3.1. Causes of Cavitation

The cylinder is the important hydraulic component in the hydraulic system; it can complete retraction and extension movements. When the piston of the cylinder is moving, the external force acting on the piston rod has two forms: external passive force and external active force. In actual applications of the cylinder, both passive and active load forces may be excessive. The consequence of excessive external passive load is that the piston rod of the hydraulic cylinder cannot move, which will cause the mechanical drive system to suspend. The consequence of excessive external active load is that one of the cylinder chambers will produce cavitation.

In the hydraulic system, the system pressure is generally the gauge pressure. As is shown in

Figure 8, cavitation is a phenomenon, which can occur in the hydraulic system, such as pumps, valves, motors and cylinders, when the hydraulic system pressure falls below the vapor pressure

Pc, which is the gauge pressure. The hydraulic system pressure area is divided into three areas: the working pressure area, cavitation pressure area and vacuum pressure area. It can be seen that the working pressure area is desired, as the hydraulic system pressure is greater than the vapor pressure

Pc. Moreover, the cavitation pressure area is included the vacuum pressure; both of the cavitation pressure areas and vacuum pressure are not desired. As the hydraulic system pressure is less than the vapor pressure

Pc, it will produce cavitation. If the hydraulic system pressure is less than 0, it will produce a vacuum, and the minimum value of the system pressure is the negative atmospheric pressure −

Pat.

In the hydraulic system with external active load, both the extension working mode and retraction working mode will produce cavitation.

Figure 8 shows two working modes with external active load.

Figure 9a shows the extension working mode with external active load, and

Figure 9b shows the retraction working mode with external active load. From

Figure 9a,b, it can be seen that the direction of the external active load

FL acting on the piston rod is the same as the direction of the cylinder piston speed

v. The difference between extension working mode and retraction working mode is that the direction of the velocity

v, the flow rate

Qa and

Qb, and the force

FL and

FP are opposite. Hence, take the extension working mode with external active load, for example, for analyzing the cavitation phenomenon.

As is shown in

Figure 9a, the output force

FP of the piston rod can be express:

where

FP is the output force of the piston rod,

Aa is the head chamber area of the cylinder,

Ab is the cylinder rod chamber area,

Pa is the cylinder head chamber pressure,

Pb is the cylinder rod chamber pressure.

As is shown in

Figure 9a, when the piston rod is extending with the external active load

FL, the output force

FP will be hindering the extension motion of the piston rod. The value of output force

FP depends on the head chamber pressure

Pa and rod chamber pressure

Pb. If the rod chamber pressure

Pb is growing to the maximum safe pressure of the hydraulic system, and the head chamber pressure

Pa the negative atmospheric pressure −

Pat. As a result, the output force

FP will be growing to the maximum

FPmax. Hence, in the hydraulic system, the output force

FP must be less than the maximum out force

FPmax.

When the external active load

FL acting on the piston rod is less than the maximum out force

FPmax, the force balance equation for the piston rod can be expressed:

In this situation, as Equation (3) is described, the velocity v of the cylinder piston rod is controlled by the hydraulic system, and it will not produce the cavitation phenomenon in the head chamber of the cylinder.

When the external active load

FL is greater than the maximum out force

FPmax, the force balance equation for the piston rod can be expressed:

where

FL is the external active load acting on the piston rod,

m is the total mass of the piston and load referred to the piston,

a is the acceleration of the piston and load referred to the piston.

The velocity

v of the piston can be expressed:

where

v0 is the velocity when the external active load

FL equals the output force

FP of the piston rod,

t is the acceleration time.

In this situation, as Equations (4) and (5) are described, the velocity v of the cylinder piston rod will be increasing with the acceleration time t. If the acceleration time t lasts too long, the velocity v will be increasing from velocity v0 to a great value vmax. Hence, the velocity v of the cylinder piston rod cannot be depending on the hydraulic system but on the external active load FL and the acceleration time t.

In the two working modes with external active load, if both of the cylinder rod chamber pressure

Pb and the cylinder head chamber pressure

Pa are greater than 0, which is the gauge pressure, the flow rate

Qa and

Qb can be calculated by the continuity equations:

where

Qa is the flow rate of the cylinder head chamber,

Qb is the flow rate of the cylinder rod chamber.

In the extension working mode with the eternal, active load as is shown in

Figure 9a. From Equation (6), when the velocity

v is increasing to a great value

vmax, the inflow rate

Qa of the cylinder head chamber will be increased to a great value

Qamax. However, the output flow rate

Qp of the pump is fixed. If the

Qamax is greater than the output flow rate

Qp of the pump, the cylinder head chamber will produce cavitation. As a result, the flow rate of the cylinder head chamber

Qa cannot be calculated by Equation (6). However,

Qb is the outflow rate of the cylinder rod chamber, so it cannot produce cavitation, as a result, that the flow rate

Qb can be calculated by Equation (7).

The retraction working mode with external active load is the same as the extension working mode with eternal, active load. As is shown in

Figure 9b, when the external active load

FL is greater than the maximum out force

FPmax, the cylinder rod chamber will be produced the cavitation phenomenon, as a result, that the flow rate

Qb cannot be calculated by Equation (7). Similarly, the flow rate

Qa can be calculated by Equation (6).

3.2. HPCIMS

In this section, the fluid compressibility and the dynamic effects are also ignored. HPCIMS, as is shown in

Figure 6, can be simplified as is shown in

Figure 10.

Figure 10a shows the simplified schematic of HPCIMS with the extension working mode, and it can be seen that the 2/2-valve #4 is controlling the inflow rate

Qa of the cylinder head chamber, and the 2/2-valve #3 is controlling the outflow rate

Qb of the cylinder rod chamber; as a result, the cylinder piston rod can be extended with the external active load

FL.

Figure 10b shows the simplified schematic of HPCIMS with the retraction working mode; it can be seen that the 2/2-valve #5 is controlling the inflow rate

Qa of the cylinder rod chamber, and the 2/2-valve #1 is controlling the outflow rate

Qb of the cylinder head chamber. As a result, the cylinder piston rod can be retracted with the external active load

FL. Hence, take the extension working mode, for example, and it is similar to the retraction working mode.

Assume the intrinsic parameters of the 2/2-valve #1, #2, #3, #4, and #5 are the same. As is shown in

Figure 9a, flows in 2/2-valve #4 and 2/2-valve #3 can be expressed:

where

Cd is the flow coefficient of the 2/2-valve,

W is the area gradient of the 2/2-valve,

xmax is the maximum displacement of the 2/2-valve sliding spool,

xin is the opening ratio of 2/2-valve #4,

xout is the opening ratio of 2/2-valve #3,

PS1 is the outlet pressure of the compensator,

P0 is the pressure of the tank, and

ρ is the density of the hydraulic fluid.

If the external active load FL is increasing to a big value, the head chamber pressure Pa will be decreased to a negative value. If the head chamber pressure Pa is less than the vapor pressure Pc, the head chamber will produce cavitation.

Hence, if the head chamber pressure

Pa is greater than the negative atmospheric pressure −

Pat, which is the absolute pressure 0. Take the Equations (2) and (3) into derivation; the results can be obtained:

If the pressure

Pa is less than negative atmospheric pressure −

Pat, which is the absolute pressure 0, it equals −

Pat, so the external active load

FL can be expressed:

If the pressure

Pa is greater than 0, flows in 2/2-valve #4 and 2/2-valve #3 with extension working mode can also be characterized by the following equations:

Taking the Equations (8), (9), (12) and (13) into derivation, and the results can be obtained:

The differential pressure of 2/2-valve #4 is determined by the compensator, so it can be expressed:

By defining

,

and the

P0 is the pressure of tank can be assumed as 0. Squaring Equation (14) and rearranging the following expressions, the results are obtained:

If the head chamber pressure

Pa is greater than negative atmospheric pressure −

Pat, which is the absolute pressure 0, take the Equations (10) and (16) into derivation, the pressure

Pa can be obtained:

If the head chamber pressure

Pa is less than negative atmospheric pressure −

Pat, which is the absolute pressure 0, the pressure

Pa equals −

Pat, and

Pb can be expressed:

If the cylinder head chamber pressure

Pa is less than the vapor pressure

Pc, the head chamber of the cylinder will produce cavitation. Hence, the pressure

Pa must be greater than the vapor pressure

Pc. As the opening ratio

xin of 2/2-valve #4 and the opening ratio

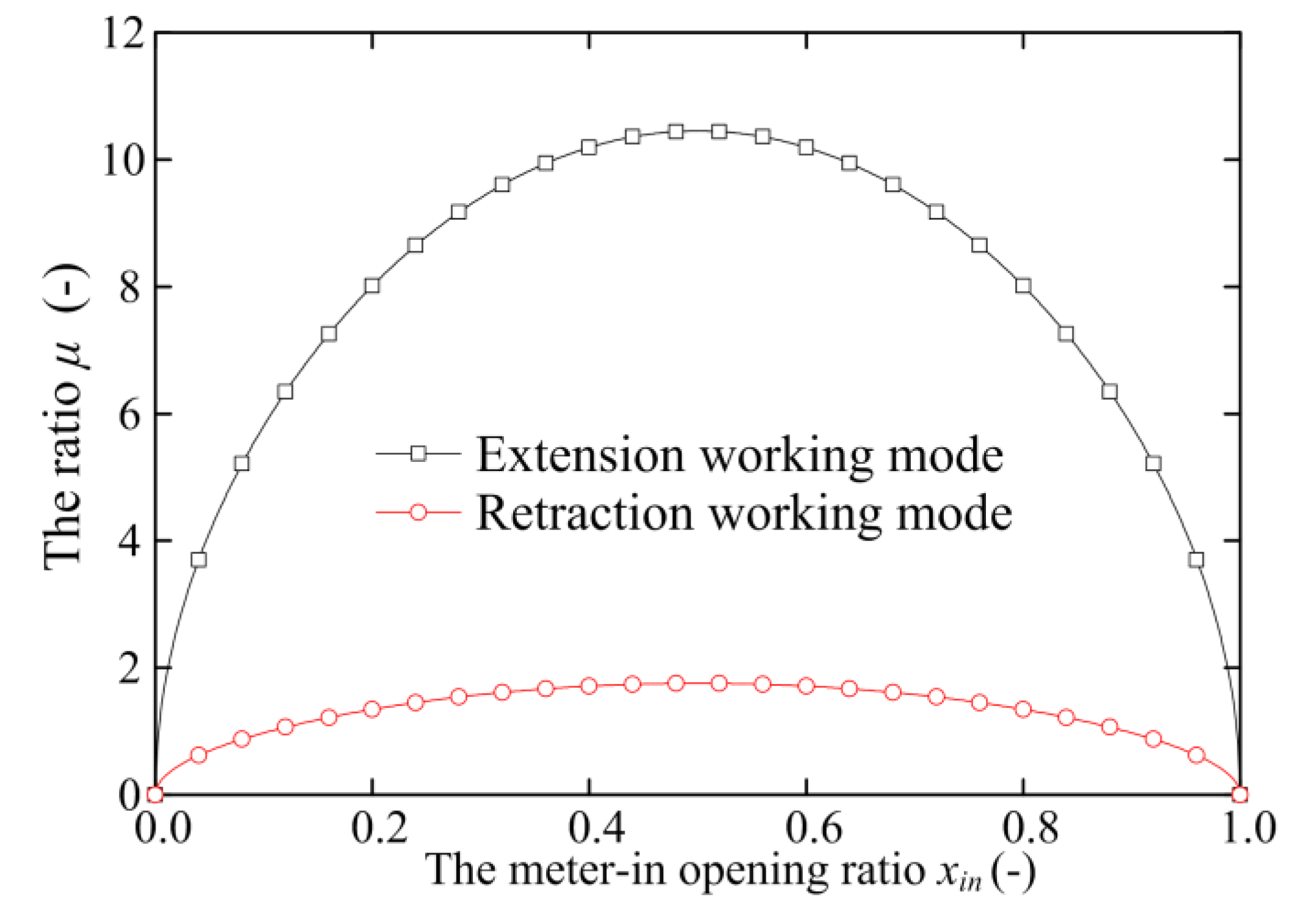

xout of 2/2-valve #3 can be independently regulated, so the ratio

μ is a variable parameter. The ratio

μmin can be expressed:

Using the same method, the results of the retraction working mode can be obtained as follows:

If the rod chamber pressure

Pb is greater than the negative atmospheric pressure −

Pat, the pressure

Pb can be expressed:

If the rod chamber pressure

Pb is less than negative atmospheric pressure −

Pat, the pressure

Pb equals −

Pat, the pressure

Pa can be expressed:

Similarly, if the cylinder rod chamber pressure

Pb is less than the vapor pressure

Pc, the rod chamber of the cylinder will produce cavitation. Hence, the pressure

Pb must be greater than the vapor pressure

Pc. Hence, the ratio

μmin can also be expressed:

In the extension working mode, the pressure Pa is the meter-in pressure, and the pressure Pb is the meter-out pressure. In the retraction working mode, the pressure Pa is the meter-out pressure, and the pressure Pb is the meter-in pressure.

Hence, the meter-in pressure Pa of extension working mode and the meter-in pressure Pb of retraction working mode can be calculated by the Equations (17) and (21). It is clear that the parameters R, Aa, Ab and ΔP are constant values. Hence, the meter-in pressure Pa of extension working mode and the meter-in pressure Pb of retraction working mode are related to the variable parameters μ and FL.

The meter-out pressure Pb, which is the cylinder head chamber pressure of extension working mode, can be calculated by Equations (16) and (18). It is clear that the pressure Pb is related to the variable parameter μ when the head chamber pressure Pa is greater than negative atmospheric pressure −Pat, and the pressure Pb is related to the variable parameter FL when the head chamber pressure Pa is less than negative atmospheric pressure −Pat. The meter-out pressure Pa of retraction working mode can be calculated by the Equations (20) and (22), it is clear the pressure Pa is related to the variable parameter μ when the rod chamber pressure Pb is greater than negative atmospheric pressure −Pat, and the pressure Pq is related to the variable parameter FL when the rod chamber pressure Pb is less than negative atmospheric pressure −Pat.

Because the meter-in valve opening ratio xin and meter-out opening ratio xout can be regulated independently, the ratio μ can be seen as an input variable parameter that can change the performance of HPCIMS. Equations (19) and (23) show that the minimum value of the ratio μ is related to the variable parameter FL.

3.3. CLSS

CLSS, as is shown in

Figure 7, can be simplified as is shown in

Figure 11.

Figure 11a shows the simplified schematic of CLSS with the extension working mode. It can be seen that the proportional directional spool 5/3-valve is controlling the inflow rate

Qa of the cylinder head chamber and the outflow rate

Qb of the cylinder rod chamber simultaneously, as a result, that the cylinder piston rod can be extended with the external active load

FL.

Figure 11b shows the simplified schematic of CLSS with the retraction working mode; it can be seen that the proportional directional spool 5/3-valve is controlling the inflow rate

Qa of the cylinder rod chamber and the outflow rate

Qb of the cylinder head chamber simultaneously, as a result, that the cylinder piston rod can be retracted with the external active load

FL. Because the meter-in orifice and the meter-out orifice of the proportional directional spool 5/3-valve are mechanically connected, so the ratio

μ between the meter-in orifice and meter-out orifice is a constant value. In the CLSS, the proportional directional spool 5/3-valve is symmetrical or asymmetrical, which is depending on the designer. The proportional directional symmetrical spool 5/3-valve is commonly used in the CLSS, which means the maximum spool displacements of the meter-in and meter-out are the same. As the mechanical connection of metering edges, so in this section, the proportional directional spool 5/3-valve the valve is symmetrical or asymmetric.

In the extension working mode, if the head chamber pressure Pa which is the meter-in pressure, is greater than the negative atmospheric pressure −Pat, the meter-in pressure Pa and the meter-out pressure Pb of the CLSS can be calculated by Equations (16) and (17). It is different from the HPCIMS; the ratio μ is fixed, which depends on the control valve. The velocity v of the cylinder piston rod can be calculated by Equation (13).

Moreover, if the head chamber pressure Pa is less than the negative atmospheric pressure −Pat, the pressure Pa equals −Pat, and Pb can also be calculated by Equation (18).

In the retraction working mode, if the rod chamber pressure Pb which is the meter-in pressure, is greater than the negative atmospheric pressure −Pat, the equations of the meter-out pressure Pa and the meter-in pressure Pb of the CLSS with retraction working mode can be calculated by Equations (20) and (21). It is different from the HPCIMS; the ratio μ is fixed, which is depending on the control valve. The velocity v of the cylinder piston rod can be calculated by Equation (12).

If the rod chamber pressure Pb is less than the negative atmospheric pressure −Pat, the pressure Pb equals −Pat, the pressure Pa can also be calculated by Equation (22).

The meter-in pressure Pa of extension working mode can be calculated by Equation (17). The meter-in pressure Pb of working retraction mode can be calculated by Equation (21). From the two equations, it is clear that the parameters μ, R, Aa, Ab, and ΔP are constant. Hence, the meter-in pressure Pa of extension working and the meter-in pressure Pb of retraction working mode are related to the external active load FL.

The meter-out pressure Pb with extension working mode can be calculated by Equations (16) and (18). From the two equations, it is clear that the pressure Pb is a constant when the meter-in pressure Pa is greater than the pressure −Pat, and the pressure Pb is related to the variable parameter FL when the meter-in pressure Pa is less than the pressure −Pat. The meter-out pressure Pa with retraction working mode can be calculated by Equations (20) and (22), it is clear that the pressure Pa is a constant when the meter-in pressure meter-in pressure Pb is greater than the pressure −Pat, and the pressure Pa is related to the variable parameter FL when the meter-in pressure meter-in pressure Pb is less than the pressure −Pat.