An Integrated Multi-Criteria Decision Support Framework for the Selection of Suppliers in Small and Medium Enterprises based on Green Innovation Ability

Abstract

:1. Introduction

2. Literature Review

2.1. Related Studies Based on MCDM Methodologies

2.2. Proposed Green Innovation Criteria in the Study

3. Methodology

3.1. Fuzzy AHP Method

- ○

- Step 1: Construct a pairwise matrix of attributes using TFNs provided in Table 3.

- ○

- Step 2: Define fuzzy synthetic extent value SYi of i as:

- ○

- Step 3: Compare the obtained values of and then calculate the possible degree of using the following equation:where represents the highest point between and .

- ○

- Step 4: Calculate minimum possibility degree of for ) using Equation (3):

- ○

- Step 5: Let us assume then weight vector can be defined as:

3.2. TOPSIS

- ○

- Step 1: Construction of a decision matrix which is defined aswhere comprises of alternatives and criteria; is the evaluation of th alternative with respect to th criterion.

- ○

- Step 2: Normalization of decision matrix as below:

- ○

- Step 3: Develop a weighted matrix from normalized decision matrix using the subsequent equation:where represents the criterion weight of th criterion; the sum of all the criteria equals to 1.

- ○

- Step 4: Use Equations (9) and (10) to respectively obtain an ideal positive solution ( and ideal negative solution (.where represents a benefit-type criterion (the larger value is the better), while, shows a cost-type criterion (the smaller value is preferred).

- ○

- Step 5: Once positive ideal and negative ideal solutions are found, then the subsequent step is to find the distance from these points using Euclidean distance [55]. Equation (11) shall be used to find the distance for a benefit-type criterion, while Equation (12) shall find the distance for a cost-type criterion.

- ○

- Step 6: This step shall use Equation (13) to obtain the relative closeness score () of the solutions.

- ○

- Step 7: This is the final step that ranks the alternatives based on relative closeness scores, the better the score the better ranking.

3.3. Grey System Theory

3.4. Fuzzy AHP and TOPSIS-Grey Integrated Methodology

- ○

- Step 1: Establish the structure of the problem by defining the goal to be achieved, criteria, and sub-criteria used for evaluation, and alternatives which are to be evaluated.

- ○

- Step 2: Involve experts to provide their judgment regarding the criteria and sub-criteria and then apply Fuzzy AHP to obtain weights of criteria and sub-criteria.

- ○

- Step 3: Use linguistics values given in Table 4 to rate the alternatives with respect to each sub-criterion.

- ○

- Step 4: Define the decision matrix of TOPSIS-Grey as:where shows the grey evaluation of th alternative for th criterion by decision-maker ; ] depicts th decision-maker’s evaluation for th alternative.

- ○

- Step 5: Normalize using Equation (20) (benefit-type criterion) and Equation (21) (cost-type criterion):where is the lower value of the interval and is the upper value of the interval.

- ○

- Step 6: Use Equations (22) and (23) respectively to find out positive ideal alternative and negative ideal alternative as below:where is a benefit-type criterion whose larger value is preferred while is a cost-type criterion whose smaller value is better.

- ○

- Step 7: Compute the positive ideal solution () and negative ideal solution () using Equations (24) and (25), respectively as below:

- ○

- Step 8: Use Equation (26) to compute the relative closeness score () as follows:

- ○

- Step 9: Based on score, rank the alternatives; the higher the score the higher the ranking.

4. Results and Analysis

4.1. Fuzzy AHP Results

4.1.1. Hierarchical Structure

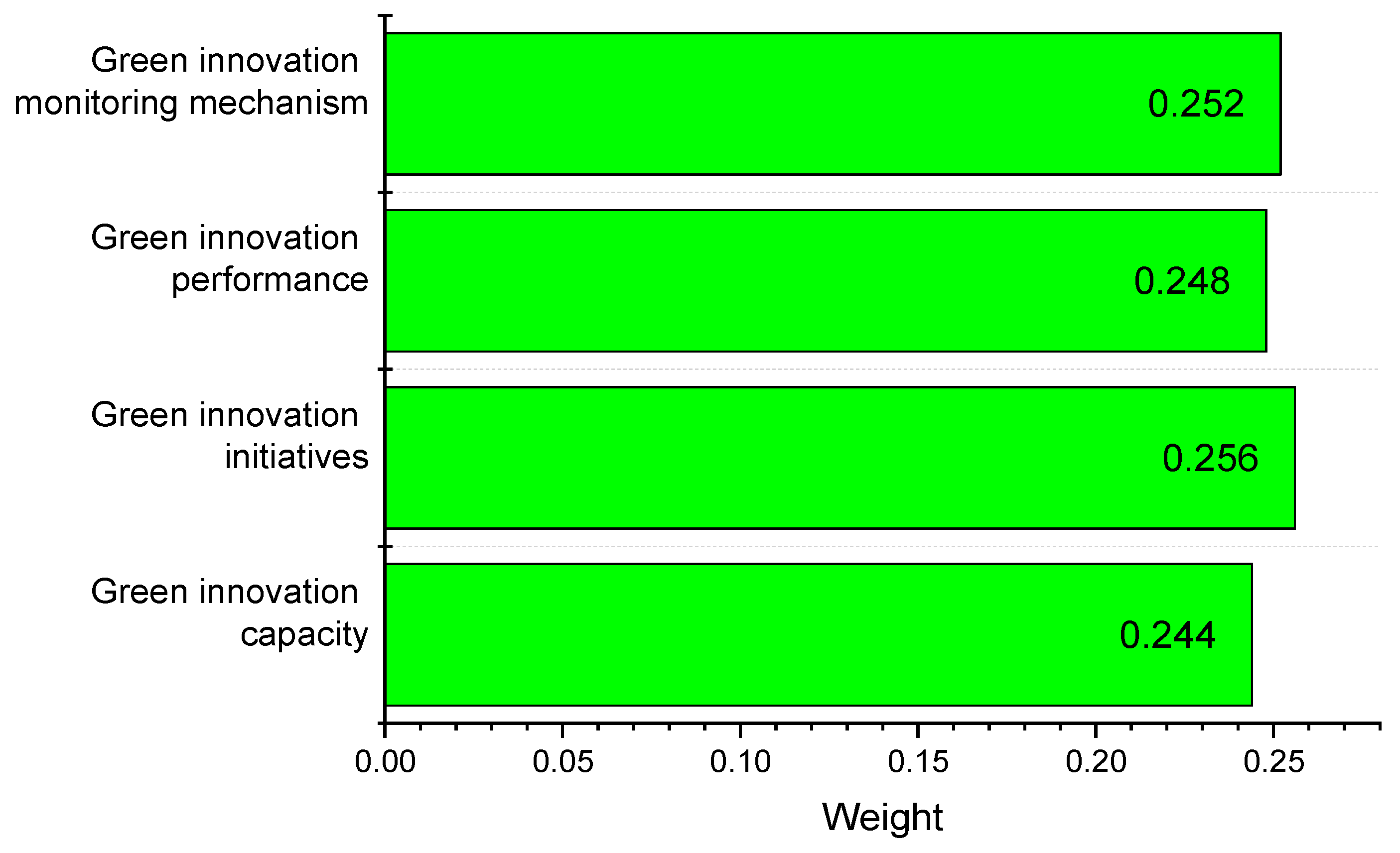

4.1.2. Main Criteria Weights

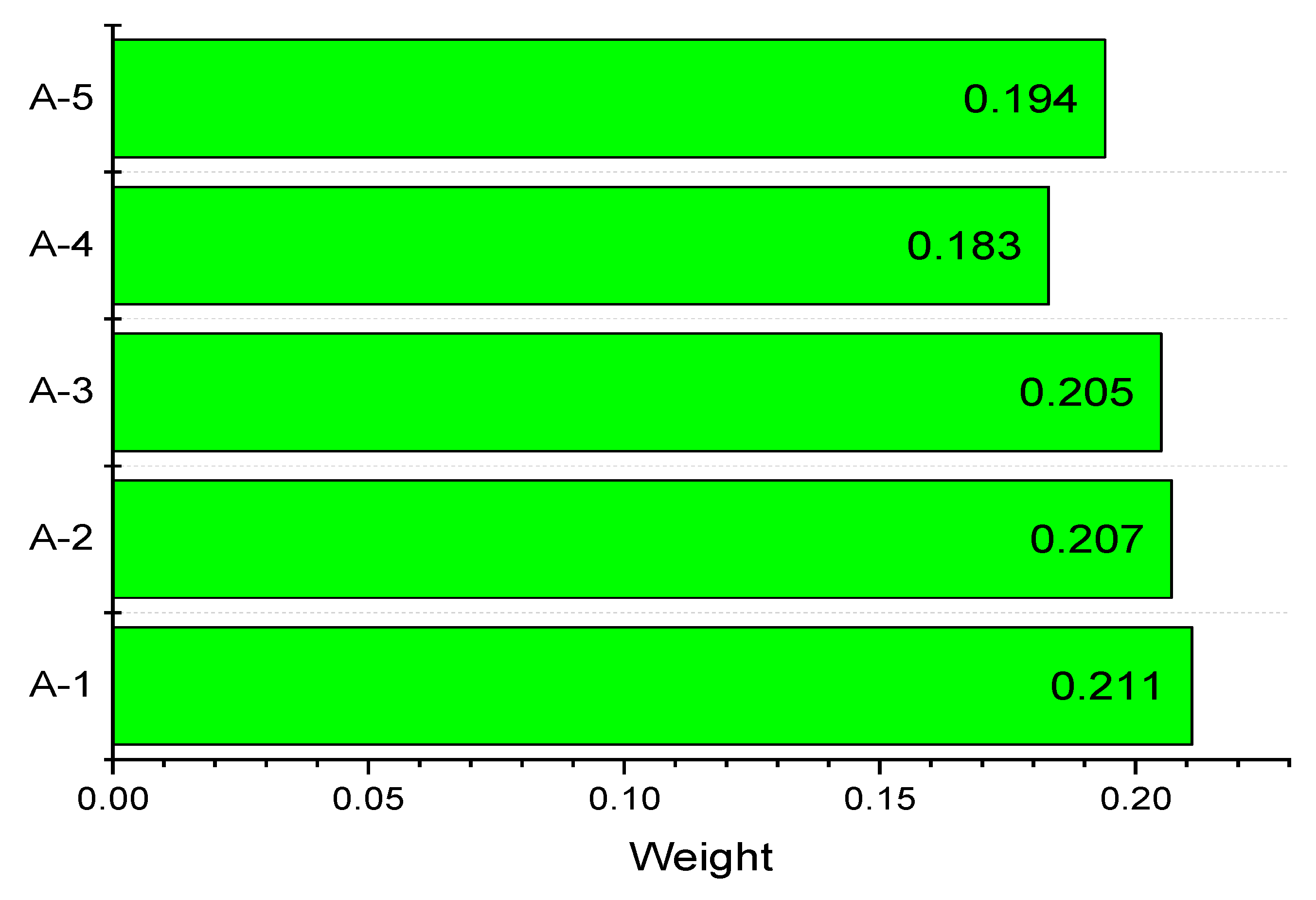

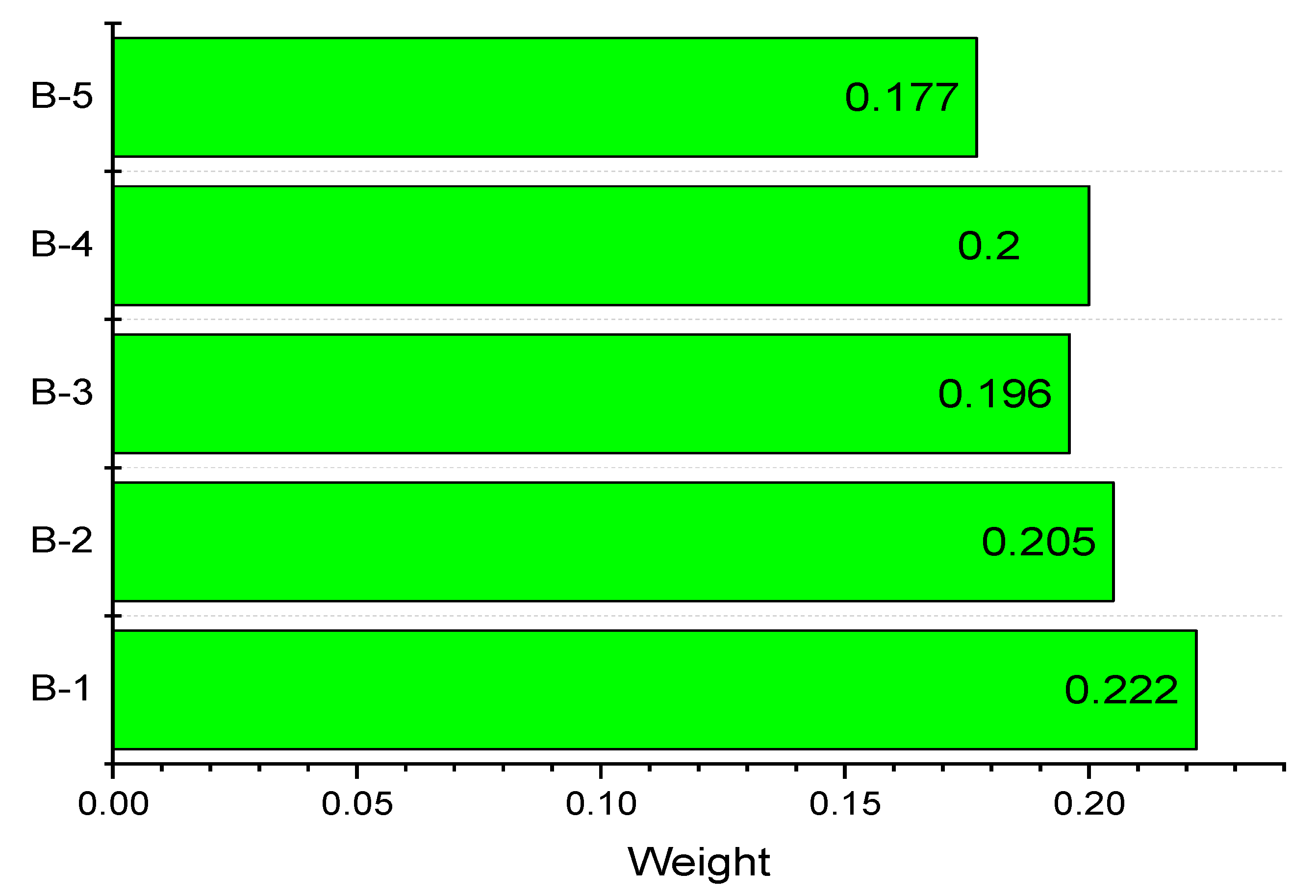

4.1.3. Sub-Criteria Initial Weights

4.1.4. Final Weights of Sub-Criteria

4.1.5. Ranking of Alternatives Using TOPSIS-Grey

4.2. Discussion

5. Conclusions

Limitations and Future Research Directions

Author Contributions

Funding

Conflicts of Interest

Appendix A

| A-1 | A-2 | A-3 | A-4 | A-5 | |

|---|---|---|---|---|---|

| A-1 | 1, 1, 1 | 0.771, 1.096, 1.541 | 0.739, 1.019, 1.407 | 0.779, 1.122, 1.609 | 0.742, 1.122, 1.689 |

| A-2 | 0.649, 0.913, 1.296 | 1, 1, 1 | 0.798, 1.161, 1.633 | 0.687, 1.034, 1.579 | 0.742, 1.122, 1.689 |

| A-3 | 0.711, 0.982, 1.353 | 0.612, 0.861, 1.253 | 1, 1, 1 | 0.926, 1.303, 1.763 | 0.687, 1.015, 1.455 |

| A-4 | 0.622, 0.891, 1.284 | 0.633, 0.967, 1.455 | 0.567, 0.767, 1.079 | 1, 1, 1 | 0.649, 0.926, 1.296 |

| A-5 | 0.592, 0.891, 1.348 | 0.592, 0.891, 1.348 | 0.687, 0.985, 1.455 | 0.771, 1.079, 1.541 | 1, 1, 1 |

| CR = 0.0028 | |||||

| B-1 | B-2 | B-3 | B-4 | B-5 | |

|---|---|---|---|---|---|

| B-1 | 1, 1, 1 | 0.771, 1.161, 1.689 | 0.687, 1, 1.455 | 0.926, 1.284, 1.763 | 0.802, 1.172, 1.673 |

| B-2 | 0.592, 0.861, 1.296 | 1, 1, 1 | 0.786, 1.106, 1.594 | 0.671, 0.899, 1.253 | 0.913, 1.284, 1.79 |

| B-3 | 0.687, 1, 1.455 | 0.627, 0.905, 1.272 | 1, 1, 1 | 0.675, 0.976, 1.407 | 0.798, 1.043, 1.373 |

| B-4 | 0.567, 0.779, 1.079 | 0.798, 1.113, 1.49 | 0.711, 1.024, 1.482 | 1, 1, 1 | 0.798, 1.122, 1.505 |

| B-5 | 0.598, 0.853, 1.246 | 0.559, 0.779, 1.096 | 0.728, 0.958, 1.253 | 0.664, 0.891, 1.253 | 1, 1, 1 |

| CR = 0.0037 | |||||

| C-1 | C-2 | C-3 | C-4 | C-5 | |

|---|---|---|---|---|---|

| C-1 | 1, 1, 1 | 0.753, 1, 1.328 | 0.592, 0.813, 1.183 | 0.622, 0.874, 1.234 | 0.896, 1.272, 1.73 |

| C-2 | 0.753, 1, 1.328 | 1, 1, 1 | 0.786, 1.106, 1.594 | 0.728, 1, 1.373 | 0.861, 1.241, 1.747 |

| C-3 | 0.845, 1.23, 1.689 | 0.627, 0.905, 1.272 | 1, 1, 1 | 0.675, 0.976, 1.407 | 0.798, 1.043, 1.373 |

| C-4 | 0.81, 1.144, 1.609 | 0.728, 1, 1.373 | 0.711, 1.024, 1.482 | 1, 1, 1 | 0.728, 1.059, 1.505 |

| C-5 | 0.578, 0.786, 1.116 | 0.572, 0.806, 1.161 | 0.728, 0.958, 1.253 | 0.664, 0.944, 1.373 | 1, 1, 1 |

| CR = 0.0040 | |||||

| D-1 | D-2 | D-3 | D-4 | D-5 | |

|---|---|---|---|---|---|

| D-1 | 1, 1, 1 | 0.649, 0.913, 1.296 | 0.687, 0.944, 1.328 | 0.81, 1.144, 1.609 | 0.896, 1.272, 1.73 |

| D-2 | 0.771, 1.096, 1.541 | 1, 1, 1 | 0.687, 0.985, 1.455 | 0.728, 1, 1.373 | 0.861, 1.241, 1.747 |

| D-3 | 0.753, 1.059, 1.455 | 0.687, 1.015, 1.455 | 1, 1, 1 | 0.81, 1.144, 1.609 | 0.798, 1.043, 1.373 |

| D-4 | 0.622, 0.874, 1.234 | 0.728, 1, 1.373 | 0.622, 0.874, 1.234 | 1, 1, 1 | 0.896, 1.328, 1.896 |

| D-5 | 0.578, 0.786, 1.116 | 0.572, 0.806, 1.161 | 0.728, 0.958, 1.253 | 0.527, 0.753, 1.116 | 1, 1, 1 |

| CR = 0.0034 | |||||

Appendix B

| A-1 | A-2 | A-3 | A-4 | A-5 | B-1 | B-2 | B-3 | B-4 | B-5 | C-1 | C-2 | C-3 | C-4 | C-5 | D-1 | D-2 | D-3 | D-4 | D-5 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Supplier-1 | 4.417, 5.833 | 4.083, 5.5 | 2.833, 4.167 | 5, 6.25 | 3.75, 5 | 3.5, 4.75 | 3.75, 5.167 | 4.417, 5.833 | 3.833, 5.083 | 4.25, 5.667 | 3.167, 4.583 | 3.917, 5.25 | 4.5, 5.75 | 5.583, 7.333 | 4.333, 5.583 | 4.75, 5.917 | 4.667, 6.083 | 4.833, 6.417 | 4.417, 5.833 | 3.75, 5.167 |

| Supplier-2 | 3.667, 4.917 | 4, 5.417 | 2.917, 4 | 4.167, 5.417 | 3.25, 4.667 | 3.417, 4.75 | 4.083, 5.417 | 4.25, 5.583 | 3.417, 4.667 | 3.917, 5.5 | 3.333, 4.583 | 3.333, 4.667 | 4.083, 5.75 | 5.083, 6.583 | 3.833, 5 | 4.75, 6.333 | 4.5, 5.917 | 4.583, 5.917 | 4, 5.25 | 3.75, 4.833 |

| Supplier-3 | 4, 5.583 | 4.25, 5.667 | 3.083, 4.333 | 4.636, 5.909 | 3.917, 5.333 | 3.333, 4.667 | 3.917, 5.5 | 4.25, 5.75 | 3.583, 4.833 | 4, 5.5 | 3.25, 4.583 | 3.917, 5.333 | 4, 5.417 | 5.583, 7.5 | 4.667, 6.167 | 4.583, 6.083 | 4.833, 6.25 | 5.333, 6.833 | 4.5, 5.917 | 4.667, 6.083 |

| Supplier-4 | 3.833, 5 | 3.667, 4.833 | 1.917, 3.25 | 3.583, 4.833 | 2.917, 4.333 | 2.333, 3.75 | 3.417, 4.75 | 3.667, 5.167 | 3.25, 4.333 | 3.25, 4.75 | 3.417, 4.667 | 3.25, 4.667 | 3.667, 5.167 | 5.5, 7 | 4.167, 5.583 | 4.417, 5.667 | 3.583, 5.083 | 5.25, 6.667 | 4.083, 5.583 | 3.583, 5 |

| Supplier-5 | 3.667, 4.917 | 3.417, 4.75 | 1.667, 3.083 | 3.25, 4.417 | 2.667, 4 | 2.25, 3.583 | 4.083, 5.333 | 3.333, 4.75 | 3.417, 4.833 | 3.083, 4.417 | 2.917, 4.417 | 3.583, 4.75 | 3.75, 5.167 | 4.75, 6.5 | 3.25, 4.75 | 3.917, 5.583 | 3.333, 4.75 | 4.75, 6.167 | 3.917, 5.333 | 4.417, 5.667 |

| Supplier-6 | 3.667, 4.917 | 4.25, 5.667 | 3.25, 4.75 | 4.333, 5.667 | 2.917, 4.25 | 3.917, 5.333 | 3.25, 4.583 | 3.667, 5.167 | 4.667, 6.083 | 4, 5.5 | 4.583, 5.833 | 3.833, 5.083 | 4.333, 5.833 | 5.75, 7.583 | 4.167, 5.583 | 3.25, 4.5 | 3.167, 4.5 | 4.083, 5.417 | 4.75, 6.167 | 4.333, 5.583 |

| A-1 | A-2 | A-3 | A-4 | A-5 | B-1 | B-2 | B-3 | B-4 | B-5 | C-1 | C-2 | C-3 | C-4 | C-5 | D-1 | D-2 | D-3 | D-4 | D-5 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Supplier-1 | 0.757, 1 | 0.721, 0.971 | 0.596, 0.877 | 0.8, 1 | 0.703, 0.938 | 0.656, 0.891 | 0.682, 0.939 | 0.757, 1 | 0.63, 0.836 | 0.75, 1 | 0.543, 0.786 | 0.016, 0.266 | 0.771, 0.986 | 0.736, 0.967 | 0.703, 0.905 | 0.75, 0.934 | 0.747, 0.973 | 0.707, 0.939 | 0.716, 0.946 | 0.616, 0.849 |

| Supplier-2 | 0.629, 0.843 | 0.706, 0.956 | 0.614, 0.842 | 0.667, 0.867 | 0.609, 0.875 | 0.641, 0.891 | 0.742, 0.985 | 0.729, 0.957 | 0.562, 0.767 | 0.691, 0.971 | 0.571, 0.786 | 0.125, 0.375 | 0.7, 0.986 | 0.67, 0.868 | 0.622, 0.811 | 0.75, 1 | 0.72, 0.947 | 0.671, 0.866 | 0.649, 0.851 | 0.616, 0.795 |

| Supplier-3 | 0.686, 0.957 | 0.75, 1 | 0.649, 0.912 | 0.742, 0.945 | 0.734, 1 | 0.625, 0.875 | 0.712, 1 | 0.729, 0.986 | 0.589, 0.795 | 0.706, 0.971 | 0.557, 0.786 | 0, 0.266 | 0.686, 0.929 | 0.736, 0.989 | 0.757, 1 | 0.724, 0.961 | 0.773, 1 | 0.78, 1 | 0.73, 0.959 | 0.767, 1 |

| Supplier-4 | 0.657, 0.857 | 0.647, 0.853 | 0.404, 0.684 | 0.573, 0.773 | 0.547, 0.812 | 0.437, 0.703 | 0.621, 0.864 | 0.629, 0.886 | 0.534, 0.712 | 0.574, 0.838 | 0.586, 0.8 | 0.125, 0.391 | 0.629, 0.886 | 0.725, 0.923 | 0.676, 0.905 | 0.697, 0.895 | 0.573, 0.813 | 0.768, 0.976 | 0.662, 0.905 | 0.589, 0.822 |

| Supplier-5 | 0.629, 0.843 | 0.603, 0.838 | 0.351, 0.649 | 0.52, 0.707 | 0.5, 0.75 | 0.422, 0.672 | 0.742, 0.97 | 0.571, 0.814 | 0.562, 0.795 | 0.544, 0.779 | 0.5, 0.757 | 0.109, 0.328 | 0.643, 0.886 | 0.626, 0.857 | 0.527, 0.77 | 0.618, 0.882 | 0.533, 0.76 | 0.695, 0.902 | 0.635, 0.865 | 0.726, 0.932 |

| Supplier-6 | 0.629, 0.843 | 0.75, 1 | 0.684, 1 | 0.693, 0.907 | 0.547, 0.797 | 0.734, 1 | 0.591, 0.833 | 0.629, 0.886 | 0.767, 1 | 0.706, 0.971 | 0.786, 1 | 0.047, 0.281 | 0.743, 1 | 0.758, 1 | 0.676, 0.905 | 0.513, 0.711 | 0.507, 0.72 | 0.598, 0.793 | 0.77, 1 | 0.712, 0.918 |

| A-1 | A-2 | A-3 | A-4 | A-5 | B-1 | B-2 | B-3 | B-4 | B-5 | C-1 | C-2 | C-3 | C-4 | C-5 | D-1 | D-2 | D-3 | D-4 | D-5 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A+ | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| A- | 0.629 | 0.603 | 0.351 | 0.52 | 0.5 | 0.422 | 0.591 | 0.571 | 0.534 | 0.544 | 0.5 | 0.391 | 0.629 | 0.626 | 0.527 | 0.513 | 0.507 | 0.598 | 0.635 | 0.589 |

| A-1 | A-2 | A-3 | A-4 | A-5 | B-1 | B-2 | B-3 | B-4 | B-5 | C-1 | C-2 | C-3 | C-4 | C-5 | D-1 | D-2 | D-3 | D-4 | D-5 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Supplier-1 | 0.003 | 0.004 | 0.009 | 0.002 | 0.004 | 0.007 | 0.006 | 0.003 | 0.008 | 0.003 | 0.012 | 0.008 | 0.003 | 0.004 | 0.004 | 0.004 | 0.003 | 0.005 | 0.004 | 0.007 |

| Supplier-2 | 0.008 | 0.004 | 0.009 | 0.006 | 0.008 | 0.008 | 0.004 | 0.004 | 0.013 | 0.004 | 0.011 | 0.004 | 0.005 | 0.007 | 0.008 | 0.003 | 0.004 | 0.007 | 0.007 | 0.008 |

| Supplier-3 | 0.005 | 0.003 | 0.007 | 0.003 | 0.003 | 0.009 | 0.004 | 0.004 | 0.011 | 0.004 | 0.012 | 0.009 | 0.005 | 0.004 | 0.003 | 0.004 | 0.003 | 0.003 | 0.004 | 0.002 |

| Supplier-4 | 0.007 | 0.007 | 0.023 | 0.01 | 0.011 | 0.023 | 0.009 | 0.008 | 0.015 | 0.009 | 0.01 | 0.004 | 0.008 | 0.004 | 0.005 | 0.005 | 0.012 | 0.003 | 0.006 | 0.009 |

| Supplier-5 | 0.008 | 0.009 | 0.027 | 0.014 | 0.015 | 0.025 | 0.004 | 0.011 | 0.012 | 0.012 | 0.015 | 0.004 | 0.007 | 0.008 | 0.012 | 0.008 | 0.015 | 0.005 | 0.008 | 0.003 |

| Supplier-6 | 0.008 | 0.003 | 0.005 | 0.005 | 0.012 | 0.004 | 0.01 | 0.008 | 0.003 | 0.004 | 0.002 | 0.007 | 0.003 | 0.003 | 0.005 | 0.017 | 0.017 | 0.011 | 0.003 | 0.004 |

| A-1 | A-2 | A-3 | A-4 | A-5 | B-1 | B-2 | B-3 | B-4 | B-5 | C-1 | C-2 | C-3 | C-4 | C-5 | D-1 | D-2 | D-3 | D-4 | D-5 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Supplier-1 | 0.008 | 0.008 | 0.017 | 0.014 | 0.011 | 0.016 | 0.007 | 0.011 | 0.005 | 0.011 | 0.004 | 0.004 | 0.008 | 0.007 | 0.008 | 0.012 | 0.015 | 0.007 | 0.005 | 0.003 |

| Supplier-2 | 0.002 | 0.007 | 0.016 | 0.006 | 0.007 | 0.015 | 0.009 | 0.009 | 0.003 | 0.009 | 0.004 | 0.008 | 0.007 | 0.003 | 0.004 | 0.015 | 0.013 | 0.004 | 0.002 | 0.002 |

| Supplier-3 | 0.006 | 0.009 | 0.02 | 0.01 | 0.014 | 0.014 | 0.01 | 0.01 | 0.004 | 0.009 | 0.004 | 0.004 | 0.005 | 0.007 | 0.012 | 0.013 | 0.017 | 0.01 | 0.006 | 0.009 |

| Supplier-4 | 0.003 | 0.003 | 0.006 | 0.003 | 0.005 | 0.005 | 0.004 | 0.005 | 0.002 | 0.004 | 0.005 | 0.009 | 0.003 | 0.005 | 0.007 | 0.009 | 0.005 | 0.009 | 0.004 | 0.002 |

| Supplier-5 | 0.002 | 0.003 | 0.004 | 0.002 | 0.003 | 0.004 | 0.009 | 0.003 | 0.004 | 0.003 | 0.003 | 0.006 | 0.003 | 0.003 | 0.003 | 0.008 | 0.003 | 0.005 | 0.003 | 0.006 |

| Supplier-6 | 0.002 | 0.009 | 0.027 | 0.008 | 0.004 | 0.025 | 0.003 | 0.005 | 0.014 | 0.009 | 0.016 | 0.004 | 0.008 | 0.008 | 0.007 | 0.002 | 0.002 | 0.002 | 0.008 | 0.005 |

References

- Knap, A.H.; Rusyn, I. Environmental Exposures Due to Natural Disasters. Rev. Environ. Health 2016, 31, 89–92. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Stocker, T.F.; Qin, D.; Plattner, G.K.; Tignor, M.M.B.; Allen, S.K.; Boschung, J.; Nauels, A.; Xia, Y.; Bex, V.; Midgley, P.M. Climate Change 2013 the Physical Science Basis: Working Group I Contribution to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change. 2013, Volume 9781107057. Available online: https://www.ipcc.ch/report/ar5/wg1/ (accessed on 10 March 2020).

- Ghisetti, C.; Mancinelli, S.; Mazzanti, M.; Zoli, M. Financial Barriers and Environmental Innovations: Evidence from EU Manufacturing Firms. Clim. Policy 2017, 17 (Suppl. 1), S131–S147. [Google Scholar] [CrossRef]

- Pachauri; Rajendra, K.M.; Leo, V.Y.; Jean-Pascal, B.; Sander, V.K.; Line, L.-R.; Noëmie, V.B. Climate Change 2014: Synthesis Report. Contribution of Working Groups I, II and III to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change. 2014. Available online: https://www.ipcc.ch/report/ar5/syr/ (accessed on 10 March 2020).

- The Sustainable Development Goals Report 2016; United Nations: New York, NJ, USA, 2016; Available online: https://www.un.org/development/desa/publications/sustainable-development-goals-report-2016.html (accessed on 10 March 2020).

- Shah, S.A.A.; Solangi, Y.A. A Sustainable Solution for Electricity Crisis in Pakistan: Opportunities, Barriers, and Policy Implications for 100% Renewable Energy. Environ. Sci. Pollut. Res. 2019, 26, 29687–29703. [Google Scholar] [CrossRef] [PubMed]

- Somsuk, N.; Laosirihongthong, T. Prioritization of Applicable Drivers for Green Supply Chain Management Implementation toward Sustainability in Thailand. Int. J. Sustain. Dev. World Ecol. 2017, 24, 175–191. [Google Scholar] [CrossRef]

- Gurtu, A.; Searcy, C.; Jaber, M.Y. Sustainable Supply Chains. In Green Supply Chain Management for Sustainable Business Practice; IGI Global: Hershey, PA, USA, 2016; pp. 1–26. [Google Scholar]

- Chang, C.H.; Chen, Y.S. Green Organizational Identity and Green Innovation. Manag. Decis. 2013, 51, 1056–1070. [Google Scholar] [CrossRef]

- dos Santos, B.M.; Godoy, L.P.; Campos, L.M.S. Performance Evaluation of Green Suppliers Using Entropy-TOPSIS-F. J. Clean. Prod. 2019, 207, 498–509. [Google Scholar] [CrossRef]

- Fahimnia, B.; Sarkis, J.; Davarzani, H. Green Supply Chain Management: A Review and Bibliometric Analysis. Int. J. Prod. Econ. 2015, 162, 101–114. [Google Scholar] [CrossRef]

- Konys, A. Green Supplier Selection Criteria: From a Literature Review to a Comprehensive Knowledge Base. Sustainability 2019, 11, 4208. [Google Scholar] [CrossRef] [Green Version]

- Zhu, Q.; Sarkis, J.; Lai, K. hung. Green Supply Chain Management: Pressures, Practices and Performance within the Chinese Automobile Industry. J. Clean. Prod. 2007, 15, 1041–1052. [Google Scholar] [CrossRef]

- Mohammed, A.; Harris, I.; Soroka, A.; Nujoom, R. A Hybrid MCDM-Fuzzy Multi-Objective Programming Approach for a G-Resilient Supply Chain Network Design. Comput. Ind. Eng. 2019, 127, 297–312. [Google Scholar] [CrossRef]

- Hong, Z.; Guo, X. Green Product Supply Chain Contracts Considering Environmental Responsibilities. Omega 2019, 83, 155–166. [Google Scholar] [CrossRef]

- Solangi, Y.A.; Tan, Q.; Mirjat, N.H.; Ali, S. Evaluating the Strategies for Sustainable Energy Planning in Pakistan: An Integrated SWOT-AHP and Fuzzy-TOPSIS Approach. J. Clean. Prod. 2019, 236, 117655. [Google Scholar] [CrossRef]

- Xu, L.; Shah, S.A.A.; Zameer, H.; Solangi, Y.A. Evaluating Renewable Energy Sources for Implementing the Hydrogen Economy in Pakistan: A Two-Stage Fuzzy MCDM Approach. Environ. Sci. Pollut. Res. 2019, 26, 33202–33215. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Xu, L.; Solangi, Y.A. Strategic Renewable Energy Resources Selection for Pakistan: Based on SWOT-Fuzzy AHP Approach. Sustain. Cities Soc. 2020, 52, 101861. [Google Scholar] [CrossRef]

- Musaad, O.; Sultan, A.; Zhuo, Z.; Musaad, O.; Otaibi, A.; Siyal, Z.A.; Hashmi, H.; Shah, S.A.A. A Fuzzy Multi-Criteria Analysis of Barriers and Policy Strategies for Small and Medium Enterprises to Adopt Green Innovation. Symmetry 2020, 12, 116. [Google Scholar] [CrossRef] [Green Version]

- Luthra, S.; Govindan, K.; Kannan, D.; Mangla, S.K.; Garg, C.P. An Integrated Framework for Sustainable Supplier Selection and Evaluation in Supply Chains. J. Clean. Prod. 2017, 140, 1686–1698. [Google Scholar] [CrossRef]

- Rezaei, J.; Nispeling, T.; Sarkis, J.; Tavasszy, L. A Supplier Selection Life Cycle Approach Integrating Traditional and Environmental Criteria Using the Best Worst Method. J. Clean. Prod. 2016, 135, 577–588. [Google Scholar] [CrossRef]

- Awasthi, A.; Kannan, G. Green Supplier Development Program Selection Using NGT and VIKOR under Fuzzy Environment. Comput. Ind. Eng. 2016, 91, 100–108. [Google Scholar] [CrossRef]

- Hashemi, S.H.; Karimi, A.; Tavana, M. An Integrated Green Supplier Selection Approach with Analytic Network Process and Improved Grey Relational Analysis. Int. J. Prod. Econ. 2015, 159, 178–191. [Google Scholar] [CrossRef]

- Tsui, C.W.; Wen, U.P. A Hybrid Multiple Criteria Group Decision-Making Approach for Green Supplier Selection in the TFT-LCD Industry. Math. Probl. Eng. 2014, 2014, 709872. [Google Scholar] [CrossRef]

- Hsu, C.W.; Kuo, T.C.; Chen, S.H.; Hu, A.H. Using DEMATEL to Develop a Carbon Management Model of Supplier Selection in Green Supply Chain Management. J. Clean. Prod. 2013, 56, 164–172. [Google Scholar] [CrossRef]

- Akman, G. Evaluating Suppliers to Include Green Supplier Development Programs via Fuzzy C-Means and VIKOR Methods. Comput. Ind. Eng. 2015, 86, 69–82. [Google Scholar] [CrossRef]

- Zafar, A.; Zafar, M.; Sarwar, A.; Raza, H.; Khan, M.T. A Fuzzy AHP Method for Green Supplier Selection and Evaluation. In Proceedings of the International Conference on Management Science and Engineering Management, Ontario, ON, Canada, 5–8 August 2019; Springer: Berlin/Heidelberg, Germany, 2019; pp. 1355–1366. [Google Scholar]

- Sharma, D.G.; Rawani, A.M. Green Supplier Selection for Indian Cement Industry: AHP Based Approach. Int. Res. J. Eng. Technol. 2016, 2368–2373. [Google Scholar]

- Banaeian, N.; Mobli, H.; Fahimnia, B.; Nielsen, I.E.; Omid, M. Green Supplier Selection Using Fuzzy Group Decision Making Methods: A Case Study from the Agri-Food Industry. Comput. Oper. Res. 2018, 89, 337–347. [Google Scholar] [CrossRef]

- Lin, R.H. An Integrated Model for Supplier Selection under a Fuzzy Situation. Int. J. Prod. Econ. 2012, 138, 55–61. [Google Scholar] [CrossRef]

- Chan, F.T.S.; Kumar, N.; Tiwari, M.K.; Lau, H.C.W.; Choy, K.L. Global Supplier Selection: A Fuzzy-AHP Approach. Int. J. Prod. Res. 2008, 46, 3825–3857. [Google Scholar] [CrossRef]

- Chen, C.T.; Lin, C.T.; Huang, S.F. A Fuzzy Approach for Supplier Evaluation and Selection in Supply Chain Management. Int. J. Prod. Econ. 2006, 102, 289–301. [Google Scholar] [CrossRef]

- Hussain, M.; Al-Aomar, R. A Model for Assessing the Impact of Sustainable Supplier Selection on the Performance of Service Supply Chains. Int. J. Sustain. Eng. 2018, 11, 366–381. [Google Scholar] [CrossRef]

- Kannan, D.; De Sousa Jabbour, A.B.L.; Jabbour, C.J.C. Selecting Green Suppliers Based on GSCM Practices: Using Fuzzy TOPSIS Applied to a Brazilian Electronics Company. Eur. J. Oper. Res. 2014, 233, 432–447. [Google Scholar] [CrossRef]

- Govindan, K.; Rajendran, S.; Sarkis, J.; Murugesan, P. Multi Criteria Decision Making Approaches for Green Supplier Evaluation and Selection: A Literature Review. J. Clean. Prod. 2015, 98, 66–83. [Google Scholar] [CrossRef]

- Haeri, S.A.S.; Rezaei, J. A Grey-Based Green Supplier Selection Model for Uncertain Environments. J. Clean. Prod. 2019, 221, 768–784. [Google Scholar] [CrossRef]

- Fallahpour, A.; Olugu, E.U.; Musa, S.N.; Khezrimotlagh, D.; Wong, K.Y. An Integrated Model for Green Supplier Selection under Fuzzy Environment: Application of Data Envelopment Analysis and Genetic Programming Approach. Neural Comput. Appl. 2016, 27, 707–725. [Google Scholar] [CrossRef]

- Shabanpour, H.; Yousefi, S.; Saen, R.F. Forecasting Efficiency of Green Suppliers by Dynamic Data Envelopment Analysis and Artificial Neural Networks. J. Clean. Prod. 2017, 142, 1098–1107. [Google Scholar] [CrossRef]

- Govindan, K.; Sivakumar, R. Green Supplier Selection and Order Allocation in a Low-Carbon Paper Industry: Integrated Multi-Criteria Heterogeneous Decision-Making and Multi-Objective Linear Programming Approaches. Ann. Oper. Res. 2016, 238, 243–276. [Google Scholar] [CrossRef]

- Cucchiella, F.; D’Adamo, I. Issue on Supply Chain of Renewable Energy. Energy Convers. Manag. 2013, 76, 774–780. [Google Scholar] [CrossRef]

- Awasthi, A.; Govindan, K.; Gold, S. Multi-Tier Sustainable Global Supplier Selection Using a Fuzzy AHP-VIKOR Based Approach. Int. J. Prod. Econ. 2018, 195, 106–117. [Google Scholar] [CrossRef]

- Zameer, H.; Wang, Y.; Yasmeen, H. Reinforcing Green Competitive Advantage through Green Production, Creativity and Green Brand Image: Implications for Cleaner Production in China. J. Clean. Prod. 2020, 247, 119119. [Google Scholar] [CrossRef]

- Oroojeni Mohammad Javad, M.; Darvishi, M. Green Supplier Selection for the Steel Industry Using BWM and Fuzzy TOPSIS: A Case Study of Khouzestan Steel Company. Sustain. Futures 2020, 2, 100012. [Google Scholar] [CrossRef]

- Hsu, C.W.; Hu, A.H. Applying Hazardous Substance Management to Supplier Selection Using Analytic Network Process. J. Clean. Prod. 2009, 17, 255–264. [Google Scholar] [CrossRef]

- Wang, Z.; Mathiyazhagan, K.; Xu, L.; Diabat, A. A Decision Making Trial and Evaluation Laboratory Approach to Analyze the Barriers to Green Supply Chain Management Adoption in a Food Packaging Company. J. Clean. Prod. 2016, 117, 19–28. [Google Scholar] [CrossRef]

- Shi, H.; Quan, M.Y.; Liu, H.C.; Duan, C.Y. A Novel Integrated Approach for Green Supplier Selection with Interval-Valued Intuitionistic Uncertain Linguistic Information: A Case Study in the Agri-Food Industry. Sustainability 2018, 10, 733. [Google Scholar] [CrossRef] [Green Version]

- Lee, E.K.; Ha, S.; Kim, S.K. Supplier Selection and Management System Considering Relationships in Supply Chain Management. IEEE Trans. Eng. Manag. 2001, 48, 307–318. [Google Scholar]

- Saaty, T.L. The Analytic Hierarchy Process; McGrawHill: New York, NY, USA, 1990; Volume 45, Available online: https://www.sciencedirect.com/science/article/abs/pii/037722179090057I (accessed on 10 March 2020).

- Zadeh, L.A. Fuzzy Sets as a Basis for a Theory of Possibility. Fuzzy Sets Syst. 1978, 1, 3–28. [Google Scholar] [CrossRef]

- Solangi, Y.A.; Shah, S.A.A.; Zameer, H.; Ikram, M.; Saracoglu, B.O. Assessing the Solar PV Power Project Site Selection in Pakistan: Based on AHP-Fuzzy VIKOR Approach. Environ. Sci. Pollut. Res. 2019, 26, 30286–30302. [Google Scholar] [CrossRef]

- Chang, D.-Y. Applications of the Extent Analysis Method on Fuzzy AHP. Eur. J. Oper. Res. 1996, 95, 649–655. [Google Scholar] [CrossRef]

- Hwang, C.-L.; Yoon, K. Multiple Criteria Decision Making. Lect. Notes Econ. Math. Syst. 1981, 186, 58–191. [Google Scholar]

- Xu, L.; Wang, Y.; Shah, S.A.A.; Zameer, H.; Solangi, Y.A.; Das Walasai, G.; Siyal, Z.A. Economic Viability and Environmental Efficiency Analysis of Hydrogen Production Processes for the Decarbonization of Energy Systems. Processes 2019, 7, 494. [Google Scholar] [CrossRef] [Green Version]

- Shah, S.A.A. Feasibility Study of Renewable Energy Sources for Developing the Hydrogen Economy in Pakistan. Int. J. Hydrog. Energy 2019, in press. [Google Scholar] [CrossRef]

- Zavadskas, E.K.; Vilutienė, T.; Turskis, Z.; Tamosaitienė, J. Contractor Selection for Construction Works By Applying Saw-G and Topsis Grey Techniques. J. Bus. Econ. Manag. 2010, 11, 34–55. [Google Scholar] [CrossRef]

- Deng, J. Introduction to Grey Theory. J. Grey Syst. 1989, 1, 1–24. [Google Scholar]

- Oztaysi, B. A Decision Model for Information Technology Selection Using AHP Integrated TOPSIS-Grey: The Case of Content Management Systems. Knowl. -Based Syst. 2014, 70, 44–54. [Google Scholar] [CrossRef]

- Shah, S.A.A.; Solangi, Y.A.; Ikram, M. Analysis of Barriers to the Adoption of Cleaner Energy Technologies in Pakistan Using Modified Delphi and Fuzzy Analytical Hierarchy Process. J. Clean. Prod. 2019, 235, 1037–1050. [Google Scholar] [CrossRef]

- Gupta, H.; Barua, M.K. Supplier Selection among SMEs on the Basis of Their Green Innovation Ability Using BWM and Fuzzy TOPSIS. J. Clean. Prod. 2017, 152, 242–258. [Google Scholar] [CrossRef]

- Toloo, M.; Nalchigar, S. A New DEA Method for Supplier Selection in Presence of Both Cardinal and Ordinal Data. Expert Syst. Appl. 2011, 38, 14726–14731. [Google Scholar] [CrossRef]

- Wu, H.H.; Chang, S.Y. A Case Study of Using DEMATEL Method to Identify Critical Factors in Green Supply Chain Management. Appl. Math. Comput. 2015, 256, 394–403. [Google Scholar] [CrossRef]

| Research Focus | Research Findings | Method | Year | Reference |

|---|---|---|---|---|

| Sustainable supplier selection for an automobile company in India | In this research, it is revealed that environmental costs, product quality, and product price are three top-ranking criteria for the selection of a sustainable supplier. | Analytical Hierarchy Process (AHP) and Kriterijumska Optimizacija I Kompromisno Resenje (VIKOR) | 2017 | [20] |

| Supplier selection within a food supply chain context | Research findings show that price is the most significant criterion for supplier selection. | Best Worst method (BWM) | 2016 | [21] |

| Evaluating the green supplier growth program | The results of this study show that ISO 14000 certification is a feasible alternative for a greener supplier development program. | Normal Group Technique (NGT) and VIKOR | 2016 | [22] |

| Green supplier selection for Iranian automotive company | This study reveals that economic criteria are preferable than environmental criteria; whereas, the cost is a more critical sub-criterion than technology and quality for analyzing the green supplier. | Analytical Hierarchy Process (ANP) and Grey Relational Analysis (GRA) | 2015 | [23] |

| the green supplier selection in the electronics industry | Results present that current capacity and R&D capability are vital criteria for the selection of a green supplier in the electronics industry. | AHP and ELimination Et Choice Translating REality (ELECTRE)-III | 2014 | [24] |

| Supplier selection for carbon management in green SCM | The findings indicate that the management system of carbon and training related to carbon management are the most important criteria for selecting a supplier. | Decision making trial and evaluation laboratory (DEMATEL) | 2013 | [25] |

| Assessing suppliers for green development program in the automobile industry | The findings of this study show that quality, preventing pollution, and green image are the most necessary criteria for supplier selection to include green development programs. | Fuzzy c-means and VIKOR | 2015 | [26] |

| The green supplier selection for a textile industry | The analysis of this study shows that quality is a preferable criterion followed respectively by green product and cost for the supplier selection. | Fuzzy AHP | 2019 | [27] |

| Green supplier selection for Indian cement industry | The research findings present that safety, quality, and cost are crucial criteria for selecting a green supplier in the cement industry. | AHP | 2016 | [28] |

| Supplier selection for the agri-food industry | The analysis indicates that service level is the most important criterion for the green supplier selection. | Fuzzy TOPSIS, Fuzzy VIKOR, and Fuzzy GRA | 2018 | [29] |

| Criteria | Sub-Criteria | Reference |

|---|---|---|

| Green innovation capacity (A) | Supplier’s economic competitiveness (A1) | [30,31,32,33] |

| Capacity of supplier’s general innovation (A2) | [20,32,34,35] | |

| Awareness about sustainability management (A3) | [12,35,36] | |

| Trained human resources (A4) | [12,20,33] | |

| Production efficiency (A5) | [35,37,38] | |

| Green innovation initiatives (B) | Share of renewable energy utilization (B1) | [39,40] |

| Energy efficiency and conservation (B2) | [29,39] | |

| Green transportation (B3) | [12,20,22,41] | |

| Green recycling (B4) | [12,20,22,41] | |

| Green warehousing (B5) | [20,22,41] | |

| Green innovation performance (C) | Water conservation (C1) | [12,29] |

| Level of environmental implications on society (C2) | [12,33,42] | |

| Level of R&D expenditure on environmental initiatives (C3) | [32,41,43] | |

| Carbon emission reduction (C4) | [12,29,39] | |

| Indoor environment quality (C5) | [12,42,43] | |

| Green innovation monitoring and follow-up (D) | Environmental audits to ensure compliance (D1) | [41,43,44] |

| Stringent enforcement of green practices (D2) | [41,45,46] | |

| Implementation of environmental management system (D3) | [10,29,33,47] | |

| Incentives for green production (D4) | [32,33,43] | |

| Technical assistant for technological upgradation (D5) | [12,32,43] |

| Linguistic Preference | TFNs |

| Preferred equally | (1,1,1) |

| Preferred moderately | (2/3, 1, 3/2) |

| Preferred strongly | (3/2, 2,5/2) |

| Preferred very-strongly | (5/2, 3, 7/2) |

| Preferred extremely | (7/2, 4, 9/2) |

| Linguistic | ⊗ X |

| Very-low (VL) | [0, 1] |

| Low (L) | [1, 3] |

| Moderate-low (ML) | [3, 4] |

| Moderate (M) | [4, 5] |

| Moderate-high (MH) | [5, 6] |

| High (H) | [6, 9] |

| Very-high (VH) | [9, 10] |

| Green Innovation Capacity (A) | Green Innovation Initiatives (B) | Green Innovation Performance (C) | Green Innovation Monitoring Mechanism (D) | |

|---|---|---|---|---|

| Green innovation capacity (A) | 1, 1, 1 | 0.587, 0.825, 1.193 | 0.81, 1.134, 1.593 | 0.728, 1, 1.373 |

| Green innovation initiatives (B) | 0.838, 1.212, 1.704 | 1, 1, 1 | 0.541, 0.724, 1 | 0.874, 1.23, 1.704 |

| Green innovation performance (C) | 0.628, 0.882, 1.234 | 1, 1.381, 1.847 | 1, 1, 1 | 0.601, 0.779, 1.019 |

| Green innovation monitoring mechanism (D) | 0.728, 1, 1.373 | 0.587, 0.813, 1.144 | 0.982, 1.284, 1.664 | 1, 1, 1 |

| CR = 0.0274 | ||||

| Criteria | Main Criteria Weight | Sub-Criteria | Code | Sub-Criteria Weight | Global Weight | Rank |

|---|---|---|---|---|---|---|

| Green innovation capacity (A) | 0.244 | Supplier’s economic competitiveness | A-1 | 0.211 | 0.051 | 8 |

| Capacity of supplier’s general innovation | A-2 | 0.207 | 0.051 | 12 | ||

| Awareness about sustainability management | A-3 | 0.205 | 0.050 | 14 | ||

| Trained human resources | A-4 | 0.183 | 0.045 | 18 | ||

| Production efficiency | A-5 | 0.194 | 0.047 | 16 | ||

| Green innovation initiatives (B) | 0.256 | Share of renewable energy utilization | B-1 | 0.222 | 0.057 | 1 |

| Energy efficiency and conservation | B-2 | 0.205 | 0.052 | 5 | ||

| Green transportation | B-3 | 0.196 | 0.050 | 13 | ||

| Green recycling | B-4 | 0.200 | 0.051 | 9 | ||

| Green warehousing | B-5 | 0.177 | 0.045 | 17 | ||

| Green innovation performance (C) | 0.248 | Water conservation | C-1 | 0.197 | 0.049 | 15 |

| Level of environmental implications on society | C-2 | 0.212 | 0.053 | 4 | ||

| Level of R&D expenditure on environmental initiatives | C-3 | 0.205 | 0.051 | 11 | ||

| Carbon emission reduction | C-4 | 0.208 | 0.052 | 7 | ||

| Indoor environment quality | C-5 | 0.178 | 0.044 | 19 | ||

| Green innovation monitoring mechanism (D) | 0.252 | Environmental audits to ensure compliance | D-1 | 0.209 | 0.053 | 3 |

| Stringent enforcement of green practices | D-2 | 0.211 | 0.053 | 2 | ||

| Implementation of environmental management system | D-3 | 0.208 | 0.052 | 6 | ||

| Incentives for green production | D-4 | 0.202 | 0.051 | 10 | ||

| Technical assistant for technological upgradation | D-5 | 0.170 | 0.043 | 20 |

| C+ | Ranking | |||

|---|---|---|---|---|

| Supplier-1 | 0.227 | 0.301 | 0.57 | 2 |

| Supplier-2 | 0.257 | 0.269 | 0.511 | 4 |

| Supplier-3 | 0.226 | 0.311 | 0.579 | 1 |

| Supplier-4 | 0.307 | 0.221 | 0.419 | 5 |

| Supplier-5 | 0.333 | 0.2 | 0.375 | 6 |

| Supplier-6 | 0.259 | 0.29 | 0.528 | 3 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Musaad O, A.S.; Zhuo, Z.; Siyal, Z.A.; Shaikh, G.M.; Shah, S.A.A.; Solangi, Y.A.; Musaad O, A.O. An Integrated Multi-Criteria Decision Support Framework for the Selection of Suppliers in Small and Medium Enterprises based on Green Innovation Ability. Processes 2020, 8, 418. https://doi.org/10.3390/pr8040418

Musaad O AS, Zhuo Z, Siyal ZA, Shaikh GM, Shah SAA, Solangi YA, Musaad O AO. An Integrated Multi-Criteria Decision Support Framework for the Selection of Suppliers in Small and Medium Enterprises based on Green Innovation Ability. Processes. 2020; 8(4):418. https://doi.org/10.3390/pr8040418

Chicago/Turabian StyleMusaad O, Almalki Sultan, Zhang Zhuo, Zafar Ali Siyal, Ghulam Muhammad Shaikh, Syed Ahsan Ali Shah, Yasir Ahmed Solangi, and Almalki Otaibi Musaad O. 2020. "An Integrated Multi-Criteria Decision Support Framework for the Selection of Suppliers in Small and Medium Enterprises based on Green Innovation Ability" Processes 8, no. 4: 418. https://doi.org/10.3390/pr8040418

APA StyleMusaad O, A. S., Zhuo, Z., Siyal, Z. A., Shaikh, G. M., Shah, S. A. A., Solangi, Y. A., & Musaad O, A. O. (2020). An Integrated Multi-Criteria Decision Support Framework for the Selection of Suppliers in Small and Medium Enterprises based on Green Innovation Ability. Processes, 8(4), 418. https://doi.org/10.3390/pr8040418