) | |

| Reaction with poisons rate constant (m3mol−1s−1) | |

| Deactivation rate constant (s−1) | |

| Deactivation by poison rate constant (s−1) | |

| Deactivation rate constant for a site type j (s−1) | |

| Decomposition of ethylene rate constant (s−1) | |

| Chain transfer to hydrogen rate constant for a site type j with terminal monomer M reacting with hydrogen (m3mol−1s−1) | |

| Initiator decomposition rate constant (s−1) | |

| Peroxide initiator at high-temperature rate constant (m3mol−1s−1) | |

| Peroxide generation at high-temperature rate constant (s−1) | |

| Initiation rate constant (m3mol−1s−1) | |

| Initiation rate constant for a site type j (m3mol−1s−1) | |

| Initiation rate constant in extruder (m3mol−1s−1) | |

| Thermal initiation rate constant (s−1) | |

| Propagation rate constant (m3mol−1s−1) | |

| Propagation rate constant for a site type j (m3mol−1s−1) | |

| Spontaneous chain transfer rate constant for a site type j (m3mol−1s−1) | |

| Termination by combination rate constant (m3mol−1s−1) | |

| Termination by disproportionation rate constant (m3mol−1s−1) | |

| Thermal degradation rate constant (s−1) | |

| Site transform from site j to site k rate constant (s−1) | |

| Termination with initiation radical rate constant (m3mol−1s−1) | |

| Chain transfer to chain transfer agent rate constant (m3mol−1s−1) | |

| Chain transfer to co-catalyst rate constant (m3mol−1s−1) | |

| Chain transfer to co-catalyst rate constant for a site type j (m3mol−1s−1) | |

| Chain transfer to hydrogen rate constants for a site type j (m3mol−1s−1) | |

| Chain transfer to solvent rate constants for a site type j (m3mol−1s−1) | |

| Chain transfer to monomer rate constant for a site type j (m3mol−1s−1) | |

| Chain transfer to monomer rate constant (m3mol−1s−1) | |

| Spontaneous transfer rate constant (m3mol−1s−1) | |

| Chain transfer to the polymer without a vinyl group rate constant (m3mol−1s−1) | |

| Chain transfer to a polymer with a vinyl group rate constant (m3mol−1s−1) | |

| Chain transfer to polymer rate constant (m3mol−1s−1) | |

| β-scission rate constant (m3mol−1s−1) | |

| β-scission for secondary radical rate constant (s−1) | |

| β-scission for tertiary radical rate constant (s−1) | |

| Heat dispersion coefficient (J/m·s·K) | |

| bubble to emulsion mass transfer coefficient (s−1) | |

| Bubble to cloud mass transfer coefficient (s−1) | |

| Cloud to emulsion mass transfer coefficient (s−1) | |

| Elutriation constant in emulsion phase (kg/m2s) | |

| Length of the reactor (m) | |

| Monomer used during the polymerization (mol/m3) | |

| Melt flow index or Melt index (g/min) | |

| Molecular weight (kg/mol) | |

| Number average molecular weight (kg/mol) | |

| Weight average molecular weight (kg/mol) | |

| Mass inside the reactor (kg) | |

| Mass of the polymer inside the reactor (kg) | |

| Metal atoms (mol) | |

| Number of active sites j | |

| Oxygen (mol/m3) | |

| Pressure (Pa) | |

| Poison (mol/m3) | |

| Potential active site of type j (mol) | |

| Uninitiated site of type j produced from activation reaction (mol) | |

| Uninitiated site of type j produced from chain transfer to hydrogen reaction (mol) | |

| Living polymer chain with a chain length one produced by the initiation reaction (mol) | |

| Living polymer chain of type j with a chain length one produced by the initiation reaction (mol) | |

| Growth living chain with a chain length m with the terminal monomer M (mol) | |

| Growth living chain with a chain length n with the terminal monomer M (mol) | |

| Growth living chain with a chain length n + m with the terminal monomer M (mol) | |

| Growth living chain of type j + k with a chain length n + m (mol) | |

| Growth living polymer chain of type j with a chain length n with the terminal monomer M (mol) | |

| Growth living polymer chain of type k with a chain length m with the terminal monomer M (mol) | |

| Growth living chain with a chain length n + 1 with the terminal monomer M (mol) | |

| Growth living polymer chain of type j with a chain length n + 1 with the terminal monomer M (mol) | |

| Dead polymer chain (mol) | |

| Dead polymer chain of type j (mol) | |

| Impurity site of type j (mol) | |

| Deactivated site of type j (mol) | |

| Polydispersity index | |

| Impurity (mol/m3) | |

| Heat transfer via the cooling jacket (J/s) | |

| Dead polymer with n chain length of type j (mol) | |

| The mass flow rate of the catalyst (kg/s) | |

| The mass flow rate of the hydrogen (kg/s) | |

| Inlet flow rate (kg/s) | |

| The mass flow rate of the monomer (kg/s) | |

| The mass flow rate (kg/s) | |

| Outlet flow rate (kg/s) | |

| Outflow rate of the polyolefin in the slurry phase (kg/s) | |

| Rate expression for the active sites (mol/kg catalyst per second) | |

| Reactant used during polymerization process | |

| Radical (mol) | |

| Living radical with the chain length 1 (mol) | |

| Living radical with the chain length 2 (mol) | |

| Living radical with m chain length (mol) | |

| Living radical with n chain length (mol) | |

| Living radical with n chain length of type j (mol) | |

| Living radical with n chain length of type k (mol) | |

| Living radical with n + 1 chain length (mol) | |

| Living radical with m – r chain length (mol) | |

| Living radical with m chain length (mol) | |

| Inert molecule (mol) | |

| Gas constant (J/mol·K) | |

| Deactivation reaction rate (kg/s) | |

| Reynold Number | |

| Hydrogen consumption rate (kg/s) | |

| Polymerization rate (kg/s) | |

| Polymerization rate (mol/L·s) | |

| Rv | Volumetric production rate of polymer (m3s−1) |

| Sub-product (mol/m3) | |

| Temperature (K) | |

| Cooling jacket tube temperature (K) | |

| Reference temperature (K) | |

| Heat transfer constant or internal energy (W/m2K) | |

| Velocity (m/s) | |

| Volume (m3) | |

| Vp | The volume of polymer phase present in the reactor (m3) |

| Vertical-stirred bed reactor | |

| The volume of the gas (m3) | |

| The volume of the liquid in the cooling jacket tube (m3) | |

| Well-stirred semi-batch reactor | |

| The weight of particle solid (kg) | |

| Zeroth moment of chain length distribution of the dead polymer (mol) | |

| The first moment of chain length distribution of the dead polymer (mol) | |

| The second moment of chain length distribution of the dead polymer (mol) | |

| Zeroth moment of chain length distribution of the dead polymer chain (mol) | |

| The first moment of chain length distribution of the dead polymer chain (mol) | |

| The second moment of chain length distribution of the dead polymer chain (mol) | |

| The n moment of chain length distribution of the dead polymer chain (mol) | |

| Inert molecule (mol) | |

| Zeroth moment of chain length distribution of the living polymer (mol) | |

| The first moment of chain length distribution of the living polymer (mol) | |

| The second moment of chain length distribution of the living polymer (mol) | |

| Zeroth moment of chain length distribution of the living polymer chain (mol) | |

| The first moment of chain length distribution of the living polymer chain (mol) | |

| The second moment of chain length distribution of the living polymer chain (mol) | |

| Monomer conversion | |

| Ziegler-Natta |

References

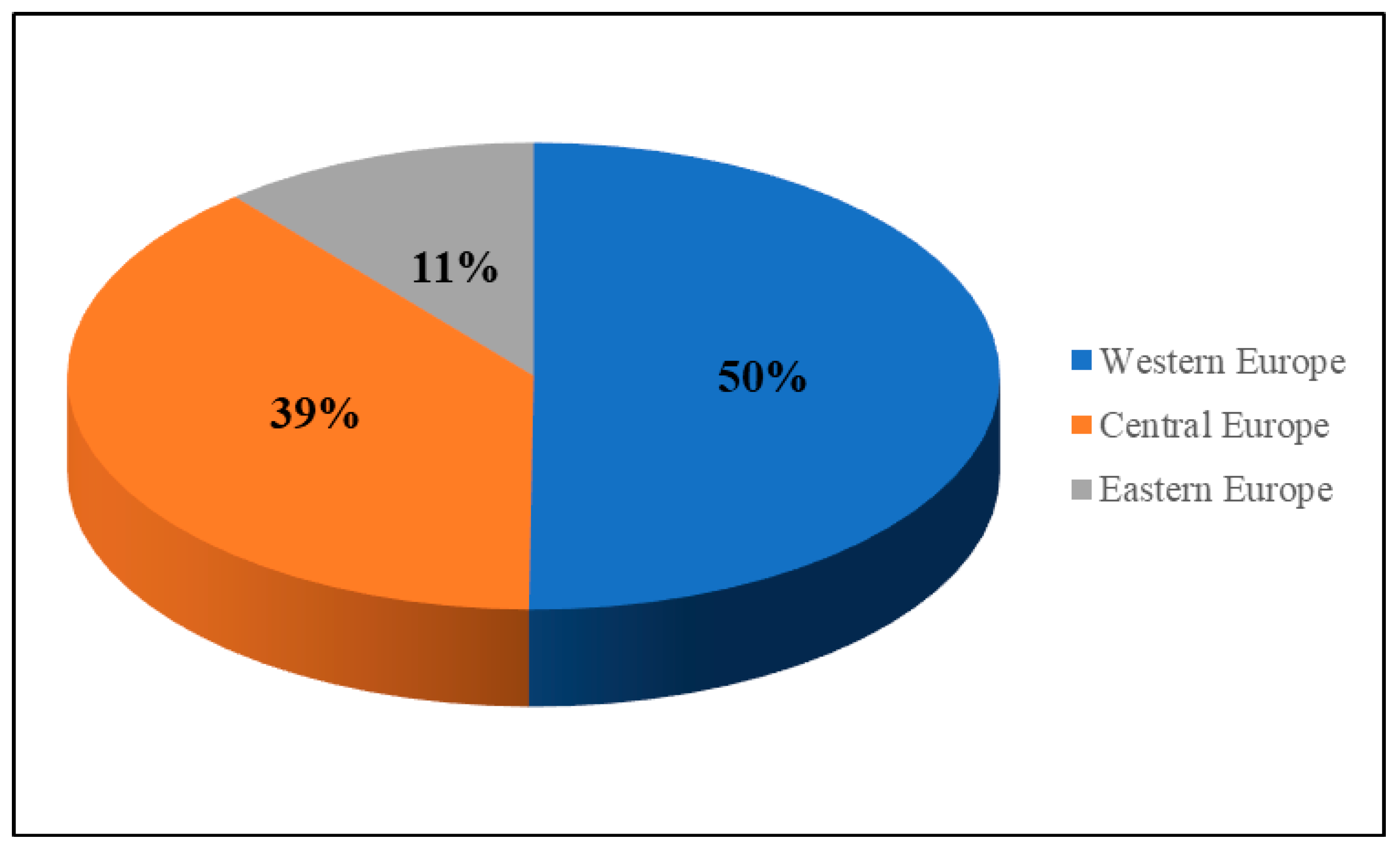

- Szabó, K.P. MOL Group Polyolefin Development in CEE Context. In Proceedings of the 18th Annual CEE & Turkey Refining and Petrochemicals Conference, Budapest, Hungary, 13–15 October 2015. [Google Scholar]

- Leute, U.; Dollhopf, W. A Review of the experimental data from the high pressure phase in polyethylene. Colloid Polym. Sci. 1980, 258, 353–359. [Google Scholar] [CrossRef]

- Crossland, B.; Bett, K.E.; Ford, H.; Gardner, A.K. Review of some of the major engineering developments in the high-pressure polyethylene process, 1933–1983. Proc. Inst. Mech. Eng. Part A J. Power Energy 1986, 200, 237–253. [Google Scholar] [CrossRef]

- Romano, U.; Garbassi, F. The environmental issue. A challenge for new generation polyolefins. Pure Appl. Chem. 2000, 72, 1383–1388. [Google Scholar] [CrossRef] [Green Version]

- Sato, H.; Ogawa, H. Review on Development of Polypropylene Manufacturing Process. RD Rep. 2009, 2, 1–11. [Google Scholar]

- Qiao, J.; Guo, M.; Wang, L.; Liu, D.; Zhang, X.; Yu, L.; Liu, Y. Recent advances in polyolefin technology. Polym. Chem. 2011, 2, 1611–1623. [Google Scholar] [CrossRef]

- Wang, D.; Wang, J.; Guo, F.; Gao, Y.; Du, W.; Yang, G. Progress in technology and catalysts for gas phase polyethylene processes. Adv. Sci. Eng. 2016, 8, 25–31. [Google Scholar]

- Gupta, S.K. Low-density polyethylene (LDPE) polymerization—A review. Curr. Sci. 1987, 56, 979–984. [Google Scholar]

- Boaen, N.K.; Hillmyer, M.A. Post-polymerization functionalization of polyolefins. Chem. Soc. Rev. 2005, 34, 267–275. [Google Scholar] [CrossRef]

- Mishra, V.; Kumar, R. Living radical polymerization: A review. J. Sci. Res. 2012, 56, 141–176. [Google Scholar]

- Yu, W.; Liu, J.; Zhou, C. Rheo-chemistry in reactive processing of polyolefin. Int. Polym. Proc. 2012, 27, 286–298. [Google Scholar] [CrossRef]

- Hamielec, A.E.; Soares, J.B.P. Polymerization reaction engineering—Metallocene catalysts. Prog. Polym. Sci. 1996, 21, 651–706. [Google Scholar] [CrossRef]

- Lefebvre, F.; Thivolle-Cazat, J.; Dufaud, V.; Niccolai, G.P.; Basset, J.M. Oxide supported surface organometallic complexes as a new generation of catalysts for carbon-carbon bond activation. Appl. Catal. A Gen. 1999, 182, 1–8. [Google Scholar] [CrossRef]

- Tuchbreiter, A.; Mülhaupt, R. The polyolefin challenges: Catalyst and process design, tailor-made materials, high-throughput development and data mining. Macromol. Symp. 2001, 173, 1–20. [Google Scholar] [CrossRef]

- McKenna, T.F.; Soares, J.B.P. Single particle modelling for olefin polymerization on supported catalysts: A review and proposals for future developments. Chem. Eng. Sci. 2001, 56, 3931–3949. [Google Scholar] [CrossRef]

- Coates, G.W.; Hustad, P.D.; Reinartz, S. Catalysts for the Living Insertion Polymerization of Alkenes: Access to New Polyolefin Architectures Using Ziegler–Natta Chemistry. Angew. Chem. Int. Ed. 2002, 41, 2236–2257. [Google Scholar] [CrossRef]

- Mülhaupt, R. Catalytic Polymerization and Post Polymerization Catalysis Fifty Years after the Discovery of Ziegler’s Catalysts. Macromol. Chem. Phys. 2003, 204, 289–327. [Google Scholar] [CrossRef]

- Makio, H.; Kashiwa, N.; Fujita, T. FI Catalysts: A New Family of High Performance Catalysts for Olefin Polymerization. Adv. Synth. Catal. 2002, 344, 477–493. [Google Scholar] [CrossRef]

- Domski, G.J.; Rose, J.M.; Coates, G.W.; Bolig, A.D.; Brookhart, M. Living alkene polymerization: New methods for the precision synthesis of polyolefins. Prog. Polym. Sci. 2007, 32, 30–92. [Google Scholar] [CrossRef]

- Nomura, K.; Kitiyanan, B. Recent progress in precise synthesis of polyolefins containing polar functionalities by transition metal catalysis. Curr. Org. Synth. 2008, 5, 217–226. [Google Scholar] [CrossRef]

- Camacho, D.H.; Guan, Z. Designing late-transition metal catalysts for olefin insertion polymerization and copolymerization. Chem. Comm. 2010, 46, 7879–7893. [Google Scholar] [CrossRef] [PubMed]

- McKenna, T.F.L.; Di Martino, A.; Weickert, G.; Soares, J.B.P. Particle Growth During the Polymerisation of Olefins on Supported Catalysts, 1–Nascent. Polym. Struc. Macromol. React. Eng. 2010, 4, 40–64. [Google Scholar] [CrossRef]

- Heurtefeu, B.; Bouilhac, C.; Cloutet, É.; Taton, D.; Deffieux, A.; Cramail, H. Polymer support of “single-site” catalysts for heterogeneous olefin polymerization. Prog. Polym. Sci. 2011, 36, 89–126. [Google Scholar] [CrossRef]

- Choi, Y.; Soares, J.B.P. Supported single-site catalysts for slurry and gas-phase olefin polymerisation. Can. J. Chem. Eng. 2012, 90, 646–671. [Google Scholar] [CrossRef]

- Baier, M.C.; Zuideveld, M.A.; Mecking, S. Post-Metallocenes in the Industrial Production of Polyolefins. Angew. Chem. Int. Ed. 2014, 53, 9722–9744. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Shamiri, A.; Chakrabarti, M.; Jahan, S.; Hussain, M.; Kaminsky, W.; Aravind, P.; Yehye, W. The Influence of Ziegler-Natta and Metallocene Catalysts on Polyolefin Structure, Properties, and Processing Ability. Materials 2014, 7, 5069–5108. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Argyle, M.D.; Bartholomew, C.H. Heterogeneous catalyst deactivation and regeneration: A review. Catalysts 2015, 5, 145–269. [Google Scholar] [CrossRef]

- Pingwei, L.; Weifeng, L.; Wen-Jun, W.; Bo-Geng, L.; Shiping, Z. A Comprehensive Review on Controlled Synthesis of Long-Chain Branched Polyolefins: Part 1, Single Catalyst Systems. Macromol. React. Eng. 2016, 10, 156–179. [Google Scholar] [Green Version]

- Weifeng, L.; Pingwei, L.; Wen-Jun, W.; Bo-Geng, L.; Shiping, Z. A Comprehensive Review on Controlled Synthesis of Long-Chain-Branched Polyolefins: Part 2, Multiple Catalyst Systems and Prepolymer Modification. Macromol. React. Eng. 2016, 10, 180–200. [Google Scholar]

- Sauter, D.; Taoufik, M.; Boisson, C. Polyolefins, a Success Story. Polymers 2017, 9, 1–13. [Google Scholar]

- Alizadeh, A.; McKenna, T.F.L. Particle Growth during the Polymerization of Olefins on Supported Catalysts. Part 2: Current Experimental Understanding and Modeling Progresses on Particle Fragmentation, Growth, and Morphology Development. Macromol. React. Eng. 2018, 12, 1–24. [Google Scholar] [CrossRef]

- Kim, S.D.; Kang, Y. Heat and mass transfer in three-phase fluidized-bed reactors—An overview. Chem. Eng. Sci. 1997, 52, 3639–3660. [Google Scholar] [CrossRef]

- Khan, M.J.H.; Hussain, M.A.; Mansourpour, Z.; Mostoufi, N.; Ghasem, N.M.; Abdullah, E.C. CFD simulation of fluidized bed reactors for polyolefin production—A review. J. Ind. Eng. Chem. 2014, 20, 3919–3946. [Google Scholar] [CrossRef]

- Abbasi, M.R.; Shamiri, A.; Hussain, M. A review on modeling and control of olefin polymerization in fluidized-bed reactors. Rev. Chem. Eng. 2018, 1–23. [Google Scholar] [CrossRef]

- Pingwei, L.; Weifeng, L.; Wen-Jun, W.; Bo-Geng, L.; Shiping, Z. A Comprehensive Review on Controlled Synthesis of Long-Chain Branched Polyolefins: Part 3, Characterization of Long-Chain Branched Polymers. Macromol. React. Eng. 2017, 11, 1–20. [Google Scholar]

- Isaeva, V.I.; Aizenshtein, E.M.; Soboleva, O.N. World production and use of polypropylene fibres and thread—A review. Fibre Chem. 1997, 29, 269–281. [Google Scholar] [CrossRef]

- Briskman, B.A. Radiation effects in thermal properties of polymers. An analytical review. I. Polyethylene. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. 2001, 185, 116–122. [Google Scholar] [CrossRef]

- Gulrez Syed, K.H.; Ali Mohsin, M.E.; Shaikh, H.; Anis, A.; Pulose, A.M.; Yadav, M.K.; Al-Zahrani, S.M. A review on electrically conductive polypropylene and polyethylene. Polym. Comput. 2014, 35, 900–914. [Google Scholar] [CrossRef]

- Mohebbi, A.; Mighri, F.; Ajji, A.; Rodrigue, D. Current issues and challenges in polypropylene foaming: A review. Cell. Polym. 2015, 34, 299–337. [Google Scholar] [CrossRef]

- Kumar, A.; Gupta, R.K. Fundamentals of Polymer Engineering Second Edition Revised and Expanded; Marcel Dekker Inc.: New York, NY, USA, 2003; pp. 1–693. [Google Scholar]

- Soares, J.B.P.; Pérez, O. Coordination polymerization. In Handbook of Polymer Synthesis, 1st ed.; Saldivar-Guerra, E., Vivaldo-Lima, E., Eds.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2013; pp. 85–103. [Google Scholar]

- Witold, K. Principles of Coordination. In Polymerisation Heterogenous and Homogenous Catalysys in Polymer Chemistry-Polymerisation of Hydrocarbon, Heterocyclic and Heterounsaturated Monomers; Witold, K., Ed.; John Wiley & Sons Inc.: Hoboken, NJ, USA, 2001; pp. 1–522. [Google Scholar]

- Calhoun, A.; Peacock, A.J. Polymer Chemistry: Properties and Application; Hanser, C., Ed.; Hanser: Cincinnati, OH, USA, 2006; pp. 21–31. [Google Scholar]

- Bird, R.B.; Stewart, W.E.; Lightfoot, E.N. Transport Phenomena, 2nd ed.; Anderson, W., Ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2002; pp. 1–895. [Google Scholar]

- Ibrehem, A.S.; Hussain, M.A.; Ghasem, N.M. Modified mathematical model for gas phase olefin polymerization in fluidized-bed catalytic reactor. Chem. Eng. J. 2009, 149, 353–362. [Google Scholar] [CrossRef]

- Kiparissides, C.; Alexopoulos, A.; Roussos, A.; Dompazis, G.; Kotoulas, C. Population Balance Modeling of Particulate Polymerization Processes. Ind. Eng. Chem. Res. 2004, 43, 7290–7302. [Google Scholar] [CrossRef]

- Ramkrishna, D.; Mahoney, A.W. Population balance modeling. Promise for the future. Chem. Eng. Sci. 2002, 57, 595–606. [Google Scholar] [CrossRef]

- Salahuddin, N.F.; Shamiri, A.; Hussain, M.A.; Mostoufi, N. Fuzzy-GMC Control of Gas-Phase Propylene Copolymerization in Fluidized Bed Reactor. In Proceedings of the 24th Regional Symposium on Chemical Engineering (RSCE 2017), Semarang, Indonesia, 15–16 November 2017. [Google Scholar]

- Abbasi, M.R.; Shamiri, A.; Hussain, M.A. Dynamic modeling and Molecular Weight Distribution of ethylene copolymerization in an industrial gas-phase Fluidized-Bed Reactor. Adv. Powder Technol. 2016, 27, 1526–1538. [Google Scholar] [CrossRef] [Green Version]

- Khan, M.J.H.; Hussain, M.A.; Mujtaba, I.M. Developed Hybrid Model for Propylene Polymerisation at Optimum Reaction Conditions. Polymers 2016, 8, 47. [Google Scholar] [CrossRef]

- Shamiri, A.; Wong, S.W.; Zanil, M.F.; Hussain, M.A.; Mostoufi, N. Modified two-phase model with hybrid control for gas phase propylene copolymerization in fluidized bed reactors. Chem. Eng. J. 2015, 264, 706–719. [Google Scholar] [CrossRef]

- Zavala, V.M.; Biegler, L.T. Large-Scale Parameter Estimation in Low-Density Polyethylene Tubular Reactors. Ind. Eng. Chem. Res. 2006, 45, 7867–7881. [Google Scholar] [CrossRef]

- Zavala, V.M.; Laird, C.D.; Biegler, L.T. Interior-point decomposition approaches for parallel solution of large-scale nonlinear parameter estimation problems. Chem. Eng. Sci. 2008, 63, 4834–4845. [Google Scholar] [CrossRef]

- Biegler, L.T. Nonlinear programming strategies for dynamic chemical process optimization. Theor. Found. Chem. Eng. 2014, 48, 541–554. [Google Scholar] [CrossRef]

- Ho, Y.K.; Shamiri, A.; Mjalli, F.S.; Hussain, M.A. Control of industrial gas phase propylene polymerization in fluidized bed reactors. J. Process Control 2012, 22, 947–958. [Google Scholar] [CrossRef]

- Shamiri, A.; Hussain, M.A.; Mjalli, F.S.; Shafeeyan, M.S.; Mostoufi, N. Experimental and Modeling Analysis of Propylene Polymerization in a Pilot-Scale Fluidized Bed Reactor. Ind. Eng. Chem. Res. 2014, 53, 8694–8705. [Google Scholar] [CrossRef]

- Shamiri, A.; Hussain, M.A.; Mjalli, F.S.; Mostoufi, N.; Hajimolana, S. Dynamics and Predictive Control of Gas Phase Propylene Polymerization in Fluidized Bed Reactors. Chin. J. Chem. Eng. 2013, 21, 1015–1029. [Google Scholar] [CrossRef]

- Shamiri, A.; Hussain, M.A.; Mjalli, F.S.; Mostoufi, N.; Shafeeyan, M.S. Dynamic modeling of gas phase propylene homopolymerization in fluidized bed reactors. Chem. Eng. Sci. 2011, 66, 1189–1199. [Google Scholar] [CrossRef]

- Shamiri, A.; Hussain, M.A.; Mjalli, F.S.; Mostoufi, N. Kinetic modeling of propylene homopolymerization in a gas-phase fluidized-bed reactor. Chem. Eng. J. 2010, 161, 240–249. [Google Scholar] [CrossRef]

- Vallerio, M.; Logist, F.; Van Erdeghem, P.; Dittrich, C.; Van Impe, J. Model-Based Optimization of the Cooling System of an Industrial Tubular LDPE Reactor. Ind. Eng. Chem. Res. 2013, 52, 1656–1666. [Google Scholar] [CrossRef] [Green Version]

- Sarmoria, C.; Asteasuain, M.; Brandolin, A. Prediction of molecular weight distributions in polymers using probability generating functions. Can. J. Chem. Eng. 2012, 90, 263–273. [Google Scholar] [CrossRef]

- Shamiri, A.; Hussain, M.A.; Mjalli, F.S.; Mostoufid, N. Improved single phase modeling of propylene polymerization in a fluidized bed reactor. Comput. Chem. Eng. 2012, 36, 35–47. [Google Scholar] [CrossRef]

- Ashrafi, O.; Mostoufi, N.; Sotudeh-Gharebagh, R. Two phase steady-state particle size distribution in a gas-phase fluidized bed ethylene polymerization reactor. Chem. Eng. Sci. 2012, 73, 1–7. [Google Scholar] [CrossRef]

- Ibrehem, A.S.; Hussain, M.A.; Ghasem, N.M. Mathematical model and advanced control for gas-phase olefin polymerization in fluidized-bed catalytic reactors. Chin. J. Chem. Eng. 2008, 16, 84–89. [Google Scholar] [CrossRef]

- Asteasuain, M.; Brandolin, A. Optimal operation of ethylene polymerization reactors for tailored molecular weight distribution. J. Appl. Polym. Sci. 2007, 105, 2621–2630. [Google Scholar] [CrossRef]

- Asteasuain, M.; Brandolin, A. Modeling and optimization of a high-pressure ethylene polymerization reactor using gPROMS. Comput. Chem. Eng. 2008, 32, 396–408. [Google Scholar] [CrossRef]

- Asteasuain, M.; Brandolin, A. High-Pressure Polymerization of Ethylene in Tubular Reactors: A Rigorous Dynamic Model Able to Predict the Full Molecular Weight Distribution. Macromol. React. Eng. 2009, 3, 398–411. [Google Scholar] [CrossRef]

- Ashrafi, O.; Nazari-Pouya, H.; Mostoufi, N.; Sotudeh-Gharebagh, R. Particle size distribution in gas-phase polyethylene reactors. Adv. Powder Technol. 2008, 19, 321–334. [Google Scholar] [CrossRef]

- Khazraei, P.K.F.; Dhib, R. Modeling of ethylene polymerization with difunctional initiators in tubular reactors. J. Appl. Polym. Sci. 2008, 109, 3908–3922. [Google Scholar] [CrossRef]

- Salau, N.P.G.; Neumann, G.A.; Trierweiler, J.O.; Secchi, A.R. Dynamic behavior and control in an industrial fluidized-bed polymerization reactor. Ind. Eng. Chem. Res. 2008, 47, 6058–6069. [Google Scholar] [CrossRef]

- Brandolin, A.; Sarmoria, C.; Failla, M.D.; Vallés, E.M. Mathematical Modeling of the Reactive Modification of High−Density Polyethylene. Effect of Vinyl Content. Ind. Eng. Chem. Res. 2007, 46, 7561–7570. [Google Scholar] [CrossRef]

- Agrawal, N.; Rangaiah, G.P.; Ray, A.K.; Gupta, S.K. Multi-objective optimization of the operation of an industrial low-density polyethylene tubular reactor using genetic algorithm and its jumping gene adaptations. Ind. Eng. Chem. Res. 2006, 45, 3182–3199. [Google Scholar] [CrossRef]

- Kiashemshaki, A.; Mostoufi, N.; Sotudeh-Gharebagh, R. Two-phase modeling of a gas phase polyethylene fluidized bed reactor. Chem. Eng. Sci. 2006, 61, 3997–4006. [Google Scholar] [CrossRef]

- Jafari, R.; Sotudeh-Gharebagh, R.; Mostoufi, N. Performance of the wide-ranging models for fluidized bed reactors. Adv. Powder Technol. 2004, 15, 533–548. [Google Scholar] [CrossRef]

- Harshe, Y.M.; Utikar, R.P.; Ranade, V.V. A computational model for predicting particle size distribution and performance of fluidized bed polypropylene reactor. Chem. Eng. Sci. 2004, 59, 5145–5156. [Google Scholar] [CrossRef]

- Khare, N.P.; Lucas, B.; Seavey, K.C.; Liu, Y.A.; Sirohi, A.; Ramanathan, S.; Chen, C.C. Steady-state and dynamic modeling of gas-phase polypropylene processes using stirred-bed reactors. Ind. Eng. Chem. Res. 2004, 43, 884–900. [Google Scholar] [CrossRef]

- Alizadeh, M.; Mostoufi, N.; Pourmahdian, S.; Sotudeh-Gharebagh, R. Modeling of fluidized bed reactor of ethylene polymerization. Chem. Eng. J. 2004, 97, 27–35. [Google Scholar] [CrossRef]

- Asteasuain, M.; Sarmoria, C.; Brandolin, A. Controlled rheology of polypropylene: Modeling of molecular weight distributions. J. Appl. Polym. Sci. 2003, 88, 1676–1685. [Google Scholar] [CrossRef]

- Asteasuain, M.; P’erez, M.V.; Sarmoria, C.; Brandolin, A. Modelling Molecular Weight Distribution, Vinyl Content and Branching in the Reactive Extrusion of High Density Polyethylene. Lat. Am. Appl. Res. 2003, 33, 241–249. [Google Scholar]

- Chatzidoukas, C.; Perkins, J.D.; Pistikopoulos, E.N.; Kiparissides, C. Optimal grade transition and selection of closed-loop controllers in a gas-phase olefin polymerization fluidized bed reactor. Chem. Eng. Sci. 2003, 58, 3643–3658. [Google Scholar] [CrossRef]

- Cervantes, A.M.; Tonelli, S.; Brandolin, A.; Bandoni, J.A.; Biegler, L.T. Large-scale dynamic optimization for grade transitions in a low density polyethylene plant. Comput. Chem. Eng. 2002, 26, 227–237. [Google Scholar] [CrossRef] [Green Version]

- Meier, G.B.; Weickert, G.; van Swaaij, W.P.M. FBR for catalytic propylene polymerization: Controlled mixing and reactor modeling. AIChE J. 2002, 48, 1268–1283. [Google Scholar] [CrossRef]

- Asteasuain, M.; Sarmoria, C.; Brandolin, A. Peroxide modification of polyethylene. Prediction of molecular weight distributions by probability generating functions. Polymers 2002, 43, 2363–2373. [Google Scholar] [CrossRef]

- Asteasuain, M.; Tonelli, S.M.; Brandolin, A.; Bandoni, J.A. Dynamic simulation and optimisation of tubular polymerisation reactors in gPROMS. Comput. Chem. Eng. 2001, 25, 509–515. [Google Scholar] [CrossRef]

- Asteasuain, M.; Pereda, S.; Lacunza, M.H.; Ugrin, P.E.; Brandolin, A. Industrial high pressure ethylene polymerization initiated by peroxide mixtures: A reduced mathematical model for parameter adjustment. Polym. Eng. Sci. 2001, 41, 711–726. [Google Scholar] [CrossRef]

- Asteasuain, M.; Ugrin, P.E.; Lacunza, M.H.; Brandolin, A. Effect of multiple feedings in the operation of a high-pressure polymerization reactor for ethylene polymerization. Polym. React. Eng. 2001, 9, 163–182. [Google Scholar] [CrossRef]

- Brandolin, A.; Sarmoria, C.; Lótpez-Rodríguez, A.; Whiteley, K.S.; Del Amo Fernandez, B. Prediction of molecular weight distributions by probability generating functions. Application to industrial autoclave reactors for high pressure polymerization of ethylene and ethylene-vinyl acetate. Polym. Eng. Sci. 2001, 41, 1413–1426. [Google Scholar] [CrossRef]

- Ghasem, N.M. Effect of Polymer Particle Size and Inlet Gas Temperature on Industrial Fluidized Bed Polyethylene Reactors. Chem. Eng. Technol. 1999, 22, 777–783. [Google Scholar] [CrossRef]

- Ghasem, N.M. Effect of Polymer Growth Rate and Diffusion Resistance on the Behavior of Industrial Polyethylene Fluidized Bed Reactor. Chem. Eng. Technol. 2001, 24, 1049–1057. [Google Scholar] [CrossRef]

- Fernandes, F.A.N.; Lona, L.M.F. Fluidized bed reactor for polyethylene production. The influence of polyethylene prepolymerization. Braz. J. Chem. Eng. 2000, 17, 163–170. [Google Scholar] [CrossRef]

- Fernandes, F.A.N.; Lona, L.M.F. Fluidized-bed reactor modeling for polyethylene production. J. Appl. Polym. Sci. 2001, 81, 321–332. [Google Scholar] [CrossRef]

- Fernandes, F.A.N.; Lona, L.M.F. Heterogeneous modeling for fluidized-bed polymerization reactor. Chem. Eng. Sci. 2001, 56, 963–969. [Google Scholar] [CrossRef]

- Hatzantonis, H.; Yiannoulakis, H.; Yiagopoulos, A.; Kiparissides, C. Recent developments in modeling gas-phase catalyzed olefin polymerization fluidized-bed reactors: The effect of bubble size variation on the reactor’s performance. Chem. Eng. Sci. 2000, 55, 3237–3259. [Google Scholar] [CrossRef]

- Pladis, P.; Kiparissides, C. Dynamic modeling of multizone, multifeed high-pressure LDPE autoclaves. J. Appl. Polym. Sci. 1999, 73, 2327–2348. [Google Scholar] [CrossRef]

- Hatzantonis, H.; Goulas, A.; Kiparissides, C. A comprehensive model for the prediction of particle-size distribution in catalyzed olefin polymerization fluidized-bed reactors. Chem. Eng. Sci. 1998, 53, 3251–3267. [Google Scholar] [CrossRef]

- Khang, D.Y.; Lee, H.H. Particle size distribution in fluidized beds for catalytic polymerization. Chem. Eng. Sci. 1997, 52, 421–431. [Google Scholar] [CrossRef]

- Brandolin, A.; Lacunza, M.H.; Ugrin, P.E.; Capiati, N.J. High Pressure Polymerization of Ethylene. An Improved Mathematical Model for Industrial Tubular Reactors. Polym. React. Eng. 1996, 4, 193–241. [Google Scholar] [CrossRef]

- Zacca, J.J.; Debling, J.A.; Ray, W.H. Reactor residence time distribution effects on the multistage polymerization of olefins. 1. Basic principles and illustrative examples, polypropylene. Chem. Eng. Sci. 1996, 51, 4859–4886. [Google Scholar] [CrossRef]

- McAuley, K.B.; Talbot, J.P.; Harris, T.J. A comparison of two-phase and well-mixed models for fluidized-bed polyethylene reactors. Chem. Eng. Sci. 1994, 49, 2035–2045. [Google Scholar] [CrossRef]

- Choi, K.Y.; Zhao, X.; Tang, S.H. Population Balance Modeling for a Continuous Gas-Phase Olefin Polymerization Reactor. J. Appl. Polym. Sci. 1994, 53, 1589–1597. [Google Scholar] [CrossRef]

- Kiparissides, C.; Verros, G.; Macgregor, J.F. Mathematical-Modeling, Optimization, and Quality-Control of High-Pressure Ethylene Polymerization Reactors. J. Macromol. Sci.-Rev. Macromol. Chem. Phys. 1993, C33, 437–527. [Google Scholar] [CrossRef]

- McAuley, K.B.; Macgregor, J.F.; Hamielec, A.E. A Kinetic-Model for Industrial Gas-Phase Ethylene Copolymerization. AIChE J. 1990, 36, 837–850. [Google Scholar] [CrossRef]

- Choi, K.Y.; Ray, W.H. The dynamic behavior of continuous stirred-bed reactors for the solid catalyzed gas phase polymerization of propylene. Chem. Eng. Sci. 1988, 43, 2587–2604. [Google Scholar] [CrossRef]

- Brandolin, A.; Capiati, N.J.; Farber, J.N.; Valles, E.M. Mathematical model for high-pressure tubular reactor for ethylene polymerization. Ind. Eng. Chem. Res. 1988, 27, 784–790. [Google Scholar] [CrossRef]

- Choi, K.-Y.; Harmon Ray, W. The dynamic behaviour of fluidized bed reactors for solid catalysed gas phase olefin polymerization. Chem. Eng. Sci. 1985, 40, 2261–2279. [Google Scholar] [CrossRef]

- Zacca, J.J.; Ray, W.H. Modelling of the liquid phase polymerization of olefins in loop reactors. Chem. Eng. Sci. 1993, 48, 3743–3765. [Google Scholar] [CrossRef]

- Yang, Y.; Zou, X.; Xiao, F.; Dong, H. Integrated product-process design approach for polyethylene production. Chem. Eng. Trans. 2017, 61, 1009–1014. [Google Scholar]

- Khare, N.P.; Seavey, K.C.; Liu, Y.A.; Ramanathan, S.; Lingard, S.; Chen, C.-C. Steady-State and Dynamic Modeling of Commercial Slurry High-Density Polyethylene (HDPE) Processes. Ind. Eng. Chem. Res. 2002, 41, 5601–5618. [Google Scholar] [CrossRef]

- Debling, J.A.; Zacca, J.J.; Ray, W.H. Reactor residence-time distribution effects on the multistage polymerization of olefins 3. Multi layered products: Impact polypropylene. Chem. Eng. Sci. 1997, 52, 1969–2001. [Google Scholar] [CrossRef]

- Floyd, S.; Choi, K.Y.; Taylor, T.W.; Ray, W.H. Polymerization of olefins through heterogeneous catalysis III. Polymer particle modelling with an analysis of intraparticle heat and mass transfer effects. Inst. Syst. Res. Technol. Rep. 1986, 32, 2935–2960. [Google Scholar] [CrossRef]

- Busch, J. Continuous Simulation with Ordinary Differential Equations; University of Hamburg: Hamburg, Germany, 2013. [Google Scholar]

- Lustman, L.; Neta, B.; Grago, W. Solution of ordinary differential initial value problem on an intel hypercube. Comput. Math. Appl. 1992, 23, 65–72. [Google Scholar] [CrossRef]

- Akhtar, M.N.; Durad, M.H.; Ahmed, A. Solving initial value ordinary differential equations by Monte Carlo method. Proc. Inst. Appl. Math. 2015, 4, 149–174. [Google Scholar]

- Bayram, M.; Partal, T.; Buyukoz, G.O. Numerical methods for simulation of stochastic differential equations. Adv. Diff. Equ. 2018, 17, 1–10. [Google Scholar] [CrossRef]

- Lubich, C.; Roche, M. Roesenbrock method for differential algebraic systems with solution-dependet singular matrix multiplying the derivative. Computing 1990, 43, 325–342. [Google Scholar] [CrossRef]

- Roche, M. Rosenbrock methods for differential algebraic equations. Num. Math. 1987, 52, 45–46. [Google Scholar] [CrossRef]

- Bui, T. Explicit and Implicit Methods in Solving Differential Equations; University of Connecticut: Storrs, CT, USA, 2009. [Google Scholar]

- Causon, D.M.; Mingham, C.G. Introductory Finite Difference Methods for PDES; Ventus Publishing ApS: Frederiksberg, Germany, 2010; pp. 1–144. [Google Scholar]

- Györi, I. The method of lines for the solution of some nonlinear partial differential equations. Comput. Math Appl. 1988, 15, 635–658. [Google Scholar] [CrossRef]

- Sereno, C.; Rodrigues, A.; Villadsen, J. Solution of partial differential equations systems by the moving finite element method. Comput. Chem. Eng. 1992, 16, 583–592. [Google Scholar] [CrossRef]

- Van Lent, J. Multigrid Methods for Time-Dependent Partial Differential Equations. Ph.D. Thesis, Katholieke Universiteit Leuven, Leuven, Belgium, 2006. [Google Scholar]

| No. | Review Area | Review Aspect | Ref. |

|---|---|---|---|

| 1. | Thermodynamic Properties | Different methods to determine enthalpy and entropy | [2] |

| 2. | Process Design | Design criteria, process condition, protection of instruments against overpressure, instruments for heating up and cooling down, and different types of stirrers for polymerization reactors such as autoclave reactor, high-pressure autoclave reactor, tubular reactor, fluidized bed reactor to improve the process efficiency. | [3,4,5,6] |

| 3. | Process Routes | The implementation of the solvent polymerization process, solvent polymerization without deashing, the bulk polymerization process without solvent, the vapor phase polymerization process without deashing and atactic polymer, Unipol I and II, Innovene G, Spherilene S & C, and Borstars in producing the polyolefin. | [5,7] |

| 4. | Olefin Synthesis | The implementation of free-radical methodology, carbine and nitrene methodology, and transition metal C–H bond activation methodology to synthesize the polyolefin. | [8,9,10,11] |

| 5. | Catalyst | The utilization of a metallocene catalyst system, Ziegler–Natta catalyst system, Fujita group Invented (FI) catalyst system, and oxide-supported surface organometallic complexes in olefin polymerization synthesis. | [6,12,13,14,15,16,17,18,19,20,21,22,23,24,25,26,27,28,29,30,31] |

| 6. | Process Modeling | The implementation of mathematical models, namely macroscale modeling, mesoscale modeling, microscale modeling, single particle modeling, computational fluids dynamic modeling, microelements modeling, 2D finite element modeling, single pore modeling, and parti-level fragmentation modeling to determine the properties of the polyolefin, and the mass and heat transfer phenomena during the polymerization process. | [8,11,12,22,31,32,33,34] |

| 7. | Quality Control | Different types of analysis such as nuclear magnetic resonance (NMR), temperature rising elution fractionation (TREF), gel permeation chromatography (GPC), rheological characterization (zero shear viscosity, zero shear viscosity, shear thinning behavior, dynamic modulus, loss angle, Van-Gurp-Palmen plot, Cole-Cole plot, activation energy, thermorheological complexity, strain-hardening effect, relaxation time, damping function, nonlinear dynamical oscillatory shear, and long-chain branching index), dynamic mechanical analysis, differential scanning calorimeter, neutron scattering, and molecular topology fractionation. | [12,13,22,35] |

| 8. | Polyolefin Demand | The analysis of global production and consumption of polypropylene from 1985 until 2000 in the textile industry. | [36] |

| 9. | Physical and Chemical Properties of the Polyolefin | The influence of process conditions on the thermal properties, specific heat capacity, melting point, relative thermal conductivity, density, thermal diffusivity, crystallinity, amorphous phase properties, coefficient of linear thermal expansion, electrical properties, foam structure, shear, and rheological properties. | [37,38,39] |

| Model Type/Polyolefin | Process Condition | Model Assumption (s) | Ref. |

|---|---|---|---|

| Two-Phase Model/Ethylene-propylene copolymer |

|

| [48] |

| Two-phase Model/Ethylene-1-butene copolymer |

|

| [49] |

| Two-Phase Model/Polypropylene |

|

| [50] |

| Two-Phase Model/Ethylene-propylene copolymer |

|

| [51] |

| Single-phase model/Polyethylene |

|

| [52,53,54] |

| Two-Phase Model/Polypropylene |

|

| [55,56,57,58,59] |

| Single-phase Model/Low-density of Polyethylene |

|

| [60] |

| Single-phase Model/Low-density of Polyethylene |

|

| [61] |

| Single-phase model/Polypropylene |

|

| [62] |

| Two-Phase Model/Ethylene-1-butene copolymer |

|

| [63] |

| Three-Phase Model/Ethylene-1-butene copolymer |

|

| [45,64] |

| Single-phase Model/Low-density of Polyethylene |

|

| [65,66,67] |

| Single-phase Model/Ethylene-1-butene Copolymer |

|

| [68] |

| Single-phase Model/Low-density of Polyethylene |

|

| [69] |

| Two-Phase Model/ Ethylene-1-butene copolymer |

|

| [70] |

| Single-phase Model/High-density of Polyethylene |

|

| [71] |

| Single-phase Model/Low-density of Polyethylene |

|

| [72] |

| Two-Phase Model/ Ethylene-1-butene copolymer |

|

| [73] |

| Two-Phase Model/Polyethylene |

|

| [74] |

| Single-phase Model/Polypropylene |

|

| [75] |

| Single-phase Model/Polypropylene |

|

| [76] |

| Two-Phase Model/ Ethylene-1-butene copolymer |

|

| [77] |

| Single-phase Model/Polypropylene |

|

| [78] |

| Single-phase Model/High-density Polyethylene |

|

| [79] |

| Single-phase Model/Ethylene-1-butene Copolymer |

|

| [80] |

| Single-phase Model/Low-density of Polyethylene |

|

| [81] |

| Single-phase Model/Polypropylene |

|

| [82] |

| Single-phase Model/High-density Polyethylene |

|

| [83] |

| Single-phase Model/Low-density Polyethylene |

|

| [84] |

| Single-phase Model/Low-density Polyethylene |

|

| [85,86] |

| Single-phase Model/Low-density Polyethylene and Ethylene-vinyl |

|

| [87] |

| Single-phase Model/Polyethylene |

|

| [88,89] |

| Two-Phase Model/Ethylene-1-butene copolymer |

|

| [90,91,92] |

| Single-phase Model/Ethylene-1-butene Copolymer |

|

| [93] |

| Single-phase Model/Low-density Polyethylene |

|

| [94] |

| Single-phase Model/Polyethylene |

|

| [95] |

| Single-phase Model/Polyolefin |

|

| [96] |

| Single-phase Model/Low-density Polyethylene |

|

| [97] |

| Single-phase Model/Polyolefin |

|

| [98] |

| Single-phase Model/Polyethylene |

|

| [99] |

| Single-phase Model/Ethylene-1-butene Copolymer |

|

| [100] |

| Single-phase Model/Low-density Polyethylene |

|

| [101] |

| Two-Phase Model/Ethylene-1-butene Copolymer |

|

| [102] |

| Single-phase Model/Polypropylene |

|

| [103] |

| Single-phase Model/Low-density Polyethylene |

|

| [104] |

| Single-phase Model/Polyethylene and Polypropylene |

|

| [105] |

| Reaction Mechanism | Ref. |

|---|---|

| Activation of Active Sites | [45,48,49,50,51,55,56,57,58,59,62,64,70,75,76,80,92,93,95,98,102] |

| Spontaneous Site Activation | [70] |

| Site Activation by Hydrogen | [70] |

| Initiation of Active Sites | [45,48,49,51,55,56,57,58,59,62,63,64,68,70,73,76,77,80,82,92,93,95,98,100,102] |

| Propagation | [45,48,49,50,51,55,56,57,58,59,62,63,64,68,70,73,75,76,77,80,82,88,89,90,91,92,93,95,96,98,99,100,102,103,105] |

| Site Transformation | [75,98] |

| Chain Transfer to Monomer | [45,48,49,50,51,55,56,57,58,59,62,63,64,68,70,73,75,76,77,80,88,89,91,92,95,102] |

| Chain Transfer to Hydrogen | [45,48,49,51,55,56,57,58,59,62,63,64,68,70,73,75,76,77,80,88,89,91,92,95,98,100,102] |

| Chain Transfer to Co-Catalyst | [48,49,50,51,55,56,57,58,59,62,63,68,73,75,76,77,88,89,92,102] |

| Spontaneous Transfer | [48,49,50,51,55,56,57,58,59,62,63,68,70,73,75,76,77,80,88,89,91,92,95,102] |

| Deactivation Reaction | [48,49,50,51,55,56,57,58,59,62,70,73,75,76,77,80,82,93,95,96,98,100,102] |

| Site Deactivation by Hydrogen | [70] |

| Site Deactivation by Oxygen | [70] |

| Oxygen Elimination by Alkyl Aluminum | [70] |

| Reaction with Poisons | [48,49,50,51,55,56,57,58,59,62,95,96,102] |

| Reaction Mechanism | Ref. |

|---|---|

| Initiator Decomposition/Peroxide Initiation | [52,53,54,60,61,65,66,67,69,72,78,81,84,85,86,87,94,97,101] |

| Peroxide Initiation at High Temperature | [86,97] |

| Generation of Peroxide at High Temperature | [86,97] |

| Oxygen Initiation | [65,66,67,72,81,84,85,86,97,104] |

| Thermal Initiation | [65,66,67,69,85,86,97] |

| Generation of Inert | [65,66,67,85] |

| Initiation (Extruder) | [71,79,83] |

| Chain Initiation | [52,53,54,60,61,94,101] |

| Hydrogen Abstraction (Extruder) | [83] |

| Hydrogen Abstraction without a Vinyl Group (Extruder) | [71,79] |

| Hydrogen Abstraction with a Vinyl Group (Extruder) | [71,79] |

| Propagation | [52,53,54,60,61,65,66,67,69,72,81,84,85,86,87,94,97,101,104] |

| Double Bond Propagation | [86,97] |

| Double Bond Propagation (extruder) | [71] |

| Chain Transfer to Monomer | [52,53,54,60,61,65,66,67,69,86,87,94,97,101] |

| Chain Transfer to Polymer | [52,53,54,60,65,66,67,69,72,78,85,86,87,94,97,101,104] |

| Chain Transfer to Polymer (Extruder) | [83] |

| Chain Transfer to Polymer without a Vinyl Group (extruder) | [71,79] |

| Chain Transfer to Polymer without a Vinyl Group (extruder) | [71,79] |

| Chain Transfer to Chain Transfer Agent/Solvent | [52,53,54,60,61,65,66,67,72,85,86,87,94,97,101,104] |

| Incorporation of Chain Transfer Agent | [52,53,54] |

| Termination by Combination | [52,53,54,60,61,65,66,67,69,72,81,84,86,87,94,97,101,104] |

| Termination by Combination (extruder) or | [71,79,83] |

| Termination with Initiation Radical (extruder) | [71] |

| Termination by Disproportionation | [52,53,54,60,78,94,101] |

| Thermal Degradation | [65,66,67,72,78,81,84,85,86,87,97,104] |

| Intramolecular Chain Transfer/Backbitting | [52,53,54,60,66,67,69,72,85,94,97,101] |

| β-Scission | [53,54,60,78,94] |

| β-Scission (Extruder) | [83] |

| β-Scission for Sec-radicals | [52,66,67,69,72,85,97,101] |

| β-Scission for Tert-radicals | [52,66,67,72,85,97,101] |

| Retardation by the Impurities | [101] |

| Decomposition of Ethylene | [101] |

| Methods | Main Feature | Ref. |

|---|---|---|

| Euler’s Method | Ability to solve simple and linear ordinary differential equation (ODEs) with the presence of initial values | [111,112,113] |

| Monte Carlo Method | Ability to compute the ODEs with random values | [113,114] |

| Rosenbrock Method | Ability to solve stiff ODEs | [113,115,116] |

| Backward Euler’s Method | Ability to solve stiff ODEs with larger step size | [117] |

| Finite Difference Method | Ability to solve partial differential equations (PDEs) by approximating the nonlinear system to linear system | [118] |

| Method of Lines | Ability to solve PDE by approximating the PDE system with an ODE system. In general, the spatial independent variables are substituted by algebraic approximation (as a function of time) | [119] |

| Finite Element Method | Ability to solve PDEs with the presence of boundary conditions | [120] |

| Multigrid Methods | Ability to solve high order PDEs, especially parabolic systems. | [121] |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Atan, M.F.; Hussain, M.A.; Abbasi, M.R.; Khan, M.J.H.; Fazly Abdul Patah, M. Advances in Mathematical Modeling of Gas-Phase Olefin Polymerization. Processes 2019, 7, 67. https://doi.org/10.3390/pr7020067

Atan MF, Hussain MA, Abbasi MR, Khan MJH, Fazly Abdul Patah M. Advances in Mathematical Modeling of Gas-Phase Olefin Polymerization. Processes. 2019; 7(2):67. https://doi.org/10.3390/pr7020067

Chicago/Turabian StyleAtan, Mohd Farid, Mohd Azlan Hussain, Mohammad Reza Abbasi, Mohammad Jakir Hossain Khan, and Muhamad Fazly Abdul Patah. 2019. "Advances in Mathematical Modeling of Gas-Phase Olefin Polymerization" Processes 7, no. 2: 67. https://doi.org/10.3390/pr7020067