Numerical Investigation on the Sieving Performance of Elliptical Vibrating Screen

Abstract

1. Introduction

2. Sieving Characteristics

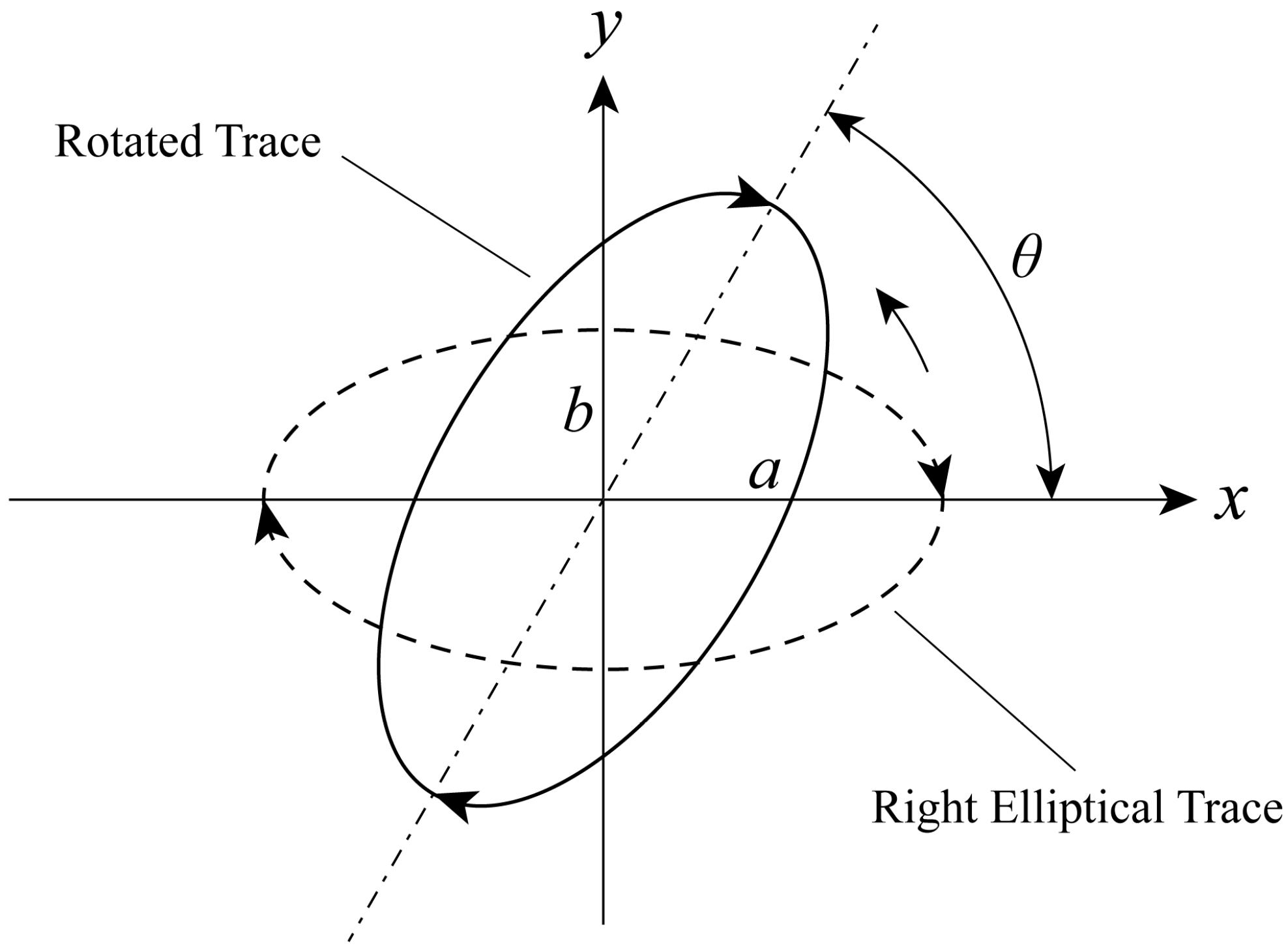

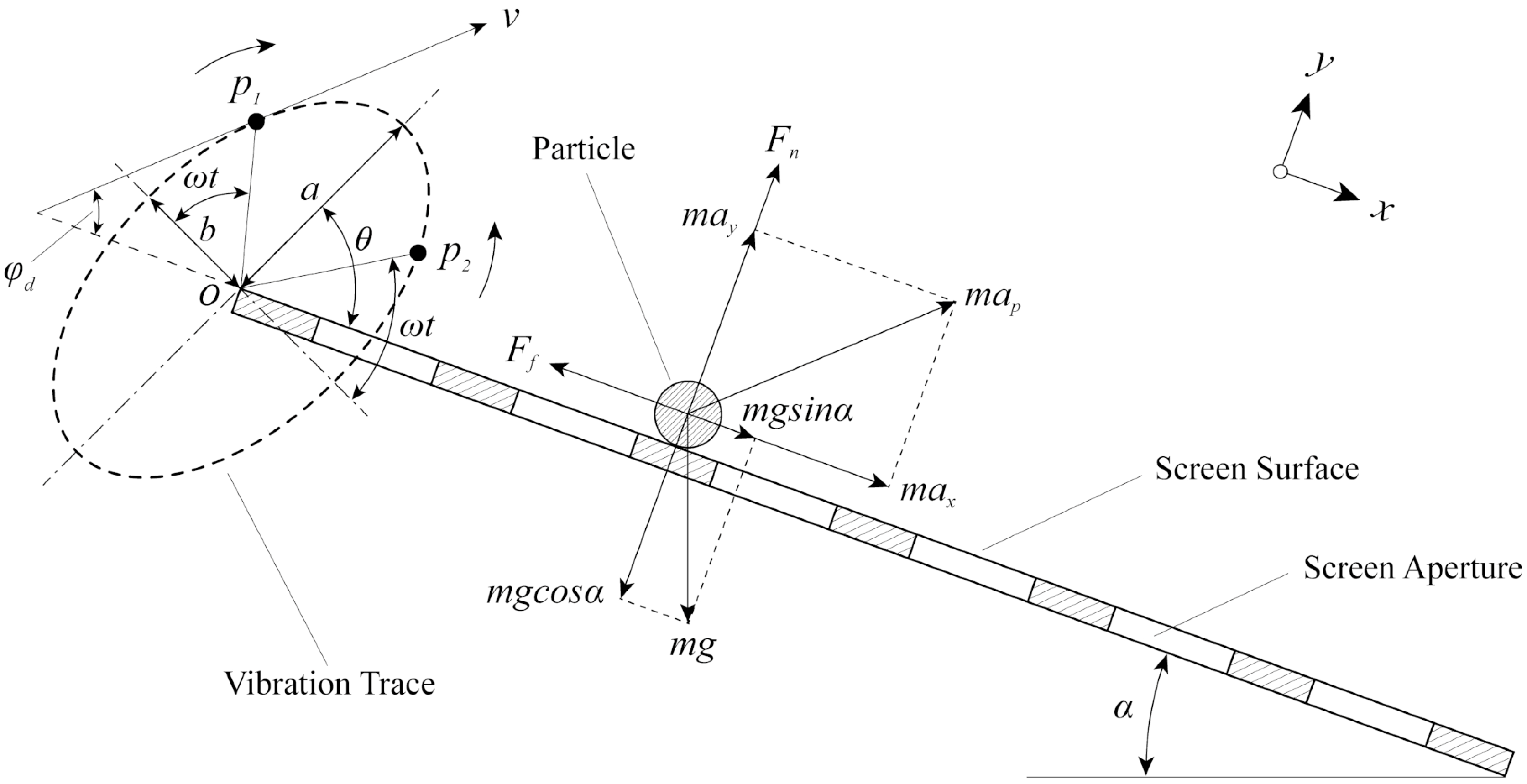

2.1. Kinetic Analysis of the Screen

2.2. Motion Analysis of Particle

3. Numerical Experiments

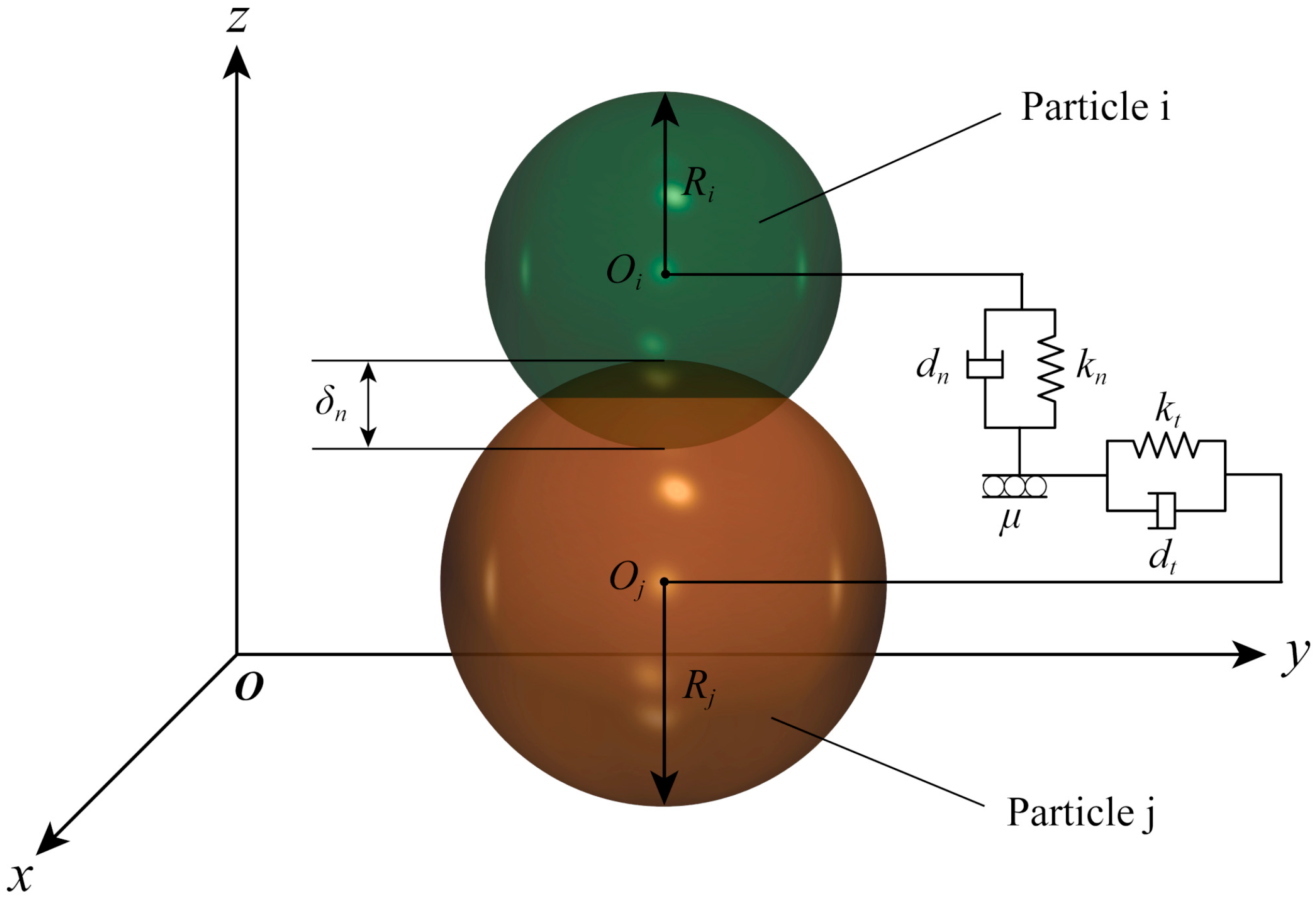

3.1. DEM Description

3.2. Simulation Model

3.3. Performance Evaluation

4. Results and Discussion

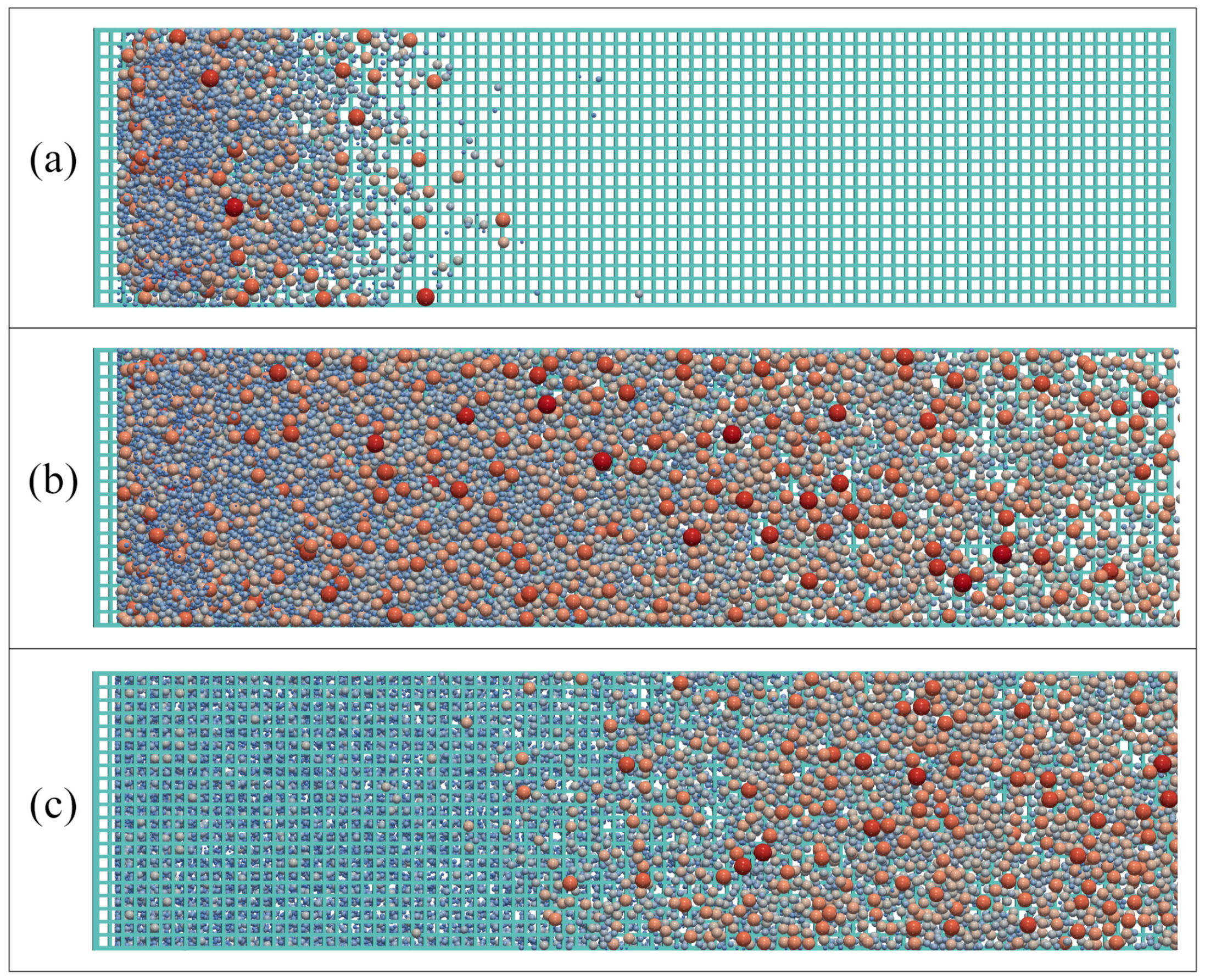

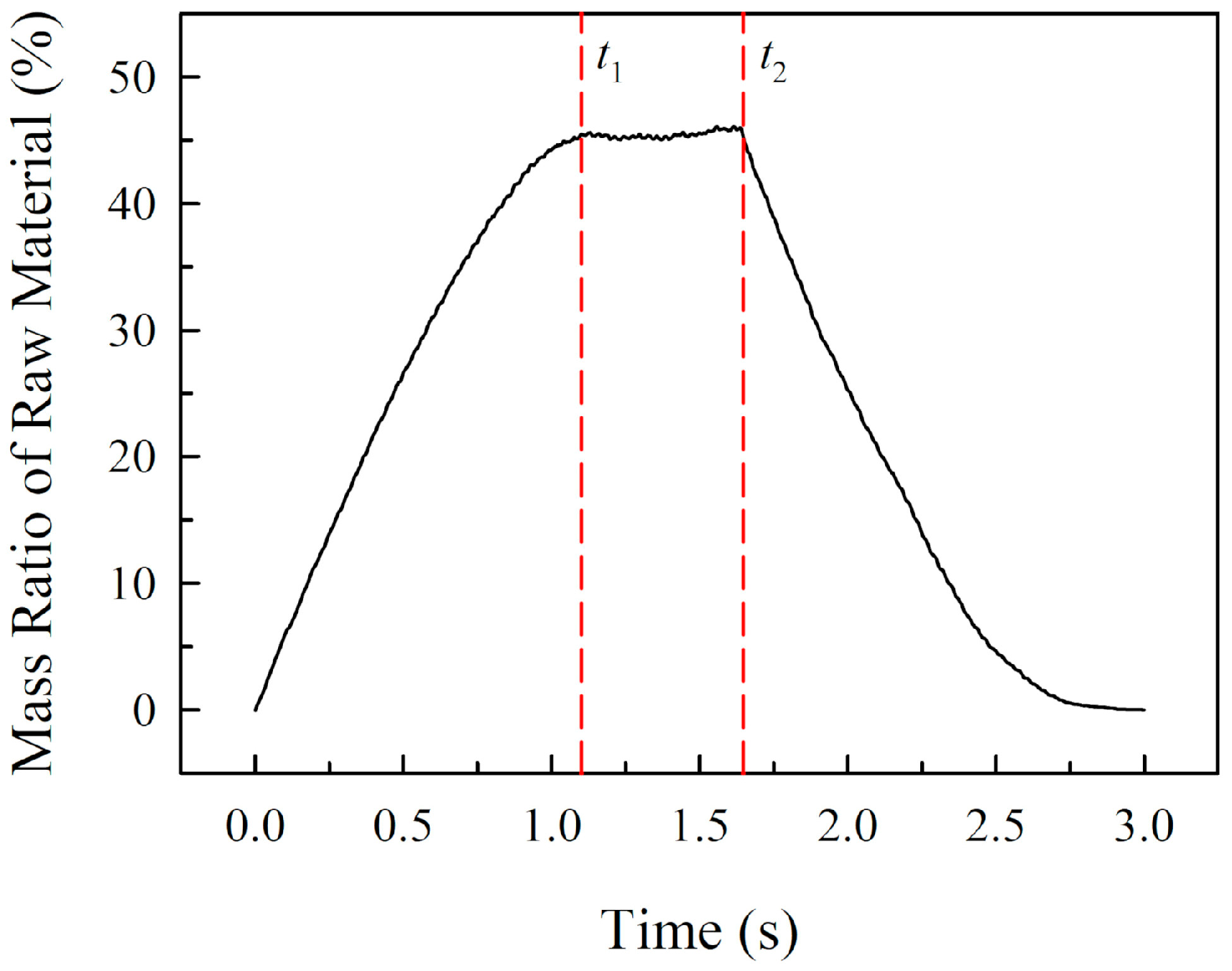

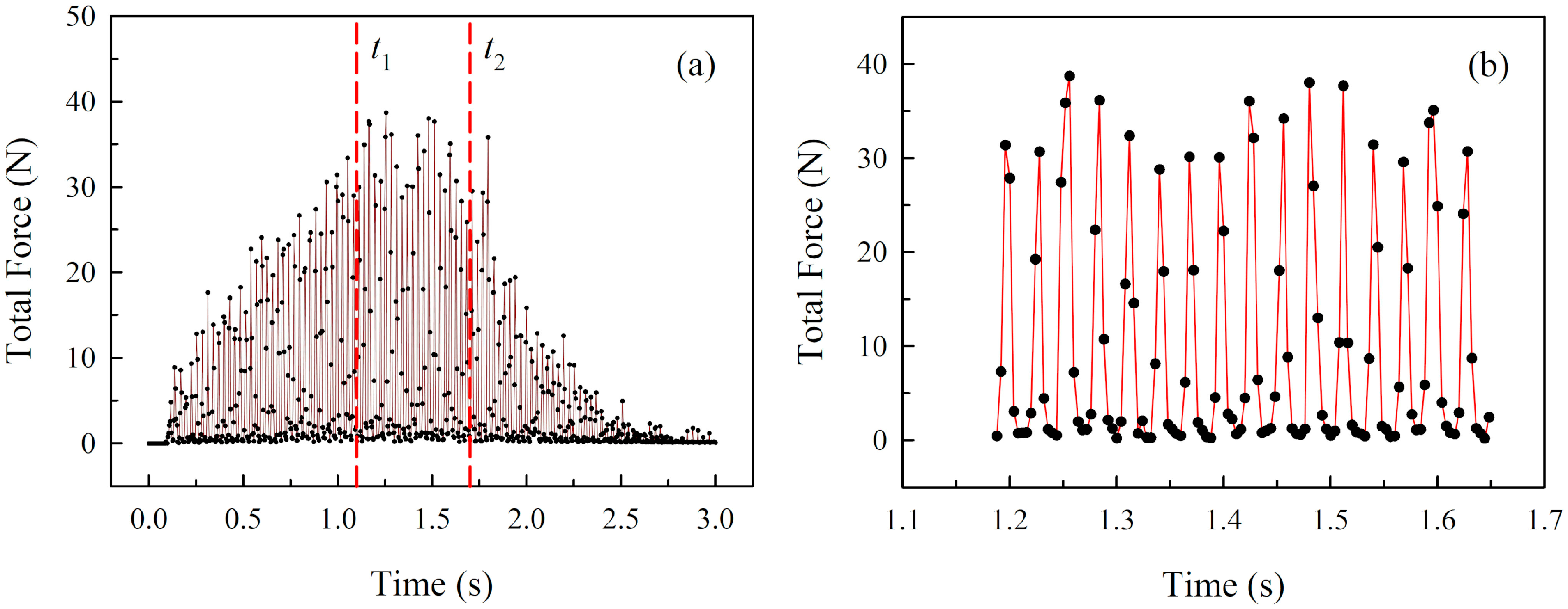

4.1. Sieving Process

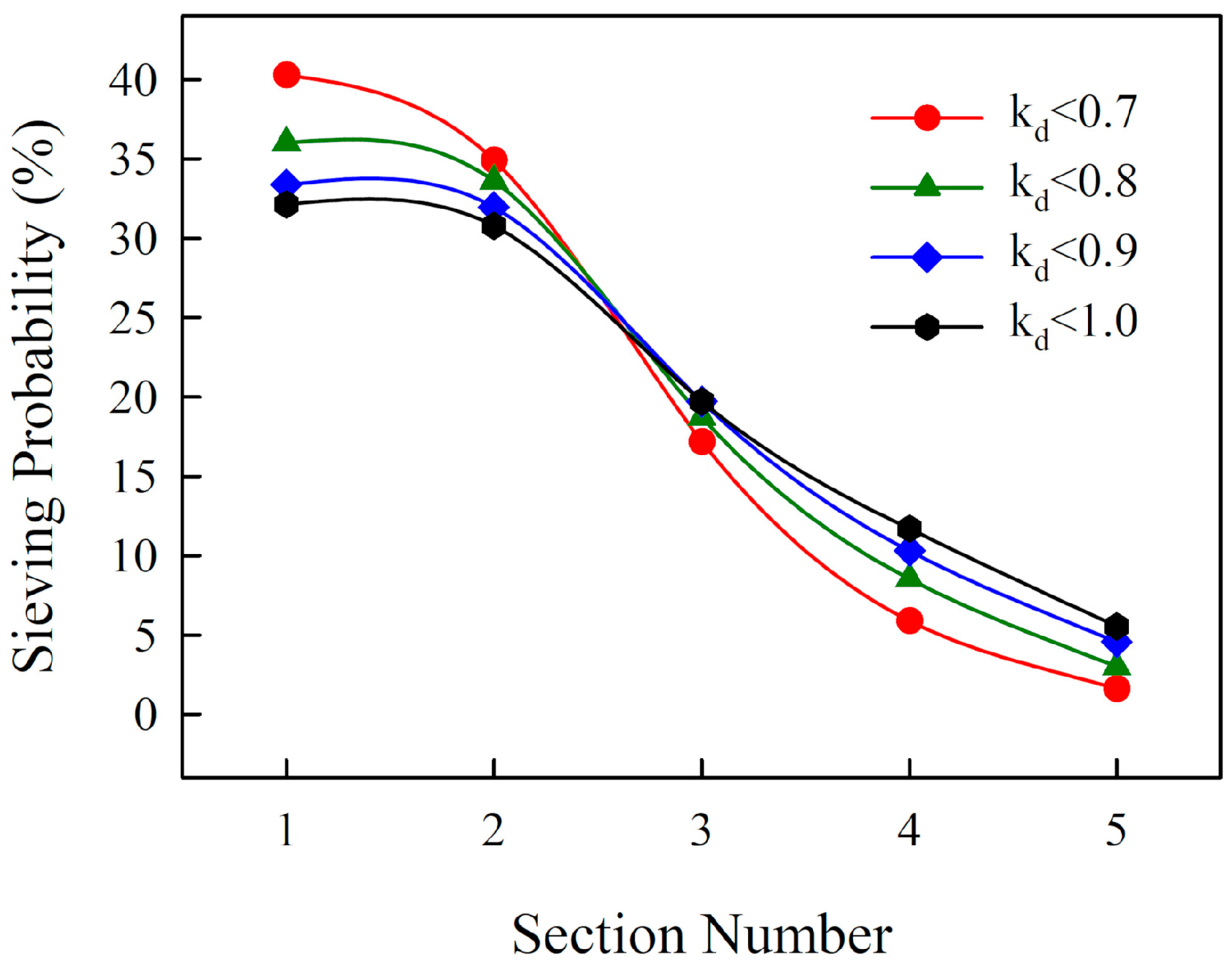

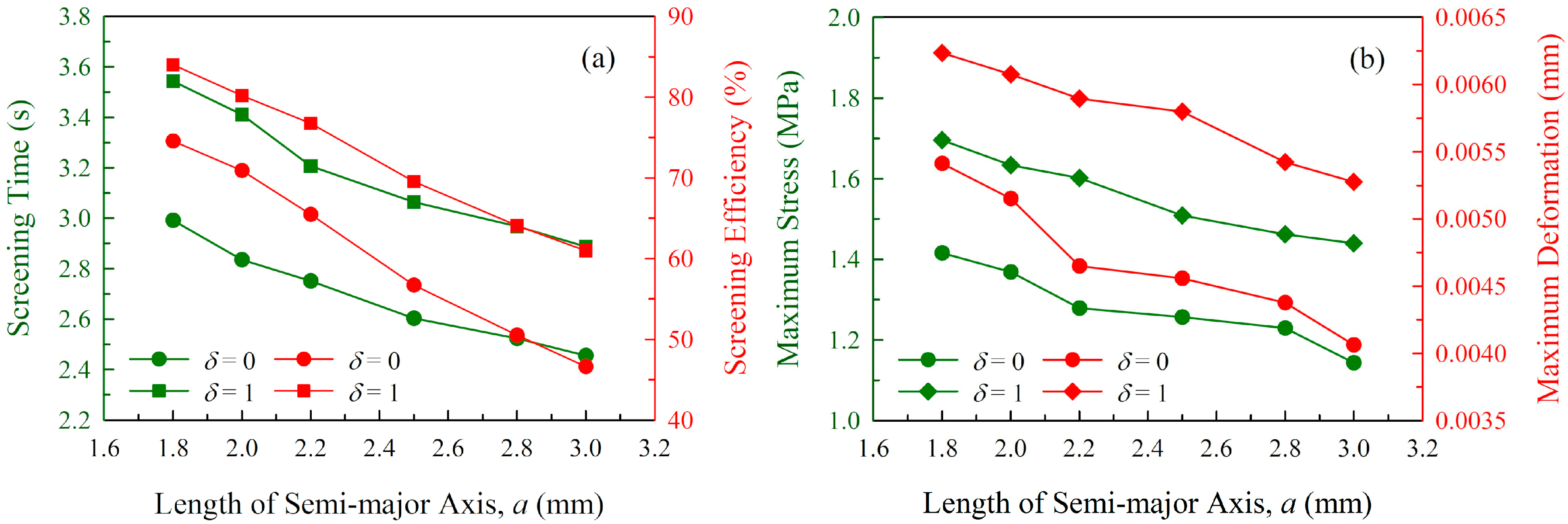

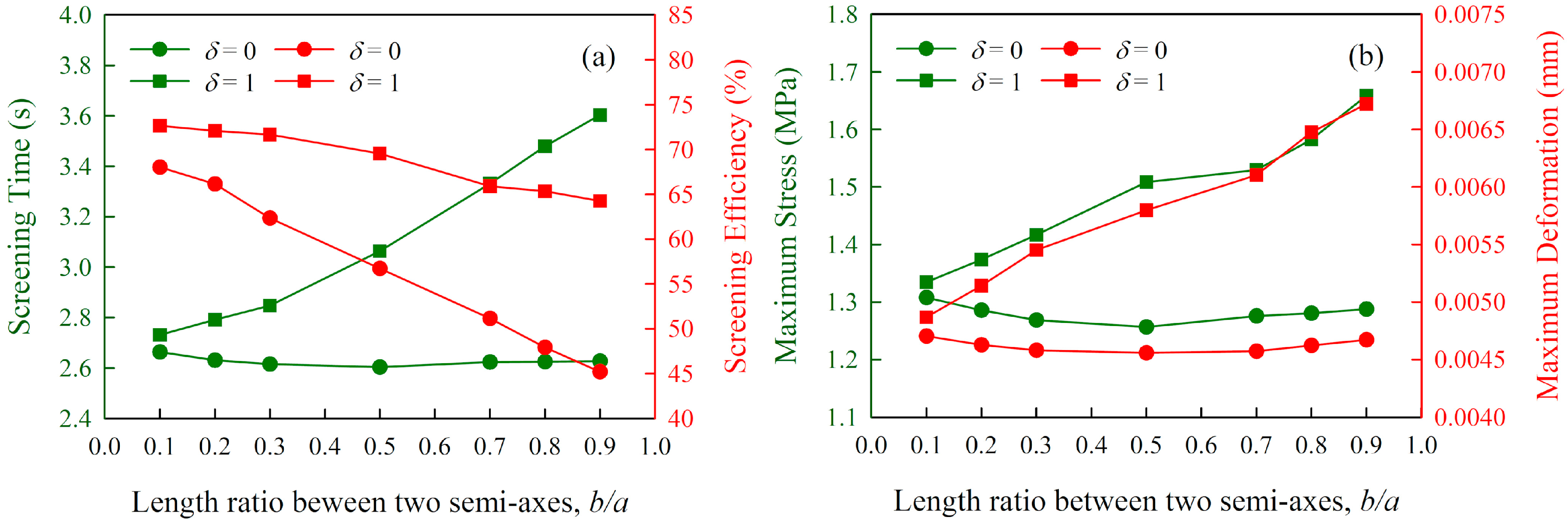

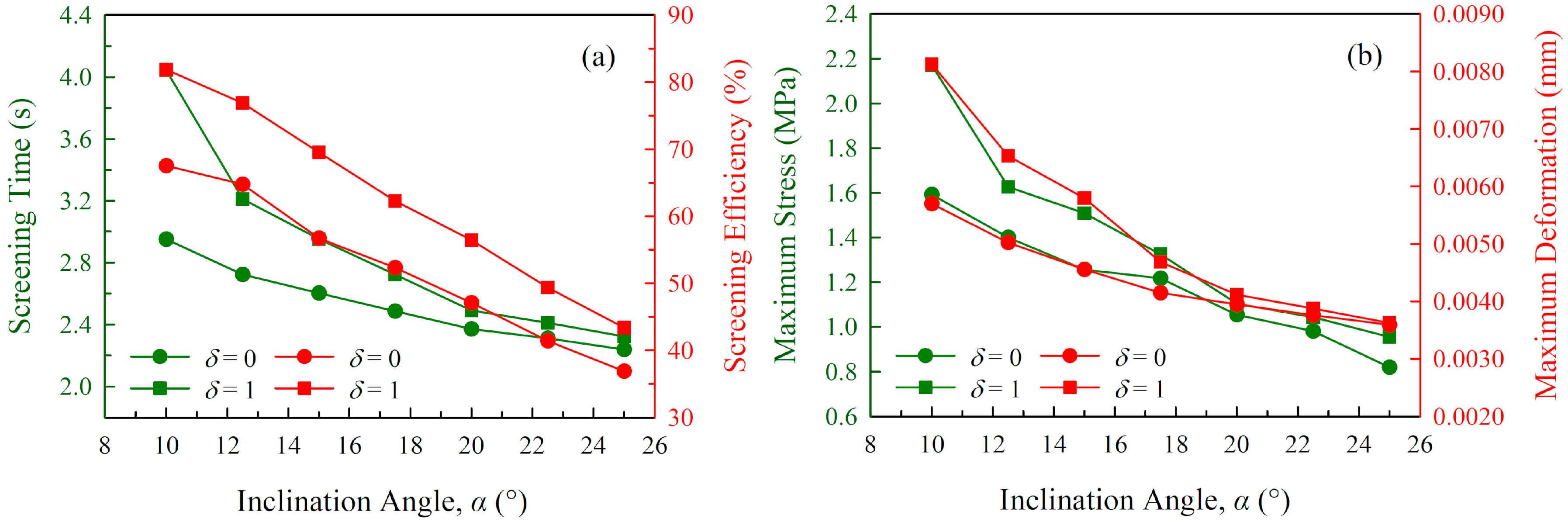

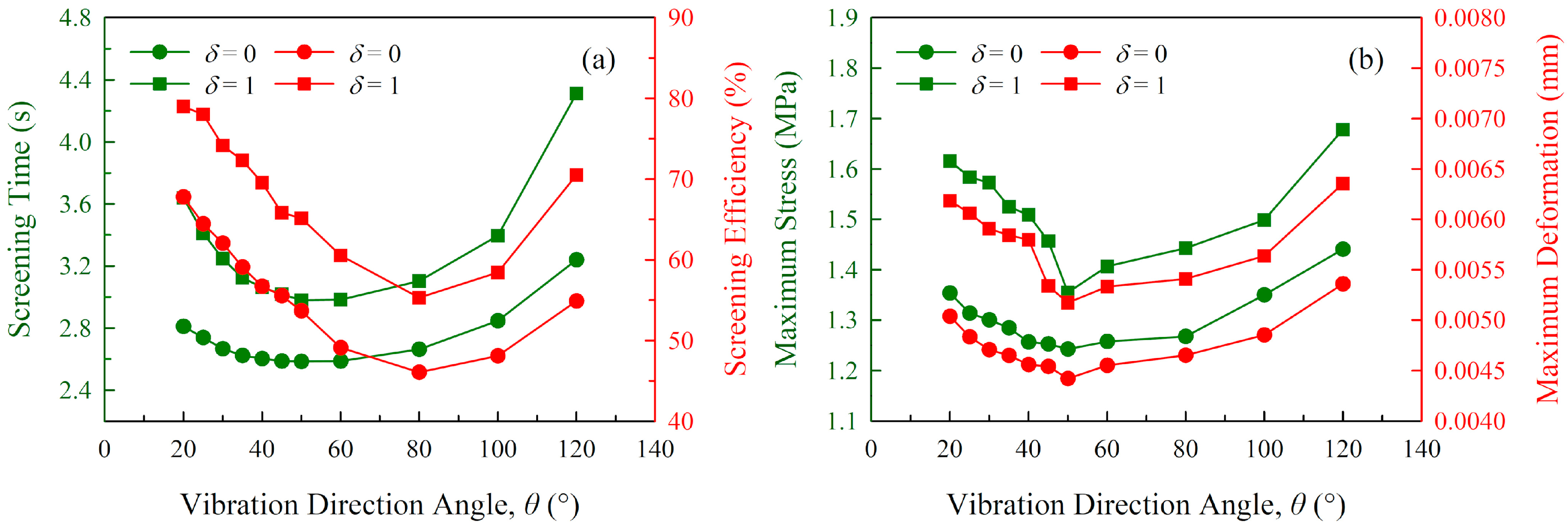

4.2. Univariate Analysis

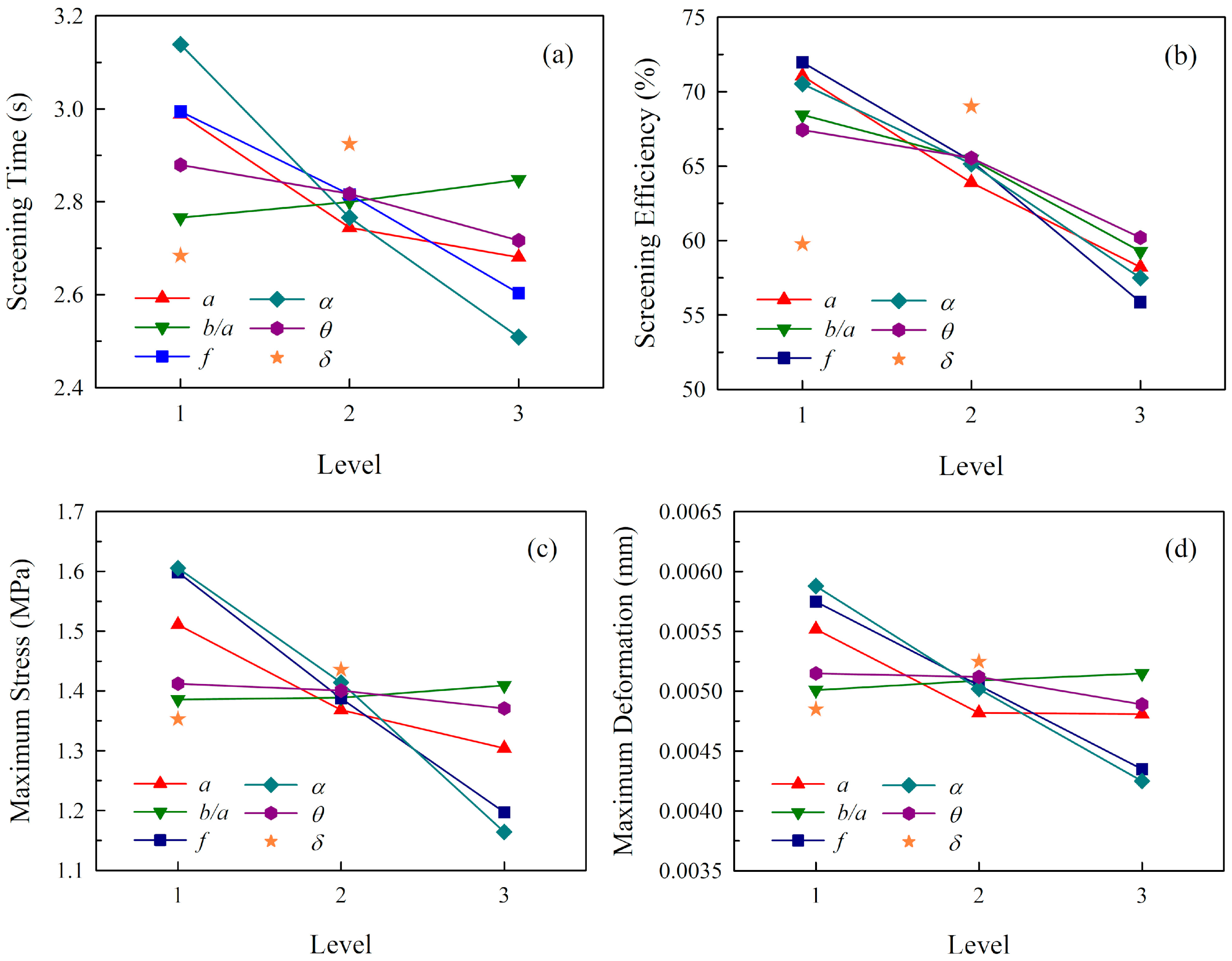

4.3. Multivariate Analysis

4.4. Relationship of Performance Indexes

5. Conclusions

- (1)

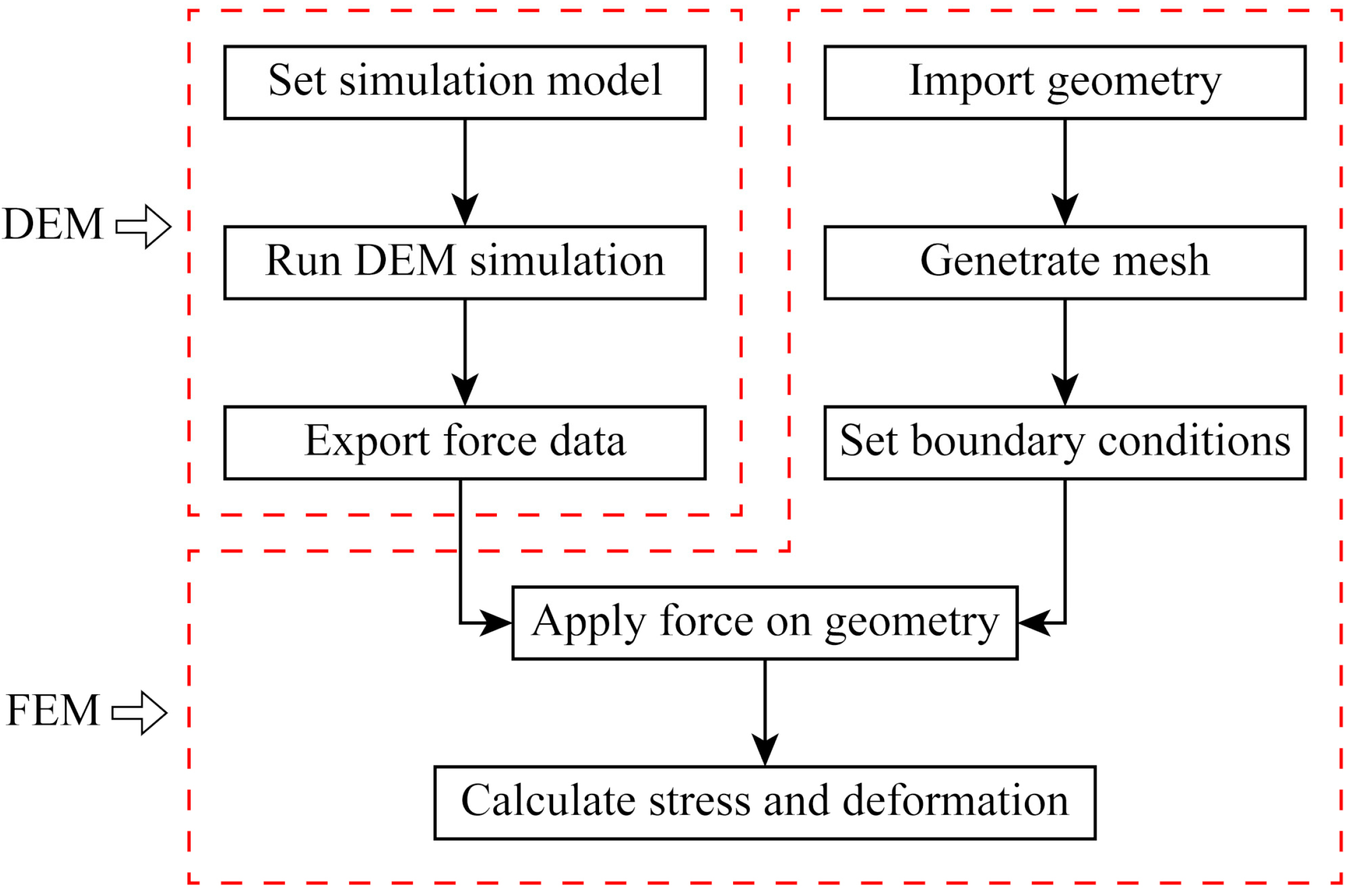

- DEM simulation is an effective approach in modeling the entire screening process related to massive granular materials and is conducive for lightening the data-collecting burden in experiments. Moreover, the stress and deformation distribution of a screen deck can be observed intuitively by coupling DEM with FEM. The analysis results indicate that the maximum stress mainly occurs in the side edges of the material input area, whereas the maximum deformation is concentrated in the middle of the material input area, which provides an optimization direction for reducing the fatigue and damage of screen decks.

- (2)

- The single-factor experiments and univariate analysis were conducted, and the results have clearly demonstrated the influence of six technical parameters. Meanwhile, Taguchi orthogonal experiments were designed in order to reveal the relative importance of sieving parameters and the optimal parameter scheme for each performance index. The results indicate that the importance of these parameters for screening efficiency is ranked as , whereas that for screening time, maximum stress and maximum deformation are identically ranked as . The optimal parameter scheme for maximizing the screening efficiency is: , , , , and , whereas that for minimizing the screening time, maximum stress and maximum deformation is: , , , , and .

- (3)

- The four performance indexes including the screening time, screening efficiency, maximum stress and maximum deformation are closely related to each other. More specifically, a poor processing capability directly promotes the retention time of particles on the screen surface; thus, when the materials receive more adequate passage opportunities, then the screening efficiency is enhanced. However, continuously feeding materials have no sufficient energy to eject and travel through the screen deck, but tend to accumulate in the material input field; thus, the time investment of the entire screening process and the impact force are correspondingly increased. The strong positive correlations among screening results are technically unavoidable due to the design of elliptical vibrating screens, therefore the relational functions were presented for a trade-off in terms of a multi-index optimization problem.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Jiang, H.; Zhao, Y.; Duan, C.; Zhang, C.; Diao, H.; Wang, Z.; Fan, X. Properties of technological factors on screening performance of coal in an equal-thickness screen with variable amplitude. Fuel 2017, 188, 511–521. [Google Scholar] [CrossRef]

- Liu, J.; Liu, H.; Yao, X.-L.; Liu, Y. Evaluating the sustainability impact of consolidation policy in China’s coal mining industry: A data envelopment analysis. J. Clean. Prod. 2016, 112, 2969–2976. [Google Scholar] [CrossRef]

- Dong, H.; Liu, C.; Zhao, Y.; Zhao, L. Influence of vibration mode on the screening process. Int. J. Min. Sci. Technol. 2013, 23, 95–98. [Google Scholar] [CrossRef]

- Cundall, P.A.; Strack, O.D.L. A discrete numerical model for granular assemblies. Géotechnique 1979, 29, 47–65. [Google Scholar] [CrossRef]

- Horabik, J.; Molenda, M. Parameters and contact models for DEM simulations of agricultural granular materials: A review. Biosyst. Eng. 2016, 147, 206–225. [Google Scholar] [CrossRef]

- Qiu, X. DEM Simulations in Mining and Mineral Processing. In Proceedings of the 7th International Conference on Discrete Element Methods; Springer: Singapore, 2017; pp. 37–43. [Google Scholar] [CrossRef]

- Deen, N.G.; Van Sint Annaland, M.; Van der Hoef, M.A.; Kuipers, J.A.M. Review of discrete particle modeling of fluidized beds. Chem. Eng. Sci. 2007, 62, 28–44. [Google Scholar] [CrossRef]

- Eppinger, T.; Seidler, K.; Kraume, M. DEM-CFD simulations of fixed bed reactors with small tube to particle diameter ratios. Chem. Eng. J. 2011, 166, 324–331. [Google Scholar] [CrossRef]

- Chu, K.W.; Wang, B.; Yu, A.B.; Vince, A. CFD-DEM modelling of multiphase flow in dense medium cyclones. Powder Technol. 2009, 193, 235–247. [Google Scholar] [CrossRef]

- Wang, G.; Tong, X. Screening efficiency and screen length of a linear vibrating screen using DEM 3D simulation. Min. Sci. Technol. 2011, 21, 451–455. [Google Scholar] [CrossRef]

- Cleary, P.W.; Sinnott, M.D.; Morrison, R.D. Separation performance of double deck banana screens—Part 1: Flow and separation for different accelerations. Miner. Eng. 2009, 22, 1218–1229. [Google Scholar] [CrossRef]

- Cleary, P.W.; Sinnott, M.D.; Morrison, R.D. Separation performance of double deck banana screens—Part 2: Quantitative predictions. Miner. Eng. 2009, 22, 1230–1244. [Google Scholar] [CrossRef]

- Jahani, M.; Farzanegan, A.; Noaparast, M. Investigation of screening performance of banana screens using LIGGGHTS DEM solver. Powder Technol. 2015, 283, 32–47. [Google Scholar] [CrossRef]

- Wang, Z.; Liu, C.; Wu, J.; Jiang, H.; Zhao, Y. Impact of screening coals on screen surface and multi-index optimization for coal cleaning production. J. Clean. Prod. 2018, 187, 562–575. [Google Scholar] [CrossRef]

- Jafari, A.; Saljooghi Nezhad, V. Employing DEM to study the impact of different parameters on the screening efficiency and mesh wear. Powder Technol. 2016, 297, 126–143. [Google Scholar] [CrossRef]

- Wang, X.; Li, Z.; Tong, X.; Ge, X. The influence of particle shape on screening: Case studies regarding DEM simulations. Eng. Comput. 2018, 35, 1512–1527. [Google Scholar] [CrossRef]

- Dong, K.; Esfandiary, A.H.; Yu, A.B. Discrete particle simulation of particle flow and separation on a vibrating screen: Effect of aperture shape. Powder Technol. 2017, 314, 195–202. [Google Scholar] [CrossRef]

- Zhao, L.; Zhao, Y.; Bao, C.; Hou, Q.; Yu, A. Optimisation of a circularly vibrating screen based on DEM simulation and Taguchi orthogonal experimental design. Powder Technol. 2017, 310, 307–317. [Google Scholar] [CrossRef]

- Li, Z.; Tong, X.; Zhou, B.; Wang, X. Modeling and parameter optimization for the design of vibrating screens. Miner. Eng. 2015, 83, 149–155. [Google Scholar] [CrossRef]

- Combarros, M.; Feise, H.J.; Zetzener, H.; Kwade, A. Segregation of particulate solids: Experiments and DEM simulations. Particuology 2014, 12, 25–32. [Google Scholar] [CrossRef]

- Delaney, G.W.; Cleary, P.W.; Hilden, M.; Morrison, R.D. Testing the validity of the spherical DEM model in simulating real granular screening processes. Chem. Eng. Sci. 2012, 68, 215–226. [Google Scholar] [CrossRef]

- Yin, Z.; Zhang, H.; Han, T. Simulation of particle flow on an elliptical vibrating screen using the discrete element method. Powder Technol. 2016, 302, 443–454. [Google Scholar] [CrossRef]

- Wen, B.; Zhang, H.; Liu, S.; He, Q.; Zhao, C. Theory and Techniques of Vibrating Machinery and Their Applications; Science Press: Bejing, China, 2010. [Google Scholar]

- Di Renzo, A.; Di Maio, F.P. Comparison of contact-force models for the simulation of collisions in DEM-based granular flow codes. Chem. Eng. Sci. 2004, 59, 525–541. [Google Scholar] [CrossRef]

- Chen, J.; Furuichi, M.; Nishiura, D. Discrete Element Simulation and Validation of a Mixing Process of Granular Materials. Materials 2020, 13, 1208. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.C.; Wright, B.D.; Yang, R.Y.; Xu, B.H.; Yu, A.B. Rolling friction in the dynamic simulation of sandpile formation. Phys. A Stat. Mech. Appl. 1999, 269, 536–553. [Google Scholar] [CrossRef]

- Xiao, J.; Tong, X. Characteristics and efficiency of a new vibrating screen with a swing trace. Particuology 2013, 11, 601–606. [Google Scholar] [CrossRef]

| Granular Parameter | Value |

| Particle shape | Spherical |

| Particle size (mm) | Mean: 2.5, 5 (Std Dev: 0.55) |

| Mass of all feeding particles (kg) | 2 |

| Feeding rate (kg/s) | 1.2 |

| Feeding height (mm) | 80 |

| Geometric Parameter | Value |

| Screen length (mm) | 600 |

| Screen width (mm) | 150 |

| Screen thickness (mm) | 2 |

| Aperture size (mm) | 5 (square) |

| Perforating ratio (%) | 49.58 |

| Vibration trajectory | Elliptical |

| Length of semi-major axis, | 1.8–3 |

| Length ratio of semi-minor axis, | 0.1–0.9 |

| Vibration frequency, | 18–35 |

| Inclination angle, | 10–25 |

| Vibration direction angle, | 20–120 |

| Vibration direction, | 0 (clockwise), 1 (anticlockwise) |

| Material Properties | Particle | Wall |

| Poisson’s Ratio | 0.3 | 0.29 |

| Shear Modulus (MPa) | 23 | 7992 |

| Density (kg/m3) | 2678 | 7861 |

| Collision Properties | Particle–Particle | Particle–Wall |

| Coefficient of Restitution | 0.1 | 0.2 |

| Coefficient of Static Friction | 0.545 | 0.5 |

| Coefficient of Rolling Friction | 0.01 | 0.01 |

| Level | Factor | |||||

|---|---|---|---|---|---|---|

| 1 | 2.2 | 0.25 | 20 | 15 | 30 | 0 |

| 2 | 2.5 | 0.5 | 22.5 | 17.5 | 40 | 1 |

| 3 | 2.8 | 0.75 | 25 | 20 | 50 | |

| No. | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2.2 | 0.25 | 20 | 15 | 30 | 0 | 3.684 | 89.918 | 2.105 | 0.00763 | |

| 2 | 2.2 | 0.5 | 22.5 | 17.5 | 40 | 0 | 2.732 | 70.757 | 1.408 | 0.00506 | |

| 3 | 2.2 | 0.75 | 25 | 20 | 50 | 0 | 2.416 | 44.099 | 1.054 | 0.00397 | |

| 4 | 2.5 | 0.25 | 20 | 17.5 | 40 | 0 | 2.752 | 72.100 | 1.562 | 0.00536 | |

| 5 | 2.5 | 0.5 | 22.5 | 20 | 50 | 0 | 2.416 | 49.729 | 1.266 | 0.00417 | |

| 6 | 2.5 | 0.75 | 25 | 15 | 30 | 0 | 2.672 | 51.990 | 1.292 | 0.00456 | |

| 7 | 2.8 | 0.25 | 22.5 | 15 | 50 | 0 | 2.596 | 59.667 | 1.209 | 0.00443 | |

| 8 | 2.8 | 0.5 | 25 | 17.5 | 30 | 0 | 2.444 | 51.426 | 1.099 | 0.00408 | |

| 9 | 2.8 | 0.75 | 20 | 20 | 40 | 0 | 2.448 | 48.331 | 1.185 | 0.00439 | |

| 10 | 2.2 | 0.25 | 25 | 20 | 40 | 1 | 2.496 | 64.580 | 1.076 | 0.00401 | |

| 11 | 2.2 | 0.5 | 20 | 15 | 50 | 1 | 3.404 | 84.014 | 1.853 | 0.00678 | |

| 12 | 2.2 | 0.75 | 22.5 | 17.5 | 30 | 1 | 3.200 | 73.041 | 1.571 | 0.00566 | |

| 13 | 2.5 | 0.25 | 22.5 | 20 | 30 | 1 | 2.568 | 70.602 | 1.103 | 0.00421 | |

| 14 | 2.5 | 0.5 | 25 | 15 | 40 | 1 | 3.092 | 69.210 | 1.404 | 0.00509 | |

| 15 | 2.5 | 0.75 | 20 | 17.5 | 50 | 1 | 2.968 | 69.809 | 1.584 | 0.00555 | |

| 16 | 2.8 | 0.25 | 25 | 17.5 | 50 | 1 | 2.500 | 53.899 | 1.260 | 0.00441 | |

| 17 | 2.8 | 0.5 | 20 | 20 | 30 | 1 | 2.712 | 67.685 | 1.303 | 0.00476 | |

| 18 | 2.8 | 0.75 | 22.5 | 15 | 40 | 1 | 3.384 | 68.391 | 1.770 | 0.00679 | |

| Performance Index | ||||||

|---|---|---|---|---|---|---|

| Screening time | 2.8 | 0.25 | 25 | 20 | 50 | 0 |

| Screening efficiency | 2.2 | 0.25 | 20 | 15 | 30 | 1 |

| Maximum stress | 2.8 | 0.25 | 25 | 20 | 50 | 0 |

| Maximum deformation | 2.8 | 0.25 | 25 | 20 | 50 | 0 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Z.; Tong, X.; Li, Z. Numerical Investigation on the Sieving Performance of Elliptical Vibrating Screen. Processes 2020, 8, 1151. https://doi.org/10.3390/pr8091151

Chen Z, Tong X, Li Z. Numerical Investigation on the Sieving Performance of Elliptical Vibrating Screen. Processes. 2020; 8(9):1151. https://doi.org/10.3390/pr8091151

Chicago/Turabian StyleChen, Zhiquan, Xin Tong, and Zhanfu Li. 2020. "Numerical Investigation on the Sieving Performance of Elliptical Vibrating Screen" Processes 8, no. 9: 1151. https://doi.org/10.3390/pr8091151

APA StyleChen, Z., Tong, X., & Li, Z. (2020). Numerical Investigation on the Sieving Performance of Elliptical Vibrating Screen. Processes, 8(9), 1151. https://doi.org/10.3390/pr8091151