Opportunities and Barriers of Hydrogen–Electric Hybrid Powertrain Vans: A Systematic Literature Review

Abstract

1. Introduction

- The growth of the city areas and urban population [2]. It is a fact that this phenomenon has been growing continuously since 1950. Over 50% of the global population has lived in in urban areas [3] since 2007, and the trend evolution projects that 60% of the global population will live in cities by 2030. The number of mega-cities (cities with a population of over ten million people) expected by 2030 could reach 41 [4]. One of the consequences, among others, is the inevitable impact in greenhouse gas and pollutant emissions, opening the discussion about the measures that have to be taken to achieve the abatement of the emissions caused by the road transport.

- The new business opportunities offered by e-commerce. The European business-to-consumer (B2C) ecommerce turnover has practically doubled from 2013 to 2018. Not much is certain today, but the buying behavior after COVID-19 will rely heavily on e-commerce.

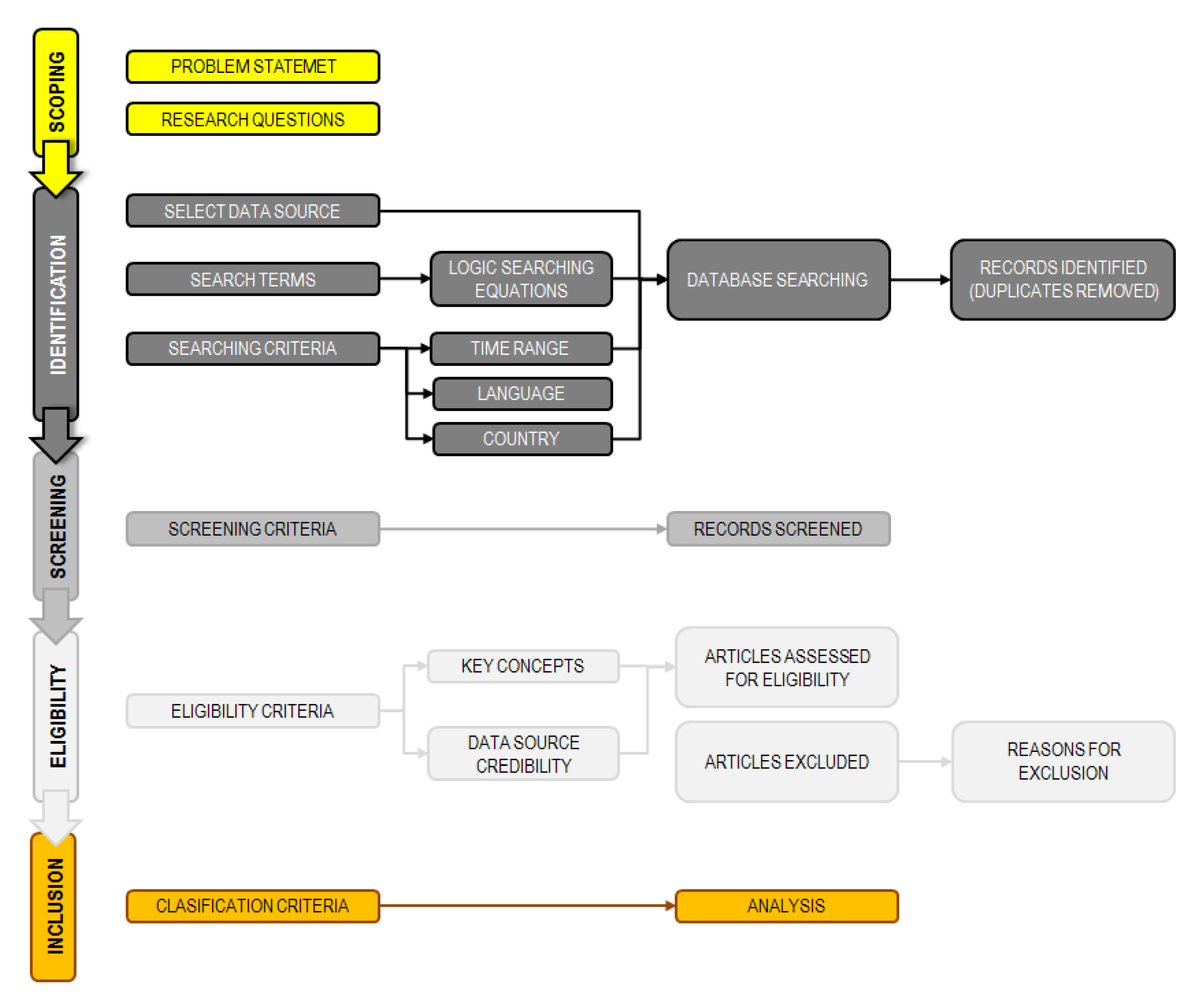

2. Methodology

2.1. Scope

2.2. Review Method

3. Results

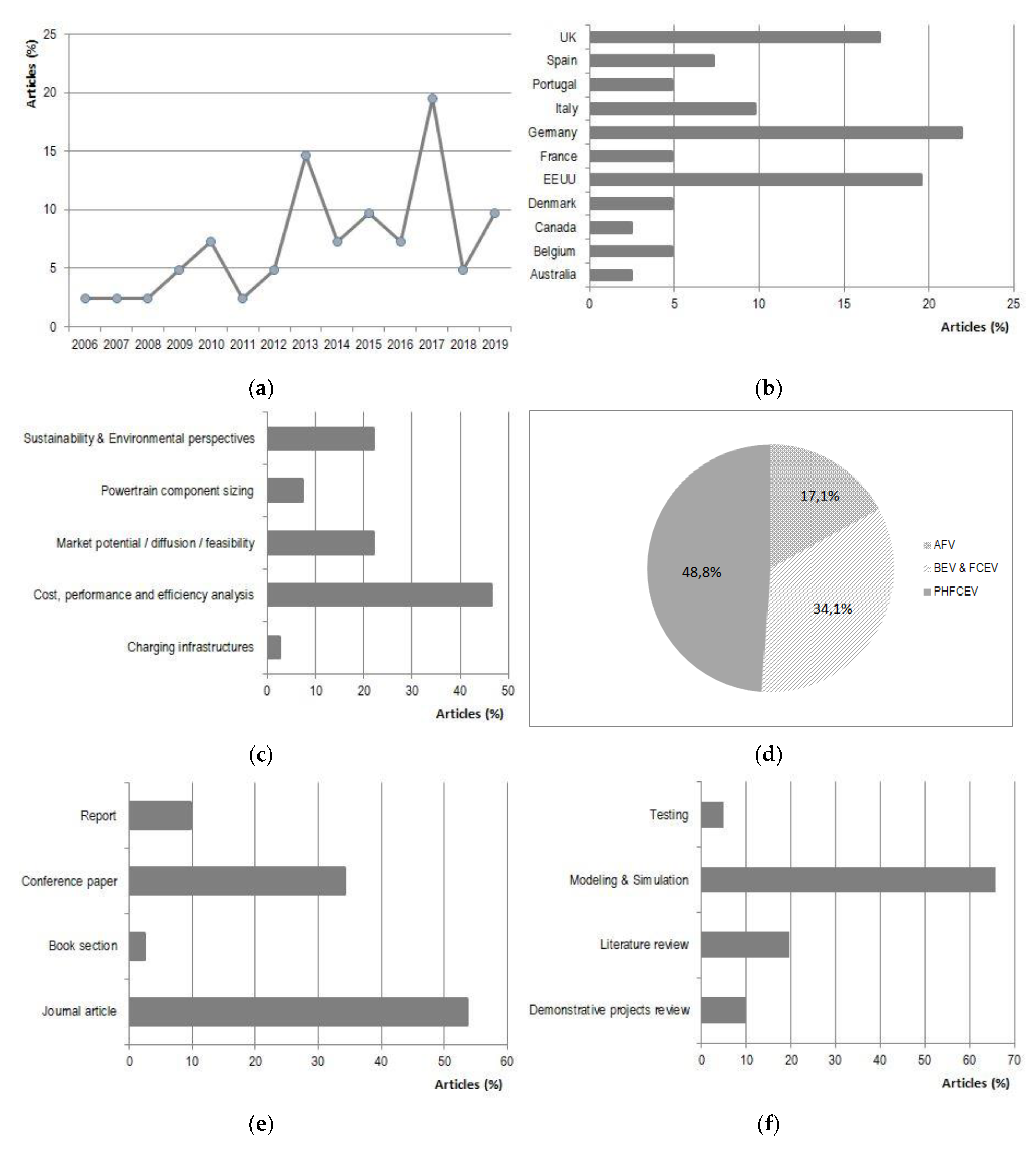

3.1. Selected Studies and Bibliographic Analysis

- Number fraction of documents published from 2006 to 2019 (Figure 2a).

- Number fraction of documents published per country (Figure 2b).

- Number fraction of documents published per analysis topic (Figure 2c).

- Number fraction of documents published per powertrain configuration (Figure 2d).

- Number fraction of articles published per type of document (Figure 2e).

- Number fraction of articles published per type of methodology used to address the issue (Figure 2f).

- Number fraction of articles published per type of vehicle class (Figure 2g).

3.2. Summary of Results of the Main Research Topics. Methodology Used to Address the Issues

3.3. Identification of Key Features Evaluated in the Selected Studies

- Economic attributes: purchase price and operational costs.

- Technological attributes: range, environmental efficiency and vehicle performances.

- Operational attributes: refueling infrastructure, refueling time, fuel cost, fuel production, usage intensity and route planning.

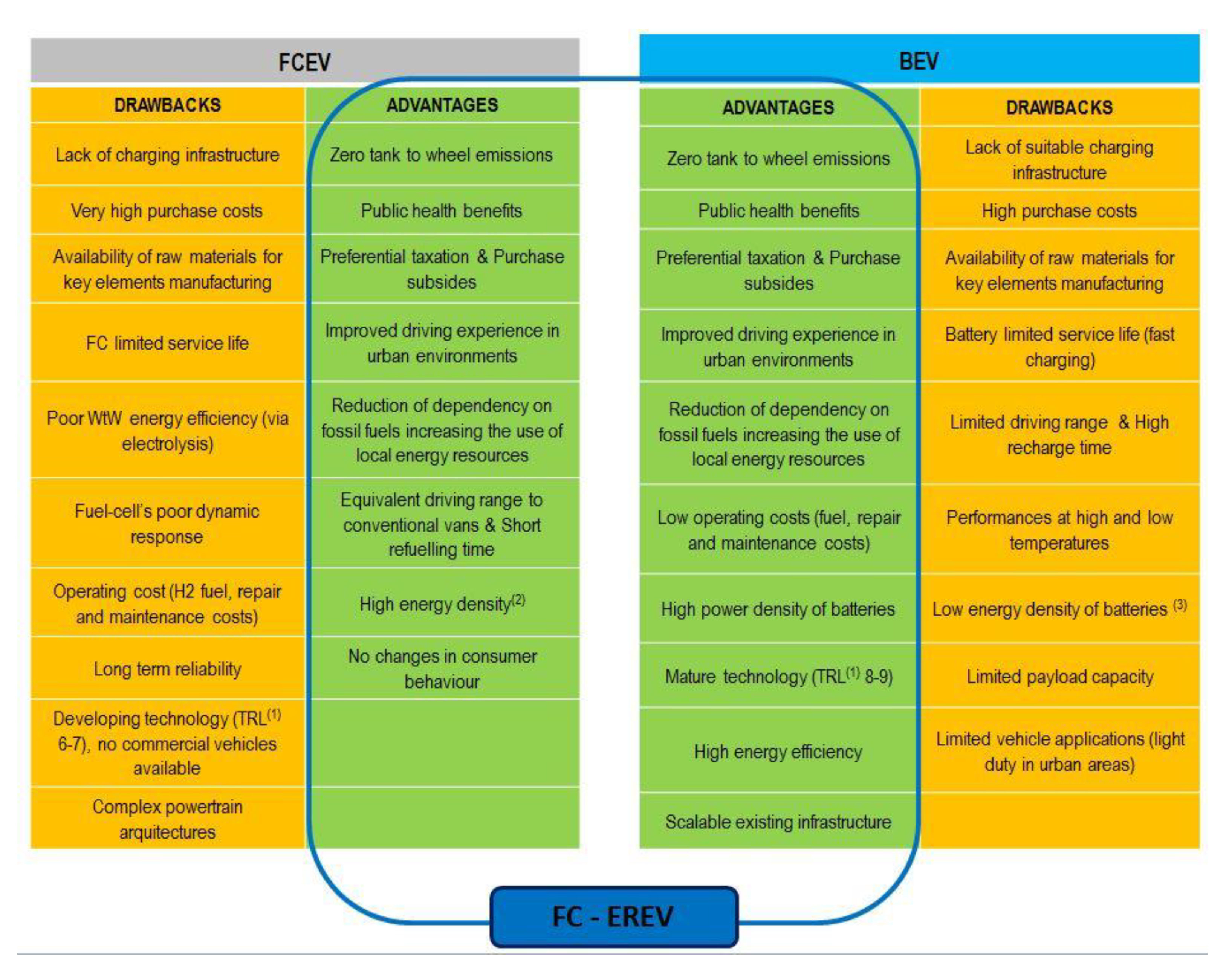

4. Discussion

4.1. Fleet Operator Prospects

4.2. Electric Energy System Prospects. Energy Production and Supply Issues

4.3. Environmental Concerns

4.4. Assessment of FC-EREV Powertrain Deployment in Vans for Metropolitan Delivery Tasks

5. Conclusions

- Economic attributes: purchase price and operational costs.

- Technological attributes: range, environmental efficiency and vehicle performances.

- Operational attributes: refueling infrastructure, refueling time, fuel cost, fuel production, usage intensity and route planning.

- User requirements for light-duty vans are related to the total cost of ownership (purchase and operating costs), autonomy between refueling (range), performance (payload, maximum gradeability rate, top speed, acceleration, etc.), operating time per day, flexibility to assign a delivery route, uptime (reliability and service maintenance intervals) and service life.

- Refueling infrastructure is a key issue for BEV and FCEV technologies. Nowdays, the number of available electric public recharging stations, although fast-growing, are limited. The situation is even worse in actual hydrogen refueling stations.

- FC-EREV van purchase price is strongly influenced by the sizing of the powertrain components used and its costs over time. Different hardware configurations and energy management strategies adapted to particular duty conditions (range over 200 km and/or high usage intensity working conditions) could lead to a cost-effectiveness configuration.

- FC-EREV van operational costs depend on the distance traveled per year, the number of years of ownership, maintenance expenses, the fuel cost (electricity and hydrogen) and the proportion of each energy used, this last factor is influenced by duty cycle conditions, the degree of hybridization ratio, the energy management strategy and the range available with electricity and hydrogen. The current fuel cost, to a larger extent the hydrogen cost, and the high maintenance expenses, because of greater technical complexity than BEV, could lead to a longer ownership period and it could reduce the final second-hand resale price.

- FC-EREV van has clear advantages when the averaged real range needed is more than 200 km and/or high usage intensity conditions that could affect the energy consumption, as route profile (steep slopes), high load, high traffic density, delivery plan with frequent stop-and-go, adverse ambient conditions (hot or cold days) and aggressive driving style.

- FC-EREV van powertrain and energy management strategy flexibility configuration allows to fulfill a great variety of user-defined performance parameters, such as range, payload, driving speed and maximum gradeability rate, with fewer effects on fuel consumption and vehicle dynamics in hard-duty conditions. Powertrain configuration and energy management strategies have a strong influence on fuel efficiency.

- The hydrogen refueling time in an FC-EREV van is equivalent to a diesel-powered van, giving a similar feeling to the users. The electricity recharging time depends on the recharging infrastructure power outlet and the onboard vehicle charger capacity.

- FC-EREV van environmental performances are more uncertain than BEVs due to variable powertrain configuration, the wider selection of energy pathways available to produce hydrogen than electricity and the current FC technology readiness, but FC-EREV vans could provide advantageous life cycle GHG reduction in hard duty conditions and/or daily trips over 200 km. In any case, as BEVs, depends on the use of renewable energy sources.

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| AFP | Alternative Fuels and Powertrains |

| AFV | Alternative Fuel Vehicle |

| BEV | Battery Electric Vehicle |

| B2C | Business to Costumer |

| CADC | Common Artemis Driving Cycles |

| CD | Battery Charge Depleting mode |

| CS | Battery Charge Sustaining mode |

| DoD | Battery Depth of Discharge |

| DOE | US Department of Energy |

| DoH | Degree of Hybridization |

| ECV | Electric Commercial Vehicle |

| EFV | Electric Freight Vehicles |

| EREV | Extended Range Electric Vehicle |

| EU | European Union |

| FCEV | Fuel Cell Electric Vehicle |

| FC-EREV | Fuel Cell Extended Range Electric Vehicle |

| FC-PHEV | Fuel Cell Plug-in Hybrid Electric Vehicle |

| HEV | Hybrid Electric Vehicle |

| HRS | Hydrogen Refueling Station |

| GHG | Greenhouse Gas Emissions |

| GVM | Gross Vehicle Mass rating |

| ICE | Internal Combustion Engine |

| LCA | Life Cycle Assessment |

| LCV | Light Commercial Vehicle |

| LDV | Light-Duty Vehicle |

| NEDC | New European Driving Cycle |

| PCU | Power Control Unit |

| PEM | Proton-Exchange Membrane |

| PHEV | Plug-in Hybrid Electric Vehicle |

| UDC | Urban Delivery Cycle |

| US | United States |

| SoC | Battery State of Charge |

| TCO | Total Cost of Ownership |

| TtW | Tank to Wheel |

| WHVC | World Harmonized Vehicle Cycle |

| WtW | Well to Wheel |

Appendix A

| Keywords | Hydrogen, van, freight, logistics, delivery, urban, city, sustainable | ||

| Combined Terms | Fuel cell, Hydrogen range extender, Urban freight, City logistics, Last-mile delivery, Delivery van, Light commercial vehicles, Medium duty vehicles, Sustainable Logistics, Sustainable supply chain | ||

| B1 | Light commercial vehicles | AND | Fuel cell |

| B2 | Urban freight | AND | Fuel cell |

| B3 | Sustainable supply chain | AND | Fuel cell |

| B4 | Medium duty vehicles | AND | Fuel cell |

| B5 | City logistics | AND | Fuel cell |

| B6 | Delivery van | AND | Fuel cell |

| B7 | Urban logistics | AND | Fuel cell |

| B8 | Last-mile delivery | AND | Fuel cell |

| B9 | Sustainable logistics | AND | Fuel cell |

| B10 | Delivery van | AND | Hydrogen Range Extender |

| B11 | Light commercial vehicles | AND | Hydrogen Range Extender |

| B12 | Last-mile delivery | AND | Hydrogen Range Extender |

Appendix B

| Number of Selected Documents for Analysis | Summary of Dimensions Considered as Inclusion Criteria |

|---|---|

| 41 | Market feasibility, Environmental concerns, charging infrastructures issues, economic aspects or technical features of FC-EREV technologies in light and light/medium duty vehicles for urban delivery tasks Comparison between FCEV and BEV technologies in light and light/medium duty vehicles for urban delivery tasks |

Appendix C

| Authors (Ref., Year) | Publisher—Journal | SJR 2019 | Document Type | Country | Vehicle Type |

|---|---|---|---|---|---|

| Adebusuyi et al., 2012 [27] | IEE—Electrical Systems for Aircraft, Railway and Ship Propulsion | NAQ | Conference paper | Denmark | PC & CV |

| Arnhold et al., 2017 [28] | Springer—ATZ Elektronik worldwide | 0.19 | Journal article | Germany | PC & CV |

| Bartolozzi et al., 2013 [29] | Elsevier—Applied energy | 3.61 | Article | Italy | CV |

| Bergmann et al., 2017 [30] | Springer—Internationaler Motorenkongress | NAQ | Conference paper | Germany | CV |

| Juan et al., 2016 [31] | MDPI—Energies | 0.64 | Article | Spain | CV |

| Kleiner et al., 2017a [7] | EVS—30th International Electric Vehicle Symposium | NAQ | Conference paper | Germany | CV |

| Kleiner et al., 2017b [32] | EVS—30th International Electric Vehicle Symposium | NAQ | Conference paper | Germany | CV |

| Kleiner et al., 2015 [33] | EVS—28th International Electric Vehicle Symposium | NAQ | Conference paper | Germany | CV |

| Millo et al., 2016 [34] | Elsevier—International Journal of Hydrogen Energy | 1,14 | Article | Italy | CV |

| Ntziachristos et al., 2012 [35] | Publications Office of the EU—JRC Scientific and Policy Reports | NI | Report | Italy | PC and CV |

| Özdemir et al., 2015 [36] | EEVC—2015 European Battery, Hybrid and Fuel Cell Electric Vehicle Congress | NI | Conference paper | Germany | PC and CV |

| Propfe et al., 2011 [37] | EEVC—2011 European Electric Vehicle Congress | NI | Conference paper | Germany | CV |

| Wood et al., 2013 [38] | SAE—2013 Commercial Vehicle Engineering Congress | 0.38 | Conference paper | US | CV |

| Ruf et al., 2017 [39] | Fuel Cells and Hydrogen 2 Joint Undertaking (FCH2JU) —N°FCH/OP/contract 180, Reference Number FCH JU2017 D4259 | NI | Report | US | CV |

| Van Mierlo et al., 2006 [40] | Elsevier—Energy Conversion and Management | 2.92 | Journal article | Belgium | PC and CV |

| Offer et al., 2010 [41] | Elsevier—Energy Policy | 2.17 | Journal article | UK | PC and CV |

| Thomas, 2009 [42] | Elsevier—International Journal of Hydrogen Energy | 1.14 | Journal article | US | PC and CV |

| Thomas, 2009 [43] | Elsevier—International Journal of Hydrogen Energy | 1.14 | Journal article | US | PC and CV |

| Kelouwani et al., 2013 [23] | Elsevier—Journal of Power Sources | 2.11 | Journal article | Canada | PC and CV |

| Robinius et al., 2018 [44] | TU Wien Energy and Environment Research Centre | 13.02 | Report | Germany | PC and CV |

| Baptista et al., 2010b [45] | Elsevier—International Journal of Hydrogen Energy | 1.14 | Journal article | Portugal | PC and CV |

| Jensen et al., 2013 [46] | IEEE—Transactions on Vehicular Technology | 1.63 | Journal article | Denmark | PC and CV |

| Kromer and Heywood, 2007 [47] | MIT—Sloan Automotive Laboratory | NI | Report | US | PC and CV |

| Sharer et al., 2013 [48] | MDPI—World Electric Vehicle Journal | 0.19 | Journal article | US | CV |

| Jokela et al., 2019 [25] | SAE | 0.32 | Conference paper | UK | CV |

| Sim et al., 2019 [49] | MDPI—Energies | 0.64 | Journal article | EEUU | CV |

| Walters et al., 2015 [24] | Electrical Systems for Aircraft, Railway and Ship Propulsion (ESARS) | NAQ | Conference paper | Germany | PC |

| Fernández et al., 2016 [17] | Elsevier—International Journal of Hydrogen Energy | 1.14 | Article | Spain | PC |

| Wu et al., 2019 [50] | MDPI—World Electric Vehicle Journal | 0.19 | Article | UK | PC |

| Bendjedia et al., 2018 [51] | Elsevier—International Journal of Hydrogen Energy | 1.14 | Article | France | PC |

| Baptista et al., 2010a [52] | MDPI—World Electric Vehicle Journal | 0.19 | Article | Portugal | PC |

| Álvarez et al., 2018 [53] | Springer—Nanostructured Materials for Next-Generation Energy Storage and Conversion: Fuel Cells | NI | Book Section | Spain | PC |

| Browne et al., 2014 [54] | Elsevier—Procedia Social and Behavioral Sciences | NAQ | Conference paper | UK | CV |

| Lewis et al., 2017 [55] | IEEE—Transportation and Electrification Conference and Expo (ITEC 2017) | 0.29 | Conference paper | US | CV |

| Steenberghen et al., 2008 [8] | Elsevier—Journal of Cleaner Production | 1.89 | Journal article | Belgium | PC and CV |

| Ramachandran and Stimming, 2015 [56] | RSC—Energy and Environmental Science | 13.02 | Journal article | US | PC and CV |

| Ceraolo et al., 2017 [57] | IEEE—International Conference of Electrical and Electronic Technologies for Automotive (AEIT 2017) | NI | Conference paper | Italy | CV |

| Hardman et al., 2013 [58] | Elsevier—International Journal of Hydrogen Energy | 1.14 | Journal article | UK | PC and CV |

| Maniatopoulos et al., 2015 [59] | Elsevier—Renewable and Sustainable Energy Reviews | 3.63 | Journal article | Australia | PC and CV |

| Jones et al., 2020 [60] | Elsevier—Renewable and Sustainable Energy Reviews | 3.63 | Journal article | UK | CV |

| Le Duigou and Smatti, 2014 [61] | Elsevier—International Journal of Hydrogen Energy | 1.14 | Conference paper | France | PC |

Appendix D

| Authors | Problem Addressed | Research Challenge |

|---|---|---|

| Adebusuyi et al., 2012 [27] | Comparison of three types of vehicle hybridization powertrains reviewing the actual running costs using as a basis the NEDC city cycle. | Running cost; Plug-in hybrid FCEV; Light commercial vehicles |

| Bergmann et al., 2017 [30] | Definition of the electric traction motor power, battery capacity and FCEV range extender configuration for medium-duty electrical distribution vehicles based on typical requirements for a distribution vehicle and analysis of operation costs. | Medium-duty electrical distribution vehicles; Load profiles; Powertrain sizing; Daily mileage; FCEV range extender configurations; Energy consumption; Operation cost; Prices for energy; Urban Delivery Cycle (UDC) |

| Kleiner et al., 2017b [32] | Analysis of maintenance and repair costs and resale value for different alternative commercial vehicle powertrains. | Electric vehicle; Freight transport; LCC (Life Cycle Cost) |

| Kleiner et al., 2015 [33] | Techno-economic assessment of electric vehicle configurations focused on light commercial vehicles based on a total cost model. | Alternative powertrains; Battery electric vehicle; Fuel cell electric vehicle; Light duty commercial vehicle (N1); Total cost of ownership |

| Ntziachristos and Panagiota, 2012 [35] | Evaluation of alternative fuelled powertrains based on energy efficiency, GHG and AP emissions, infrastructure and costs criteria, using information from published studies, and engineering assessments. | Greenhouse gas (GHG); Electric and hybrid vehicle; Energy efficiency; Energy security; Air Pollutants (AP); Infrastructure; Costs |

| Özdemir et al., 2015 [36] | Description of trends in the electrified transport logistic vehicles with their detailed technical specifications. | Electrified transport logistic vehicles; Technical specifications; Fleet implementation |

| Offer et al., 2010 [41] | Qualitative comparisons and infrastructural requirements, and quantitative evaluation of the lifecycle cost for battery electric vehicles (BEV), hydrogen fuel cell electric vehicles (FCEV) and hydrogen fuel cell plug-in hybrid vehicles (FCHEV). | Electric vehicle; Fuel cell vehicle; Hybrid vehicle; Life cycle costs |

| Kelouwani et al., 2013 [23] | Implementation of an energy management strategy for fuel cell plug-in hybrid electric vehicles using a real-time power splitting method that preserves the battery pack life. | Electric vehicles; Energy efficiency; Energy management; Fuel cells; Nonlinear optimal control; Vehicle dynamics |

| Sharer et al., 2013 [48] | Evaluation of limitations of battery and hydrogen-powered medium-duty vehicles by assessing the fuel displacement and cost–benefit potential of adding fuel cell systems to double the current range of BEVs. | Hydrogen-powered vehicles; Battery electric vehicles; Fuel cell range extender; Medium-duty vehicle market; Fuel displacement; Cost–benefit potential; Powertrain cost; Optimized component sizing; Energy management strategy |

| Jokela et al., 2019 [25] | Combined model based on a component sizing process with an energy management strategy (EMS) optimization for determining powertrain performance and total system costs focused on Fuel-Cell Hybrid Electric Vehicle (FCHEV) architectures for commercial vehicles. | Component sizing; Fuel cell powered vehicle; Light, Medium- and heavy-duty trucks; Optimization; Ownership cost |

| Sim et al., 2019 [49] | Component sizing algorithm to minimize overall ownership cost, while ensuring the fuel cell-powered commercial vehicle configuration matches or exceeds the performance and cargo capacity of a conventional vehicle. | Component sizing; Fuel cell powered vehicle; Medium- and heavy-duty trucks; Optimization; Ownership cost |

| Walters et al., 2015 [24] | Overview of the state-of-the-art in battery and range extension technology, showing key issues in range extender configurations development working with hydrogen. | Fuel Cell; Hybrid; Plug-In; Range; Range-Extender |

| Fernández et al., 2016 [17] | Study of an Extended Range Electric Vehicle (EREV) based in a Fuel Cell Electric Vehicle (FCEV) in order to determine the working conditions that will lead to better efficiency and performance, referring to capacity of both energy sources | Electric vehicle; Extended range; Fuel cell |

| Wu et al., 2019 [50] | Component sizing of a battery electric vehicle using a trailer-based demountable fuel cell range extender based on user requirements | Battery electric vehicle; Hydrogen fuel cell; Range extender |

| Álvarez et al., 2018 [53] | Study of an Extended Range Electric Vehicle (EREV) based in a Fuel Cell Electric Vehicle (FCEV) in order to determine the working conditions that will lead to better efficiency and performance, referring to capacity of both energy sources | Electric vehicle; Extended range; Fuel cell |

| Lewis et al., 2017 [55] | Sizing powertrain components (fuel cell stack and battery size) using real world GPS data to define routes and duty cycles, to perform vehicle powertrain capabilities.to complete the most demanding parcel and delivery duty cycles. | Fuel cell; Hybrid electric vehicle; Medium-duty truck |

| Ceraolo et al., 2017 [57] | Comparison model to analyze conventional, full electric and hybrid versions of commercial vans. | Full electric van; Hybrid van; Cost; Performance; Efficiency; Powertrain layout |

| Jones et al., 2020 [60] | Study of the use of hydrogen vehicles for addressing sustainability concerns in urban logistics by undertaking a total cost of ownership analysis. | Alternative vehicles; Hydrogen fuel cell vehicles; Freight transport; Policy; Total cost of ownership; Urban logistics |

| Le Duigou et al., 2014 [61] | Techno-economic comparison in terms of Total Cost of Ownership (TCO) framework for ICE, BEV, HEV, FCEV and FC-RE powertrains, analysing the major TCO-influencing parameters. | Battery electric vehicles; Hydrogen fuel cell vehicles; Range-extender; Total Cost of Ownership (TCO) |

| Authors | Problem Addressed | Research Challenge |

|---|---|---|

| Arnhold et al., 2017 [28] | Comparison of FCEV and BEV vehicles in different categories: refueling and charging infrastructure, user requirements, public acceptance, energy system, efficiency and energy demand. | Advantages and barriers; FCEV; BEV; Refueling infrastructure; User requirements; Public acceptance; Energy system |

| Kleiner et al., 2017a [7] | Analysis of market conditions where alternative powertrain technologies can enter the market and gain market shares. | Electric vehicle; Freight transport; Light and heavy commercial vehicle; Market development; Total cost of ownership (TCO); CO2 emissions |

| Wood et al., 2013 [38] | Analysis of use small hydrogen fuel-cell stacks to extend the range of battery electric vehicles identifying optimal component configurations for minimizing life cycle costs, as well as potential future scenarios where fuel cell range extended vehicles where economically competitive | Fuel cell extender range; Optimal component sizing; Life cycle costs; Energy management strategies |

| Ruf et al., 2017 [39] | Analysis of business cases for fuel cell powered delivery vans for inner-city delivery logistics | Business Cases; Fuel cell extender range; Total cost of Ownership (TCO); Well to Wheel (WtW) emissions |

| Van Mierlo et al., 2006 [40] | Performances comparison of hybrid electric vehicles and battery electric vehicles with future hydrogen fuel cell-based systems which are now in R&D phase. | Battery electric vehicles; Fuel cell electric vehicles; Hybrid electric vehicles; Well to wheel efficiency; Delivery vans |

| Baptista et al., 2010b [45] | Analysis of the impact of the market share increase of hydrogen-based light-duty vehicles in terms of energy consumption and CO2 emissions. | Fleet life cycle analysis (LCA); Market penetration scenarios; Plug-in hybrid fuel cell vehicle; Vehicle life cycle analysis |

| Kromer et al., 2007 [47] | Evaluation of the potential of electric and hybrid-electric powertrains to reduce energy consumption and greenhouse gas (GHG) emissions | Electric and hybrid powertrains; Light-duty fleet; Tank-to-wheel energy consumption; Well-to-wheel energy; GHG emissions; Cost |

| Steenberghen et al., 2008 [8] | Presentation of technical development status, their market potential, and barriers to their implementation for LPG, hydrogen and biofuels-based powertrains in various market segments. | Alternative fuels; Barriers to implementation; Energy policy; Market incentives; Transport |

| Hardman et al., 2013 [58] | Study to bring greater clarity to the characteristics of disruptive innovation of battery electric and hydrogen fuel cell vehicles in a way that informs on the viability of these emerging technologies. | Battery electric vehicles; Disruptive technologies; Fuel cell vehicles; Niche markets |

| Authors | Problem Addressed | Research Challenge |

|---|---|---|

| Bartolozzi et al., 2013 [29] | Investigation of the potential of the use of hydrogen produced from renewable sources as automotive fuel conducting a life cycle assessment for evaluating the environmental sustainability applied to a fleet of hydrogen vehicles for urban commercial delivery. A comparison of vehicles equipped with either fuel cell, standard electric and internal combustion engine is done. | Automotive fuel; Environmental sustainability; Life Cycle Assessment (LCA); Renewable energy |

| Juan et al., 2016 [31] | Analysis of several open research challenges related to the introduction of EVs in logistics and transportation (L&T) activities, including: environmental-related issues; and strategic, planning and operational issues associated with “standard” EVs and with hydrogen-based EVs. | Electric vehicles; Hydrogen-based EVs; Green vehicle routing problems; Logistics and transportation; Recharge stations allocation and capability; Driving-range; Environmental issues; Optimization problems |

| Propfe et al., 2011 [37] | Identify CO2 potential reduction of DHL delivery fleet in different scenarios based on a comparison of different types of powertrains running in a new developed driving cycle that matches the requirements of delivery trucks. | CO2 efficiency; Light commercial vehicles (LCV); Alternative drive trains; Urban driving cycle |

| Thomas, 2009 [42] | Evaluation of several alternative vehicle and fuel options to assess the societal benefits (greenhouse gas emissions) of replacing conventional gasoline cars. | Alternative fuelled vehicles; Dynamic simulation; Urban air pollution |

| Thomas, 2009 [43] | Comparison of alternative transportation options including hybrid electric vehicles and plug-in hybrids fuelled by gasoline, diesel fuel, natural gas, and ethanol, and all-electric vehicles powered by either batteries or fuel cells from environmental impact point of view (air pollution) and oil consumption. | Battery electric vehicle; Fuel cell electric vehicle; Plug-in electric vehicle; Dynamic simulation; Energy security; Greenhouse gases; Hydrogen infrastructure; Societal cost savings |

| Baptista et al., 2010a [52] | Well-to-Wheel (WTW) Life-Cycle Analysis (LCA) for two hydrogen powered vehicle powertrain options (fuel cell plug-in hybrid vehicle, FC-PHEV; and fuel cell hybrid vehicle, HEV-FC), in comparison to the conventional ICE Diesel Taxi and a full electric vehicle (EV). | Energy consumption; Fuel cell hybrid vehicle; Life cycle analysis (LCA) |

| Browne et al., 2014 [54] | Analysis of annual average distance travelled, fuel consumption and CO2 emissions for electric van fleet adoption. | Light goods vehicles; Van fleet; Urban areas; Annual average distance travelled; Fuel consumption; Emissions; Whole life costs |

| Ramachandran et al., 2015 [56] | Comparison the use of alternative powertrain technologies on the basis of their overall efficiency and GHG emissions involved in the conversion of the primary energy source to the actual energy required at wheels through a well-to-wheel analysis. | Alternative fuelled vehicle; Greenhouse gas (GHG) emissions; Biofuels; Battery electric vehicle; Fuel cell electric vehicle; Efficiency; Well to wheel analysis; Electricity mix; Life cycle analysis (LCA) |

| Maniatopoulos et al., 2015 [59] | Review of the potential reduction of GHG emissions in road transport through the total replacement of petroleum-fuelled vehicles with hydrogen and battery electrical vehicles. | Battery electric vehicle; Fuel cell electric vehicle; Hydrogen economy; Road transport; Sustainable energy strategy; GHG emissions |

| Authors | Problem Addressed | Research Challenge |

|---|---|---|

| Millo et al., 2016 [34] | Investigation of the usage of a Fuel Cell (FC) as a range extender in a full electric light duty commercial vehicle in the framework of the collaborative European project ARTEMIS (Automotive PEMFC range extender with high temperature improved stacks) | Electric vehicle; Battery electric vehicle; Fuel cell electric vehicle; HT-PEM fuel cell; Range extender |

| Jensen et al., 2013 [46] | Analysis of different EV setups with FC strategies are presented and compared. | Battery electric vehicle; Fuel-cell hybrid electric vehicle |

| Bendjedia et al., 2018 [51] | Study of an optimal sizing methodology for an Energy Storage System (ESS) composed by a fuel cell and an assistant source to show the benefits of hybridization according to the range in terms of weight, cost and fuel consumption. | Energy Storage System; Fuel cell; Hydrogen consumption; Sizing; Energy management strategy |

| Authors | Problem Addressed | Research Challenge |

|---|---|---|

| Robinius et al., 2018 [44] | Performing a techno-economic analysis of the required infrastructure for refueling battery and fuel cell electric vehicles at multiple scales. | Hydrogen Fuelling; Electric Charging |

References

- Aditjandra, P.T.; Galatioto, F.; Bell, M.J.; Zunder, T.H. Evaluating the impacts of urban freight traffic: Application of micro-simulation at a large establishment. Eur. J. Transp. Infrastruct. Res. 2016, 16, 4–22. [Google Scholar] [CrossRef]

- European Environment Agency (EEA). Analysing and Managing Urban Growth. Available online: https://www.eea.europa.eu/articles/analysing-and-managing-urban-growth (accessed on 24 July 2020).

- Seto, K.; Dhakal, S.; Bigio, A.; Blanco, H.; Delgado, G.C.; Dewar, D.; McMahon, J. Human settlements, infrastructure and spatial planning. In Climate Change 2014 Mitigation of Climate Change. IPCC Working Group III Contribution to AR5; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2014. [Google Scholar] [CrossRef]

- Cox, W. Demographia World Urban Areas & Population Projections; Wendel Cox Consultancy: St. Louis, MO, USA, 2019. [Google Scholar]

- European Commission. Directorate General for Mobility and Transport. White Paper on Transport. Roadmap to a Single European Transport Area—Towards a Competitive and Resource-Efficient Transport System; European Commission: Brussels, Belgium, 2011. [Google Scholar] [CrossRef]

- Gevaers, R.; van de Voorde, E.; Vanelslander, T. Cost Modelling and Simulation of Last-mile Characteristics in an Innovative B2C Supply Chain Environment with Implications on Urban Areas and Cities. Proced. Soc. Behav. Sci. 2014, 125, 398–411. [Google Scholar] [CrossRef]

- Kleiner, F.; Friedrich, H.E. Scenario analyses for the techno-economical evaluation of the market diffusion of future commercial vehicle concepts. In Proceedings of the International Battery, Hybrid and Fuel Cell Electric Vehicle Symposium, Evs30 Symposium, Stuttgart, Germany, 9–11 October 2017; pp. 1–13. [Google Scholar]

- Steenberghen, T.; López, E. Overcoming barriers to the implementation of alternative fuels for road transport in Europe. J. Clean. Prod. 2008, 16, 577–590. [Google Scholar] [CrossRef]

- Pelletier, S.; Jabali, O.; Laporte, G. Goods distribution with electric vehicles: Review and research perspectives. Transp. Sci. 2016, 50, 3–22. [Google Scholar] [CrossRef]

- Margaritis, D.; Anagnostopoulou, A.; Tromaras, A.; Boile, M. Electric commercial vehicles: Practical perspectives and future research directions. Res. Transp. Bus. Manag. 2016, 18, 4–10. [Google Scholar] [CrossRef]

- Quak, H.; Nesterova, N.; van Rooijen, T. Possibilities and Barriers for Using Electric-powered Vehicles in City Logistics Practice. Transp. Res. Proced. 2016, 12, 157–169. [Google Scholar] [CrossRef]

- Christensen, L.; Klauenberg, J.; Kveiborg, O.; Rudolph, C. Suitability of commercial transport for a shift to electric mobility with Denmark and Germany as use cases. Res. Transp. Econ. 2017, 64, 48–60. [Google Scholar] [CrossRef]

- Birky, A.K.; Laughlin, M.; Tartaglia, K.; Price, R.; Lim, B.; Lin, Z. Electrification Beyond Light Duty: Class 2b−3 Commercial Vehicles; Oak Ridge National Laboratory: Springfield, VA, USA, 2017.

- Wang, J.; Wang, H.; Fan, Y. Techno-Economic Challenges of Fuel Cell Commercialization. Engineering 2018, 4, 352–360. [Google Scholar] [CrossRef]

- Biresselioglu, M.E.; Demirbag Kaplan, M.; Yilmaz, B.K. Electric mobility in Europe: A comprehensive review of motivators and barriers in decision making processes. Transp. Res. Part A Policy Pract. 2018, 109, 1–13. [Google Scholar] [CrossRef]

- Wang, M.; Thoben, K.D.; Bernardo, M.; Daudi, M. Diversity in Employment of Electric Commercial Vehicles in Urban Freight Transport: A Literature Review. Logist. Res. 2018, 11, 1–21. [Google Scholar] [CrossRef]

- Fernández, R.Á.; Cilleruelo, F.B.; Martínez, I.V. A new approach to battery powered electric vehicles: A hydrogen fuel-cell-based range extender system. Int. J. Hydrog. Energy 2016, 41, 4808–4819. [Google Scholar] [CrossRef]

- Olsson, J.; Hellström, D.; Pålsson, H. Framework of Last Mile Logistics Research: A Systematic Review of the Literature. Sustainability 2019, 11, 7131. [Google Scholar] [CrossRef]

- European Automobile Manufacturers Association (ACEA). Vehicles In Use—Europe 2018; European Automobile Manufacturers Association: Brussels, Belgium, 2018; pp. 1–19. [Google Scholar]

- Kelouwani, S.; Agbossou, K.; Dubé, Y.; Boulon, L. Fuel cell plug-in hybrid electric vehicle anticipatory and real-time blended-mode energy management for battery life preservation. J. Power Sources 2013, 221, 406–418. [Google Scholar] [CrossRef]

- Walters, M.; Kuhlmann, A.; Ogrzewalla, J. Fuel cell range extender for battery electric vehicles. In Proceedings of the International Conference on Electrical Systems for Aircraft, Railway, Ship Propulsion and Road Vehicles (ESARS), Aagen, Germany, 3–5 March 2015; pp. 5–10. [Google Scholar] [CrossRef]

- Jokela, T.; Iraklis, A.; Kim, B.; Gao, B. Combined Sizing and EMS Optimization of Fuel-Cell Hybrid Powertrains for Commercial Vehicles. In Proceedings of the WCX SAE World Congress Experience, Detroit, MI, USA, 9–11 April 2019; pp. 1–13. [Google Scholar] [CrossRef]

- Paré, G.; Trudel, M.C.; Jaana, M.; Kitsiou, S. Synthesizing information systems knowledge: A typology of literature reviews. Inf. Manag. 2015, 52, 183–199. [Google Scholar] [CrossRef]

- Mulrow, C. Systematic Reviews: Rationale for systematic reviews. BMJ 1994, 309, 597–599. [Google Scholar] [CrossRef]

- Moher, D.; Liberati, A.; Tetzlaff, J.; Altman, D.G.; Altman, D.; Antes, G.; Atkins, D.; Barbour, V.; Barrowman, N.; Berlin, J.A.; et al. Preferred reporting items for systematic reviews and meta-analyses: The PRISMA statement. PLoS Med. 2009, 6, e1000097. [Google Scholar] [CrossRef]

- Halevi, G.; Moed, H.; Bar-Ilan, J. Suitability of Google Scholar as a source of scientific information and as a source of data for scientific evaluation—Review of the Literature. J. Informetr. 2017, 11, 823–834. [Google Scholar] [CrossRef]

- Adebusuyi, A.; Ashwood, L. A review of 3 hybridization options for light commercial and passenger vehicles. In Proceedings of the International Conference on Electrical Systems for Aircraft, Railway and Ship Propulsion (ESARS), Bologna, Italy, 16–18 October 2012; pp. 7–10. [Google Scholar] [CrossRef]

- Arnhold, O.; Grüger, F.; Wanitschke, A.; Goldammer, K. Debate and appeal role of hydrogen and battery electric vehicles in mobility. ATZelektronik Worldw. 2017, 12, 16–21. [Google Scholar] [CrossRef]

- Bartolozzi, I.; Rizzi, F.; Frey, M. Comparison between hydrogen and electric vehicles by life cycle assessment: A case study in Tuscany, Italy. Appl. Energy 2013, 101, 103–111. [Google Scholar] [CrossRef]

- Bergmann, D.; Wedowski, S.; Maiterth, J.; Marten, C.; Ghetti, S.; Walters, M.; Morra, P. Range extender systems for electric drivetrains in medium duty distribution vehicles. In Proceedings of the Internationaler Motorenkongress, Baden, Germany, 21–22 February 2017; pp. 703–721. [Google Scholar] [CrossRef]

- Juan, A.A.; Mendez, C.A.; Faulin, J.; de Armas, J.; Grasman, S.E. Electric vehicles in logistics and transportation: A survey on emerging environmental, strategic, and operational challenges. Energies 2016, 9, 86. [Google Scholar] [CrossRef]

- Kleiner, F.; Friedrich, H.E. Maintenance & repair cost calculation and assessment of resale value for different alternative commercial vehicle powertrain technologies. In Proceedings of the International Battery, Hybrid and Fuel Cell Electric Vehicle Symposium, EVS30 Symposium, Stuttgart, Germany, 9–11 October 2017; pp. 1–16. [Google Scholar]

- Kleiner, F.; Özdemir, E.D.; Schmid, S.A.; Beermann, M.; Çatay, B.; Moran, B.; Lim, O.T.; Friedrich, H.E. Electrification of Transport Logistic Vehicles: A Techno-Economic Assessment of Battery and Fuel Cell Electric Transporter. In Proceedings of the 2015 EVS28 International Electric Vehicle Symposium and Exhibition (EVS 2015), Kintex, Korea, 3–6 May 2015; pp. 1–11. [Google Scholar]

- Millo, F.; Caputo, S.; Piu, A. Analysis of a HT-PEMFC range extender for a light duty full electric vehicle (LD-FEV). Int. J. Hydrog. Energy 2016, 41, 16489–16498. [Google Scholar] [CrossRef]

- Ntziachristos, L.; Panagiota, D. Sustainability Assessment of Road Transport Technologies; European Commission; Joint Research Centre: Ispra, Italy, 2012. [Google Scholar] [CrossRef]

- Özdemir, E.D.; Kleiner, F.; Beermann, M.; Çatay, B.; Beers, E.; Moran, B.; Lim, O.T.; Schmid, S.A. Status and trends for electrified transport logistic vehicles. In Proceedings of the European Battery, Hybrid and Fuel Cell Electric Vehicle Congress, Brussels, Belgium, 2–4 December 2015; pp. 1–8. [Google Scholar]

- Propfe, B.; Schlaghecken, G.; Jüchter, A.; Schmid, S.A. Identifying the potential CO2-efficiency for the Deutsche Post DHL delivery fleet based on vehicle technology scenarios. In Proceedings of the European Electric Vehicle Congress, Brussels, Belgium, 26–28 October 2011; pp. 1–6. [Google Scholar]

- Wood, E.; Wang, L.; Gonder, J.; Ulsh, M. Overcoming the Range Limitation of Medium-Duty Battery Electric Vehicles through the use of Hydrogen Fuel-Cells. SAE Int. J. Commer. Veh. 2013, 6, 563–574. [Google Scholar] [CrossRef]

- Ruf, Y.; Kaufmann, M.; Lange, S.; Pfister, J.; Heieck, F.; Endres, A. Fuel Cells and Hydrogen Applications for Regions and Cities; Roland Berger: Brussels, Belgium; Frankfurt, Germany, 2017. [Google Scholar]

- Van Mierlo, J.; Maggetto, G.; Lataire, P. Which energy source for road transport in the future? A comparison of battery, hybrid and fuel cell vehicles. Energy Convers. Manag. 2006, 47, 2748–2760. [Google Scholar] [CrossRef]

- Offer, G.J.; Howey, D.; Contestabile, M.; Clague, R.; Brandon, N.P. Comparative analysis of battery electric, hydrogen fuel cell and hybrid vehicles in a future sustainable road transport system. Energy Policy 2010, 38, 24–29. [Google Scholar] [CrossRef]

- Thomas, C.E. Fuel cell and battery electric vehicles compared. Int. J. Hydrog. Energy 2009, 34, 6005–6020. [Google Scholar] [CrossRef]

- Thomas, C.E. Transportation options in a carbon-constrained world: Hybrids, plug-in hybrids, biofuels, fuel cell electric vehicles, and battery electric vehicles. Int. J. Hydrog. Energy 2009, 34, 9279–9296. [Google Scholar] [CrossRef]

- Robinius, M.; Linßen, J.; Grube, T.; Reuß, M.; Stenzel, P.; Syranidis, K.; Kuckertz, P.; Stolten, D. Comparative Analysis of Infrastructures: Hydrogen Fueling and Electric Charging of Vehicles; Energy & Environment: Leipzig, Germany, 2018. [Google Scholar]

- Baptista, P.; Tomás, M.; Silva, C. Plug-in hybrid fuel cell vehicles market penetration scenarios. Int. J. Hydrog. Energy 2010, 35, 10024–10030. [Google Scholar] [CrossRef]

- Jensen, H.C.B.; Schaltz, E.; Koustrup, P.S.; Andreasen, S.J.; Kær, S.K. Evaluation of fuel-cell range extender impact on hybrid electrical vehicle performance. IEEE Trans. Veh. Technol. 2013, 62, 50–60. [Google Scholar] [CrossRef]

- Kromer, M.A.; Heywood, J.B. Electric Powertrains: Opportunities and Challenges in the U.S. Light-Duty Vehicle Fleet; Sloan Automotive Laboratory: Cambridge, MA, USA, 2007. [Google Scholar]

- Sharer, P.; Rousseau, A. Benefits of fuel cell range extender for medium-duty vehicle applications. World Electr. Veh. J. 2013, 6, 452–463. [Google Scholar] [CrossRef]

- Sim, K.; Vijayagopal, R.; Kim, N.; Rousseau, A. Optimization of component sizing for a fuel cell-powered truck to minimize ownership cost. Energies 2019, 12, 1125. [Google Scholar] [CrossRef]

- Wu, D.; Ren, J.; Davies, H.; Shang, J.; Haas, O. Intelligent hydrogen fuel cell range extender for battery electric vehicles. World Electr. Veh. J. 2019, 10, 29. [Google Scholar] [CrossRef]

- Bendjedia, B.; Rizoug, N.; Boukhnifer, M.; Bouchafaa, F.; Benbouzid, M. Influence of secondary source technologies and energy management strategies on Energy Storage System sizing for fuel cell electric vehicles. Int. J. Hydrog. Energy 2018, 43, 11614–11628. [Google Scholar] [CrossRef]

- Baptista, P.; Ribau, J.; Bravo, J.; Silva, C.; Adcock, P.; Kells, A. Fuel cell hybrid taxi well-to-wheel life-cycle analysis. In Proceedings of the EVS25 World Battery, Hybrid and Fuel Cell Electric Vehicle Symposium, Shenzhen, China, 5–9 November 2010; pp. 798–803. [Google Scholar] [CrossRef]

- Álvarez, R.; Corbera, S. Hydrogen fuel cell as range extender in Electric Vehicle Powertrains: Fuel optimization strategies. In Nanostructured Materials for Next-Generation Energy Storage and Conversion; Springer: Heidelberg, Germany, 2018; pp. 359–383. [Google Scholar]

- Browne, M.; Rizet, C.; Allen, J. A Comparative Assessment of the Light Goods Vehicle Fleet and the Scope to Reduce its CO2 Emissions in the UK and France. Proced. Soc. Behav. Sci. 2014, 125, 334–344. [Google Scholar] [CrossRef]

- Lewis, M.; Hearn, C.; Feng, X.; Hanlin, J.; Levin, J.; Ambrosio, J.; Guggenheim, P.; Walker, C. Design and modeling for hydrogen fuel cell conversion of parcel delivery trucks. In Proceedings of the 2017 IEEE Transportation Electrification Conference and Expo (ITEC), Chicago, IL, USA, 22–24 June 2017; pp. 674–678. [Google Scholar] [CrossRef]

- Ramachandran, S.; Stimming, U. Well to wheel analysis of low carbon alternatives for road traffic. Energy Environ. Sci. 2015, 8, 3313–3324. [Google Scholar] [CrossRef]

- Ceraolo, M.; Lutzemberger, G.; Sani, L.; Valenti, G.; Pretto, A.; Pugi, L. Full electric and hybrid series vans: Cost, performance and efficiency evaluation for different powertrain layout. In Proceedings of the 2017 International Conference of Electrical and Electronic Technologies for Automotive, Torino, Italy, 15 June 2017. [Google Scholar] [CrossRef]

- Hardman, S.; Steinberger-Wilckens, R.; van der Horst, D. Disruptive innovations: The case for hydrogen fuel cells and battery electric vehicles. Int. J. Hydrog. Energy 2013, 38, 15438–15451. [Google Scholar] [CrossRef]

- Maniatopoulos, P.; Andrews, J.; Shabani, B. Towards a sustainable strategy for road transportation in Australia: The potential contribution of hydrogen. Renew. Sustain. Energy Rev. 2015, 52, 24–34. [Google Scholar] [CrossRef]

- Jones, J.; Genovese, A.; Tob-Ogu, A. Hydrogen vehicles in urban logistics: A total cost of ownership analysis and some policy implications. Renew. Sustain. Energy Rev. 2020, 119, 1–15. [Google Scholar] [CrossRef]

- Le Duigou, A.; Smatti, A. On the comparison and the complementarity of batteries and fuel cells for electric driving. Int. J. Hydrog. Energy 2014, 39, 17873–17883. [Google Scholar] [CrossRef]

- De Cauwer, C.; Messagie, M.; Heyvaert, S.; Coosemans, T.; van Mierlo, J. Electric vehicle use and energy consumption based on real world electric vehicle fleet trip and charge data its impact on existing EV research models. World Electr. Veh. J. 2015, 7, 436–446. [Google Scholar]

- Fetene, G.M.; Kaplan, S.; Mabit, S.L.; Jensen, A.F.; Prato, C.G. Harnessing big data for estimating the energy consumption and driving range of electric vehicles. Transp. Res. Part D Transp. Environ. 2017, 54, 1–11. [Google Scholar] [CrossRef]

- Fiori, C.; Marzano, V. Modelling energy consumption of electric freight vehicles in urban pickup/delivery operations: Analysis and estimation on a real-world dataset. Transp. Res. Part D Transp. Environ. 2018, 65, 658–673. [Google Scholar] [CrossRef]

- Hosseini, S.E.; Wahid, M.A. Hydrogen production from renewable and sustainable energy resources: Promising green energy carrier for clean development. Renew. Sustain. Energy Rev. 2016, 57, 850–866. [Google Scholar] [CrossRef]

| Authors, Year, Ref. (Ref., Year) | Vehicle Type | Powertrain |

|---|---|---|

| Steenberghen et al., 2008 [8] | Passenger & commercial vehicles | AFV |

| Pelletier et al., 2016 [9] | Commercial vehicles | BEV |

| Margaritis et al., 2016 [10] | Commercial vehicles | BEV |

| Quak et al., 2016 [11] | Commercial vehicles | BEV |

| Christensen et al., 2017 [12] | Passenger & commercial vehicles | BEV |

| Birky et al., 2017 [13] | Commercial vehicles | BEV |

| J. Wang et al., 2018 [14] | Passenger vehicles | FCEV |

| Biresselioglu et al., 2018 [15] | Passenger vehicles | BEV |

| M. Wang et al., 2018 [16] | Commercial vehicles | BEV |

| Year | Manufacturer | Battery Capacity (kW h) | H2 Capacity (kg) | Range (km) | GVM (3) (kg) | Capacity | |||

|---|---|---|---|---|---|---|---|---|---|

| Model | Payload (kg) | Volume (m3) | |||||||

| DHL | 2017 | Ford-StreetScooter | WORK XL | 76 | --- | 200 (1) | 4050 (4) | 1150 | 20 |

| DHL | 2016 | StreetScooter | WORK L | 40 | --- | 80 (1) 187 (2) | 2600 | 905 | 8 |

| DHL | 2019 | Ford-StreetScooter | H2 Panel Van | 40 | 6 | 500 (1) | 4050 (4) | 800 | 10 |

| FedEx | 2018 | Chanje | V8100 | 100 | --- | 240 (1) | 7500 | 2700 | 19 |

| UPS | 2018 | Work horse | P80-E | 62 | --- | 130 (1) | 7500 | 3450 | 23 |

| TNT | 2015 | Fiat | e-Ducato | 62 | --- | 200 (2) | 3500 | 680 | 17 |

| United States | European Union | Duty Classification | ||

|---|---|---|---|---|

| Vehicle Class | Mass (t) | Vehicle Class | Mass (t) | |

| 1 | ≤2.72 | N1 | ≤3.5 | Light truck |

| 2a | ≤3.86 | Light truck | ||

| 2b | ≤4.54 | N2 | ≤12 | Light/Medium truck |

| 3 | 4.54–6.35 | Medium truck | ||

| 4 | 6.35–7.26 | Medium truck | ||

| Authors (Ref., Year) | Powertrain | Research Topic | Methodology |

|---|---|---|---|

| Adebusuyi et al., 2012 [27] | FC-EREV | Cost, performance and efficiency analysis | Testing |

| Arnhold et al., 2017 [28] | BEV and FCEV | Market potential/diffusion/feasibility | Demonstrative projects review |

| Bartolozzi et al., 2013 [29] | BEV and FCEV | Sustainability and Environmental perspectives | Modeling and Simulation |

| Bergmann et al., 2017 [30] | EREV | Cost, performance and efficiency analysis | Modeling and Simulation |

| Juan et al., 2016 [31] | BEV and FCEV | Sustainability and Environmental perspectives | Literature review |

| Kleiner et al., 2017a [7] | AFV | Market potential/diffusion/feasibility | Modeling and Simulation |

| Kleiner et al., 2017b [32] | AFV | Cost, performance and efficiency analysis | Modeling and Simulation |

| Kleiner et al., 2015 [33] | BEV and FCEV | Cost, performance and efficiency analysis | Demonstrative projects review |

| Millo et al., 2016 [34] | FC-EREV | Powertrain and Battery Systems | Modeling and Simulation |

| Ntziachristos et al., 2012 [35] | AFV | Cost, performance and efficiency analysis | Literature review |

| Özdemir et al., 2015 [36] | BEV and FCEV | Cost, performance and efficiency analysis | Literature review |

| Propfe et al., 2011 [37] | BEV and FCEV | Sustainability and Environmental perspectives | Modeling and Simulation |

| Wood et al., 2013 [38] | FC-EREV | Market potential/diffusion/feasibility | Modeling and Simulation |

| Ruf et al., 2017 [39] | FC-EREV | Market potential/diffusion/feasibility | Demonstrative projects review |

| Van Mierlo et al., 2006 [40] | BEV and FCEV | Market potential/diffusion/feasibility | Literature review |

| Offer et al., 2010 [41] | FC-PHEV | Cost, performance and efficiency analysis | Literature review |

| Thomas, 2009 [42] | BEV and FCEV | Sustainability and Environmental perspectives | Modeling and Simulation |

| Thomas, 2009 [43] | AFV | Sustainability and Environmental perspectives | Modeling and Simulation |

| Kelouwani et al., 2013 [23] | FC-PHEV | Cost, performance and efficiency analysis | Modeling and Simulation |

| Robinius et al., 2018 [44] | BEV and FCEV | Charging infrastructures | Modeling and Simulation |

| Baptista et al., 2010b [45] | FC-PHEV | Market potential/diffusion/feasibility | Modeling and Simulation |

| Jensen et al., 2013 [46] | FC-EREV | Powertrain and Battery Systems | Modeling and Simulation |

| Kromer et al., 2007 [47] | BEV and FCEV | Market potential/diffusion/feasibility | Modeling and Simulation |

| Sharer et al., 2013 [48] | FC-EREV | Cost, performance and efficiency analysis | Modeling and Simulation |

| Jokela et al., 2019 [25] | FC-EREV | Cost, performance and efficiency analysis | Modeling and Simulation |

| Sim et al., 2019 [49] | FC-EREV | Cost, performance and efficiency analysis | Modeling and Simulation |

| Walters et al., 2015 [24] | FC-EREV | Cost, performance and efficiency analysis | Modeling and Simulation |

| Fernández et al., 2016 [17] | FC-EREV | Cost, performance and efficiency analysis | Modeling and Simulation |

| Wu et al., 2019 [50] | FC-EREV | Cost, performance and efficiency analysis | Literature review |

| Bendjedia et al., 2018 [51] | FC-EREV | Powertrain and Battery Systems | Modeling and Simulation |

| Baptista et al., 2010a [52] | FC-EREV | Sustainability and Environmental perspectives | Modeling and Simulation |

| Álvarez et al., 2018 [53] | FC-EREV | Cost, performance and efficiency analysis | Modeling and Simulation |

| Browne et al., 2014 [54] | AFV | Sustainability and Environmental perspectives | Demonstrative projects review |

| Lewis et al., 2017 [55] | FC-EREV | Cost, performance and efficiency analysis | Modeling and Simulation |

| Steenberghen et al., 2008 [8] | AFV | Market potential/diffusion/feasibility | Literature review |

| Ramachandran et al., 2015 [56] | AFV | Sustainability and Environmental perspectives | Modeling and Simulation |

| Ceraolo et al., 2017 [57] | PHEV | Cost, performance and efficiency analysis | Modeling and Simulation |

| Hardman et al., 2013 [58] | BEV and FCEV | Market potential/diffusion/feasibility | Literature review |

| Maniatopoulos et al., 2015 [59] | BEV and FCEV | Sustainability and Environmental perspectives | Modeling and Simulation |

| Jones et al., 2020 [60] | BEV and FCEV | Cost, performance and efficiency analysis | Testing |

| Le Duigou et al., 2014 [61] | FC-EREV | Cost, performance and efficiency analysis | Modeling and Simulation |

| Attributes | Description |

|---|---|

| Purchase price | The acquisition cost of the vehicle is an essential part of the whole life of ownership cost and is also affected by the aids for the purchase and legal fees and taxes. |

| Operational costs | The running costs are mainly dependent of annual mileages, fuel cost, road and parking taxes, maintenance and insurance costs. |

| Range | Total vehicle range measured in specific conditions, such as NDEC and WLTC driving cycles. |

| Environmental efficiency | Data related to whole life cycle emissions analysis, well-to-wheel (WtW) or tank-to-wheel (TtW) studies. |

| Vehicle performances | This factor concerns to payload (load and volume capacity), driving speed, acceleration, maximum gradeability and powertrain configuration (energy storage systems, energy management strategies) |

| Refueling infrastructure | Recharge and refueling issues. |

| Refueling time | Time needed to get full vehicle range. |

| Fuel cost | Costs associated with the production, transportation, storage and delivery of fuel to the vehicle. |

| Fuel production | Facts related to fuel production and supply issues. |

| Usage intensity | This factor includes duty cycle characteristics, such as daily trips, route profile (slope), nominal load (usually a payload factor of 50% is considered), driving style and ambient conditions (hot or cold temperatures), and reliability and dealer support over the vehicle service life. |

| Route planning | Daily on-road route plan involving several delivery points taking into account several constraints (e.g., time, distance and vehicle characteristics). |

| Economic Features | Technological Features | Operational Features | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Authors | Purchase Price | Operational Costs | Range | Environmental Efficiency | Vehicle Performances | Refueling Infrastructure | Refueling Time | Fuel Cost | Fuel Production | Usage Intensity | Route Planning |

| Adebusuyi et al., 2012 [27] | X | X | X | ||||||||

| Arnhold et al., 2017 [28] | X | X | X | X | |||||||

| Bartolozzi et al., 2013 [29] | X | X | |||||||||

| Bergmann et al., 2017 [30] | X | X | X | X | X | ||||||

| Juan et al., 2016 [31] | X | X | X | X | |||||||

| Kleiner et al., 2017a [7] | X | X | X | X | X | X | |||||

| Kleiner et al., 2017b [32] | X | ||||||||||

| Kleiner et al., 2015 [33] | X | X | X | X | X | ||||||

| Millo et al., 2016 [34] | X | X | |||||||||

| Ntziachristos et al., 2012 [35] | X | X | X | X | X | ||||||

| Özdemir et al., 2015 [36] | X | X | |||||||||

| Propfe et al., 2011 [37] | X | X | X | X | X | ||||||

| Wood et al., 2013 [38] | X | X | X | X | X | ||||||

| Ruf et al., 2017 [39] | X | X | X | X | |||||||

| Van Mierlo et al., 2006 [40] | X | X | X | ||||||||

| Offer et al., 2010 [41] | X | X | X | X | X | ||||||

| Thomas, 2009 [42] | X | X | X | X | X | X | X | X | X | ||

| Thomas, 2009 [43] | X | X | |||||||||

| Kelouwani et al., 2013 [23] | X | ||||||||||

| Robinius et al., 2018 [44] | X | ||||||||||

| Baptista et al., 2010b [45] | X | X | |||||||||

| Jensen et al., 2013 [46] | X | X | X | ||||||||

| Kromer et al., 2007 [47] | X | X | X | X | X | ||||||

| Sharer et al., 2013 [48] | X | X | X | X | X | ||||||

| Jokela et al., 2019 [25] | X | X | X | X | X | X | |||||

| Sim et al., 2019 [49] | X | X | X | X | X | ||||||

| Walters, et al., 2015 [24] | X | X | |||||||||

| Fernandez et al., 2016 [17] | X | X | |||||||||

| Wu et al., 2019 [50] | X | X | X | X | X | X | X | ||||

| Bendjedia et al., 2018 [51] | X | X | |||||||||

| Baptista et al., 2010a [52] | X | X | |||||||||

| Álvarez et al., 2018 [53] | X | X | |||||||||

| Browne at al., 2014 [54] | X | X | X | ||||||||

| Lewis et al., 2017 [55] | X | X | X | ||||||||

| Steenberghen et al., 2008 [8] | X | X | X | ||||||||

| Ramachandran et al., 2015 [56] | X | X | |||||||||

| Ceraolo et al., 2017 [57] | X | X | X | X | X | ||||||

| Hardman et al., 2013 [58] | X | X | X | ||||||||

| Maniatopoulus et al., 2015 [59] | X | X | X | X | |||||||

| Jones et al., 2020 [60] | X | X | X | X | |||||||

| Le Duigou et al., 2014 [61] | X | X | X | X | |||||||

| Number of papers per attribute | 18 | 21 | 25 | 17 | 22 | 10 | 2 | 16 | 8 | 8 | 1 |

| Fleet Operator | Electrical Energy System | Environmental Concerns | |

|---|---|---|---|

| Linked attributes | Range Vehicle performances Usage intensity Refueling features (time and infrastructure) Total cost of ownership (purchase price and operational costs). | Fuel production efficiency and cost Supply features | Whole life cycle environment efficiency |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Castillo, O.; Álvarez, R.; Domingo, R. Opportunities and Barriers of Hydrogen–Electric Hybrid Powertrain Vans: A Systematic Literature Review. Processes 2020, 8, 1261. https://doi.org/10.3390/pr8101261

Castillo O, Álvarez R, Domingo R. Opportunities and Barriers of Hydrogen–Electric Hybrid Powertrain Vans: A Systematic Literature Review. Processes. 2020; 8(10):1261. https://doi.org/10.3390/pr8101261

Chicago/Turabian StyleCastillo, Oscar, Roberto Álvarez, and Rosario Domingo. 2020. "Opportunities and Barriers of Hydrogen–Electric Hybrid Powertrain Vans: A Systematic Literature Review" Processes 8, no. 10: 1261. https://doi.org/10.3390/pr8101261

APA StyleCastillo, O., Álvarez, R., & Domingo, R. (2020). Opportunities and Barriers of Hydrogen–Electric Hybrid Powertrain Vans: A Systematic Literature Review. Processes, 8(10), 1261. https://doi.org/10.3390/pr8101261