1. Introduction

The inherently laminar regime characterizing momentum transport at microfluidic scales makes it possible to accurately design

a priori device geometries and operating conditions able to perform specific tasks as regards the transport of chemical species or even of mesoscopic objects suspended in a carrier fluid. In single-phase mixtures, that is, when the suspended species are molecules and can be considered as point-sized, the interaction between convective and diffusive transport is typically exploited to improve the rate of homogenization of the concentration profiles within the mixture [

1]. Here, the synergistic interaction between advection and diffusion occurs via the amplification of concentration gradients by cross-sectional velocity components (e.g., triggered by complex boundary geometries [

2] as well as inertial [

3], electro-osmotic [

4], and magnetohydrodynamic effects [

5] or a combination of the above [

6]), which sustain the homogenizing action of the Fickian flux as the mixture flows downstream the device. Symmetrically, the outcome of tracer mixing experiments can be used to infer properties of the velocity profiles within the microfludic channels, especially as regards the occurrence of slip boundary conditions for the flow when the characteristic dimension of the cross-section falls below the micrometric scale [

7,

8].

An even richer physical phenomenology is observed when the size of the entities suspended in the carrier fluid increases from that of solubilized molecules to mesoscopic objects (henceforth referred to as particles), that is, when the flowing mixture is distinctly two-phase. In this case, microfluidics-assisted processes are typically used for separating and sorting the dispersed phase based on some physical feature of the particles (e.g., size, electric charge, shape and so on). In certain regimes, quantified by sufficiently large values of the particle Reynolds number

(

,

and

being the density, viscosity and local velocity of the supending fluid, respectively, and

being the instantaneous particle velocity), the transport features of the embedded particles can be controlled exploiting their inertia, which makes them deviate from the streamlines of the underlying suspending flow [

9,

10]. At vanishing values of

, that is, in the the overdamped regime [

11], particles tend to trace over the streamlines of the carrier flow and approaches alternative to inertial effects must be used to control their motion. These approaches are based on a tailored design of the solid surfaces of the device that exploits the mesoscopic character of the particle, that is, the fact that the particle size is not altogether negligible with respect to the smallest characteristic dimension of the channel geometry. Historically, the simplest example of wall effects for controlling the transport features of particles is provided by hydrodynamic chromatography (HDC), which was first proposed at the beginning of the 1970s [

12], and thereafter used to perform the size-based separation of solutions suspending particles of different dimensions [

13] and even macromolecules [

14]. The HDC separation mechanisms has been explained through a simple one-way coupling, excluded volume model: The (supposedly spherical) particle is assumed to follow the flow streamline of the unperturbed single-phase Poiseuille flow computed at the particle center of mass. Besides, because of its finite size, the distance between the particle center and the channel walls must be greater or at most equal to the particle radius. Thus, adjacent to the channel walls, there is an annular volume (excluded volume) of thickness equal to the particle radius that is not accessible to the center of the particle. Owing to the no-slip condition of the suspending flow, this region is characterized by low velocity values, which vanish when approaching the solid walls. By this effect, bigger particles tend, on the average, to experience larger velocity values and move faster with respect to smaller ones. Specifically, an analytical expression of the average particle velocity versus particle size can be obtained based on the assumption that cross-sectional diffusion causes the center of the particle to visit all of the accessible positions with equal probability. By this property, the time-averaged particle velocity for an ensemble of realizations of Brownian trajectories can be computed as the spatial average of the flow velocity over the core channel cross-section that is accessible to the particle of prescribed size (ergodic property). Thus, by this approach, the average particle velocity increases with increasing particle size and approaches the average velocity of the flow at vanishing values of the particle radius [

13].

A more recent and elegant use of the excluded volume effect to control particle motion is the so-called Deterministic Lateral Displacemenet (DLD) separation mechanism [

15], which constitutes the focus object of this article. Here, the core of the device is represented by a channel with rectangular cross-section (typically very shallow) that is filled with a spatially periodic pattern of identical impermeable obstacles. The shape of the obstacles is generally cylindrical, even though different choices have been considered for reducing the hydraulic resistance and/or preventing clogging of the device by particle clustering [

16,

17].

Figure 1 shows the patterned geometry of a tilted array, specified by the lattice vectors

and

, which define the elementary periodic cell of the system.

In what follows, it is assumed that

. The key point underpinning the separation mechanism is that the lattice is at an angle, say

, with respect to the lateral walls of the hosting channel. Specifically,

can be defined as the smallest angle between the lattice vectors and the direction of the walls that confine the array laterally. The height,

H, width,

W and length,

L, of the channel are in the order of few micrometers, millimeters and centimeters, respectively, whereas the characteristic length

ℓ of the lattice vector(s) is of the same order as

H, so that the number of repeated elementary cells within the device ranges from

to

. DLD-based microseparators have been proven effective for a variety of biological/clinical applications, such as isolating blood cell subtypes [

18], extracting circulating tumor cells [

19,

20,

21,

22], selecting large cells from a replicating population for tissue engineering [

23], purifying human blood from parasites [

24] and purification of fungal spores [

25], enrichment of leukocites [

26]. A further scale down of DLD devices has been recently attempted for separating suspended objects in the range of few tens of nanometers, thus shifting the domain of clinical applications of the technique from the cell size to that of viruses and exosomes [

27] and even DNA strands [

28].

The DLD device is filled with a buffer solution (acqueous, in the vast majority of cases) that is pushed through the lattice by a pressure drop, for example, provided by a syringe pump. Depending on the material used for manufacturing the device (PDMS is a common choice in view of its suitability for lithography-etching microfabrication techniques) the characteristic fluid velocity ranges from 10 m/s to order one mm/s, corresponding to an overall pressure drop over the entire channel length in the order of tens of KPa. The maximum allowed velocity is clearly slaved to the maximum pressure that can be withstood by the structure. Typically, characteristic lengths and velocities used in DLD are characterized by values of the Reynolds number well below unity, so that strictly creeping flow conditions can safely be assumed.

It has been experimentally observed [

15] that a focused stream of suspended particles of various dimensions continuously introduced at some point upstream the periodic lattice separates into different streams, each containing particles of specified dimension and each characterized by its own average migration angle

.

Figure 1 represents schematically the situation where the suspension is a mixture of particles of three different diameters, which have been labelled with different fluorescent markers. As the divided streams separate from each other while flowing through the structure, their width increases due to existence of Brownian (diffusive) components of particle motion that arise as a consequence of the thermal fluctuations of the molecules constituting the suspending fluid. The dispersion bandwidth is quantified by the variance,

, of the scattered values of the individual displacements

along the cross-sectional coordinate associated with particles one and the same size (

Figure 1). Experimental results [

28] show that the variance

can attain unexpectedly large values and that its extent is only weakly reduced when the flow rate through the device is increased.

By enforcing crude approximations as regards the fluid-particle and the obstacle-particle interactions, the basic mechanisms driving the size-based separation has been explained in a purely kinematic (i.e., diffusionless) setting, based on the structure of the unperturbed single-phase Stokes flow through the obstacle lattice. Here the particle is assumed to behave just as a point-sized tracer at its geometric center would. Thus, so long as the particle does not touch the obstacle surface, its center is expected to trace over the flow streamlines. At the particle-obstacle contact, the obstacle surface is assumed to annihilate the component of the particle displacement ortogonal to its surface leaving the tangential component unaltered (see

Figure 2).

As a result, the particle glides around the obstacle surface and it detaches from it when the local velocity of the flow at its center is precisely tangent to the obstacle surface. In the case of spherical particles and cylindrical obstacles, the global trajectory of the particle center is a piecewise alternated collection of segments of flow streamlines and arcs of circumferences of radius equal the sum of the particle and of the obstacle radii. The classical picture put forward in the seminal article by Huang et al. [

15], where the separation method was first proposed, is the case where the lattice angle stems from a rational number

with

integer. In this case, the flow through the unit periodic cell divides into

N flux tubes, each carrying an equal fraction

of the total flowrate. These flux tubes, which have been referred to as ’lanes,’ are identified by critical streamlines that originate from and terminate onto, the surface of (different) obstacles. For particles below a critical size,

(see

Figure 2), the steric exclusion by the obstacle is not enough to make the particle center change lane [

29]. Thus the average direction of such particles will be the same as that pertaining to the flux tubes of the unperturbed flow. Because the flow is ultimately confined by the lateral channel walls, the particle deflection with respect to the wall direction equals zero. For particle bigger than the critical size, the particle radius is such that the particle center is forced to change lane at each obstacle collision, so that on the large scale, its average direction will be collinear with the lattice angle

. Thus, in this kinematic model, the response curve yielding the particle migration angle versus the particle size is a piecewise constant curve, jumping discontinuously from zero the the value

, the discontinuity being located at the critical particle radius,

. Multidirectional sorting modes, where mutiple critical radius value can be identified have also been predicted based on the lattice geometry in the case where the obstacle radius approaches zero [

30]. Clearly, this purely kinematic model overlooks many relevant aspects of particle transport, which can be unambiguously identified in experiments, and that are ultimately related to the existence of fluctuating (i.e., diffusive) components of particle motion and approaches that include the effect of particle diffusion have also been proposed [

31]. Among these approaches, an excluded-volume model inspired by that used in Hydrodynamic Chromatography, explicitly accounting for particle diffusion, has been put forward by one of these authors and co-authors in a series of recent articles [

32,

33,

34,

35,

36] for tackling transport of finite-size particles in DLD devices. In all of these works, a two-dimensional setting was enforced, thus assuming that the effect of the top and bottom walls of the channel hosting the obstacle lattice could be neglected. In what follows, this assumption is relaxed and the whole three-dimensionality of the problem is considered, as regards both momentum transport of the suspending fluid and particle transport. We find that when the height of the channel is comparable to the size

ℓ of the lattice vectors

and

, new phenomena which cannot be captured in the 2D setting occur. We provide preliminary numerical evidence suggesting that these phenomena can have a sizeable impact on the particle migration angle

, whose predicted value in the 3D setting is in better agreement with the experimental observations with respect to that obtained from a 2D setting of the problem.

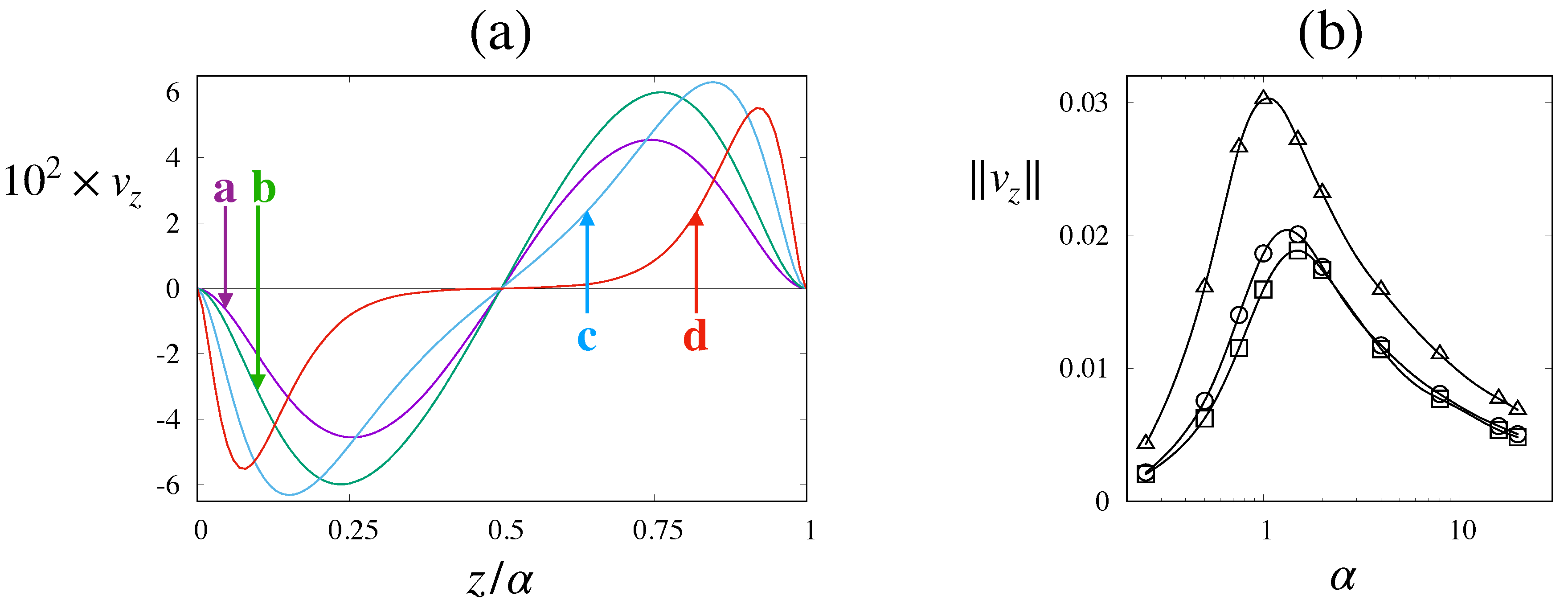

4. Particle Transport

Before discussing the transport features of particles evolving under the periodic Stokes flow according to the excluded-volume model, a preliminary observation is in place about the physical interpretation of the particle number density

in Equation (

7), (and of the cumulative particle concentration

C as defined by Equation (

9)) in a context where the particle size is comparable to that of the periodic cell. Clearly, unlike the case of point-sized tracers, the finite size of the particle, together with the diluted suspension assumption, implies that the number of particles that can be embedded in a single periodic cell is not statistically significant (for large particle sizes this number may reduce to few units, depending on the geometry of the lattice). In this contex, the product

represents the probability of finding (the center of) a particle released a time

at the origin of the coordinate system in a volume element centered at

at time

t. Accordingly, the cumulative particle concentration

represents the probability of finding the particle at the relative cell position

at time

t, regardless of the specific location of the cell within the periodic lattice. This much clarified, we next analyze the effects of the presence of a non-vanishing vertical component of the velocity on particle transport by using the excluded-volume model for particles that was described in

Section 2.3. Let us then consider the features of the solution of Equation (

11) subject to the boundary condition Equation (

12). Because the cumulative particle concentration evolves in a closed domain (periodic boundary conditions are enforced at opposite vertical faces of the unit periodic cell) and owing to the presence of the dissipative Laplacian term, the evolving field

associated with a generic initial condition is expected to approach a steady-state solution

that solves

with the same boundary conditions as those enforced for

. When steady-sate conditions have been reached, macrotransport behavior for the particle ensemble settles in and the average particle velocity

becomes a (vector-valued) constant

which allows to obtain the average deflection angle of the particles of the assigned size as

(note that

by symmetry of the boundary value problem). In order to investigate the approach to this condition, we next consider the evolution of the cumulative particle distribution starting from an initial condition where particles are evenly distributed within the effective transport domain

. Panels-(a) through -(c) of

Figure 11 show the time-evolution of

onto the surface of the effective obstacle (the horizontal axis is here the angular coordinate of the unfolded cylinder).

Given that the cumulative particle number density spans a very large interval of values,

is represented in place of

C for visualization purposes. At short times (

Figure 11a), all particles are pushed towards the effective obstacle surface by the main (planar) components of the flow. As a consequence, the field

onto the effective obstacle surface is essentially independent of the

z coordinate and the average particle velocity as given in Equation (

10) is not influenced by the three-dimensionality of the problem. However, as time goes by, the weak vertical components of the flow onto the effective cylinder make particles migrate towards the floor and ceiling of the cell as can be gathered by the data in

Figure 11b. At steady-state (

Figure 11c), the 3D structure of the particle concentration field is strongly dependent on the

z coordinate. Note that the time-scale quantifying the transient evolution from an essentially two-dimensional to a full three-dimensional structure of the cumulative particle number density is of the order of few hundreds (dimensionless) time units, which physically correspond to a situation where particles cross an approximately equal number of obstacle rows downstream the injection point. As in typical implementations of the DLD technique, the obstacle array is composed of order

obstacle rows, the migration phenomenon above described falls well within the space/time limits of the process. Panels-(d) through (i) of

Figure 11 show the structure of

at the symmetry plane

and at the ceiling of the effective transport domain

. At short times (compare panels-(d) and (c)), the planar structure of the concentration field is similar, whereas at large times the symmetry plane becomes progressively devoid of particles. The impact of particle size and flowrate on this migration process can be appreciated by considering the cases shown in

Figure 12 that shows for a particle size

(equal to half of that considered in

Figure 11) the structure of the steady-state cumulative particle concentration onto the effective obstacle surface, as well as the one-dimensional profiles onto selected circumferences therein contained at different values of the particle Péclet number. Because particles of different size suspended in one and the same flow possess different

values (in view of the fact that the bare particle diffusivity depends on particle size) a reference Péclet number,

, where

is next considered by targeting a reference particle size

. iAs reference value we choose

, which correspond to particle of diameter equal to 1

m in the device geometry considered in Reference [

15] with an average flow velocity

U = 400

m/s.

At

, the oscillations about the average value (here set to unity,

), result contained and almost no 3D effect can be observed. At

, deviations from the uniform concentration condition are more significant and so is the difference between the values of

C onto the circumference at the symmetry plane and at the ceiling of the effective transport domain. For a quantitative comparison,

Figure 13 reports the one-dimensional concentration profiles onto the same selected circumferences as those of

Figure 12 for the particle size

corresponding to the same

values.

Note how, at the higher value of the reference Péclet number, the concentration on the circumference at the symmetry plane is almost uniformly vanishing, whereas a peak value three orders of magnitude larger than the average concentration develops at the circumference resulting from the intersection between the effective obstacle and the cell ceiling.

Because the two fields are markedly different, (the difference increasing at increasing

), sizeable effect can be expected as regards the average migration velocity

and, consequently, on the average particle migration angle

. In order to gain a quantitative appreciation of the 3D effect, we attempted the prediction of the average migration angle based on the 2D and the 3D representation of the problem for the particle size

corresponding to a dimensional particle diameter of 0.8

m in the experiment reported in Reference [

15]. As we found no indication of the channel depth or of the working temperature in the discussion of the experimental data in Reference [

15], we fixed

for the cell aspect ratio, and assumed

K as a working temperature to estimate the diffusion coefficient from the Stokes-Einstein relationship, so that the particle Péclet number could be fixed. Under these assumptions, the reference Péclet number corresponding to the experiment where the flowrate was fixed at

reported in Reference [

15] can be estimated as

. With these estimated operating parameters, we computed the 2D and 3D prediction of the average migration angle

, obtaining

and

, respectively, to be compared to the experimentally determined value

. Thus in this case, considering a full 3D setting of the problem allows to lower the relative error of the predicted value with respect to the experimental resul from

to

. The above result should only be taken as an indication of possible improvements allowed by the 3D approach to the numerical prediction of particle transport features. In point of fact, the very steep boundary layer developed by the cumulative particle concentration for large particles at high values of the Péclet number demands that an independent validation of the numerical results stemming from the Eulerian approach to the particle number density be developed. This could be done, for example, by enforcing ensemble averages over a large number of particles governed by the Langevin equation equivalent to the Eulerian excluded-volume model.