Enhanced Anti-Fouling Behavior and Performance of PES Membrane by UV Treatment

Abstract

1. Introduction

2. Materials and Methods

2.1. Chemicals

2.2. Polymeric Dope Solution Preparation

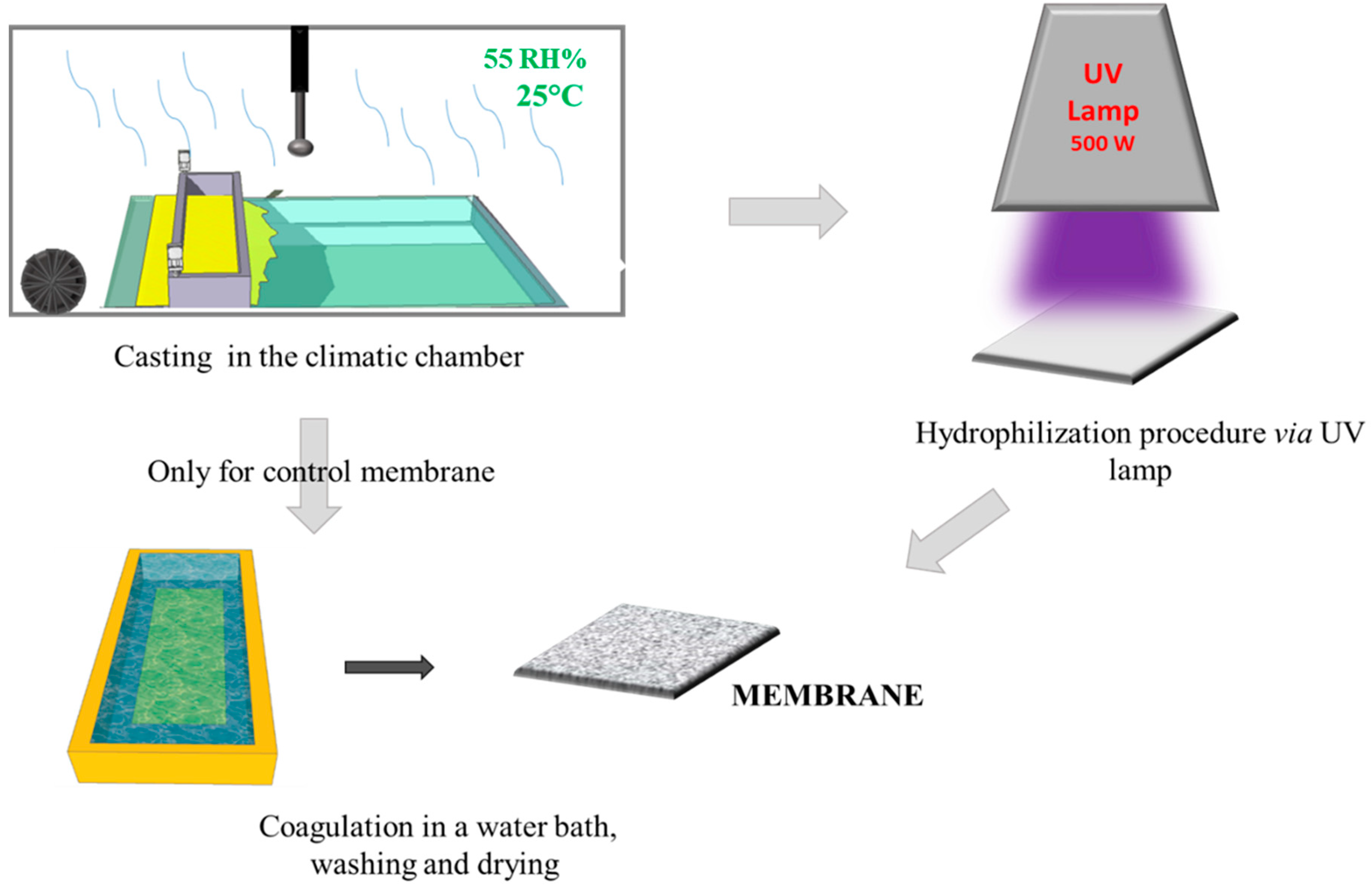

2.3. Membrane Preparation and Hydrophilization Procedure

2.4. Viscosity Measurement

2.5. Attenuated Total Reflectance Fourier Transform Infrared Spectroscopy (ATR-FTIR)

2.6. Scanning Electron Microscopy (SEM)

2.7. Atomic Force Microscopy (AFM)

2.8. Thickness

2.9. Porosity

2.10. Pore Size

2.11. Contact Angle

2.12. Pure Water Permeability

2.13. Anti-Fouling Tests

3. Results and Discussion

3.1. ATR-FTIR

3.2. Membrane Morphology and Properties

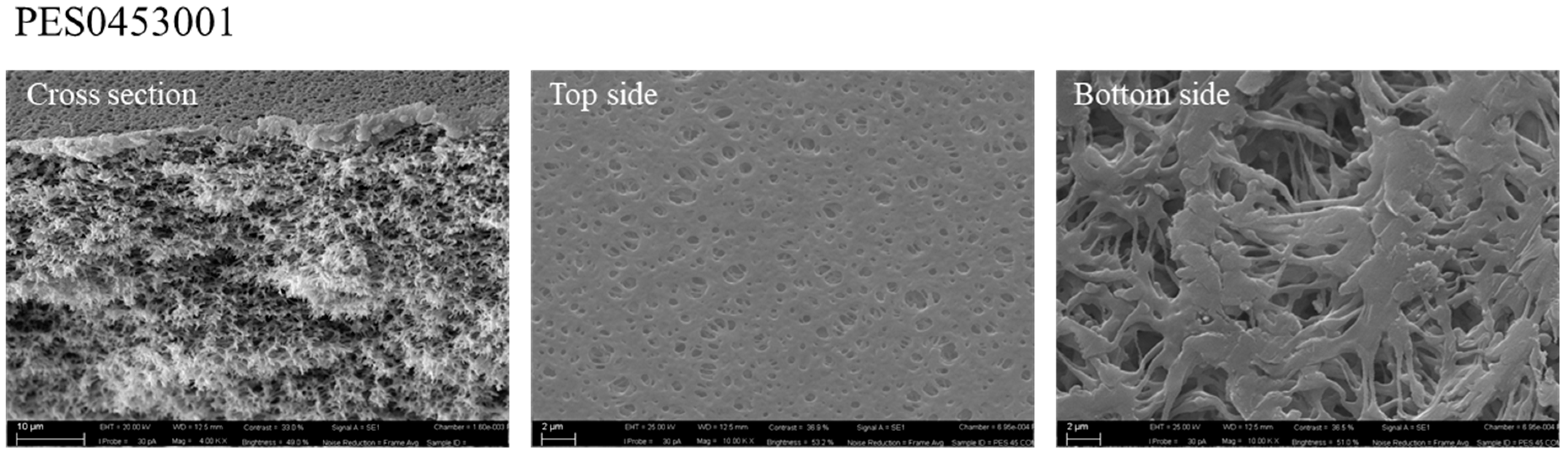

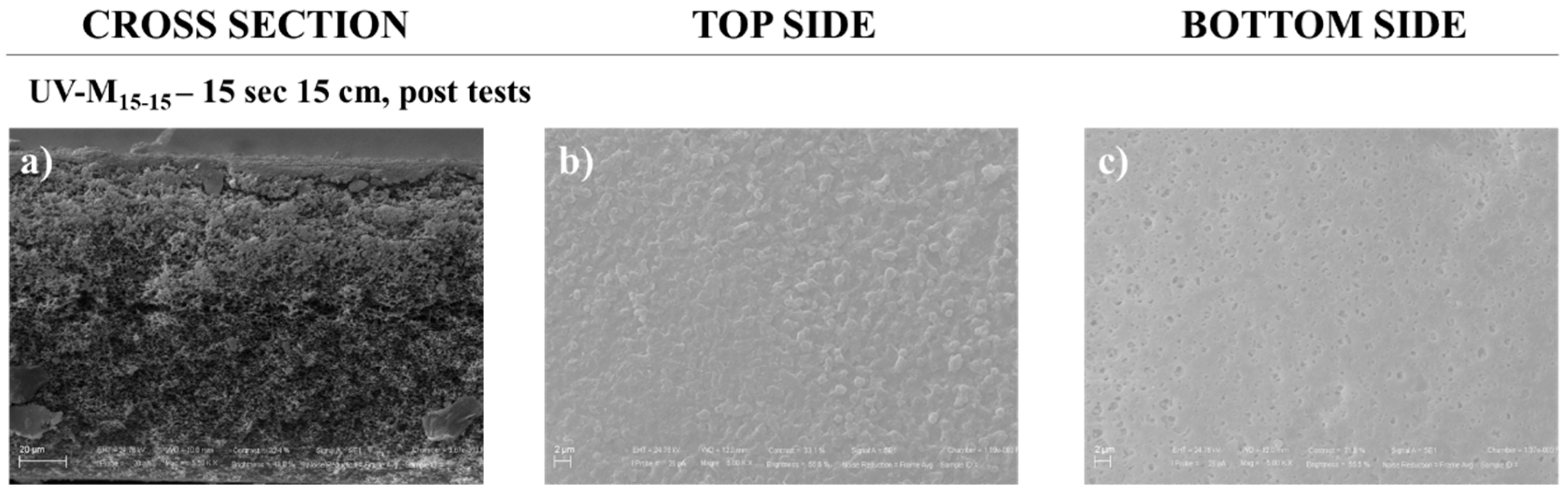

3.2.1. SEM

- -

- A sponge-like structure for all membranes produced (Figure 3a,d,g,l).

- -

- The top side of the membrane exposed for 60 s (UV-M60-30) appears more porous (Figure 3m) than the top side (Figure 3b) of the control membrane (UV-M0). The opposite trend was observed for the membranes exposed for 15 s for UV-M15-15 (Figure 3e) and for UV-M15-30 (Figure 3h). The selective layer was similar for the UV-M15-15 and UV-M15-30 membranes (Figure 3d,g) while it decreased for the UV-M60-30 membrane (Figure 3l).

- -

3.2.2. Viscosity, Thickness, Porosity, Pore Size, and Pure Water Permeability

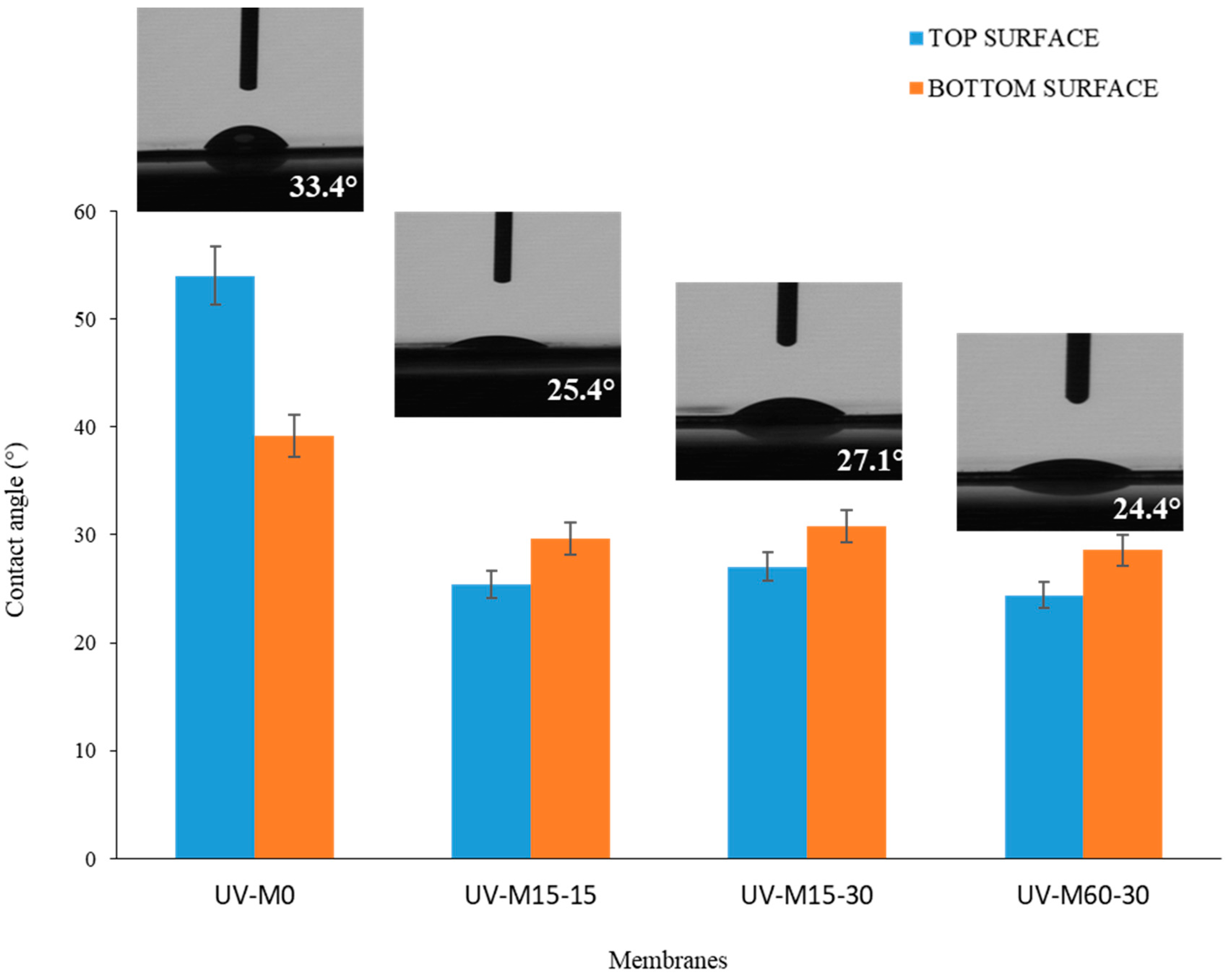

3.2.3. Water Contact Angle

3.2.4. Commercial PES Membrane Properties

3.2.5. Anti-Fouling Tests

3.3. AFM Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Figoli, A.; Marino, T.; Simone, S.; Di Nicolò, E.; Li, X.-M.; He, T.; Tornaghi, S.; Drioli, E. Towards non-toxic solvents for membrane preparation: A review. Green Chem. 2014, 16, 4034. [Google Scholar] [CrossRef]

- Fane, A.G.; Tang, C.Y.; Wang, R. Membrane Technology for Water: Microfiltration, Ultrafiltration, Nanofiltration, and Reverse Osmosis. In Treatise on Water Science; Wilderer, P., Ed.; Elsevier Science: Amsterdam, The Netherlands, 2011; Volume 4, pp. 301–335. ISBN 978-0-444-53199-5. [Google Scholar]

- Russo, F.; Ursino, C.; Avruscio, E.; Desiderio, G.; Perrone, A.; Santoro, S.; Galiano, F.; Figoli, A. Innovative Poly (Vinylidene Fluoride) (PVDF) Electrospun Nanofiber Membrane Preparation Using DMSO as a Low Toxicity Solvent. Membranes 2020, 10, 36. [Google Scholar] [CrossRef] [PubMed]

- Rana, D.; Matsuura, T. Surface modifications for antifouling membranes. Chem. Rev. 2010, 110, 2448–2471. [Google Scholar] [CrossRef] [PubMed]

- Baker, R.W. Membrane Technology and Applications; John Wiley & Sons, Ltd.: London, UK, 2004; ISBN 0470854456. [Google Scholar]

- Noble, R.D.; Stern, S.A. Membrane Separations Technology—Principles and Applications, 3rd ed.; Elsevier Science: Amsterdam, The Netherlands, 1995; ISBN 9780080536187. [Google Scholar]

- Oulad, F.; Zinadini, S.; Zinatizadeh, A.A.; Derakhshan, A.A. Novel (4,4-diaminodiphenyl sulfone coupling modified PES/PES) mixed matrix nanofiltration membranes with high permeability and anti-fouling property. Sep. Purif. Technol. 2020, 236, 116292. [Google Scholar] [CrossRef]

- Figoli, A.; Ursino, C.; Galiano, F. Innovative coating membranes for water treatment. In Functional Nanostractured Membranes; Drioli, E., Giorno, L., Gugliuzza, A., Eds.; Pan Stanford: Singapore, 2018; p. 604. ISBN 978-981-4774-79-6. [Google Scholar]

- Drioli, E.; Giorno, L. Membrane Operations: Innovative Separations and Transformations; Wiley-VCH: Weinheim, Germany, 2009; ISBN 9783527320387. [Google Scholar]

- Bildyukevich, A.V.; Plisko, T.V.; Liubimova, A.S.; Volkov, V.V.; Usosky, V.V. Hydrophilization of polysulfone hollow fiber membranes via addition of polyvinylpyrrolidone to the bore fluid. J. Membr. Sci. 2017, 524, 537–549. [Google Scholar] [CrossRef]

- Solvay. Processing Guide for Polymer Membranes. Available online: https://www.solvay.com/sites/g/files/srpend221/files/2018-08/Membranes-Processing-Guide_EN-v4.6_0.pdf (accessed on 20 November 2020).

- Peyravi, M.; Rahimpour, A.; Jahanshahi, M.; Javadi, A.; Shockravi, A. Tailoring the surface properties of PES ultrafiltration membranes to reduce the fouling resistance using synthesized hydrophilic copolymer. Microporous Mesoporous Mater. 2012, 160, 114–125. [Google Scholar] [CrossRef]

- Galiano, F.; Figoli, A.; Deowan, S.A.; Johnson, D.; Altinkaya, S.A.; Veltri, L.; De Luca, G.; Mancuso, R.; Hilal, N.; Gabriele, B.; et al. A step forward to a more efficient wastewater treatment by membrane surface modification via polymerizable bicontinuous microemulsion. J. Membr. Sci. 2015, 482, 103–114. [Google Scholar] [CrossRef]

- Ursino, C.; Castro-Muñoz, R.; Drioli, E.; Gzara, L.; Albeirutty, M.H.; Figoli, A. Progress of nanocomposite membranes for water treatment. Membranes 2018, 8, 18. [Google Scholar] [CrossRef]

- Kumari, P.; Modi, A.; Bellare, J. Enhanced flux and antifouling property on municipal wastewater of polyethersulfone hollow fiber membranes by embedding carboxylated multi-walled carbon nanotubes and a vitamin E derivative. Sep. Purif. Technol. 2020, 235, 116199. [Google Scholar] [CrossRef]

- Susanto, H.; Desiriani, R.; Adi, A.; Hermita, D. Incorporation of Nanoparticles as Antifouling Agents into PES UF Membrane. Mater. Today Proc. 2019, 13, 217–223. [Google Scholar] [CrossRef]

- Esfahani, M.R.; Aktij, S.A.; Dabaghian, Z.; Firouzjaei, M.D.; Rahimpour, A.; Eke, J.; Escobar, I.C.; Abolhassani, M.; Greenlee, L.F.; Esfahani, A.R.; et al. Nanocomposite membranes for water separation and purification: Fabrication, modification, and applications. Sep. Purif. Technol. 2019, 213, 465–499. [Google Scholar] [CrossRef]

- Kusworo, T.D.; Widayat, W.; Utomo, D.P.; Pratama, Y.H.S.; Arianti, R.A.V. Performance evaluation of modified nanohybrid membrane polyethersulfone-nano ZnO (PES-nano ZnO) using three combination effect of PVP, irradiation of ultraviolet and thermal for biodiesel purification. Renew. Energy 2020, 148, 935–945. [Google Scholar] [CrossRef]

- Pieracci, J.; Crivello, J.V.; Belfort, G. Photochemical modification of 10kDa polyethersulfone ultrafiltration membranes for reduction of biofouling. J. Membr. Sci. 1999, 156, 223–240. [Google Scholar] [CrossRef]

- Garcia-Ivars, J.; Iborra-Clar, M.I.; Alcaina-Miranda, M.I.; Mendoza-Roca, J.A.; Pastor-Alcañiz, L. Surface photomodification of flat-sheet PES membranes with improved antifouling properties by varying UV irradiation time and additive solution pH. Chem. Eng. J. 2016, 283, 231–242. [Google Scholar] [CrossRef]

- Ng, L.Y.; Ahmad, A.; Mohammad, A.W. Alteration of polyethersulphone membranes through UV-induced modification using various materials: A brief review. Arab. J. Chem. 2017, 10, S1821–S1834. [Google Scholar] [CrossRef]

- Russo, F.; Galiano, F.; Pedace, F.; Aricò, F.; Figoli, A. Dimethyl Isosorbide as a Green Solvent for Sustainable Ultrafiltration and Microfiltration Membrane Preparation. ACS Sustain. Chem. Eng. 2020, 8, 659–668. [Google Scholar] [CrossRef]

- Díez, B.; Rosal, R. A critical review of membrane modification techniques for fouling and biofouling control in pressure-driven membrane processes. Nanotechnol. Environ. Eng. 2020, 5, 15. [Google Scholar] [CrossRef]

- Anastas, P.T.; Warner, J.C. Green Chemistry: Theory and Practice; Oxford University Press: Oxford, UK, 1998; ISBN 0198502346/9780198502340. [Google Scholar]

- Walter, R.S. The Circular Economy. Nature 2016, 531, 435–438. [Google Scholar]

- Solvay. Rhodiasolv® PolarClean—A Novel Safe & Powerful Solvent for Innovative Plant Protection Products. Available online: https://www.solvay.us/en/markets-and-products/featured-products/Rhodiasolv-PolarClean.html (accessed on 20 November 2020).

- Ursino, C.; Russo, F.; Ferrari, R.M.; De Santo, M.P.; Di Nicolò, E.; He, T.; Galiano, F.; Figoli, A. Polyethersulfone hollow fiber membranes prepared with Polarclean® as a more sustainable solvent. J. Membr. Sci. 2020, 608, 118216. [Google Scholar] [CrossRef]

- Russo, F.; Castro-Muñoz, R.; Galiano, F.; Figoli, A. Unprecedented preparation of porous Matrimid® 5218 membranes. J. Membr. Sci. 2019, 585, 166–174. [Google Scholar] [CrossRef]

- Marino, T.; Blasi, E.; Tornaghi, S.; Di, E.; Figoli, A. Polyethersulfone membranes prepared with Rhodiasolv® Polarclean as water soluble green solvent. J. Membr. Sci. 2018, 549, 192–204. [Google Scholar] [CrossRef]

- Crivello, J.W.; Belfort, G.; Yamagishi, H. Low Fouling Ultrafiltration and Microfiltration Aryl Polysulfone. US Patent US5468390A, 21 November 1995. [Google Scholar]

- Susanto, H.; Ulbricht, M. Characteristics, performance and stability of polyethersulfone ultrafiltration membranes prepared by phase separation method using different macromolecular additives. J. Membr. Sci. 2009, 327, 125–135. [Google Scholar] [CrossRef]

- Wienk, I.M.; Boom, R.M.; Beerlage, M.A.M.; Bulte, A.M.W.; Smolders, C.A.; Strathmann, H. Recent advances in the formation of phase inversion membranes made from amorphous or semi-crystalline polymers. J. Membr. Sci. 1996, 113, 361–371. [Google Scholar] [CrossRef]

- Urkiaga, A.; Iturbe, D.; Etxebarria, J. Effect of different additives on the fabrication of hydrophilic polysulfone ultrafiltration membranes. Desalin. Water Treat. 2015, 56, 3415–3426. [Google Scholar] [CrossRef]

- Ahmad, A.L.; Abdulkarim, A.A.; Ooi, B.S.; Ismail, S. Recent development in additives modifications of polyethersulfone membrane for flux enhancement. Chem. Eng. J. 2013, 223, 246–267. [Google Scholar] [CrossRef]

- Anthony, E.; Allegrezza, J.; Bellantoni, E.C. Porous Membrane Formed from Interpenetrating Polymer Network Having Hydrophilic Surface. US Patent US5079272, 7 January 1992. [Google Scholar]

- Farrukh, M.M.; Bosch, P.; Giagnorio, M.; Tiraferri, A.; Sangermano, M. Solvent-stable UV-cured acrylic polysulfone membranes. Polym. Int. 2017, 66, 64–69. [Google Scholar] [CrossRef]

- Lilleby Helberg, R.M.; Dai, Z.; Ansaloni, L.; Deng, L. PVA/PVP blend polymer matrix for hosting carriers in facilitated transport membranes: Synergistic enhancement of CO2 separation performance. Green Energy Environ. 2020, 5, 59–68. [Google Scholar] [CrossRef]

- Iulianelli, A.; Russo, F.; Galiano, F.; Desiderio, G.; Basile, A.; Figoli, A. PLA Easy Fil—White-based membranes for CO2 separation. Greenh. Gases Sci. Technol. 2019, 9, 360–369. [Google Scholar] [CrossRef]

- Ursino, C.; Di Nicolò, E.; Gabriele, B.; Criscuoli, A.; Figoli, A. Development of a novel perfluoropolyether (PFPE) hydrophobic/hydrophilic coated membranes for water treatment. J. Membr. Sci. 2019, 581, 58–71. [Google Scholar] [CrossRef]

- Barner-Kowollik, C.; Davis, T.P.; Stenzel, M.H. Probing mechanistic features of conventional, catalytic and living free radical polymerizations using soft ionization mass spectrometric techniques. Polymer 2004, 45, 7791–7805. [Google Scholar] [CrossRef]

- Barros, J.A.G.; Fechine, G.J.M.; Alcantara, M.R.; Catalani, L.H. Poly(N-vinyl-2-pyrrolidone) hydrogels produced by Fenton reaction. Polymer 2006, 47, 8414–8419. [Google Scholar] [CrossRef]

- Parisi, O.I.; Puoci, F.; Iemma, F.; Curcio, M.; Cirillo, G.; Spizzirri, U.G.; Picci, N. Flavonoids preservation and release by methacrylic acid-grafted (N-vinyl-pyrrolidone). Pharm. Dev. Technol. 2013, 18, 1058–1065. [Google Scholar] [CrossRef] [PubMed]

- Zhu, X.; Lu, P.; Chen, W.; Dong, J. Studies of UV crosslinked poly(N-vinylpyrrolidone) hydrogels by FTIR, Raman and solid-state NMR spectroscopies. Polymer 2010, 51, 3054–3063. [Google Scholar] [CrossRef]

- Ettori, A.; Gaudichet-Maurin, E.; Schrotter, J.C.; Aimar, P.; Causserand, C. Permeability and chemical analysis of aromatic polyamide based membranes exposed to sodium hypochlorite. J. Membr. Sci. 2011, 375, 220–230. [Google Scholar] [CrossRef]

- Simone, S.; Conidi, C.; Ursino, C.; Cassano, A.; Figoli, A. Clarification of Orange Press Liquors by PVDF Hollow Fiber Membranes. Membranes 2016, 6, 9. [Google Scholar] [CrossRef]

- Marino, T.; Russo, F.; Rezzouk, L.; Bouzid, A.; Figoli, A. PES-kaolin mixed matrix membranes for arsenic removal from water. Membranes 2017, 7, 57. [Google Scholar] [CrossRef]

- Zuo, D.Y.; Xu, W.L.; Liu, H.T. Effects of polyvinylpyrrolidone on structure and performance of composite scaffold of chitosan superfine powder and polyurethane. Adv. Polym. Technol. 2012, 31, 310–318. [Google Scholar] [CrossRef]

- Susanto, H.; Stahra, N.; Ulbricht, M. High performance polyethersulfone microfiltration membranes having high flux and stable hydrophilic property. J. Membr. Sci. 2009, 342, 153–164. [Google Scholar] [CrossRef]

- Guillen, G.R.; Pan, Y.; Li, M.; Hoek, E.M. V Preparation and Characterization of Membranes Formed by Nonsolvent Induced Phase Separation: A Review. Ind. Eng. Chem. Res. 2011, 50, 3798–3817. [Google Scholar] [CrossRef]

- Yamagishi, H.; Crivello, J.V.; Belfort, G. Development of a novel photochemical technique for modifying poly(arylsulfone) ultrafiltration membranes. J. Membr. Sci. 1995, 105, 237–247. [Google Scholar] [CrossRef]

- Hendrik, D.W. Roesink Cornelis, A. Smolders Marcellinus, H.V. Mulder; Koenhen, D.M. Process for the preparation of hydrophilic membranes and such membranes. US Patent US4798847A, 17 January 1989. [Google Scholar]

- Chen, Z.; Rana, D.; Matsuura, T.; Meng, D.; Lan, C.Q. Study on structure and vacuum membrane distillation performance of pvdf membranes: II. influence of molecular weight. Chem. Eng. J. 2015, 276, 174–184. [Google Scholar] [CrossRef]

- Hassankiadeh, N.T.; Cui, Z.; Kim, J.H.; Shin, D.W.; Sanguineti, A.; Arcella, V.; Lee, Y.M.; Drioli, E. PVDF hollow fiber membranes prepared from green diluent via thermally induced phase separation: Effect of PVDF molecular weight. J. Membr. Sci. 2014, 471, 237–246. [Google Scholar] [CrossRef]

- Kang, G.-D.; Cao, Y.-M. Application and modification of poly(vinylidene fluoride) (PVDF) membranes—A review. J. Membr. Sci. 2014, 463, 145–165. [Google Scholar] [CrossRef]

- Cassie, A.B.D.; Baxter, S. Wettability of porous surfaces. Trans. Faraday Soc. 1944, 40, 546. [Google Scholar] [CrossRef]

- Vatsha, B.; Ngila, J.C.; Moutloali, R.M. Preparation of antifouling polyvinylpyrrolidone (PVP 40K) modified polyethersulfone (PES) ultrafiltration (UF) membrane for water purification. Phys. Chem. Earth 2014, 67–69, 125–131. [Google Scholar] [CrossRef]

- Seman, M.N.A.; Khayet, M.; Hilal, N. Comparison of two different UV-grafted nanofiltration membranes prepared for reduction of humic acid fouling using acrylic acid and N-vinylpyrrolidone. Desalination 2012, 287, 19–29. [Google Scholar] [CrossRef]

- Rahimpour, A. UV photo-grafting of hydrophilic monomers onto the surface of nano-porous PES membranes for improving surface properties. Desalination 2011, 265, 93–101. [Google Scholar] [CrossRef]

- Hua, H.; Li, N.; Wu, L.; Zhong, H.; Wu, G.; Yuan, Z.; Lin, X.; Tang, L. Anti-fouling ultrafiltration membrane prepared from polysulfone-graft-methyl acrylate copolymers by UV-induced grafting method. J. Environ. Sci. 2008, 20, 565–570. [Google Scholar] [CrossRef]

- Nabe, A.; Staude, E.; Belfort, G. Surface modification of polysulfone ultrafiltration membranes and fouling by BSA solutions. J. Membr. Sci. 1997, 133, 57–72. [Google Scholar] [CrossRef]

- Vrijenhoek, E.M.; Hong, S.; Elimelech, M. Influence of membrane surface properties on initial rate of colloidal fouling of reverse osmosis and nanofiltration membranes. J. Membr. Sci. 2001, 188, 115–128. [Google Scholar] [CrossRef]

- Riedl, K.; Girard, B.; Lencki, R.W. Influence of membrane structure on fouling layer morphology during apple juice clarification. J. Membr. Sci. 1998, 139, 155–166. [Google Scholar] [CrossRef]

- Kwak, S.Y.; Jung, S.G.; Yoon, Y.S.; Ihm, D.W. Details of surface features in aromatic polyamide reverse osmosis membranes characterized by scanning electron and atomic force microscopy. J. Polym. Sci. Part B Polym. Phys. 1999, 37, 1429–1440. [Google Scholar] [CrossRef]

- Hirose, M.; Ito, H.; Kamiyama, Y. Effect of skin layer surface structures on the flux behaviour of RO membranes. J. Membr. Sci. 1996, 121, 209–215. [Google Scholar] [CrossRef]

| Membrane Name | UV (s) | Lamp Distance (cm) |

|---|---|---|

| UV-M0 | - | - |

| UV-M15-15 | 15 | 15 |

| UV-M60-15 | 60 | |

| UV-M15-30 | 15 | 30 |

| UV-M60-30 | 60 |

| Membrane Name | Thickness (µm) | Porosity (%) | Mean Pore Size (µm) | Pure Water Permeability (L/m2h bar) |

|---|---|---|---|---|

| UV-M0 | 120 ± 2 | 86.5 ± 3 | 0.37 ± 0.08 | 16,324 ± 1660 |

| UV-M15-15 | 85.4 ± 4 | 85.8 ± 2 | 0.43 ± 0.03 | 25,301 ± 525 |

| UV-M15-30 | 105.4 ± 4 | 85.0 ± 3 | 0.45 ± 0.02 | 19,274 ± 770 |

| UV-M60-30 | 99.4 ± 3 | 87.2 ± 2 | 0.73 ± 0.01 | 35,418 ± 1440 |

| Membrane Type | Thickness (µm) | CAw (°) | Porosity (%) | Pore Size (µm) | PWP (L/m2hbar) |

|---|---|---|---|---|---|

| PES0453001 | 122 ± 2 | 34° ± 0.8 | 83 ± 2 | 0.45 ± 0.02 | 18,482 ± 322 |

| Membrane Name | PWP (L/m2h bar) | PHA (L/m2h bar) | PWN (L/m2h bar) | Reduction (%) | Recovery (%) | Rejection (R%) |

|---|---|---|---|---|---|---|

| UV-M15-15 | 25,301 ± 525 | 525 ± 15 | 25,180 ± 43 | 97.92 | 97.45 | 92.95 |

| PES0453001 | 18,482 ± 32 | 445 ± 12 | 939 ± 24 | 97.59 | 2.67 | 93.50 |

| Membrane Type | Material | Pore Size (µm) | CA (°) | Rejection (%) | Ref. |

|---|---|---|---|---|---|

| UV-M15-15 | PVP-PES | 0.43 | 25 | 92.95 | This work |

| PES0453001 | PES | 0.45 | 34 | 93.50 | This work |

| PES (3100P) | PVP-PES | 0.02 | 38 | 90 | [56] |

| 5NVP-3 | NVP-PES | 0.001 | - | 96 | [57] |

| PES-nano ZnO | ZnO-PVP-PES | - | 52.22 | 91 | [18] |

| AA-PES | Acrylic acid (AA)-PES | 0.006 | 64.1 | 96 | [58] |

| PSF-g-MA | Methyl acrylate-PSF | - | 51 | - | [59] |

| Membrane | Roughness Average Sa (µm) | RMS Sq (µm) | Peak to Peak Sz (µm) |

|---|---|---|---|

| PES0453001 * | 0.06 ± 0.00 | 0.08 ± 0.00 | 0.79 ± 0.06 |

| PES0453001 ** | 0.26 ± 0.03 | 1.73 ± 0.10 | 0.83 ± 0.20 |

| UV-M15-15 * | 0.21 ± 0.20 | 1.72 ± 0.03 | 0.16 ± 0.08 |

| UV-M15-15 ** | 0.31 ± 0.00 | 2.17 ± 0.05 | 0.24 ± 0.04 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Russo, F.; Bulzomì, M.; Di Nicolò, E.; Ursino, C.; Figoli, A. Enhanced Anti-Fouling Behavior and Performance of PES Membrane by UV Treatment. Processes 2021, 9, 246. https://doi.org/10.3390/pr9020246

Russo F, Bulzomì M, Di Nicolò E, Ursino C, Figoli A. Enhanced Anti-Fouling Behavior and Performance of PES Membrane by UV Treatment. Processes. 2021; 9(2):246. https://doi.org/10.3390/pr9020246

Chicago/Turabian StyleRusso, Francesca, Maria Bulzomì, Emanuele Di Nicolò, Claudia Ursino, and Alberto Figoli. 2021. "Enhanced Anti-Fouling Behavior and Performance of PES Membrane by UV Treatment" Processes 9, no. 2: 246. https://doi.org/10.3390/pr9020246

APA StyleRusso, F., Bulzomì, M., Di Nicolò, E., Ursino, C., & Figoli, A. (2021). Enhanced Anti-Fouling Behavior and Performance of PES Membrane by UV Treatment. Processes, 9(2), 246. https://doi.org/10.3390/pr9020246