Progressive Development and Challenges Faced by Solar Rotary Desiccant-Based Air-Conditioning Systems: A Review

Abstract

:Contents

- 1.

- Introduction

- 2.

- The Desiccant Materials

- 2.1.

- Silica Gel

- 2.2.

- Activated Alumina

- 2.3.

- Molecular Sieve

- 2.4.

- Advanced Desiccant Materials

- 2.4.1.

- Polymer Desiccants

- 2.4.2.

- Composite Desiccant

- 3.

- Working Principles of Rotary Desiccant Cooling Systems

- 3.1.

- The Rotary Desiccant Dehumidification System

- 3.2.

- The Cooling System

- 3.3.

- The Regenerative Heating Source

- 4.

- Research Progress in Configuration of Rotary Desiccant Cooling System

- 4.1.

- Pennington Cycle

- 4.2.

- Modified Ventilation Cycle

- 4.3.

- Recirculation Cycle

- 4.4.

- Dunkle Cycle

- 4.5.

- SENS Cycle

- 4.6.

- REVERS Cycle

- 4.7.

- DINC Cycle

- 5.

- Use of Solar Energy for Rotary Desiccant Cooling System

- 5.1.

- Solar Collectors

- 5.2.

- Nontracking Solar Collectors

- 5.2.1.

- Flat-Plate Solar Collectors (FPSCs)

- 5.2.2.

- Evacuated Tube Solar Collectors (ETSCs)

- 5.2.3.

- Compound Parabolic Solar Collectors (CPSC)

- 6.

- Recent Advancements in the Field of Desiccant Cooling Systems

- 7.

- Recent Applications of Solar-Assisted Desiccant Dehumidification and Cooling System

- 7.1.

- Solar Driven Rotary Hybrid Desiccant Air-Conditioning Systems

- 7.2.

- Use of Rotary Hybrid Desiccant Cooling for Preservation Purpose

- 8.

- Conclusions

- Reference

1. Introduction

2. The Desiccant Materials

2.1. Silica Gel

2.2. Activated Alumina

2.3. Molecular Sieves

2.4. Advanced Desiccant Material

2.4.1. Polymer Desiccants

2.4.2. Composite Desiccant

3. Working Principles of Rotary Desiccant-Based Cooling Systems

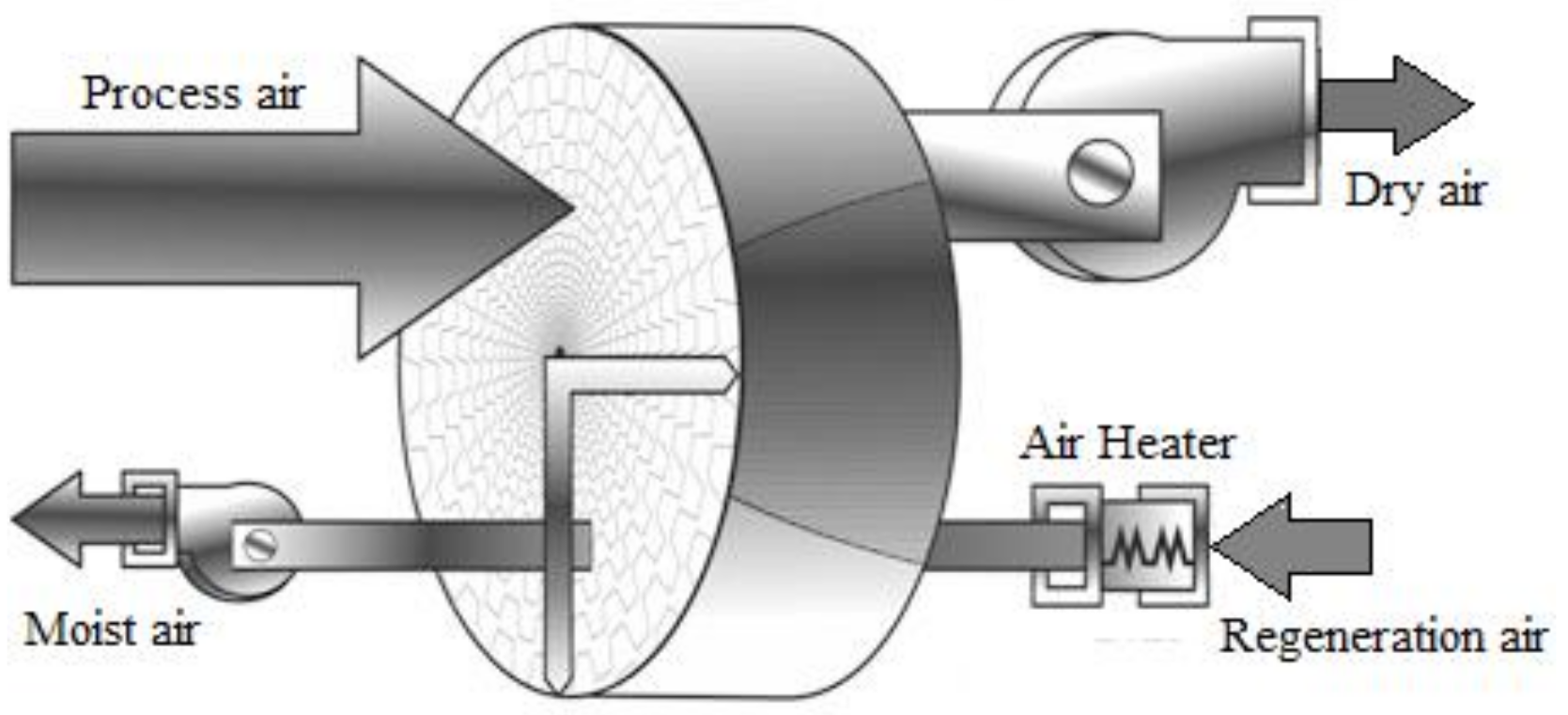

3.1. The Rotary Desiccant Dehumidification System

3.2. The Cooling System

3.3. The Regenerative Heating Source

4. Research Progress in Configuration of Rotary Desiccant Cooling System

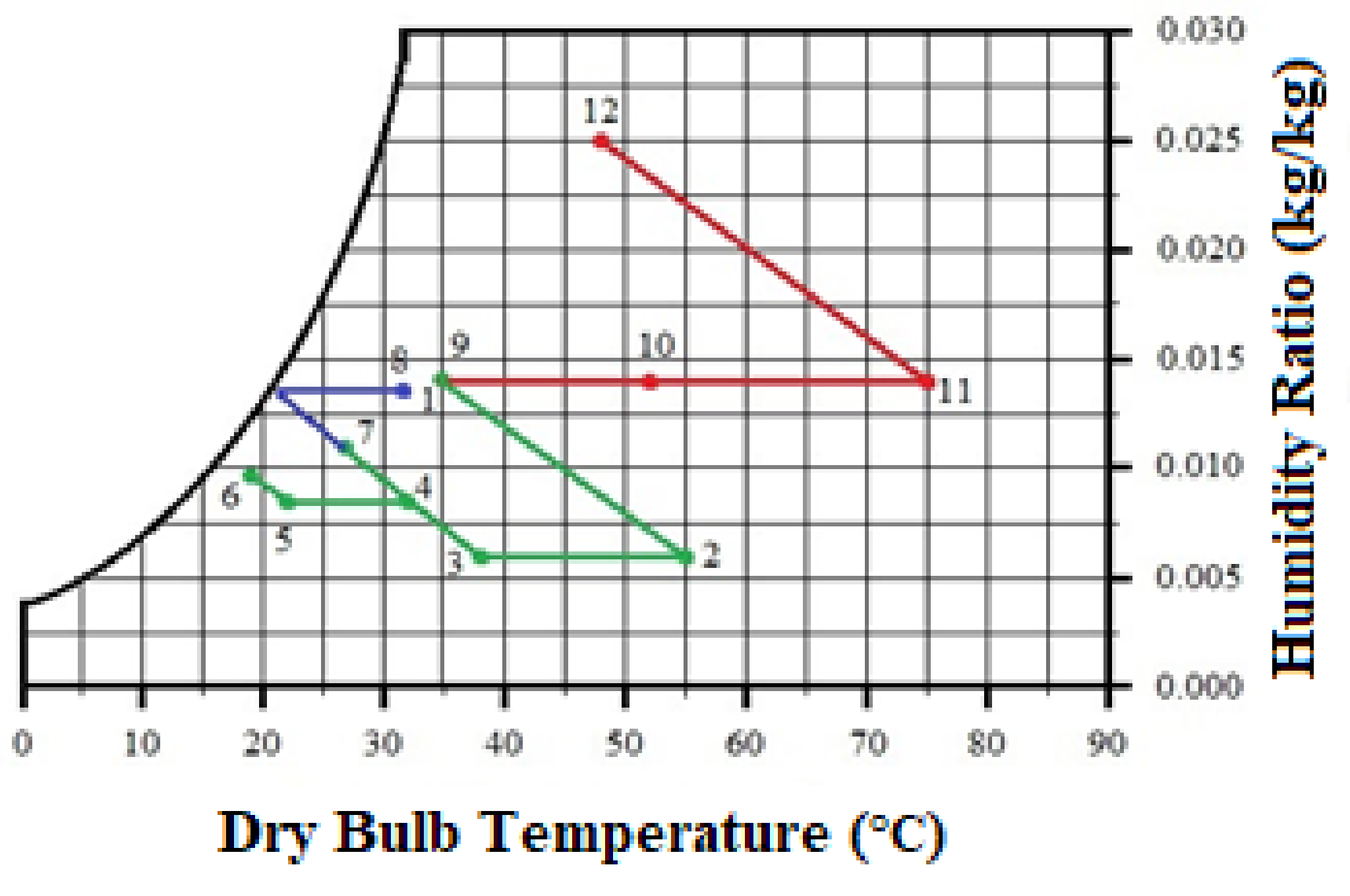

4.1. Pennington Cycle

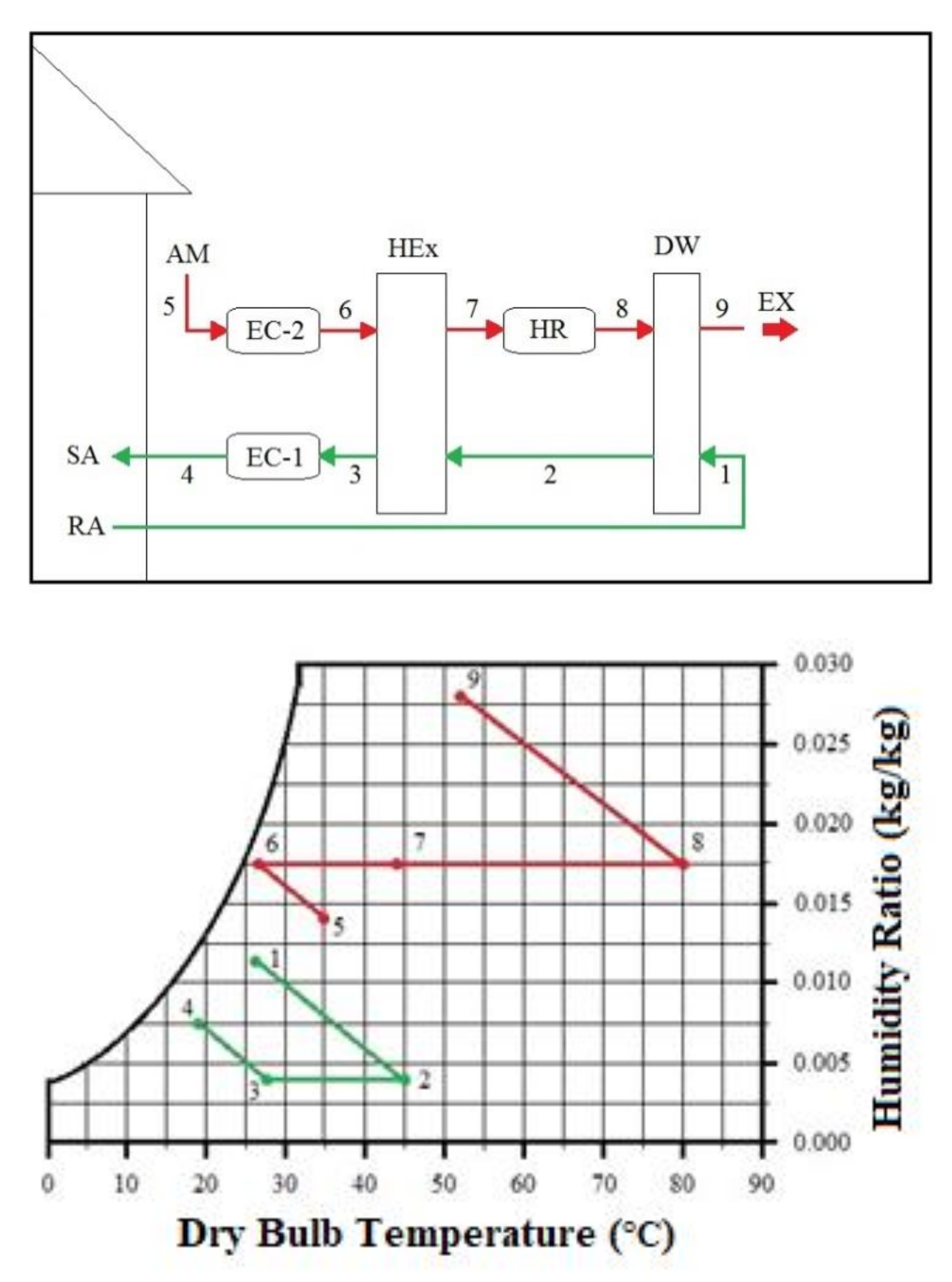

4.2. Modified Ventilation Cycle

4.3. Recirculation Cycle

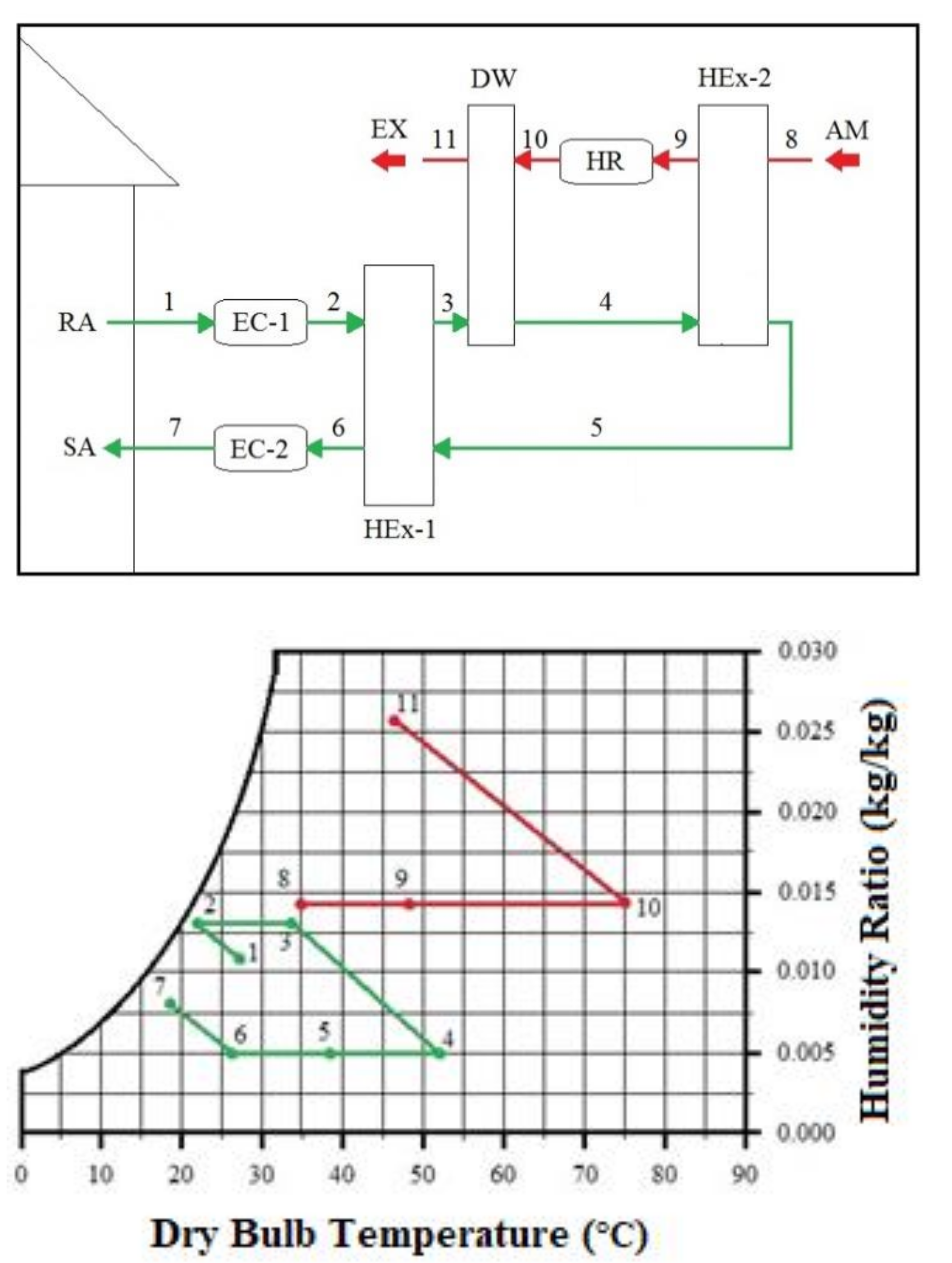

4.4. Dunkle Cycle

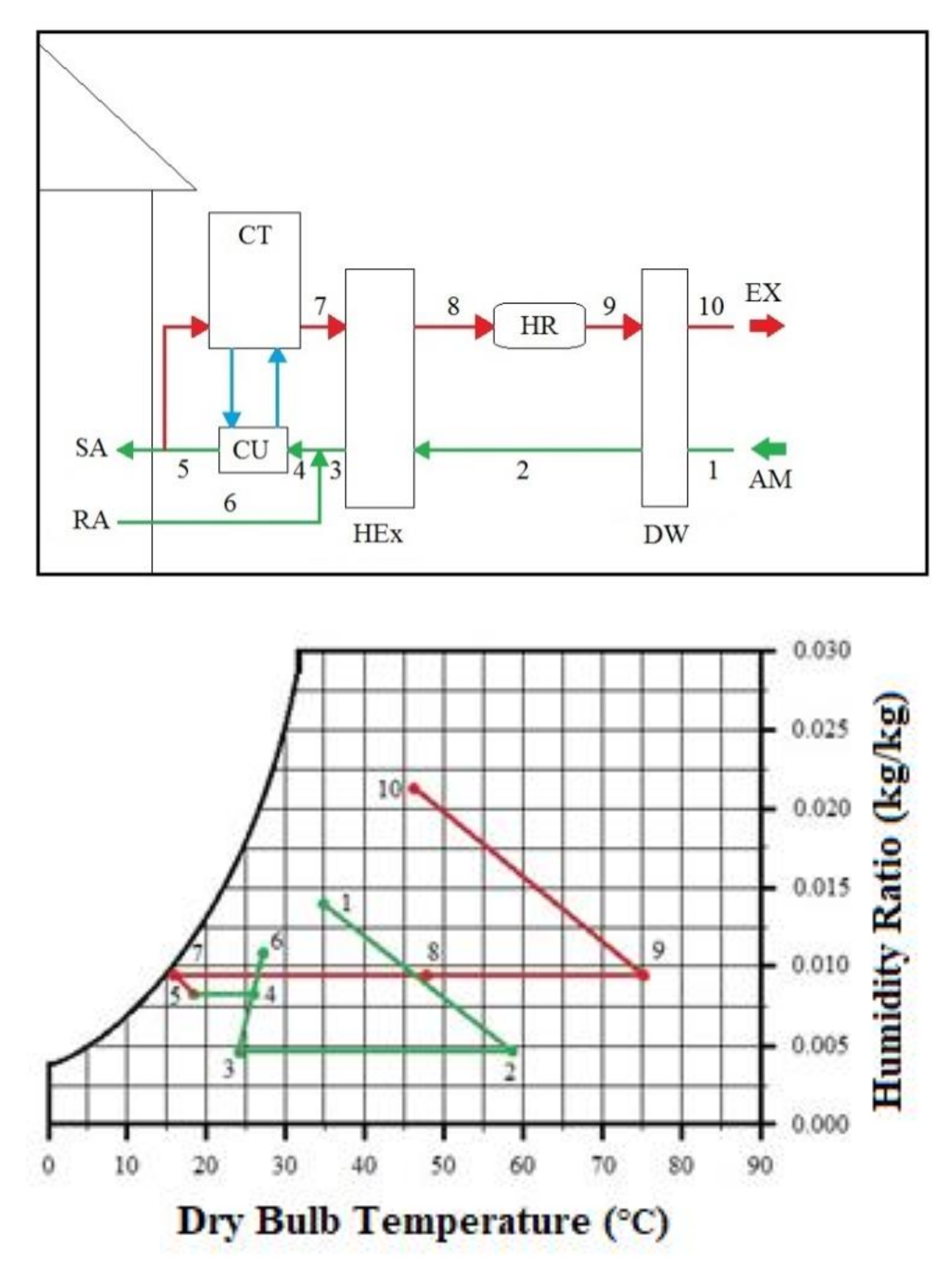

4.5. SENS Cycle

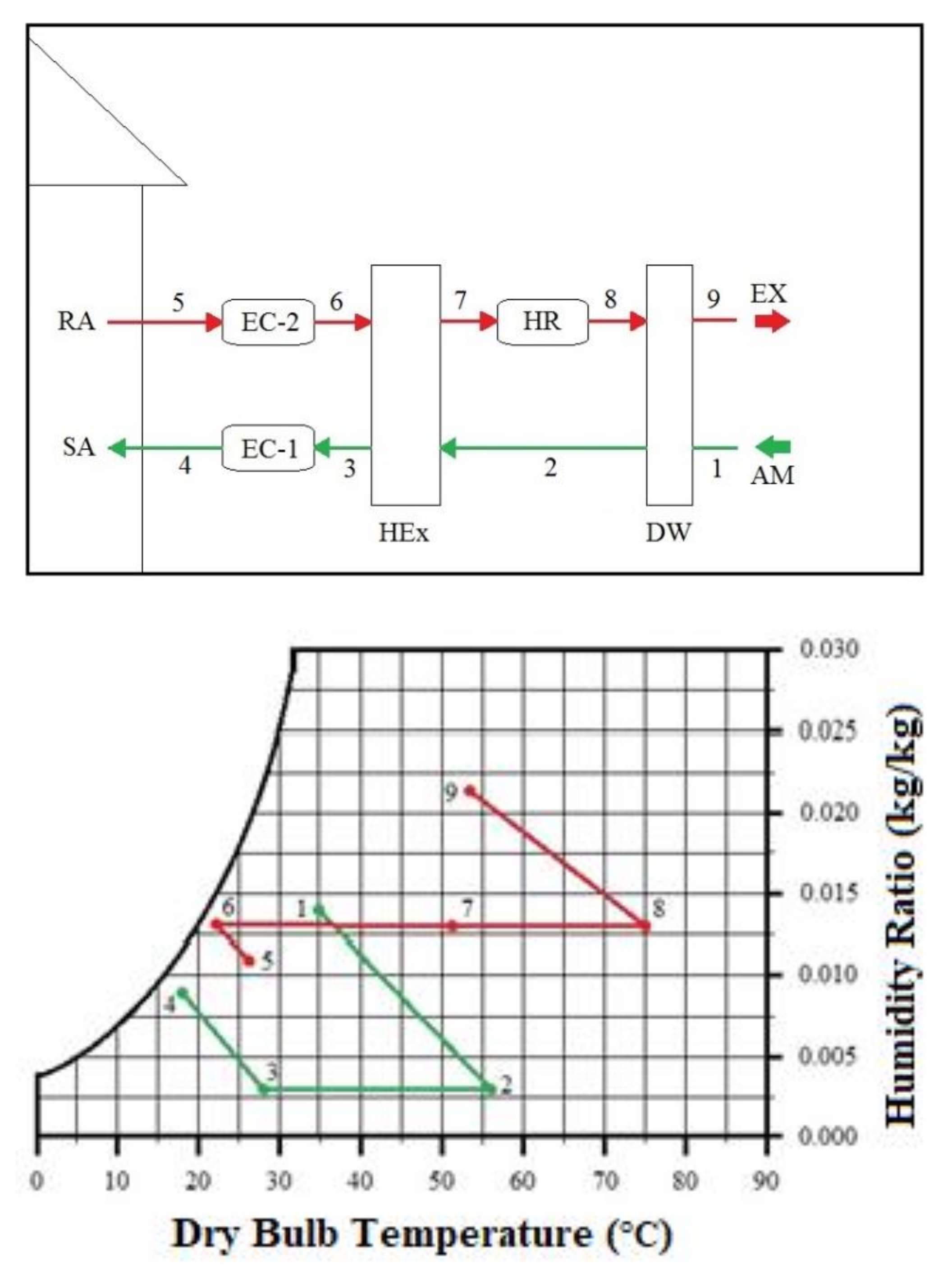

4.6. REVERS Cycle

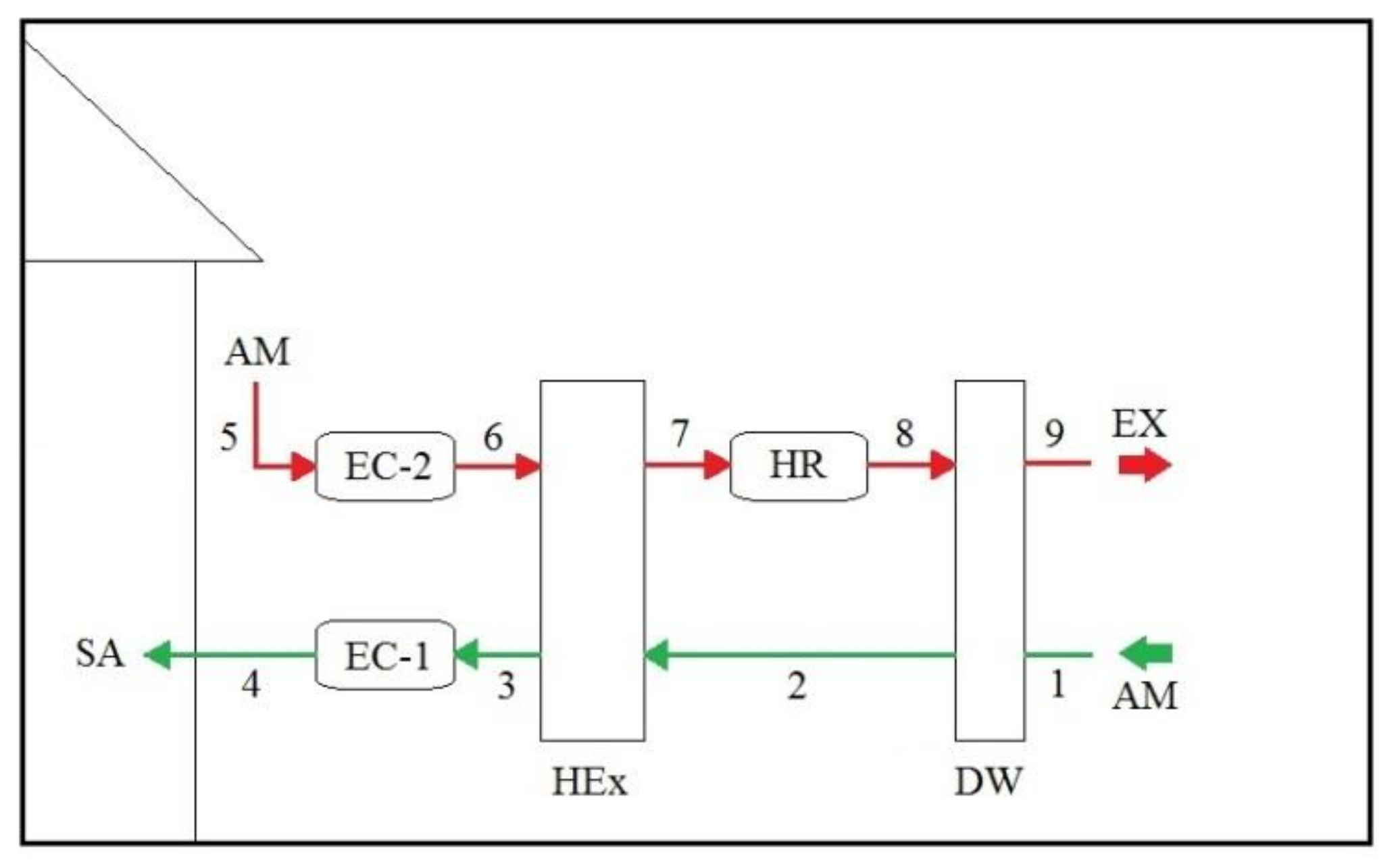

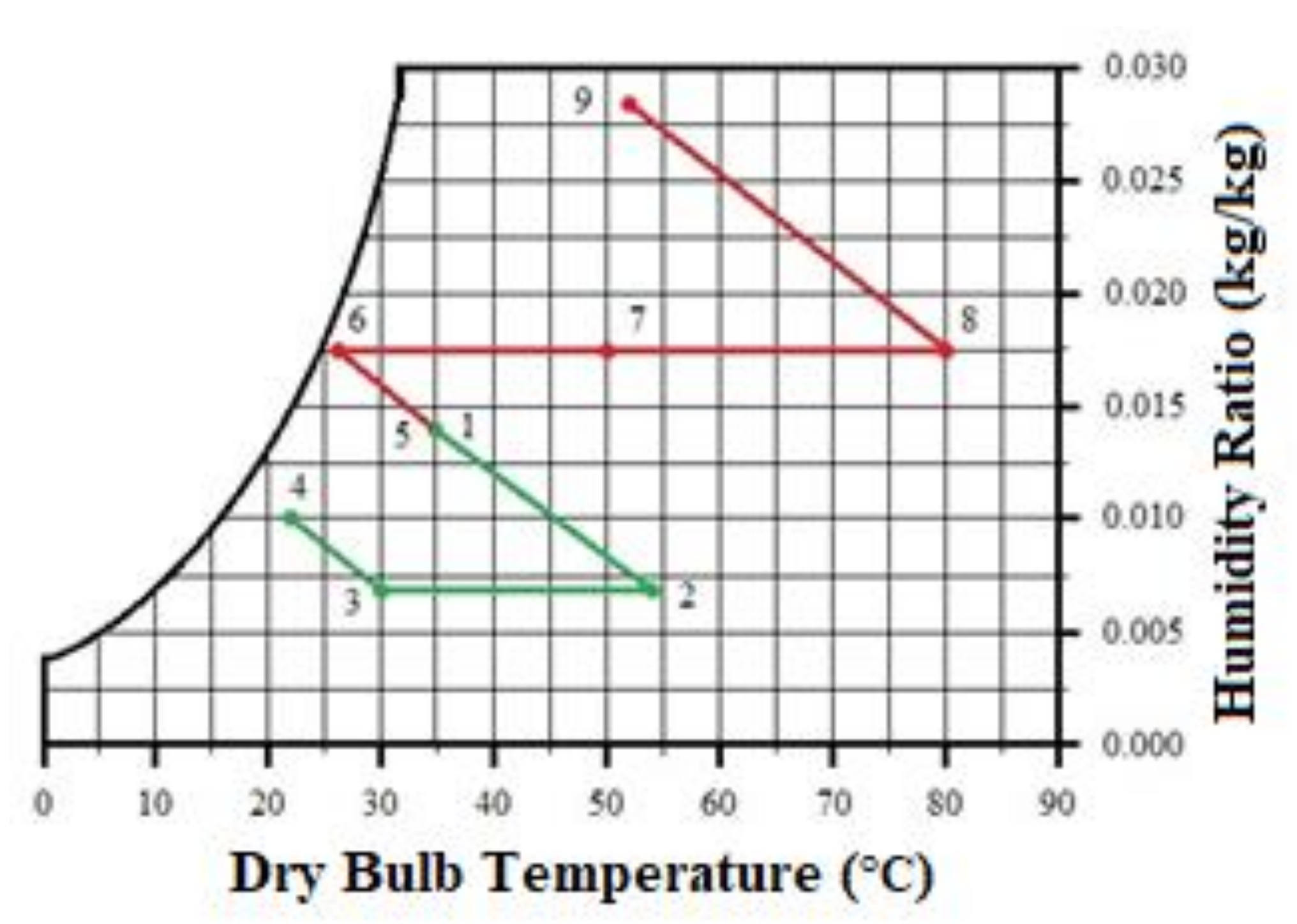

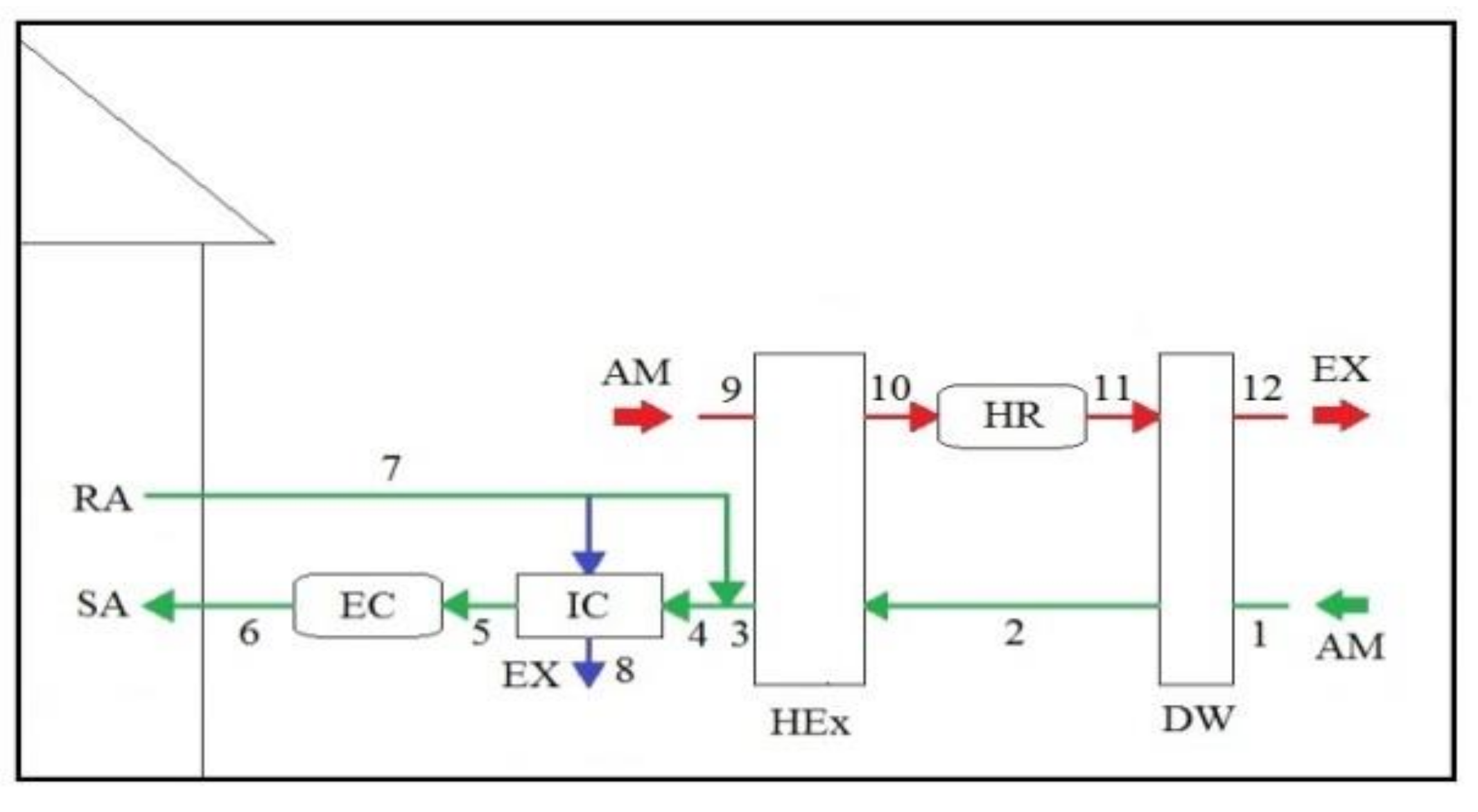

4.7. DINC Cycle

5. Use of Solar Energy for Rotary Desiccant Cooling System

5.1. Solar Collectors

5.2. Nontracking Solar Collectors

5.2.1. Flat-Plate Solar Collectors (FPSCs)

5.2.2. Evacuated Tube Solar Collectors (ETSCs)

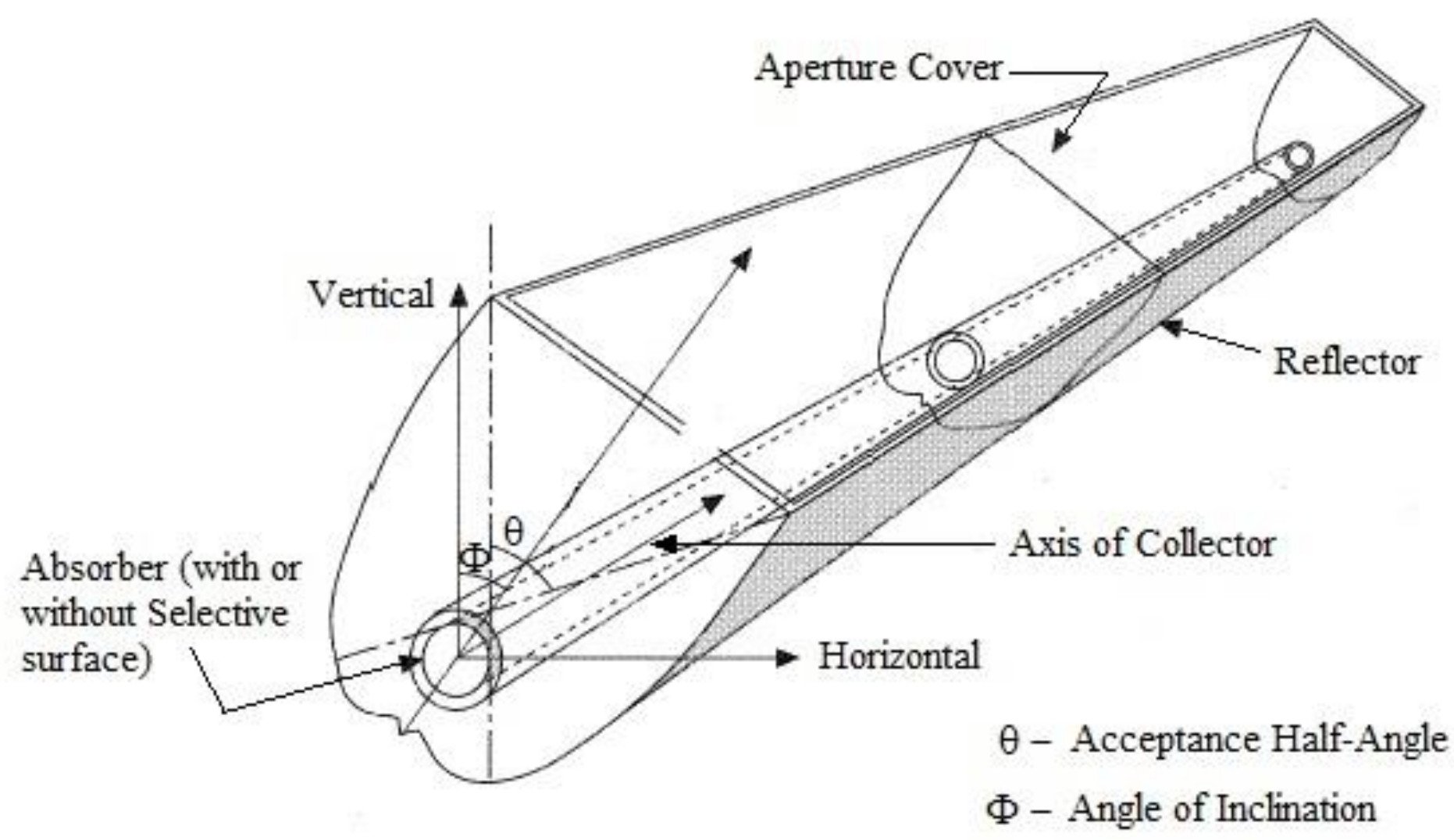

5.2.3. Compound Parabolic Solar Collector (CPSC)

6. Recent Advancements in the Field of Desiccant Cooling Systems

7. Recent Applications of Solar-Assisted Desiccant Dehumidification and Cooling System

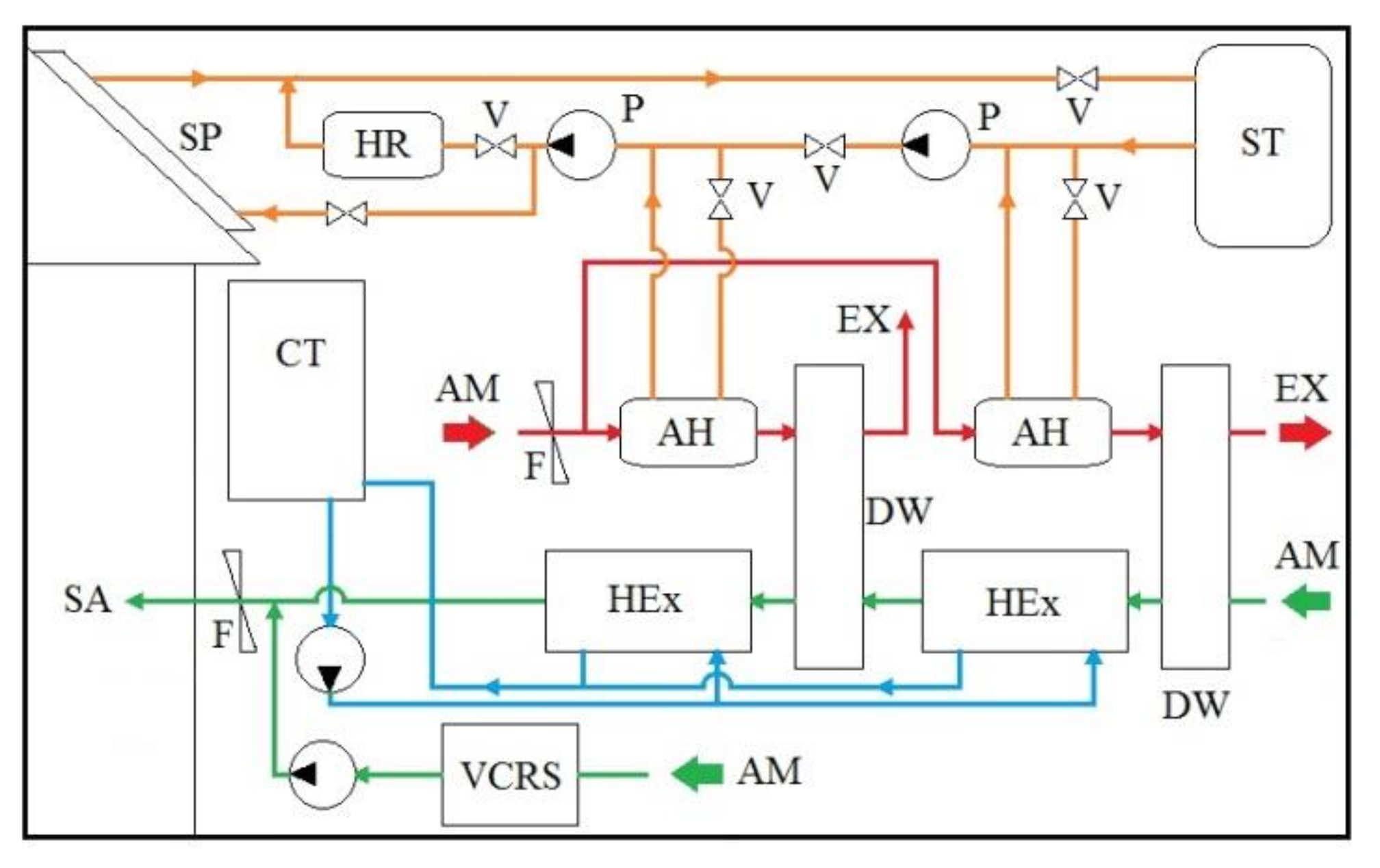

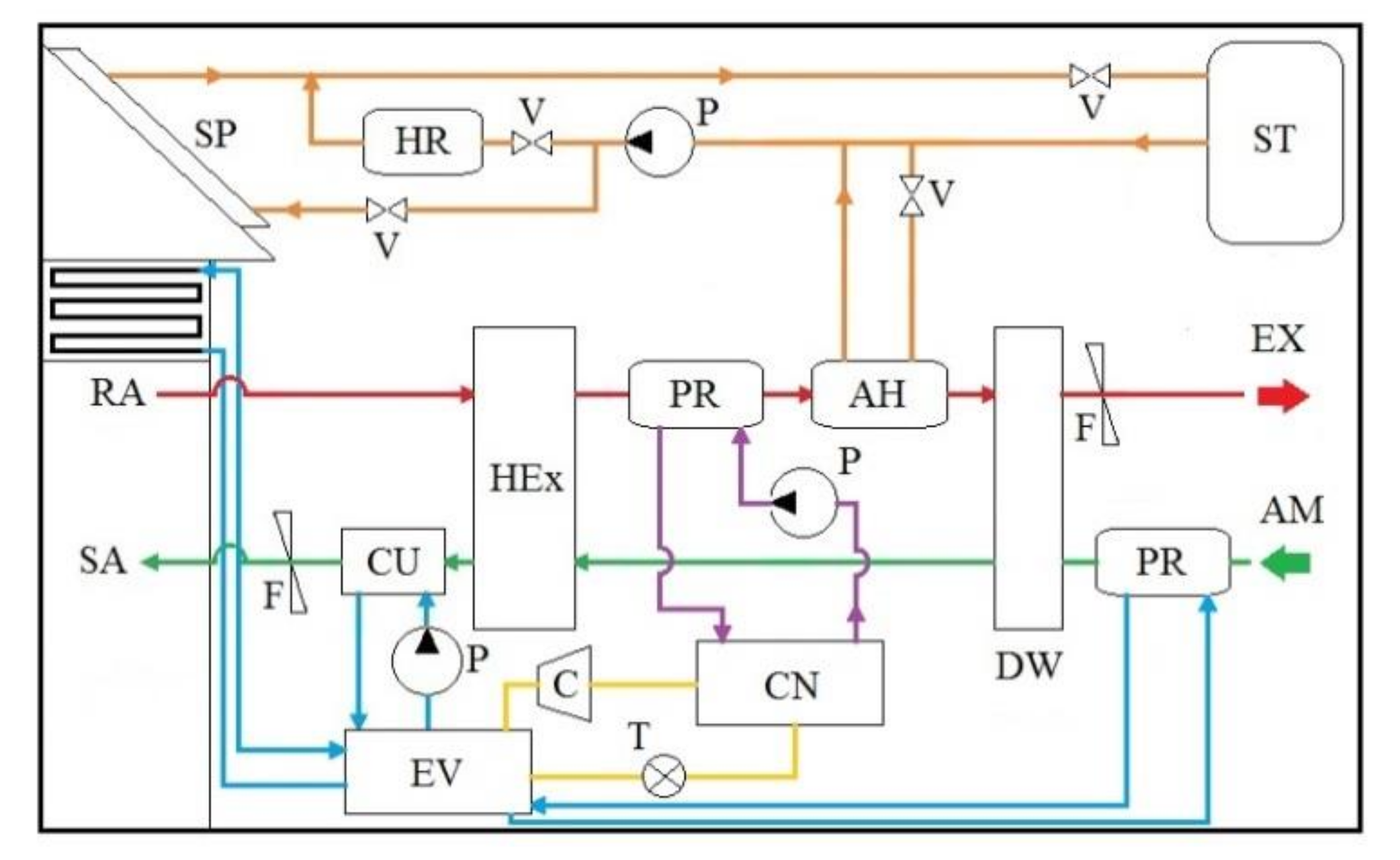

7.1. Solar Driven Rotary Hybrid Desiccant Air-Conditioning Systems

7.2. Use of Rotary Hybrid Desiccant Cooling for Preservation Purpose

8. Conclusions

- It has been seen that a vapor-compression system is commonly implemented in these hybrid systems. Although these hybrids systems consume both solar energy and electricity, significant electrical power savings can be obtained compared to conventional vapor-compression systems, due to the optimal use of solar energy. According to the above literature, to eliminate the obstacles in the path of environmentally friendly desiccant air-conditioning further suggestions can be summarized as follows.

- To take a step forward, more concentrated studies on the development and evaluation of advanced desiccant materials are still required.

- Development of multistage dehumidification systems with staged regeneration, to reduce required reactivation temperature and to increase thermal utilization rate.

- One method to decrease the large size and/or number of solar collectors necessary for heating the regeneration air, is to use condenser heat to increase the temperature of the regeneration air and then transfer it through the collectors. In this arrangement, the cooling effect of the air-conditioning system can be used to bring the air within the comfort conditions.

- Determination of the best operating approaches to improve system applicability under various seasons, weather and locations.

- Small and compact system designs in order to achieve a hybrid desiccant air-conditioning system that can be extended to small offices and residential buildings, thus decreasing building energy consumption.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| AH | Air Heater |

| AM | Ambient |

| C | Compressor |

| CHP | Combined Heat and Power |

| CN | Condenser |

| COP | Coefficient of Performance |

| COPTh | Coefficient of Performance (based on thermal consumption) |

| COPTot,HS | Coefficient of Performance (based on total energy consumption/Hybrid system) |

| COPEl | Coefficient of Performance (based on electrical consumption) |

| COPEl,HS | Coefficient of Performance(based on electrical consumption/Hybrid system) |

| CPSC | Compound Parabolic Solar Collector |

| CT | Cooling Tower |

| CU | Cooling Unit |

| CW | Cooling Water |

| DBT | Dry Bulb Temperature |

| DDCS | Desiccant Dehumidification and Cooling Systems |

| DW | Desiccant Wheel |

| EC | Evaporative Cooling |

| ETSCs | Evacuated Tube Solar Collectors |

| EV | Evaporator |

| EX | Exhaust |

| F | Fan |

| FPSCs | Flat-Plate Solar Collectors |

| HEx | Heat Exchanger |

| HR | Heater |

| HVAC | Heating, Ventilating and Air-Conditioning |

| IC | Indirect Cooling |

| P | Pump |

| PR | Preheater |

| PV | Photo Voltaic |

| RA | Return Air |

| RC | Radiant Ceiling |

| RF | Radiant Floor |

| RH | Relative Humidity |

| SADDCS | Solar-Assisted Desiccant Dehumidification and Cooling System |

| SA | Supply Air |

| SF | Solar Fraction |

| SJTU | Shanghai Jiao Tong University |

| SP | Solar Panels |

| ST | Storage Tank |

| T | Throttle valve |

| TSDCS | Two-stage Desiccant Cooling System |

| V | Valve |

| VAC | Vapor Absorption Cooling |

| VC | Vapor Compression |

| VCRS | Vapor-Compression Refrigeration System |

References

- Wrobel, J.; Walter, P.S.; Schmitz, G. Performance of a solar assisted air conditioning system at different locations. Sol. Energy 2013, 92, 69–83. [Google Scholar] [CrossRef]

- Wang, S.K. Handbook of Air Conditioning and Refrigeration; McGraw-Hill: New York, NY, USA, 2001. [Google Scholar]

- Subramanyam, N.; Maiya, M.; Murthy, S. Parametric studies on a desiccant assisted air-conditioner. Appl. Therm. Eng. 2004, 24, 2679–2688. [Google Scholar] [CrossRef]

- Dhar, P.; Singh, S. Studies on solid desiccant based hybrid air-conditioning systems. Appl. Therm. Eng. 2001, 21, 119–134. [Google Scholar] [CrossRef]

- Zhang, L.; Dang, C.; Hihara, E. Performance analysis of a no-frost hybrid air conditioning system with integrated liquid desiccant dehumidification. Int. J. Refrig. 2010, 33, 116–124. [Google Scholar] [CrossRef]

- Daou, K.; Wang, R.Z.; Xia, Z.Z. Desiccant cooling air conditioning: A review. Renew. Sustain. Energy Rev. 2006, 10, 55–77. [Google Scholar] [CrossRef]

- La, D.; Dai, Y.; Li, Y.; Wang, R.; Ge, T. Technical development of rotary desiccant dehumidification and air conditioning: A review. Renew. Sustain. Energy Rev. 2010, 14, 130–147. [Google Scholar] [CrossRef]

- Zhang, L.Z.; Niu, J.L. A pre-cooling Munters environmental control desiccant cooling cycle in combination with chilled-ceiling panels. Energy 2003, 28, 275–292. [Google Scholar] [CrossRef]

- Ge, T.S.; Dai, Y.J.; Wang, R.Z. Review on solar powered rotary desiccant wheel cooling system. Renew. Sustain. Energy Rev. 2014, 39, 476–497. [Google Scholar] [CrossRef]

- Lu, Z.; Wang, R.; Xia, Z. Experimental analysis of an adsorption air conditioning with micro-porous silica gel-water. Appl. Therm. Eng. 2013, 50, 1015–1020. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, R.; Xia, Z. Experimental performance of a silica gel–water adsorption chiller. Appl. Therm. Eng. 2005, 25, 359–375. [Google Scholar] [CrossRef]

- Alam, K.C.A.; Saha, B.B.; Kang, Y.T. Heat exchanger design effect on the system performance of silica gel adsorption refriger-ation systems. Int. J. Heat Mass Transf. 2000, 43, 4419–4431. [Google Scholar] [CrossRef]

- Enteria, N.; Yoshino, H.; Mochida, A.; Satake, A.; Yoshie, R.; Takaki, R.; Yonekura, H.; Mitamura, T.; Tanaka, Y. Performance of solar-desiccant cooling system with Silica-Gel (SiO2) and Titanium Dioxide (TiO2) desiccant wheel applied in East Asian climates. Sol. Energy 2012, 86, 1261–1279. [Google Scholar] [CrossRef]

- Wu, J.; Li, S. Study on cyclic characteristics of silica gel–water adsorption cooling system driven by variable heat source. Energy 2009, 34, 1955–1962. [Google Scholar] [CrossRef]

- Srivastava, N.C.; Eames, I.W. A review of adsorbents and adsorbates in solid-vapour adsorption heat pump systems. Appl. Therm. Eng. 1998, 18, 707–714. [Google Scholar] [CrossRef]

- Pramuang, S.; Exell, R. The regeneration of silica gel desiccant by air from a solar heater with a compound parabolic concentrator. Renew. Energy 2007, 32, 173–182. [Google Scholar] [CrossRef]

- Chung, T.-W.; Chung, C.-C. Increase in the amount of adsorption on modified silica gel by using neutron flux irradiation. Chem. Eng. Sci. 1998, 53, 2967–2972. [Google Scholar] [CrossRef]

- Abd-Elrahman, W.; Hamed, A.; El-Emam, S.; Awad, M. Experimental investigation on the performance of radial flow desiccant bed using activated alumina. Appl. Therm. Eng. 2011, 31, 2709–2715. [Google Scholar] [CrossRef]

- Hamed, A.; Abd-Elrahman, W.; El-Emam, S.; Awad, M. Theoretical and experimental investigation on the transient coupled heat and mass transfer in a radial flow desiccant packed bed. Energy Convers. Manag. 2013, 65, 262–271. [Google Scholar] [CrossRef]

- Karamanis, D.; Vardoulakis, E. Application of zeolitic materials prepared from fly ash to water vapor adsorption for solar cooling. Appl. Energy 2012, 97, 334–339. [Google Scholar] [CrossRef]

- Rao, Z.; Wang, S.; Zhang, Z. Energy saving latent heat storage and environmental friendly humidity-controlled materials for indoor climate. Renew. Sustain. Energy Rev. 2012, 16, 3136–3145. [Google Scholar] [CrossRef]

- Kubota, M.; Hanada, T.; Yabe, S.; Matsuda, H. Regeneration characteristics of desiccant rotor with microwave and hot-air heating. Appl. Therm. Eng. 2013, 50, 1576–1581. [Google Scholar] [CrossRef]

- Kubota, M.; Hanada, T.; Yabe, S.; Kuchar, D.; Matsuda, H. Water desorption behavior of desiccant rotor under microwave irradiation. Appl. Therm. Eng. 2011, 31, 1482–1486. [Google Scholar] [CrossRef]

- White, S.D.; Goldsworthy, M.; Reece, R.; Spillmann, T.; Gorur, A.; Lee, D.Y. Characterization of desiccant wheels with alternative materials at low regeneration tempera-tures. Int. J. Refrig. 2011, 34, 1786–1791. [Google Scholar] [CrossRef]

- Beery, E.K.; Ladisch, M.R. Chemistry and properties of starch based desiccants. Enzym. Microb. Technol. 2001, 28, 573–581. [Google Scholar] [CrossRef]

- Jia, C.; Dai, Y.; Wu, J.; Wang, R. Experimental comparison of two honeycombed desiccant wheels fabricated with silica gel and composite desiccant material. Energy Convers. Manag. 2006, 47, 2523–2534. [Google Scholar] [CrossRef]

- Pennington, N.A. Humidity Changer for Air Conditioning. U.S. Patent 2,700,537, 25 January 1955. [Google Scholar]

- Löf, G.O.G.; Cler, G.; Brisbane, T. Performance of a Solar Desiccant Cooling System. J. Sol. Energy Eng. 1988, 110, 165–171. [Google Scholar] [CrossRef] [Green Version]

- Kanoğlu, M.; Bolattürk, A.; Altuntop, N. Effect of ambient conditions on the first and second law performance of an open desiccant cooling process. Renew. Energy 2007, 32, 931–946. [Google Scholar] [CrossRef]

- Bourdoukan, P.; Wurtz, E.; Joubert, P. Comparison between the conventional and recirculation modes in desiccant cooling cycles and deriving critical efficiencies of components. Energy 2010, 35, 1057–1067. [Google Scholar] [CrossRef]

- Waugaman, D.G.; Kini, A.; Kettleborough, C.F. A Review of Desiccant Cooling Systems. J. Energy Resour. Technol. 1993, 115, 1–8. [Google Scholar] [CrossRef]

- Dunkle, R.V. A method of solar air conditioning. Mech. Chem. Eng. Trans. Inst. Eng. 1965, 73, 73–78. [Google Scholar]

- Maclaine-Cross, I.L. A Theory of Combined Heat and Mass Transfer in Regenerations. Ph.D. Thesis, Monash University, Clayton, Australia, 1974. [Google Scholar]

- Kang, T.S. Adiabatic Desiccant Open Cooling Cycles. Master’s Thesis, University of New South Wales, Sidney, Australia, April 1985. [Google Scholar]

- Maclaine-Cross, I.L. High-Performance Adiabatic Desiccant Open-Cooling Cycles. J. Sol. Energy Eng. 1985, 107, 102–104. [Google Scholar] [CrossRef]

- Waugaman, D.G.; Kettleborough, C.F. Combining direct and indirect evaporative cooling with a rotating desiccant wheel in residential applications. In Proceedings of the ASME International Thermal and Solar Energy Conference, Honolulu, HI, USA, 22–27 March 1987. [Google Scholar]

- Pesaran, A.A.; Wipke, K. Desiccant Cooling Using Unglazed Transpired Solar Collectors; NREL/TP-432-4827; National Renewable Energy Laboratory: Golden, CO, USA, 1992.

- Soteris, A.K. Solar thermal collectors and applications. Prog. Energy Combust. Sci. 2004, 30, 231–295. [Google Scholar]

- Xu, X.; Yang, L.; Zhang, X.; Peng, D. Review on the Development of Flat-Plate Solar Collector and its Building-Integrated Designing. In Proceedings of ISES World Congress 2007 (Vol. I–Vol. V); Springer: Berlin/Heidelberg, Germany, 2008; pp. 623–626. [Google Scholar]

- Goswami, D.Y. Principles of Solar Engineering, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2015; pp. 127–129. [Google Scholar]

- Soteris, A.K. Solar Energy Engineering: Processes Systems; Academic Press: Cambridge, MA, USA, 2014; p. 125. [Google Scholar]

- Tyagi, V.V.; Kaushik, S.C.; Tyagi, S.K. Advancement in solar photovoltaic/thermal (PV/T) hybrid collector technology. Renew. Sustain. Energy Rev. 2012, 16, 1383–1398. [Google Scholar] [CrossRef]

- Morrison, G.; Budihardjo, I.; Behnia, M. Water-in-glass evacuated tube solar water heaters. Sol. Energy 2004, 76, 135–140. [Google Scholar] [CrossRef]

- Gao, Y.; Zhang, Q.; Fan, R.; Lin, X.; Yu, Y. Effects of thermal mass and flow rate on forced-circulation solar hot-water system: Comparison of water-in-glass and U-pipe evacuated-tube solar collectors. Sol. Energy 2013, 98, 290–301. [Google Scholar] [CrossRef]

- Badar, A.W.; Buchholz, R.; Ziegler, F. Single and two-phase flow modeling and analysis of a coaxial vacuum tube solar collector. Sol. Energy 2012, 86, 175–189. [Google Scholar] [CrossRef]

- Hazami, M.; Kooli, S.; Naili, N.; Farhat, A. Long-term performances prediction of an evacuated tube solar water heating system used for single-family households under typical Nord-African climate (Tunisia). Sol. Energy 2013, 94, 283–298. [Google Scholar] [CrossRef]

- Yamaguchi, H.; Sawada, N.; Suzuki, H.; Ueda, H.; Zhang, X.R. Preliminary Study on a Solar Water Heater Using Supercritical Carbon Dioxide as Working Fluid. J. Sol. Energy Eng. 2010, 132, 11010. [Google Scholar] [CrossRef]

- Ma, L.; Lu, Z.; Zhang, J.; Liang, R. Thermal performance analysis of the glass evacuated tube solar collector with U-tube. Build. Environ. 2010, 45, 1959–1967. [Google Scholar] [CrossRef]

- Ayompe, L.; Duffy, A. Thermal performance analysis of a solar water heating system with heat pipe evacuated tube collector using data from a field trial. Sol. Energy 2013, 90, 17–28. [Google Scholar] [CrossRef] [Green Version]

- Hayek, M.; Assaf, J.; Lteif, W. Experimental Investigation of the Performance of Evacuated-Tube Solar Collectors under Eastern Mediterranean Climatic Conditions. Energy Procedia 2011, 6, 618–626. [Google Scholar] [CrossRef] [Green Version]

- Xu, L.; Wang, Z.; Yuan, G.; Li, X.; Ruan, Y. A new dynamic test method for thermal performance of all-glass evacuated solar air collectors. Sol. Energy 2012, 86, 1222–1231. [Google Scholar] [CrossRef]

- Tang, R.; Yang, Y.; Gao, W. Comparative studies on thermal performance of waterin-glass evacuated tube solar water heaters with different collector tilt-angles. Sol. Energy 2011, 85, 1381–1389. [Google Scholar] [CrossRef]

- Nkwetta, D.N.; Smyth, M.; Zacharopoulos, A.; Hyde, T. In-door experimental analysis of concentrated and non-concentrated evacuated tube heat pipe collectors for medium temperature applications. Energy Build. 2012, 47, 674–681. [Google Scholar] [CrossRef]

- Budihardjo, I.; Morrison, G.L. Performance Model for Water-in-Glass Evacuated Tube Solar Water Heaters. In Proceedings of ISES World Congress 2007 (Vol. I–Vol. V); Springer: Berlin/Heidelberg, Germany, 2008; Volume 83, pp. 49–56. [Google Scholar] [CrossRef]

- Nkwetta, D.N.; Smyth, M.; Zacharopoulos, A.; Hyde, T. Experimental field evaluation of novel concentrator augmented solar collectors for medium temperature applications. Appl. Therm. Eng. 2013, 51, 1282–1289. [Google Scholar] [CrossRef]

- Sharma, S.; Iwata, T.; Kitano, H.; Sagara, K. Thermal performance of a solar cooker based on an evacuated tube solar collector with a PCM storage unit. Sol. Energy 2005, 78, 416–426. [Google Scholar] [CrossRef]

- Sharma, N.; Diaz, G. Performance model of a novel evacuated-tube solar collector based on mini channels. Sol. Energy 2011, 85, 881–890. [Google Scholar] [CrossRef]

- Kumar, R.; Adhikari, R.; Garg, H.; Kumar, A. Thermal performance of a solar pressure cooker based on evacuated tube solar collector. Appl. Therm. Eng. 2001, 21, 1699–1706. [Google Scholar] [CrossRef]

- Madduri, A.; Loeder, D.; Beutler, N.; He, M.; Sanders, S. Concentrated evacuated tubes for solar-thermal energy generation using stirling engine. In Proceedings of the 2012 IEEE Energytech, Cleveland, OH, USA, 29–31 May 2012; pp. 1–6. [Google Scholar]

- Çağlar, A.; Yamalı, C. Performance analysis of a solar-assisted heat pump with an evacuated tubular collector for domestic heating. Energy Build. 2012, 54, 22–28. [Google Scholar] [CrossRef]

- Liang, R.; Ma, L.; Zhang, J.; Zhao, D. Theoretical and experimental investigation of the filled-type evacuated tube solar collector with U tube. Sol. Energy 2011, 85, 1735–1744. [Google Scholar] [CrossRef]

- Kumar, A.; Kumar, S.; Nagar, U.; Yadav, A. Experimental Study of Thermal Performance of One-Ended Evacuated Tubes for Producing Hot Air. J. Sol. Energy 2013, 2013, 524715. [Google Scholar] [CrossRef] [Green Version]

- Lamnatou, C.; Papanicolaou, E.; Belessiotis, V.; Kyriakis, N. Experimental investigation and thermodynamic performance analysis of a solar dryer using an evacuated-tube air collector. Appl. Energy 2012, 94, 232–243. [Google Scholar] [CrossRef]

- Hayek, M. Investigation of evacuated-tube solar collectors performance using computational fluid dynamics. In Proceedings of the 2009 International Conference on Advances in Computational Tools for Engineering Applications, Beirut, Lebanon, 15–17 July 2009; pp. 240–244. [Google Scholar]

- Gao, J.; Ge, X. The study of solar heat pump with all-glass evacuated tube. In Proceedings of the 2009 International Conference on Electrical Machines and Systems, Tokyo, Japan, 15–18 November 2009; pp. 1–4. [Google Scholar]

- Zambolin, E.; Del Col, D. Experimental analysis of thermal performance of flat plate and evacuated tube solar collectors in sta-tionary standard and daily conditions. Sol. Energy 2010, 84, 1382–1396. [Google Scholar] [CrossRef]

- Kim, Y.; Han, G.; Seo, T. An evaluation on thermal performance of CPC solar collector. Int. Commun. Heat Mass Transf. 2008, 35, 446–457. [Google Scholar] [CrossRef]

- Tang, R.; Gao, W.; Yu, Y.; Chen, H. Optimal tilt-angles of all-glass evacuated tube solar collectors. Energy 2009, 34, 1387–1395. [Google Scholar] [CrossRef]

- Mehta, J.; Rane, M. Liquid Desiccant based Solar Air Conditioning System with Novel Evacuated Tube Collector as Regenerator. Procedia Eng. 2013, 51, 688–693. [Google Scholar] [CrossRef]

- Senthilkumar, S.; Yasodha, N. Design and Development of a Three Dimensional Compound Parabolic Concentrator and Study of Optical and Thermal Performance. Int. J. Energy Sci. 2012, 2, 64–68. [Google Scholar]

- Henning, H.M.; Erpenbeck, T.; Hindenburg, C.; Santamaria, I.S. The potential of solar energy use in desiccant cooling cycles. Int. J. Refrig. 2001, 24, 220–229. [Google Scholar] [CrossRef]

- Beggs, C.B.; Sleigh, P.A.; Halliday, S.P. Solar desiccant cooling model. DETR Seminar (Desiccant and Solar Desiccant Systems). In Proceedings of the CIBSE National Conference, London, UK, 6 April 2000. [Google Scholar]

- Mavroudaki, P.; Beggs, C.; Sleigh, A.; Halliday, S. The potential for solar powered single-stage desiccant cooling in southern Europe. Appl. Therm. Eng. 2002, 22, 1129–1140. [Google Scholar] [CrossRef]

- Halliday, S.; Beggs, C.; Sleigh, P. The use of solar desiccant cooling in the UK: A feasibility study. Appl. Therm. Eng. 2002, 22, 1327–1338. [Google Scholar] [CrossRef]

- Finocchiaro, P.; Beccali, M.; Nocke, B. Advanced solar assisted desiccant and evaporative cooling system equipped with wet heat exchangers. Sol. Energy 2012, 86, 608–618. [Google Scholar] [CrossRef] [Green Version]

- Baniyounes, A.M.; Rasul, M.G.; Khan, M.M.K. Experimental assessment of a solar desiccant cooling system for an institutional building in sub-tropical Queens-Land, Australia. Energy Build 2013, 62, 78–86. [Google Scholar] [CrossRef]

- Baniyounes, A.M.; Liu, G.; Rasul, M.; Khan, M. Analysis of solar desiccant cooling system for an institutional building in subtropical Queensland, Australia. Renew. Sustain. Energy Rev. 2012, 16, 6423–6431. [Google Scholar] [CrossRef]

- Fong, K.; Lee, C.; Chow, T.; Fong, A. Investigation on solar hybrid desiccant cooling system for commercial premises with high latent cooling load in subtropical Hong Kong. Appl. Therm. Eng. 2011, 31, 3393–3401. [Google Scholar] [CrossRef]

- Khalid, A.; Mahmood, M.; Asif, M.; Muneer, T. Solar assisted, pre-cooled hybrid desiccant cooling system for Pakistan. Renew. Energy 2009, 34, 151–157. [Google Scholar] [CrossRef]

- Hürdoğan, E.; Büyükalaca, O.; Yılmaz, T.; Hepbasli, A.; Uçkan, I. Investigation of solar energy utilization in a novel desiccant based air conditioning system. Energy Build. 2012, 55, 757–764. [Google Scholar] [CrossRef]

- La, D.; Dai, Y.J.; Li, Y.; Ge, T.S.; Wang, R.Z. Case study and theoretical analysis of a solar driven two-stage rotary desiccant cooling system assisted by vapour compression air-conditioning. Sol. Energy 2011, 85, 2997–3009. [Google Scholar] [CrossRef]

- José, M.C.L.; Francisco, F.H.; Fernando, D.M.; Antonio, C.A. The optimization of the operation of a solar desiccant air handling unit coupled with a radiant floor. Energy Build 2013, 62, 427–435. [Google Scholar]

- Marco, B.; Pietro, F.; Bettina, N. Energy performance evaluation of a demo solar desiccant cooling system with heat recovery for the regeneration of the adsorption material. Renew Energy 2012, 44, 40–52. [Google Scholar]

- Wurm, J.; Kosar, D.; Clemens, T. Solid desiccant technology review. Bull. Int. Inst. Refrig. 2002, 82, 2–31. [Google Scholar]

- Harriman, L.G., III; Judge, J. Dehumidification equipment advances. ASHRAE J. 2002, 44, 22–29. [Google Scholar]

- McGahey, K. New commercial applications for desiccant-based cooling. ASHRAE J. 1998, 40, 41–45. [Google Scholar]

- Yu, N.; Wang, R.; Lu, Z.; Wang, L. Development and characterization of silica gel–LiCl composite sorbents for thermal energy storage. Chem. Eng. Sci. 2014, 111, 73–84. [Google Scholar] [CrossRef]

- Simonova, I.A.; Freni, A.; Restuccia, G.; Aristov, Y.I. Water sorption on composite “silica modified by calcium nitrate”. Microporous Mesoporous Mater. 2009, 122, 223–228. [Google Scholar] [CrossRef]

- Cortés, F.B.; Chejne, F.; Carrasco-Marín, F.; Perez-Cadenas, A.F.; Moreno-Castilla, C. Water sorption on silica- and zeolite-supported hygroscopic salts for cooling system applications. Energy Convers. Manag. 2012, 53, 219–223. [Google Scholar] [CrossRef]

- Chen, H.-J.; Cui, Q.; Tang, Y.; Chen, X.-J.; Yao, H.-Q. Attapulgite based LiCl composite adsorbents for cooling and air conditioning applications. Appl. Therm. Eng. 2008, 28, 2187–2193. [Google Scholar] [CrossRef]

- Tso, C.Y.; Chao, C.Y. Activated carbon, silica-gel and calcium chloride composite adsorbents for energy efficient solar adsorption cooling and dehumidification systems. Int. J. Refrig. 2012, 35, 1626–1638. [Google Scholar] [CrossRef]

- Seo, Y.-K.; Yoon, J.W.; Lee, J.S.; Hwang, Y.K.; Jun, C.-H.; Chang, J.-S.; Wuttke, S.; Bazin, P.; Vimont, A.; Daturi, M.; et al. Energy-Efficient Dehumidification over Hierachically Porous Metal-Organic Frameworks as Advanced Water Adsorbents. Adv. Mater. 2012, 24, 806–810. [Google Scholar] [CrossRef]

- Akiyama, G.; Matsuda, R.; Sato, H.; Hori, A.; Takata, M.; Kitagawa, S. Effect of functional groups in MIL-101 on water sorption behavior. Microporous Mesoporous Mater. 2012, 157, 89–93. [Google Scholar] [CrossRef]

- Henninger, S.K.; Jeremias, F.; Kummer, H.; Janiak, C. MOFs for use in adsorption heat pump processes. Eur. J. Inorg. Chem. 2012, 2012, 2625–2634. [Google Scholar] [CrossRef]

- Thorpe, G. The modelling and potential applications of a simple solar regenerated grain cooling device. Postharvest Biol. Technol. 1998, 13, 151–168. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Singh, R.P.; Das, R.K. Progressive Development and Challenges Faced by Solar Rotary Desiccant-Based Air-Conditioning Systems: A Review. Processes 2021, 9, 1785. https://doi.org/10.3390/pr9101785

Singh RP, Das RK. Progressive Development and Challenges Faced by Solar Rotary Desiccant-Based Air-Conditioning Systems: A Review. Processes. 2021; 9(10):1785. https://doi.org/10.3390/pr9101785

Chicago/Turabian StyleSingh, Ranjan Pratap, and Ranadip K. Das. 2021. "Progressive Development and Challenges Faced by Solar Rotary Desiccant-Based Air-Conditioning Systems: A Review" Processes 9, no. 10: 1785. https://doi.org/10.3390/pr9101785

APA StyleSingh, R. P., & Das, R. K. (2021). Progressive Development and Challenges Faced by Solar Rotary Desiccant-Based Air-Conditioning Systems: A Review. Processes, 9(10), 1785. https://doi.org/10.3390/pr9101785