Performance Prediction Model of Solid Oxide Fuel Cell System Based on Neural Network Autoregressive with External Input Method

Abstract

:1. Introduction

2. Materials and Methods

2.1. Data Description and Test System

2.2. Applied Methodology

2.2.1. NNARX Model

2.2.2. Taguchi OA Method

2.2.3. Model Validation Criteria Metric Definitions

2.2.4. Multi-Step Ahead Prediction

3. Results and Discussion

3.1. Analysis of the Selected NNARX Model Structure

3.2. Comparison and Prediction Analysis

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Stambouli, A.B.; Traversa, E. Solid oxide fuel cells (SOFCs): A review of an environmentally clean and efficient source of energy. Renew. Sustain. Energy Rev. 2002, 6, 433–455. [Google Scholar] [CrossRef]

- E4tech. The Fuel Cell Industry Review 2017; E4tech: London, UK, 2017; Available online: http://www.fuelcellindustryreview.com (accessed on 20 January 2020).

- Kaur, G. Solid Oxide Fuel Cell Components: Interfacial Compatibility of SOFC Glass Seals; Springer: Berlin/Heidelberg, Germany, 2016. [Google Scholar]

- Ma, R.; Gao, F.; Breaz, E.; Huangfu, Y.; Briois, P. Multidimensional Reversible Solid Oxide Fuel Cell Modeling for Embedded Applications. IEEE Trans. Energy Convers. 2018, 33, 692–701. [Google Scholar] [CrossRef]

- Wang, K.; Hissel, D.; Péra, M.C.; Steiner, N.; Marra, D.; Sorrentino, M.; Pianese, C.; Monteverde, M.; Cardone, P.; Saarinen, J. A Review on solid oxide fuel cell models. Int. J. Hydrog. Energy 2011, 36, 7212–7228. [Google Scholar] [CrossRef]

- Gebregergis, A.; Pillay, P.; Bhattacharyya, D.; Rengaswemy, R. Solid oxide fuel cell modeling. IEEE Trans. Ind. Electron. 2009, 56, 139–148. [Google Scholar] [CrossRef] [Green Version]

- Klotz, A.D.; Leonide, A.; Weber, A.; Ivers-Tiffée, E. Electrochemical model for SOFC and SOEC mode predicting performance and efficiency. Int. J. Hydrog. Energy 2014, 39, 20844–20849. [Google Scholar] [CrossRef]

- Hajimolana, S.A.; Hussain, M.A.; Daud, W.M.A.W.; Soroush, M.; Shamiri, A. Mathematical modeling of solid oxide fuel cells: A review. Renew. Sustain. Energy Rev. 2011, 15, 1893–1917. [Google Scholar] [CrossRef]

- Stempien, J.P.; Liu, Q.; Ni, M.; Sun, Q.; Chan, S.H. Physical principles for the calculation of equilibrium potential for co-electrolysis of steam and carbon dioxide in a Solid Oxide Electrolyzer Cell (SOEC). Electrochim. Acta 2014, 147, 490–497. [Google Scholar] [CrossRef]

- Wang, C.; Nehrir, M.H. A physically based dynamic model for solid oxide fuel cells. IEEE Trans. Energy Convers. 2007, 22, 887–897. [Google Scholar] [CrossRef]

- Andersson, M.; Yuan, J.; Sundén, B. Review on modeling development for multiscale chemical reactions coupled transport phenomena in solid oxide fuel cell. Appl. Energy 2010, 87, 1461–1476. [Google Scholar] [CrossRef] [Green Version]

- Peksen, M. A coupled 3D thermofluid–thermomechanical analysis of a planar type production scale SOFC stack. Int. J. Hydrog. Energy 2011, 36, 11914–11928. [Google Scholar] [CrossRef]

- Rossia, I.; Traversoa, A.; Tucker, D. SOFC/Gas Turbine Hybrid System: A simplified framework for dynamic simulation. Appl. Energy 2019, 238, 1543–1550. [Google Scholar] [CrossRef]

- Huang, Q.A.; Hui, R.; Wang, B.; Zhang, J. A review of AC impedance modeling and validation in SOFC diagnosis. Electrochim. Acta 2007, 52, 8144–8164. [Google Scholar] [CrossRef]

- Zhongliang, L.; Rachid, O.; Daniel, H.; Stefan, G. Data-driven diagnosis of PEM fuel cell: A comparative study. Control Eng. Pract. 2014, 28, 1–12. [Google Scholar]

- Wu, Y.; Breaz, E.; Gao, F.; Miraoui, A. A Modified Relevance Vector Machine for PEM Fuel-Cell Stack Aging Prediction. IEEE Trans. Ind. Appl. 2016, 52, 2573–2581. [Google Scholar] [CrossRef]

- Ogaji, S.O.T.; Singh, R.; Pilidis, P.; Diacakis, M. Modelling fuel cell performance using artificial intelligence. J. Power Sources 2006, 154, 192–197. [Google Scholar] [CrossRef]

- Puranik, S.V.; Keyhani, A.; Khorrami, F. Neural Network Modeling of Proton Exchange Membrane Fuel Cell. IEEE Trans. Energy Convers. 2010, 25, 474–483. [Google Scholar] [CrossRef]

- Bozorgmehri, S.; Hamedi, M. Modeling and optimization of anode-supported solid oxide fuel cells on cell parameters via artificial neural network and genetic algorithm. Fuel Cells 2012, 1, 11–23. [Google Scholar] [CrossRef]

- Milewski, J.; Świrski, K. Modelling the SOFC behaviours by artificial neural network. Int. J. Hydrog. Energy 2009, 34, 5546–5553. [Google Scholar] [CrossRef]

- Arriagada, J.; Olausson, P.; Selimovic, A. Artificial neural network simulator for SOFC performance prediction. J. Power Sources 2002, 112, 54–60. [Google Scholar] [CrossRef]

- Chettibi, N.; Mellit, A.; Sulligoi, G.; Pavan, A.M. Adaptive Neural Network-Based Control of a Hybrid AC/DC Microgrid. IEEE Trans. Smart Grid 2018, 9, 1667–1679. [Google Scholar] [CrossRef] [Green Version]

- Wu, X.J.; Zhu, X.J.; Cao, G.Y.; Tu, H.Y. Nonlinear modeling of a SOFC stack based on ANFIS identification. Simul. Model. Pract. Theory 2008, 16, 399–409. [Google Scholar] [CrossRef]

- Sorrentino, M.; Marra, D.; Pianese, C.; Guida, M.; Postiglione, F.; Wang, K.; Pohjoranta, A. On the Use of Neural Networks and Statistical Tools for Nonlinear Modeling and On-field Diagnosis of Solid Oxide Fuel Cell Stacks. Energy Procedia 2014, 45, 298–307. [Google Scholar] [CrossRef] [Green Version]

- Wu, X.J.; Zhu, X.J.; Cao, G.Y.; Tu, H.Y. Modeling a SOFC stack based on GA-RBF neural networks identification. J. Power Sources 2007, 167, 145–150. [Google Scholar] [CrossRef]

- Jaeger, H. Tutorial on Training Recurrent Neural Networks, Covering BPPT, RTRL, EKF and the Echo State Network Approach; Technical Report; Fraunhofer Institute for Autonomous Intelligent Systems (AIS), Since 2003: International University Bremen, Bremen, Germany, 2005; pp. 10–18. [Google Scholar]

- Moghaddamnia, A.; Remesan, R.; Kashani, M.H.; Mohammadi, M.; Han, D.; Piri, J. Comparison of LLR, MLP, Elman, NNARX and ANFIS Models—With a case study in solar radiation estimation. J. Atmos. Sol.-Terr. Phys. 2017, 71, 975–982. [Google Scholar] [CrossRef]

- Montgomery, D.C. Design and Analysis of Experiments, 8th ed.; Wiley: New York, NY, USA, 2012. [Google Scholar]

- Phillip, J.R. Taguchi Techniques for Quality Engineering, 2nd ed.; McGraw-Hill: New York, NY, USA, 2017. [Google Scholar]

- Roy, A.R.K. Design of Experiments Using the Taguchi Approach: 16 Steps to Product and Process Improvement; Wiley: New York, NY, USA, 2001. [Google Scholar]

- Lee, D.; Lin, J.K.; Tsai, C.H.; Wu, S.H.; Cheng, Y.N.; Lee, R.Y. Analysis of long-term and thermal cycling tests for a commercial solid oxide fuel cell. J. Electron. Energy Convers. Storage 2017, 14, 0411021–0411028. [Google Scholar] [CrossRef]

- Ljung, L. System Identification: Theory for User; Prentice–Hall: Upper Saddle River, NJ, USA, 1999. [Google Scholar]

- Hagan, M.T.; Menhaj, M.B. Training feedforward networks with the Marquardt algorithm. IEEE Trans. Neural Netw. 1994, 5, 989–993. [Google Scholar] [CrossRef]

- Söderström, T.; Stoica, P. System Identification; Prentice Hall International: London, UK, 1898. [Google Scholar]

- Mechaqrane, A.; Zouak, M. A comparison of linear and neural network ARX models applied to a prediction of the indoor temperature of a building. Neural Comput. Appl. 2004, 13, 32–37. [Google Scholar]

- Kashani, M.N.; Shahhosseini, S. A methodology for modeling batch reactors using generalized dynamic neural networks. Chem. Eng. J. 2010, 159, 195–202. [Google Scholar] [CrossRef]

- Lyu, J.; Zhang, J. BP neural network prediction model for suicide attempt among Chinese rural residents. J. Affect. Disord. 2019, 246, 465–473. [Google Scholar] [CrossRef]

- Norgaard, M.; Ravn, O.; Poulsen, N.K.; Hansen, L.K. Neural Networks for Modelling and Control of Dynamic Systems; Springer: London, UK, 2003. [Google Scholar]

- Beal, M.H.; Hagan, M.T.; Demuth, H.B. Neural Network Toolbox User’s Guide; The Mathworks Inc.: Natick, MA, USA, 2016. [Google Scholar]

| Symbol | Factors | Level-1 | Level-2 | Level-3 |

|---|---|---|---|---|

| A | Hidden neural (hn) | 5 | 10 | 15 |

| B | Output order (na) | 1 | 3 | 5 |

| C | Input order (nb) | 1 | 3 | 5 |

| D | Time delay (nk) | 1 | 3 | 5 |

| Exp. Number | A | B | C | D | NSSE Training | NSSE Validation | PI | SN |

|---|---|---|---|---|---|---|---|---|

| 1 | 1 | 1 | 1 | 1 | 4.53 | 4.64 | 9.16 | 166.782 |

| 2 | 1 | 2 | 2 | 2 | 3.91 | 4.22 | 8.13 | 167.838 |

| 3 | 1 | 3 | 3 | 3 | 3.85 | 4.16 | 8.02 | 167.962 |

| 4 | 2 | 1 | 2 | 3 | 4.51 | 4.69 | 9.20 | 166.749 |

| 5 | 2 | 2 | 3 | 1 | 3.77 | 4.12 | 7.89 | 168.099 |

| 6 | 2 | 3 | 1 | 2 | 3.85 | 4.18 | 8.03 | 167.943 |

| 7 | 3 | 1 | 3 | 2 | 4.46 | 4.81 | 9.26 | 166.703 |

| 8 | 3 | 2 | 1 | 3 | 3.98 | 4.19 | 8.17 | 167.787 |

| 9 | 3 | 3 | 2 | 1 | 3.73 | 4.22 | 7.95 | 168.06 |

| Level | A(hn) | B(na) | C(nb) | D(nc) |

|---|---|---|---|---|

| Level-1 | 167.527 | 167.745 | 167.504 | 167.647 |

| Level-2 | 167.597 | 167.908 | 167.549 | 167.495 |

| Level-3 | 167.517 | 167.988 | 167.588 | 167.500 |

| Effect | 0.080 | 0.084 | 1.24330 | 0.1525 |

| Rank | 4 | 1 | 3 | 2 |

| Factor | Degrees of Freedom | Sun of Square | Mean Square | Contribution | p-Value |

|---|---|---|---|---|---|

| A(hn) | (2) | 0.0013 | - | - | - |

| B(na) | 2 | 2.8058 | 1.4029 | 97.60% | 5.353 |

| C(nb) | (2) | 0.0075 | - | - | - |

| D(nc) | 2 | 0.0377 | 0.0188 | 0.95% | 1.30 |

| Error | 4 | 0.0207 | 0.0052 | 0.41% | |

| Total | 8 | 2.86416 | 100% |

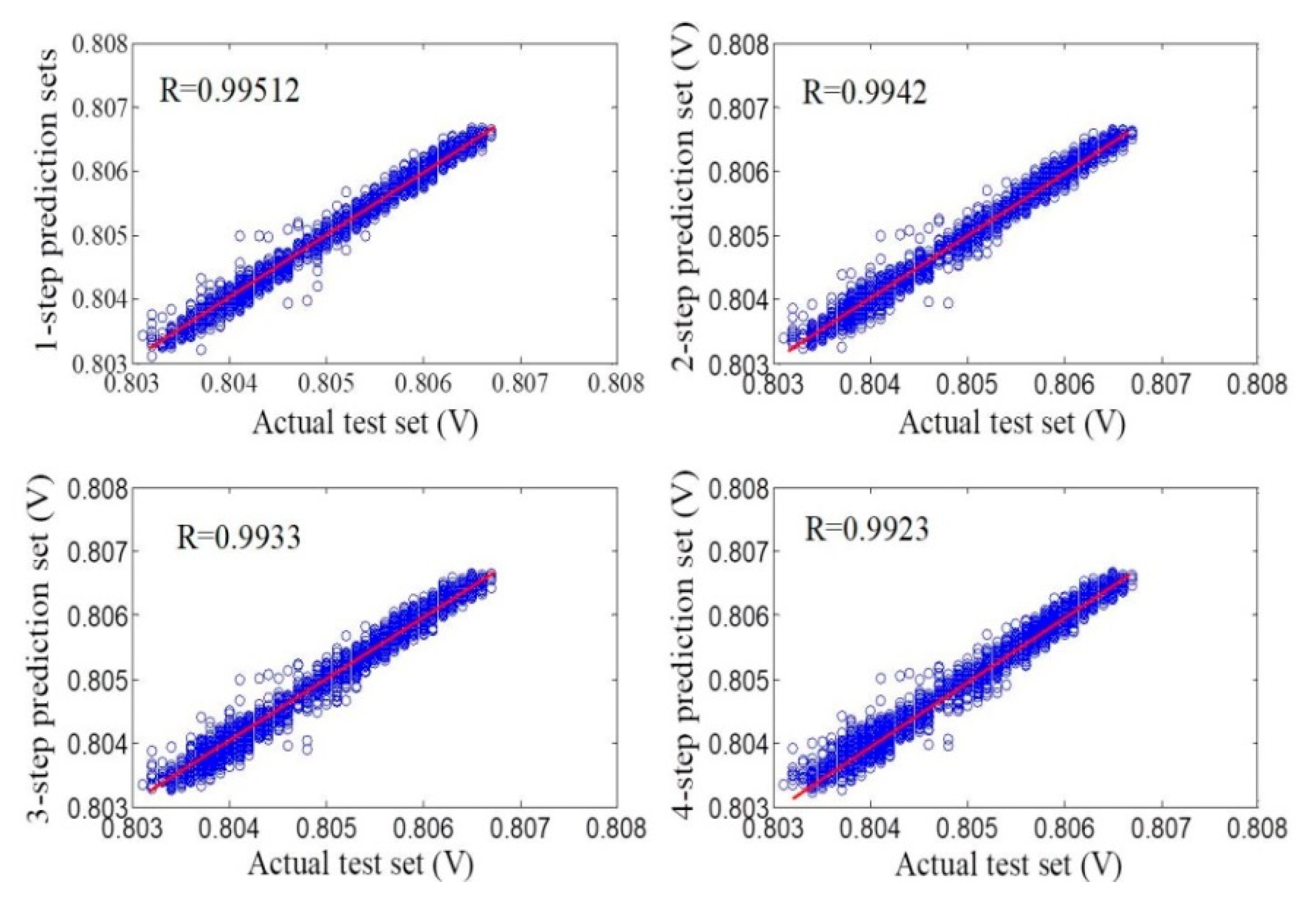

| k-Step Prediction | Performance Criteria | OA5 (A2B2C3D1) | Optimal Test (A2B3C3D1) |

|---|---|---|---|

| One-step ahead | RMSE | 9.08 | 8.96 |

| MAE | 6.673 | 6.57 | |

| MAPE (100%) | 2.352 | 2.297 | |

| R2 | 0.9911 | 0.9914 | |

| Two-step ahead | RMSE | 1.01 | 9.87 |

| MAE | 7.437 | 7.22 | |

| MAPE (100%) | 2.648 | 2.599 | |

| R2 | 0.9878 | 0.9883 | |

| Three-step ahead | RMSE | 1.10 | 1.06 |

| MAE | 8.108 | 7.75 | |

| MAPE (100%) | 2.884 | 2.813 | |

| R2 | 0.9854 | 0.9866 | |

| Four-step ahead | RMSE | 1.21 | 1.13 |

| MAE | 8.871 | 8.30 | |

| MAPE (100%) | 2.922 | 2.848 | |

| R2 | 0.9824 | 0.9847 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, S.-J.; Lin, J.-K. Performance Prediction Model of Solid Oxide Fuel Cell System Based on Neural Network Autoregressive with External Input Method. Processes 2020, 8, 828. https://doi.org/10.3390/pr8070828

Cheng S-J, Lin J-K. Performance Prediction Model of Solid Oxide Fuel Cell System Based on Neural Network Autoregressive with External Input Method. Processes. 2020; 8(7):828. https://doi.org/10.3390/pr8070828

Chicago/Turabian StyleCheng, Shan-Jen, and Jing-Kai Lin. 2020. "Performance Prediction Model of Solid Oxide Fuel Cell System Based on Neural Network Autoregressive with External Input Method" Processes 8, no. 7: 828. https://doi.org/10.3390/pr8070828