A Kraft Mill-Integrated Hydrothermal Liquefaction Process for Liquid Fuel Co-Production

Abstract

1. Introduction

2. Materials and Methods

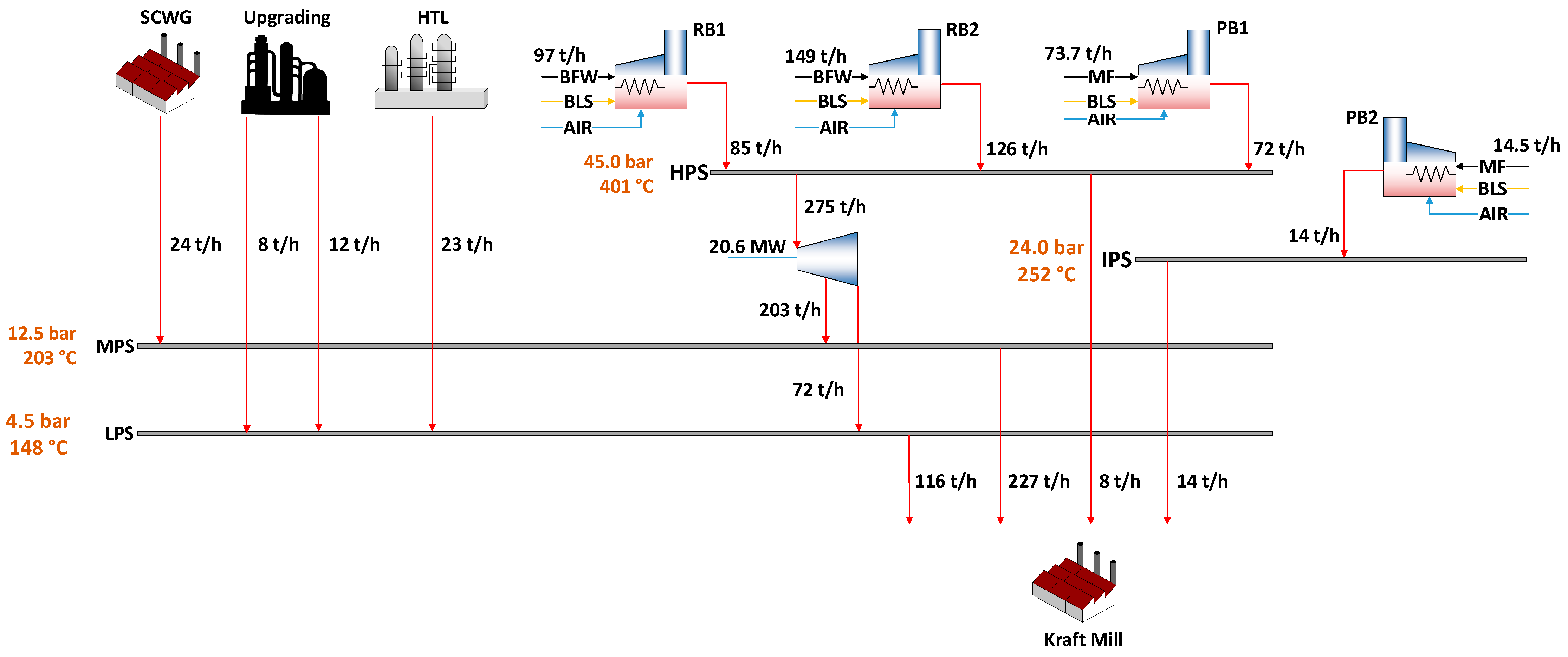

2.1. Total Site Heat Integration (TSHI)

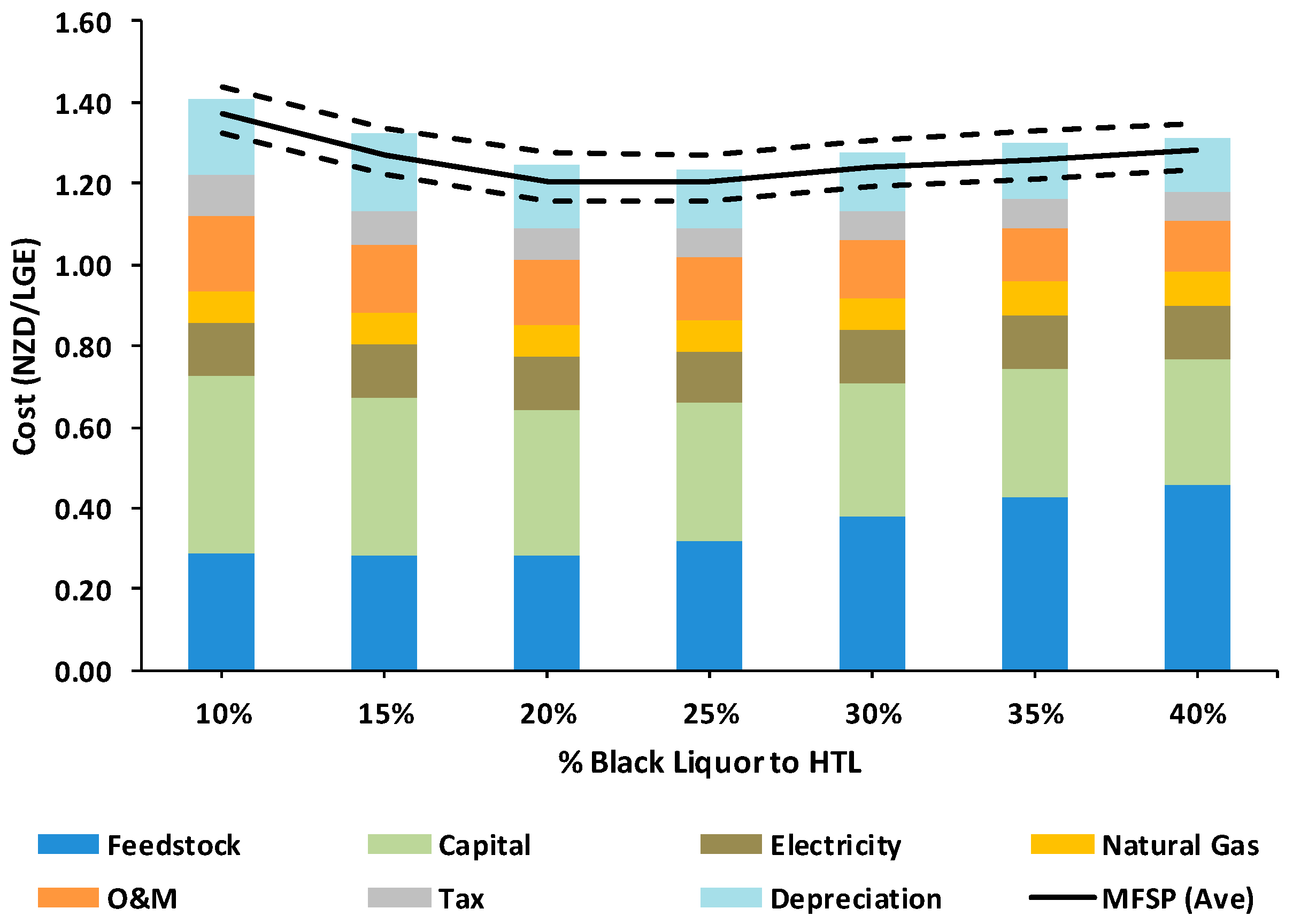

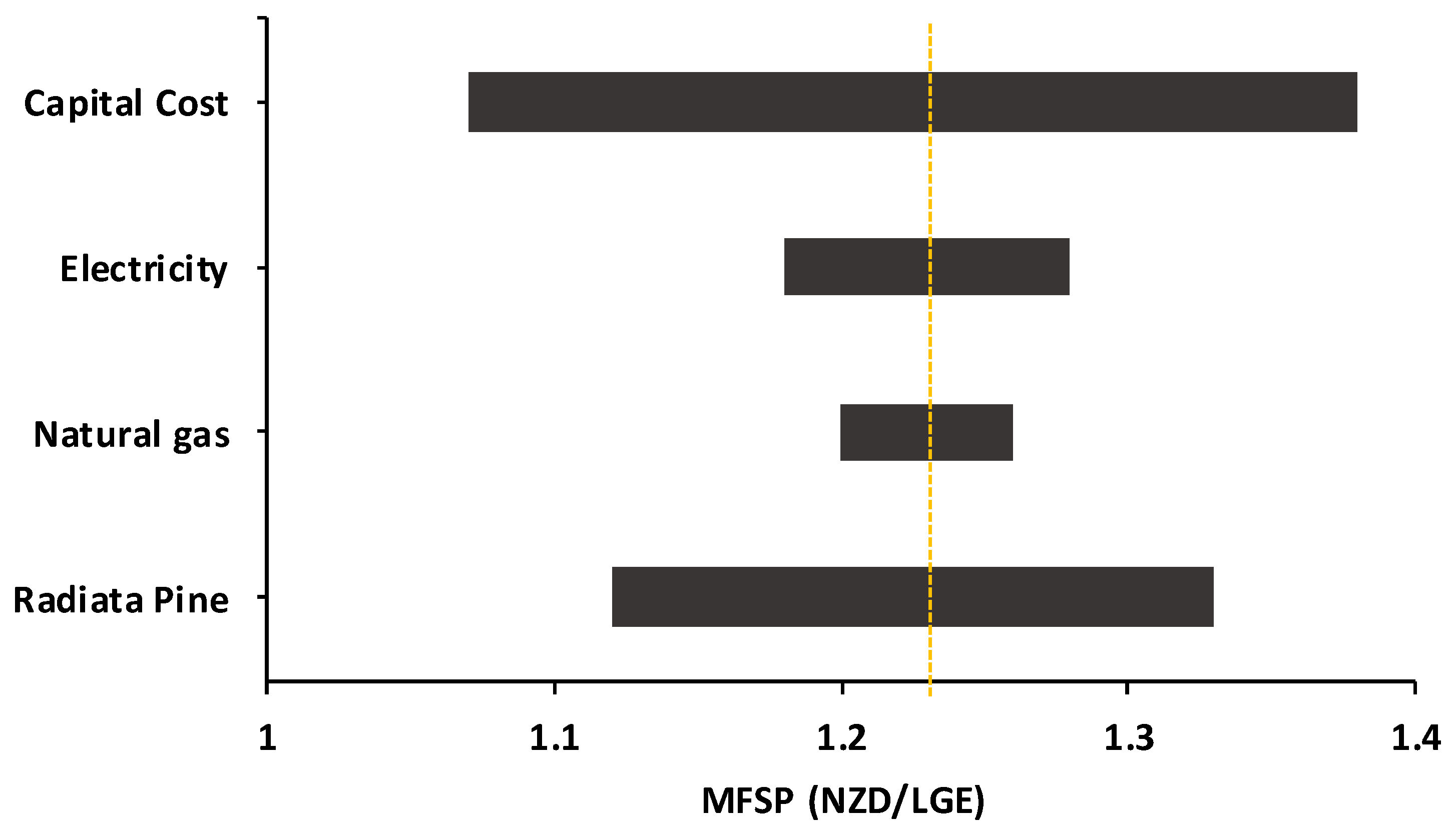

2.2. Economic Assessment

2.3. Environmental Impact

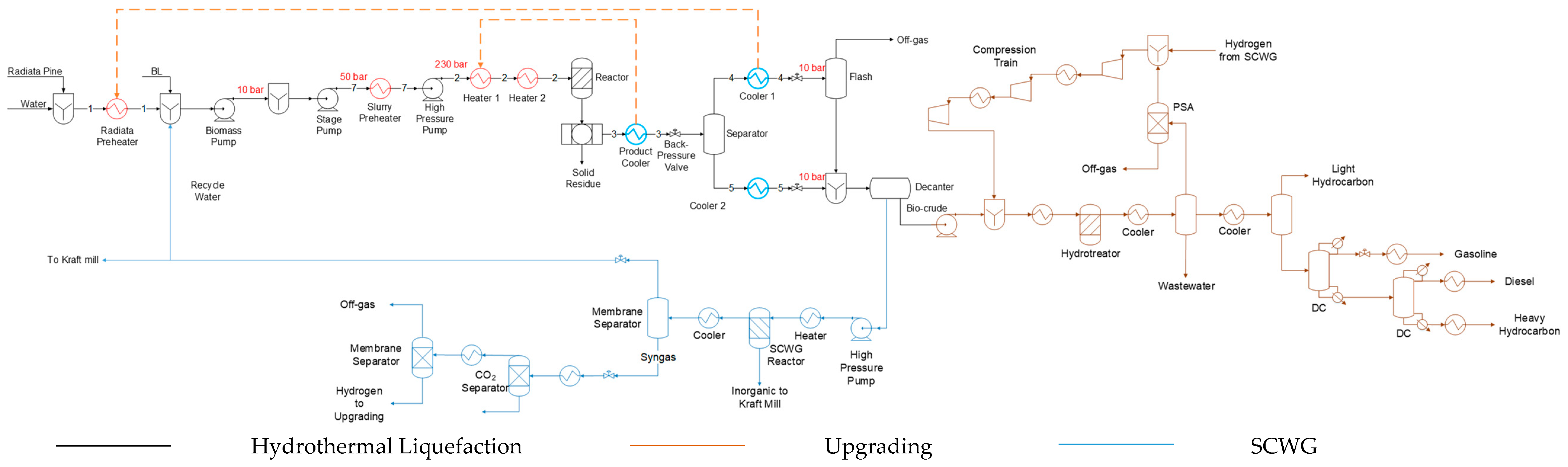

2.4. Process Flowsheet

- (1)

- SCWG is able to treat the phenolic compounds that are in the aqueous phase,

- (2)

- SCWG produces syngas that has lower contamination, and

- (3)

- The alkali salts are insoluble in the SCWG processing conditions due to the change in thermophysical properties above the critical point, which is important in the inorganic recovery of the process.

3. Results

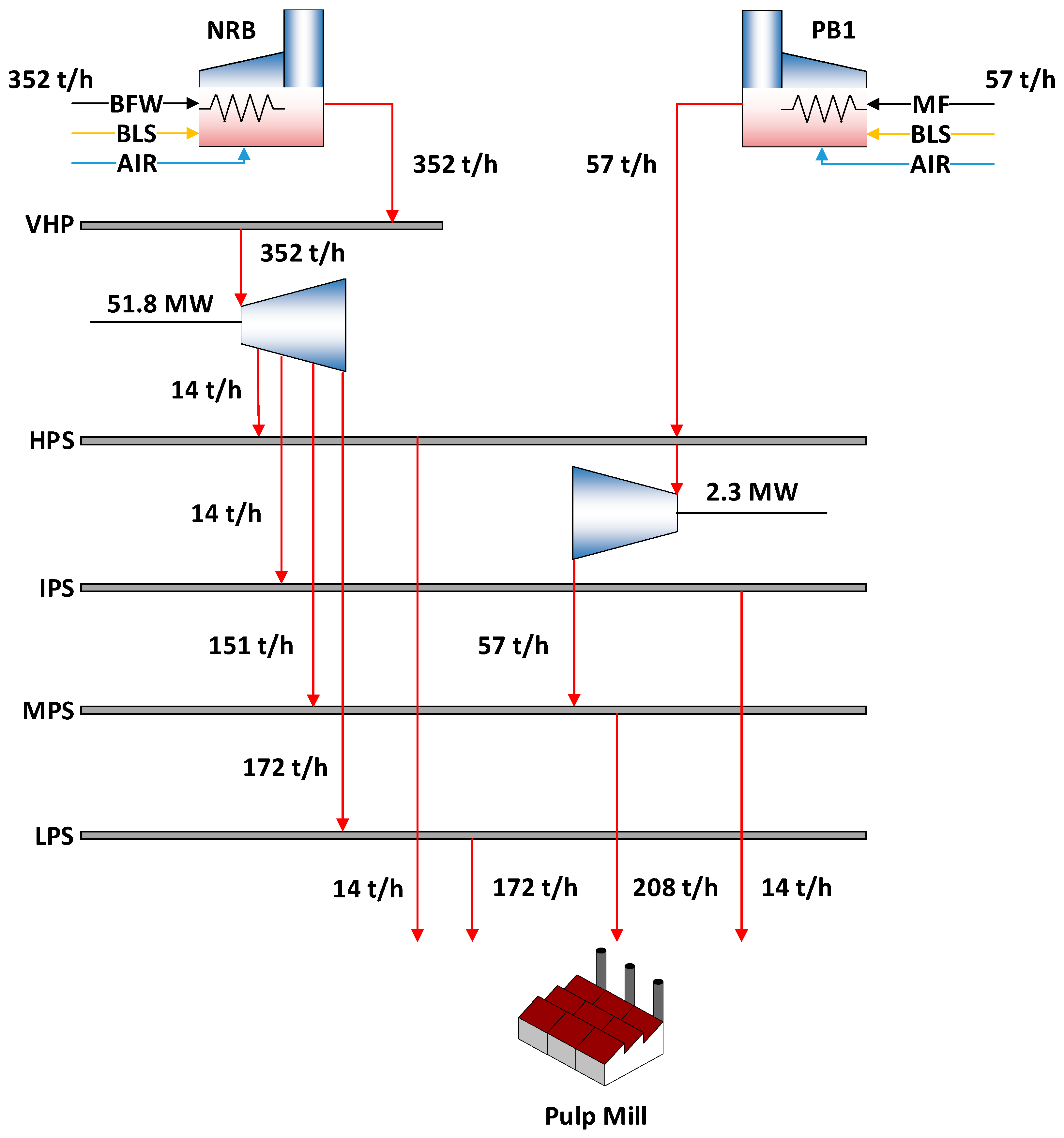

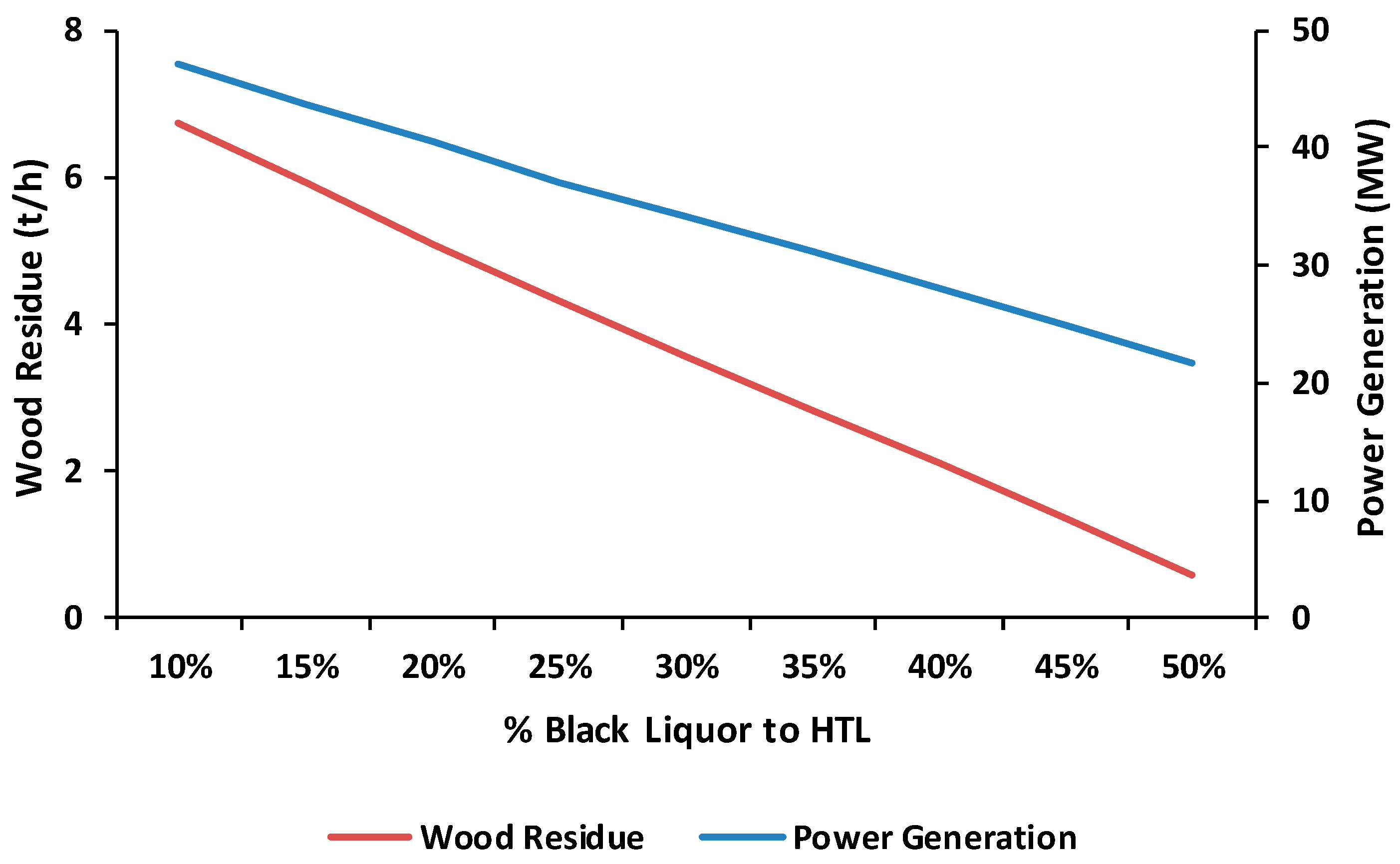

3.1. Scenario 1: Kraft Mill with Hydrothermal Liquefaction System

3.1.1. Integration of Hydrothermal Liquefaction with Kraft Mill

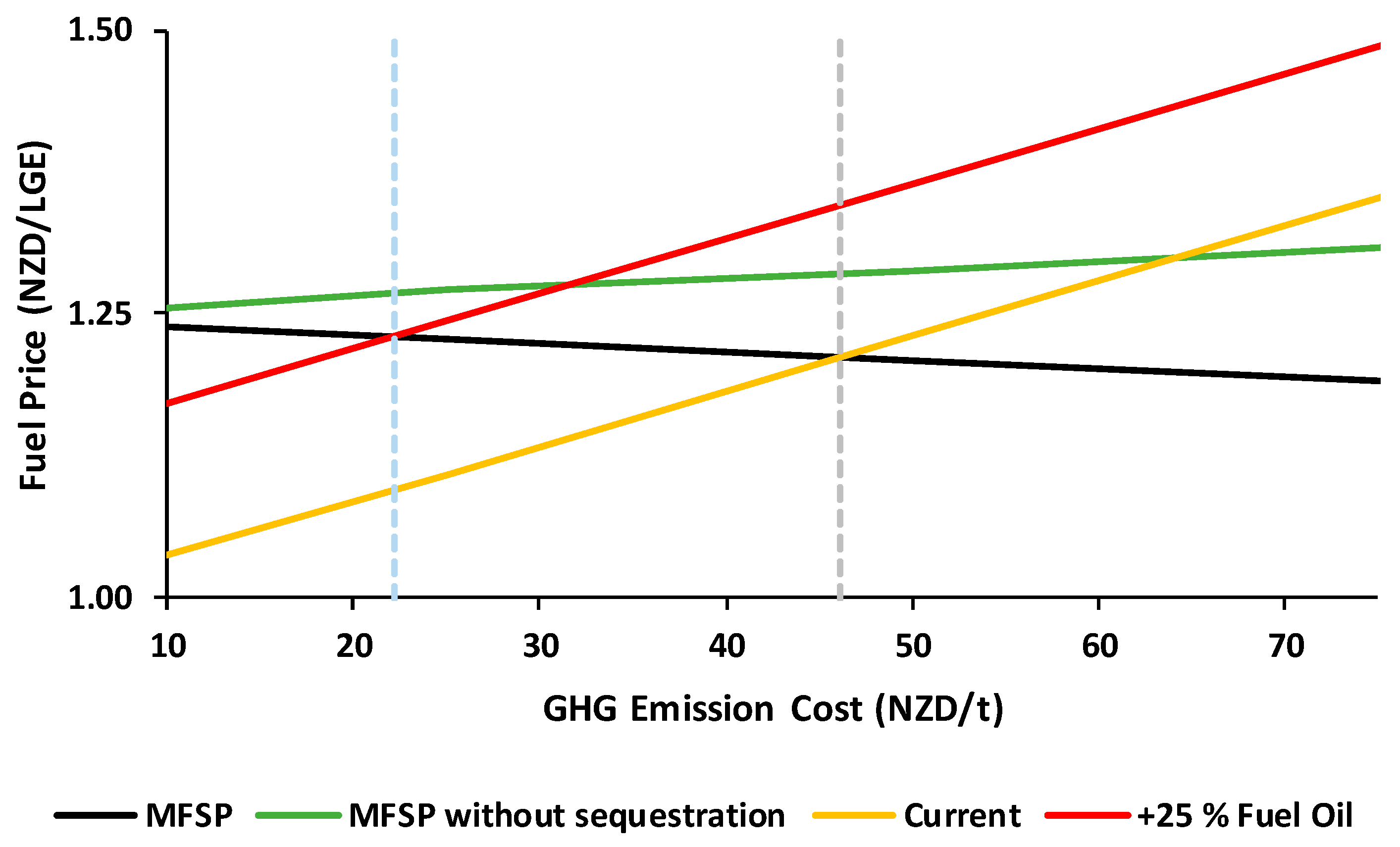

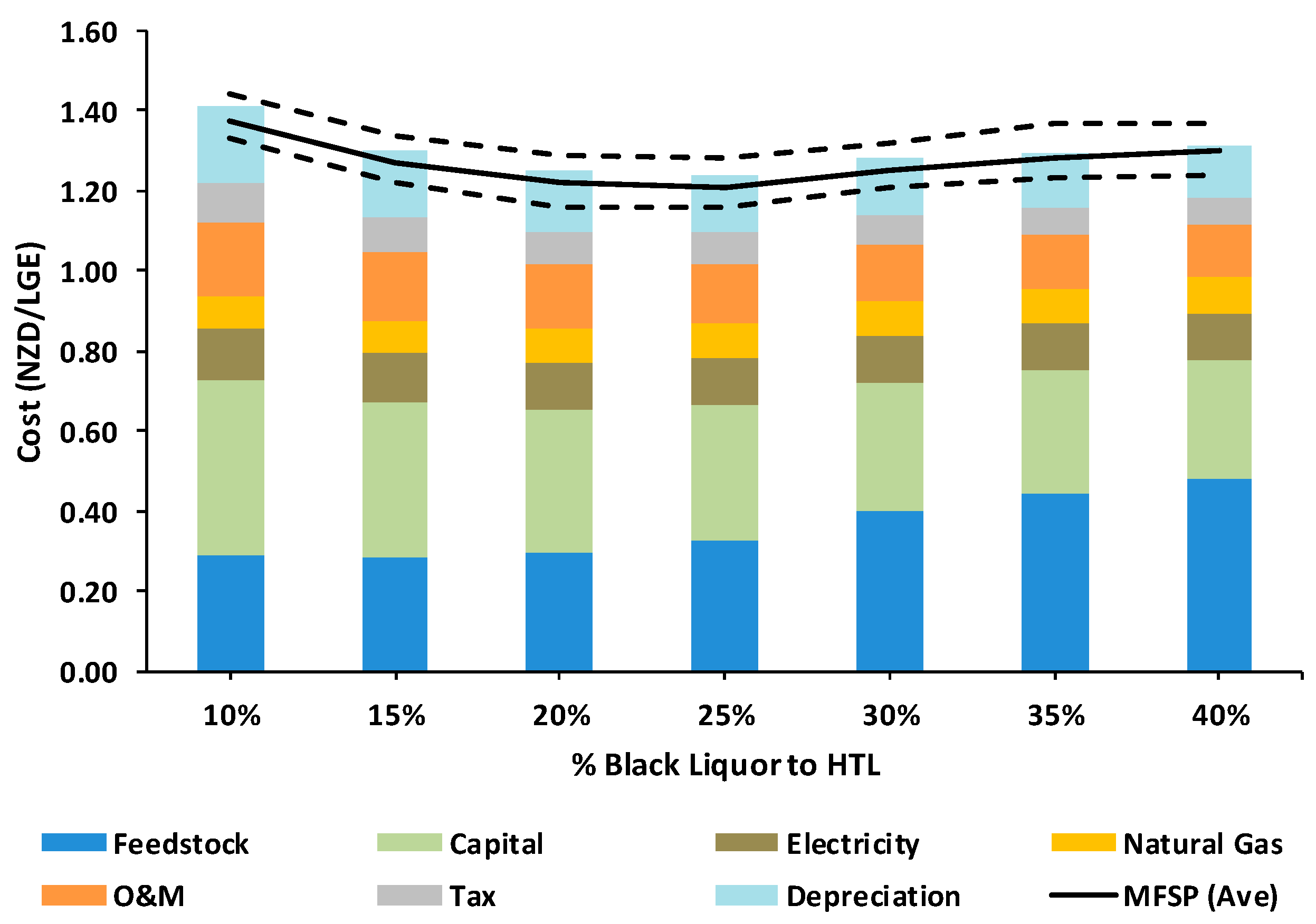

3.1.2. Economic Assessment

3.1.3. GHG Emission

3.1.4. Biofuel Policy Consideration

3.2. Scenario 2: Mechanical Vapour Recompression of Black Liquor Evaporators

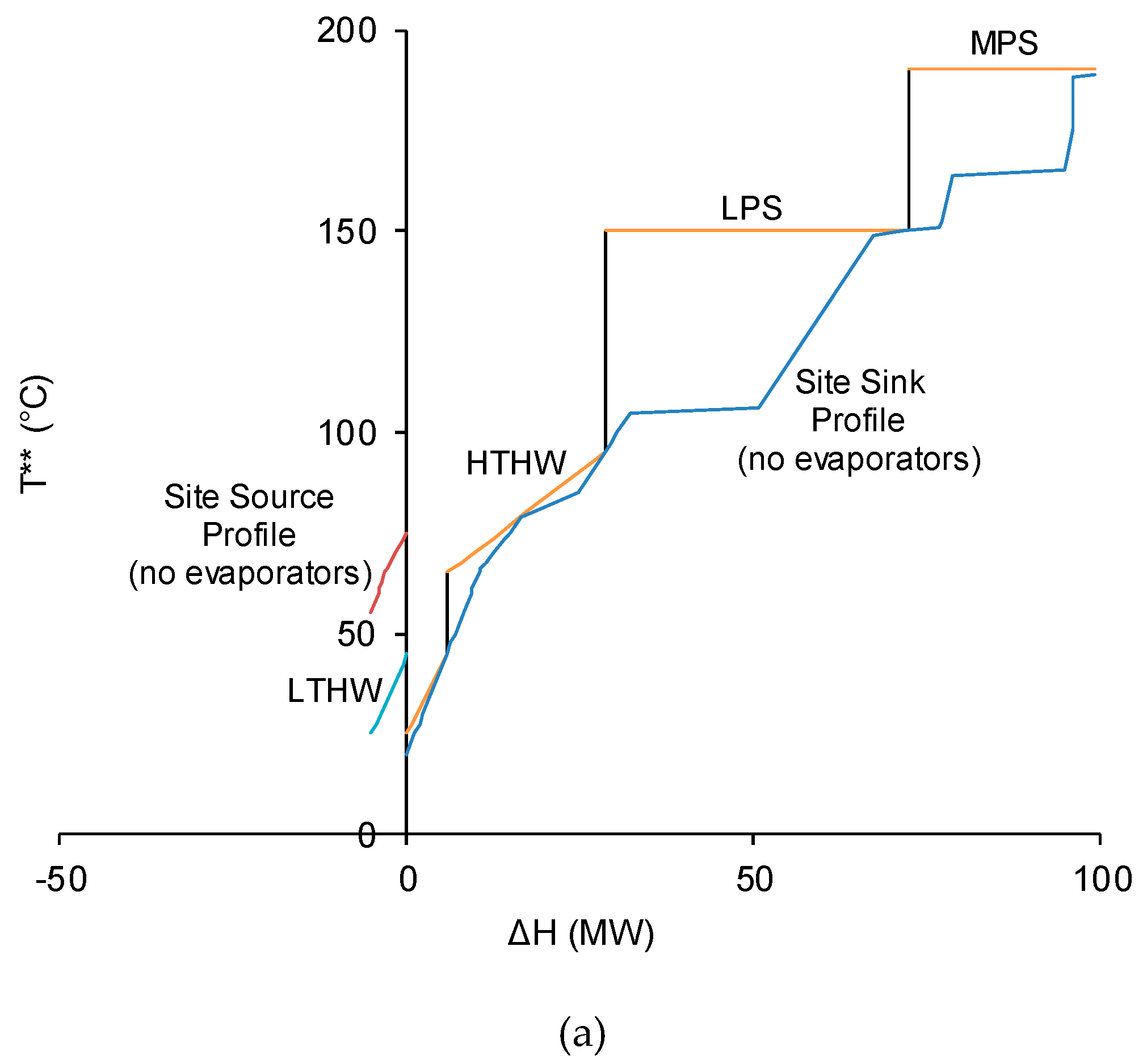

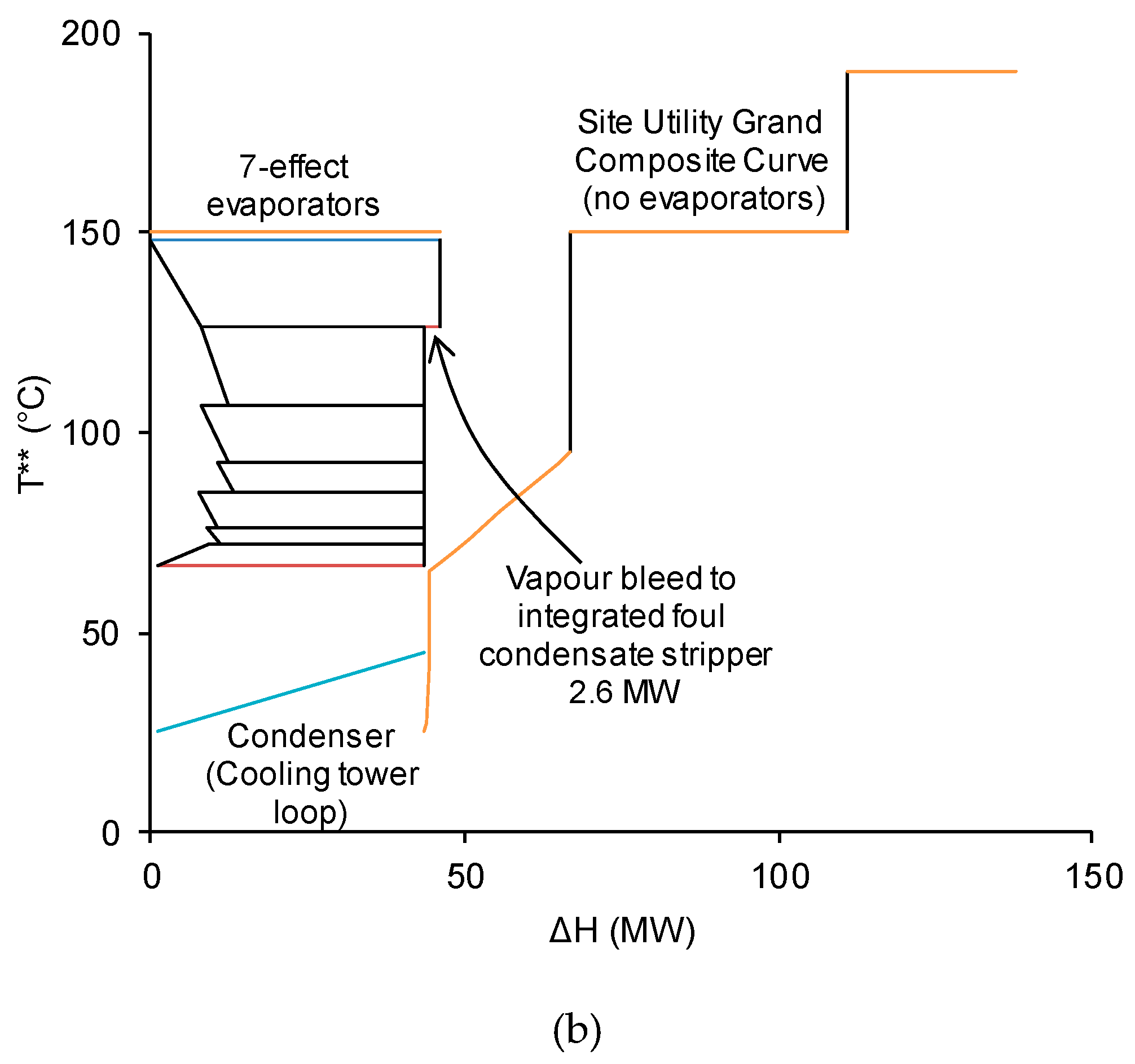

3.2.1. Total Site Heat Integration for Conventional 7-Effect Black Liquor Evaporators

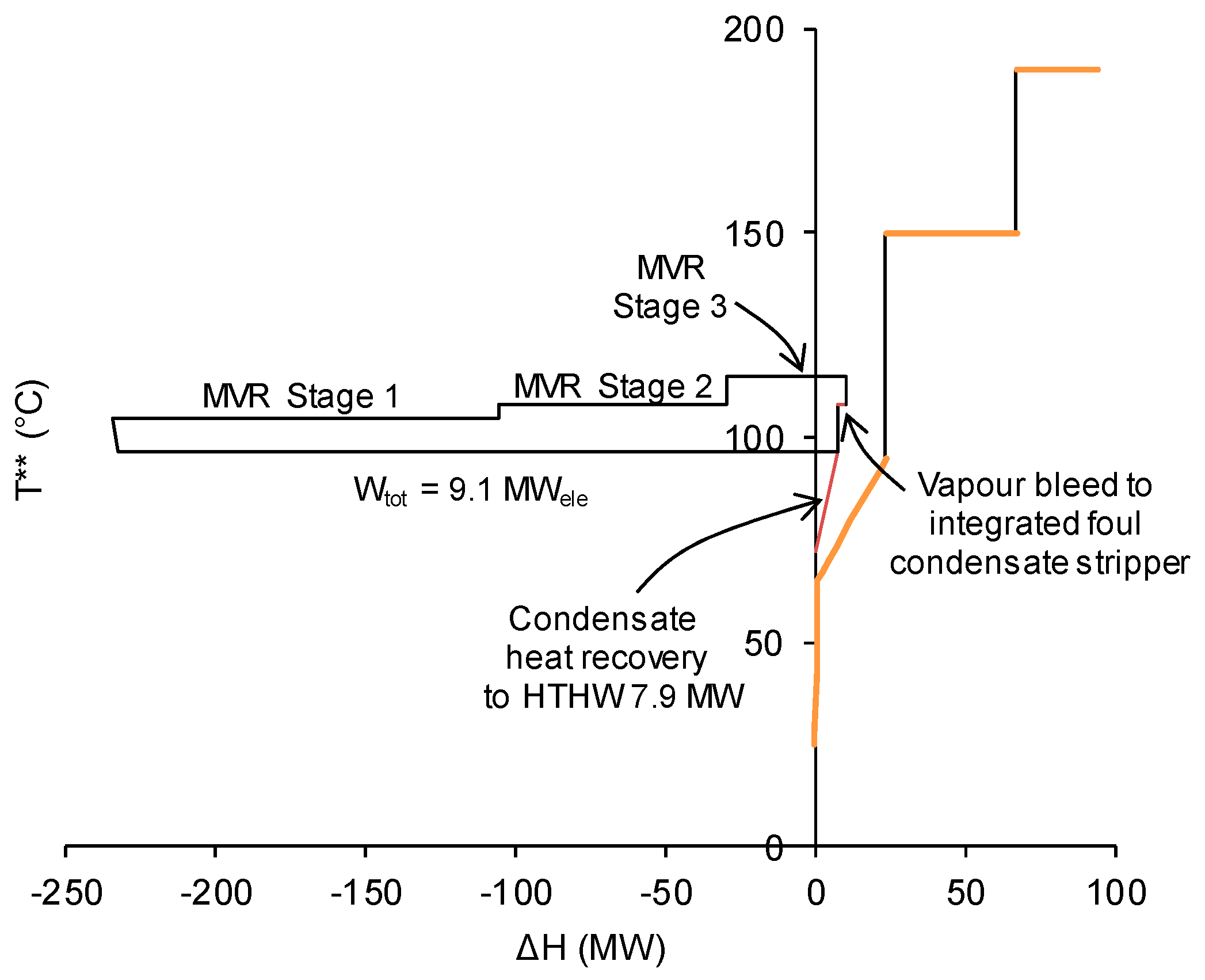

3.2.2. Black Liquor Evaporators with Vapour Recompression

3.3. Scenario 3: New Modern Recovery Boiler

4. Conclusions and Directions of Future Work

Author Contributions

Funding

Conflicts of Interest

References

- Brundland, G.H. World Commission on Environment and Development. In Our Common Future; Oxford University Press: Oxford, NY, USA, 1987. [Google Scholar]

- Statista. Oil Demand Distribution by Sector Worldwide 2016; Statista: Hamburg, Germany, 2019. [Google Scholar]

- Fernando, S.; Adhikari, S.; Chandrapal, C.; Murali, N. Biorefineries: Current Status, Challenges, and Future Direction. Energy Fuels 2006, 20, 1727–1737. [Google Scholar]

- Morais, A.R.C.; Bogel-Lukasik, R. Green chemistry and the biorefinery concept. Sustain. Chem. Process. 2013, 1, 18. [Google Scholar] [CrossRef]

- Stephen, J.D.; Sokhansanj, S.; Bi, X.; Sowlati, T.; Kloeck, T.; Townley-Smith, L.; Stumborg, M.A. The impact of agricultural residue yield range on the delivered cost to a biorefinery in the Peace River region of Alberta, Canada. Biosyst. Eng. 2010, 105, 298–305. [Google Scholar] [CrossRef]

- Ghatak, H.R. Biorefineries from the perspective of sustainability: Feedstocks, products, and processes. Renew. Sustain. Energy Rev. 2011, 15, 4042–4052. [Google Scholar]

- Pettersson, K.; Mahmoudkhani, M.; von Schenk, A. Opportunities for biorefineries in the pulping industry. In Systems Perspectives on Biorefineries; Chalmers University of Technology: Göteborg, Sweden, 2013. [Google Scholar]

- Elliot, D.C.; Biller, P.; Ross, A.B.; Schmidt, A.J.; Jones, S.B. Hydrothermal Liquefaction of Biomass: Developments from Batch to Continuous Process. Bioresour. Technol. 2015, 178, 147–156. [Google Scholar] [CrossRef] [PubMed]

- Uematsu, M.; Frank, E.U. Static Dielectric Constant of Water and Steam. J. Phys. Chem. Ref. Data 1980, 9, 1291–1306. [Google Scholar]

- Toor, S.S.; Rosendahl, L.; Rudolf, A. Hydrothermal liquefaction of biomass: A review of subcritical water technologies. Energy 2011, 36, 2328–2342. [Google Scholar] [CrossRef]

- Xu, C.; Lad, N. Production of Heavy Oils with High Caloric Values by Direct Liquefaction of Woody Biomass in Sub/Near-Critical Water. Energy Fuels 2008, 22, 635–642. [Google Scholar] [CrossRef]

- Demirbas, A. Competitive Liquid Biofuels from Biomass. Appl. Energy 2011, 88, 17–28. [Google Scholar] [CrossRef]

- Rowlands, W.N.; Humphreys, L.J.; Thew, R.W.C.; Spankie, J.A.; Uloth, V.C.; Watson, P.A.; Pudlas, M.W. Integrated Kraft Pulp Mill and Thermochemical Conversion System. 2017. Available online: https://patentscope.wipo.int/search/en/detail.jsf?docId=WO2016058098 (accessed on 24 February 2019).

- Huet, M.; Roubaud, A.; Chirat, C.; Lachenal, D. Hydrothermal treatment of black liquor for energy and phenolic platform molecules recovery in a pulp mill. Biomass Bioenergy 2016, 89, 105–112. [Google Scholar] [CrossRef]

- Kosinkova, J.; Ramirez, J.A.; Nguyen, J.; Ristovski, Z.; Brown, R.; Lin, C.S.K.; Rainey, T.J. In the field: Hydrothermal liquefaction of bagasse using ethanol and black liquor as solvents. Biofuels Bioprod. Biorefin. 2015, 9, 630–638. [Google Scholar] [CrossRef]

- Ong, B.H.Y.; Walmsley, T.G.; Atkins, M.J.; Walmsley, M.R.W. Hydrothermal liquefaction of Radiata Pine with Kraft black liquor for integrated biofuel production. J. Clean. Prod. 2018, 199, 737–750. [Google Scholar] [CrossRef]

- Funkenbusch, L.T.; Mullins, M.E.; Vamling, L.; Belkhieri, T.; Srettiwat, N.; Winjobi, O.; Shonnard, D.R.; Rogers, T.N. Technoeconomic assessment of hydrothermal liquefaction oil from lignin with catalytic upgrading for renewable fuel and chemical production. Wires Energy Environ. 2018, 8, 1–12. [Google Scholar] [CrossRef]

- Melin, K.; Välimäki, A.; Oasmaa, A.; Lehtonen, J. The Effect of Hydrothermal Liquefaction of Black Liquor in Bio-Oil Quality. In Proceedings of the 27th European Biomass Conference and Exhibition, Lisbon, Portugal, 27–30 May 2019; pp. 1144–1145. [Google Scholar]

- Lappalainen, J.; Baudouin, D.; Hornung, U.; Schuler, J.; Melin, K.; Bjelić, S.; Vogel, F.; Konttinen, J.; Joronen, T. Sub- and Supercritical Water Liquefaction of Kraft Lignin and Black Liquor Derived Lignin. Energies 2020, 13, 3309. [Google Scholar] [CrossRef]

- Anastasakis, K.; Biller, P.; Madsen, R.; Glasius, M.; Johannsen, I. Continuous Hydrothermal Liquefaction of Biomass in a Novel Pilot Plant with Heat Recovery and Hydraulic Oscillation. Energies 2018, 11, 2695. [Google Scholar] [CrossRef]

- Okoro, O.V.; Sun, Z.; Birch, J. Techno-Economic Assessment of a Scaled-Up Meat Waste Biorefinery System: A Simulation Study. Materiel 2019, 12, 1030. [Google Scholar] [CrossRef]

- Shemfe, M.B.; Fidalgo, B.; Gu, S. Heat integration for bio-oil hydroprocessing coupled with aqueous phase steam reforming. Chem. Eng. Res. Des. 2016, 107, 73–80. [Google Scholar] [CrossRef]

- Magdeldin, M.; Kohl, T.; Järvinen, M. Techno-economic assessment of the by-products contribution from non-catalytic hydrothermal liquefaction of lignocellulose residues. Energy 2017, 137, 679–695. [Google Scholar] [CrossRef]

- Knorr, D.; Lukas, J.; Schoen, P.; Harris Group Inc. Production of Advanced Biofuels via Liquefaction: Hydrothermal Liquefaction Reactor Design; National Renewable Energy Lab.(NREL): Atlanta, GA, USA, 2013.

- Ong, B.H.Y.; Walmsley, T.G.; Atkins, M.J.; Varbanov, P.S.; Walmsley, M.R.W. A heat- and mass-integrated design of hydrothermal liquefaction process co-located with a Kraft pulp mill. Energy 2019, 189, 116235. [Google Scholar] [CrossRef]

- Medina-Flores, J.M.; Picón-Núñez, M. Modelling the power production of single and multiple extraction steam turbines. Chem. Eng. Sci. 2010, 65, 2811–2820. [Google Scholar] [CrossRef]

- Martinez Hernandez, E.; Ng, K.S. Design of biorefinery systems for conversion of corn stover into biofuels using a biorefinery engineering framework. Clean Technol. Environ. Policy 2017, 20, 1–14. [Google Scholar] [CrossRef]

- Ministry of Business, Innovation and Employment. Electricity Demand and Generation Scenariost; Ministry of Business, Innovation and Employment: Wellington, New Zealand, 2018.

- Ministry for the Environment. Guidance for Voluntary, Corporate Greenhouse Gas. Reporting: Data and Methods for the 2007 Calendar Year; Ministry for the Environment: Wellington, New Zealand, 2008.

- Ministry for the Environment. New Zealand’s Greenhouse Gas. Inventory; Ministry for the Environment: Wellington, New Zealand, 2017.

- Environmental Protection Authority. Liquid Fossil Fuels 2019. Available online: https://www.epa.govt.nz/industry-areas/emissions-trading-scheme/industries-in-the-emissions-trading-scheme/liquid-fossil-fuels/?accordion-anchor=75 (accessed on 2 June 2020).

- Ong, B.H.Y. A Kraft Mill-Integrated Biorefinery Design for New Zealand; University of Waikato: Hamilton, New Zealand, 2019. [Google Scholar]

- Ong, B.H.Y.; Walmsley, T.G.; Atkins, M.J.; Walmsley, M.R.W. Total site mass, heat and power integration using process integration and process graph. J. Clean. Prod. 2017, 167, 32–43. [Google Scholar] [CrossRef]

- Klemes, J.J. Handbook of Process. Integration (PI): Minimisation of Energy and Water Use, Waste and Emissions; Woodhead Publishing in Energy, Woodhead Pub: Cambridge, UK, 2013; ISBN 9780857095930. [Google Scholar]

- Friedler, F.; Tarjan, K.; Huang, Y.W.; Fan, L.T. Graph-Theoretic Approach to Process Synthesis: Axioms and Theorems. Chem. Eng. Sci. 1992, 47, 1973–1988. [Google Scholar] [CrossRef]

- Elliot, D.C. Historical Developments in Hydroprocessing Bio-Oils. Energy Fuels 2007, 21, 1792–1815. [Google Scholar] [CrossRef]

- Tran, H.; Vakkilainnen, E.K. The Kraft Chemical Recovery Process; TAPPIE Press: St. Petersburg, FL, USA, 2012. [Google Scholar]

- Zhu, Y.; Biddy, M.J.; Jones, S.B.; Elliot, D.C.; Schmidt, A.J. Techno-economic analysis of liquid fuel production from woody biomass via hydrothermal liquefaction ({HTL}) and upgrading. Appl. Energy 2014, 129, 384–394. [Google Scholar] [CrossRef]

- Alcaraz, S.; Hall, P. Mapping of Primary Processing Heat Demand and Forestry Resources to Allow Identification of Industrial Symbiosis Opportunities at A Regional Level Scion Report for MBIE; Scion: Rotorua, New Zealand, 2018. [Google Scholar]

- Robertson, K. Estimating Regional Supply and Delivered Cost of Forest and Wood Processing Biomass Available for Bioenergy; University of Canterbury: Christchurch, New Zealand, 2006. [Google Scholar]

- Ship & Bunker. Singapore Bunker Prices. Ship Bunker 2019. Available online: https://shipandbunker.com/prices/apac/sea/sg-sin-singapore (accessed on 2 June 2020).

- Gerrard, A.M. Guide to Capital Cost Estimating, 4th ed.; Institution of Chemical Engineers (IChemE): Warwickshire, UK, 2000. [Google Scholar]

- Magdeldin, M.; Kohl, T.; Järvinen, M. Techno-economic Assessment of Integrated Hydrothermal Liquefaction and Combined Heat and Power Production from Lignocellulose Residues. J. Sustain. Dev. Energy Water Environ. Syst. 2018, 6, 89–113. [Google Scholar] [CrossRef]

- Nie, Y.; Bi, X. Life-cycle assessment of transportation biofuels from hydrothermal liquefaction of forest residues in British Columbia. Biotechnol. Biofuels 2018, 11, 23. [Google Scholar] [CrossRef]

- He, Y.; Zhou, X.; Jiang, L.; Li, M.; Du, Z.; Zhou, G.; Shao, J.; Wang, X.; Xu, Z.; Bai, S.H.; et al. Effects of biochar application on soil greenhouse gas fluxes: A meta-analysis. Gcb Bioenergy 2017, 9, 743–755. [Google Scholar] [CrossRef]

- Department of the Environment and Energy. National Greenhouse Accounts Factors; Department of the Environment and Energy: Canberra, Australia, 2017.

- Castello, D. Supercritical Water Gasification of Biomass; University of Trento: Trento, Italy, 2013. [Google Scholar]

- Gutiérrez Ortiz, F.J.; Ollero, P.; Serrera, A.; Galera, S. An energy and exergy analysis of the supercritical water reforming of glycerol for power production. Int. J. Hydrog. Energy 2012, 37, 209–226. [Google Scholar] [CrossRef]

- Motoring, A.A. How Petrol Prices are Calculated. Available online: https://www.aa.co.nz/cars/owning-a-car/fuel-prices-and-types/how-petrol-prices-are-calculated/ (accessed on 1 June 2020).

- New Zealand Productivity Commission. Low—Emissions Economy; New Zealand Productivity Commission: Wellington, New Zealand, 2018.

- Wetterlund, E.; Pettersson, K.; Harvey, S. Systems analysis of integrating biomass gasification with pulp and paper production—Effects on economic performance, CO2 emissions and energy use. Energy 2011, 36, 932–941. [Google Scholar] [CrossRef]

- Suckling, I.D.; De Miguel Mercader, F.; Monge, J.J.; Wakelin, S.J.; Hall, P.W.; Bennett, P.J. New Zealand Biofuels Roadmap Summary Report: Growing A Biofuelled New Zealand; Scion: Rotorua, New Zealand, 2018. [Google Scholar]

- Martins, F.; Gay, J.C. Biofuels: From Boom to Bust? 2017. Available online: https://www.bain.com/insights/biofuels-from-boom-to-bust/ (accessed on 1 June 2020).

- Sharan, P.; Bandyopadhyay, S. Integration of thermo-vapor compressor with multiple-effect evaporator. Appl. Energy 2016, 184, 560–573. [Google Scholar] [CrossRef]

- Walmsley, T.G.; Atkins, M.J.; Ong, B.H.Y.; Klemeš, J.J.; Walmsley, M.R.W. Total site heat integration of multi-effect evaporators with vapour recompression for older kraft mills. Chem. Eng. Trans. 2017, 61, 265–270. [Google Scholar]

- Hyöty, P.A.; Ojala, S.T. Super Combustion of Black Liquor. In Proceedings of the International Recovery Boiler Conferen Cetampere Hall, Tampere, Finland, 11 June 2014; pp. 49–53. [Google Scholar]

| Materials | Cost |

|---|---|

| Radiata pine | 95.00 NZD/t |

| Radiata pine (+125 km) | 160.00 NZD/t |

| Radiata pine (+350 km) | 250.00 NZD/t |

| Sodium hydroxide | 500.00 NZD/t |

| Sodium sulphate | 220.0 NZD/t |

| Hydrotreating catalyst | 50.20 NZD/kg |

| Utilities | |

| Natural gas | 10.00 NZD/GJ |

| Electricity | 90.00 NZD/MWh |

| Cooling water | 2.50 NZD/MWh |

| GHG emission | 25.00 NZD/t |

| Item | GHG Factor t CO2-e/Unit | Unit |

|---|---|---|

| Electricity | 0.085 [28] | MWh |

| Natural gas | 0.058 [29] | GJ |

| Wastewater | 0.188 [30] | t |

| Component | Bio-Crude |

|---|---|

| Carbon | 73.4 |

| Hydrogen | 6.5 |

| Nitrogen | 0.1 |

| Sulphur | 0.6 |

| Oxygen | 18.9 |

| Ash | 0.5 |

| Installed Costs | NZD Million | Operating Cost | NZD Million/y |

|---|---|---|---|

| Biomass preparation | 33.3 | Variable operating cost | 65.1 |

| HTL | 111.7 | Feedstock | 8.2 |

| Upgrading | 124.7 | Natural gas | 6.3 |

| SCWG | 60.0 | Catalysts and chemicals | 21.5 |

| Utilities | 39.8 | Utilities | |

| Contingency | 40.9 | Fixed costs | 40.3 |

| Total installed cost | 423.5 | Revenue from by-products | 33.2 |

| Indirect costs | 234.3 | Capital depreciation | 22.5 |

| Total capital investment | 657.8 | Annualised investment | 52.9 |

| Tax | 11.8 | ||

| MFSP per L of product | 1.11 NZD/L | ||

| MFSP per LGE of product | 1.23 NZD/LGE | ||

| New Zealand | Australia | |

|---|---|---|

| Grid emissions factor (t CO2-e/MWh) | 0.085 | 0.830 |

| GHG emissions by the HTL system | kt CO2-e/y | kt CO2-e/y |

| Natural gas | 160.8 | 160.8 |

| Electricity | 27.0 | 263.7 |

| Wastewater | 6.5 | 6.5 |

| Carbon sequestration | 291.8 | 291.8 |

| Net GHG emissions from HTL system | −97.5 | 139.2 |

| GHG emissions offset from fuel substitution | −344.3 | −344.3 |

| Total net GHG emissions reduction | −441.8 | −205.1 |

| Components | NZD/LGE |

|---|---|

| Refined Fuel | 0.559 |

| Fuel excise | 0.703 |

| Goods and Services Tax (GST) | 0.269 |

| Emissions Trading Scheme (ETS) | 0.062 |

| Shipping | 0.041 |

| Importer Margin | 0.450 |

| Total | 2.084 |

| 2-Stage MVR | 3-Stage MVR | 4-Stage MVR | ||||

|---|---|---|---|---|---|---|

| Rate | Benefits (NZD M/y) | Rate | Benefits (NZD M/y) | Rate | Benefits (NZD M/y) | |

| Electricity use | ||||||

| MVR electricity use | 8.3 MW | –6.20 | 7.5 MW | –5.60 | 7.1 MW | –5.32 |

| Cogeneration reduction | 10.0 MW | –7.43 | 9.8 MW | –7.30 | 9.5 MW | –7.12 |

| Steam use | ||||||

| LPS use reduction | 37.9 MW | 37.9 MW | 37.9 MW | |||

| Increased heat recovery | 4.1 MW | 3.3 MW | 2.1 MW | |||

| Steam flow reduction | 74.8 t/h | 17.68 | 73.3 t/h | 17.34 | 71.2 t/h | 16.9 |

| Other | ||||||

| Cooling tower reduction | 35.1 MW | 0.73 | 35.1 MW | 0.73 | 35.1 MW | 0.73 |

| Carbon liability reduction | 62.6 kt/y | 1.56 | 61.4 kt/y | 1.53 | 59.7 kt/y | 1.49 |

| Additional maintenance | 1.2% | –0.14 | 1.2% | –0.16 | 1.2% | –0.18 |

| Operation and maintenance (O&M) cost reduction | 6.20 | 6.54 | 6.45 | |||

| Capital cost (uninstalled) | 3.49 | 3.91 | 4.32 | |||

| Capital cost (installed) | 10.47 | 11.73 | 12.95 | |||

| Key Indicators | ||||||

| Levelised profit | 4.65 M NZD/y | 4.83 M NZD/y | 4.63 M NZD/y | |||

| Simple payback | 1.7 y | 1.8 y | 2.0 y | |||

| Internal rate of return | 57% | 53% | 47% | |||

| SECnet * | 145 | 130 | 130 | |||

| Old Recovery Boiler | New Recovery Boiler | New Recovery Boiler + HTL | |

|---|---|---|---|

| Steam produced (t/h) | 362 | 352 | 288.7 |

| Power generation (MW) | 30.5 | 54.1 | 41.7 |

| Wood residue used (t/h) | 72 | 8.4 | 5.4 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ong, B.H.Y.; Walmsley, T.G.; Atkins, M.J.; Walmsley, M.R.W. A Kraft Mill-Integrated Hydrothermal Liquefaction Process for Liquid Fuel Co-Production. Processes 2020, 8, 1216. https://doi.org/10.3390/pr8101216

Ong BHY, Walmsley TG, Atkins MJ, Walmsley MRW. A Kraft Mill-Integrated Hydrothermal Liquefaction Process for Liquid Fuel Co-Production. Processes. 2020; 8(10):1216. https://doi.org/10.3390/pr8101216

Chicago/Turabian StyleOng, Benjamin H. Y., Timothy G. Walmsley, Martin J. Atkins, and Michael R. W. Walmsley. 2020. "A Kraft Mill-Integrated Hydrothermal Liquefaction Process for Liquid Fuel Co-Production" Processes 8, no. 10: 1216. https://doi.org/10.3390/pr8101216

APA StyleOng, B. H. Y., Walmsley, T. G., Atkins, M. J., & Walmsley, M. R. W. (2020). A Kraft Mill-Integrated Hydrothermal Liquefaction Process for Liquid Fuel Co-Production. Processes, 8(10), 1216. https://doi.org/10.3390/pr8101216