Optimizing the Processing Factor and Formulation of Oat-Based Cookie Dough for Enhancement in Stickiness and Moisture Content Using Response Surface Methodology and Superimposition

Abstract

1. Introduction

2. Materials and Methods

2.1. Design of Experiment Based on RSM

2.2. Experiment Design

2.3. Raw Materials

2.4. Cookie Dough Preparation

2.5. Cookie Dough Formulation

2.6. Stickiness Analysis

2.7. Moisture Content Analysis

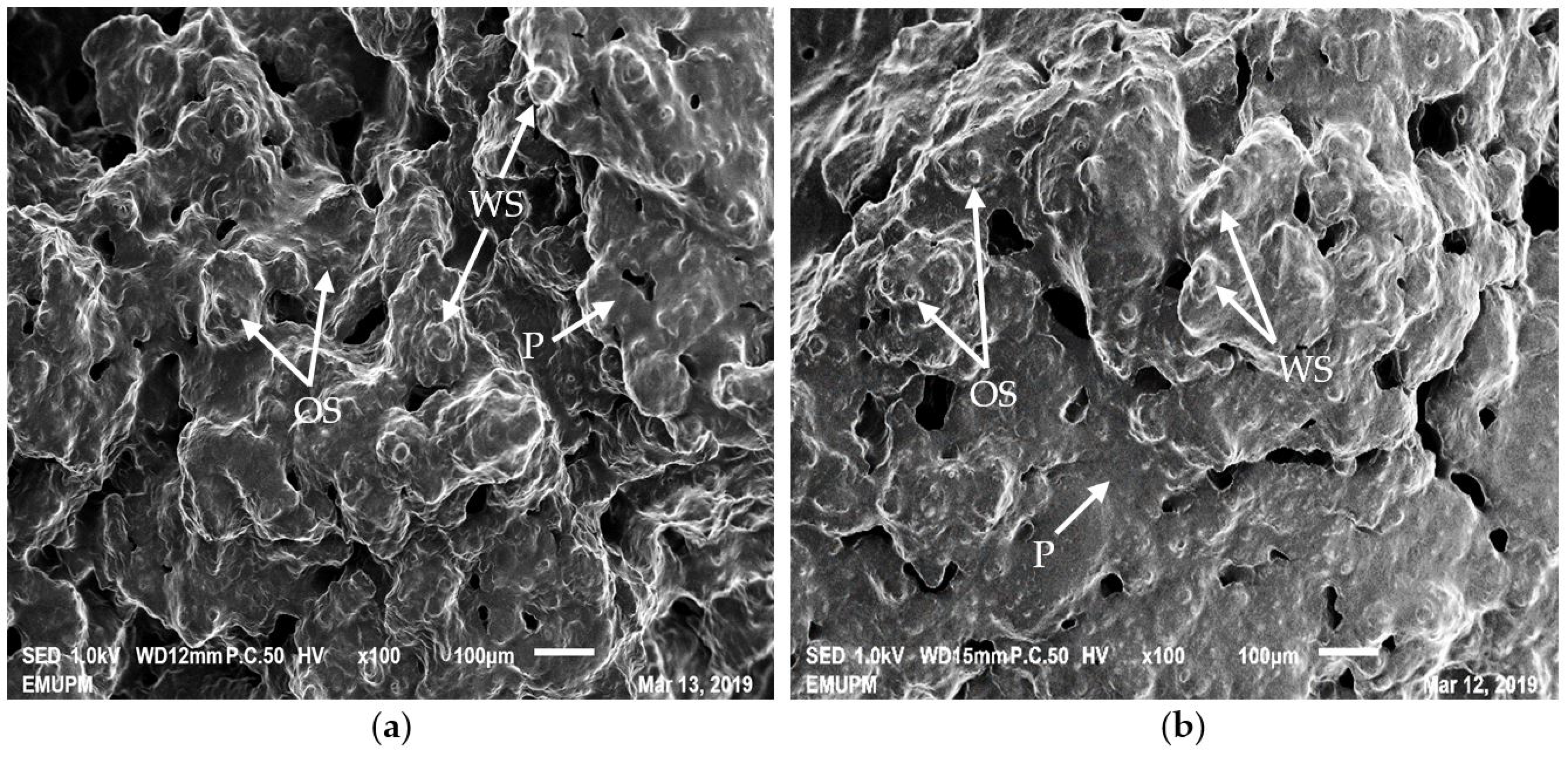

2.8. Microstructure Analysis

3. Results and Discussion

3.1. Statistical Analysis of Stickiness

3.2. Effect of Factors on Stickiness

3.3. Statistical Analysis of Moisture Content

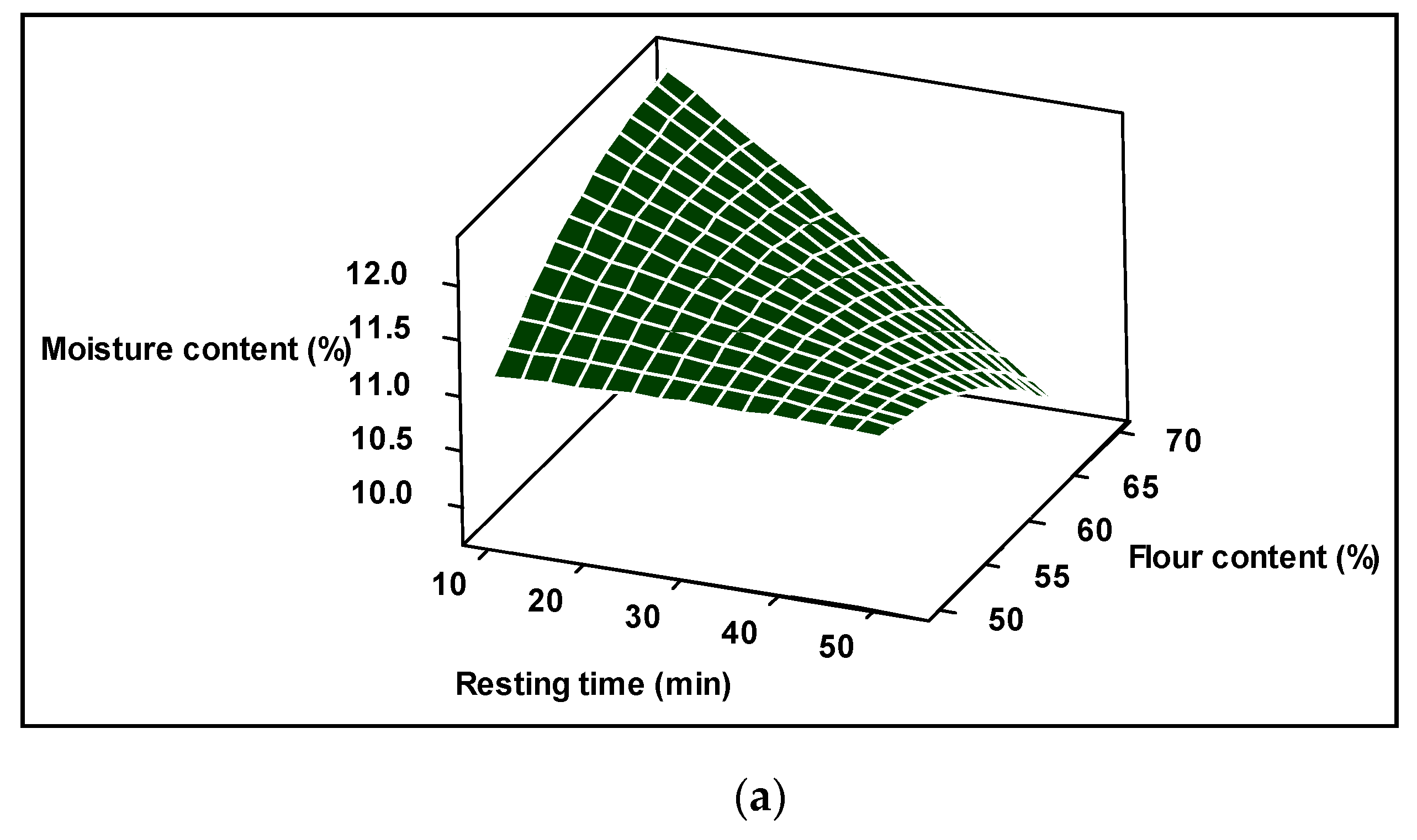

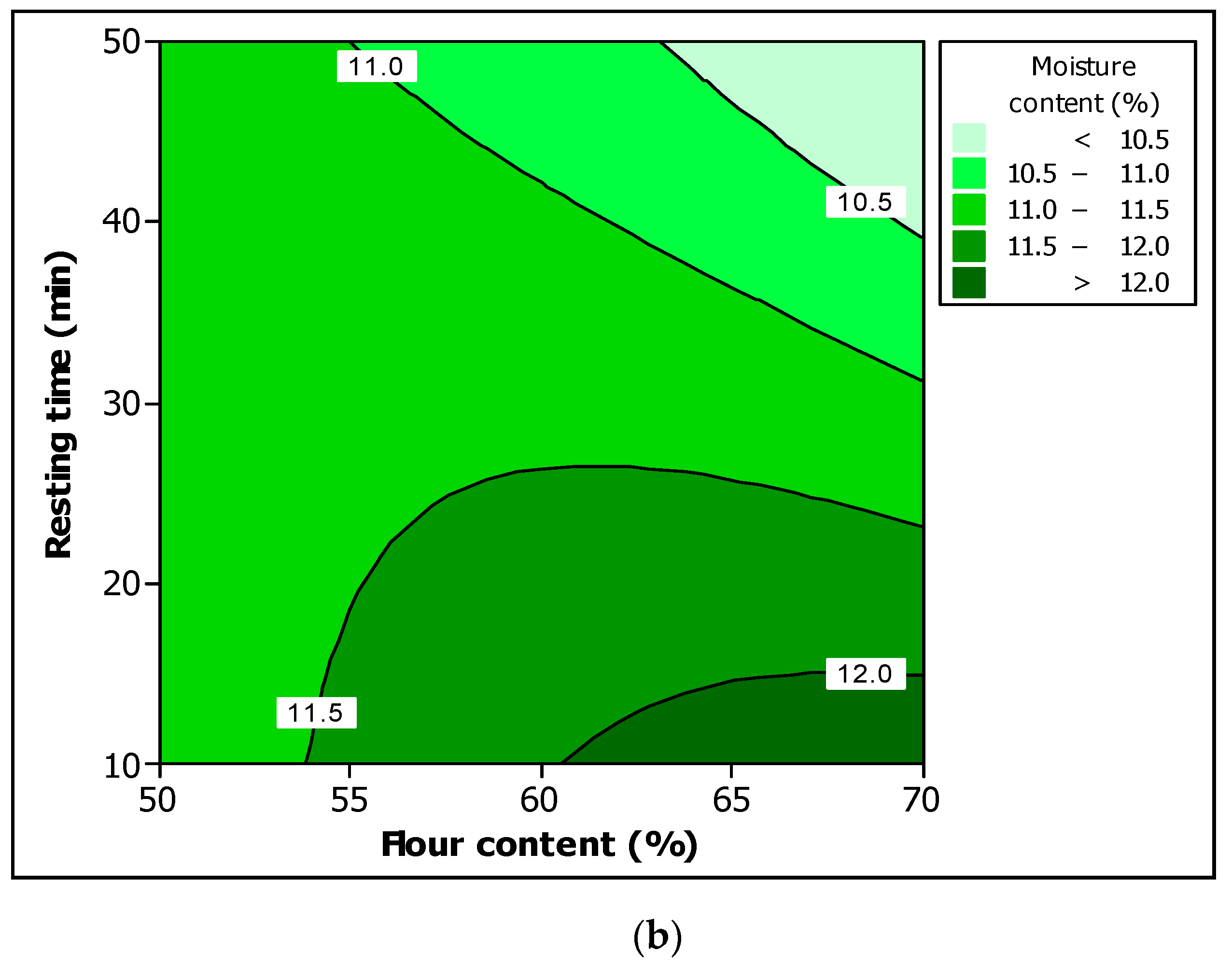

3.4. Effect of Factors on Moisture Content

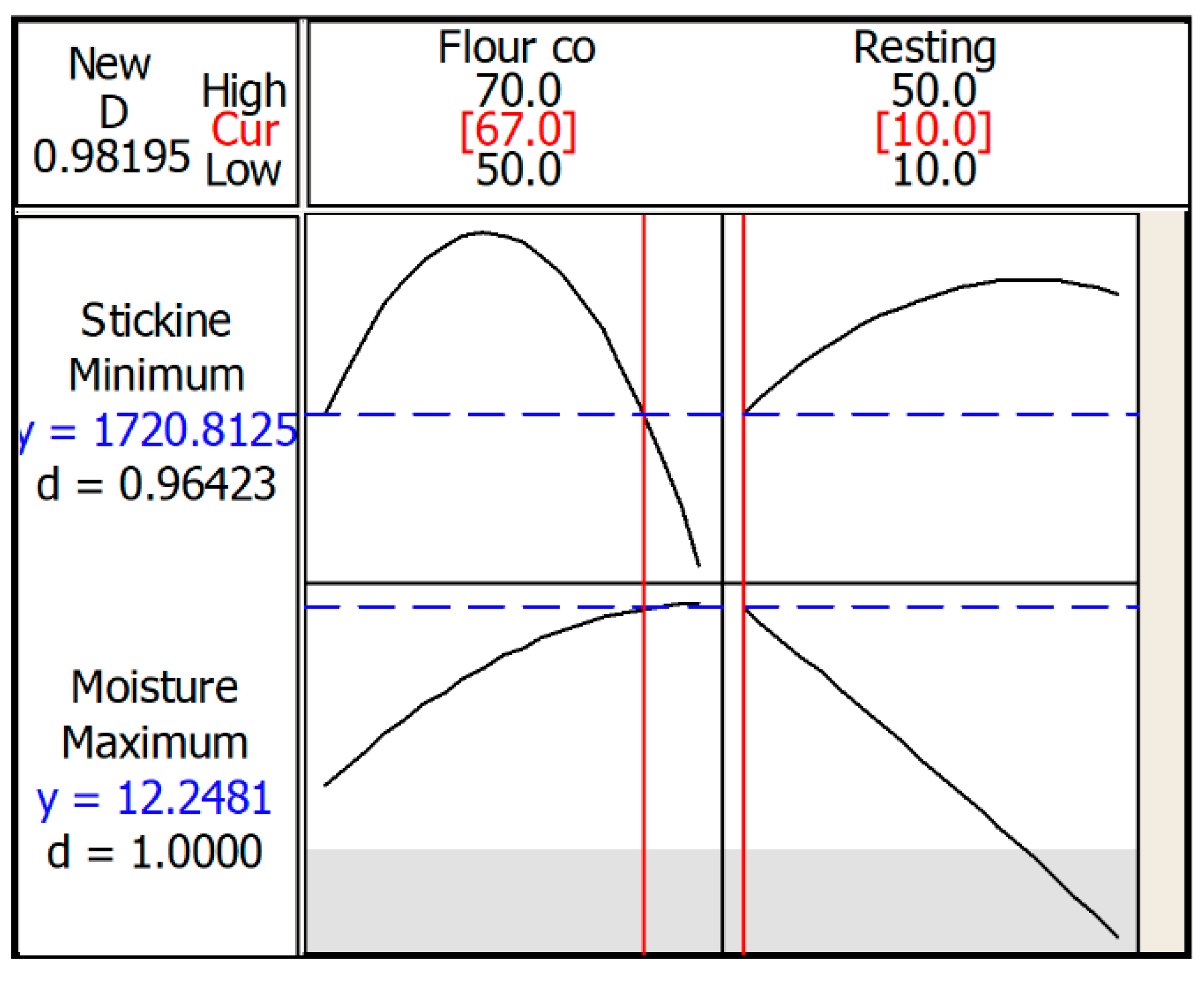

3.5. Optimization of the Responses

3.6. Experimental Validation

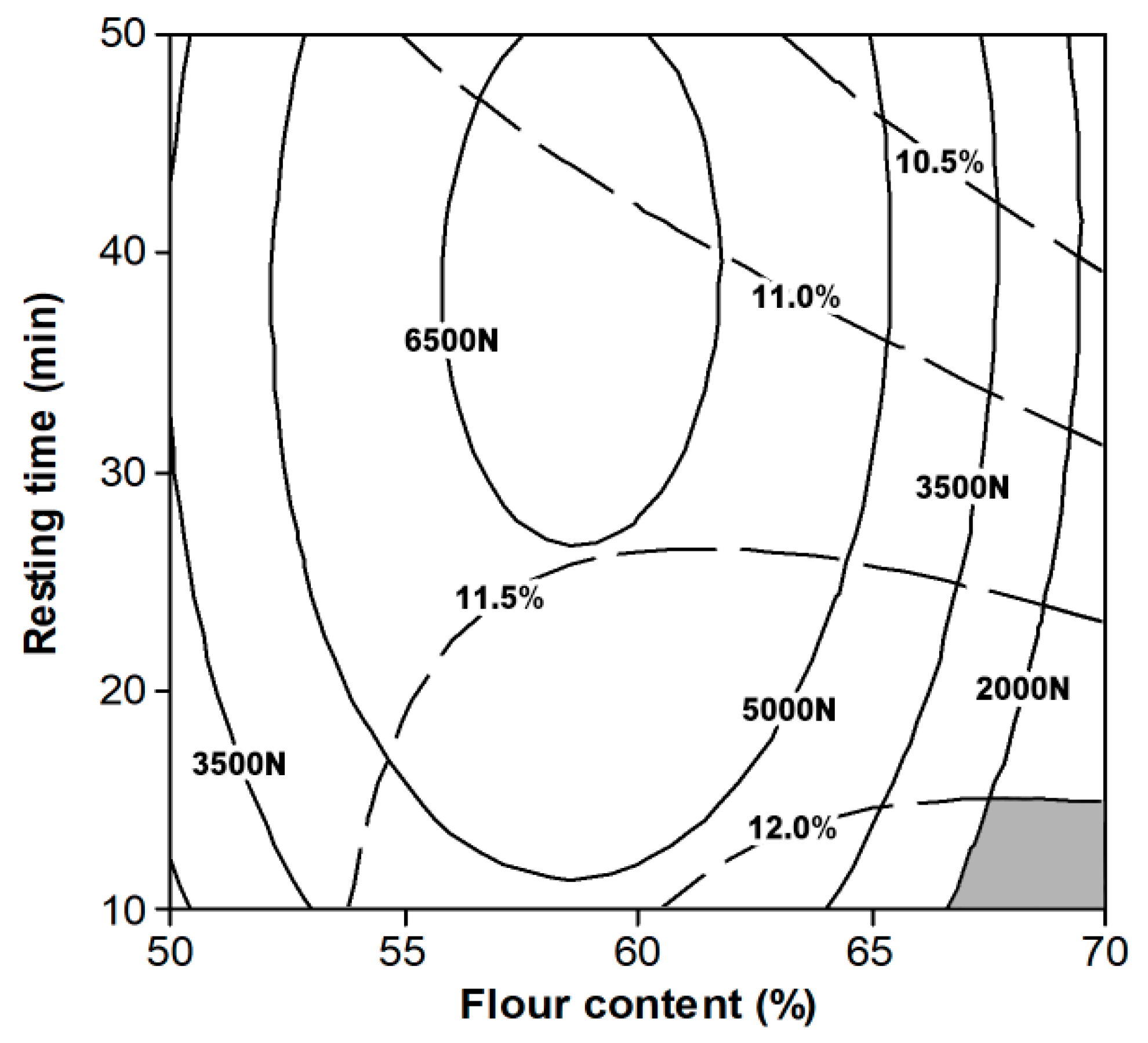

3.7. Contour Plots Superimposition

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Anozie, G.; China, M.; Beleya, E. Sensory evaluation and proximate composition of snacks produced from campsite flour of dioscorea alata and telfairia occidentalis seeds flours. J. Home Econ. Res. 2014, 20, 100–108. [Google Scholar]

- Davidson, I. Biscuit, Cookie and Cracker Production: Process, Production and Packaging Equipment; Academic Press: Cambridge, MA, USA, 2018. [Google Scholar]

- Carcea, M. Nutritional Value of Grain-Based Foods. Foods 2020, 9, 504. [Google Scholar] [CrossRef] [PubMed]

- Andersson, A.A.; Dimberg, L.; Åman, P.; Landberg, R. Recent findings on certain bioactive components in whole grain wheat and rye. J. Cereal Sci. 2014, 59, 294–311. [Google Scholar] [CrossRef]

- Hossain, A.; Brennan, M.A.; Mason, S.L.; Guo, X.; Zeng, X.A.; Brennan, C.S. The effect of astaxanthin-rich microalgae “Haematococcus pluvialis” and wholemeal flours incorporation in improving the physical and functional properties of cookies. Foods 2017, 6, 57. [Google Scholar] [CrossRef]

- Kowalczewski, P.Ł.; Walkowiak, K.; Masewicz, Ł.; Bartczak, O.; Lewandowicz, J.; Kubiak, P.; Baranowska, H.M. Gluten-Free Bread with Cricket Powder—Mechanical Properties and Molecular Water Dynamics in Dough and Ready Product. Foods 2019, 8, 240. [Google Scholar] [CrossRef] [PubMed]

- Oliveira, L.C.; Rosell, C.M.; Steel, C.J. Effect of the addition of whole-grain wheat flour and of extrusion process parameters on dietary fibre content, starch transformation and mechanical properties of a ready-to-eat breakfast cereal. Int. J. Food Sci. Technol. 2015, 50, 1504–1514. [Google Scholar] [CrossRef]

- Tolve, R.; Pasini, G.; Vignale, F.; Favati, F.; Simonato, B. Effect of Grape Pomace Addition on the Technological, Sensory, and Nutritional Properties of Durum Wheat Pasta. Foods 2020, 9, 354. [Google Scholar] [CrossRef]

- Ye, E.Q.; Chacko, S.A.; Chou, E.L.; Kugizaki, M.; Liu, S. Greater whole-grain intake is associated with lower risk of type 2 diabetes, cardiovascular disease, and weight gain. J. Nutr. 2012, 142, 1304–1313. [Google Scholar] [CrossRef]

- Knudsen, M.D.; Kyro, C.; Olsen, A.; Dragsted, L.O.; Skeie, G.; Lund, E.; Aman, P.; Nilsson, L.M.; Bueno-de-Mesquita, H.B.; Tjonneland, A.; et al. Self-reported whole-grain intake and plasma alkylresorcinol concentrations in combination in relation to the incidence of colorectal cancer. Am. J. Epidemiol. 2014, 179, 1188–1196. [Google Scholar] [CrossRef]

- Cho, S.S.; Qi, L.; Fahey, G.C., Jr.; Klurfeld, D.M. Consumption of cereal fiber, mixtures of whole grains and bran, and whole grains and risk reduction in type 2 diabetes, obesity, and cardiovascular disease. Am. J. Clin. Nutr. 2013, 98, 594–619. [Google Scholar] [CrossRef]

- Zhou, A.L.; Hergert, N.; Rompato, G.; Lefevre, M. Whole grain oats improve insulin sensitivity and plasma cholesterol profile and modify gut microbiota composition in C57BL/6J mice. J. Nutr. 2015, 145, 222–230. [Google Scholar] [CrossRef]

- Krotkiewski, M. Use of fibres in different weight reduction programs. Diet. Fiber Obes. Curr. Top. Nutr. Dis. 1985, 14, 85–109. [Google Scholar]

- Agin, B.; Jegtvig, S. Superfoods for Dummies; John Wiley & Sons: Hoboken, NJ, USA, 2009. [Google Scholar]

- Holm, J.; Björck, I. Bioavailability of starch in various wheat-based bread products: Evaluation of metabolic responses in healthy subjects and rate and extent of in vitro starch digestion. Am. J. Clin. Nutr. 1992, 55, 420–429. [Google Scholar] [CrossRef] [PubMed]

- Mamat, H.; Hill, S.E. Effect of fat types on the structural and textural properties of dough and semi-sweet biscuit. J. Food Sci. Technol. 2014, 51, 1998–2005. [Google Scholar] [CrossRef] [PubMed]

- Hartel, R.W.; Joachim, H.; Elbe, V.; Hofberger, R. Confectionery Science and Technology; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar]

- Czubaszek, A.; Karolini-Skaradziñska, Z. Effects of wheat flour supplementation with oat products on dough and bread quality. Pol. J. Food Nutr. Sci. 2005, 14, 281. [Google Scholar]

- Khatkar, B. Effect of protein contents and water absorption values on dynamic rheological properties of wheat flour dough. J. Food Sci. Technol. Mysore 2005, 42, 321–325. [Google Scholar]

- Grausgruber, H.; Hatzenbichler, E.; Ruckenbauer, P. Analysis of repeated stickiness measures of wheat dough using a texture analyzer. J. Texture Stud. 2003, 34, 69–82. [Google Scholar] [CrossRef]

- Dobraszczyk, B. The rheological basis of dough stickiness. J. Texture Stud. 1997, 28, 139–162. [Google Scholar] [CrossRef]

- Hoseney, R.; Smewing, J. Instrumental measurement of stickiness of doughs and other foods. J. Texture Stud. 1999, 30, 123–136. [Google Scholar] [CrossRef]

- Adhikari, B.; Howes, T.; Bhandari, B.; Truong, V. Stickiness in foods: A review of mechanisms and test methods. Int. J. Food Prop. 2001, 4, 1–33. [Google Scholar] [CrossRef]

- Fendri, L.B.; Chaari, F.; Maaloul, M.; Kallel, F.; Abdelkafi, L.; Chaabouni, S.E.; Ghribi-Aydi, D. Wheat bread enrichment by pea and broad bean pods fibers: Effect on dough rheology and bread quality. LWT 2016, 73, 584–591. [Google Scholar] [CrossRef]

- Sangnark, A.; Noomhorm, A. Effect of dietary fiber from sugarcane bagasse and sucrose ester on dough and bread properties. LWT-Food Sci. Technol. 2004, 37, 697–704. [Google Scholar] [CrossRef]

- Ahmed, J.; Thomas, L. Effect of β-glucan concentrate on the water uptake, rheological and textural properties of wheat flour dough. Int. J. Food Prop. 2015, 18, 1801–1816. [Google Scholar] [CrossRef]

- Wenjun, L.; Margaret, B.; Luca, S.; Charles, B. The Effect of Oat Bran on the Dough Rheology and Quality of Chinese Steamed Bread. Grain Oil Sci. Technol. 2018, 1, 126–130. [Google Scholar]

- Campbell, G.M.; Ross, M.; Motoi, L. Bran in bread: Effects of particle size and level of wheat and oat bran on mixing, proving and baking. In Bubbles in Food 2; Elsevier: Amsterdam, The Netherlands, 2008; pp. 337–354. [Google Scholar]

- Osella, C.; Sanchez, H.; De La Torre, M. Effect of dough water content and mixing conditions on energy imparted to dough and bread quality. Cereal Foods World 2007, 52, 70. [Google Scholar]

- Manohar, R.S.; Rao, P.H. Effects of water on the rheological characteristics of biscuit dough and quality of biscuits. Eur. Food Res. Technol. 1999, 209, 281–285. [Google Scholar] [CrossRef]

- Aprodu, I.; Badiu, E.A.; Banu, I. Influence of protein and water addition on gluten-free dough properties and bread quality. Int. J. Food Eng. 2016, 12, 355–363. [Google Scholar] [CrossRef]

- Sudha, M.; Vetrimani, R.; Leelavathi, K. Influence of fibre from different cereals on the rheological characteristics of wheat flour dough and on biscuit quality. Food Chem. 2007, 100, 1365–1370. [Google Scholar] [CrossRef]

- Yoshino, D.; Matsumoto, H. Colloid titration of wheat proteins, dough, and flour. Cereal Chem. 1966, 43, 187–195. [Google Scholar]

- Hamed, A.; Ragaee, S.; Marcone, M.; Abdel-Aal, E.S.M. Quality of Bread and Cookie Baked from Frozen Dough and Batter Containing β-Glucan-Rich Barley Flour Fraction. J. Food Qual. 2015, 38, 316–327. [Google Scholar] [CrossRef]

- Lai, H.; Lin, T. Bakery products: Science and technology. Bak. Prod. Sci. Technol. 2006, 2, 3–65. [Google Scholar]

- Czitrom, V. One-factor-at-a-time versus designed experiments. Am. Stat. 1999, 53, 126–131. [Google Scholar]

- Box, G.E.; Wilson, K.B. On the experimental attainment of optimum conditions. In Breakthroughs in Statistics; Springer: Berlin/Heidelberg, Germany, 1992; pp. 270–310. [Google Scholar]

- Czyrski, A.; Jarzębski, H. Response Surface Methodology as a Useful Tool for Evaluation of the Recovery of the Fluoroquinolones from Plasma—The Study on Applicability of Box-Behnken Design, Central Composite Design and Doehlert Design. Processes 2020, 8, 473. [Google Scholar] [CrossRef]

- Basri, M.S.M.; Mustapha, F.; Mazlan, N.; Ishak, M.R. Optimization of Rice Husk Ash-Based Geopolymers Coating Composite for Enhancement in Flexural Properties and Microstructure Using Response Surface Methodology. Coatings 2020, 10, 165. [Google Scholar] [CrossRef]

- Asante-Sackey, D.; Rathilal, S.; Pillay, L.V.; Kweinor Tetteh, E. Ion Exchange Dialysis for Aluminium Transport through a Face-Centred Central Composite Design Approach. Processes 2020, 8, 160. [Google Scholar] [CrossRef]

- Kaleem, M.; Ahmad, A.; Amir, R.M.; Kaukab Raja, G. Ultrasound-Assisted Phytochemical Extraction Condition Optimization Using Response Surface Methodology from Perlette Grapes (Vitis vinifera). Processes 2019, 7, 749. [Google Scholar] [CrossRef]

- Basheer, A.O.; M Hanafiah, M.; Abdulhakim Alsaadi, M.; Al-Douri, Y.; Malek, M.; Mohammed Aljumaily, M.; Saadi Fiyadh, S. Synthesis and characterization of natural extracted precursor date palm fibre-based activated carbon for aluminum removal by RSM optimization. Processes 2019, 7, 249. [Google Scholar] [CrossRef]

- Shim, S.; Won, S.; Reza, A.; Kim, S.; Ahmed, N.; Ra, C. Design and Optimization of Fluidized Bed Reactor Operating Conditions for Struvite Recovery Process from Swine Wastewater. Processes 2020, 8, 422. [Google Scholar] [CrossRef]

- Tran, Q.T.; Vu Thi, T.L.; Do, T.L.; Pham Thi, H.M.; Hoang Thi, B.; Chu, Q.T.; Lai Phuong, P.T.; Do, H.N.; Hoang Than, H.T.; Ta Thi, T.T. Optimization of Microwave-Assisted Extraction Process of Callicarpa candicans (Burm. f.) Hochr Essential Oil and Its Inhibitory Properties against Some Bacteria and Cancer Cell Lines. Processes 2020, 8, 173. [Google Scholar] [CrossRef]

- Tabaraki, R.; Nateghi, A. Optimization of ultrasonic-assisted extraction of natural antioxidants from rice bran using response surface methodology. Ultrason. Sonochem. 2011, 18, 1279–1286. [Google Scholar] [CrossRef]

- Majid, M.A.A.; Abidin, I.H.Z.; Majid, H.; Chik, C.T. Issues of halal food implementation in Malaysia. J. Appl. Environ. Biol. Sci. 2015, 5, 50–56. [Google Scholar]

- Webster, F.; Wood, P. Oat utilization: Past, present and future. Oats Chem. Technol. 2011, 347–361. [Google Scholar]

- Dovesfarm.co.uk. US Cups Conversion Table. Available online: https://www.dovesfarm.co.uk/uploads/files/DovesFarm_US_Cups_Conversion_Table.pdf (accessed on 1 May 2020).

- Réhault-Godbert, S.; Guyot, N.; Nys, Y. The golden egg: Nutritional value, bioactivities, and emerging benefits for human health. Nutrients 2019, 11, 684. [Google Scholar]

- Chen, W.; Hoseney, R. Development of an objective method for dough stickiness. LWT-Food Sci. Technol. 1995, 28, 467–473. [Google Scholar] [CrossRef]

- Agrahar-Murugkar, D.; Dixit-Bajpai, P. Physicochemical, textural, color, nutritional, scanning electron microscopy and sensorial characterization of calcium-rich breads fortified with sesame, malted finger millet, cumin and moringa leaves. Nutr. Food Sci. 2019, 50, 47–60. [Google Scholar] [CrossRef]

- Yildiz, O.; Meral, R.; Dogan, I.S. Determination of stickiness values of different flour combinations. Int. J. Food Eng. 2012, 8, 1–11. [Google Scholar] [CrossRef]

- Fustier, P.; Castaigne, F.; Turgeon, S.; Biliaderis, C. Flour constituent interactions and their influence on dough rheology and quality of semi-sweet biscuits: A mixture design approach with reconstituted blends of gluten, water-solubles and starch fractions. J. Cereal Sci. 2008, 48, 144–158. [Google Scholar] [CrossRef]

- Laukemper, R.; Jekle, M.; Becker, T. Time-dependent adhesion behavior between dough and contact surfaces in bakeries. J. Food Eng. 2019, 255, 24–31. [Google Scholar] [CrossRef]

- Roman-Gutierrez, A.; Sabathier, J.; Guilbert, S.; Galet, L.; Cuq, B. Characterization of the surface hydration properties of wheat flours and flour components by the measurement of contact angle. Powder Technol. 2003, 129, 37–45. [Google Scholar] [CrossRef]

- van Velzen, E.J.; van Duynhoven, J.P.; Pudney, P.; Weegels, P.L.; van der Maas, J.H. Factors associated with dough stickiness as sensed by attenuated total reflectance infrared spectroscopy. Cereal Chem. 2003, 80, 378–382. [Google Scholar] [CrossRef]

- Tang, X.; Liu, J. A comparative study of partial replacement of wheat flour with whey and soy protein on rheological properties of dough and cookie quality. J. Food Qual. 2017, 2017, 1–10. [Google Scholar] [CrossRef]

- Rodriguez-Sandoval, E.; Franco, C.M.L.; Manjarres-Pinzon, K. Effect of fructooligosaccharides on the physicochemical properties of sour cassava starch and baking quality of gluten-free cheese bread. Starch-Stärke 2014, 66, 678–684. [Google Scholar] [CrossRef]

- Kim, Y.R.; Cornillon, P.; Campanella, O.; Stroshine, R.; Lee, S.; Shim, J.Y. Small and large deformation rheology for hard wheat flour dough as influenced by mixing and resting. J. Food Sci. 2008, 73, E1–E8. [Google Scholar] [CrossRef] [PubMed]

- Wu, J.; Hoseney, R. Rheological changes in cracker sponges during an 18-hour fermentation. Cereal Chem. 1989, 66, 182–185. [Google Scholar]

- Wang, L.; White, P. Structure and physicochemical properties of starches from oats with different lipid contents. Cereal Chem. 1994, 71, 443–450. [Google Scholar]

- Dachana, K.; Rajiv, J.; Indrani, D.; Prakash, J. Effect of dried moringa (Moringa oleifera lam) leaves on rheological, microstructural, nutritional, textural and organoleptic characteristics of cookies. J. Food Qual. 2010, 33, 660–677. [Google Scholar] [CrossRef]

- Brites, L.T.G.F.; Ortolan, F.; Silva, D.W.D.; Bueno, F.R.; Rocha, T.D.S.; Chang, Y.K.; Steel, C.J. Gluten-free cookies elaborated with buckwheat flour, millet flour and chia seeds. Food Sci. Technol. 2019, 39, 458–466. [Google Scholar] [CrossRef]

- Majzoobi, M.; Layegh, B.; Farahnaky, A. Inclusion of oat flour in the formulation of regular salted dried noodles and its effects on dough and noodle properties. J. Food Process. Preserv. 2014, 38, 48–58. [Google Scholar] [CrossRef]

- Sarabhai, S.; Prabhasankar, P. Influence of whey protein concentrate and potato starch on rheological properties and baking performance of Indian water chestnut flour based gluten free cookie dough. LWT-Food Sci. Technol. 2015, 63, 1301–1308. [Google Scholar] [CrossRef]

- Agyare, K.; Addo, K.; Xiong, Y.; Akoh, C. Effect of structured lipid on alveograph characteristics, baking and textural qualities of soft wheat flour. J. Cereal Sci. 2005, 42, 309–316. [Google Scholar] [CrossRef]

- Assifaoui, A.; Champion, D.; Chiotelli, E.; Verel, A. Rheological behaviour of biscuit dough in relation to water mobility. Int. J. Food Sci. Technol. 2006, 41, 124–128. [Google Scholar] [CrossRef]

- Hazelton, J.L.; DesRochers, J.L.; Walker, C.E. Biscuits, Cookies, and Crackers|Chemistry of Biscuit Making. In Encyclopedia of Food Sciences and Nutrition, 2nd ed.; Caballero, B., Ed.; Academic Press: Oxford, UK, 2003; pp. 533–539. [Google Scholar] [CrossRef]

- Bushuk, W. Distribution of Water in Dough and Bread. Baker’s Dig. 1966, 40, 38–41. [Google Scholar]

- Milašinović Šeremešić, M.; Dokić, L.; Nikolić, I.; Radosavljević, M.; Šoronja Simović, D. Rheological and textural properties of short (cookie) dough made with two types of resistant starch. J. Texture Stud. 2013, 44, 115–123. [Google Scholar] [CrossRef]

- Ghodke, S.; Ananthanarayan, L.; Rodrigues, L. Use of response surface methodology to investigate the effects of milling conditions on damaged starch, dough stickiness and chapatti quality. Food Chem. 2009, 112, 1010–1015. [Google Scholar] [CrossRef]

- Yi, J.; Kerr, W.L.; Johnson, J.W. Effects of waxy wheat flour and water on frozen dough and bread properties. J. Food Sci. 2009, 74, E278–E284. [Google Scholar] [CrossRef]

- Létang, C.; Piau, M.; Verdier, C. Characterization of wheat flour–water doughs. Part I: Rheometry and microstructure. J. Food Eng. 1999, 41, 121–132. [Google Scholar] [CrossRef]

- Almoraie, N.M. The effect of walnut flour on the physical and sensory characteristics of wheat bread. Int. J. Food Sci. 2019, 2019, 1–7. [Google Scholar] [CrossRef]

- Thacker, B.H.; Doebling, S.W.; Hemez, F.M.; Anderson, M.C.; Pepin, J.E.; Rodriguez, E.A. Concepts of Model Verification and Validation; Los Alamos National Lab: Los Alamos, NM, USA, 2004. [Google Scholar]

- Jampala, P.; Tadikamalla, S.; Preethi, M.; Ramanujam, S.; Uppuluri, K.B. Concurrent production of cellulase and xylanase from Trichoderma reesei NCIM 1186: Enhancement of production by desirability-based multi-objective method. 3 Biotech 2017, 7, 14. [Google Scholar] [CrossRef]

| Factors | Levels | Total Number of Experimental Runs | |

|---|---|---|---|

| Full Factorial Design | RSM | ||

| 2 | 5 | 25 (52) | 13 |

| 3 | 5 | 125 (53) | 20 |

| 4 | 5 | 625 (54) | 31 |

| 5 | 5 | 3125 (56) | 52 |

| Factor | Unit | Notation | Level | ||||

|---|---|---|---|---|---|---|---|

| −2 | −1 | 0 | 1 | 2 | |||

| Flour content | % | V1 | 50 | 55 | 60 | 65 | 70 |

| Resting time | min | V2 | 10 | 20 | 30 | 40 | 50 |

| Sample | Coded factor | Uncoded Factor | ||

|---|---|---|---|---|

| V1 | V2 | V1 | V2 | |

| S1 | 0 | 0 | 60 | 30 |

| S2 | 1 | 1 | 65 | 40 |

| S3 | 0 | −2 | 60 | 10 |

| S4 | 0 | 0 | 60 | 30 |

| S5 | 0 | 0 | 60 | 30 |

| S6 | −1 | 1 | 55 | 40 |

| S7 | 2 | 0 | 70 | 30 |

| S8 | 2 | 0 | 70 | 30 |

| S9 | 0 | 2 | 60 | 50 |

| S10 | −1 | −1 | 55 | 20 |

| S11 | 1 | 1 | 65 | 40 |

| S12 | −2 | 0 | 50 | 30 |

| S13 | 0 | 2 | 60 | 50 |

| S14 | −1 | −1 | 55 | 20 |

| S15 | 1 | −1 | 65 | 20 |

| S16 | −1 | −1 | 55 | 20 |

| S17 | −1 | 1 | 55 | 40 |

| S18 | 0 | 0 | 60 | 30 |

| S19 | 0 | 0 | 60 | 30 |

| S20 | 0 | 0 | 60 | 30 |

| S21 | 0 | 0 | 60 | 30 |

| S22 | −2 | 0 | 50 | 30 |

| S23 | 0 | −2 | 60 | 10 |

| S24 | 0 | 0 | 60 | 30 |

| S25 | 2 | 0 | 70 | 30 |

| S26 | 0 | 0 | 60 | 30 |

| S27 | 0 | 0 | 60 | 30 |

| S28 | −2 | 0 | 50 | 30 |

| S29 | 0 | 2 | 60 | 50 |

| S30 | 0 | 0 | 60 | 30 |

| S31 | −1 | 1 | 55 | 40 |

| S32 | 1 | −1 | 65 | 20 |

| S33 | 0 | 0 | 60 | 30 |

| S34 | 0 | 0 | 60 | 30 |

| S35 | 0 | −2 | 60 | 10 |

| S36 | 0 | 0 | 60 | 30 |

| S37 | 1 | 1 | 65 | 40 |

| S38 | 1 | −1 | 65 | 20 |

| S39 | 0 | 0 | 60 | 30 |

| Characters | Values (%) | |

|---|---|---|

| Wheat Flour | Quick Oat | |

| Moisture | 13.42 ± 0.10 | 8.50 ± 0.08 |

| Ash * | 0.55 ± 0.01 | 1.83 ± 0.02 |

| Protein * | 10.24 ± 0.08 | 14.21 ± 0.12 |

| Wet gluten * | 25.31 ± 0.11 | 0.93 ± 0.03 |

| Ingredients | Weight (g) |

|---|---|

| Quick oat | 27–45 |

| Wheat flour | 60–84 |

| Brown sugar | 25 |

| Coarse grain sugar | 25 |

| Chocolate chip | 30 |

| Cashew nut | 7 |

| Almond slice | 10 |

| Egg | 15 |

| Butter | 125 |

| Baking powder | 3 |

| Composition | Cup Percentage (% cup) | No. of Cup | Weight (g) | |||

|---|---|---|---|---|---|---|

| Oat | Flour | Oat | Flour | Oat | Flour | |

| 50O/50F | 50 | 50 | 0.50 | 0.50 | 45.0 | 60.0 |

| 45O/55F | 45 | 55 | 0.45 | 0.55 | 40.5 | 66.0 |

| 40O/60F | 40 | 60 | 0.40 | 0.60 | 36.0 | 72.0 |

| 35O/65F | 35 | 65 | 0.35 | 0.65 | 31.5 | 78.0 |

| 30O/70F | 30 | 70 | 0.30 | 0.70 | 27.0 | 84.0 |

| Sample | Coded Factor | Uncoded Factor | Response | |||

|---|---|---|---|---|---|---|

| V1 | V2 | V1 | V2 | Stickiness (N) | Moisture Content (%) | |

| S1 | 0 | 0 | 60 | 30 | 6285 | 11.36 |

| S2 | 1 | 1 | 65 | 40 | 4540 | 10.82 |

| S3 | 0 | −2 | 60 | 10 | 4779 | 11.96 |

| S4 | 0 | 0 | 60 | 30 | 6918 | 11.42 |

| S5 | 0 | 0 | 60 | 30 | 6732 | 11.35 |

| S6 | −1 | 1 | 55 | 40 | 6204 | 11.18 |

| S7 | 2 | 0 | 70 | 30 | 1645 | 11.09 |

| S8 | 2 | 0 | 70 | 30 | 1528 | 11.03 |

| S9 | 0 | 2 | 60 | 50 | 6214 | 10.74 |

| S10 | −1 | −1 | 55 | 20 | 5960 | 11.52 |

| S11 | 1 | 1 | 65 | 40 | 4958 | 10.82 |

| S12 | −2 | 0 | 50 | 30 | 2844 | 11.15 |

| S13 | 0 | 2 | 60 | 50 | 6843 | 10.69 |

| S14 | −1 | −1 | 55 | 20 | 5589 | 11.49 |

| S15 | 1 | −1 | 65 | 20 | 4040 | 11.72 |

| S16 | −1 | −1 | 55 | 20 | 5477 | 11.46 |

| S17 | −1 | 1 | 55 | 40 | 6909 | 11.15 |

| S18 | 0 | 0 | 60 | 30 | 6600 | 11.31 |

| S19 | 0 | 0 | 60 | 30 | 6698 | 11.36 |

| S20 | 0 | 0 | 60 | 30 | 6742 | 11.34 |

| S21 | 0 | 0 | 60 | 30 | 6546 | 11.35 |

| S22 | −2 | 0 | 50 | 30 | 3379 | 11.14 |

| S23 | 0 | −2 | 60 | 10 | 4779 | 11.96 |

| S24 | 0 | 0 | 60 | 30 | 6645 | 11.47 |

| S25 | 2 | 0 | 70 | 30 | 1571 | 11.11 |

| S26 | 0 | 0 | 60 | 30 | 6845 | 11.38 |

| S27 | 0 | 0 | 60 | 30 | 6774 | 11.39 |

| S28 | −2 | 0 | 50 | 30 | 3110 | 11.16 |

| S29 | 0 | 2 | 60 | 50 | 6530 | 10.79 |

| S30 | 0 | 0 | 60 | 30 | 6745 | 11.41 |

| S31 | −1 | 1 | 55 | 40 | 6558 | 11.20 |

| S32 | 1 | −1 | 65 | 20 | 3568 | 11.81 |

| S33 | 0 | 0 | 60 | 30 | 6421 | 11.44 |

| S34 | 0 | 0 | 60 | 30 | 6356 | 11.40 |

| S35 | 0 | −2 | 60 | 10 | 4779 | 11.96 |

| S36 | 0 | 0 | 60 | 30 | 6599 | 11.39 |

| S37 | 1 | 1 | 65 | 40 | 5054 | 10.83 |

| S38 | 1 | −1 | 65 | 20 | 3801 | 11.77 |

| S39 | 0 | 0 | 60 | 30 | 6614 | 11.45 |

| Term | Notation | Coefficient | Std. Error of Coefficient | p |

|---|---|---|---|---|

| Constant | 6608.22 | 79.33 | 0.000 | |

| Flour content | V1 | −553.17 | 55.15 | 0.000 |

| Resting time | V2 | 452.44 | 55.15 | 0.000 |

| Flour content *Flour content | V1 *V1 | −1073.78 | 39.91 | 0.000 |

| Resting time *Resting time | V2 *V2 | −246.82 | 39.91 | 0.000 |

| Flour content *Resting time | V1 *V2 | 41.50 | 95.53 | 0.667 |

| R2 = 0.9644 R2(adj) = 0.9590 | ||||

| Term | Notation | Coefficient | Std. Error of Coefficient | p |

|---|---|---|---|---|

| Constant | 11.3892 | 0.008807 | 0.000 | |

| Flour content | V1 | −0.0186 | 0.006123 | 0.005 |

| Resting time | V2 | −0.3081 | 0.006123 | 0.000 |

| Flour content *Flour content | V1 *V1 | −0.0686 | 0.004431 | 0.000 |

| Resting time *Resting time | V2 *V2 | −0.0094 | 0.004431 | 0.041 |

| Flour content *Resting time | V1 *V2 | −0.1575 | 0.010605 | 0.000 |

| R2 = 0.9891 R2(adj) = 0.9875 | ||||

| Sample | Stickiness (N) | Moisture Content (%) | ||||

|---|---|---|---|---|---|---|

| Actual | Predicted | Relative Deviation (%) | Actual | Predicted | Relative Deviation (%) | |

| SV1 | 1832 | 1720 | 6.45 | 12.05 | 12.25 | 1.55 |

| SV2 | 1913 | 1720 | 11.16 | 12.17 | 12.25 | 0.57 |

| SV3 | 1859 | 1720 | 8.02 | 11.97 | 12.25 | 2.21 |

| Average | 8.54 | Average | 1.44 | |||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohd Basri, M.S.; Mohd Jais, N.; Sulaiman, A.; Mohd Nor, M.Z.; Abdul Karim Shah, N.N.; Ariffin, S.H. Optimizing the Processing Factor and Formulation of Oat-Based Cookie Dough for Enhancement in Stickiness and Moisture Content Using Response Surface Methodology and Superimposition. Processes 2020, 8, 797. https://doi.org/10.3390/pr8070797

Mohd Basri MS, Mohd Jais N, Sulaiman A, Mohd Nor MZ, Abdul Karim Shah NN, Ariffin SH. Optimizing the Processing Factor and Formulation of Oat-Based Cookie Dough for Enhancement in Stickiness and Moisture Content Using Response Surface Methodology and Superimposition. Processes. 2020; 8(7):797. https://doi.org/10.3390/pr8070797

Chicago/Turabian StyleMohd Basri, Mohd Salahuddin, Nurain Mohd Jais, Alifdalino Sulaiman, Mohd Zuhair Mohd Nor, Nor Nadiah Abdul Karim Shah, and Siti Hajar Ariffin. 2020. "Optimizing the Processing Factor and Formulation of Oat-Based Cookie Dough for Enhancement in Stickiness and Moisture Content Using Response Surface Methodology and Superimposition" Processes 8, no. 7: 797. https://doi.org/10.3390/pr8070797

APA StyleMohd Basri, M. S., Mohd Jais, N., Sulaiman, A., Mohd Nor, M. Z., Abdul Karim Shah, N. N., & Ariffin, S. H. (2020). Optimizing the Processing Factor and Formulation of Oat-Based Cookie Dough for Enhancement in Stickiness and Moisture Content Using Response Surface Methodology and Superimposition. Processes, 8(7), 797. https://doi.org/10.3390/pr8070797