Implementation Criteria for Intelligent Systems in Motor Production Line Process Management

Abstract

:1. Introduction

1.1. Research Background

1.2. Research Objectives

1.3. Literature Review

1.3.1. Intelligent Systems and Industry 4.0

- According to some scholars [1], CPS is a network and engineering system that can integrate both cybernetic and physical worlds. That is, it can be combined with physical sensors and other integrated systems in the field of virtual computer control called “virtual-integrated systems.” Some embedded devices, such as the IoT and sensor networks, have systems similar to CPS. Embedded devices, however, emphasize device performance, whereas the CPS is a combined system of physical devices and network with emphasis on the relationship between their interaction [5].

- The CPS is typically used in automation and sensor systems (e.g., robots, autonomous driving systems, monitoring systems, and process control systems) and in manufacturing [6]. This means that the physical devices in the manufacturing system can generate the same virtual model through the CPS. The data generated by the physical system are analyzed through the network and thereafter applied to the virtual model in real time in order to accurately present the current status of the physical system. The advantage of the virtual model is that it can be optimized through big data and artificial intelligence, which in turn can be used in manufacturing systems [7].

1.3.2. Intelligent Application for Motor Production Line

2. Materials and Methods

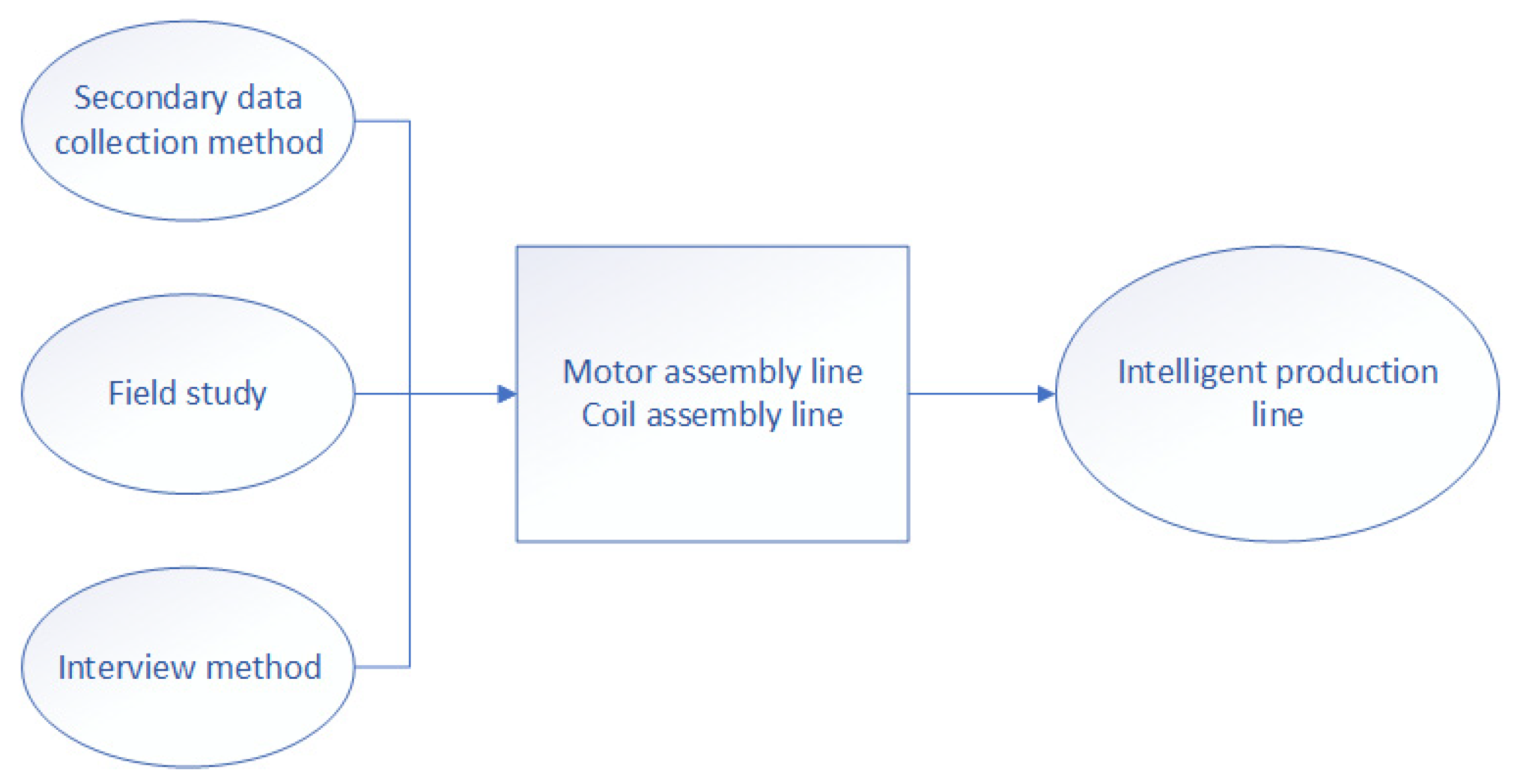

2.1. Research Architecture and Methods

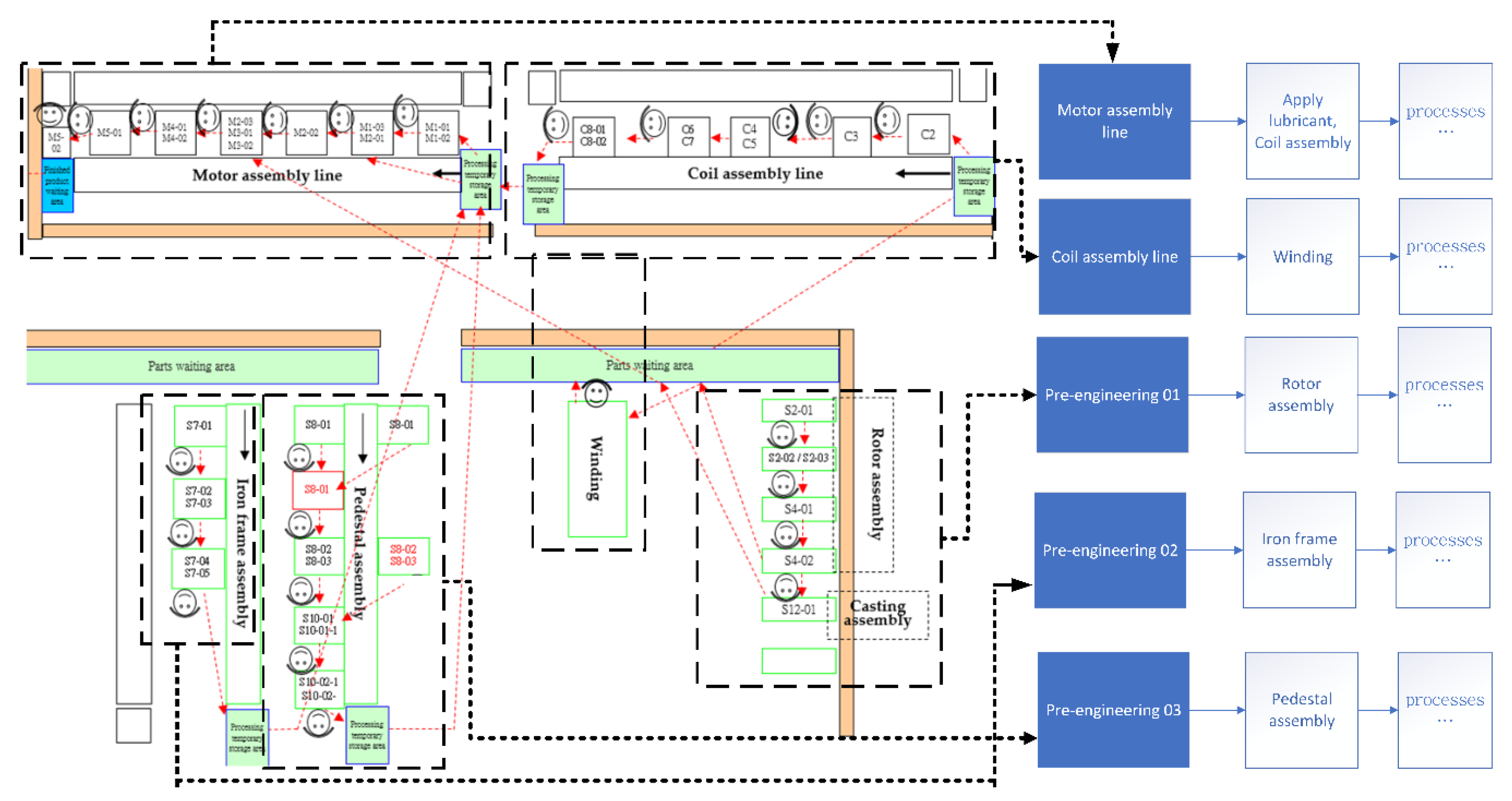

2.2. Research Objects

- Winding

- (1)

- Check if the rotor is rusty and there is a mounting sleeve; there must be five grooves. After confirmation, ensure that the machine is inserted according to the direction.

- (2)

- Press the button for the machine to start winding.

- (3)

- Use a wooden shaft to number the parts.

- (4)

- Ensure that the copper wire is not cracked. The diameter of the rotor should not exceed those of the casing and spot welding of the rotor.

- Commutator spot welding

- (1)

- Place the coil into the machine according to the direction.

- (2)

- Press the button to allow the machine to start the spot welding.

- (3)

- Check whether the appearance of parts is complete and if there are five grooves. The NG product is placed in the NG box, and good products proceed to the next step.

- (4)

- Photographs are taken and saved for every 1000 products.

- Commutator cutting

- (1)

- Place the parts of the machine according to the direction.

- (2)

- Start the button to allow machine cutting.

- (3)

- Check whether the appearance of parts is intact; put the NG product in the NG box.

- (4)

- Install the bolt gauge tool to the commutator after cutting.

- Pneumatic rectification

- (1)

- Place the parts in the machine.

- (2)

- Clean the parts with a brush.

- (3)

- Use a magnifying glass to check the appearance of parts and for foreign objects. Put the NG product into the NG box; the good products proceed to the next step.

- Air pressure removal

- (1)

- The parts are placed into the machine and aligned with the air-jet holes for air-jet cleaning.

- (2)

- Check the parts for foreign matter and whether the parts appear complete and bright. Place the NG product in the NG box; the good products proceed to the next step.

- Washer group voltage withstand, absolute resistance, and impedance tests

- (1)

- Place the washer into the machine.

- (2)

- Press the switch to initiate the washer punch.

- (3)

- Put the parts into the machine for voltage withstand, absolute resistance, and impedance tests. Put the NG products into the NG box; good products proceed to next step.

- Bearing assembly

- (1)

- Place the bearing and coil in the machine in the same direction.

- (2)

- Press the switch to initiate punching.

- (3)

- Check whether the parts are intact and correctly aligned. Place the NG product into the NG box; good products proceed to the next step.

- Bearing distance check

- (1)

- Place the parts of the inspection machine as directed.

- (2)

- Press the button to initiate machine check.

- (3)

- Check if the parameters are within range. Put the NG product into the NG box; good products proceed the next step.

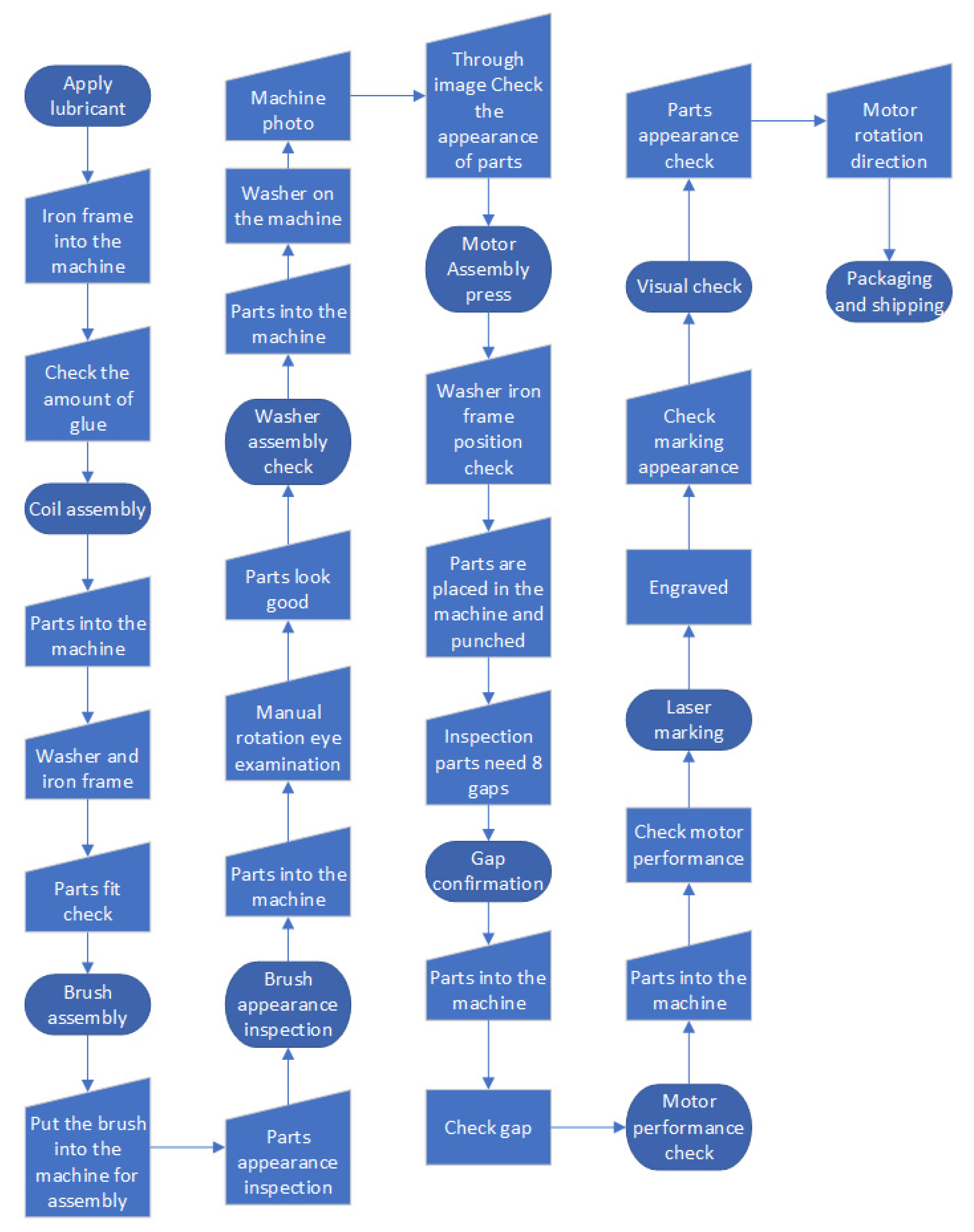

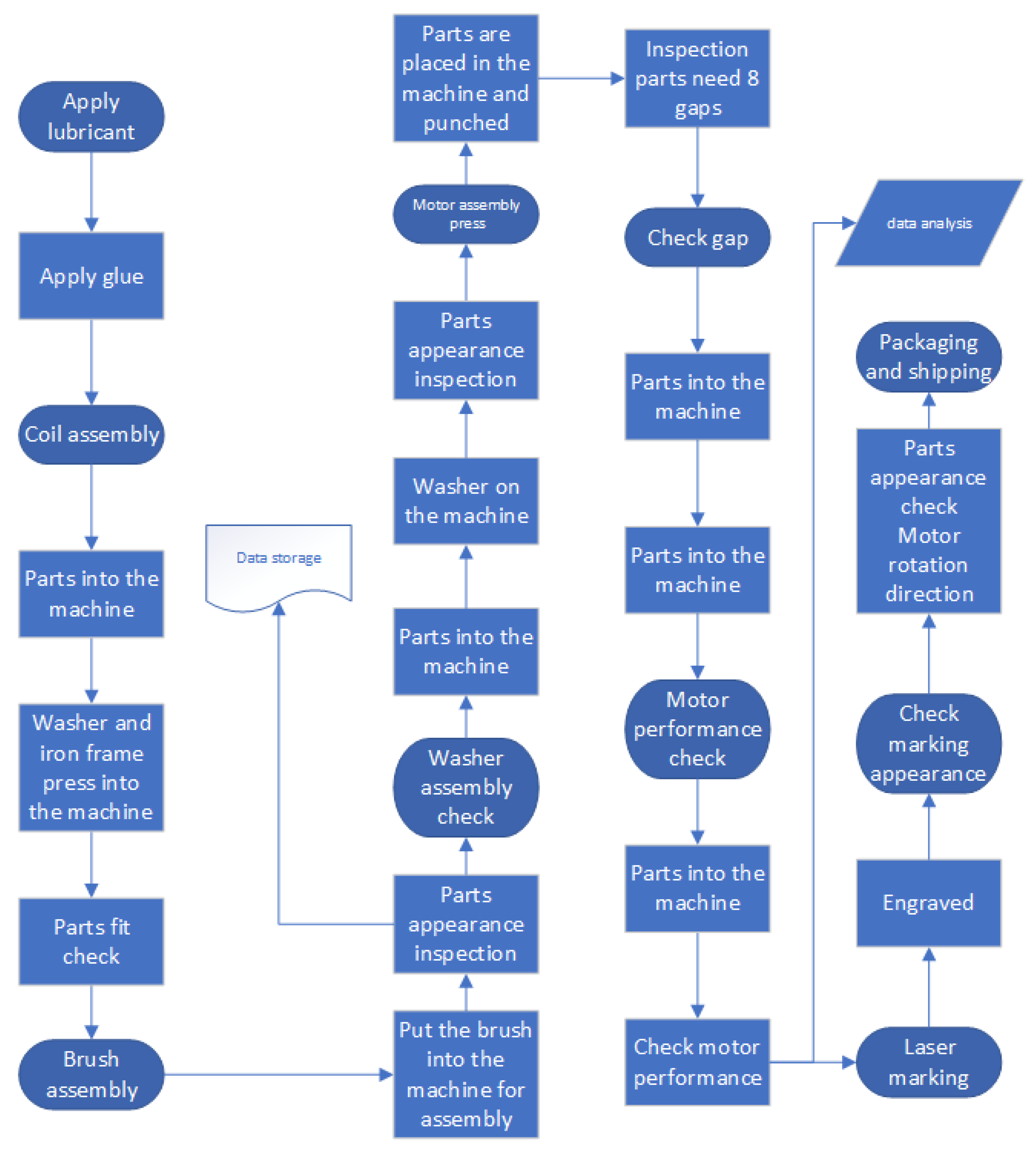

- Lubricant application

- (1)

- Align the iron frame with the coil cut groove and place it in the dispenser.

- (2)

- Press the switch to dispense the machine.

- (3)

- Check whether the parts have a sufficient amount of glue. The NG product is placed into the NG box, and the good products proceed to the next step.

- Coil assembly

- (1)

- Place the parts of the machine according to the direction.

- (2)

- Clip the iron frame into the coil with the white assistive device and take it out.

- (3)

- Check whether the parts are installed. Place the NG product into the NG box; good products proceed to the next step.

- Brush assembly

- (1)

- Align the red part of the brush with the machine.

- (2)

- Press the switch to open the terminal.

- (3)

- Assemble the parts and coils into the finished product according to the working procedure.

- (4)

- To provide a gap in the iron frame, check the positioning point. The base assembly must be accurately positioned. The NG product is placed in the NG box; good products proceed to the next step.

- Brush appearance inspection

- (1)

- Assemble the machine parts.

- (2)

- Inspect the parts for damage through closed-circuit television. The NG products are placed in the NG box, and the good products proceed to the next step.

- Washer enrollment and inspection

- (1)

- Put the small and large washers on the machine and install the parts.

- (2)

- Press the button to connect the washer.

- (3)

- Put the parts into the machine according to the indicated direction, and capture image.

- (4)

- Ensure that no washer is missing based on the image. Put the NG product into the NG box, and good products proceed to the next step.

- Motor press assembly

- (1)

- Check whether the size of the washer is correct, and the iron frame cover must fully fit the iron frame.

- (2)

- Align the machine parts.

- (3)

- Press the button to initiate pressing.

- (4)

- After installation, ensure that there are eight cut-outs in the parts. Place the NG product into the NG box; good products proceed to the next step.

- Clearance confirmation

- (1)

- Place the parts of the inspection machine.

- (2)

- Press the button for the machine to detect the gap. Place the NG box out of the specification range; the good products proceed to the next step.

- Motor performance check and lighting

- (1)

- Align the parts of the inspection machine.

- (2)

- Press the button for the machine to transport the parts until they touch the terminals.

- (3)

- Press the switch to start measurement and check the 88 items of motor performance data.

- (4)

- Check if the data are within range. Put the NG product into the NG box; good products will be automatically engraved with a number. Proceed to the next step.

- Final visual inspection

- (1)

- Use a tool to check if the screw pattern is correct.

- (2)

- Use a tool to check whether the laser marking (seal) is sufficient.

- (3)

- Check if the motor rotation direction is correct.

- (4)

- Put the motor into the machine to check whether the terminal is defective. Put the NG product into the NG box and put the good product into the box according to its number. Finally, pack and ship.

2.3. Interview Outline

- Interview questions related to production line automation.

- (1)

- Is each part numbered and recorded in the computer to manage all parts? If so, how does it work?

- (2)

- Is there a sensor installed on the production unit to detect, for example, the current production quantity or whether the parts of the unit itself are faulty? If so, what is the current function of the sensor? If none, have you considered installing it?

- (3)

- Will the photographs captured by the CCTV (Closed Circuit Television, is a photographic equipment and equipment for capturing images to improve quality, etc.) and machine-measured data be stored? If yes, are they classified and used for other applications?

- (4)

- In the motor assembly line, how many photographs are taken by the CCTV brush appearance inspection, and which of these can provide basic information for image recognition in the future?

- (5)

- Does the company currently have any expectations? To what extent has the production line been automated, such as the introduction of robotic arms? If so, can the reduced labor and machine costs after the introduction be maintained or increased to production capacity?

- (6)

- In the previous interview, the two managers mentioned that the identification of imported images requires huge data to train the AI and generate a model. How much data are currently stored in the factory? Do the images identify the manufacturer of the device?

- (7)

- In terms of data collection, it is evident that good data must be retained, but in order to introduce image recognition or other machine learning models, considerable NG data are also necessary. Are there any plans for retaining NG data?

- Production line interview questions

- (1)

- Will the photographs captured by the CCTV and machine-measured data be stored? If yes, are they classified and used for other applications?

- (2)

- To what extent is the production line currently automated, and which parts are produced using both machinery and labor?

- (3)

- The images captured by the CCTV are used for appearance inspection. How is it judged whether the product is OK or NG? Some products have missing corners but can still be used, what is the criterion for making this decision?

- (4)

- Production line standard operating procedure.

3. Results

3.1. Motor Production Line Analysis

3.2. Process Analysis of Smart Manufacturing Line

4. Discussion

5. Conclusions

Limitations of Study

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Acronym | Definition |

|---|---|

| ANN | Artificial Neural Network |

| CCTV | Closed Circuit Television Photographic equipment on the production line and equipment for capturing images to improve quality, etc |

| CNC | Computer Numerical Control |

| CPS | Cyber Physical System |

| IoT | Internet of Things |

| OPC | OPC is the interoperability standard for the secure and reliable exchange of data in the industrial automation space and in other industries. It is platform independent and ensures the seamless flow of information among devices from multiple vendors. The OPC Foundation is responsible for the development and maintenance of this standard. Source: https://opcfoundation.org/ |

| OPC UA | OPC Unified Architecture |

| SM | Solen Company Vietnam Motor Production Line |

References

- Guedes, A.S.; Silva, S.M.; Filho, B.C.; Conceição, C.A. Evaluation of electrical insulation in three-phase induction motors and classification of failures using neural networks. Electr. Power Syst. Res. 2016, 140, 263–273. [Google Scholar] [CrossRef]

- De Oliveira, J.F.; Cassimiro, B.; Pacheco, A.; Demay, M.B. Detection of defects in the manufacturing of electric motor stators using vision systems. In Proceedings of the Electric Connectors in 12th IEEE International Conference on Industry Applications (INDUSCON), Curitiba, PR, Brazil, 20–23 November 2016; pp. 1–6. [Google Scholar]

- Sun, J.; Wyss, R.; Steinecker, A.; Glocker, P. Automated fault detection using deep belief networks for the quality inspection of electromotors. Tm-Technisches Messen 2014, 81, 255–263. [Google Scholar] [CrossRef] [Green Version]

- Manyika, J.; Bughin, J. The promise and challenge of the age of artificial intelligence. Etz El-Ektrotechnik Automation 2018, 5, 4–6. [Google Scholar]

- Edward, L. Cyber Physical Systems: Design challenges, University of California, Berkeley Technical Report. In Proceedings of the IEEE International Symposium on Object and Component-Oriented Real-Time Distributed Computing (ISORC), Orlando, FL, USA, 5–7 May 2008. [Google Scholar]

- Lee, J.; Bagheri, B.; Kao, H. A cyber-physical systems architecture for Industry 4.0-based manufacturing systems. Manuf. Lett. 2015, 3, 18–23. [Google Scholar] [CrossRef]

- Lee, J.; Lapira, E.; Bagheri, B.; Kao, H. Recent advances and trends in predictive manufacturing systems in big data environment. Manuf. Lett. 2013, 1, 38–41. [Google Scholar] [CrossRef]

- Castelo-Branco, I.; Cruz-Jesus, F.; Oliveira, T. Assessing Industry 4.0 readiness in manufacturing: Evidence for the European Union. Comput. Ind. 2019, 107, 22–32. [Google Scholar] [CrossRef]

- Andez-Carames, T.M.; Blanco-Novoa, O.; Froiz-Míguez, I.; Fraga-Lamas, P. Towards an autonomous Industry 4.0 warehouse: A UAV and blockchain-based system for inventory and traceability applications in big data-driven supply chain management. Sensors 2019, 19, 10. [Google Scholar]

- Mayr, A.; Weigelt, M.; von Lindenfels, J.; Seefried, J.; Ziegler, M.; Mahr, A.; Urban, N.; Kühl, A.; Hüttel, F.; Franke, J. Electric Motor Production 4.0–Application Potentials of Industry 4.0 Technologies in the Manufacturing of Electric Motors. In Proceedings of the 2018 8th International Electric Drives Production Conference (EDPC), Schweinfurt, Germany, 4–5 December 2018; pp. 1–13. [Google Scholar]

- Rodriguez, A.; Vrancx, P.; Nowe, A.; Hostens, E. Model-free learning of wire winding control. In Proceedings of the 2013 9th Asian Control Conference (ASCC), Istanbul, Turkey, 23–26 June 2013; pp. 1–6. [Google Scholar]

- Fleischmann, H.; Spreng, S.; Kohl, J.; Kißkalt, D.; Franke, J. Distributed condition monitoring systems in electric drives manufacturing. In Proceedings of the 6th International Electric Drives Production Conference (EDPC), Nuremberg, Germany, 30 November–1 December 2016; pp. 52–59. [Google Scholar]

- Mayr, A.; Meyer, A.; Seefried, J.; Weigelt, M.; Lutz, B.; Sultani, D.; Hampl, M.; Franke, J. Potentials of machine learning in electric drives production using the example of contacting processes and selective magnet assembly. In Proceedings of the 7th International Electric Drives Production Conference, Wuerzburg, Germany, 5–6 December 2017; pp. 196–203. [Google Scholar]

- Weigelt, M.; Mayr, A.; Seefried, J.; Heisler, P.; Franke, J. Conceptual design of an intelligent ultrasonic crimping process using machine learning algorithms. Procedia Manuf. 2018, 17, 78–85. [Google Scholar] [CrossRef]

- Mayr, A.; Lutz, B.; Weigelt, M.; Gläßel, T.; Kißkalt, D.; Masuch, M.; Riedel, A.; Franke, J. Evaluation of machine learning for quality monitoring of laser welding using the example of the contacting of hairpin windings. In Proceedings of the 2018 8th International Electric Drives Production Conference (EDPC), Schweinfurt, Germany, 4–5 December 2018; pp. 1–7. [Google Scholar]

- Al-Zubaidi, S.S.; Ghani, J.A.; Haron, C. Application of ANN in milling process: A review. Model. Simul. Eng. 2011, 4, 1–7. [Google Scholar] [CrossRef]

- Ayatollahi, I.; Kittl, B.; Pauker, F.; Hackhofer, M. Prototype OPC UA server for remote control of machine tools. In Proceedings of the IN-TECH 2013 International Conference on Innovative Technologies, Budapest, Hungary, 10–13 September 2013; pp. 73–76. [Google Scholar]

- Wang, W.; Zhang, X.; Li, Y. Open CNC machine tools state data acquisition and application based on OPC specification. Procedia CIRP 2016, 56, 384–388. [Google Scholar] [CrossRef] [Green Version]

- Lammers, S.; Adam, G.; Schmid, H.J.; Mrozek, R.; Oberacker, R.; Hoffmann, M.J.; Quattrone, F.; Ponick, B. Additive manufacturing of a lightweight rotor for a permanent magnet synchronous machine. In Proceedings of the 2016 6th International Electric Drives Production Conference (EDPC), Nuremberg, Germany, 30 November–1 December 2016; pp. 41–47. [Google Scholar]

- Murakami, Y. Machine Learning Apparatus and Method for Learning Arrangement Position of Magnet in Rotor and Rotor Design Apparatus Including Machine Learning Apparatus. 2016. Available online: https://patents.google.com/patent/US20170093256 (accessed on 10 January 2020).

- Coupek, D.; Lechler, A.; Verl, A.W. Cloud-based control strategy: Downstream defect reduction in the production of electric motors. IEEE Trans. Ind. Appl. 2017, 53, 5348–5353. [Google Scholar] [CrossRef]

- Colledani, M.; Coupek, D.; Verl, A.W.; Aichele, J.; Yemane, A. A cyberphysical system for quality-oriented assembly of automotive electric motors. CIRP J. Manuf. Sci. Technol. 2018, 20, 12–22. [Google Scholar] [CrossRef]

- Lettau, U. Condition monitoring für die Akustikprüfung. Etz-Elektrotechnik Automation 2013, 5, 4–6. [Google Scholar]

- Brecher, C.; Pallasch, C.; Hoffmann, N.; Obdenbusch, M. Identifikation und lokalisierung von werkzeugen und objekten. ZWF Zeitschrift für Wirtschaftlichen Fabrikbetrieb 2016, 111, 749–753. [Google Scholar] [CrossRef]

- Berndt, S.; Sauer, S. Digitale Fabrik, Montage, instandhaltung: Visuelle ssistenz Unterstützung bei der Durchführung komplexer Montageaufgaben. wt Werkstatttechnik Online 2012, 102, 162–163. [Google Scholar]

- Marvel, J.; Newman, W.S.; Gravel, D.; Zhang, F.E.; Wang, J.; Fuhlbrigge, T. Automated learning for parameter optimization of robotic assembly tasks utilizing genetic algorithms. In Proceedings of the 2008 IEEE International Conference on Robotics and Biomimetics, Bangkok, Thailand, 22–25 February 2008; pp. 179–184. [Google Scholar]

- Vick, A.; Guhl, J.; Krüger, J. Model predictive control as a service-concept and architecture for use in cloud-based robot control. In Proceedings of the 21st International Conference on Methods and Models in Automation and Robotics (MMar), Miedzyzdroje, Poland, 29 August–1 September 2016; pp. 607–612. [Google Scholar]

| STEP | INDUSTRY 4.0 |

|---|---|

| 1. Housing and Rotor Cage Production | Use sensors to monitor production data (specifications, quality, etc.) and store them on a computer. Then, use artificial intelligence to analyze and predict the required materials to avoid excessive waste. For example, if the specifications and quality can be predicted in advance, it is set at the time of production, and when the rotor of the production line is cut, the excess parts can be cut out to save raw material consumption. |

| 2. Laminated Core Production | When cutting electrical boards, the sensors installed on the machine receive cutting force and sound and vibration frequency data. Then, use artificial intelligence and CPS virtual operation models to simulate and obtain more accurate data to aid in production. For example, when the rotor of the production line is cut, the above methods can be used to make the machine operate more accurately, and the accuracy of the finished product specifications can be improved. |

| 3. Insulation and Impregnation | In the selection of washer (insulation parts) materials, artificial intelligence is used for simulation and analysis to find the most suitable materials and specifications. Then, production and assembly are performed to find the most suitable materials and specifications. To provide a better insulation effect, accurate installation position is necessary. |

| 4. Winding | In the winding step, install the sensor to return data, and use artificial intelligence analysis to find the best winding data (number of turns and winding speed, etc.). The image recognition system can make production faster and more accurate and inspect the appearance at any time. |

| 5. Contact | Part of the rotor spot welding is equipped with an intelligent system. In addition to returning production data (resistance, temperature, etc.) to monitor the entire welding process, it can also optimize the welding quality. If image recognition is added, weld defects can be found. The severity is classified for subsequent analysis and optimization. |

| 6. Shaft Production | Use artificial intelligence to analyze and optimize shaft production data (quality, specifications, etc.) to find the best production method. It can also be used in the assembly of the bearing, installation of sensors, and monitoring of parameters (size, assembly force, shaft radius, etc.) for computer analysis and optimization to reduce the number of defective products. |

| 7. Permanent Magnet Rotor Production | The permanent magnet assembly step uses image recognition to visually inspect the magnet surface after production. The machine is equipped with a sensor during the magnetization step of the permanent magnet. After magnetization, the position and magnetic field of positive and negative poles are automatically checked to avoid affecting the motor operation. |

| 8. Final Assembly and Testing | In the motor assembly line, image recognition (e.g., brush appearance inspection and motor press-fit appearance inspection) is added to check the appearances. The data generated during the motor performance test can also be stored and analyzed using artificial intelligence in order to identify problems and aid the motor designer. |

| 9. Overall Process | Using the machine-to-machine technology, the intelligent system installed on each machine is connected to exchange and upload data in real time. Data management is performed through knowledge-based systems to speed up the entire operation and management processes. |

| RESEARCH METHOD | DATE | DESCRIPTION | COLLECTED DATA |

|---|---|---|---|

| Secondary data collection | July 2019–February 2020 | Information on research issues from existing papers, journals, cases, and company materials is obtained. After analysis, the feasible methods for “SM” motor production line are summarized, integrated, and initially evaluated. | Papers, journals, books: 28 Company production line operation process description SOP(Standard Operating Procedure): 1 copy Production line working time statistics |

| Field study | 19–22 September 2019 | Actual operation status of production line is monitored by observing motor production line and collecting data. | Production line photographs |

| Interview | 27 November 2019, 13:00–14:00 | Two practical experts were invited to laboratory for interview. | Record interviews, verbatim files, photographs |

| 31 January 2020,14:00–15:15 On February | Visited Taiwan headquarters of Solen company, interviewed three practical experts, collected questions related to the implementation and design of production line. Questions raised by interviewees are asked to obtain helpful information for research. Two experts are responsible for the production line process and machine design. One expert is responsible for the actual production line execution. | Record interview files, verbatim files, photographs | |

| 14 February 2020, from 14:00 to 14:30 | Visited Solen company Taiwan Headquarters, and a practical expert was interviewed. | Record interview files, verbatim files, photographs |

| WORKBENCH | OPERATION STATUS |

|---|---|

| 1 | Responsible for winding. Check whether the rotor parts are fully installed, put the rotor into the machine (four rotors at a time), automatically wind and mark the number, and check the appearance of parts. |

| 2 | Responsible for spot welding of commutators. Place coils in the machine for spot welding, check the appearance of parts, take photographs for every 1000 pieces produced. |

| 3 | Responsible for commutator cutting. Put parts into the machine for cutting and check the cutting status of parts. |

| 4 | Responsible for air pressure rectification and air pressure removal. Clean the parts with a brush, check the foreign matter residue with a magnifying glass, put the parts into the air pressure cleaner for cleaning, and check the appearance of parts. |

| 5 | Responsible for washer group voltage resistance, absolute resistance, and impedance tests. Put the washer into the machine for punching, and then into the test machine for voltage resistance, absolute resistance, impedance tests. |

| 6 | Responsible for bearing assembly and bearing distance inspection. Put the bearings and coils into the machine for stamping, and then place the parts into the inspection machine to check the bearing distance. |

| WORKBENCH | OPERATION STATUS |

|---|---|

| 1 | Responsible for dispensing and coil assembly. Align the iron frame with the coil and place it in the dispenser. Then, place the parts in the machine, use the auxiliary tools on the machine to snap the iron frame into the coil, and check whether the installation is complete. |

| 2 | Responsible for the assembly and appearance inspection of the brush assembly. Put the parts into the machine and assemble with the finished product of the previous workbench, then move the parts in front of the CCTV, and the personnel will check its appearance through CCTV. |

| 3 | Responsible for the assembly and inspection of the washer. Put the washer on the machine to join, move the parts to another machine to take pictures, and check whether the washer is missing according to the inspection. |

| 4 | Responsible for motor assembly press-fitting and clearance inspection. Put the parts into the machine and press the motor. Finally, check if there are eight gaps in the parts. Then, put the parts into the testing machine to check the gap. |

| 5 | Responsible for motor performance inspection and lightning engraving. Put the parts into the testing machine to check the motor performance. The machine automatically engraves the parts that passed the inspection and stores the test data. |

| 6 | Responsible for the final visual inspection. Use tools to check whether the screw pattern is sufficient. Check whether the laser marking (seal) is sufficient. Check the direction of motor rotation and appearance of the terminal. |

| 7 | Responsible for packaging and shipping. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, Y.-C.; Yeh, C.-C.; Chen, W.-H.; Hsu, K.-Y. Implementation Criteria for Intelligent Systems in Motor Production Line Process Management. Processes 2020, 8, 537. https://doi.org/10.3390/pr8050537

Lin Y-C, Yeh C-C, Chen W-H, Hsu K-Y. Implementation Criteria for Intelligent Systems in Motor Production Line Process Management. Processes. 2020; 8(5):537. https://doi.org/10.3390/pr8050537

Chicago/Turabian StyleLin, Yao-Chin, Ching-Chuan Yeh, Wei-Hung Chen, and Kai-Yen Hsu. 2020. "Implementation Criteria for Intelligent Systems in Motor Production Line Process Management" Processes 8, no. 5: 537. https://doi.org/10.3390/pr8050537

APA StyleLin, Y.-C., Yeh, C.-C., Chen, W.-H., & Hsu, K.-Y. (2020). Implementation Criteria for Intelligent Systems in Motor Production Line Process Management. Processes, 8(5), 537. https://doi.org/10.3390/pr8050537