Research and Application of Double-Reheat Boiler in China

Abstract

:1. Introduction

2. Brief History of Double-Reheat Boiler

3. Scheme for Heating Surface Arrangement

3.1. Inverse U-Type Double-Reheat Boiler

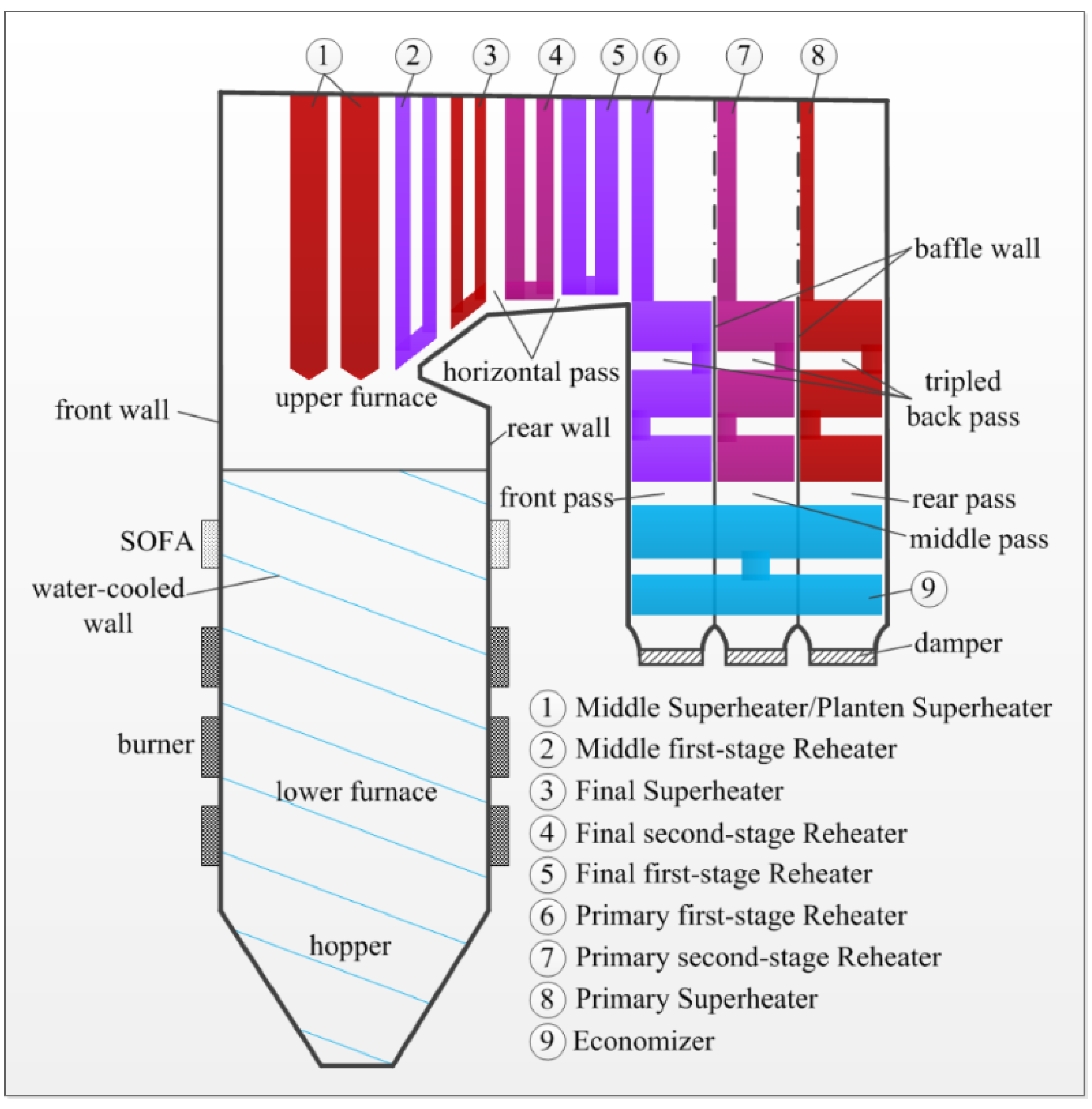

3.1.1. Inverse U-Type with Triple Back Passes

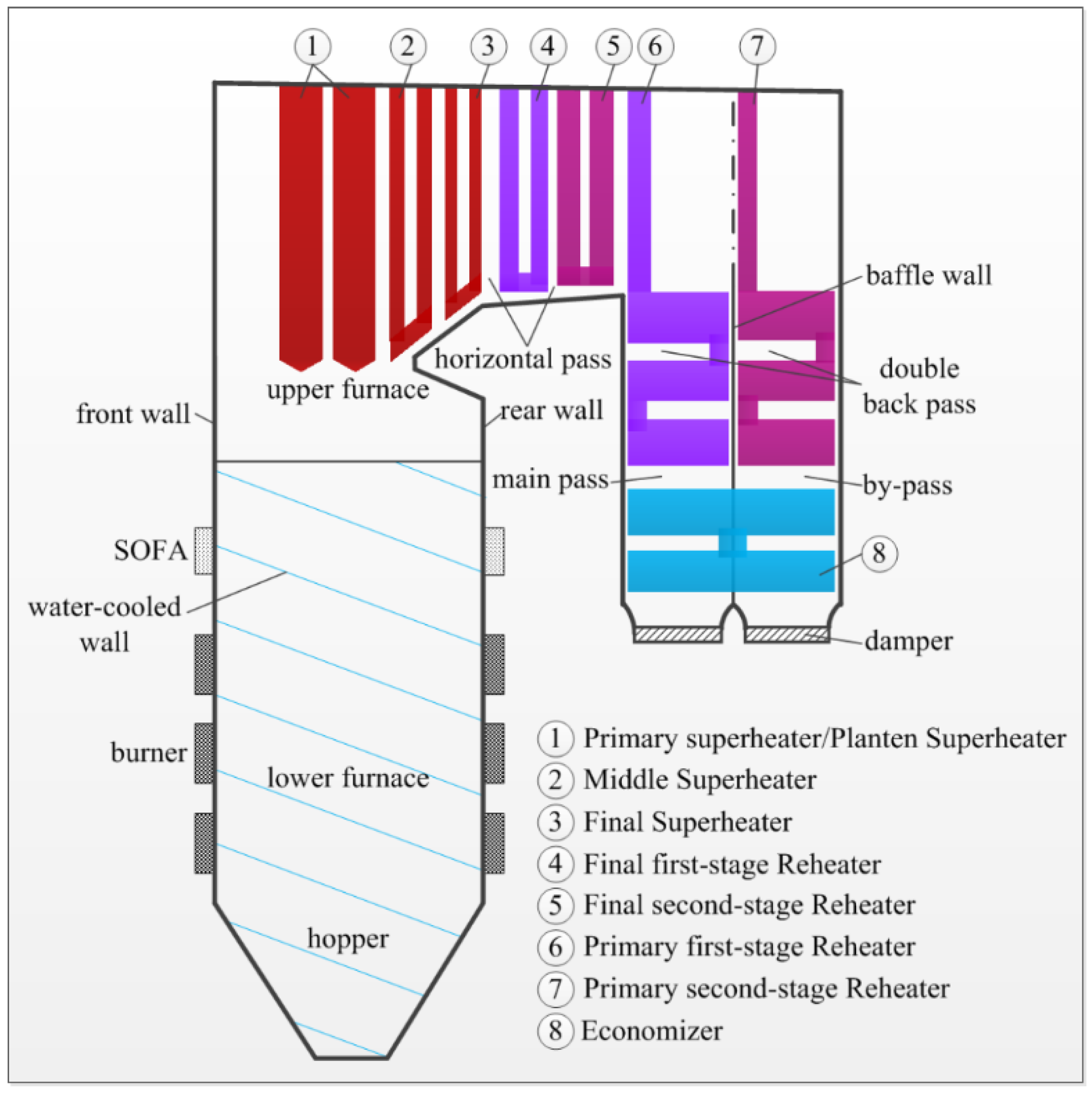

3.1.2. Inverse U-Type with Double Back Passes

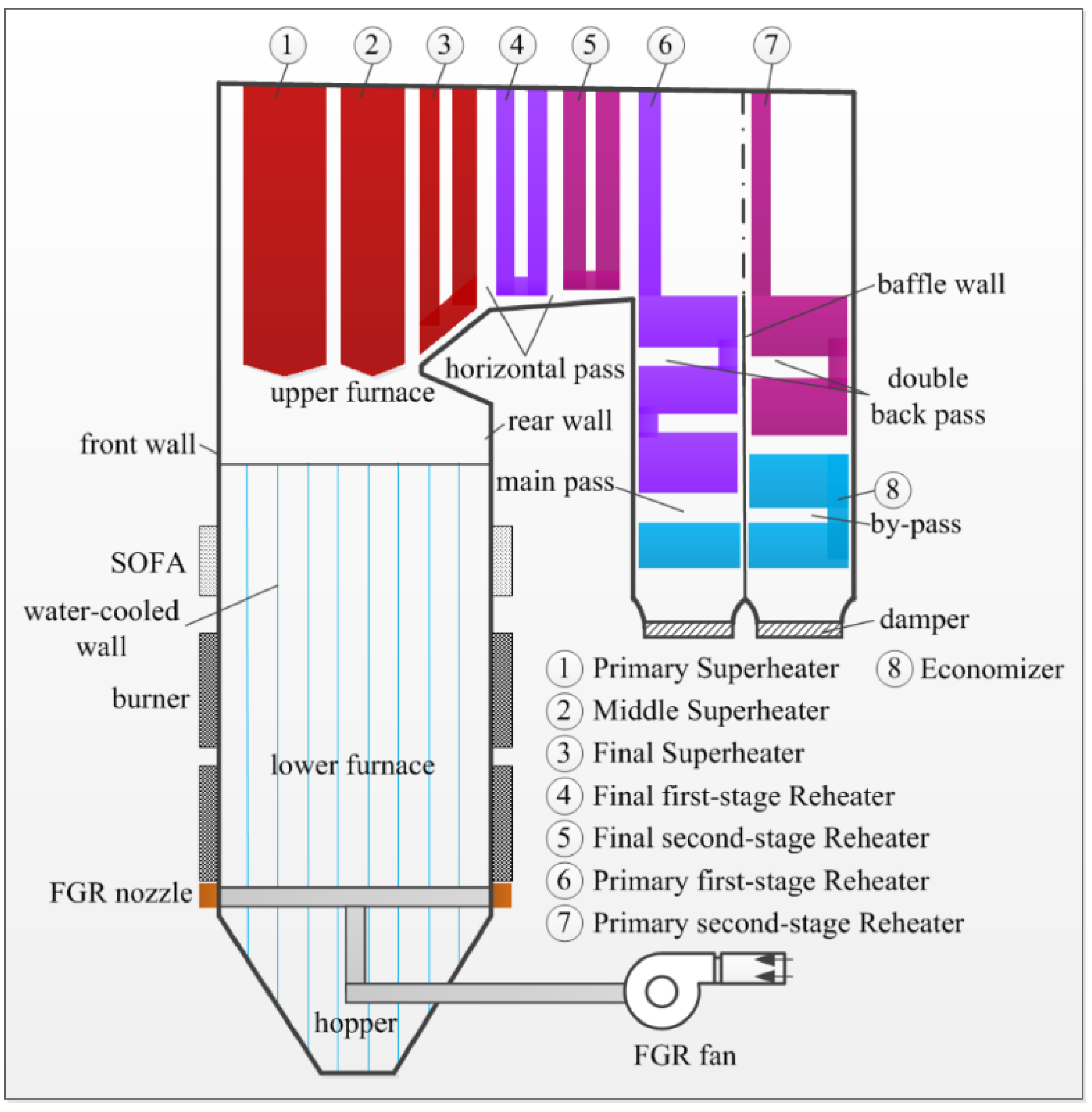

3.2. Tower-Type Double-Reheat Boiler

3.3. T-Type Boiler

4. Methods for Regulating Steam Temperature

4.1. Methods for Regulating the Superheater

4.2. Methods for Regulating the Reheater

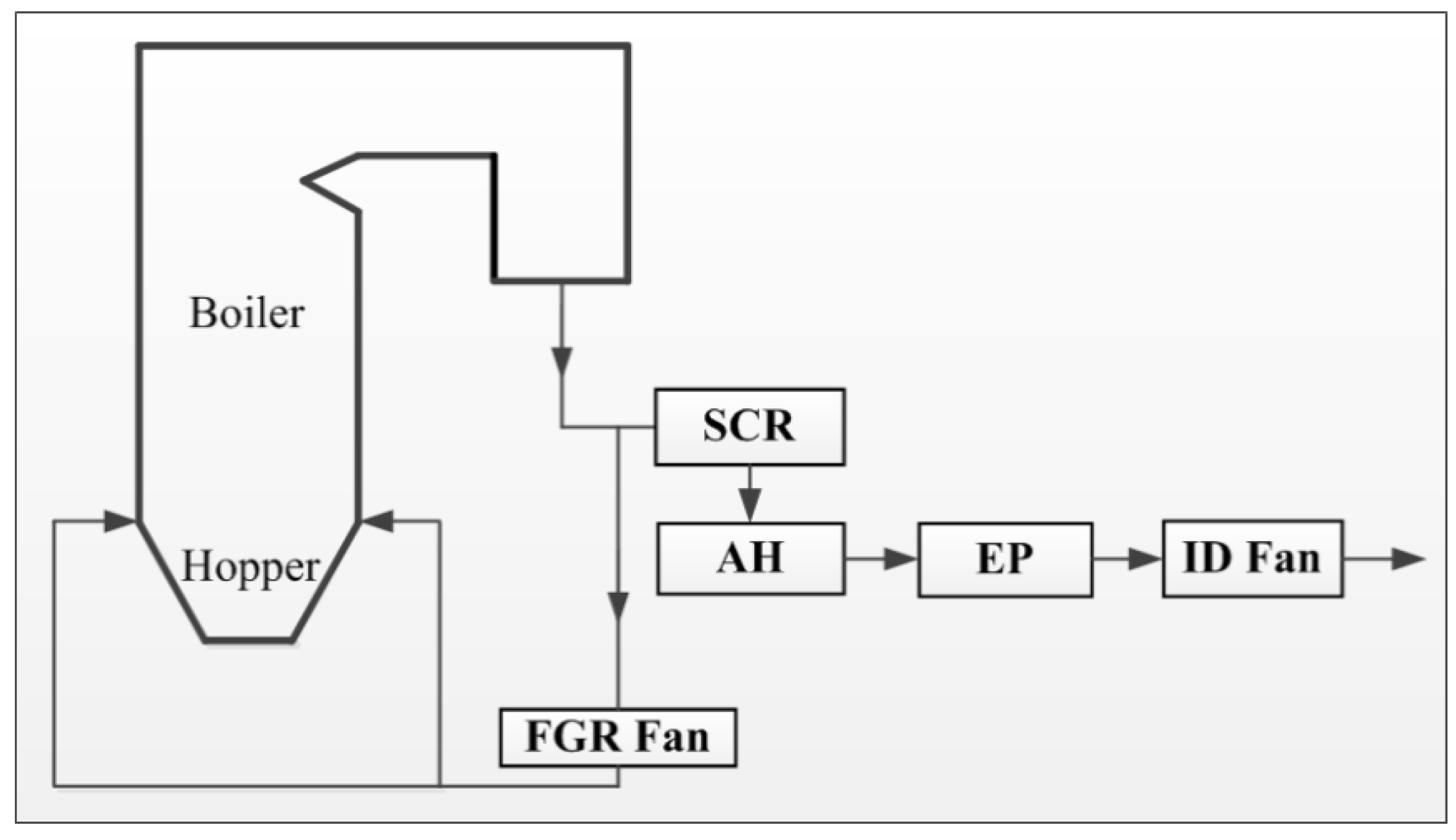

4.2.1. Inverse U-Type Double-Reheat Boiler

- Inverse U-type with triple back passes

- Inverse U-type with double back passes

4.2.2. Tower-Type Double-Reheat Boiler

4.2.3. T-Typed Boiler

5. Conclusions

- The double-reheat technology in China had significant breakthroughs in terms of parameters, capacity, and system optimization. China has achieved many basic design schemes and experience for the operation and maintenance of double-reheat boiler as well as of the advanced 35 MPa/700 °C pulverized coal fired power plants.

- The core work of designing USC double-reheat boiler is to arrange the heating surface, since the double-reheat boiler has more complicated water-vapor circuitry. It is difficult to reasonably arrange the radiative and convective heating surfaces to meet the requirements of heat absorption. In addition, the parameters of working fluid nearly reach the limitation of metal material, which brings challenges for safe operation of water-cooled wall.

- The combined heating surface of the tangentially-fired tower-type double-reheat boiler has the advantage of regulating the steam temperature with TB combined with FGR. This is because the low-temperature part of the final second-stage reheater is arranged as the radiative or semi-radiative heating surface and the high-temperature part of final second-stage reheater is arranged as the convective heating surface.

- The steam pressure and temperature of the double-reheat boiler are approaching the limitation of tube material. It is very important to control the temperature deviation for safe and stable operation of the boiler, especially to decrease the temperature deviation of combustion and fluid sides, since a small overheating could cause the failure of the tube.

- It is an important development direction to improve the flexibility of the double-reheat boiler. This is because the double-reheat boiler has the characteristic of inherent lack of flexibility, since the water-vapor circle is complicated, while the thick wall components and the regenerative heater series are bigger compared to those of single-reheat boiler. However, the grid loads are fluctuating as more and more renewable energy power stations have connected to the grid in recent years; the double-reheat units should participate in the peaking operation.

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| USC | ultra-supercritical |

| SOFA | separate over fire air |

| TB | tilting burners |

| SA | spray attemperation |

| SCR | selective catalytic reduction |

| EP | electrostatic precipitator |

| FGR | flue gas recirculation |

| BMCR | boiler maximum continuous rating |

| FGD | flue gas damper |

| SH | superheater |

| AH | air heater |

| ID fan | induced draft fan |

References

- Chang, S.; Jian, Z. Clean Coal Technologies in China: Current Status and Future Perspectives. Engineering 2016, 2, 447–459. [Google Scholar] [CrossRef]

- Perrone, D.; Castiglione, T. Numerical simulations on Oxy-MILD combustion of pulverized coal in an industrial boiler. Fuel Process. Technol. 2018, 181, 361–374. [Google Scholar] [CrossRef]

- Liu, Y.; Bisson, T. Recent developments in novel sorbents for flue gas clean up. Fuel Process. Technol. 2010, 91, 1175–1197. [Google Scholar] [CrossRef]

- Tumanovskii, A.; Somova, E. Review of the coal-fired, over-supercritical and ultra-supercritical steam power plants. Therm. Eng. 2017, 64, 83–96. [Google Scholar] [CrossRef]

- Feng, W. China’s national demonstration project achieves around 50% net efficiency with 600 °C class materials. Fuel 2018, 223, 344–353. [Google Scholar] [CrossRef]

- Beér, B. High efficiency electric power generation: The environmental role. Prog. Energy Combust. Sci. 2007, 33, 107–134. [Google Scholar] [CrossRef] [Green Version]

- Oliver, T. Clean fossil-fuelled power generation. Energy Policy 2008, 36, 4310–4316. [Google Scholar] [CrossRef]

- Bugge, J.; Blum, R. High-efficiency coal-fired power plants development and perspectives. Energy 2006, 31, 1437–1445. [Google Scholar] [CrossRef]

- Dong, J.; Zhou, T. Coupled Heat Transfer Simulation of the Spiral Water Wall in a Double Reheat Ultra-supercritical Boiler. J. Therm. Sci. 2018, 27, 592–601. [Google Scholar] [CrossRef]

- Mehdi, R.; Aghagoli, A. Thermodynamic Analysis of a Steam Power Plant with Double Reheat and Feed Water Heaters. Adv. Mech. Eng. 2014, 6, 940818. [Google Scholar]

- Yang, Y. Application status and development of USC unit with double-reheat cycles. Power Syst. Eng. 2013, 29, 37–38. (In Chinese) [Google Scholar]

- Tian, D.; Zhong, L. Influence of vertical burner tilt angle on the gas temperature deviation in a 700MW low NOx tangentially fired pulverised-coal boiler. Fuel Process. Technol. 2015, 138, 616–628. [Google Scholar] [CrossRef]

- Xu, L.; Huang, Y. Experimental research of mitigation strategy for high-temperature corrosion of waterwall fireside in a 630 MWe tangentially fired utility boiler based on combustion adjustments. Fuel Process. Technol. 2019, 188, 1–15. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, L. Effect of FGR position on the characteristics of combustion, emission and flue gas temperature deviation in a 1000 MW tower-type double-reheat boiler with deep-air-staging. Fuel 2019, 246, 285–294. [Google Scholar] [CrossRef]

- Wang, Y.; Mou, C. Flexibility and efficiency co-enhancement of thermal power plant by control strategy improvement considering time varying and detailed boiler heat storage characteristics. Energy 2021, 232, 121048. [Google Scholar] [CrossRef]

- Pang, L.; Zhang, S. Flexibility Improvement Study on the Double Reheat Power Generation Unit with a High Temperature Molten Salt Thermal Energy Storage. Proc. Chin. Soc. Electr. Eng. 2021, 41, 2682–2690. (In Chinese) [Google Scholar]

- Wang, Z.; Liu, M. Flexibility and efficiency enhancement for double-reheat coal-fired power plants by control optimization considering boiler heat storage. Energy 2020, 201, 117594. [Google Scholar] [CrossRef]

- Zhao, Z.; Su, S. Exergy analysis of the turbine system in a 1000 MW double reheat ultra-supercritical power plant. Energy 2017, 119, 540–548. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Mu, C. Review of the development and application of double-reheat power generation technology. Therm. Power Gener. 2017, 46, 1–11. (In Chinese) [Google Scholar]

- Jiang, M.; Huang, B. Prospects on Coal-fired Power Generation Technology Development. Proc. CSEE 2012, 32, 1–8. [Google Scholar]

- National Development and Reform Commission. The Electric Power Development Planning “In 10th Five-Year” (2001–2005); National Development and Reform Commission: Beijing, China, 2001. (In Chinese) [Google Scholar]

- National Development and Reform Commission. The Electric Power Development Planning “In 12th Five-Year” (2011–2015); National Development and Reform Commission: Beijing, China, 2011. (In Chinese) [Google Scholar]

- National Development and Reform Commission. Action Plan for Retrofitting and Upgrading of Energy Conservation and Emission Reduction for Thermal Power Plants(2014–2020); National Development and Reform Commission: Beijing, China, 2013. (In Chinese) [Google Scholar]

- Industry Information. The New World Record of Thermal Power Efficiency Equiped with 1 GW Double-Reheat Boiler Produced; Harbin Boiler Co., Ltd.: Harbin, China, 2016; Volume 5, p. 38. (In Chinese) [Google Scholar]

- He, W. Match Characteristics and Influence Factors of Dongfang Double-Reheat Boiler Reheating; Chongqing University: Chongqing, China, 2015. (In Chinese) [Google Scholar]

- Zhang, Y.; Mao, Y. The design & operation of the first domestic 600MW double-reheat ultra-supercritical boiler. Boil. Manuf. 2016, 1, 1–6. (In Chinese) [Google Scholar]

- Yao, D.; Zhu, Y. Design characteristics of 1000 MW double-reheat ultra-supercritical towe boiler. Boil. Technol. 2017, 48, 1–6. (In Chinese) [Google Scholar]

- Jiang, D.; Huang, J. Engineering practice of a 1000 MW double-reheat ultra-supercritical boiler. Power Equip. 2016, 30, 421–424. (In Chinese) [Google Scholar]

- Wang, X.; Mei, Z. Experimental study on optimization and adjustment of wall temperature of reheater tubes in an ultra-supercritical double-reheat boiler. Therm. Power Gener. 2017, 46, 101–106. (In Chinese) [Google Scholar]

- Wang, L.; Liu, H. Analysis of superheater over-temperature of 1000MW double-reheat tower-type boiler & its countermeasure. Shaanxi Electr. Power 2016, 44, 80–87. (In Chinese) [Google Scholar]

- Zhao, Z.; Gao, K. Debugging and Optimization of Analog Control System for Ultra-Supercritical Units; Electric Power Press: Beijing, China, 2016; pp. 122–128. (In Chinese) [Google Scholar]

- Zhao, Z.; Hao, D. Control and optimization of water/coal ratio for an ultra-supercritical 1000 MW unit. Therm. Power Gener. 2017, 46, 136–140. (In Chinese) [Google Scholar]

- Zhao, Z.; Hao, D. Double-reheat ultra-supercritical unit reheat steam temperature control. Therm. Power Gener. 2015, 44, 113–118. (In Chinese) [Google Scholar]

- Xu, L. Discussion on the Reheat Steam Temperature Regulation Scheme in Double-reheat Unit. Electr. Power Surv. Des. 2016, 4, 39–44. (In Chinese) [Google Scholar]

- Xu, W.; Zhang, J. Study on the Steam Temperature Characteristic of a 660 MW Flexible Double-Reheat Boiler based on Response Surface Analysis. J. Eng. Therm. Energy Power 2020, 35, 110–116. (In Chinese) [Google Scholar]

- Che, D.F. Boilers-Theory, Design and Operation; Xi’an Jiaotong University Press: Xi’an, China, 2008. [Google Scholar]

- Yao, X.; Jiang, D. The Double-reheat Unit Thermal Economy Research in Different Boiler Reheater Temperature Control Methods. Electr. Power Surv. Des. 2016, 3, 8–15. (In Chinese) [Google Scholar]

- Li, C. Engineering application of reheat steam temperature control mode for double-reheat tower boilers. Therm. Power Gener. 2016, 45, 68–74. (In Chinese) [Google Scholar]

- Tao, Q.; Wang, Y. Research on the Characteristicsof Reheat Steam Temperature Controlled by Gas Recirculation in Double-Reheat Boiler. J. Eng. Therm. Energy Power 2020, 35, 51–57. [Google Scholar]

| Boiler Type | Combustion Method | Regulating Methods of the Main Steam Temperature | Regulating Methods of the Main Steam Temperature | |

|---|---|---|---|---|

| Inverse U-type | Triple back passes | Wall-fired | water/coal ratio + SA | FGD + SA |

| Double back passes | Wall-fired | FGR + FGD + SA | ||

| Tangentially-fired | FGR + TB + FGD + SA | |||

| Tower-type | Tangentially-fired | TB + FGR + FGD + SA | ||

| T-type | Tangentially-fired | TB + SA | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, H.; Yu, P.; Xue, J.; Deng, L.; Che, D. Research and Application of Double-Reheat Boiler in China. Processes 2021, 9, 2197. https://doi.org/10.3390/pr9122197

Liu H, Yu P, Xue J, Deng L, Che D. Research and Application of Double-Reheat Boiler in China. Processes. 2021; 9(12):2197. https://doi.org/10.3390/pr9122197

Chicago/Turabian StyleLiu, Hu, Pengfei Yu, Jingwen Xue, Lei Deng, and Defu Che. 2021. "Research and Application of Double-Reheat Boiler in China" Processes 9, no. 12: 2197. https://doi.org/10.3390/pr9122197