Abstract

The use of bioenergy has increased globally in recent years, as has the utilization of biomaterials for various new product solutions through various biorefinery concepts. In this study, we introduce the concept of using a mechanical dewatering press in combination with thermal drying in a pellet plant. The purpose of the study is to increase the understanding of the effects a mechanical dewatering press has in a pellet production chain and investigate whether a pellet plant could thus become a biorefinery. The evaluations in this study are based on industrial data and initial tests at the university. The results show that the concept of using the mechanical dewatering press together with a packed moving bed dryer reduces energy use by 50%, compared to using only a packed moving bed dryer. The press water could be used as a raw material for biogas, bioplastics, and biohydrogen. Hence, this study points out the possibilities of a pellet plant increasing the efficiency of the drying step, while moving towards becoming a biorefinery.

1. Introduction

The total global use of biomass for energy is about 10% [1] of total energy use and this amount would need to increase for a successful transition towards a sustainable bio-economy. The use of wood fuel pellets in Europe has increased significantly, mainly as a result of the EU 2020 target for renewable energy sources. Satisfying current needs for energy from biomass pellets requires a variety of feedstocks to be dried and pre-treated prior to pelletization. A traditional pellet plant process operates in a single product production chain, as do most biofuel production plants. This is not congruent with the concept of a biorefinery, which should produce at least one energy product and at least one high value chemical/material product [2]. Pellet plants already handle large amounts of biomasses in different types of sub-steps. Therefore, by choosing these steps wisely and by combining their material flows in order to reach a complete utilization of more biomass components, pellet plants could become biorefineries.

A biorefinery plant should be run in a sustainable way. Linked to the fact that solid biofuels have a low value, it is important that the process is as energy efficient as possible. All the sub-processes within a pellet production chain are energy-demanding, especially the drying step. Drying is also associated with major costs; approximately 25% of total pellet production costs can be related to the drying process [3,4,5,6]. When designing the pellet production process, one way to reduce this cost is to meet the heat demand with a low temperature energy supply. In other words, if waste energy from saw or pulp mills could be used as an energy source, the drying costs would be reduced [7,8]. In addition to the cost and energy demand incurred by drying, many pellet producers conclude that the lack of drying capacity is a major barrier to increased production. Therefore, if the drying capacity could increase at the same time as the energy efficiency was improved, production could increase, and greater profit margins could be gained.

The most commonly used dryers for the drying of biomasses are the rotary dryer, the pneumatic (or flash) dryer, and the packed moving bed dryer; however, other dryers also exist [9,10,11,12,13,14]. Regardless of the choice of dryer, hygroscopic materials, such as biomass, behave differently during the drying process depending on the moisture content. A typical drying rate curve for biomass can be divided into three drying stages [12] that approximately correspond to moisture contents above 50%, between 50% and 20%, and below 20% [15]. During the first two stages of drying, the rate-controlling step is the diffusion of water vapor across the air–moisture interface. This means that the drying capacity is typically limited by the input of thermal energy to the dryer. In the third drying stage, the rate-controlling step is the transport of moisture through the biomass as a result of concentration gradients in the solid. In this third drying step, the residence time of the biomass in the dryer limits the drying capacity. Hence, two completely different mechanisms limit the drying capacity depending on the drying stage.

Even though there are two completely different mechanisms that limit drying capacity, it is most common to use a single dryer when designing a pellet production process; however, some producers use combinations of dryer types [1]. The potential of increasing drying efficiency with the development of two-, three- or multi-stage dryers has been shown in earlier studies. These studies focus on the use of lower drying temperatures and exhaust air recycling systems, as well as adapting drying techniques to the drying rate, for example, a technique for drying below the fiber saturation point [10,15,16,17,18,19,20]. Frodeson et al. (2013) have shown, based on industrial data, that pellet plants have the potential to increase their drying capacity as well as their energy efficiency by implementing a two-step drying technique [17]. Furthermore, Ståhl and Berghel (2008) show that the increased recirculation of drying gases causes a more energy-efficient operation of dryers and that recirculation gives a significantly higher dew point, which means that more energy can be recovered in the condenser [21]. However, these studies all focus on dryers based on evaporative drying and there is a possibility of increasing energy efficiency in the drying step by removing some of the water in the feedstock by mechanical dewatering.

Mechanical dewatering, or compression drying, is a process of forcing free water to move under high hydrostatic pressure through a solid biomass structure [22] and it has been shown that it is more energy efficient than traditional evaporative drying [23,24,25]. Laurila et al. (2014) designed a laboratory scale compression dryer and indicated that compression drying is a fast and effective solution for effective moisture reduction. The lowest moisture content achieved in the study was 30%, which is approximately 7 to 12% above fiber saturation point [26]. A drying curve was also presented, which showed that the moisture content in the dewatered biomass levels out at 30 to 40% moisture even if the pressure is increased [26]. Takahiro et al. (2010) developed a continuous dewatering system and found that, in cases where roller compression was in combination with thermal drying, the primary energy basis was 58% of the energy required for thermal drying alone [25]. There are some studies in the area of bark dewatering which focus on increasing the heating value. An attempt to dewater bark was conducted on a pilot scale and moisture contents of 65–53% were achieved [27]. Holmberg and Stenström (2014) present technical solutions for the installation of dewatering systems for bark. The laboratory results from their study show that mechanical dewatering in combination with thermal heating of the bark, before pressing, will increase water removal. The potential for increased dewatering would be at least 15–20% [28]. Askaner (1976) also conducted laboratory tests to heat the bark before dewatering and received similar results [29]. Thus, the possibilities of reducing energy requirements and increasing drying efficiency by providing a mechanical dewatering press have been established. However, compared to other drying processes, only a small amount of research is presented [30,31] and it has been difficult to scale up this technique to an industrial level, which is correlated to the time-dependent nature of the pressing of material or the reabsorption of water depending on chosen compression dryer technique [22].

Mechanical dewatering in combination with thermal heating generates high pressure on the fibers, resulting in a collapse of the fibrous cell walls [32]. This causes carbohydrate groups and lignins to be washed out with the press water [32]. It is therefore likely that extractives are similarly lost, and this may affect both pellet production and pellet quality. Lignin and carbohydrate, such as xylan and cellulose, have positive binding properties, while extractives affect bonding properties negatively [33,34,35,36,37,38,39,40,41]. As for the press water from mechanical dewatering, it creates new opportunities for pellet plants to become biorefineries with increased utilization of biomass components, as it includes both particles and biomass components.

The press water is, similar to the condensate water from biomass dryers [42], toxic to aquatic organisms [43]. Thus, the press water must be purified, preferably on site, before being released into receiving water bodies. However, if the press water has been produced in quantities that would make it economically viable to use as a feedstock, that is, in processes producing biogas, bioplastic, and biohydrogen, it could be profitable. A mechanical dewatering press at a pellet factory that produces 100,000 tons of pellets a year would also produce about 45,000 tons of press water per year. Hence, the pellet production plant could become an energy efficient biorefinery. However, as no study has been conducted on implementing a mechanical dewatering press in a pellet production chain, there is a gap of knowledge within this field.

The purpose of this study is to increase the understanding of the effects a mechanical dewatering press has in a pellet production chain and investigate whether a pellet plant could thus become a biorefinery. The aims are to implement a concept, consisting of a mechanical dewatering press with a packed moving bed dryer in a pellet process chain, then (a) investigate both its energy and mass flow rates, (b) study its effects on the pelletability of the altered feedstock, and (c) discuss possible new products that could be extracted from the press water or propose possible press water treatment methods. The concept idea in this study is based on investigations from a dewatering press and packed moving bed dryer booth on an industrial scale.

2. Materials and Methods

This study is a comparison between two different dewatering systems that will achieve the same outgoing material moisture content. The first dewatering concept is a single packed moving bed dryer where the dewatering is facilitated by thermal drying in a single step. The second dewatering concept includes a mechanical dewatering press in combination with a packed moving bed dryer.

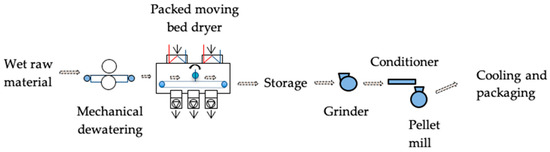

2.1. The Industrial Packed Moving Bed (PMB) Dryer

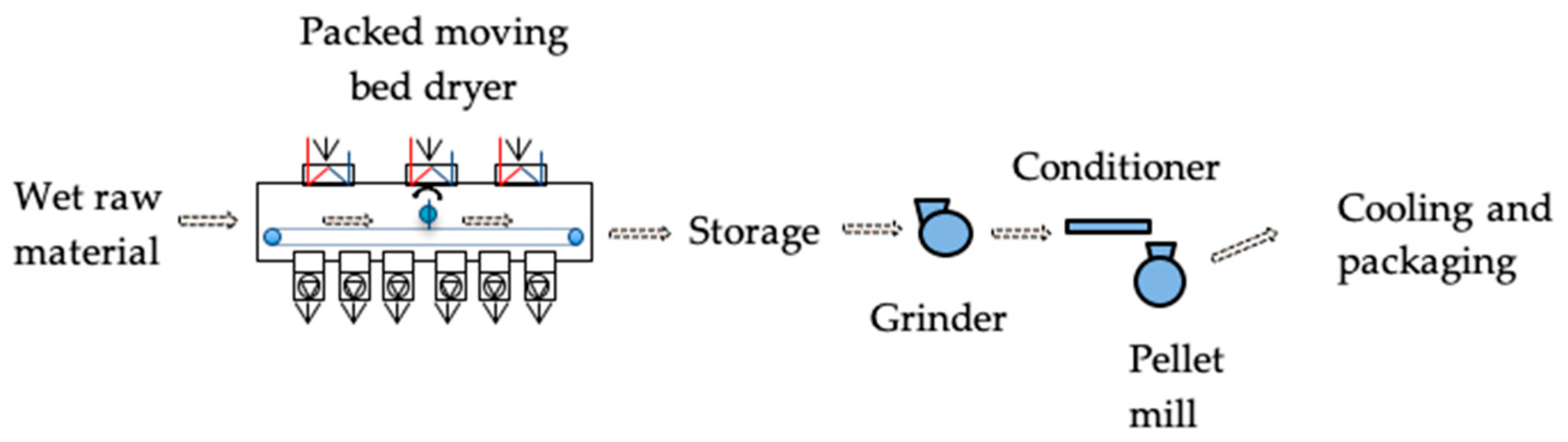

The data on the industrial packed moving bed (PMB) used in this study is based on a PMB dryer located at Stora Enso Timber AB, a combined sawmill pellet plant in Grums, Sweden. Both the sawmill and the pellet plant dryers are supplied with waste energy from a nearby pulp mill. The PMB dryer is 36 m in length and designed for a sawdust production flow of 9 ton/h (ds). It is equipped with six fans for the outlet air and the inlet dry air is distributed into three heat exchangers where it is heated. This is the whole setup design for the PMB dryer in the pellet plant (see Figure 1). All data for the PMB dryer and concept one is based on an earlier study by Frodeson et al. (2013), where more information about method and materials can be found [17].

Figure 1.

The pellet production chain and setup for using a single packed moving bed (PMB) dryer.

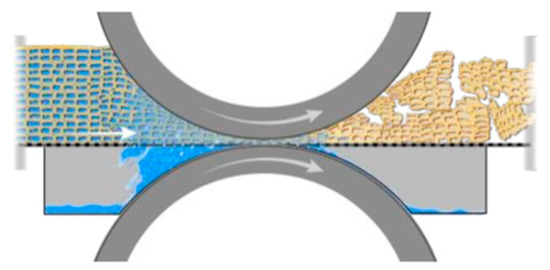

2.2. Continuous Dewatering Press (CDP)

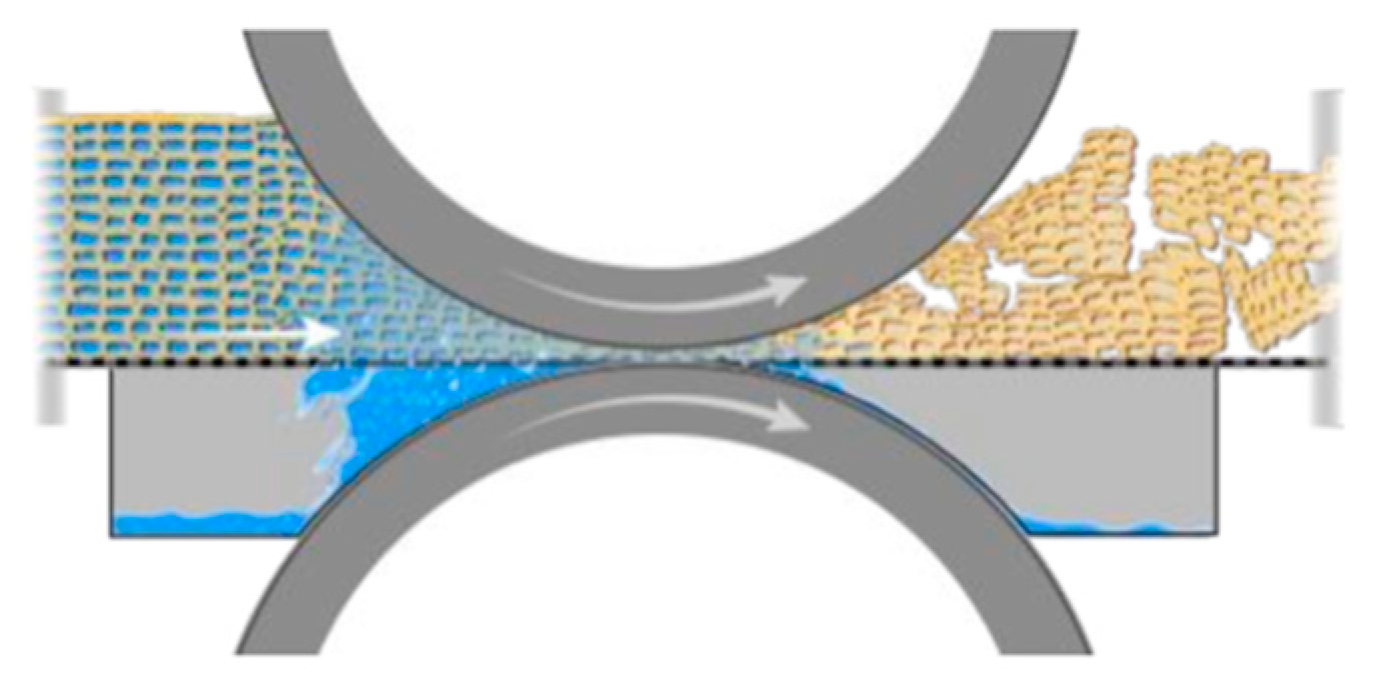

In order to investigate the potential of including mechanical dewatering in the pellet production chain, data from the Drinor AB pilot continuous dewatering press (CDP) located in Älvdalen, Sweden at Rindi Pellet AB was used. This CDP is the first manufactured unit and, during this study, the CDP was installed as a separate single production unit to enable a full scale tests series. The CDP technology has been developed to handle green biomass, such as woodchips and sawdust, that are transported by a perforated steel band into a constant cylindrical nip (see Figure 2). The water is squeezed out at high pressure, and a separation is allowed by the perforation in the steel band. The separation through the steel band minimizes re-absorption. After the cylindrical nip the moisture content of the biomass is between 35–40%, independent of the inlet moisture content. The patented CDP technology consists of two cylindrical rollers and two turning rollers for the belt. The diameter of the rollers is 600 mm and the footprint of each machine is 20 m3. The machines operate at speeds between 0.3–1 m/s and material bed heights are up to 50 mm.

Figure 2.

A concept picture of the mechanical dewatering continuous dewatering press (CDP) technique.

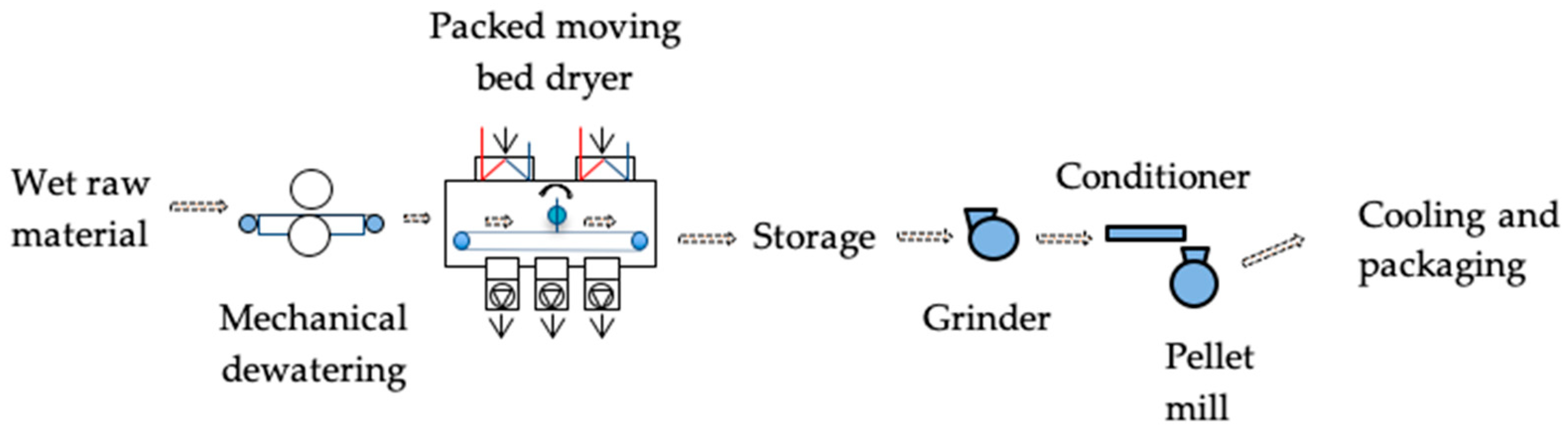

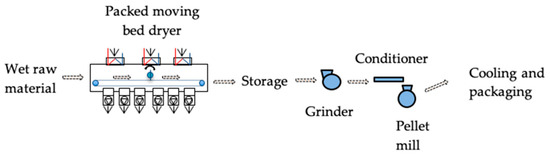

The CDP is implemented as a mechanical dewatering technique used before the PMB dryer (see Figure 3). The CDP removes some of the water before it enters the PMB dryer, whereas the second step dries the feedstock to the desired final moisture content.

Figure 3.

The setup for including a mechanical dewatering press before the PMB dryer in a pellet production chain.

2.3. Energy and Mass Balance for the PMB and the CDP + PMB

The first concept consists of one PMB dryer and is hereinafter referred to as PMB. The second concept is a combination of a CDP press and a PMB dryer and is hereinafter referred to as CDP + PMB.

Mass flow analysis and energy flow analysis were used to evaluate the two dewatering concepts. The ambient conditions used were assumed to be 7 °C and 60% RH for the energy and mass balances, respectively. It was also assumed that the temperature of the inlet sawdust flow was equal to the ambient air temperature. The outlet sawdust flow temperature was 3 °C below the temperature of the outlet moist air in the last fan. For analysis of the drying capacity of the PMB dryer, the dryer was divided into six zones, which were correlated to the fan numbers. The drying potential for each zone was determined based on measured industrial data [17]. For analysis of the drying capacity of the PMB in the CDP + PMB, the outlet sawdust flow from the CDP was given the need for a drying capacity linked to the number of zones, or fans, which became three. The specific heat capacities used in the energy and mass balances were 1.4 kJ/kg for sawdust, 1.0 kJ/kg for air, 1.8 kJ/kg for vapor, and 2500 kJ/kg for vaporization heat. All data for moisture content is based on wet basis and determined according to SS-EN 14774-1 [44]. The analyses for both the PMB and the CDP + PMB concepts were based on the data presented in Table 1.

Table 1.

Inlet data for the PMB and the CDP + PMB.

The following steps were taken to determine the energy balance for the CDP + PMB. The determination of the potential for implementing the CDP in the production chain is based on the energy and mass balances from using only the PMB. The amount of water mechanically removed in the CDP is based on measured data. To determine the need for drying energy and the size of the PMB dryer, the outgoing moisture content from the CDP was used as the inlet moisture content in the PMB dryer. The need for drying capacity was then determined based on the number of zones in the PMB dryer with the purpose of reaching down to 12.5% moisture content.

2.4. Effects of the Mechanical Dewatering Technique on Sawdust

The material properties correlated to particle size distribution and bulk density were tested based on unpressed and CDP-pressed sawdust from Scotch pine (Picea sylvestris) received from the Rindi Pellets plant in Älvdalen, Sweden. Before the test, the sawdust was dried in a bed drier using ambient air at an approximate temperature of 20 °C until an equilibrium moisture content in the sawdust of about 7% was reached. For particle size distribution, the sawdust was sieved for 10 min, using a shaking machine from Pascall Engineering, with six different sieve sizes: 4.0, 2.0, 1.4, 1.0, 0.71, and 0.355 mm. The bulk density (kg/m3) for unpressed and CDP-pressed sawdust was determined by measuring the weight of a 5 liter bucket, according to SS-EN 15103:2010 [45].

3. Results and Discussion

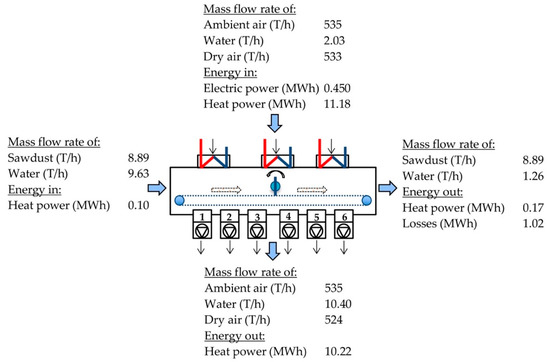

3.1. Energy and Mass Balances for Concept One

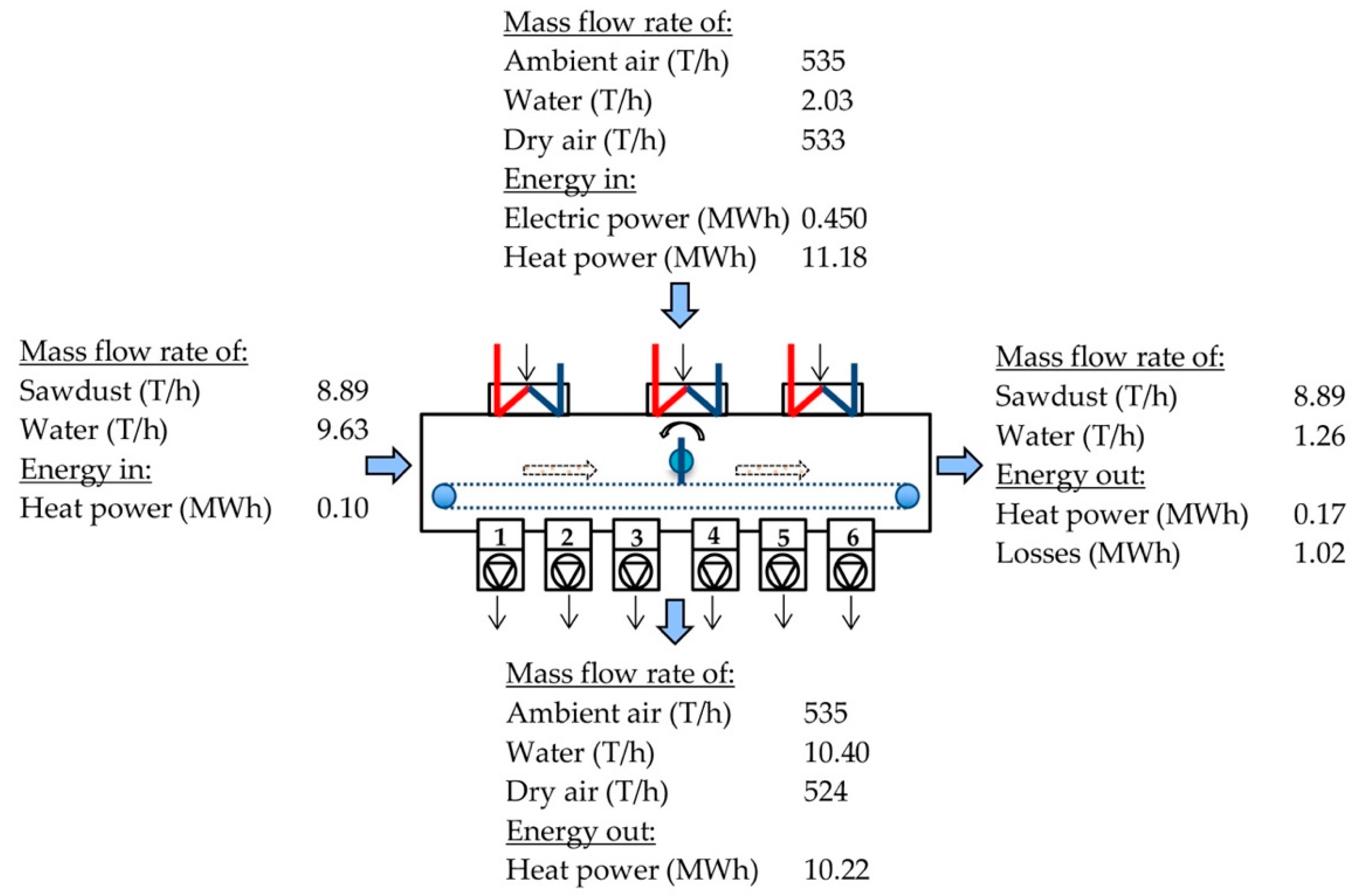

The theoretical calculations for using the PMB, based on industrial data, show that when drying 8.9 tons of sawdust per hour, from 52% to 12.5% (wb), 11.2 MW of heat power is used (see Figure 4). Furthermore, they show that about 8.4 tons of water and 10.2 MW of heat are released into ambient air.

Figure 4.

The energy and mass balance for the PMB.

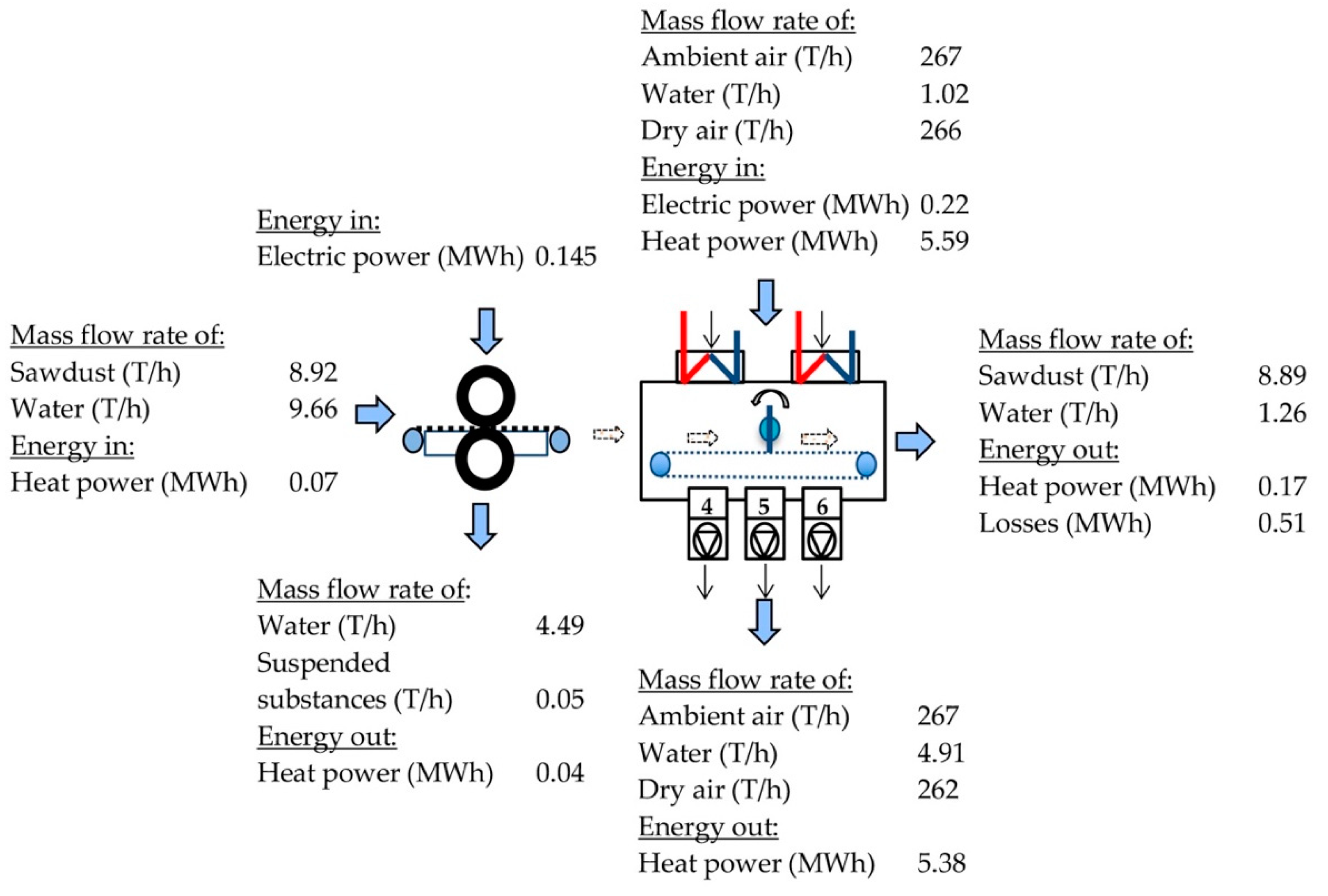

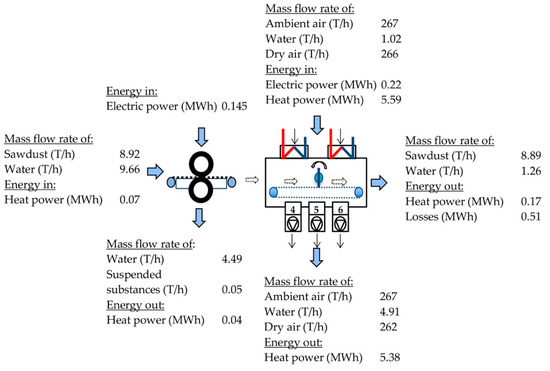

3.2. Energy and Mass Balances for Concept Two

As shown in Figure 5, including the CDP press in the pellet production chain, using the same set of data, shows that 0.15 MW of electricity (for the CDP) and 5.6 MW of heat power (for the PMB) are used when 8.9 tons of sawdust per hour are dewatered from 52% to 36.7% and then dried to 12.5% (wb). In the CDP press, 4.5 tons of water per hour are pressed out and the amount of water which is evaporated and heat which is released into the ambient air from the belt dryer decreases to 4.9 tons per hour and 5.4 MW, respectively (see Figure 5). Compared with the PMB dryer, a decrease in energy use of about 50% is achieved.

Figure 5.

The energy and mass balance for the CDP + PMB.

The results, presented in Figure 4 and Figure 5, also show that the use of electricity is about the same, regardless of whether the PMB or the CDP + PMB are used for water removal. The PMB uses 0.45 MW of electrical power for the fans in the dryer and the CDP + PMB uses a total of 0.37 MW for both the CDP and the fans in the PMB dryer.

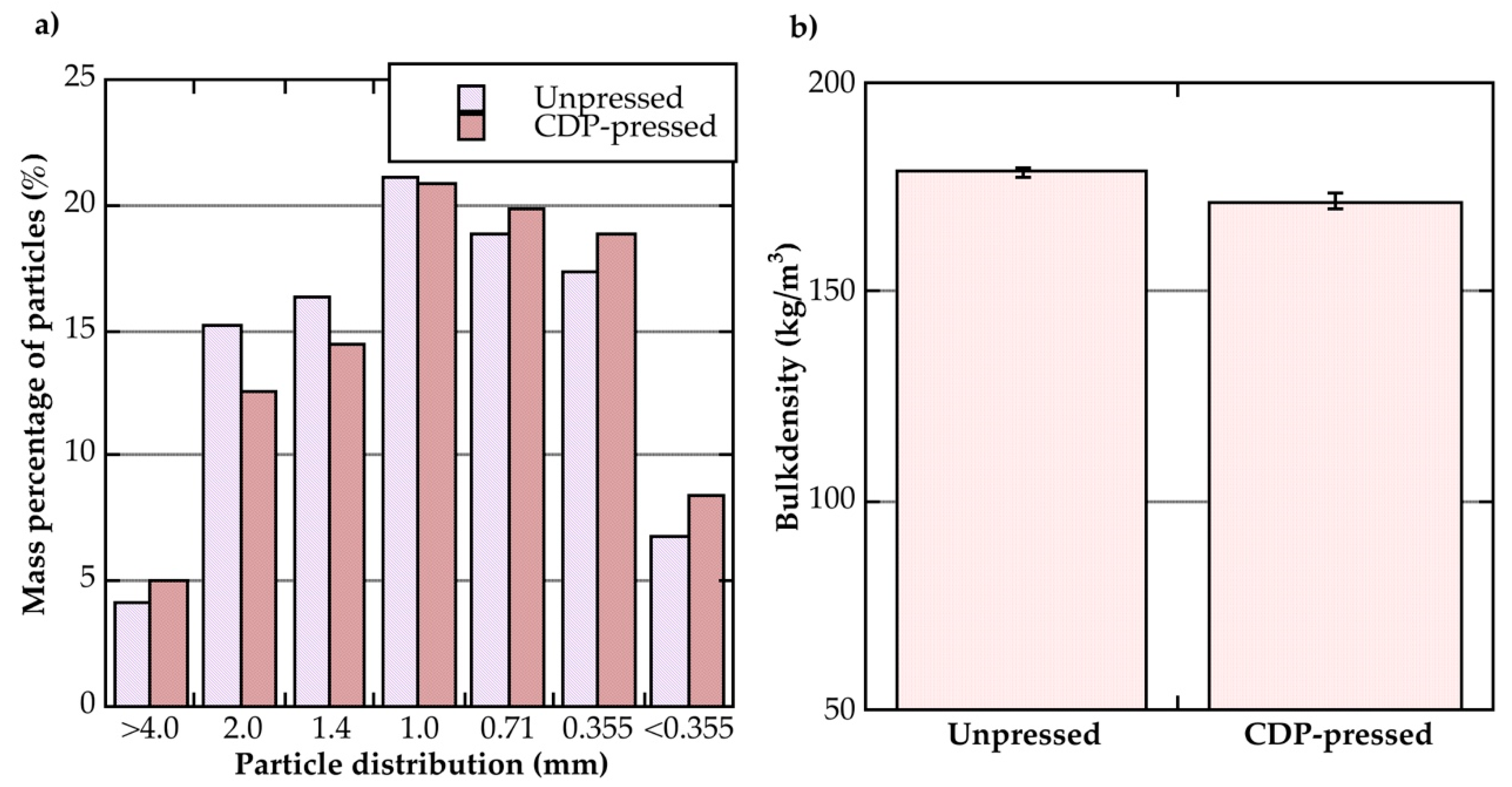

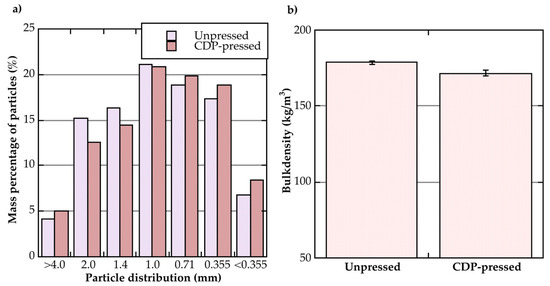

3.3. Effects on the Sawdust When Using the CDP

The particle size distribution differs between unpressed and CDP-pressed sawdust (see Figure 6a). CDP-pressed sawdust has larger amounts of small particles than unpressed sawdust, due to the crushing of fibers in the cylindrical nip. The number of very small particles may have been greater if all the material could have been tested, but the smallest particles were washed out with the press water and are thus not included in the analysis. The bulk density of CDP-pressed sawdust is lower than that of unpressed sawdust (see Figure 6b). These variations are small, so it is difficult to make any robust conclusions after these first tests. However, it is likely that these variations are due to pressed fibers having been broken and becoming more voluminous, which results in slightly lower bulk weight.

Figure 6.

Effects on sawdust properties for unpressed and CDP-pressed sawdust: (a) Particle distribution for sawdust sieved at a moisture content of 12% and divided into seven different sieves; (b) bulk density for unpressed and CDP-pressed sawdust tested at 6% moisture content.

3.4. The Press Water and Possible New Products

The second concept (CDP + PMB) not only decreases energy use, but also creates a mass flow of press water. This water contains fibers, extractives, hemicelluloses and lignin, and this is accounted for in the calculations so that the same amount of sawdust is dried in both concepts. It could be seen as a loss of substances, and thus a lower pellet yield and altered pelletability—or it could be perceived as a new feedstock. A biorefinery approach would focus on the press water as a source of suspended organic material and water-soluble substances, which could be extracted with suitable methods and made into new products or profitable chemicals.

As a biogas feedstock, the press water has, according to preliminary data, a yield comparable to horse manure or straw at the lower end and ensilage or vegetables at the higher end. A more visionary option might be to use the press water as a raw material for bioplastics and biohydrogen. Hemicellulose has been found to be suitable as a substrate for fermentation to hydrogen and acetic acid. Biohydrogen is usable as it is, and the acetic acid is a preferred substrate for bacteria that accumulate in polyhydroxyalkanoate, which is the basis for the biodegradable bioplastic PHA. Hence, a pellet plant can be transformed into a new biorefinery by applying the second concept. If a sufficient amount of substances can be extracted in the CDP, the rest of the press water might not need to be cleaned before being released into the surroundings and the CDP + PMB could be used in any stand-alone pellet plant. If no extraction occurs, or an insufficient amount of substances are extracted, then a cleaning method will be needed. Cleaning technologies suitable for biomass dryer condensate should also work for press water. Common options include pH adjustment and filtration or flotation. If the mechanical dewatering press is placed near a pulp and paper mill with aerobic wastewater treatment, it may, considering that the micro-organisms in these purification plants can withstand a 0.2% mixing of steam dryer condensate without the activity decreasing by more than 10% [46], be feasible to lead the press water to the mill-activated sludge basin.

3.5. Further Work

The concept of using a mechanical dewatering press in combination with a packed moving bed dryer is shown to be an energy efficient method for the removal of water. Initial studies on the CDP in Älvdalen have shown that, independent of the inlet moisture content of the material, the outlet moisture content is constant. These conditions create new options and opportunities for the design of processes for the pretreatment of biomaterials. Mechanical dewatering makes it possible to wash the feedstock, meaning that bioenergy plants could include dirty raw materials, such as bark, stumps or residues, which are raw materials that often include soil and gravel particles that are not desirable in its ordinary feedstock. By installing a washing step before the CDP these feedstocks can be included and the CDP + PMB option would thus create a broader raw materials base. However, the washing will affect the outlet water flow from the CDP. The cell-structure of bark is very different compared to that of wood. Bark exists to protect the tree and its cellular structure differs from that of wood, which means that dewatering also becomes different. However, this has not yet been studied and this option needs further research.

The CDP + PMB may be further improved by preheating the feedstock. Initial tests with the CDP have shown that the mechanical dewatering rate increases if the feedstock is pre-heated with steam. Furthermore, it affects the mass and energy balances, as the energy used for the CDP reduces the energy need for the thermal drying step as the feedstock is preheated to around 50 °C during pressing, and thus enters the thermal dryer at a higher inlet temperature. Additionally, more substances are extracted from the feedstock, with a notable increase in the potential of, for example, biogas production from the press water. However, only initial tests have been conducted and further studies are needed, including evaluations of the total energy use.

In this study the thermal drying step is based on a packed moving bed dryer, often used at pellet plants for its potential to use low-temperature heat sources. However, a packed moving bed is not optimized for dry biomasses below fiber saturation point, where a flash or pneumatic dryer would be more suitable [10,15,16,17,18,19,20]. Therefore, a concept with the CDP and a flash dryer could increase the drying rate even further. Beyond that, the variation in particle sizes is an important parameter to consider when designing the drying steps. The particle surface area increases with decreasing particle size. The difference in surface area is important for thermal drying, since the fine fraction dries faster and thus becomes over-dried [47]. Results from initial tests by the authors show that the smallest particles are drier than larger particles after the CDP. Hence, a solution where the smallest particles bypass the thermal drying step in concept two can avoid over-drying and reduce energy use. This could also create a new particle flow based on very small particles suitable for powder burners, pretreatment for pyrolysis, gasification, chemical refining, and biogas feedstock. This should increase the possibility of a pellet plant acting as a biorefinery. However, this study has shown the potential of a new concept for the drying of biomaterials so that both the energy use can be reduced and new material flows could be created. However, it must be clarified that the results are based on two separate production units and further studies must be conducted.

4. Concluding Remarks

The most obvious finding to emerge from this study are that using a mechanical dewatering press in a drying concept reduces thermal energy use by 50%. Another finding is that the use of electric energy is in the same range for the PMB as it is for the concept CDP + PMB for drying biomass from 52% MC to 12.5% MC. Furthermore, the mechanical compression effects the material properties of sawdust. Regarding the biorefinery option, several promising paths to achieve greater product versatility have been identified. Research questions imperative for the evolution of plants from single product pellet producers towards biorefineries have also been identified, that is, studies of the pellet quality from CDP-pressed sawdust and experimental evaluation of the press water as feedstock for new bio-products.

Author Contributions

Conceptualization: S.F., J.B. and M.S.; methodology: S.F., J.B.; formal analysis: S.F., J.B.; investigation: S.F., J.B., M.S. and K.G.; resources: S.F., C.R. and A.T.; data curation: S.F., C.R. and A.T.; writing—original draft preparation: S.F., J.B., M.S. and K.G.; writing—review and editing: S.F., J.B., M.S., K.G., C.R. and A.T.; funding acquisition: S.F.

Funding

This work was financed by the Swedish Agency for Economic and Regional Growth through the project FOSBE (grant number 202001239).

Acknowledgments

Many thanks to Stora Enso Timber AB in Grums, Sweden and Rindi Pellets AB in Älvdalen, Sweden for their cooperation.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- Stenström, S. Drying of biofuels from the forest—A review. Dry. Technol. 2017, 35, 1167–1181. [Google Scholar] [CrossRef]

- Cherubini, F. The biorefinery concept: Using biomass instead of oil for producing energy and chemicals. Energy Convers. Manag. 2010, 51, 1412–1421. [Google Scholar] [CrossRef]

- Monteiro, E.; Mantha, V.; Rouboa, A. Portuguese pellets market: Analysis of the production and utilization constrains. Energy Policy 2012, 42, 129–135. [Google Scholar] [CrossRef]

- Mani, S.; Sokhansanj, S.; Bi, X.; Turhollow, A. Economics of Producing Fuel Pellets from Biomass. Am. Soc. Agric. Biol. Eng. 2006, 22, 421–426. [Google Scholar] [CrossRef]

- Thek, G.; Obernberger, I. Wood pellet production costs under Austrian and in comparison to Swedish framework conditions. Biomass Bioenergy 2004, 27, 671–693. [Google Scholar] [CrossRef]

- Uasuf, A.; Becker, G. Wood pellets production costs and energy consumption under different framework conditions in Northeast Argentina. Biomass Bioenergy 2011, 35, 1357–1366. [Google Scholar] [CrossRef]

- Wolf, A.; Vidlund, A.; Andersson, E. Energy-efficient pellet production in the forest industry-a study of obstacles and success factors. Biomass Bioenergy 2006, 30, 38–45. [Google Scholar] [CrossRef]

- Andersson, E.; Harvey, S.; Berntsson, T. Energy efficient upgrading of biofuel integrated with a pulp mill. Energy 2006, 31, 1384–1394. [Google Scholar] [CrossRef]

- Ståhl, M.; Granström, K.; Berghel, J.; Renström, R. Industrial processes for biomass drying and their effects on the quality properties of wood pellets. Biomass Bioenergy 2004, 27, 621–628. [Google Scholar] [CrossRef]

- Pang, S.; Mujumdar, A.S. Drying of Woody Biomass for Bioenergy: Drying Technologies and Optimization for an Integrated Bioenergy Plant. Dry. Technol. 2010, 28, 690–701. [Google Scholar] [CrossRef]

- Wimmerstedt, R. Recent advances in biofuel drying. Chem. Eng. Process. Process Intensif. 1999, 38, 441–447. [Google Scholar] [CrossRef]

- Mujumdar, A.S. Principles, Classification, and Selection of Dryers. In Handbook of Industrial Drying, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2006; pp. 3–32. [Google Scholar] [CrossRef]

- Berghel, J. The Effect of Using a Heating Tube in an Existing Spouted Bed Superheated Steam Dryer. Dry. Technol. 2011, 29, 183–188. [Google Scholar] [CrossRef]

- Olazar, M.; Lopez, G.; Altzibar, H.; Amutio, M.; Bilbao, J. Drying of Biomass in a Conical Spouted Bed with Different Types of Internal Devices. Dry. Technol. 2011, 30, 207–216. [Google Scholar] [CrossRef]

- Pang, S. Improving MDF Fibre Drying Operation by Application of a Mathematical Model. Dry. Technol. 2001, 19, 1789–1805. [Google Scholar] [CrossRef]

- Spets, J.-P.; Ahtila, P. Reduction of Organic Emissions by Using a Multistage Drying System for Wood-Based Biomasses. Dry. Technol. 2004, 22, 541–561. [Google Scholar] [CrossRef]

- Frodeson, S.; Berghel, J.; Renström, R. The Potential of Using Two-Step Drying Techniques for Improving Energy Efficiency and Increasing Drying Capacity in Fuel Pellet Industries. Dry. Technol. 2013, 31, 1863–1870. [Google Scholar] [CrossRef]

- Kudra, T. Energy Aspects in Drying. In Handbook of Industrial Drying, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2006; pp. 1075–1101. [Google Scholar] [CrossRef]

- Poirier, D. Conveyor dryers. In Handbook of Industrial Drying, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2006; pp. 411–422. [Google Scholar]

- Borde, I.; Levy, A. Pneumatic and Flash Drying. In Handbok of Industrial Drying, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2006; pp. 397–410. [Google Scholar]

- Ståhl, M.; Berghel, J. Validation of a mathematical model by studying the effects of recirculation of drying gases. Dry. Technol. 2008, 26, 786–792. [Google Scholar] [CrossRef]

- Liu, Z.; Haygreen, J.G. Drying rates of wood chips during compression drying. Wood Fiber Sci. 2007, 17, 214–227. [Google Scholar]

- Haygreen, J.G. Potential for compression drying of green wood chip fuel. For. Prod. J. 1981, 31, 43–54. [Google Scholar]

- Haygreen, J.G. Mechanics of compression drying solid wood cubes and chip mats. For. Prod. J. 1982, 32. [Google Scholar]

- Yoshida, T.; Sasaki, H.; Takano, T.; Sawabe, O. Dewatering of high-moisture wood chips by roller compression method. Biomass Bioenergy 2010, 34, 1053–1058. [Google Scholar] [CrossRef]

- Laurila, J.; Havimo, M.; Lauhanen, R. Compression drying of energy wood. Fuel Process. Technol. 2014, 124, 286–289. [Google Scholar] [CrossRef]

- Impola, R. Kuoren Kasittely Polttoaineeksi-PUUT07. In Proceedings of the VTT Symposium, Jyväskylä, Finland, 28–30 April 2000; pp. 217–232. [Google Scholar]

- Holmberg, A.; Stenström, S. Dewatering and drying of bark. Int. J. Energy Eng. 2014, 4, 8–16. [Google Scholar]

- Askaner, A. Barkpressning. Ph.D. Thesis, Department of Chemical Engineering, Chalmers University of Technology, Gothenburg, Sweden, 1976. [Google Scholar]

- Adachi, K.; Inoue, M.; Kanayama, K. Water removal of wet veneer by roller pressing. J. Wood Sci. 2004, 479–483. [Google Scholar] [CrossRef]

- Wingate-Hill, R.; Cunningham, R.B. Moisture removal from green sapwood during platen pressing. N. Z. J. For. Sci. 1986, 16, 109–117. [Google Scholar]

- Yin, J.; Yuan, T.; Lu, Y.; Song, K.; Li, H.; Zhao, G.; Yin, Y. Effect of compression combined with steam treatment on the porosity, chemical compositon and cellulose crystalline structure of wood cell walls. Carbohydr. Polym. 2017, 155, 163–172. [Google Scholar] [CrossRef]

- Frodeson, S.; Henriksson, G.; Berghel, J. Pelletizing Pure Biomass Substances to Investigate the Mechanical Properties and Bonding Mechanisms. BioResources 2018, 13, 1202–1222. [Google Scholar] [CrossRef]

- Frodeson, S.; Henriksson, G.; Berghel, J. Effects of moisture content during densification of biomass pellets, focusing on polysaccharide substances. Biomass Bioenergy 2019, 122, 322–330. [Google Scholar] [CrossRef]

- Kaliyan, N.; Vance Morey, R. Factors affecting strength and durability of densified biomass products. Biomass Bioenergy 2009, 33, 337–359. [Google Scholar] [CrossRef]

- Whittaker, C.; Shield, I. Factors affecting wood, energy grass and straw pellet durability—A review. Renew. Sustain. Energy Rev. 2017, 71, 1–11. [Google Scholar] [CrossRef]

- Nielsen, N.P.K.; Holm, J.K.; Felby, C. Effect of Fiber Orientation on Compression and Frictional Properties of Sawdust Particles in Fuel Pellet Production. Energy Fuels 2009, 23, 3211–3216. [Google Scholar] [CrossRef]

- Samuelsson, R.; Thyrel, M.; Sjöström, M.; Lestander, T.A. Effect of biomaterial characteristics on pelletizing properties and biofuel pellet quality. Fuel Process. Technol. 2009, 90, 1129–1134. [Google Scholar] [CrossRef]

- Nielsen, N.P.K.; Gardner, D.J.; Felby, C. Effect of extractives and storage on the pelletizing process of sawdust. Fuel 2010, 89, 94–98. [Google Scholar] [CrossRef]

- Samuelsson, R.; Larsson, S.H.; Thyrel, M.; Lestander, T.A. Moisture content and storage time influence the binding mechanisms in biofuel wood pellets. Appl. Energy 2012, 99, 109–115. [Google Scholar] [CrossRef]

- Stelte, W.; Sanadi, A.R.; Shang, L.; Holm, J.K.; Ahrenfeldt, J.; Henriksen, U.B. Recent developments in biomass pelletization—A Review. BioResources 2012, 7, 4451–4490. [Google Scholar]

- Granström, K.M.; Sandberg, M. Characterization of Wood-Dryer Condensate with Assessment of Toxicity to Microorganisms. J. Environ. Eng. 2017, 143, 04017019. [Google Scholar] [CrossRef]

- Ek, M. Rening och Kemisk Karakterisering av Kondensat och Torkgaser från Torkning av Biobränsle: Treatment and Chemical Characterisation of Condensate and Drying Gases from Drying of Biofuel; Värmeforsk: Stockholm, Sweden, 2000; p. 30. [Google Scholar]

- SIS. S.S.I. SS-EN 14774-1 Solid Biofuels—Determination of Moisture Content—Oven Dry Method—Part 1: Total Moisture—Reference Method; SIS Förlag AB: Stockholm, Sweden, 2009. [Google Scholar]

- SIS. S.S.I. SS-EN 15103 Solid Biofuels—Determination of Bulk Density; SIS Förlag AB: Stockholm, Sweden, 2010. [Google Scholar]

- Sandberg, M.; Granström, K.M. A chance at biological treatment for dryer condensates? In Proceedings of the NDC 2011, Helsinki, Finland, 18–21 June 2011. [Google Scholar]

- Berghel, J. Improved Fluidized Bed Drying Technology for Wood Fuels. Ph.D. Thesis, Karlstad University Studies, Karlstad, Sweden, 2004. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).