Experimental Study on the Flow and Heat Transfer of Graphene-Based Lubricants in a Horizontal Tube

Abstract

:1. Introduction

2. Materials and Physical Properties

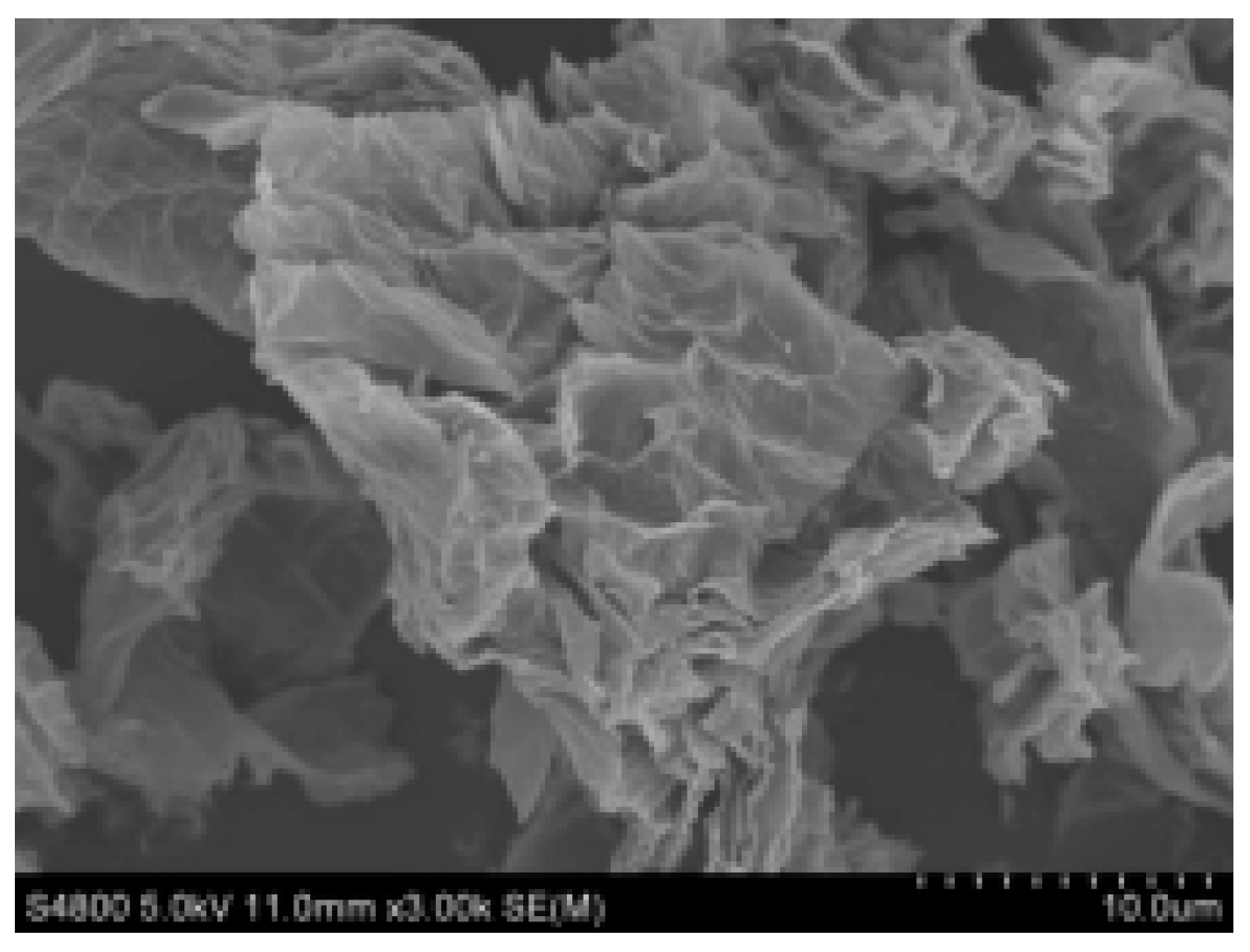

2.1. Graphene Material

2.2. Graphene Lubricant

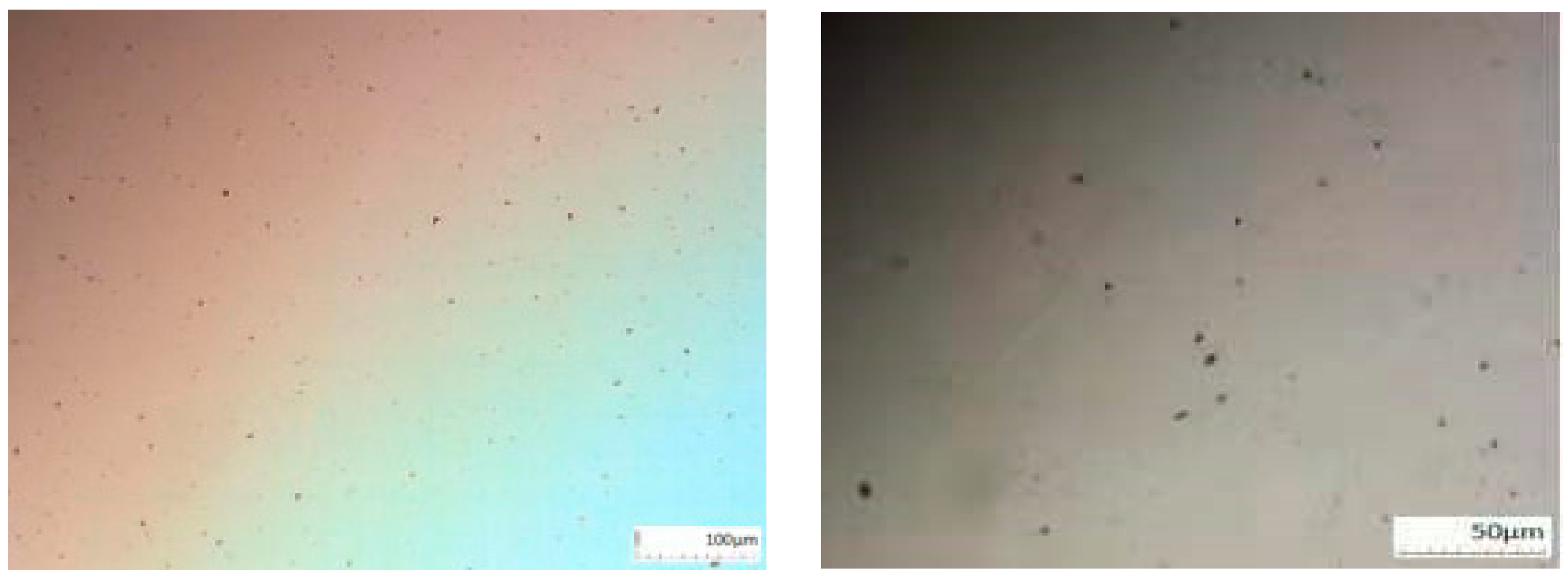

2.2.1. Micro-Characteristic Test

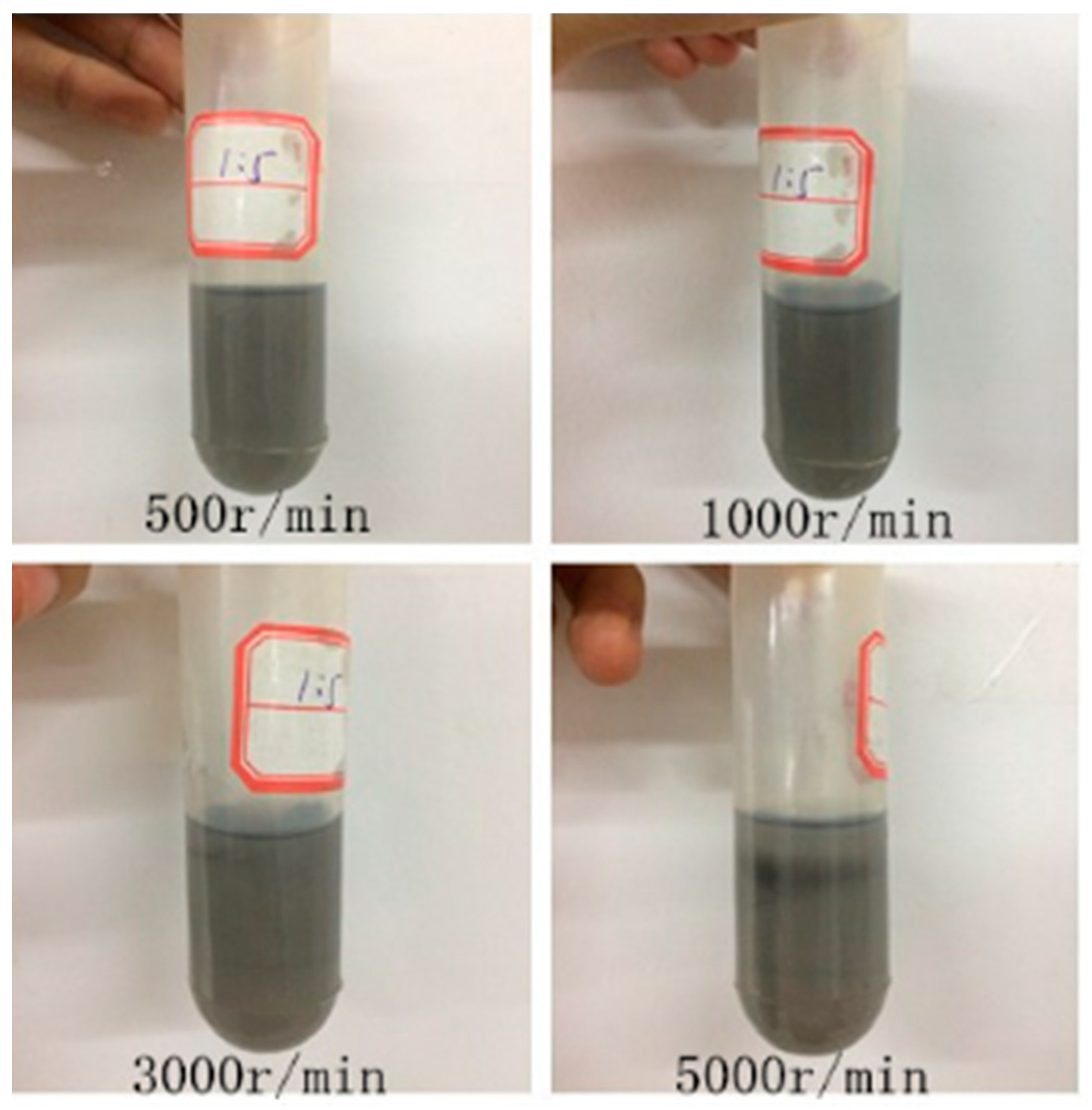

2.2.2. Stability Test

2.2.3. Thermal Conductivity Test

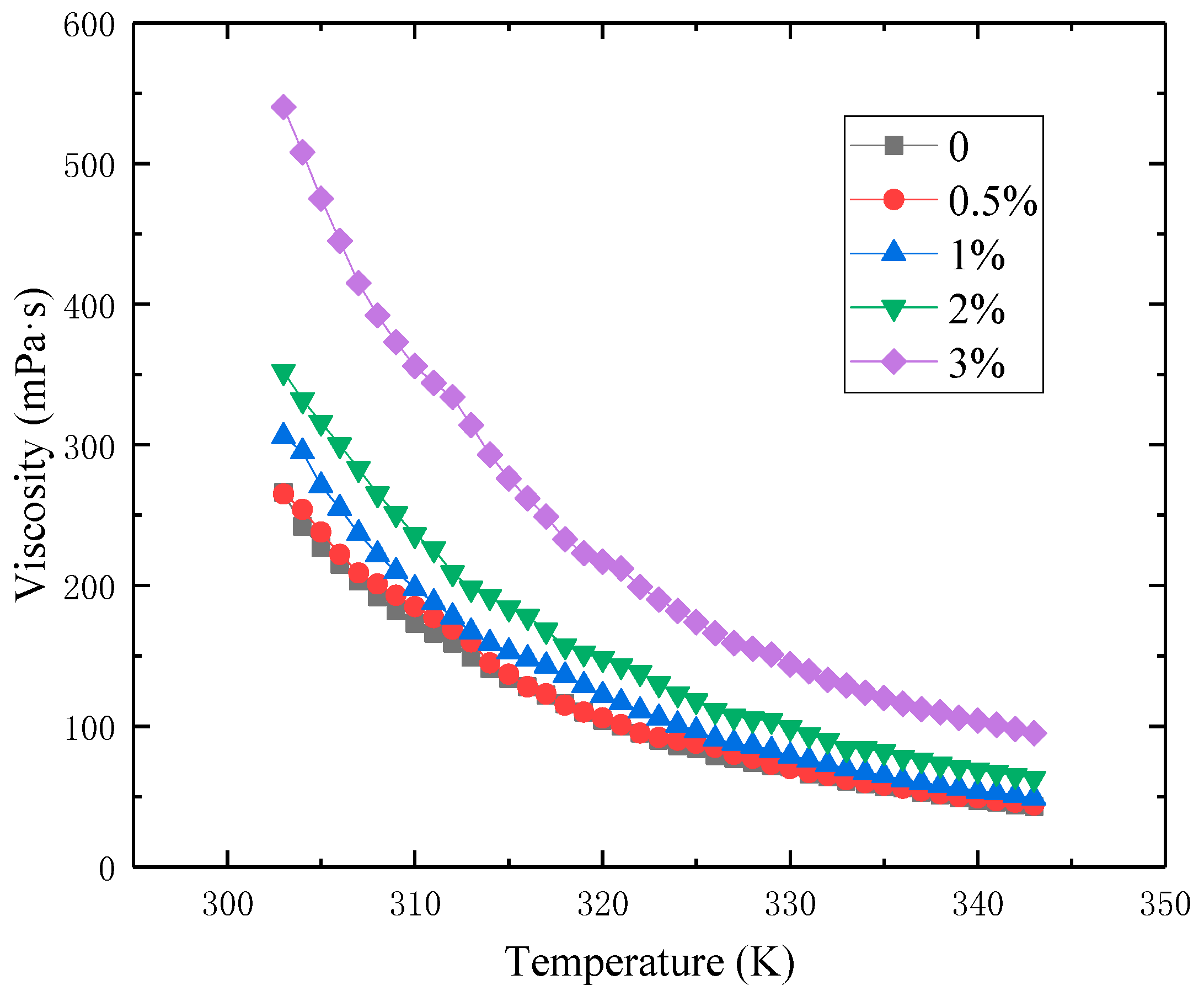

2.2.4. Viscosity Test

2.2.5. Specific Heat Capacity Test

3. Experimental Study on Flow and Heat Transfer

3.1. Experimental System

3.2. Experimental Data Treatment

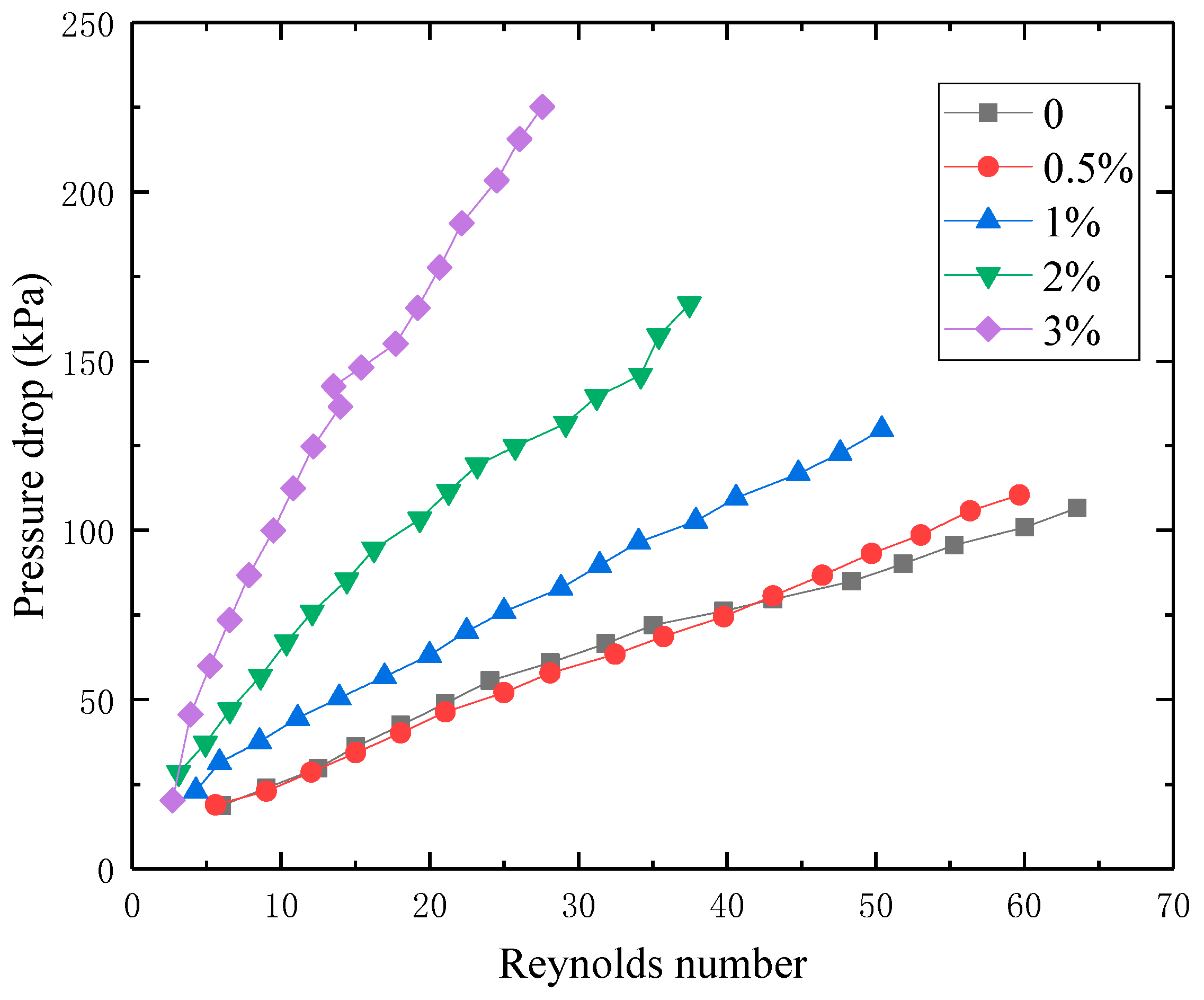

3.3. Pressure Drop Characteristics

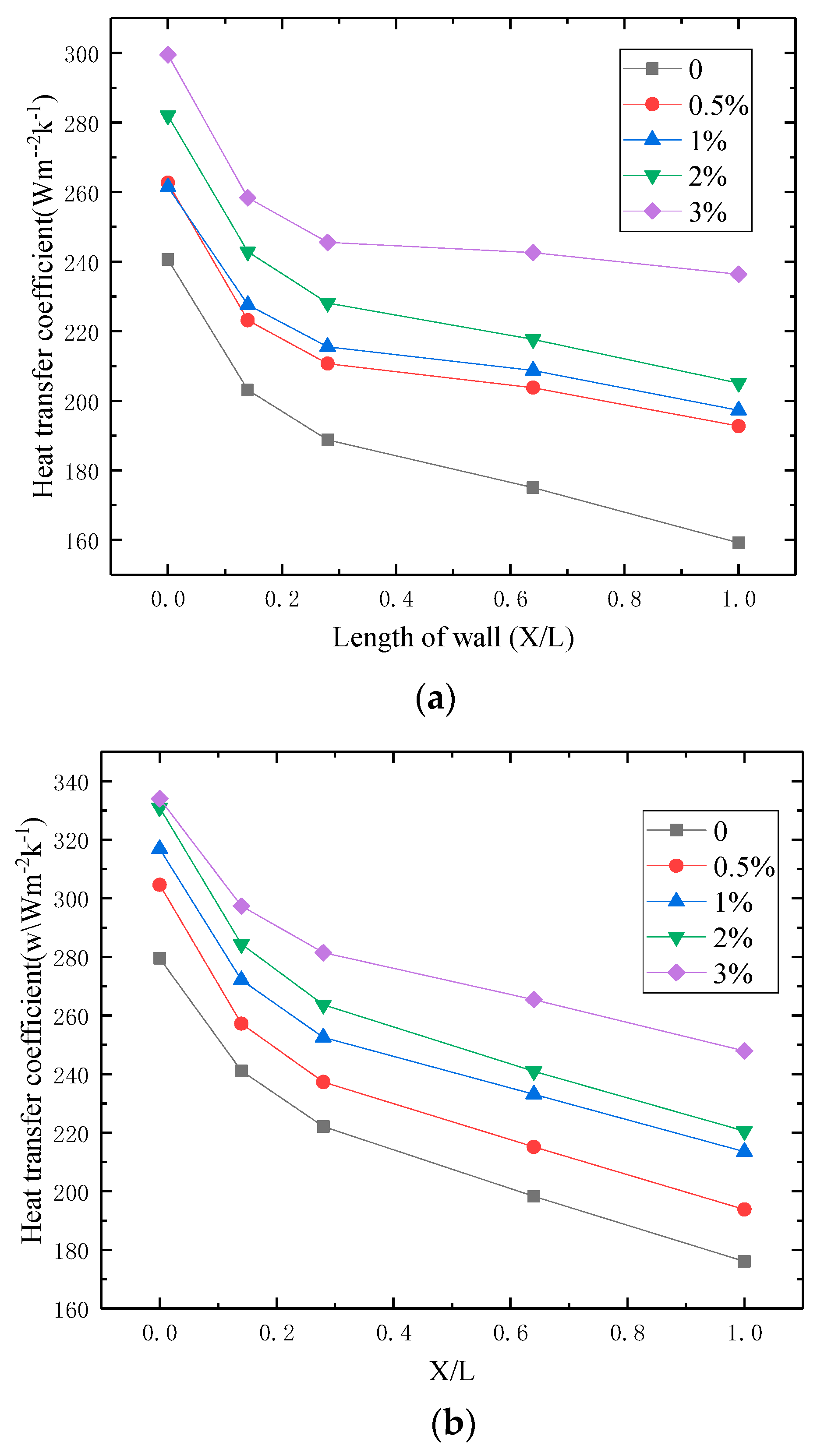

3.4. Heat Transfer Characteristics

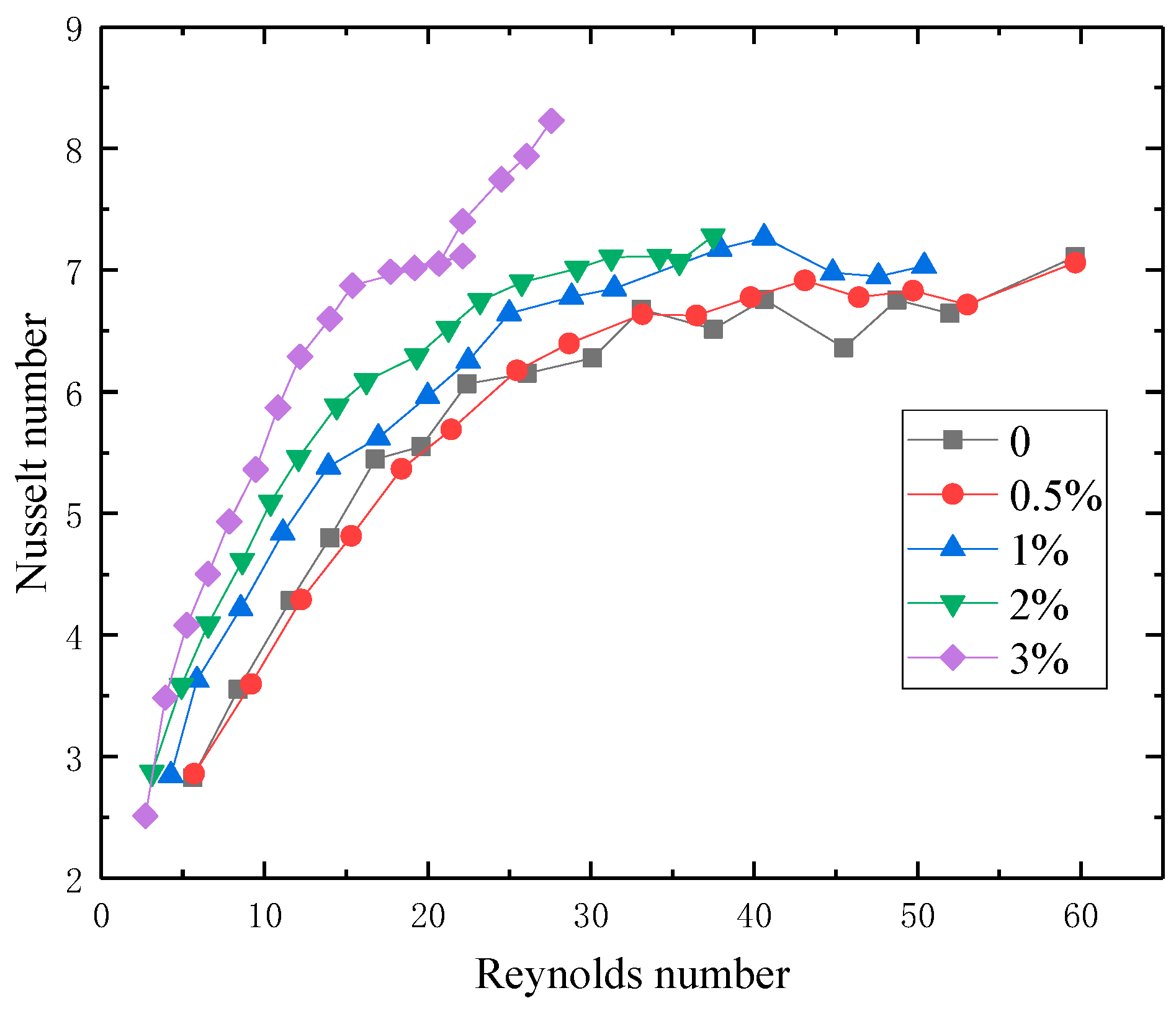

3.5. Discussion

4. Conclusions

- (1)

- The graphene lubricant prepared using the two-step approach has good stability, according to examination via an electron microscope and centrifuge, with good dispersibility and no agglomeration.

- (2)

- The thermal conductivity and viscosity of the graphene lubricant increase with the increase in graphene concentration, and the thermal conductivity of the same concentration of graphene decreases with the increase in temperature.

- (3)

- The specific heat capacity of the graphene lubricant increases with the increase in temperature. At the same temperature, the specific heat capacity of nano-graphene lubricant is larger than that of base lubricant, and increases with the increase in graphene concentration.

- (4)

- When the concentration is equal, the convective heat transfer Nu of graphene lubricant increases with the increase in Re. When Re is equal, the convective heat transfer Nu increases with the increase in the concentration of graphene particles, and the maximum Nu increases by 40%.

Author Contributions

Funding

Conflicts of Interest

References

- Uysal, S.C.; Liese, E.; Nix, A.C.; Black, J. A Thermodynamic Model to Quantify the Impact of Cooling Improvements on Gas Turbine Efficiency. J. Turbomach. 2018, 140. [Google Scholar] [CrossRef] [Green Version]

- Kapsiz, M.; Durat, M.; Ficici, F. Friction and wear studies between cylinder liner and piston ring pair using Taguchi design method. Adv. Eng. Softw. 2011, 42, 595–603. [Google Scholar] [CrossRef]

- Tung, S.C.; McMillan, M.L. Automotive tribology overview of current advances and challenges for the future. Tribol. Int. 2004, 37, 517–536. [Google Scholar] [CrossRef]

- Vianna, T.; Sworski, A.; Caudill, T.; Forbus, R. Student poster abstract: Investigations of lubrication circuit heat transfer rates using nanofluid and polypropylene glycol. Tribol. Lubr. Technol. 2010, 66, 16–17. [Google Scholar]

- Choi, S.U.S.; Eastman, J. Enhancing Thermal Conductivity of Fluids with Nanoparticles. In Proceedings of the 1995 International Mechanical Engineering Congress and Exhibition, San Francisco, CA, USA, 12–17 November 1995; Volume 66. [Google Scholar]

- Ahmadi, M.H.; Mirlohi, A.; Alhuyi Nazari, M.; Ghasempour, R. A review of thermal conductivity of various nanofluids. J. Mol. Liq. 2018, 265, 181–188. [Google Scholar] [CrossRef]

- Pelević, N.; van der Meer, T.H. Numerical investigation of the effective thermal conductivity of nano-fluids using the lattice Boltzmann model. Int. J. Therm. Sci. 2012, 62, 154–159. [Google Scholar] [CrossRef]

- Tawfik, M.M. Experimental studies of nanofluid thermal conductivity enhancement and applications: A review. Renew. Sustain. Energy Rev. 2017, 75, 1239–1253. [Google Scholar] [CrossRef] [Green Version]

- Fotukian, S.M.; Nasr Esfahany, M. Experimental investigation of turbulent convective heat transfer of dilute γ-Al2O3/water nanofluid inside a circular tube. Int. J. Heat Fluid Flow 2010, 31, 606–612. [Google Scholar] [CrossRef]

- Abbasian Arani, A.A.; Amani, J. Experimental investigation of diameter effect on heat transfer performance and pressure drop of TiO2–water nanofluid. Exp. Therm. Fluid Sci. 2013, 44, 520–533. [Google Scholar] [CrossRef]

- Zeinali Heris, S.; Etemad, S.G.; Nasr Esfahany, M. Experimental investigation of oxide nanofluids laminar flow convective heat transfer. Int. Commun. Heat Mass Transf. 2006, 33, 529–535. [Google Scholar] [CrossRef]

- Wen, D.; Ding, Y. Experimental investigation into convective heat transfer of nanofluids at the entrance region under laminar flow conditions. Int. J. Heat Mass Transf. 2004, 47, 5181–5188. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, Z.G.; Grulke, E.A.; Anderson, W.B.; Wu, G. Heat transfer properties of nanoparticle-in-fluid dispersions (nanofluids) in laminar flow. Int. J. Heat Mass Transf. 2005, 48, 1107–1116. [Google Scholar] [CrossRef]

- Geim, A.K.; Novoselov, K.S. The rise of graphene. Nat. Mater. 2007, 6, 183–191. [Google Scholar] [CrossRef]

- Singh, V.; Joung, D.; Zhai, L.; Das, S.; Khondaker, S.I.; Seal, S. Graphene based materials: Past, present and future. Prog. Mater. Sci. 2011, 56, 1178–1271. [Google Scholar] [CrossRef]

- Novoselov, K.S.; Geim, A.K.; Morozov, S.V.; Jiang, D.; Katsnelson, M.I.; Grigorieva, I.V.; Dubonos, S.V.; Firsov, A.A. Two-dimensional gas of massless Dirac fermions in graphene. Nature 2005, 438, 197–200. [Google Scholar] [CrossRef]

- Balandin, A.A.; Ghosh, S.; Bao, W.; Calizo, I.; Teweldebrhan, D.; Miao, F.; Lau, C.N. Superior thermal conductivity of single-layer graphene. Nano Lett. 2008, 8, 902–907. [Google Scholar] [CrossRef]

- Lee, C.; Wei, X.; Kysar, J.W.; Hone, J. Measurement of the Elastic Properties and Intrinsic Strength of Monolayer Graphene. Science 2008, 321, 385–388. [Google Scholar] [CrossRef]

- Baby, T.; Sundara, R. Enhanced convective heat transfer using graphene dispersed nanofluids. Nanoscale Res. Lett. 2011, 6, 289. [Google Scholar] [CrossRef] [Green Version]

- Ma, W.; Yang, F.; Shi, J.; Wang, F.; Zhang, Z.; Wang, S. Silicone based nanofluids containing functionalized graphene nanosheets. Colloids Surf. A Physicochem. Eng. Asp. 2013, 431, 120–126. [Google Scholar] [CrossRef]

- Hajjar, Z.; Rashidi, A.M.; Ghozatloo, A. Enhanced thermal conductivities of graphene oxide nanofluids. Int. Commun. Heat Mass Transf. 2014, 57, 128–131. [Google Scholar] [CrossRef]

- Rasheed, A.K.; Khalid, M.; Rashmi, W.; Gupta, T.C.S.M.; Chan, A. Graphene based nanofluids and nanolubricants—Review of recent developments. Renew. Sustain. Energy Rev. 2016, 63, 346–362. [Google Scholar] [CrossRef]

- Amrollahi, A.; Rashidi, A.M.; Lotfi, R. Convection heat transfer of functionalized MWNT in aqueous fluids in laminar and turbulent flow at the entrance region. Int. Commun. Heat Mass Transf. 2010, 37, 717–723. [Google Scholar] [CrossRef]

| Model | Exterior | Specific Area (≥m2/g) | Particle Size (D50, μm) | The Mass Fraction of Carbon (%) | Thickness (nm) |

|---|---|---|---|---|---|

| N002-PDR | Black powder | 500–800 | <10.0 | 95 | <10 |

| Weight Friction (%) | A | B | C | Viscosity Index |

|---|---|---|---|---|

| 0 | 6.15 × 1010 | 15.62 | 26.83 | 244 |

| 0.5 | 4.52 × 1010 | 15.91 | 25.22 | 244 |

| 1 | 1.89 × 1011 | 14.88 | 33.49 | 253 |

| 2 | 8.45 × 1010 | 15.59 | 41.28 | 284 |

| 3 | 2.12 × 1011 | 15.21 | 63.03 | 291 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cai, Z.; Tian, M.; Zhang, G. Experimental Study on the Flow and Heat Transfer of Graphene-Based Lubricants in a Horizontal Tube. Processes 2020, 8, 1675. https://doi.org/10.3390/pr8121675

Cai Z, Tian M, Zhang G. Experimental Study on the Flow and Heat Transfer of Graphene-Based Lubricants in a Horizontal Tube. Processes. 2020; 8(12):1675. https://doi.org/10.3390/pr8121675

Chicago/Turabian StyleCai, Zhongpan, Maocheng Tian, and Guanmin Zhang. 2020. "Experimental Study on the Flow and Heat Transfer of Graphene-Based Lubricants in a Horizontal Tube" Processes 8, no. 12: 1675. https://doi.org/10.3390/pr8121675

APA StyleCai, Z., Tian, M., & Zhang, G. (2020). Experimental Study on the Flow and Heat Transfer of Graphene-Based Lubricants in a Horizontal Tube. Processes, 8(12), 1675. https://doi.org/10.3390/pr8121675