Energetic Valorisation of Olive Biomass: Olive-Tree Pruning, Olive Stones and Pomaces

Abstract

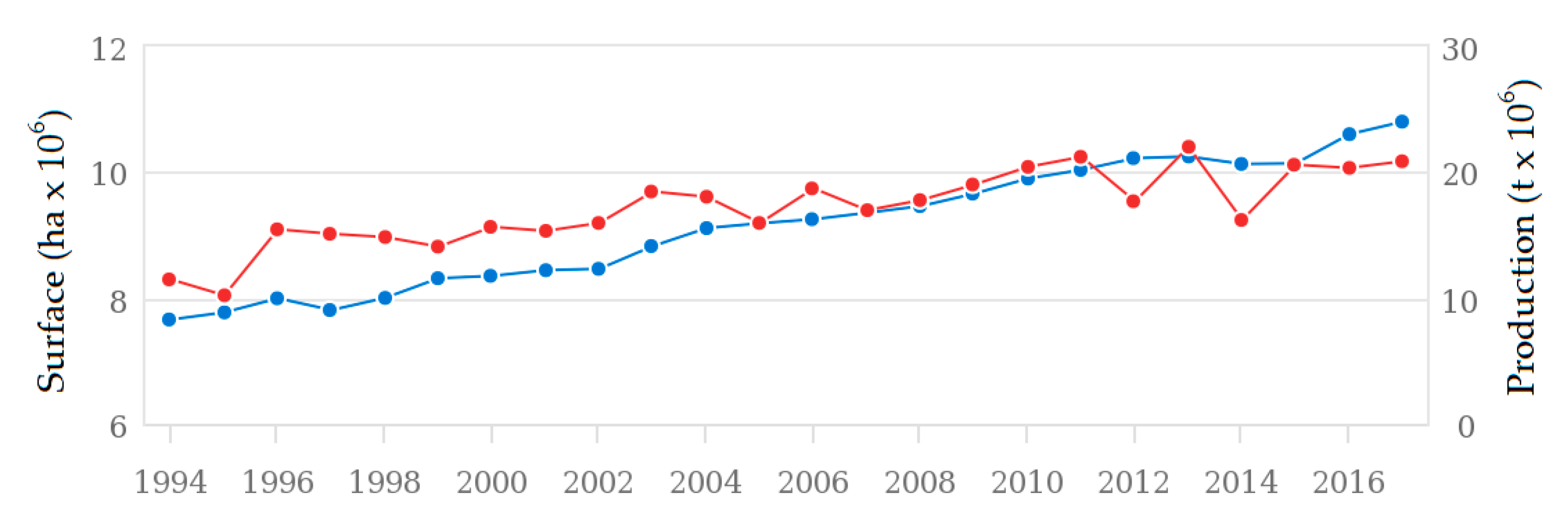

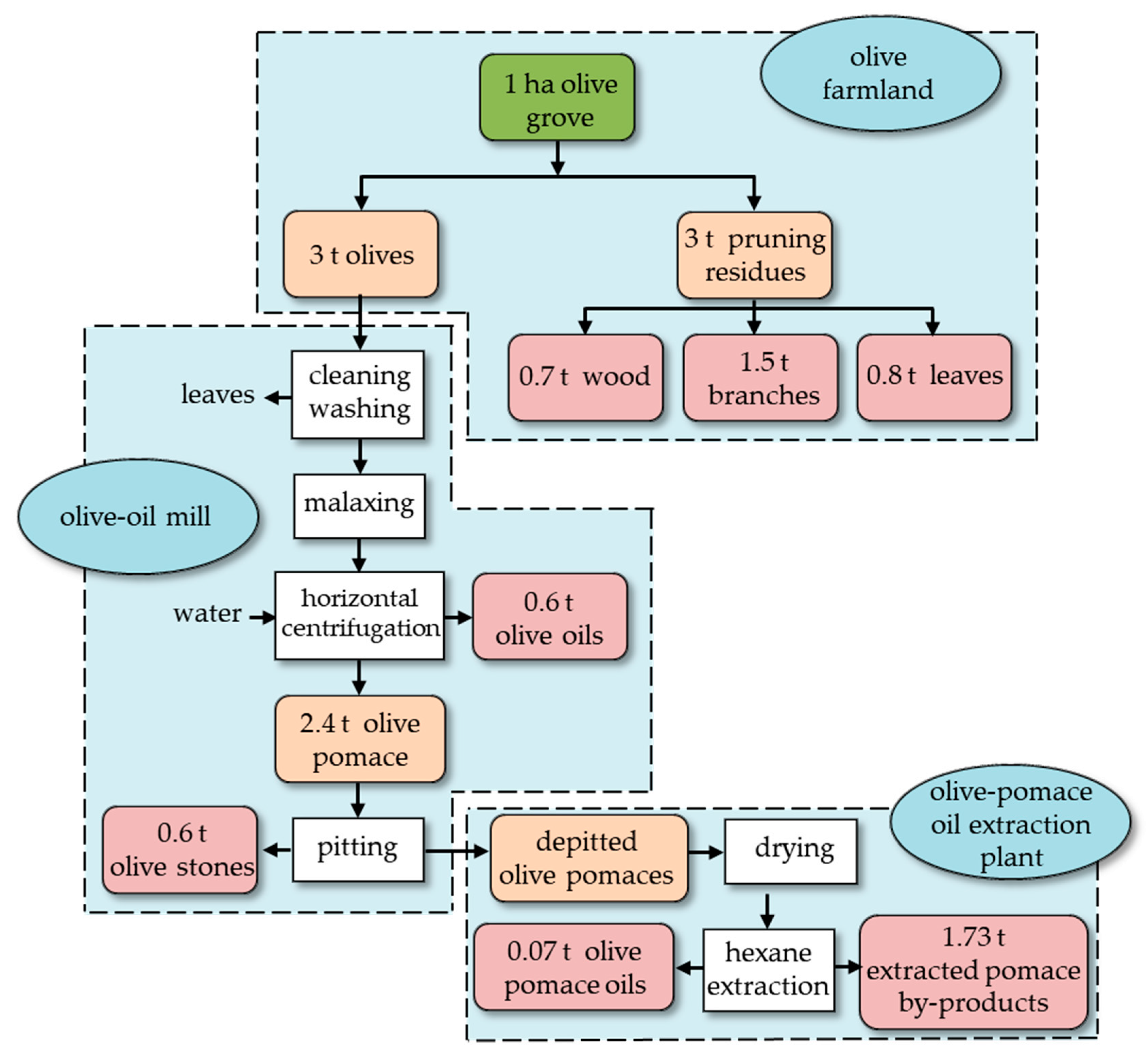

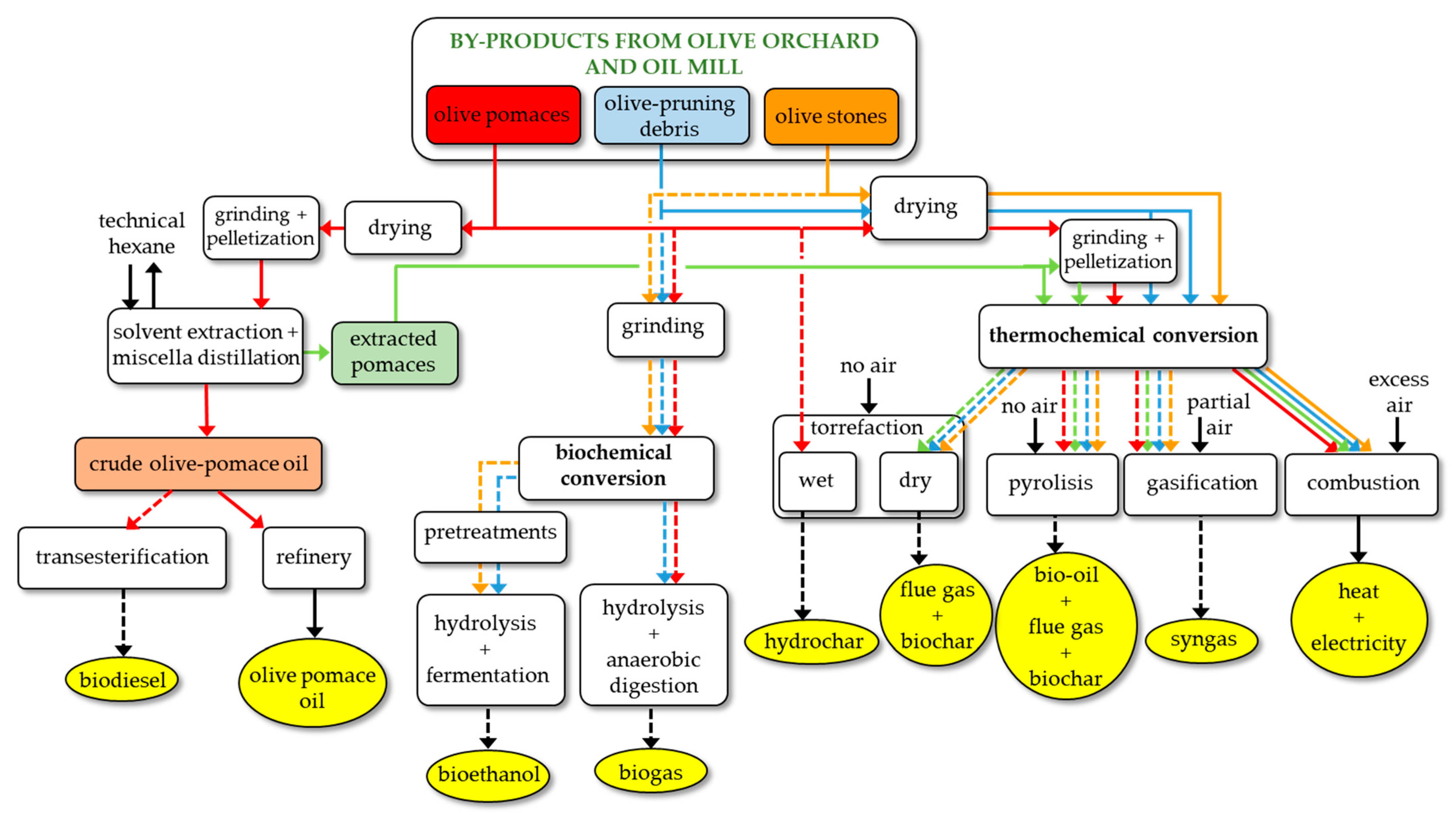

1. Introduction

2. Olive-Pruning Debris

2.1. Bioethanol Production

2.1.1. Pre-Treatment

- Ultrasound pre-treatment

- Ozonation

- Steam explosion

- Autohydrolysis or liquid hot water (LHW) pre-treatment

- Extrusion

- Dilute-acid hydrolysis

- Alkaline peroxide pre-treatment

2.1.2. Hydrolysis

2.1.3. Fermentation

2.2. Methane Generation

2.3. Pellets Production

2.4. Torrefaction

2.5. Pyrolysis

2.6. Gasification

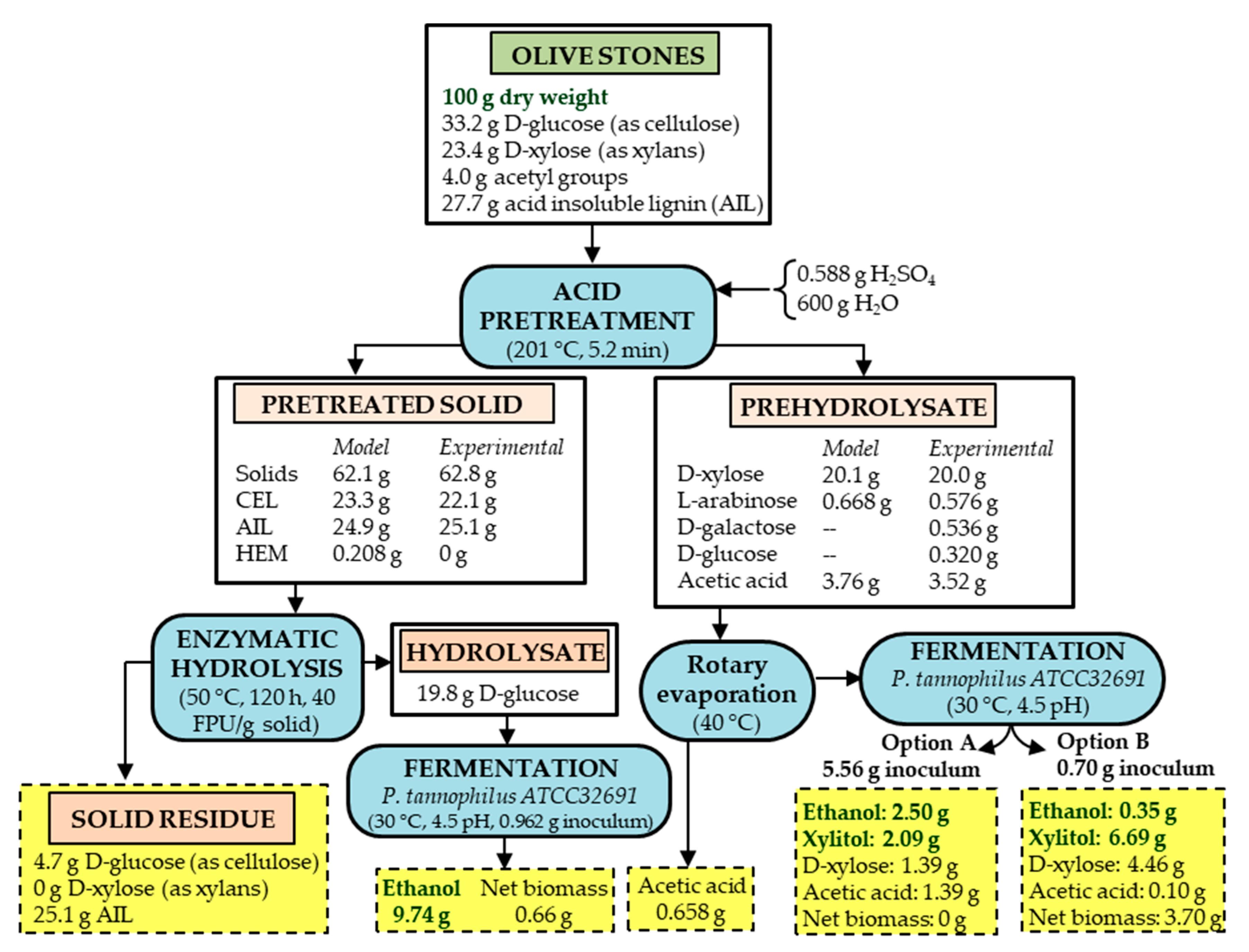

3. Olive Stones

3.1. Preliminary Treatments: Cleaning and Drying

3.2. Biochemical Conversion

3.3. Thermochemical Conversion of Olive Stones

3.3.1. Torrefaction

3.3.2. Pyrolysis

3.3.3. Gasification

3.3.4. Combustion

4. Olive Pomace from Olive Mills and Pomace Extracted from Extraction Plants

4.1. Biodiesel Production

4.2. Anaerobic Digestion

4.3. Pellets Production

4.4. Wet Torrefaction

4.5. Pyrolysis

4.6. Gasification

5. Biofuels from Olive Biomass. Potential Application in Engines

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Feng, C.H.; Wang, W.; Makino, Y.; García-Martín, J.F.; Alvarez-Mateos, P.; Song, X.Y. Evaluation of storage time and temperature on physicochemical properties of immersion vacuum cooled sausages stuffed in the innovative casings modified by surfactants and lactic acid. J. Food Eng. 2019, 257, 34–43. [Google Scholar] [CrossRef]

- Feng, C.H.; Makino, Y. Colour analysis in sausages stuffed in modified casings with different storage days using hyperspectral imaging—A feasibility study. Food Control 2020, 111, 107047. [Google Scholar] [CrossRef]

- Cuevas, M.; Martínez-Cartas, M.L.; Pérez-Villarejo, L.; Hernández, L.; García-Martín, J.F.; Sánchez, S. Drying kinetics and effective water diffusivities in olive stone and olive-tree pruning. Renew. Energy 2019, 132, 911–920. [Google Scholar] [CrossRef]

- Cuevas, M.; Sánchez, S.; Bravo, V.; García, J.F.; Baeza, J.; Parra, C.; Freer, J. Determination of optimal pre-treatment conditions for ethanol production from olive-pruning debris by simultaneous saccharification and fermentation. Fuel 2010, 89, 2891–2896. [Google Scholar] [CrossRef]

- The Food and Agriculture Organization. Crops. Available online: http://www.fao.org/faostat/en/#data/QC/visualize (accessed on 3 February 2020).

- Sánchez, S.; Moya, A.J.; Moya, M.; Romero, I.; Torrero, R.; Bravo, V.; San Miguel, M.P. Aprovechamiento del residuo de poda del olivar mediante conversión termoquímica. Ing. Quim. 2002, 391, 184–202. [Google Scholar]

- Garcia-Maraver, A.; Rodriguez, M.L.; Serrano-Bernardo, F.; Diaz, L.F.; Zamorano, M. Factors affecting the quality of pellets made from residual biomass of olive trees. Fuel Process. Technol. 2015, 129, 1–7. [Google Scholar] [CrossRef]

- Pérez, A.; Martín-Lara, M.A.; Gálvez-Pérez, A.; Calero, M.; Ronda, A. Kinetic analysis of pyrolysis and combustion of the olive tree pruning by chemical fractionation. Bioresour. Technol. 2018, 249, 557–566. [Google Scholar] [CrossRef]

- Iáñez-Rodríguez, I.; Martín-Lara, M.Á.; Blázquez, G.; Osegueda, Ó.; Calero, M. Thermal analysis of olive tree pruning and the by-products obtained by its gasification and pyrolysis: The effect of some heavy metals on their devolatilization behavior. J. Energy Chem. 2019, 32, 105–117. [Google Scholar] [CrossRef]

- García Martín, J.F.; Sánchez, S.; Bravo, V.; Cruz, N.; Cuevas, M.; Rigal, L.; Doumeng, C. Hidrólisis ácida del residuo de poda de olivo en un reactor de extrusión. Afinidad 2008, 65, 39–44. [Google Scholar]

- García, J.F.; Sánchez, S.; Bravo, V.; Rigal, L.; Cuevas, M. Acid hydrolysis of olive-pruning debris for D-xylose production. Collect. Czechoslov. Chem. Commun. 2008, 73, 637–648. [Google Scholar] [CrossRef]

- Martínez-Patiño, J.C.; Ruiz, E.; Romero, I.; Cara, C.; López-Linares, J.C.; Castro, E. Combined acid/alkaline-peroxide pretreatment of olive tree biomass for bioethanol production. Bioresour. Technol. 2017, 239, 326–335. [Google Scholar] [CrossRef] [PubMed]

- Cara, C.; Ruiz, E.; Ballesteros, M.; Manzanares, P.; Negro, M.J.; Castro, E. Production of fuel ethanol from steam-explosion pretreated olive tree pruning. Fuel 2008, 87, 692–700. [Google Scholar] [CrossRef]

- Peinado, S.; Mateo, S.; Sánchez, S.; Moya, A.J. Effectiveness of sodium borohydride treatment on acid hydrolyzates from olive-tree pruning biomass for bioethanol production. Bioenergy Res. 2019, 12, 302–311. [Google Scholar] [CrossRef]

- Mateo, S.; Puentes, J.G.; Moya, A.J.; Sánchez, S. Ethanol and xylitol production by fermentation of acid hydrolysate from olive pruning with Candida tropicalis NBRC 0618. Bioresour. Technol. 2015, 190, 1–6. [Google Scholar] [CrossRef]

- García, J.F.; Sánchez, S.; Bravo, V.; Cuevas, M.; Rigal, L.; Gaset, A. Xylitol production from olive-pruning debris by sulphuric acid hydrolysis and fermentation with Candida tropicalis. Holzforschung 2011, 65, 59–65. [Google Scholar] [CrossRef]

- Mata-Sánchez, J.; Pérez-Jiménez, J.A.; Díaz-Villanueva, M.J.; Serrano, A.; Núñez-Sánchez, N.; López-Giménez, F.J. Statistical evaluation of quality parameters of olive stone to predict its heating value. Fuel 2013, 113, 750–756. [Google Scholar] [CrossRef]

- Saleh, M.; Cuevas, M.; García, J.F.; Sánchez, S. Valorization of olive stones for xylitol and ethanol production from dilute acid pretreatment via enzymatic hydrolysis and fermentation by Pachysolen tannophilus. Biochem. Eng. J. 2014, 90, 286–293. [Google Scholar] [CrossRef]

- Mata-Sánchez, J.; Pérez-Jiménez, J.A.; Díaz-Villanueva, M.J.; Serrano, A.; Núñez-Sánchez, N.; López-Giménez, F.J. Development of olive stone quality system based on biofuel energetic parameters study. Renew. Energy 2014, 66, 251–256. [Google Scholar] [CrossRef]

- Fernández-Bolaños, J.; Felizón, B.; Heredia, A.; Guillén, R.; Jiménez, A. Characterization of the lignin obtained by alkaline delignification and of the cellulose residue from steam-exploded olive stones. Bioresour. Technol. 1999, 68, 121–132. [Google Scholar] [CrossRef]

- Barreca, F.; Fichera, C.R. Use of olive stone as an additive in cement lime mortar to improve thermal insulation. Energy Build. 2013, 62, 507–513. [Google Scholar] [CrossRef]

- Rodríguez, G.; Lama, A.; Rodríguez, R.; Jiménez, A.; Guillén, R.; Fernández-Bolaños, J. Olive stone an attractive source of bioactive and valuable compounds. Bioresour. Technol. 2008, 99, 5261–5269. [Google Scholar] [CrossRef] [PubMed]

- Cuevas, M.; Saleh, M.; García-Martín, J.F.; Sánchez, S. Acid and enzymatic fractionation of olive stones for ethanol production using Pachysolen tannophilus. Processes 2020, 8, 195. [Google Scholar] [CrossRef]

- Martín-Lara, M.A.; Hernáinz, F.; Calero, M.; Blázquez, G.; Tenorio, G. Surface chemistry evaluation of some solid wastes from olive-oil industry used for lead removal from aqueous solutions. Biochem. Eng. J. 2009, 44, 151–159. [Google Scholar] [CrossRef]

- Fernández-Bolaños, J.; Felizón, B.; Heredia, A.; Rodríguez, R.; Guillén, R.; Jiménez, A. Steam-explosion of olive stones: Hemicellulose solubilization and enhancement of enzymatic hydrolysis of cellulose. Bioresour. Technol. 2001, 79, 53–61. [Google Scholar] [CrossRef]

- Lama-Muñoz, A.; Romero-García, J.M.; Cara, C.; Moya, M.; Castro, E. Low energy-demanding recovery of antioxidants and sugars from olive stones as preliminary steps in the biorefinery context. Ind. Crops Prod. 2014, 60, 30–38. [Google Scholar] [CrossRef]

- Pattara, C.; Cappelletti, G.M.; Cichelli, A. Recovery and use of olive stones: Commodity, environmental and economic assessment. Renew. Sustain. Energy Rev. 2010, 14, 1484–1489. [Google Scholar] [CrossRef]

- García, G.B.; Calero De Hoces, M.; Martínez García, C.; Cotes Palomino, M.T.; Gálvez, A.R.; Martín-Lara, M.Á. Characterization and modeling of pyrolysis of the two-phase olive mill solid waste. Fuel Process. Technol. 2014, 126, 104–111. [Google Scholar] [CrossRef]

- Blanco-López, M.C.; Blanco, C.G.; Martínez-Alonso, A.; Tascón, J.M.D. Composition of gases released during olive stones pyrolysis. J. Anal. Appl. Pyrolysis 2002, 65, 313–322. [Google Scholar] [CrossRef]

- Skodras, G.; Grammelis, P.; Basinas, P.; Kakaras, E.; Sakellaropoulos, G. Pyrolysis and combustion characteristics of biomass and waste-derived feedstock. Ind. Eng. Chem. Res. 2006, 45, 3791–3799. [Google Scholar] [CrossRef]

- Vera, D.; Jurado, F.; Margaritis, N.K.; Grammelis, P. Experimental and economic study of a gasification plant fuelled with olive industry wastes. Energy Sustain. Dev. 2014, 23, 247–257. [Google Scholar] [CrossRef]

- García, R.; Pizarro, C.; Lavín, A.G.; Bueno, J.L. Characterization of Spanish biomass wastes for energy use. Bioresour. Technol. 2012, 103, 249–258. [Google Scholar] [CrossRef] [PubMed]

- Skoulou, V.; Koufodimos, G.; Samaras, Z.; Zabaniotou, A. Low temperature gasification of olive kernels in a 5-kW fluidized bed reactor for H2-rich producer gas. Int. J. Hydrog. Energy 2008, 33, 6515–6524. [Google Scholar] [CrossRef]

- Di Giovacchino, L. I sottoprodotti della lavorazione delle olive in oleificio. In Tecnologie di Lavorazione Delle Olive in Frantoio; Di Giovacchino, L., Ed.; Tecnica Alimentare: Milano, Italy, 2010; pp. 243–258. ISBN 978-88-481-2554-3. [Google Scholar]

- Yang, B.; Boussaid, A.; Mansfield, S.D.; Gregg, D.J.; Saddler, J.N. Fast and efficient alkaline peroxide treatment to enhance the enzymatic digestibility of steam-exploded softwood substrates. Biotechnol. Bioeng. 2002, 77, 678–684. [Google Scholar] [CrossRef]

- Zheng, Y.; Zhao, J.; Xu, F.; Li, Y. Pretreatment of lignocellulosic biomass for enhanced biogas production. Prog. Energy Combust. Sci. 2014, 42, 35–53. [Google Scholar] [CrossRef]

- Nitayavardhana, S.; Shrestha, P.; Rasmussen, M.L.; Lamsal, B.P.; van Leeuwen, J.H.; Khanal, S.K. Ultrasound improved ethanol fermentation from cassava chips in cassava-based ethanol plants. Bioresour. Technol. 2010, 8, 2741–2747. [Google Scholar] [CrossRef]

- Perrone, O.M.; Colombari, F.M.; Rossi, J.S.; Moretti, M.M.S.; Bordignon, S.E.; Nunes, C.D.C.C.; Gomes, E.; Boscolo, M.; Da-Silva, R. Ozonolysis combined with ultrasound as a pretreatment of sugarcane bagasse: Effect on the enzymatic saccharification and the physical and chemical characteristics of the substrate. Bioresour. Technol. 2016, 218, 69–76. [Google Scholar] [CrossRef]

- Martínez-Patiño, J.C.; Gullón, B.; Romero, I.; Ruiz, E.; Brnčić, M.; Žlabur, J.Š.; Castro, E. Optimization of ultrasound-assisted extraction of biomass from olive trees using response surface methodology. Ultrason. Sonochem. 2019, 51, 487–495. [Google Scholar] [CrossRef]

- García, A.; González Alriols, M.; Labidi, J. Evaluation of the effect of ultrasound on organosolv black liquor from olive tree pruning residues. Bioresour. Technol. 2012, 108, 155–161. [Google Scholar] [CrossRef]

- Ponnusamy, V.K.; Nguyen, D.D.; Dharmaraja, J.; Shobana, S.; Banu, J.R.; Saratale, R.G.; Chang, S.W.; Kumar, G. A review on lignin structure, pretreatments, fermentation reactions and biorefinery potential. Bioresour. Technol. 2019, 271, 462–472. [Google Scholar] [CrossRef]

- Peretz, R.; Gerchman, Y.; Mamane, H. Ozonation of tannic acid to model biomass pretreatment for bioethanol production. Bioresour. Technol. 2017, 241, 1060–1066. [Google Scholar] [CrossRef]

- Negro, M.J.; Alvarez, C.; Ballesteros, I.; Romero, I.; Ballesteros, M.; Castro, E.; Manzanares, P.; Moya, M.; Oliva, J.M. Ethanol production from glucose and xylose obtained from steam exploded water-extracted olive tree pruning using phosphoric acid as catalyst. Bioresour. Technol. 2014, 153, 101–107. [Google Scholar] [CrossRef] [PubMed]

- Barbanera, M.; Buratti, C.; Cotana, F.; Foschini, D.; Lascaro, E. Effect of steam explosion pretreatment on sugar production by enzymatic hydrolysis of olive tree pruning. Energy Procedia 2015, 81, 146–154. [Google Scholar] [CrossRef]

- Tortosa, J.F.; Rubio, M.; Gómez, D. Autohidrólisis de tallo de maiz en suspensión acuosa. Afinidad 1995, 52, 181–188. [Google Scholar]

- Overend, R.P.; Chornet, E. Fractionation of lignocellulosics by steam-aqueous pretreatments. Philos. Trans. R. Soc. London. Ser. A Math. Phys. Sci. 1987, 321, 523–536. [Google Scholar]

- García Martín, J.F.; Cuevas, M.; Bravo, V.; Sánchez, S. Ethanol production from olive prunings by autohydrolysis and fermentation with Candida tropicalis. Renew. Energy 2010, 35, 1602–1608. [Google Scholar] [CrossRef]

- García, J.F.; Sánchez, S.; Bravo, V.; Cuevas, M. Autohydrolysis and acid post-hydrolysis of olive-pruning debris. Afinidad 2010, 67, 279–282. [Google Scholar]

- Gatt, E.; Rigal, L.; Vandenbossche, V. Biomass pretreatment with reactive extrusion using enzymes: A review. Ind. Crops Prod. 2018, 122, 329–339. [Google Scholar] [CrossRef]

- García Martín, J.F.; Sánchez, S.; Cuevas, M. Evaluation of the effect of the dilute acid hydrolysis on sugars release from olive prunings. Renew. Energy 2013, 51, 382–387. [Google Scholar] [CrossRef]

- Martínez-Patiño, J.C.; Lu-Chau, T.A.; Gullón, B.; Ruiz, E.; Romero, I.; Castro, E.; Lema, J.M. Application of a combined fungal and diluted acid pretreatment on olive tree biomass. Ind. Crops Prod. 2018, 121, 10–17. [Google Scholar] [CrossRef]

- Romero, I.; Moya, M.; Sánchez, S.; Ruiz, E.; Castro, E.; Bravo, V. Ethanolic fermentation of phosphoric acid hydrolysates from olive tree pruning. Ind. Crops Prod. 2007, 25, 160–168. [Google Scholar] [CrossRef]

- Ho, M.C.; Ong, V.Z.; Wu, T.Y. Potential use of alkaline hydrogen peroxide in lignocellulosic biomass pretreatment and valorization – A review. Renew. Sustain. Energy Rev. 2019, 112, 75–86. [Google Scholar] [CrossRef]

- Sun, Y.; Cheng, J. Hydrolysis of lignocellulosic materials for ethanol production: A review. Bioresour. Technol. 2002, 83, 1–11. [Google Scholar] [CrossRef]

- Palmqvist, E.; Grage, H.; Meinander, N.Q.; Hahn-Hägerdal, B. Main and interaction effects of acetic acid, furfural, and p- hydroxybenzoic acid on growth and ethanol productivity of yeasts. Biotechnol. Bioeng. 1999, 63, 46–55. [Google Scholar] [CrossRef]

- García, J.F.; Sánchez, S.; García, J. Ethanol from biomass: Application to the olive-pruning debris. In Liquid Fuels: Types, Properties and Production; Carasillo, D.A., Ed.; Nova Science Publishers: Hauppauge, NY, USA, 2012; pp. 239–254. ISBN 9781614704355. [Google Scholar]

- Bayrock, D.P.; Ingledew, W.M. Ethanol production in multistage continuous, single stage continuous, Lactobacillus-contaminated continuous, and batch fermentations. World J. Microbiol. Biotechnol. 2005, 21, 83–88. [Google Scholar] [CrossRef]

- Sánchez, S.; Bravo, V.; García, J.F.; Cruz, N.; Cuevas, M. Fermentation of D-glucose and D-xylose mixtures by Candida tropicalis NBRC 0618 for xylitol production. World J. Microbiol. Biotechnol. 2008, 24, 709–716. [Google Scholar] [CrossRef]

- Sánchez, S.; Bravo, V.; Castro, E.; Moya, A.J.; Camacho, F. The fermentation of mixtures of D-glucose and D-xylose by Candida shehatae, Pichia stipitis or Pachysolen tannophilus to produce ethanol. J. Chem. Technol. Biotechnol. 2002, 77, 641–648. [Google Scholar] [CrossRef]

- Moya, A.J.; Bravo, V.; Mateo, S.; Sánchez, S. Fermentation of acid hydrolysates from olive-tree pruning debris by Pachysolen tannophilus. Bioprocess Biosyst. Eng. 2008, 31, 611–617. [Google Scholar] [CrossRef]

- Costa, P.; Dell’Omo, P.P.; La Froscia, S. Multistage milling and classification for improving both pellet quality and biogas production from hazelnut and olive pruning. Ann. Chim. Sci. des Mater. 2018, 42, 471–487. [Google Scholar] [CrossRef]

- Messineo, A.; Maniscalco, M.P.; Volpe, R. Biomethane recovery from olive mill residues through anaerobic digestion: A review of the state of the art technology. Sci. Total Environ. 2020, 703, 135508. [Google Scholar] [CrossRef]

- Carone, M.T.; Pantaleo, A.; Pellerano, A. Influence of process parameters and biomass characteristics on the durability of pellets from the pruning residues of Olea europaea L. Biomass Bioenergy 2011, 35, 402–410. [Google Scholar] [CrossRef]

- Zambon, I.; Colosimo, F.; Monarca, D.; Cecchini, M.; Gallucci, F.; Proto, A.R.; Lord, R.; Colantoni, A. An innovative agro-forestry supply chain for residual biomass: Physicochemical characterisation of biochar from olive and hazelnut pellets. Energies 2016, 9, 526. [Google Scholar] [CrossRef]

- Martín-Lara, M.A.; Ronda, A.; Zamora, M.C.; Calero, M. Torrefaction of olive tree pruning: Effect of operating conditions on solid product properties. Fuel 2017, 202, 109–117. [Google Scholar] [CrossRef]

- Martín-Lara, M.A.; Blázquez, G.; Zamora, M.C.; Calero, M. Kinetic modelling of torrefaction of olive tree pruning. Appl. Therm. Eng. 2017, 113, 1410–1418. [Google Scholar] [CrossRef]

- Zabaniotou, A.; Rovas, D.; Monteleone, M. Management of olive grove pruning and solid waste from olive oil extraction via thermochemical processes. Waste Biomass Valorization 2015, 6, 831–842. [Google Scholar] [CrossRef]

- Calahorro, C.V.; Serrano, V.G.; Alvaro, J.H.; García, A.B. The use of waste matter after olive grove pruning for the preparation of charcoal. The influence of the type of matter, particle size and pyrolysis temperature. Bioresour. Technol. 1992, 40, 17–22. [Google Scholar] [CrossRef]

- Hidayat, A.; Rochmadi; Wijaya, K.; Nurdiawati, A.; Kurniawan, W.; Hinode, H.; Yoshikawa, K.; Budiman, A. Esterification of palm fatty acid distillate with high amount of free fatty acids using coconut shell char based catalyst. Energy Procedia 2015, 75, 969–974. [Google Scholar] [CrossRef]

- Álvarez-Mateos, P.; García-Martín, J.F.; Guerrero-Vacas, F.J.; Naranjo-Calderón, C.; Barrios, C.C.; Pérez Camino, M.D.C.; Barrios, C.C. Valorization of a high-acidity residual oil generated in the waste cooking oils recycling industries. Grasas Aceites 2019, 40, e335. [Google Scholar] [CrossRef]

- Bartoli, M.; Rosi, L.; Giovannelli, A.; Frediani, P.; Frediani, M. Characterization of bio-oil and bio-char produced by low-temperature microwave-assisted pyrolysis of olive pruning residue using various absorbers. Waste Manag. Res. 2020, 38, 213–225. [Google Scholar] [CrossRef]

- Nilsson, S.; Gómez-Barea, A.; Fuentes-Cano, D.; Haro, P.; Pinna-Hernández, G. Gasification of olive tree pruning in fluidized bed: Experiments in a laboratory-scale plant and scale-up to industrial operation. Energy Fuels 2017, 31, 542–554. [Google Scholar] [CrossRef]

- Nilsson, S.; Gómez-Barea, A.; Fuentes-Cano, D.; Campoy, M. Gasification kinetics of char from olive tree pruning in fluidized bed. Fuel 2014, 125, 192–199. [Google Scholar] [CrossRef]

- Gallucci, F.; Longo, L.; Santangelo, E.; Guerriero, E.; Paolini, V.; Carnevale, M.; Colantoni, A.; Tonolo, A. Assessment of syngas produced from gasification of olive tree pruning in a downdraft reactor. In Proceedings of the European Biomass Conference and Exhibition Proceedings, Copenhagen, Denmark, 14–18 May 2018. [Google Scholar]

- Vera, D.; De Mena, B.; Jurado, F.; Schories, G. Study of a downdraft gasifier and gas engine fueled with olive oil industry wastes. Appl. Therm. Eng. 2013, 51, 119–129. [Google Scholar] [CrossRef]

- Sánchez, J.M.; Jiménez, J.A.P.; Villanueva, M.J.D.; Serrano, A.; Núñez, N.; Giménez, J.L. New techniques developed to quantify the impurities of olive stone as solid biofuel. Renew. Energy 2015, 78, 566–572. [Google Scholar] [CrossRef]

- Vega-Nieva, D.J.; Ortiz Torres, L.; Míguez Tabares, J.L.; Morán, J. Measuring and predicting the slagging of woody and herbaceous Mediterranean biomass fuels on a domestic pellet boiler. Energy Fuels 2016, 30, 1085–1095. [Google Scholar] [CrossRef]

- Miranda, M.T.; Cabanillas, A.; Rojas, S.; Montero, I.; Ruiz, A. Combined combustion of various phases of olive wastes in a conventional combustor. Fuel 2007, 86, 367–372. [Google Scholar] [CrossRef]

- Gómez-de la Cruz, F.J.; Casanova-Peláez, P.J.; Palomar-Carnicero, J.M.; Cruz-Peragón, F. Drying kinetics of olive stone: A valuable source of biomass obtained in the olive oil extraction. Energy 2014, 75, 146–152. [Google Scholar] [CrossRef]

- Gómez-De La Cruz, F.J.; Palomar-Carnicero, J.M.; Casanova-Peláez, P.J.; Cruz-Peragón, F. Experimental determination of effective moisture diffusivity during the drying of clean olive stone: Dependence of temperature, moisture content and sample thickness. Fuel Process. Technol. 2015, 137, 320–326. [Google Scholar] [CrossRef]

- Coimbra, M.A.; Waldron, K.W.; Selvendran, R.R. Isolation and characterisation of cell wall polymers from the heavily lignified tissues of olive (Olea europaea) seed hull. Carbohydr. Polym. 1995, 27, 285–294. [Google Scholar] [CrossRef]

- Cuevas, M.; Sánchez, S.; Bravo, V.; Cruz, N.; García, J.F. Fermentation of enzymatic hydrolysates from olive stones by Pachysolen tannophilus. J. Chem. Technol. Biotechnol. 2009, 84, 461–467. [Google Scholar] [CrossRef]

- Cuevas, M.; García, J.F.; Hodaifa, G.; Sánchez, S. Oligosaccharides and sugars production from olive stones by autohydrolysis and enzymatic hydrolysis. Ind. Crops Prod. 2015, 70, 100–106. [Google Scholar] [CrossRef]

- Cuevas, M.; Sánchez, S.; García, J.F.; Baeza, J.; Parra, C.; Freer, J. Enhanced ethanol production by simultaneous saccharification and fermentation of pretreated olive stones. Renew. Energy 2015, 74, 839–847. [Google Scholar] [CrossRef]

- Cuevas, M.; Saleh, M.; García-Martín, J.F.; Sánchez, S. Influence of solid loading on D-xylose production through dilute sulphuric acid hydrolysis of olive stones. Grasas Aceites 2015, 66, e084. [Google Scholar]

- Antonopoulou, G.; Kampranis, A.; Ntaikou, I.; Lyberatos, G. Enhancement of liquid and gaseous biofuels production from agro-industrial residues after thermochemical and enzymatic pretreatment. Front. Sustain. Food Syst. 2019, 3, 92. [Google Scholar] [CrossRef]

- Montané, D.; Salvadó, J.; Torras, C.; Farriol, X. High-temperature dilute-acid hydrolysis of olive stones for furfural production. Biomass Bioenergy 2002, 22, 295–304. [Google Scholar] [CrossRef]

- Nabarlatz, D.; Ebringerová, A.; Montané, D. Autohydrolysis of agricultural by-products for the production of xylo-oligosaccharides. Carbohydr. Polym. 2007, 69, 20–28. [Google Scholar] [CrossRef]

- Hernández, V.; Romero-García, J.M.; Dávila, J.A.; Castro, E.; Cardona, C.A. Techno-economic and environmental assessment of an olive stone based biorefinery. Resour. Conserv. Recycl. 2014, 92, 145–150. [Google Scholar] [CrossRef]

- Goldfarb, J.L.; Buessing, L.; Gunn, E.; Lever, M.; Billias, A.; Casoliba, E.; Schievano, A.; Adani, F. Novel integrated biorefinery for olive mill waste management: Utilization of secondary waste for water treatment. ACS Sustain. Chem. Eng. 2017, 5, 876–884. [Google Scholar] [CrossRef]

- Acharya, B.; Sule, I.; Dutta, A. A review on advances of torrefaction technologies for biomass processing. Biomass Convers. Biorefinery 2012, 2, 349–369. [Google Scholar] [CrossRef]

- Costa, F.F.; Wang, G.; Costa, M. Combustion kinetics and particle fragmentation of raw and torrified pine shells and olive stones in a drop tube furnace. Proc. Combust. Inst. 2015, 35, 3591–3599. [Google Scholar] [CrossRef]

- Cuevas, M.; Martínez Cartas, M.L.; Sánchez, S. Effect of short-time hydrothermal carbonization on the properties of hydrochars prepared from olive-fruit endocarps. Energy Fuels 2019, 33, 313–322. [Google Scholar] [CrossRef]

- Álvarez-Murillo, A.; Román, S.; Ledesma, B.; Sabio, E. Study of variables in energy densification of olive stone by hydrothermal carbonization. J. Anal. Appl. Pyrolysis 2015, 113, 307–314. [Google Scholar] [CrossRef]

- Sánchez, F.; San Miguel, G. Improved fuel properties of whole table olive stones via pyrolytic processing. Biomass Bioenergy 2016, 92, 1–11. [Google Scholar] [CrossRef]

- Martín-Lara, M.A.; Ronda, A.; Blázquez, G.; Pérez, A.; Calero, M. Pyrolysis kinetics of the lead-impregnated olive stone by non-isothermal thermogravimetry. Process Saf. Environ. Prot. 2018, 113, 448–458. [Google Scholar] [CrossRef]

- Bartocci, P.; D’Amico, M.; Moriconi, N.; Bidini, G.; Fantozzi, F. Pyrolysis of olive stone for energy purposes. Energy Procedia 2015, 82, 374–380. [Google Scholar] [CrossRef]

- Marcilla, A.; García, A.N.; Pastor, M.V.; León, M.; Sánchez, A.J.; Gómez, D.M. Thermal decomposition of the different particles size fractions of almond shells and olive stones. Thermal behaviour changes due to the milling processes. Thermochim. Acta 2013, 564, 24–33. [Google Scholar] [CrossRef]

- Gomez-Martin, A.; Chacartegui, R.; Ramirez-Rico, J.; Martinez-Fernandez, J. Performance improvement in olive stone’s combustion from a previous carbonization transformation. Fuel 2018, 228, 254–262. [Google Scholar] [CrossRef]

- Adánez, J.; De Diego, L.F.; García-Labiano, F.; Abad, A.; Abanades, J.C. Determination of biomass char combustion reactivities for FBC applications by a combined method. Ind. Eng. Chem. Res. 2001, 40, 4317–4323. [Google Scholar] [CrossRef]

- Karakaş, C.; Özçimen, D.; İnan, B. Potential use of olive stone biochar as a hydroponic growing medium. J. Anal. Appl. Pyrolysis 2017, 125, 17–23. [Google Scholar] [CrossRef]

- Molina-Sabio, M.; Jesús Sánchez-Montero, M.; Juarez-Galan, J.M.; Salvador, F.; Rodríguez-Reinoso, F.; Salvador, A. Development of porosity in a char during reaction with steam or supercritical water. J. Phys. Chem. B 2006, 110, 12360–12364. [Google Scholar] [CrossRef]

- Alslaibi, T.M.; Abustan, I.; Ahmad, M.A.; Foul, A.A. Cadmium removal from aqueous solution using microwaved olive stone activated carbon. J. Environ. Chem. Eng. 2013, 1, 589–599. [Google Scholar] [CrossRef]

- Hazzaa, R.; Hussein, M. Adsorption of cationic dye from aqueous solution onto activated carbon prepared from olive stones. Environ. Technol. Innov. 2015, 4, 36–51. [Google Scholar] [CrossRef]

- Moreno, N.; Caballero, Á.; Morales, J.; Rodríguez-Castellón, E. Improved performance of electrodes based on carbonized olive stones/S composites by impregnating with mesoporous TiO2 for advanced Li-S batteries. J. Power Sources 2016, 313, 21–29. [Google Scholar] [CrossRef]

- Moreno, N.; Caballero, A.; Hernán, L.; Morales, J. Lithium-sulfur batteries with activated carbons derived from olive stones. Carbon N. Y. 2014, 70, 241–248. [Google Scholar] [CrossRef]

- Gómez-Barea, A.; Arjona, R.; Ollero, P. Pilot-plant gasification of olive stone: A technical assessment. Energy Fuels 2005, 19, 598–605. [Google Scholar] [CrossRef]

- Di Blasi, C.D.; Signorelli, G.; Portoricco, G. Countercurrent fixed-bed gasification of biomass at laboratory scale. Ind. Eng. Chem. Res. 1999, 38, 2581. [Google Scholar] [CrossRef]

- Skoulou, V.; Swiderski, A.; Yang, W.; Zabaniotou, A. Process characteristics and products of olive kernel high temperature steam gasification (HTSG). Bioresour. Technol. 2009, 100, 2444–2451. [Google Scholar] [CrossRef]

- Dogru, M. Experimental results of olive pits gasification in a fixed bed downdraft gasifier system. Int. J. Green Energy 2013, 10, 348–361. [Google Scholar] [CrossRef]

- Margaritis, N.K.; Grammelis, P.; Vera, D.; Jurado, F. Assessment of operational results of a downdraft biomass gasifier coupled with a gas engine. Procedia—Soc. Behav. Sci. 2012, 48, 857–867. [Google Scholar] [CrossRef]

- Rosúa, J.M.; Pasadas, M. Biomass potential in Andalusia, from grapevines, olives, fruit trees and poplar, for providing heating in homes. Renew. Sustain. Energy Rev. 2012, 16, 4190–4195. [Google Scholar] [CrossRef]

- Morán, J.C.; Míguez, J.L.; Porteiro, J.; Patiño, D.; Granada, E. Low-quality fuels for small-scale combustion boilers: An experimental study. Energy Fuels 2015, 29, 3064–3081. [Google Scholar] [CrossRef]

- González, J.F.; González-García, C.M.; Ramiro, A.; González, J.; Sabio, E.; Gañán, J.; Rodríguez, M.A. Combustion optimisation of biomass residue pellets for domestic heating with a mural boiler. Biomass Bioenergy 2004, 27, 145–154. [Google Scholar] [CrossRef]

- Mami, M.A.; Mätzing, H.; Gehrmann, H.J.; Stapf, D.; Bolduan, R.; Lajili, M. Investigation of the olive mill solid wastes pellets combustion in a counter-current fixed bed reactor. Energies 2018, 11, 1965. [Google Scholar] [CrossRef]

- Grammelis, P.; Kakaras, E. Biomass combustion modeling in fluidized beds. Energy Fuels 2005, 19, 292–297. [Google Scholar] [CrossRef]

- Scala, F.; Chirone, R. Characterization and early detection of bed agglomeration during the fluidized bed combustion of olive husk. Energy Fuels 2006, 20, 120–132. [Google Scholar] [CrossRef]

- Abreu, P.; Casaca, C.; Costa, M. Ash deposition during the co-firing of bituminous coal with pine sawdust and olive stones in a laboratory furnace. Fuel 2010, 89, 4040–4048. [Google Scholar] [CrossRef]

- De Moraes Pinheiro, S.M.; Font, A.; Soriano, L.; Tashima, M.M.; Monzó, J.; Borrachero, M.V.; Payá, J. Olive-stone biomass ash (OBA): An alternative alkaline source for the blast furnace slag activation. Constr. Build. Mater. 2018, 178, 327–338. [Google Scholar] [CrossRef]

- Font, A.; Soriano, L.; de Moraes Pinheiro, S.M.; Tashima, M.M.; Monzó, J.; Borrachero, M.V.; Payá, J. Design and properties of 100% waste-based ternary alkali-activated mortars: Blast furnace slag, olive-stone biomass ash and rice husk ash. J. Clean. Prod. 2020, 243, 118568. [Google Scholar] [CrossRef]

- Topal, H.; Taner, T.; Naqvi, S.A.H.; Altınsoy, Y.; Amirabedin, E.; Ozkaymak, M. Exergy analysis of a circulating fluidized bed power plant co-firing with olive pits: A case study of power plant in Turkey. Energy 2017, 140, 40–46. [Google Scholar] [CrossRef]

- Vamvuka, D.; Papas, M.; Galetakis, M.; Sfakiotakis, S. Thermal valorization of an animal sludge for energy recovery via co-combustion with olive kernel in a fluidized bed unit: Optimization of emissions. Energy Fuels 2016, 30, 5825–5834. [Google Scholar] [CrossRef]

- Manzanares, P.; Ballesteros, I.; Negro, M.J.; González, A.; Oliva, J.M.; Ballesteros, M. Processing of extracted olive oil pomace residue by hydrothermal or dilute acid pretreatment and enzymatic hydrolysis in a biorefinery context. Renew. Energy 2020, 145, 1235–1245. [Google Scholar] [CrossRef]

- García-Martín, J.F.; Barrios, C.C.; Alés-Álvarez, F.J.; Dominguez-Sáez, A.; Alvarez-Mateos, P. Biodiesel production from waste cooking oil in an oscillatory flow reactor. Performance as a fuel on a TDI diesel engine. Renew. Energy 2018, 125, 546–556. [Google Scholar] [CrossRef]

- Liang, M.H.; Jiang, J.G. Advancing oleaginous microorganisms to produce lipid via metabolic engineering technology. Prog. Lipid Res. 2013, 52, 395–408. [Google Scholar] [CrossRef] [PubMed]

- Lama-Muñoz, A.; Álvarez-Mateos, P.; Rodríguez-Gutiérrez, G.; Durán-Barrantes, M.M.; Fernández-Bolaños, J. Biodiesel production from olive-pomace oil of steam-treated alperujo. Biomass Bioenergy 2014, 67, 443–450. [Google Scholar] [CrossRef]

- Dodos, G.S.; Tsesmeli, C.E.; Zannikos, F. Evaluation of the antimicrobial activity of synthetic and natural phenolic type antioxidants in biodiesel fuel. Fuel 2017, 201, 150–161. [Google Scholar] [CrossRef]

- Hernández, D.; Astudillo, L.; Gutiérrez, M.; Tenreiro, C.; Retamal, C.; Rojas, C. Biodiesel production from an industrial residue: Alperujo. Ind. Crops Prod. 2014, 52, 495–498. [Google Scholar] [CrossRef]

- Akgün, N.; Išcan, E. Effects of process variables for biodiesel production by transesterification. Eur. J. Lipid Sci. Technol. 2007, 5, 486–492. [Google Scholar] [CrossRef]

- Yücel, Y. Optimization of biocatalytic biodiesel production from pomace oil using response surface methodology. Fuel Process. Technol. 2012, 99, 97–102. [Google Scholar] [CrossRef]

- Ouachab, N.; Tsoutsos, T. Study of the acid pretreatment and biodiesel production from olive pomace oil. J. Chem. Technol. Biotechnol. 2013, 88, 1175–1181. [Google Scholar] [CrossRef]

- Willson, R.M.; Wiesman, Z.; Brenner, A. Analyzing alternative bio-waste feedstocks for potential biodiesel production using time domain (TD)-NMR. Waste Manag. 2010, 30, 1881–1888. [Google Scholar] [CrossRef]

- Alvarez Serafni, M.S.; Tonetto, G.M. Production of fatty acid methyl esters from an olive oil industry waste. Brazilian J. Chem. Eng. 2019, 36, 285–297. [Google Scholar] [CrossRef]

- Ayadi, I.; Belghith, H.; Gargouri, A.; Guerfali, M. Screening of new oleaginous yeasts for single cell oil production, hydrolytic potential exploitation and agro-industrial by-products valorization. Process Saf. Environ. Prot. 2018, 119, 104–114. [Google Scholar] [CrossRef]

- Kamoun, O.; Ayadi, I.; Guerfali, M.; Belghith, H.; Gargouri, A.; Trigui-Lahiani, H. Fusarium verticillioides as a single-cell oil source for biodiesel production and dietary supplements. Process Saf. Environ. Prot. 2018, 118, 68–78. [Google Scholar] [CrossRef]

- Kamoun, O.; Muralitharan, G.; Belghith, H.; Gargouri, A.; Trigui-Lahiani, H. Suitable carbon sources selection and ranking for biodiesel production by oleaginous Mucor circinelloides using multi-criteria analysis approach. Fuel 2019, 257, 116117. [Google Scholar] [CrossRef]

- Tekin, A.R.; Dalgiç, A.C. Biogas production from olive pomace. Resour. Conserv. Recycl. 2000, 30, 301–313. [Google Scholar] [CrossRef]

- Milanese, M.; De Risi, A.; De Riccardis, A.; Laforgia, D. Numerical study of anaerobic digestion system for olive pomace and mill wastewater. Energy Procedia 2014, 45, 141–149. [Google Scholar] [CrossRef]

- Orive, M.; Cebrián, M.; Zufía, J. Techno-economic anaerobic co-digestion feasibility study for two-phase olive oil mill pomace and pig slurry. Renew. Energy 2016, 97, 532–540. [Google Scholar] [CrossRef]

- Riggio, V.; Comino, E.; Rosso, M. Energy production from anaerobic co-digestion processing of cow slurry, olive pomace and apple pulp. Renew. Energy 2015, 83, 1043–1049. [Google Scholar] [CrossRef]

- El Gnaoui, Y.; Sounni, F.; Bakraoui, M.; Karouach, F.; Benlemlih, M.; Barz, M.; El Bari, H. Anaerobic co-digestion assessment of olive mill wastewater and food waste: Effect of mixture ratio on methane production and process stability. J. Environ. Chem. Eng. 2020, 8, 103874. [Google Scholar] [CrossRef]

- De la Lama, D.; Borja, R.; Rincón, B. Performance evaluation and substrate removal kinetics in the semi-continuous anaerobic digestion of thermally pretreated two-phase olive pomace or “Alperujo”. Process Saf. Environ. Prot. 2017, 105, 288–296. [Google Scholar] [CrossRef]

- Elalami, D.; Carrere, H.; Abdelouahdi, K.; Garcia-Bernet, D.; Peydecastaing, J.; Vaca-Medina, G.; Oukarroum, A.; Zeroual, Y.; Barakat, A. Mild microwaves, ultrasonic and alkaline pretreatments for improving methane production: Impact on biochemical and structural properties of olive pomace. Bioresour. Technol. 2020, 299, 22591. [Google Scholar] [CrossRef]

- Barbanera, M.; Lascaro, E.; Stanzione, V.; Esposito, A.; Altieri, R.; Bufacchi, M. Characterization of pellets from mixing olive pomace and olive tree pruning. Renew. Energy 2016, 88, 185–191. [Google Scholar] [CrossRef]

- Hernández, D.; Fernández-Puratich, H.; Rebolledo-Leiva, R.; Tenreiro, C.; Gabriel, D. Evaluation of sustainable manufacturing of pellets combining wastes from olive oil and forestry industries. Ind. Crops Prod. 2019, 134, 338–346. [Google Scholar] [CrossRef]

- Lajili, M.; Guizani, C.; Escudero Sanz, F.J.; Jeguirim, M. Fast pyrolysis and steam gasification of pellets prepared from olive oil mill residues. Energy 2018, 150, 61–68. [Google Scholar] [CrossRef]

- Benavente, V.; Calabuig, E.; Fullana, A. Upgrading of moist agro-industrial wastes by hydrothermal carbonization. J. Anal. Appl. Pyrolysis 2015, 113, 89–98. [Google Scholar] [CrossRef]

- Zribi, M.; Lajili, M.; Escudero-Sanz, F.J. Hydrogen enriched syngas production via gasification of biofuels pellets/powders blended from olive mill solid wastes and pine sawdust under different water steam/nitrogen atmospheres. Int. J. Hydrog. Energy 2019, 44, 11280–11288. [Google Scholar] [CrossRef]

- Schacht, C.; Zetzl, C.; Brunner, G. From plant materials to ethanol by means of supercritical fluid technology. J. Supercrit. Fluids 2008, 46, 299–321. [Google Scholar] [CrossRef]

- Lee, Z.; Park, S. Particulate and gaseous emissions from a direct-injection spark ignition engine fueled with bioethanol and gasoline blends at ultra-high injection pressure. Renew. Energy 2020, 149, 80–90. [Google Scholar] [CrossRef]

- Redel-Macías, M.D.; Pinzi, S.; Leiva, D.; Cubero-Atienza, A.J.; Dorado, M.P. Air and noise pollution of a diesel engine fueled with olive pomace oil methyl ester and petrodiesel blends. Fuel 2012, 95, 615–625. [Google Scholar] [CrossRef]

- López, I.; Pinzi, S.; Leiva-Candia, D.; Dorado, M.P. Multiple response optimization to reduce exhaust emissions and fuel consumption of a diesel engine fueled with olive pomace oil methyl ester/diesel fuel blends. Energy 2016, 117, 398–404. [Google Scholar] [CrossRef]

- Özçelik, A.E.; Acaroğlu, M.; Köse, H. Determination of combustion characteristics of olive pomace biodiesel–Eurodiesel fuel mixtures. Energy Sources Part A Recover. Util. Environ. Eff. 2019, 42, 1476–1489. [Google Scholar] [CrossRef]

| Composition (wt.%) | Reference | ||

|---|---|---|---|

| Cellulose | Hemicellulose | Lignin | |

| 36.6 | 19.7 | 20.8 | [6] |

| 30.3 | 17.9 | 24.1 | [4] |

| 39.1 | 25.7 | 14.3 | [10] |

| 36.4 | 21.5 | 17.1 | [11] |

| 25.4 | 19.0 | 18.5 | [12] |

| 25.0 | 18.3 | 18.8 | [13] |

| 36.5 | 20.2 | 22.5 | [14] |

| 36.5 | 20.8 | 21.3 | [15] |

| Element (%) | Reference | ||||

|---|---|---|---|---|---|

| C | H | O | N | S | |

| 44.6 | 6.7 | 47.9 | 0.8 | 0.0 | [6] |

| 46.1 | 6.4 | 47.2 | 0.4 | 0.0 | [16] |

| Composition (wt.%) | Reference | ||

|---|---|---|---|

| Cellulose | Hemicellulose | Lignin | |

| 29.9 | 28.1 | 27.7 | [23] |

| 33.5 | 24.5 | 23.1 | [22] |

| 27.1 | 32.2 | 40.4 | [24] |

| 36.4 | 26.8 | 26.0 | [25] |

| Composition (wt.%). | Reference | |||||

|---|---|---|---|---|---|---|

| C | H | O | N | S | Ash | |

| 51.2 | 6.0 | 41.9 | 0.15 | 0.02 | 0.78 | [19] |

| 50.1 | 5.9 | 42.0 | 0.6 | 0.02 | 1.33 | [31] |

| 46.6 | 6.3 | 45.2 | 1.8 | 0.10 | 1.40 | [32] |

| 48.6 | 5.7 | 44.1 | 1.6 | 0.05 | 1.90 | [33] |

| Process | Moisture and Volatile Matter * % | Fat Matter * % (In Wet Basis) | Fat Matter ** % (In Dry Basis) | Production * kg/t Olives |

|---|---|---|---|---|

| Pressure | 22–35 | 5.0–8.0 | 7.0–11.0 | 250–350 |

| Three outlets | 45–55 | 3.0–4.5 | 6.0–8.0 | 450–520 |

| Two outlets | 65–75 | 2.0–3.5 | 6.0–7.5 | 800–850 |

| Pre-Treatment | Commercial Enzyme Preparation | SSF Yeast | Fermentation Yeast | Fermentation Yield (kg/kg) | Overall Yield (kg/kg OP) | Reference |

|---|---|---|---|---|---|---|

| 0.5 N H3PO4, 90 °C, 240 min | - | - | P. tannophilus | 0.38 | NP | [52] |

| 1 N C2HF3O2, 90 °C, 240 min | P. tannophilus | 0.37 | NP | [60] | ||

| 75 mM C2H2O4, 150 °C, 240 min | - | - | P. stipitis | 0.00 | 0.00 | [14] |

| 1 N H2SO4, 90 °C, 300 min | - | - | C. tropicalis | 0.42 | 0.070 | [16] |

| * log R0 = 3.54 | - | - | C. tropicalis | 0.44 | 0.072 | [47] |

| ** 230 °C, 1% (wt.) H2SO4 impregnation | Novozymes Celluclast 1.5 L and Novozymes 188 | S. cerevisiae | - | - | 0.072 | [13] |

| * 0.08 N H2SO4, 107 °C, 5 min | Novozymes Celluclast 1.5 L and Novozymes 188 | S. cerevisiae | - | - | 0.099 | [4] |

| 2.4% (wt.) H2SO4 130 °C, 84 min + 7% H2O2 (w/v), 80 °C, 90 min | Novozymes Cellic CTec3 and Novozymes 50010 | S. cerevisiae | E. coli | 0.43 | 0.15 | [12] |

| ** 1% (wt.) H3PO4, 195 °C, 10 min | Novozymes 50013 and Novozymes 50010 | S. cerevisiae | S. stipitis | 0.35 | 0.16 | [43] |

| Pre-Treatment | Commercial Enzyme Preparation | Product | Fermentation Yeast | SSF Yeast | Overall Yield (kg/kg OS) | Reference |

|---|---|---|---|---|---|---|

| 0.01 M H2SO4, 201 °C, 5.2 min | Novozymes Celluclast 1.5 L | Ethanol | P. tannophilus | - | 0.122 | [23] |

| Xylitol | P. tannophilus | - | 0.067 | |||

| *log R0 = 4.39 | Cellulase from T. reesei EC 3.2.1.4 | Ethanol | P. tannophilus | - | NP | [82] |

| Xylitol | P. tannophilus | - | NP | |||

| 0.025 M H2SO4, 195 °C, 5 min | Novozymes Celluclast 1.5 L | Ethanol | P. tannophilus | - | 0.103 | [18] |

| Xylitol | P. tannophilus | - | 0.092 | |||

| 1.5% (w/v) H2SO4, 121 °C, 60 min | Novozymes Celluclast 1.5 L and Novozymes 188 | Ethanol | - | P. tannophilus | 0.068 | [86] |

| Organosolv, 220 °C | - | Ethanol | - | S. cerevisiae | 0.131 | [84] |

| Extraction/Solvent | Esterification | Transesterification | FAME Content (wt.%) | Overall Yield (wt.%) | Reference | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Catalyst | MR | t (min) | T (°C) | Catalyst | MR | t (min) | T (°C) | ||||

| Soxhlet/hexane | 1 wt.% H2SO4 | 6:1 | 80 | 60 | 1 wt.% NaOH | 6:1 | 80 | 60 | 98.9 | - | [126] |

| Stirring/hexane | - | - | - | - | 0.54 wt.% KOH | 1:2 | 60 | 60 | 94.7 | 4.0 ± 0.0 | [128] |

| - | - | - | - | - | 1.3 wt.% Ba(OH)2 | 5:1 | 80 | 65 | 93.4 | - | [129] |

| - | - | - | - | - | 5.8 wt.% biocatalyst * | 5.3:1 | 1440 | 40 | 93.7 | - | [130] |

| Stirring/hexane | 20 wt.% H2SO4 | 35:1 | 60 | 40 | 0.6 wt.% KOH | 9:1 | 120 | 60 | 97.8 | 3.8 ± 1.8 | [131] |

| Soxhlet/hexane | - | - | - | - | 1 wt.% NaOH | 9:1 | 60 | 60 | 95.5 | 6.6 ± 1.6 | [132] |

| - | 3 wt.% Zn stearate | 30:1 | 30 | 140 | 3 wt.% Zn stearate | 30:1 | 30 | 140 | 84.1 | - | [133] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

García Martín, J.F.; Cuevas, M.; Feng, C.-H.; Álvarez Mateos, P.; Torres García, M.; Sánchez, S. Energetic Valorisation of Olive Biomass: Olive-Tree Pruning, Olive Stones and Pomaces. Processes 2020, 8, 511. https://doi.org/10.3390/pr8050511

García Martín JF, Cuevas M, Feng C-H, Álvarez Mateos P, Torres García M, Sánchez S. Energetic Valorisation of Olive Biomass: Olive-Tree Pruning, Olive Stones and Pomaces. Processes. 2020; 8(5):511. https://doi.org/10.3390/pr8050511

Chicago/Turabian StyleGarcía Martín, Juan Francisco, Manuel Cuevas, Chao-Hui Feng, Paloma Álvarez Mateos, Miguel Torres García, and Sebastián Sánchez. 2020. "Energetic Valorisation of Olive Biomass: Olive-Tree Pruning, Olive Stones and Pomaces" Processes 8, no. 5: 511. https://doi.org/10.3390/pr8050511

APA StyleGarcía Martín, J. F., Cuevas, M., Feng, C.-H., Álvarez Mateos, P., Torres García, M., & Sánchez, S. (2020). Energetic Valorisation of Olive Biomass: Olive-Tree Pruning, Olive Stones and Pomaces. Processes, 8(5), 511. https://doi.org/10.3390/pr8050511