Thermal Performance Enhancement in Flat Plate Solar Collector Solar Water Heater: A Review

Abstract

1. Introduction

2. Thermal Performance Enhancement Methods for FPSC

2.1. Current Research on FPSC Thermal Performance Improvement

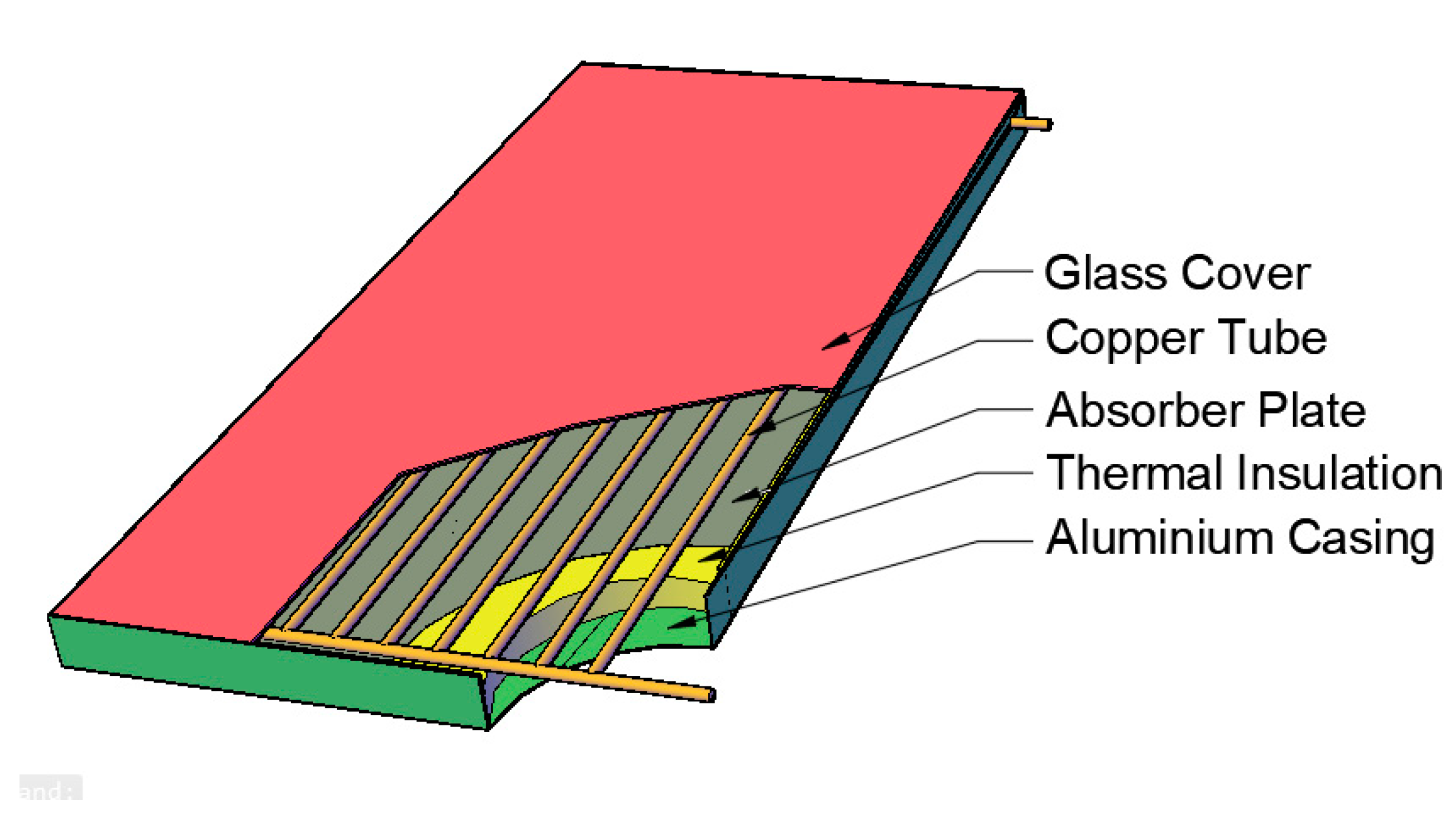

2.1.1. Modification of FPSC Design

2.1.2. Absorber Coatings

2.1.3. Heat Loss Reduction

2.1.4. Nanofluid

2.1.5. Polymer Material

2.1.6. Phase Change Material

2.1.7. Enhancement Devices

2.1.8. Turbulators

2.1.9. Heat-Transfer Enhancement Using Vibration

3. Enhancement of Heat Transfer Using Vibration

3.1. Heat-Transfer Enhancement Using Vibration at Infrasound Acoustic Range

3.2. Current Research on Heat-Transfer Enhancement Due to Vibration at Various Acoustic Range

3.2.1. Power Ultrasound Acoustic Range (20 kHz < f < 1 MHz)

3.2.2. Sound Acoustic Range (20 Hz < f < 20 kHz)

3.2.3. Infrasound Acoustic Range (f < 20 Hz)

4. Flat Plate Solar Water Heater Heat-Transfer Enhancement Using Vibration at Infrasound Acoustic Range

5. Conclusions

- Ten methods for enhancing thermal performance enhancement were identified: applications of nanofluid, absorber coatings, heat loss reduction, PCM, thermal performance enhancer, FPSC design modification, turbulators, mini and micro channel and polymer material;

- Heat-transfer enhancement using vibration creates a pressure amplitude that promotes flow alteration and fluid mixing, which enables triggering or increasing the turbulence rate within a liquid and improve heat transfer;

- Heat-transfer enhancement using vibration method on ETSC indicates a potential improvement in heat-transfer efficiency up to 78%; However, there is no such study done on FPSC;

- Vibration can potentially affect the reliability of FPSC; nevertheless, there is still a lack of research in this area.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| CPSC | compound parabolic collector |

| ETSC | evacuated-tube solar water heater |

| FPSC | flat plate solar collector solar water heater |

| HPV/T | photovoltaic thermal hybrid |

| HTF | heat-transfer fluid |

| PCM | phase change material |

| PVD | physical vapor deposition |

| PV | photovoltaic |

| SWH | solar water heater |

| TIM | transparent insulation material |

References

- Kannan, N.; Vakeesan, D. Solar energy for future world: A review. Renew. Sustain. Energy Rev. 2016, 62, 1092–1105. [Google Scholar] [CrossRef]

- Solangi, K.; Islam, R.; Saidur, R.; Rahim, N.A.; Fayaz, H. A review on global solar energy policy. Renew. Sustain. Energy Rev. 2011, 15, 2149–2163. [Google Scholar] [CrossRef]

- Bahadori, A.; Nwaoha, C. A review on solar energy utilisation in Australia. Renew. Sustain. Energy Rev. 2013, 18, 1–5. [Google Scholar] [CrossRef]

- Sakhaei, S.A.; Valipour, M.S. Performance enhancement analysis of the flat plate collectors: A comprehensive review. Renew. Sustain. Energy Rev. 2019, 102, 186–204. [Google Scholar] [CrossRef]

- Thermal Performance and Economic Analysis of Solar Photovoltaic Water Heater Under the Malaysian Climatic Condition. Master’s Thesis, Engineering Science Faculty, Kuala Lumpur, Malaysia, 2013.

- Perlin, J. History of Solar Energy; Cleveland, C.J., Ed.; Elsevier: New York, NY, USA, 2004; pp. 607–622. [Google Scholar]

- Bhutto, A.W.; Bazmi, A.A.; Zahedi, G. Greener energy: Issues and challenges for Pakistan—Solar energy prospective. Renew. Sustain. Energy Rev. 2012, 16, 2762–2780. [Google Scholar] [CrossRef]

- Sterman, J. Learning from Evidence in a Complex World. Am. J. Public Heal. 2006, 96, 505–514. [Google Scholar] [CrossRef]

- Nshimyumuremyi, E.; Junqi, W. Thermal efficiency and cost analysis of solar water heater made in Rwanda. Energy Explor. Exploit. 2018, 37, 1147–1161. [Google Scholar] [CrossRef]

- Kabir, E.; Kumar, P.; Kumar, S.; Adelodun, A.A.; Kim, K.-H. Solar energy: Potential and prospects. Renew. Sustain. Energy Rev. 2018, 82, 894–900. [Google Scholar] [CrossRef]

- Hohne, P.A.; Kusakana, K.; Numbi, B. A review of water heating technologies: An application to the South African context. Energy Rep. 2019, 5, 1–19. [Google Scholar] [CrossRef]

- Han, J.; Mol, A.P.; Lu, Y. Solar water heaters in China: A new day dawning. Energy Policy 2010, 38, 383–391. [Google Scholar] [CrossRef]

- Urmee, T.; Walker, E.; Bahri, P.A.; Baverstock, G.; Rezvani, S.; Saman, W. Solar water heaters uptake in Australia—Issues and barriers. Sustain. Energy Technol. Assess. 2018, 30, 11–23. [Google Scholar] [CrossRef]

- Mekhilef, S.; Safari, A.; Mustaffa, W.; Saidur, R.; Omar, R.; Younis, M. Solar energy in Malaysia: Current state and prospects. Renew. Sustain. Energy Rev. 2012, 16, 386–396. [Google Scholar] [CrossRef]

- Gaafar-Elnugoumi, M.; Ariffin-Bin Ahmed, Z.; Kh-Mahmoud, A.M. Current Status and Challenges of Solar Energy in Malaysia: A Review. J. Adv. Sci. Eng. Res. 2012, 2, 330–337. [Google Scholar]

- Klevinskis, A.; Bučinskas, V. Analysis of a Flat-Plate Solar Collector. Moksl. Liet. Ateit. 2012, 3, 39–43. [Google Scholar] [CrossRef]

- Hossain, M.; Saidur, R.; Fayaz, H.; Rahim, N.; Islam, R.; Ahamed, J.; Rahman, M. Review on solar water heater collector and thermal energy performance of circulating pipe. Renew. Sustain. Energy Rev. 2011, 15, 3801–3812. [Google Scholar] [CrossRef]

- Jamar, A.; Majid, Z.; Azmi, W.H.; Norhafana, M.; Razak, A.A. A review of water heating system for solar energy applications. Int. Commun. Heat Mass Transf. 2016, 76, 178–187. [Google Scholar] [CrossRef]

- Balaji, K.; Kumar, B.; Sakthivadivel, D.; Vigneswaran, V.; Iniyan, S. Experimental investigation on flat plate solar collector using frictionally engaged thermal performance enhancer in the absorber tube. Renew. Energy 2019, 142, 62–72. [Google Scholar] [CrossRef]

- Zhou, L.; Wang, Y.; Huang, Q. Parametric analysis on the performance of flat plate collector with transparent insulation material. Energy 2019, 174, 534–542. [Google Scholar] [CrossRef]

- Pandey, K.; Chaurasiya, R. A review on analysis and development of solar flat plate collector. Renew. Sustain. Energy Rev. 2017, 67, 641–650. [Google Scholar] [CrossRef]

- Suman, S.; Khan, M.K.; Pathak, M. Performance enhancement of solar collectors—A review. Renew. Sustain. Energy Rev. 2015, 49, 192–210. [Google Scholar] [CrossRef]

- Harrison, S.; Cruickshank, C.A. A review of strategies for the control of high temperature stagnation in solar collectors and systems. Energy Procedia 2012, 30, 793–804. [Google Scholar] [CrossRef]

- Ango, A.M.D.; Medale, M.; Abid, C. Optimization of the design of a polymer flat plate solar collector. Sol. Energy 2013, 87, 64–75. [Google Scholar] [CrossRef]

- Kiliç, F.; Menlik, T.; Sozen, A. Effect of titanium dioxide/water nanofluid use on thermal performance of the flat plate solar collector. Sol. Energy 2018, 164, 101–108. [Google Scholar] [CrossRef]

- Hawwash, A.; Rahman, A.K.A.; Nada, S.; Ookawara, S. Numerical Investigation and Experimental Verification of Performance Enhancement of Flat Plate Solar Collector Using Nanofluids. Appl. Therm. Eng. 2018, 130, 363–374. [Google Scholar] [CrossRef]

- Gao, Y.; Gao, C.; Xian, H.; Du, X. Thermal Properties of Solar Collector Comprising Oscillating Heat Pipe in a Flat-Plate Structure and Water Heating System in Low-Temperature Conditions. Energies 2018, 11, 2553. [Google Scholar] [CrossRef]

- Saint, R.; Garnier, C.; Pomponi, F.; Currie, J. Thermal Performance through Heat Retention in Integrated Collector-Storage Solar Water Heaters: A Review. Energies 2018, 11, 1615. [Google Scholar] [CrossRef]

- Sharafeldin, M.; Gróf, G. Experimental investigation of flat plate solar collector using CeO2 -water nanofluid. Energy Convers. Manag. 2018, 155, 32–41. [Google Scholar] [CrossRef]

- Yassen, T.A.; Mokhlif, N.; Eleiwi, M. Performance investigation of an integrated solar water heater with corrugated absorber surface for domestic use. Renew. Energy 2019, 138, 852–860. [Google Scholar] [CrossRef]

- Visa, I.; Moldovan, M.; Duta, A. Novel triangle flat plate solar thermal collector for facades integration. Renew. Energy 2019, 143, 252–262. [Google Scholar] [CrossRef]

- Müller, S.; Giovannetti, I.F.; Reineke-Koch, R.; Kastner, O.; Hafner, B. Simulation study on the efficiency of thermochromic absorber coatings for solar thermal flat-plate collectors. Sol. Energy 2019, 188, 865–874. [Google Scholar] [CrossRef]

- Tong, Y.; Lee, H.; Kang, W.; Cho, H. Energy and exergy comparison of a flat-plate solar collector using water, Al2O3 nanofluid, and CuO nanofluid. Appl. Therm. Eng. 2019, 159, 113959. [Google Scholar] [CrossRef]

- Filipović, P.; Dović, D.; Ranilović, B.; Horvat, I. Numerical and experimental approach for evaluation of thermal performances of a polymer solar collector. Renew. Sustain. Energy Rev. 2019, 112, 127–139. [Google Scholar] [CrossRef]

- Wang, D.; Liu, H.; Liu, Y.; Xu, T.; Wang, Y.; Du, H.; Wang, X.; Liu, J. Frost and High-temperature resistance performance of a novel dual-phase change material flat plate solar collector. Sol. Energy Mater. Sol. Cells 2019, 201, 110086. [Google Scholar] [CrossRef]

- Zhou, F.; Ji, J.; Yuan, W.; Zhao, X.; Huang, S. Study on the PCM flat-plate solar collector system with antifreeze characteristics. Int. J. Heat Mass Transf. 2019, 129, 357–366. [Google Scholar] [CrossRef]

- Kanimozhi, B.; Shinde, Y.N.; Bedford, S.P.; Kanth, K.S.; Kumar, S.V. Experimental Analysis of Solar Water Heater Using Porous Medium with Agitator. Mater. Today Proc. 2019, 16, 1204–1211. [Google Scholar] [CrossRef]

- Fan, M.; You, S.; Gao, X.; Zhang, H.; Li, B.; Zheng, W.; Sun, L.; Zhou, T. A comparative study on the performance of liquid flat-plate solar collector with a new V-corrugated absorber. Energy Convers. Manag. 2019, 184, 235–248. [Google Scholar] [CrossRef]

- Da Silva, F.A.; Dezan, D.J.; Pantaleão, A.V.; Salviano, L. Longitudinal vortex generator applied to heat transfer enhancement of a flat plate solar water heater. Appl. Therm. Eng. 2019, 158, 113790. [Google Scholar] [CrossRef]

- Balaji, K.; Iniyan, S.; Swami, M.V. Exergy, economic and environmental analysis of forced circulation flat plate solar collector using heat transfer enhancer in riser tube. J. Clean. Prod. 2018, 171, 1118–1127. [Google Scholar] [CrossRef]

- Balaji, K.; Iniyan, S.; Muthusamyswami, V. Experimental investigation on heat transfer and pumping power of forced circulation flat plate solar collector using heat transfer enhancer in absorber tube. Appl. Therm. Eng. 2017, 112, 237–247. [Google Scholar] [CrossRef]

- Al Sahlani, A.; Eidan, A.A. Controllable Vibrating System to Enhance the Performance of Heat Pipe Evacuated Tube Solar Collector. J. Mech. Eng. Res. Dev. 2018, 41, 67–73. [Google Scholar] [CrossRef]

- Legay, M.; Gondrexon, N.; le Person, S.; Boldo, P.; Bontemps, A. Enhancement of Heat Transfer by Ultrasound: Review and Recent Advances. Int. J. Chem. Eng. 2011, 2011, 1–17. [Google Scholar] [CrossRef]

- Setareh, M.; Saffar-Avval, M.; Abdullah, A. Experimental and numerical study on heat transfer enhancement using ultrasonic vibration in a double-pipe heat exchanger. Appl. Therm. Eng. 2019, 159, 113867. [Google Scholar] [CrossRef]

- Cheng, L.; Luan, T.; Du, W.; Xu, M. Heat transfer enhancement by flow-induced vibration in heat exchangers. Int. J. Heat Mass Transf. 2009, 52, 1053–1057. [Google Scholar] [CrossRef]

- Yakut, K.; Sahin, B. Flow-induced vibration analysis of conical rings used for heat transfer enhancement in heat exchangers. Appl. Energy 2004, 78, 273–288. [Google Scholar] [CrossRef]

- Lebon, B.; Tzanakis, I.; Tzanakis, I.; Eskin, D.G.; Grant, P. Ultrasonic liquid metal processing: The essential role of cavitation bubbles in controlling acoustic streaming. Ultrason. Sonochem. 2019, 55, 243–255. [Google Scholar] [CrossRef]

- Baeghbali, V.; Niakousari, M.; Ngadi, M. An Update on Applications of Power Ultrasound in Drying Food: A Review. J. Food Eng. Technol. 2019, 8, 29–38. [Google Scholar] [CrossRef][Green Version]

- Lebon, B.; Salloum-Abou-Jaoude, G.; Eskin, D.G.; Tzanakis, I.; Pericleous, K.; Jarry, P. Numerical modelling of acoustic streaming during the ultrasonic melt treatment of direct-chill (DC) casting. Ultrason. Sonochem. 2019, 54, 171–182. [Google Scholar] [CrossRef]

- Franco, A.; Bartoli, C. Heat Transfer Enhancement due to Acoustic Fields: A Methodological Analysis. Acoustics 2019, 1, 281–294. [Google Scholar] [CrossRef]

- Tian, S.; Barigou, M. An improved vibration technique for enhancing temperature uniformity and heat transfer in viscous fluid flow. Chem. Eng. Sci. 2015, 123, 609–619. [Google Scholar] [CrossRef]

- Oh, Y.; Park, S.; Cho, Y. A study of the effect of ultrasonic vibrations on phase-change heat transfer. Int. J. Heat Mass Transf. 2002, 45, 4631–4641. [Google Scholar] [CrossRef]

- Bulliard-Sauret, O.; Berindei, J.; Ferrouillat, S.; Vignal, L.; Memponteil, A.; Poncet, C.; Leveque, J.; Gondrexon, N. Heat transfer intensification by low or high frequency ultrasound: Thermal and hydrodynamic phenomenological analysis. Exp. Therm. Fluid Sci. 2019, 104, 258–271. [Google Scholar] [CrossRef]

- Gerber, H. Acoustic Properties of Fluid-Filled Chambers at Infrasonic Frequencies in the Absence of Convection. J. Acoust. Soc. Am. 1964, 36, 1427. [Google Scholar] [CrossRef]

- Preston, J.M.; Johnson, W.S. Acoustic Enhancement of the Rate of Heat Transfer Over a Flat Plate-An Experimental Investigation. J. Energy Resour. Technol. 1997, 119, 257–264. [Google Scholar] [CrossRef]

- Lor, W.-B.; Chu, H.-S. Effect of interface thermal resistance on heat transfer in a composite medium using the thermal wave model. Int. J. Heat Mass Transf. 2000, 43, 653–663. [Google Scholar] [CrossRef]

- Adrian, C.; Burețea, D.L. The Influence of Flow Tube Vibrations over the Efficiency of Solar Water Heating Collectors. Energy Procedia 2017, 112, 330–335. [Google Scholar] [CrossRef]

- Chandra, H. Review Paper Application of Vibration on Heat Transfer—A Review. i-Manager’s J. Fut. Eng. Technol. 2019, 15. [Google Scholar]

- Zhang, L.; Lv, J.; Bai, M.; Guo, D. Effect of Vibration on Forced Convection Heat Transfer for SiO2—Water Nanofluids. Heat Transf. Eng. 2014, 36, 452–461. [Google Scholar] [CrossRef]

- Yu, Y.; Liu, Y.; Amandolese, X. A Review on Fluid-Induced Flag Vibrations. Appl. Mech. Rev. 2019, 71, 010801. [Google Scholar] [CrossRef]

- Duan, D.; Ge, P.; Bi, W.; Ji, J. Numerical investigation on the heat transfer enhancement mechanism of planar elastic tube bundle by flow-induced vibration. Int. J. Therm. Sci. 2017, 112, 450–459. [Google Scholar] [CrossRef]

- Sahay, N.; Ierapetritou, M. Nihar SCM. IFAC Proc. Vol. 2009, 7, 405–410. [Google Scholar]

- Delouei, A.A.; Sajjadi, H.; Mohebbi, R.; Izadi, M. Experimental study on inlet turbulent flow under ultrasonic vibration: Pressure drop and heat transfer enhancement. Ultrason. Sonochem. 2019, 51, 151–159. [Google Scholar] [CrossRef] [PubMed]

- Rao, B.S.; Babu, S.R. Experimental Investigation on Natural Convection Heat Transfer Augmentation with Vibration Effection; International Research Journal of Engineering and Technology: Andhra Pradesh, India, 2019; pp. 1496–1501. [Google Scholar]

- Mishra, S.K.; Chandra, H.; Arora, A. Effect of velocity and rheology of nanofluid on heat transfer of laminar vibrational flow through a pipe under constant heat flux. Int. Nano Lett. 2019, 9, 245–256. [Google Scholar] [CrossRef]

- Su, Y.; Gao, L.; Li, L.; Li, X.; Zhang, C. A study of the vortex-induced lateral vibration and heat transfer characteristics of elastic supported single tubes with different cross-sectional shapes. Int. Commun. Heat Mass Transf. 2019, 104, 8–14. [Google Scholar] [CrossRef]

- Sarhan, A.; Karim, R.; Kadhim, Z.; Naser, J. Experimental investigation on the effect of vertical vibration on thermal performances of rectangular flat plate. Exp. Therm. Fluid Sci. 2019, 101, 231–240. [Google Scholar] [CrossRef]

| Method | Description |

|---|---|

| Modifying FPSC Design | Changing the FPSC standard design |

| Absorber Coatings | Adding a coating to the glass cover to improve absorbance |

| polymer Material | Using polymer as FPSC material to reduce cost |

| Nanofluid | Adding nanoparticle to the working fluid to increase the heat-transfer area |

| Mini and Microchannel | Shrinking the heat exchanger tube to increase the heat-transfer area |

| phase change material (PCM) | Store excess energy to be used later |

| Heat Loss Reduction | Adding extra insulation to reduce heat loss |

| Enhancement devices | Adding devices to increase heat capacity, turbulences or promote fluid mixing |

| turbulators | Adding turbulator to increase and promote fluid mixing |

| Method | Author | Configuration | Thermal Efficiency Improved | Findings |

|---|---|---|---|---|

| Modifying FPSC design | Visa et al. [31] | Novel triangle FPSC | 55% | A good result achieved from a small overall dimension of the collector. Real efficiency and reliability are not yet proving. |

| Tadahmun et al. [30] | Storage tank with corrugated absorber | 59% at 0.005 ; 65% at 0.0091 kg/s; 67% at 0.013 kg/s | With an increasing flow rate, higher efficiency achieved. Setup encounters significant thermal losses during night–time due to direct exposure to ambient temperature. | |

| Absorber coatings | Müller et al. [32] | 1—PVD 2—Black chrome 3—Thermochromic 4—Solar paint | n/a | Spectral selectivity of solar absorbers coatings can enhance thermal performance and reduce the risk of overheating or stagnation. |

| Heat loss reduction | Zhou et al. [20] | Transparent insulation material (TIM) | n/a | The operation of the collector with TIM at a small flow rate has more advantages than at a high flow rate. With TIM, cold operations (winter) has more advantages compare to without insulation. |

| Nanofluid | Thong et al. [33] | Al2O3 CuO | 56.9% efficiency 49.6% efficiency | Better efficiency achieved with higher concentration. |

| Polymer material | Filipović et al. [34] | Polymer solar collector | n/a | 30% lower efficiency compared to conventional |

| Phase change material | Wang et al. [35] | Dual-phase change material (PCM) 20% high purity graphite 80% natural grease | High temperature increased 19.6%; low temperature 24.1% increased. | Suitable for tackling freezing and overheating problems of a collector |

| Enhancement devices | Balaji et al. [19,40,41] | Rod and tube insert | 76% rod 72% tube | Rod is better than the tube because of its higher heat capacity; however, this method causes blockage in the system and increases the pressure drop. These thermal enhancer type performed better at lower Reynold’s number (<200) |

| Kanimozhi et al. [37] | Porous medium with agitator aluminum sheet metal (agitator) pebble stone (porous medium) | 63.8% | Higher heat-transfer area, however, immense pressure drops while adding more weight to the collector resulting in more robust support. | |

| Fan et al. [38] | V-corrugated absorber | 10.7% higher than non-V-corrugated absorber | Able to employ with other thermal enhancers such as nanofluid and turbulence creator. | |

| Turbulators | Felipe et al. [39] | Vortex generator delta winglet rectangular winglet | n/a | Delta-winglet vortex generator achieved higher efficiency than a rectangular winglet. |

| Heat-transfer enhancement using vibration | Sahlani et al. [42] | Forced vibration on ETSC | 78% | Efficiency increased as frequency increased. |

| Acoustic Range | Author | Type | Vibration | Thermal Efficiency Improvement |

|---|---|---|---|---|

| Power ultrasound (20 kHz < f < 1 MHz) | Amiri et al. [63] | experimental | forced | increased by 7.3% |

| Bulliard-Sauret et al. [53] | experiment | forced | n/a | |

| Lebon et al. [39] | numerical | forced | n/a | |

| Sound (20 Hz < f < 20 kHz) | Sudhakara Rao et al. [64] | experimental | forced | n/a |

| Santosh et al. [65] | numerical | forced | increased by 51% | |

| Infrasound (f < 20 Hz) | Su et al. [66] | numerical | passive | increased by 28.6%. (vertical elliptical); 21.3% (circular tube); 3.7% (horizontal elliptical); |

| Sarhan et al. [67] | experimental | forced | n/a |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shamsul Azha, N.I.; Hussin, H.; Nasif, M.S.; Hussain, T. Thermal Performance Enhancement in Flat Plate Solar Collector Solar Water Heater: A Review. Processes 2020, 8, 756. https://doi.org/10.3390/pr8070756

Shamsul Azha NI, Hussin H, Nasif MS, Hussain T. Thermal Performance Enhancement in Flat Plate Solar Collector Solar Water Heater: A Review. Processes. 2020; 8(7):756. https://doi.org/10.3390/pr8070756

Chicago/Turabian StyleShamsul Azha, Nurril Ikmal, Hilmi Hussin, Mohammad Shakir Nasif, and Tanweer Hussain. 2020. "Thermal Performance Enhancement in Flat Plate Solar Collector Solar Water Heater: A Review" Processes 8, no. 7: 756. https://doi.org/10.3390/pr8070756

APA StyleShamsul Azha, N. I., Hussin, H., Nasif, M. S., & Hussain, T. (2020). Thermal Performance Enhancement in Flat Plate Solar Collector Solar Water Heater: A Review. Processes, 8(7), 756. https://doi.org/10.3390/pr8070756