Innovation in Continuous Rectification for Tequila Production

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Material.

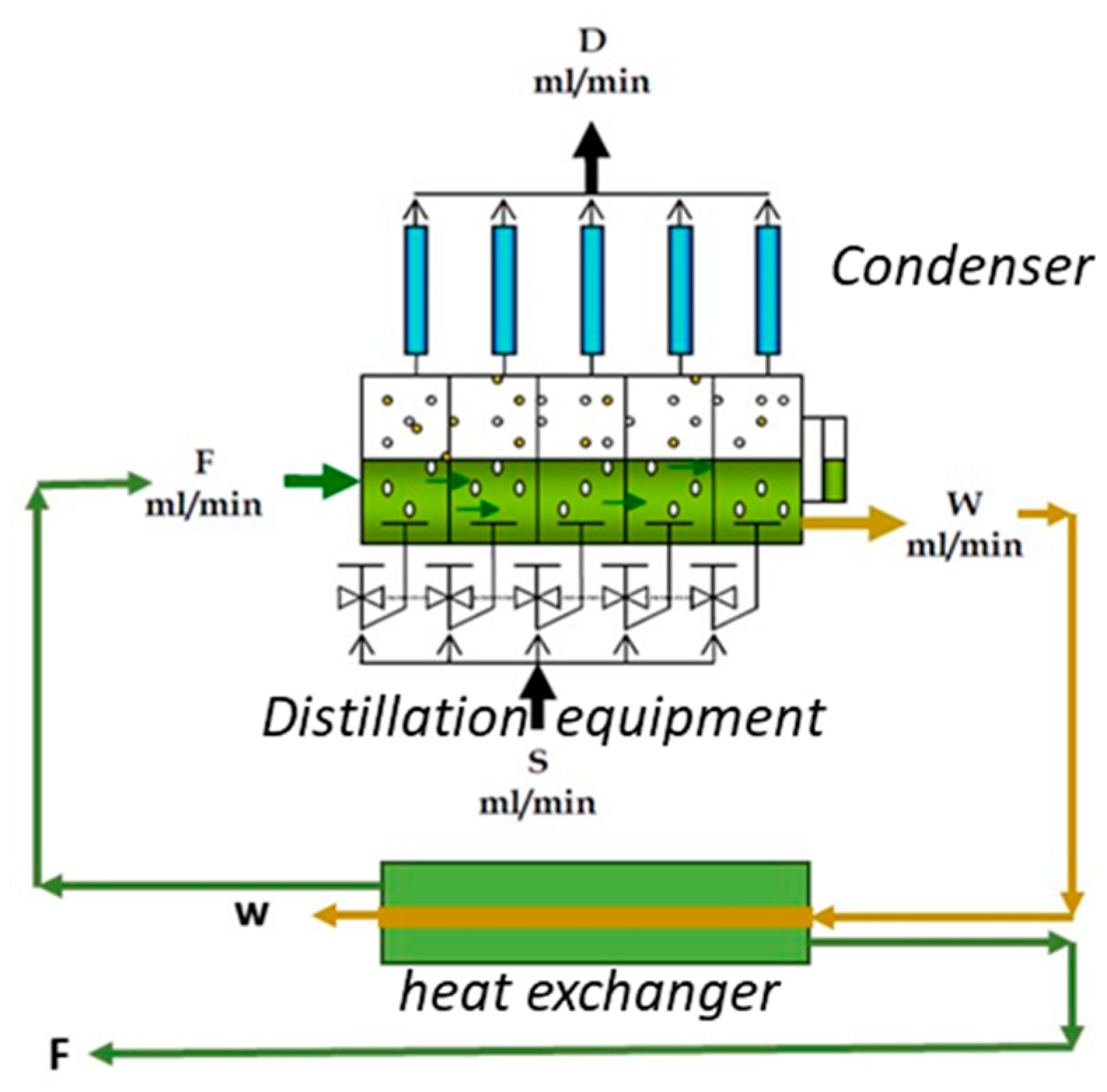

2.2. Continuous Distillation of Ordinario at Pilot Level.

2.3. Alcoholic Content

2.4. Chromatographic Characterization

2.5. Statistical Analysis.

3. Results and Discussions

3.1. Alcoholic Concentration of Distilled Fractions

3.2. Chromatographic Characterization

3.2.1. Content of Higher Alcohols and Aldehydes

3.2.2. Content of Methanol, Esters, and Furfural

3.3. Energy Consume

- Multistage distillation is more efficient than one-stage distillation for the same consumption of steam for both alternatives, due to an increment of mass transfer by a higher gradient between concentrations of phase liquid to phase vapor during the distillation process and the better distribution of vapor in each stage;

- In this technology, it is possible recuperate about 15% of sensible heat of the effluent using a heat exchanger to preheat the feed, which is a possibility to implement in the beverage industry.

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Cedeño, M.C. Tequila Production. Crit. Rev. Biotechnol. 1995, 15, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Consejo Regulador del Tequila. Available online: http://www.crt.org.mx (accessed on 15 January 2019).

- Secretaría de Economía. Bebidas Alcohólicas-Tequila-Especificaciones; NOM-006-SCFI-2012; Secretaría de Economía: México City, México, 2012. [Google Scholar]

- Benn, S.M.; Peppard, T.L. Characterization of Tequila Flavor by Instrumental and Sensory Analysis. J. Agric. Food Chem. 1996, 44, 557–566. [Google Scholar] [CrossRef]

- Prado-Jaramillo, N.; Estarrón-Espinosa, M.; Escalona-Buendía, H.; Cosío-Ramírez, R.; Martín-del-Campo, S.T. Volatile compounds generation during different stages of the Tequila production process. A preliminary study. LWT–Food Sci. Technol. 2015, 61, 471–483. [Google Scholar] [CrossRef]

- Luna, R.; López, F.; Pérez-Correa, J.R. Minimizing methanol content in experimental charentais alembic distillations. J. Ind. Eng. Chem. 2018, 57, 160–170. [Google Scholar] [CrossRef]

- Rogelio, P.-R.; Victor, G.-A.; Carlos, P.-O.; Norberto, C.; Mirna, E.; Héctor, E.G.-H. The role of distillation on the quality of tequila. Int. J. Food Sci. Technol. 2005, 40, 701–708. [Google Scholar] [CrossRef]

- Batista, F.R.M.; Meirelles, A.J.A. Computer simulation applied to studying continuous spirit distillation and product quality control. Food Control. 2011, 22, 1592–1603. [Google Scholar] [CrossRef] [Green Version]

- Sahraoui, N.; Vian, M.A.; Bornard, I.; Boutekedjiret, C.; Chemat, F. Improved microwave steam distillation apparatus for isolation of essential oils: Comparison with conventional steam distillation. J. Chromatogr. A 2008, 1210, 229–233. [Google Scholar] [CrossRef] [PubMed]

- Vorayos, N.; Kiatsiriroat, T.; Vorayos, N. Performance analysis of solar ethanol distillation. Renew. Energy 2006, 31, 2543–2554. [Google Scholar] [CrossRef]

- Maiti, D.; Jana, A.K.; Samanta, A.N. A novel heat integrated batch distillation scheme. Appl. Energy 2011, 88, 5221–5225. [Google Scholar] [CrossRef]

- Padilla, J.D.; Vega, H.; Alba, A.; Rodríguez, E. Sistema Multifuncional de Destilación, Evaporación y Extracción de Moléculas orgánicas Derivadas de Productos Naturales. MX Patent No. 013248, 9 December 2011. [Google Scholar]

- Padilla, M.F.J.; González, R.O.; Prado, R.R.; Gutiérrez, P.H.; Estarrón, E.M.; Vega, G.H.A.; Padilla de la R, J.D. Nuevo equipo y proceso de destilación fraccionada en continuo por arrastre con vapor de aceites esenciales del jugo de limón mexicano. E-Gnosis 2007, 5, 1–16. [Google Scholar]

- Piggot, R. From pot stills to continuous stills: Flavor modification by distillation. In The Alcohol Textbook, 4th ed.; Jacques, K.A., Lyons, T.P., Kelsall, D.R., Eds.; Nottingham University Press: Nottingham, UK, 2003; pp. 259–266. [Google Scholar]

- Velásquez, H.I.; Adriana Ruiz, A.A.; Junior, S. Energy and exergy analysis of etanol production process from banana fruit. Rev. Fac. Ing. Univ. Antioquia 2010, 51, 87–96. [Google Scholar]

- Wakabayashi, T.; Yoshitani, K.; Takahashi, H.; Hasebe, S. Verification of energy conservation for discretely heat integrated distillation column through commercial operation. Chem. Eng. Res. Des. 2019, 142, 1–12. [Google Scholar] [CrossRef]

- Wang, X.; Yu, X.; Xie, L.; Li, M.; Zhang, Y. Energy-saving columns: Design and control of a Kaibel and a multi-sidestream column for separating hydrocarbon mixture. Chem. Eng. Process. Process Intensif. 2018, 133, 66–82. [Google Scholar] [CrossRef]

- Alemán-Nava, G.S.; Gatti, I.A.; Parra-Saldivar, R.; Dallemand, J.-F.; Rittmann, B.E.; Iqbal, H.M.N. Biotechnological revalorization of Tequila waste and by-product streams for cleaner production—A review from bio-refinery perspective. J. Clean. Prod. 2018, 172, 3713–3720. [Google Scholar] [CrossRef]

- Martínez Morales, M.; Pérez Alvarado, E.; Garfias Lopez, L. Análisis del Mercado Potential del Tequila 100% Agave; Tesis de pregrado; Instituto Politécnico Nacional: México City, México, 2008. [Google Scholar]

| Compound | Mean concentration of Continuous Distillation (Σ Fractions 2, 3, 4 and 5).mg/100 mL of a. a. | NOM-006-SCFI-2012 mg/100 mL of a. a. |

|---|---|---|

| Aldehydes | 2.87 ± 1.02 | 40 |

| Methanol | 95.17 ± 4.59 | 300 |

| Esters | 11.67 ± 3.56 | 200 |

| Higher alcohols | 253.66 ± 86.51 | 500 |

| Furfural | 1.18 ± 0.35 | 4 |

| Compound | Fraction 1 | Fraction 2 | Fraction 3 | Fraction 4 | Fraction 5 |

|---|---|---|---|---|---|

| Mean ± S.D. | Mean ± S.D. | Mean ± S.D. | Mean ± S.D. | Mean ± S.D. | |

| Acetaldehyde | 27.97 ± 24.40 | 5.05 ± 1.44 | 4.97 ± 3.35 | 1.57 ± 0.36 | 1.50 ± 1.23 |

| Ethyl acetate | 76.48 ± 35.56 | 13.04 ± 8.35 | 11.83 ± 7.26 | 2.91 ± 0.66 | 2.87 ± 3.77 |

| Methanol | 87.28 ± 8.53 | 81.11 ± 17.03 | 93.02 ± 4.58 | 108.10 ± 7.42 | 99.84 ± 11.48 |

| 2-Butanol | 1.19 ± 0.04 | 0.41 ± 0.23 | 0.39 ± 0.41 | 0.21 ± 0.08 | 0.34 ± 0.36 |

| 1-Propanol | 30.49 ± 2.35 | 20.62 ± 7.21 | 22.42 ± 3.79 | 20.43 ± 1.07 | 20.66 ± 5.65 |

| Isobutanol | 148.66 ± 13.97 | 72.08 ± 32.46 | 74.63 ± 22.91 | 52.47 ± 6.06 | 59.21 ± 34.63 |

| 1-Butanol | 0.99 ± 0.15 | 0.60 ± 0.21 | 0.59 ± 0.20 | 0.56 ± 0.03 | 0.64 ± 0.33 |

| Isoamyl alcohol | 350.58 ± 38.21 | 180.16 ± 80.52 | 186.35 ± 55.65 | 131.83 ± 17.22 | 152.55 ± 88.84 |

| 1-Pentanol | 0.32 ± 0.12 | 0.37 ± 0.06 | 0.55 ± 0.22 | 0.36 ± 0.09 | 0.46 ± 0.12 |

| Ethyl lactate | 1.87 ± 0.55 | 2.82 ± 0.50 | 3.38 ± 1.07 | 4.70 ± 1.09 | 4.72 ± 2.53 |

| Furfural | 1.35 ± 0.11 | 1.00 ± 0.36 | 0.81 ± 0.26 | 0.86 ± 0.16 | 1.92 ± 0.96 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mirna, E.-E.; Mariela, R.-P.; Daniel, P.-d.l.R.J.; Rogelio, P.-R. Innovation in Continuous Rectification for Tequila Production. Processes 2019, 7, 283. https://doi.org/10.3390/pr7050283

Mirna E-E, Mariela R-P, Daniel P-dlRJ, Rogelio P-R. Innovation in Continuous Rectification for Tequila Production. Processes. 2019; 7(5):283. https://doi.org/10.3390/pr7050283

Chicago/Turabian StyleMirna, Estarrón-Espinosa, Ruperto-Pérez Mariela, Padilla-de la Rosa José Daniel, and Prado-Ramírez Rogelio. 2019. "Innovation in Continuous Rectification for Tequila Production" Processes 7, no. 5: 283. https://doi.org/10.3390/pr7050283

APA StyleMirna, E.-E., Mariela, R.-P., Daniel, P.-d. l. R. J., & Rogelio, P.-R. (2019). Innovation in Continuous Rectification for Tequila Production. Processes, 7(5), 283. https://doi.org/10.3390/pr7050283