Spark Plasma Sintering of Cobalt Powders in Conjunction with High Energy Mechanical Treatment and Nanomodification

Abstract

1. Introduction

2. Materials and Methods

2.1. Synthesis of Co Nanopowders

2.2. High Energy Mechanical Treatment

2.3. Spark Plasma Sintering

2.4. Experimental Plan

3. Results and Discussion

3.1. Morphology and Microstructure

3.2. Densification

3.3. Mechanical Properties

3.4. Discussion

4. Conclusions

- (1).

- Three sets of Co micro-powders were investigated in this study: untreated, HEMT processed, and nanomodified HEMT processed powders. The SPS consolidation was carried out in the temperature range 700–1000 °C.

- (2).

- The grain sizes of sintered Co pellets were largest for set I without any pre-treatment. Fine-grained products were obtained for Co powders undergoing HEMT processing and nanomodification. Nano-additives tended to inhibit grain growth by reinforcing particles at grain boundaries and limiting grain-boundary movement.

- (3).

- Very high degrees of compaction were achieved with relative densities of sintered Co pellets, ranging from 95.2% to 99.6%. Pre-treatments as well as lower sintering temperatures were found to play a key role in enhancing the sinter quality. A reduction of sintering temperature by 100 °C was observed for pre-treated Co powders as compared to untreated Co powders for a comparable sinter quality.

- (4).

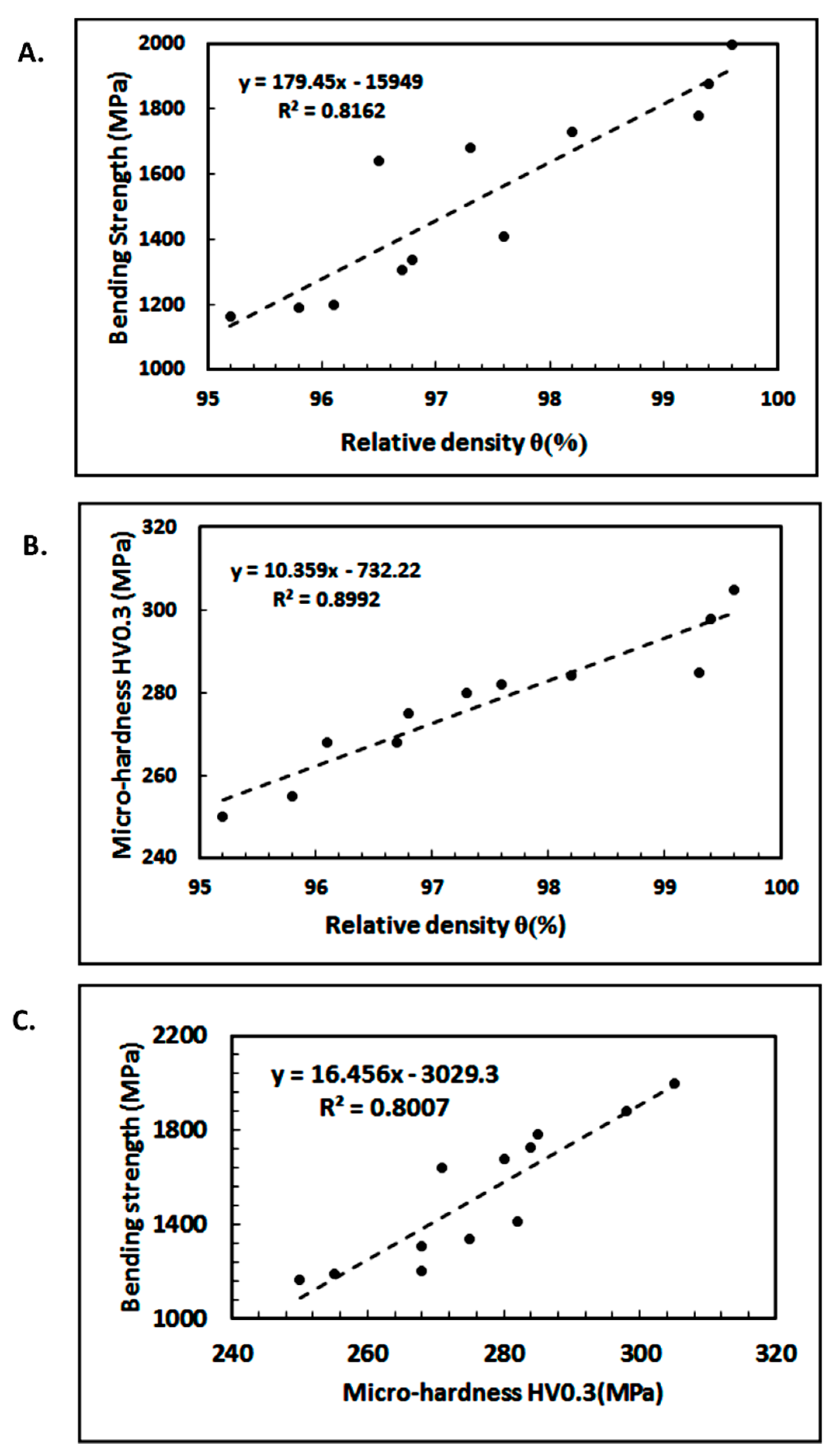

- Direct and linear co-relations were observed between the mechanical properties and densities of sintered Co pellets. Highest values of bending strength (1997 MPa), microhardness (305 MPa), and relative density (99.6%) were observed for nanomodified HEMT and SPS processed Co pellets sintered at 700 °C.

- (5).

- Lowest values of bending strength (1198 MPa), microhardness (268 MPa), and relative density (96.1%) were observed for nanomodified HEMT and SPS processed Co pellets sintered at 900 °C.

- (6).

- This study has shown that SPS operating temperatures need to be carefully optimized to prevent inadequate sintering at low temperatures and increased porosity, defect formation, and product degradation at high temperatures.

Author Contributions

Funding

Conflicts of Interest

References

- Matizamhuka, W.R. Spark plasma sintering (SPS)—An advanced sintering technique for structural nanocomposite materials. J. S. Afr. Inst. Min. Metall. 2016, 116, 1171–1180. [Google Scholar] [CrossRef]

- Lee, G.; McKittrick, J.; Ivanov, E.; Olevsky, E.A. Densification mechanism and mechanical properties of tungsten powder consolidated by spark plasma sintering. Int. J. Refr. Met. Hard Mater. 2017, 61, 22–29. [Google Scholar] [CrossRef]

- Guillon, O.; Gonzalez-Julian, J.; Dargatz, B.; Kessel, T.; Schierning, G.; Rathel, J.J.; Herrmann, M. Field-assisted sintering technology/spark plasma sintering: Mechanisms, Materials, and Technology Developments. Adv. Eng. Mater. 2014, 16, 830–849. [Google Scholar] [CrossRef]

- Suárez, M.; Fernández, A.; Menéndez, J.L.; Torrecillas, R.; Kessel, H.U.; Hennicke, J.; Kirchner, R.; Kessel, T. Challenges and opportunities for spark plasma sintering: A key technology for a new generation of materials. Sinter. Appl. 2013, 13, 319–342. [Google Scholar]

- Munir, Z.A.; Anselmi-Tamburini, U.M.; Ohyanagi, M. The effect of electric field and pressure on the synthesis and consolidation of materials: A review of the spark plasma sintering method. J. Mater. Sci. 2006, 41, 763–777. [Google Scholar] [CrossRef]

- Orrù, R.; Richeri, R.; Locci, A.M.; Cincotti, A.; Cao, G. Consolidation/synthesis of materials by electric current activated/assisted sintering. Mater. Sci. Eng. R 2009, 63, 127–287. [Google Scholar] [CrossRef]

- Mamedov, V. Spark plasma sintering as advanced PM sintering method. Powder Metall. 2002, 45, 322–328. [Google Scholar] [CrossRef]

- Huang, J.L.; Nayak, P.K. Strengthening alumina ceramic matrix nanocomposites using spark plasma sintering. In Advances in Ceramic Matrix Composites, 2nd ed.; Elsevier Inc.: Amsterdam, The Netherlands, 2018; pp. 231–247. [Google Scholar] [CrossRef]

- Xie, J. Spark Plasma Sintering: A useful technique to develop large-sized bulk metallic glasses. J. Powder Metall. Min. 2013, 2, e109. [Google Scholar] [CrossRef]

- Xie, G.Q.; Qin, F.X.; Zhu, S.L. Recent progress in Ti-based metallic glasses for application as biomaterials. Mater. Trans. 2013, 54, 1314–1323. [Google Scholar] [CrossRef]

- Mellor, I.; Doughty, G. Novel and emerging routes for titanium powder production—An overview. Key Eng. Mater. 2016, 704, 271–281. [Google Scholar] [CrossRef]

- Méar, F.O.; Xie, G.Q.; Louzguine-Luzgin, D.V.; Inoue, A. Spark plasma sintering of Mg-based amorphous ball-milled powders. Mater. Trans. 2009, 50, 588–591. [Google Scholar]

- Zheng, B.L.; Ashford, D.; Zhou, Y.Z.; Mathaudhu, S.N.; Delplanque, J.P. Influence of mechanically milled powder and high pressure on spark plasma sintering of Mg-Cu-Gd metallic glasses. Acta Mater. 2013, 6, 4414–4428. [Google Scholar] [CrossRef]

- Dudina, D.V.; Bokhonov, B.B.; Olevsky, E.A. Fabrication of porous materials by spark plasma sintering: A review. Materials 2019, 12, 541. [Google Scholar] [CrossRef] [PubMed]

- Vincent, N. Spark Plasma Sintering of Titanium and Cobalt Alloys for Biomedical Applications. Ph.D. Thesis, University Trento, Trento, Italy, 2012. [Google Scholar]

- Tang, C.F.; Pan, F.; Qu, X.H.; Jia, C.C.; Duan, B.H.; He, X.B. Spark plasma sintering cobalt base superalloy strengthened by Y–Cr–O compound through high-energy milling. J. Mater. Process. Technol. 2008, 204, 111–116. [Google Scholar] [CrossRef]

- Gezerman, A.O.; ÇorbacJoLlu, B.D. Effects of Mechanical Alloying on Sintering Behavior of Tungsten Carbide-Cobalt Hard Metal System. Adv. Mater. Sci. Eng. 2017, 2017, 8175034. [Google Scholar] [CrossRef]

- Patel, B.; Favaro, G.; Inam, F.; Reece, M.J.; Angadji, A.; Bonfield, W.; Huang, J.; Edirisinghe, M. Cobalt-based orthopaedic alloys: Relationship between forming route, microstructure and tribological performance. Mater. Sci. Eng. C 2012, 32, 1222–1229. [Google Scholar] [CrossRef]

- Cavaliere, P.; Sadeghi, B.; Shabani, A. Spark plasma sintering: Process fundamentals. In Spark Plasma Sintering of Materials; Cavaliere, P., Ed.; Springer Nature Switzerland: Cham, Switzerland, 2019. [Google Scholar] [CrossRef]

- Song, X.; Liu, X.; Zhang, J. Neck formation and self-adjusting mechanism of neck growth of conducting powders in spark plasma sintering. J. Am. Ceram. Soc. 2006, 89, 494–500. [Google Scholar] [CrossRef]

- Oke, S.R.; Ige, O.O.; Falodun, O.E.; Obadele, B.A.; Shongwe, M.B.; Olubambi, P.A. Optimization of process parameters for spark plasma sintering of nano structured SAF 2205 composite. J. Mater. Res. Technol. 2018, 7, 126–134. [Google Scholar] [CrossRef]

- Deng, S.; Li, R.; Yuan, T.; Cao, P.; Xie, S. Electromigration-enhanced densification kinetics during spark plasma sintering of tungsten powder. Metall. Mater. Trans. A 2019, 50, 2886–2897. [Google Scholar] [CrossRef]

- Knaislová, A.; Novák, P.; Cygan, S.; Jaworska, L.; Cabibbo, M. High-pressure spark plasma sintering (HP SPS): A promising and reliable method for preparing Ti–Al–Si alloys. Materials 2017, 10, 465. [Google Scholar] [CrossRef]

- Marek, I.; Vojtěch, D.; Michalcová, A.; Kubatík, T.F. The structure and mechanical properties of high-strength bulk ultrafine-grained Cobalt prepared using high-energy ball milling in combination with spark plasma sintering. Materials 2016, 9, 391. [Google Scholar] [CrossRef] [PubMed]

- Kundu, A.; Sittiho, A.; Charit, I.; Jaques, B.; Jiang, C. Development of Fe-9Cr alloy via high-energy ball milling and spark plasma sintering. JOM 2019, 71, 2846–2855. [Google Scholar] [CrossRef]

- Coutsouradis, D.; Davin, A.; Lamberigts, M. Cobalt-based superalloys for applications in gas turbines. Mater. Sci. Eng. 1987, 88, 11–19. [Google Scholar] [CrossRef]

- Suzuki, A.; Inui, H.; Pollock, T.M. L12-strengthened cobalt-base superalloys. Annu. Rev. Mater. Res. 2015, 45, 345–368. [Google Scholar] [CrossRef]

- Aherwar, A.; Singh, A.; Patnaik, A. Cobalt based alloy: A better choice biomaterial for hip implants. Trends Biomater. Artif. Organs 2016, 30, 50–55. [Google Scholar]

- Prakasam, M.; Locs, J.; Salma-Ancane, K.; Loca, D.; Largeteau, A.; Berzina-Cimdina, L. Biodegradable materials and metallic implants—A review. J. Funct. Biomater. 2017, 8, 44. [Google Scholar] [CrossRef]

- Van Minh, N.; Konyukhov, Y.; Karunakaran, G.; Ryzhonkov, D. Enhancement of densification and sintering behaviour of tungsten material via nano modification and magnetic mixing processed under spark plasma sintering. Metals Mater. Int. 2017, 23, 532–542. [Google Scholar] [CrossRef]

- Van Minh, N.; Karunakaran, G.; Konyukhov, Y. Effect of mixing modes and nano additives on the densification and sintering behavior of tungsten material under spark plasma sintering. J. Clust. Sci. 2017, 28, 2157–2165. [Google Scholar] [CrossRef]

- Tiryakioğlu, M.; Dispinar, D.; Uludağ, M.; Yazman, S.; Gemi, L. The effect of 0.5 wt.% additions of carbon nanotubes & ceramic nanoparticles on tensile properties of epoxy-matrix composites: A comparative study. Mater. Sci. Nanotechnol. 2017, 1, 15–22. [Google Scholar]

- Xing, W.Q.; Yu, X.Y.; Li, H.; Ma, L.; Zuo, W.; Dong, P.; Wang, W.X.; Ding, M. Effect of nano Al2O3 additions on the interfacial behaviour and mechanical properties of eutectic Sn-9Zn solder on low temperature wetting and soldering of 6061 aluminium alloys. J. Alloys Compd. 2017, 695, 574–582. [Google Scholar] [CrossRef]

- Gain, A.K.; Zhang, L. Effects of Ni nanoparticles addition on the microstructure, electrical and mechanical properties of Sn-Ag-Cu alloy. Materialia 2019, 5, 100234. [Google Scholar] [CrossRef]

- Gain, A.K.; Zhang, L. Interfacial microstructure, wettability and material properties of nickel (Ni) nanoparticle doped tin-bismuth-silver (Sn-Bi-Ag) solder on copper (Cu) substrate. J. Mater. Sci. Mater. Electron. 2016, 27, 1–13. [Google Scholar] [CrossRef]

- Bokhonov, B.B.; Ukhina, A.V.; Dudina, D.V.; Anisimov, A.G.; Mali, V.I.; Batraev, I.S. Carbon uptake during Spark Plasma Sintering: Investigation through the analysis of the carbide “footprint” in a Ni-W alloy. RSC Adv. 2015, 5, 80228–80237. [Google Scholar] [CrossRef]

- Fellah, F.; Schoenstein, F.; Dakhlaoui–Omrani, A.; Chérif, S.M.; Dirras, G.; Jouini, N. Nanostructured cobalt powders synthesised by polyol process and consolidated by Spark Plasma Sintering: Microstructure and mechanical properties. Mater. Charact. 2012, 69, 1–8. [Google Scholar] [CrossRef]

- Cabibbo, M. Nanostructured cobalt obtained by combining bottom-up and top-down approach. Metals 2018, 8, 962. [Google Scholar] [CrossRef]

- Rogal, L.; Kalita, D.; Tarasek, A.; Bobrowski, P.; Czerwinski, F. Effect of SiC nano-particles on microstructure and mechanical properties of the CoCrFeMnNi high entropy alloy. J. Alloys Compd. 2017, 708, 344–352. [Google Scholar] [CrossRef]

- Karunakaran, G.; Van Minh, N.; Konyukhov, Y.; Kolesnikov, E.; Venkatesh, M.; Kumar, G.S.; Gusev, A.; Kuznetsov, D. Effect of Si, B, Al2O3 and ZrO2 nano-modifiers on the structural and mechanical properties of Fe + 0.5 % C alloy. Arch. Civ. Mech. Eng. 2017, 17, 669–676. [Google Scholar] [CrossRef]

- Namini, A.B.; Motallebzadeh, A.; Nayebi, B.; Mehdi Shahedi, A.M.; Azadbeh, M. Microstructure–mechanical properties correlation in spark plasma sintered Ti–4.8 wt.% TiB2 composites. Mater. Chem. Phys. 2018, 223, 789–796. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nguyen, V.M.; Khanna, R.; Konyukhov, Y.; Nguyen, T.H.; Burmistrov, I.; Levina, V.; Golov, I.; Karunakaran, G. Spark Plasma Sintering of Cobalt Powders in Conjunction with High Energy Mechanical Treatment and Nanomodification. Processes 2020, 8, 627. https://doi.org/10.3390/pr8050627

Nguyen VM, Khanna R, Konyukhov Y, Nguyen TH, Burmistrov I, Levina V, Golov I, Karunakaran G. Spark Plasma Sintering of Cobalt Powders in Conjunction with High Energy Mechanical Treatment and Nanomodification. Processes. 2020; 8(5):627. https://doi.org/10.3390/pr8050627

Chicago/Turabian StyleNguyen, Van Minh, Rita Khanna, Yuri Konyukhov, Tien Hiep Nguyen, Igor Burmistrov, Vera Levina, Ilya Golov, and Gopalu Karunakaran. 2020. "Spark Plasma Sintering of Cobalt Powders in Conjunction with High Energy Mechanical Treatment and Nanomodification" Processes 8, no. 5: 627. https://doi.org/10.3390/pr8050627

APA StyleNguyen, V. M., Khanna, R., Konyukhov, Y., Nguyen, T. H., Burmistrov, I., Levina, V., Golov, I., & Karunakaran, G. (2020). Spark Plasma Sintering of Cobalt Powders in Conjunction with High Energy Mechanical Treatment and Nanomodification. Processes, 8(5), 627. https://doi.org/10.3390/pr8050627