A Review of Bio-Oil Production through Microwave-Assisted Pyrolysis

Abstract

:1. Introduction

2. Brief Overview of MW Interaction with Materials

3. MAP of Lignocellulosic Biomasses

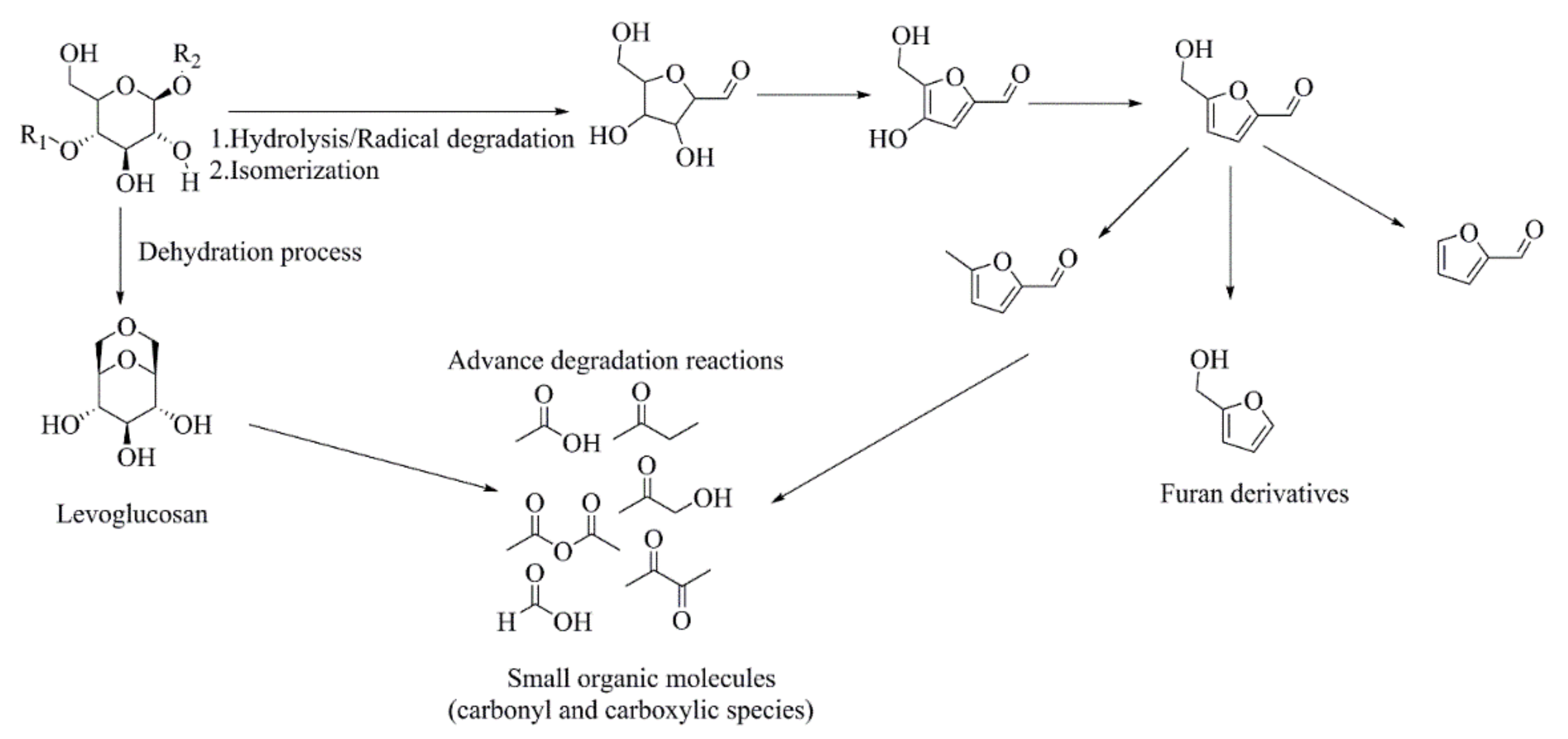

3.1. MAP of Cellulose

3.2. MAP of Hemicellulose

3.3. MAP of Lignin

3.4. MAP of Woody Biomass

4. MAP of Non-Lignocellulosic Biomasses

5. MAP Biomasses and Plastics: A Co-Pyrolysis Approach

6. Conclusions

Author Contributions

Conflicts of Interest

References

- Karl, T.R.; Trenberth, K.E. Modern global climate change. Science 2003, 302, 1719–1723. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hill, M.K. Understanding Environmental Pollution; Cambridge University Press: Cambridge, UK, 2010. [Google Scholar]

- Qualman, D. Global Plastics Production, 1917 to 2050. Available online: https://www.darrinqualman.com/global-plastics-production (accessed on 3 March 2021).

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, use, and fate of all plastics ever made. Sci. Adv. 2017, 3, e1700782. [Google Scholar] [CrossRef] [Green Version]

- De Castro, C.; Miguel, L.J.; Mediavilla, M. The role of non conventional oil in the attenuation of peak oil. Energy Policy 2009, 37, 1825–1833. [Google Scholar] [CrossRef]

- Artz, J.; Palkovits, R. Cellulose-based platform chemical: The path to application. Curr. Opin. Green Sustain. Chem. 2018, 14, 14–18. [Google Scholar] [CrossRef]

- Das, O.; Kim, N.K.; Hedenqvist, M.S.; Lin, R.J.; Sarmah, A.K.; Bhattacharyya, D. An attempt to find a suitable biomass for biochar-based polypropylene biocomposites. Environ. Manag. 2018, 62, 403–413. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Das, O.; Hedenqvist, M.S.; Johansson, E.; Olsson, R.T.; Loho, T.A.; Capezza, A.J.; Raman, R.S.; Holder, S. An all-gluten biocomposite: Comparisons with carbon black and pine char composites. Compos. Part A Appl. Sci. Manuf. 2019, 120, 42–48. [Google Scholar] [CrossRef]

- Barbalini, M.; Bartoli, M.; Tagliaferro, A.; Malucelli, G. Phytic Acid and Biochar: An Effective All Bio-Sourced Flame Retardant Formulation for Cotton Fabrics. Polymers 2020, 12, 811. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Arrigo, R.; Bartoli, M.; Malucelli, G. Poly (lactic Acid)–Biochar Biocomposites: Effect of Processing and Filler Content on Rheological, Thermal, and Mechanical Properties. Polymers 2020, 12, 892. [Google Scholar] [CrossRef] [Green Version]

- Giorcelli, M.; Bartoli, M. Development of Coffee Biochar Filler for the Production of Electrical Conductive Reinforced Plastic. Polymers 2019, 11, 17. [Google Scholar] [CrossRef] [Green Version]

- Bartoli, M.; Giorcelli, M.; Rosso, C.; Rovere, M.; Jagdale, P.; Tagliaferro, A. Influence of Commercial Biochar Fillers on Brittleness/Ductility of Epoxy Resin Composites. Appl. Sci. 2019, 9, 13. [Google Scholar] [CrossRef] [Green Version]

- Ferrero, G.; Maniatis, K.; Buekens, A.; Bridgwater, A. Pyrolysis and Gasification; Elsevier Applied Science: New York, NY, USA, 1989. [Google Scholar]

- Bridgwater, A.V.; Meier, D.; Radlein, D. An overview of fast pyrolysis of biomass. Org. Geochem. 1999, 30, 1479–1493. [Google Scholar] [CrossRef]

- Scheirs, J.; Kaminsky, W. Feedstock Recycling and Pyrolysis of Waste Plastics; John Wiley & Sons Chichester: London, UK, 2006. [Google Scholar]

- Weber, K.; Quicker, P. Properties of biochar. Fuel 2018, 217, 240–261. [Google Scholar] [CrossRef]

- Bartoli, M.; Giorcelli, M.; Jagdale, P.; Rovere, M.; Tagliaferro, A. A Review of Non-Soil Biochar Applications. Materials 2020, 13, 261. [Google Scholar] [CrossRef] [Green Version]

- Laurent, E.; Pierret, C.; Keymeulen, O.; Delmon, B. Hydrodeoxygenation of oxygenated model compounds: Simulation of the hydro-purification of bio-oils. In Advances in Thermochemical Biomass Conversion; Springer: London, UK, 1993; pp. 1403–1414. [Google Scholar]

- Wang, S.; Gu, Y.; Liu, Q.; Yao, Y.; Guo, Z.; Luo, Z.; Cen, K. Separation of bio-oil by molecular distillation. Fuel Process. Technol. 2009, 90, 738–745. [Google Scholar] [CrossRef]

- Patel, R.N.; Bandyopadhyay, S.; Ganesh, A. Extraction of cardanol and phenol from bio-oils obtained through vacuum pyrolysis of biomass using supercritical fluid extraction. Energy 2011, 36, 1535–1542. [Google Scholar] [CrossRef]

- Mohan, D.; Shi, J.; Nicholas, D.D.; Pittman, C.U., Jr.; Steele, P.H.; Cooper, J.E. Fungicidal values of bio-oils and their lignin-rich fractions obtained from wood/bark fast pyrolysis. Chemosphere 2008, 71, 456–465. [Google Scholar] [CrossRef]

- Undri, A.; Rosi, L.; Frediani, M.; Frediani, P. Microwave Pyrolysis of Polymeric Materials; Chandra, U., Ed.; IntechOpen: London, UK, 2011. [Google Scholar]

- Mutsengerere, S.; Chihobo, C.; Musademba, D.; Nhapi, I. A review of operating parameters affecting bio-oil yield in microwave pyrolysis of lignocellulosic biomass. Renew. Sustain. Energy Rev. 2019, 104, 328–336. [Google Scholar] [CrossRef]

- Undri, A.; Zaid, M.; Briens, C.; Berruti, F.; Rosi, L.; Bartoli, M.; Frediani, M.; Frediani, P. Bio-oil from pyrolysis of wood pellets using a microwave multimode oven and different microwave absorbers. Fuel 2015, 153, 464–482. [Google Scholar] [CrossRef]

- Bartoli, M.; Rosi, L.; Giovannelli, A.; Frediani, P.; Frediani, M. Bio-oil from residues of short rotation coppice of poplar using a microwave assisted pyrolysis. J. Anal. Appl. Pyrolysis 2016, 119, 224–232. [Google Scholar] [CrossRef]

- Bartoli, M.; Rosi, L.; Giovannelli, A.; Frediani, P.; Frediani, M. Pyrolysis of a-cellulose in a microwave multimode batch reactor. J. Anal. Appl. Pyrolysis 2016, 120, 284–296. [Google Scholar] [CrossRef]

- Metaxas, A.; Meredith, R.J. Industrial Microwave Heating; IET: London, UK, 1983. [Google Scholar]

- Pozar, D.M. Microwave Engineering; John Wiley & Sons: New York, NY, USA, 2009. [Google Scholar]

- Rosenkranz, P.W. Water vapor microwave continuum absorption: A comparison of measurements and models. Radio Sci. 1998, 33, 919–928. [Google Scholar] [CrossRef]

- Guo, X.; Deng, Y.; Gu, D.; Che, R.; Zhao, D. Synthesis and microwave absorption of uniform hematite nanoparticles and their core-shell mesoporous silica nanocomposites. J. Mater. Chem. 2009, 19, 6706–6712. [Google Scholar] [CrossRef]

- Clark, D.E.; Folz, D.C.; West, J.K. Processing materials with microwave energy. Mater. Sci. Eng. A 2000, 287, 153–158. [Google Scholar] [CrossRef]

- Wu, R.; Zhou, K.; Yang, Z.; Qian, X.; Wei, J.; Liu, L.; Huang, Y.; Kong, L.; Wang, L. Molten-salt-mediated synthesis of SiC nanowires for microwave absorption applications. CrystEngComm 2013, 15, 570–576. [Google Scholar] [CrossRef]

- Ni, Z.; Masel, R.I. Rapid production of metal-organic frameworks via microwave-assisted solvothermal synthesis. J. Am. Chem. Soc. 2006, 128, 12394–12395. [Google Scholar] [CrossRef]

- Kingman, S.; Rowson, N. Microwave treatment of minerals-a review. Miner. Eng. 1998, 11, 1081–1087. [Google Scholar] [CrossRef]

- Robinson, J.P.; Kingman, S.W.; Barranco, R.; Snape, C.E.; Al-Sayegh, H. Microwave Pyrolysis of Wood Pellets. Ind. Eng. Chem. Res. 2010, 49, 459–463. [Google Scholar] [CrossRef]

- Bartoli, M.; Frediani, F.; Briens, C.; Berruti, F.; Rosi, L. An Overview of Temperature Issues in Microwave-Assisted Pyrolysis. Processes 2019, 7, 658. [Google Scholar] [CrossRef] [Green Version]

- Stefanidis, S.D.; Kalogiannis, K.G.; Iliopoulou, E.F.; Michailof, C.M.; Pilavachi, P.A.; Lappas, A.A. A study of lignocellulosic biomass pyrolysis via the pyrolysis of cellulose, hemicellulose and lignin. J. Anal. Appl. Pyrolysis 2014, 105, 143–150. [Google Scholar] [CrossRef]

- Zhang, J.; Choi, Y.S.; Yoo, C.G.; Kim, T.H.; Brown, R.C.; Shanks, B.H. Cellulose–Hemicellulose and Cellulose—Lignin Interactions during Fast Pyrolysis. Acs Sustain. Chem. Eng. 2015, 3, 293–301. [Google Scholar] [CrossRef]

- O’Sullivan, A.C. Cellulose: The structure slowly unravels. Cellulose 1997, 4, 173–207. [Google Scholar] [CrossRef]

- Sjostrom, E. Wood Chemistry: Fundamentals and Applications; Elsevier: Amsterdam, The Netherlands, 2013. [Google Scholar]

- Budarin, V.L.; Clark, J.H.; Lanigan, B.A.; Shuttleworth, P.; Macquarrie, D.J. Microwave assisted decomposition of cellulose: A new thermochemical route for biomass exploitation. Bioresour. Technol. 2010, 101, 3776–3779. [Google Scholar] [CrossRef]

- Zhang, X.; Yang, W.; Dong, C. Levoglucosan formation mechanisms during cellulose pyrolysis. J. Anal. Appl. Pyrolysis 2013, 104, 19–27. [Google Scholar] [CrossRef]

- Zhang, X.; Li, J.; Yang, W.; Blasiak, W. Formation Mechanism of Levoglucosan and Formaldehyde during Cellulose Pyrolysis. Energy Fuels 2011, 25, 3739–3746. [Google Scholar] [CrossRef]

- Miura, M.; Kaga, H.; Yoshida, T.; Ando, K. Microwave pyrolysis of cellulosic materials for the production of anhydrosugars. J. Wood Sci. 2001, 47, 502–506. [Google Scholar] [CrossRef]

- Chen, L.; Liao, Y.; Guo, Z.; Cao, Y.; Ma, X. Products distribution and generation pathway of cellulose pyrolysis. J. Clean. Prod. 2019, 232, 1309–1320. [Google Scholar] [CrossRef]

- Wang, W.; Wang, M.; Huang, J.; Tang, N.; Dang, Z.; Shi, Y.; Zhaohe, M. Microwave-assisted catalytic pyrolysis of cellulose for phenol-rich bio-oil production. J. Energy Inst. 2018. [Google Scholar] [CrossRef]

- Al Shra’ah, A.; Helleur, R. Microwave pyrolysis of cellulose at low temperature. J. Anal. Appl. Pyrolysis 2014, 105, 91–99. [Google Scholar] [CrossRef]

- Zhang, Z.; Matharu, A.S. Chapter 23—Thermochemical Valorization of Paper Deinking Residue through Microwave-Assisted Pyrolysis. In Waste Biorefinery; Bhaskar, T., Pandey, A., Mohan, S.V., Lee, D.-J., Khanal, S.K., Eds.; Elsevier: Amserdam, The Netherlands, 2018. [Google Scholar]

- Undri, A.; Rosi, L.; Frediani, M.; Frediani, P. Fuel from microwave assisted pyrolysis of waste multilayer packaging beverage. Fuel 2014, 133, 7–16. [Google Scholar] [CrossRef]

- Namazi, A.B.; Allen, D.G.; Jia, C.Q. Probing microwave heating of lignocellulosic biomasses. J. Anal. Appl. Pyrolysis 2015, 112, 121–128. [Google Scholar] [CrossRef]

- Huang, Y.-F.; Chiueh, P.-T.; Kuan, W.-H.; Lo, S.-L. Effects of lignocellulosic composition and microwave power level on the gaseous product of microwave pyrolysis. Energy 2015, 89, 974–981. [Google Scholar] [CrossRef]

- Yang, H.; Yan, R.; Chen, H.; Zheng, C.; Lee, D.H.; Liang, D.T. In-Depth Investigation of Biomass Pyrolysis Based on Three Major Components: Hemicellulose, Cellulose and Lignin. Energy Fuels 2006, 20, 388–393. [Google Scholar] [CrossRef]

- Patwardhan, P.R.; Brown, R.C.; Shanks, B.H. Product distribution from the fast pyrolysis of hemicellulose. ChemSusChem 2011, 4, 636–643. [Google Scholar] [CrossRef]

- Li, T.; Remón, J.; Shuttleworth, P.S.; Jiang, Z.; Fan, J.; Clark, J.H.; Budarin, V.L. Controllable production of liquid and solid biofuels by doping-free, microwave-assisted, pressurised pyrolysis of hemicellulose. Energy Convers. Manag. 2017, 144, 104–113. [Google Scholar] [CrossRef]

- Hatakeyama, H.; Hatakeyama, T. Lignin structure, properties, and applications. In Biopolymers; Advances in Polymer Science; Springer: Berlin, Germany, 2009; pp. 1–63. [Google Scholar]

- Das, O.; Sarmah, A.K. Value added liquid products from waste biomass pyrolysis using pretreatments. Sci. Total Environ. 2015, 538, 145–151. [Google Scholar] [CrossRef] [PubMed]

- Chakar, F.S.; Ragauskas, A.J. Review of current and future softwood kraft lignin process chemistry. Ind. Crop. Prod. 2004, 20, 131–141. [Google Scholar] [CrossRef]

- Pye, E.K. Industrial lignin production and applications. Biorefineries-Industrial Processes and Products: Status quo and Future Directions; Kamm, B., Gruber, P.R., Kamm, M., Eds.; Wiley: London, UK, 2006; pp. 165–200. [Google Scholar]

- Kawamoto, H. Lignin pyrolysis reactions. J. Wood Sci. 2017, 63, 117. [Google Scholar] [CrossRef] [Green Version]

- Farag, S.; Fu, D.; Jessop, P.G.; Chaouki, J. Detailed compositional analysis and structural investigation of a bio-oil from microwave pyrolysis of kraft lignin. J. Anal. Appl. Pyrolysis 2014, 109, 249–257. [Google Scholar] [CrossRef]

- Farag, S.; Kouisni, L.; Chaouki, J. Lumped approach in kinetic modeling of microwave pyrolysis of kraft lignin. Energy Fuels 2014, 28, 1406–1417. [Google Scholar] [CrossRef]

- Fan, L.; Song, H.; Lu, Q.; Leng, L.; Li, K.; Liu, Y.; Wang, Y.; Chen, P.; Ruan, R.; Zhou, W. Screening microwave susceptors for microwave-assisted pyrolysis of lignin: Comparison of product yield and chemical profile. J. Anal. Appl. Pyrolysis 2019, 144, 14623–14631. [Google Scholar] [CrossRef]

- Brebu, M.; Vasile, C. Thermal degradation of lignin—A review. Cellul. Chem. Technol. 2010, 44, 353. [Google Scholar]

- Yerrayya, A.; Suriapparao, D.V.; Natarajan, U.; Vinu, R. Selective production of phenols from lignin via microwave pyrolysis using different carbonaceous susceptors. Bioresour. Technol. 2018, 270, 519–528. [Google Scholar] [CrossRef]

- Farag, S.; Mudraboyina, B.P.; Jessop, P.G.; Chaouki, J. Impact of the heating mechanism on the yield and composition of bio-oil from pyrolysis of kraft lignin. Biomass Bioenergy 2016, 95, 344–353. [Google Scholar] [CrossRef]

- Duan, D.; Wang, Y.; Dai, L.; Ruan, R.; Zhao, Y.; Fan, L.; Tayier, M.; Liu, Y. Ex-situ catalytic co-pyrolysis of lignin and polypropylene to upgrade bio-oil quality by microwave heating. Bioresour. Technol. 2017, 241, 207–213. [Google Scholar] [CrossRef]

- Fan, L.; Chen, P.; Zhang, Y.; Liu, S.; Liu, Y.; Wang, Y.; Dai, L.; Ruan, R. Fast microwave-assisted catalytic co-pyrolysis of lignin and low-density polyethylene with HZSM-5 and MgO for improved bio-oil yield and quality. Bioresour. Technol. 2017, 225, 199–205. [Google Scholar] [CrossRef] [PubMed]

- Undri, A.; Rosi, L.; Frediani, M.; Frediani, P. Efficient disposal of waste polyolefins through microwave assisted pyrolysis. Fuel 2014, 116, 662–671. [Google Scholar] [CrossRef]

- Fan, L.; Chen, P.; Zhou, N.; Liu, S.; Zhang, Y.; Liu, Y.; Wang, Y.; Omar, M.M.; Peng, P.; Addy, M.; et al. In-situ and ex-situ catalytic upgrading of vapors from microwave-assisted pyrolysis of lignin. Bioresour. Technol. 2018, 247, 851–858. [Google Scholar] [CrossRef] [PubMed]

- Bartoli, M.; Rosi, L.; Frediani, P.; Frediani, M. Bio-oils from microwave assisted pyrolysis of kraft lignin operating at reduced residual pressure. Fuel 2020, 278, 118175–118186. [Google Scholar] [CrossRef]

- Huang, J.; Liu, C.; Wu, D.; Tong, H.; Ren, L. Density functional theory studies on pyrolysis mechanism of β-O-4 type lignin dimer model compound. J. Anal. Appl. Pyrolysis 2014, 109, 98–108. [Google Scholar] [CrossRef]

- Kotake, T.; Kawamoto, H.; Saka, S. Mechanisms for the formation of monomers and oligomers during the pyrolysis of a softwood lignin. J. Anal. Appl. Pyrolysis 2014, 105, 309–316. [Google Scholar] [CrossRef] [Green Version]

- Bartoli, M.; Rosi, L.; Frediani, M.; Undri, A.; Frediani, P. Depolymerization of polystyrene at reduced pressure through a microwave assisted pyrolysis. J. Anal. Appl. Pyrolysis 2015, 113, 281–287. [Google Scholar] [CrossRef]

- Collard, F.-X.; Blin, J. A review on pyrolysis of biomass constituents: Mechanisms and composition of the products obtained from the conversion of cellulose, hemicelluloses and lignin. Renew. Sustain. Energy Rev. 2014, 38, 594–608. [Google Scholar] [CrossRef]

- Pepke, E. Global Wood Markets: Consumption, Production and Trade. In Proceedings of the International Forestry and Global Issues, Nancy, France, 18 May 2018. [Google Scholar]

- Thelandersson, S.; Larsen, H.J. Timber Engineering; John Wiley & Sons: London, UK, 2003. [Google Scholar]

- Kaplinsky, R.; Memedovic, O.; Morris, M.; Readman, J. The global wood furniture value chain: What prospects for upgrading by developing countries. Unido Sect. Stud. Ser. Work. Pap. 2003. [Google Scholar] [CrossRef] [Green Version]

- Smook, G.A. Handbook for Pulp & Paper Technologists; Canadian Pulp and Paper Association: Atlanta, GA, USA, 1992. [Google Scholar]

- Peksa-Blanchard, M.; Dolzan, P.; Grassi, A.; Heinimö, J.; Junginger, M.; Ranta, T.; Walter, A. Global Wood Pellets Markets and Industry: Policy Drivers, Market Status and Raw Material Potential; Iea Bioenergy Task 40; University of Minnesota: Minneapolis, MN, USA, 2007. [Google Scholar]

- Lamlom, S.; Savidge, R. A reassessment of carbon content in wood: Variation within and between 41 North American species. Biomass Bioenergy 2003, 25, 381–388. [Google Scholar] [CrossRef]

- Demeyer, A.; Nkana, J.V.; Verloo, M. Characteristics of wood ash and influence on soil properties and nutrient uptake: An overview. Bioresour. Technol. 2001, 77, 287–295. [Google Scholar] [CrossRef]

- Chave, J.; Muller-Landau, H.C.; Baker, T.R.; Easdale, T.A.; Steege, H.t.; Webb, C.O. Regional and phylogenetic variation of wood density across 2456 neotropical tree species. Ecol. Appl. 2006, 16, 2356–2367. [Google Scholar] [CrossRef] [Green Version]

- Pereira, H. Variability in the chemical composition of plantation eucalypts (Eucalyptus globulus Labill.). Wood Fiber Sci. 2007, 20, 82–90. [Google Scholar]

- Garcia-Perez, M.; Chaala, A.; Pakdel, H.; Kretschmer, D.; Roy, C. Characterization of bio-oils in chemical families. Biomass Bioenergy 2007, 31, 222–242. [Google Scholar] [CrossRef]

- Ingram, L.; Mohan, D.; Bricka, M.; Steele, P.; Strobel, D.; Crocker, D.; Mitchell, B.; Mohammad, J.; Cantrell, K.; Pittman Jr, C.U. Pyrolysis of wood and bark in an auger reactor: Physical properties and chemical analysis of the produced bio-oils. Energy Fuels 2007, 22, 614–625. [Google Scholar] [CrossRef]

- Lu, Q.; Yang, X.-l.; Zhu, X.-f. Analysis on chemical and physical properties of bio-oil pyrolyzed from rice husk. J. Anal. Appl. Pyrolysis 2008, 82, 191–198. [Google Scholar] [CrossRef]

- Özbay, N.; Pütün, A.E.; Pütün, E. Structural analysis of bio-oils from pyrolysis and steam pyrolysis of cottonseed cake. J. Anal. Appl. Pyrolysis 2001, 60, 89–101. [Google Scholar] [CrossRef]

- Djokic, M.R.; Dijkmans, T.; Yildiz, G.; Prins, W.; Van Geem, K.M. Quantitative analysis of crude and stabilized bio-oils by comprehensive two-dimensional gas-chromatography. J. Chromatogr. A 2012, 1257, 131–140. [Google Scholar] [CrossRef]

- Bartoli, M.; Rosi, L.; Frediani, M.; Frediani, P. A simple protocol for quantitative analysis of bio-oils through gas-chromatography/mass spectrometry. Eur. J. Mass Spectrom. 2016, 22, 199–212. [Google Scholar] [CrossRef]

- Undri, A.; Abou-Zahid, M.; Briens, C.; Berruti, F.; Rosi, L.; Bartoli, M.; Frediani, M.; Frediani, P. A simple procedure for chromatographic analysis of pyrolysis bio-oils. J. Anal. Appl. Pyrolysis 2015, 114, 208–221. [Google Scholar] [CrossRef]

- Huang, Y.-F.; Chiueh, P.-T.; Kuan, W.-H.; Lo, S.-L. Product distribution and heating performance of lignocellulosic biomass pyrolysis using microwave heating. Energy Procedia 2018, 152, 910–915. [Google Scholar] [CrossRef]

- Gao, Q.; Budarin, V.L.; Cieplik, M.; Gronnow, M.; Jansson, S. PCDDs, PCDFs and PCNs in products of microwave-assisted pyrolysis of woody biomass—Distribution among solid, liquid and gaseous phases and effects of material composition. Chemosphere 2016, 145, 193–199. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Stieglitz, L. Selected topics on the de novo synthesis of PCDD/PCDF on fly ash. Environ. Eng. Sci. 1998, 15, 5–18. [Google Scholar] [CrossRef]

- Born, J.G.; Mulder, P.; Louw, R. Fly ash mediated reactions of phenol and monochlorophenols: Oxychlorination, deep oxidation, and condensation. Environ. Sci. Technol. 1993, 27, 1849–1863. [Google Scholar] [CrossRef]

- Harvey, R.G. Polycyclic Aromatic Hydrocarbons: Chemistry and Carcinogenicity; CUP Archive: Cambridge, UK, 1991. [Google Scholar]

- Martín, M.T.; Sanz, A.B.; Nozal, L.; Castro, F.; Alonso, R.; Aguirre, J.L.; González, S.D.; Matía, M.P.; Novella, J.L.; Peinado, M.; et al. Microwave-assisted pyrolysis of Mediterranean forest biomass waste: Bioproduct characterization. J. Anal. Appl. Pyrolysis 2017, 127, 278–285. [Google Scholar] [CrossRef]

- Rajasekhar Reddy, B.; Vinu, R. Microwave-assisted co-pyrolysis of high ash Indian coal and rice husk: Product characterization and evidence of interactions. Fuel Process. Technol. 2018, 178, 41–52. [Google Scholar] [CrossRef]

- Ismail, K.; Ishak, M.A.M.; Ab Ghani, Z.; Abdullah, M.F.; Safian, M.T.-u.; Idris, S.S.; Tahiruddin, S.; Yunus, M.F.M.; Hakimi, N.I.N.M. Microwave-assisted pyrolysis of palm kernel shell: Optimization using response surface methodology (RSM). Renew. Energy 2013, 55, 357–365. [Google Scholar]

- Bartoli, M.; Rosi, L.; Giovannelli, A.; Frediani, P.; Passaponti, M.; Frediani, M. Microwave assisted pyrolysis of crop residues from Vitis vinifera. J. Anal. Appl. Pyrolysis 2018, 130, 305–313. [Google Scholar] [CrossRef]

- Bartoli, M.; Rosi, L.; Giovannelli, A.; Frediani, P.; Frediani, M. Characterization of bio-oil and bio-char produced by low-temperature microwave-assisted pyrolysis of olive pruning residue using various absorbers. Waste Manag. Res. 2020, 38, 213–225. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Ran, C.; Siddiqui, A.R.; Mao, X.; Kang, Q.; Fu, J.; Deng, Z.; Song, Y.; Jiang, Z.; Zhang, T.; et al. Pyrolysis of textile dyeing sludge in fluidized bed and microwave-assisted auger reactor: Comparison and characterization of pyrolysis products. J. Hazard. Mater. 2018, 359, 454–464. [Google Scholar] [CrossRef] [PubMed]

- Salema, A.A.; Ani, F.N. Microwave-assisted pyrolysis of oil palm shell biomass using an overhead stirrer. J. Anal. Appl. Pyrolysis 2012, 96, 162–172. [Google Scholar] [CrossRef]

- Beneroso, D.; Monti, T.; Kostas, E.T.; Robinson, J. Microwave pyrolysis of biomass for bio-oil production: Scalable processing concepts. Chem. Eng. J. 2017, 316, 481–498. [Google Scholar] [CrossRef]

- Salema, A.A.; Afzal, M.T.; Bennamoun, L. Pyrolysis of corn stalk biomass briquettes in a scaled-up microwave technology. Bioresour. Technol. 2017, 233, 353–362. [Google Scholar] [CrossRef] [PubMed]

- Tyrebirth. Available online: https://www.tyrebirth.com/it/ (accessed on 2 March 2021).

- Wang, Y.; Zeng, Z.; Tian, X.; Dai, L.; Jiang, L.; Zhang, S.; Wu, Q.; Wen, P.; Fu, G.; Liu, Y.; et al. Production of bio-oil from agricultural waste by using a continuous fast microwave pyrolysis system. Bioresour. Technol. 2018, 269, 162–168. [Google Scholar] [CrossRef]

- Hussain, K.; Bashir, N.; Hussain, Z.; Sulaiman, S.A. Cement catalyzed conversion of biomass into upgraded bio-oil through microwave metal interaction pyrolysis in aluminum coil reactor. J. Anal. Appl. Pyrolysis 2018, 129, 37–42. [Google Scholar] [CrossRef]

- Bashir, N.; Hussain, K.; Hussain, Z.; Naz, M.Y.; Ibrahim, K.A.; Abdel-Salam, N.M. Effect of metal coil on product distribution of highly upgraded bio-oil produced by microwave-metal interaction pyrolysis of biomass. Chem. Eng. Process. Process Intensif. 2018, 130, 140–147. [Google Scholar] [CrossRef]

- Halim, S.A.; Swithenbank, J. Characterisation of Malaysian wood pellets and rubberwood using slow pyrolysis and microwave technology. J. Anal. Appl. Pyrolysis 2016, 122, 64–75. [Google Scholar] [CrossRef]

- Nhuchhen, D.R.; Afzal, M.T.; Dreise, T.; Salema, A.A. Characteristics of biochar and bio-oil produced from wood pellets pyrolysis using a bench scale fixed bed, microwave reactor. Biomass Bioenergy 2018, 119, 293–303. [Google Scholar] [CrossRef]

- Abas, F.Z.; Ani, F.N.; Zakaria, Z.A. Microwave-assisted production of optimized pyrolysis liquid oil from oil palm fiber. J. Clean. Prod. 2018, 182, 404–413. [Google Scholar] [CrossRef]

- Mushtaq, F.; Abdullah, T.A.T.; Mat, R.; Ani, F.N. Optimization and characterization of bio-oil produced by microwave assisted pyrolysis of oil palm shell waste biomass with microwave absorber. Bioresour. Technol. 2015, 190, 442–450. [Google Scholar] [CrossRef]

- Bartoli, M.; Rosi, L.; Giovannelli, A.; Frediani, P.; Frediani, M. Production of bio-oils and bio-char from Arundo donax through microwave assisted pyrolysis in a multimode batch reactor. J. Anal. Appl. Pyrolysis 2016, 122, 479–489. [Google Scholar] [CrossRef]

- Dong, Q.; Li, H.; Niu, M.; Luo, C.; Zhang, J.; Qi, B.; Li, X.; Zhong, W. Microwave pyrolysis of moso bamboo for syngas production and bio-oil upgrading over bamboo-based biochar catalyst. Bioresour. Technol. 2018, 266, 284–290. [Google Scholar] [CrossRef]

- Dong, Q.; Li, X.; Wang, Z.; Bi, Y.; Yang, R.; Zhang, J.; Luo, H.; Niu, M.; Qi, B.; Lu, C. Effect of iron(III) ion on moso bamboo pyrolysis under microwave irradiation. Bioresour. Technol. 2017, 243, 755–759. [Google Scholar] [CrossRef]

- Dong, Q.; Niu, M.; Bi, D.; Liu, W.; Gu, X.; Lu, C. Microwave-assisted catalytic pyrolysis of moso bamboo for high syngas production. Bioresour. Technol. 2018, 256, 145–151. [Google Scholar] [CrossRef]

- Tarves, P.C.; Serapiglia, M.J.; Mullen, C.A.; Boateng, A.A.; Volk, T.A. Effects of hot water extraction pretreatment on pyrolysis of shrub willow. Biomass Bioenergy 2017, 107, 299–304. [Google Scholar] [CrossRef]

- Feng, Y.; Li, G.; Li, X.; Zhu, N.; Xiao, B.; Li, J.; Wang, Y. Enhancement of biomass conversion in catalytic fast pyrolysis by microwave-assisted formic acid pretreatment. Bioresour. Technol. 2016, 214, 520–527. [Google Scholar] [CrossRef]

- Grycova, B.; Pryszcz, A.; Lestinsky, P.; Chamradova, K. Influence of potassium hydroxide and method of carbonization treatment in garden and corn waste microwave pyrolysis. Biomass Bioenergy 2018, 118, 40–45. [Google Scholar] [CrossRef]

- Choi, J.; Nam, H.; Capareda, S.C. Effect of metal salts impregnation and microwave-assisted solvent pretreatment on selectivity of levoglucosenone and levoglucosan from vacuum pyrolysis of ashe juniper waste. J. Environ. Chem. Eng. 2019, 7, 102796. [Google Scholar] [CrossRef]

- Wan, Y.; Chen, P.; Zhang, B.; Yang, C.; Liu, Y.; Lin, X.; Ruan, R. Microwave-assisted pyrolysis of biomass: Catalysts to improve product selectivity. J. Anal. Appl. Pyrolysis 2009, 86, 161–167. [Google Scholar] [CrossRef]

- Mohamed, B.A.; Ellis, N.; Kim, C.S.; Bi, X. Microwave-assisted catalytic biomass pyrolysis: Effects of catalyst mixtures. Appl. Catal. B Environ. 2019, 253, 226–234. [Google Scholar] [CrossRef]

- Mohamed, B.A.; Kim, C.S.; Ellis, N.; Bi, X. Microwave-assisted catalytic pyrolysis of switchgrass for improving bio-oil and biochar properties. Bioresour. Technol. 2016, 201, 121–132. [Google Scholar] [CrossRef]

- Shang, H.; Lu, R.-R.; Shang, L.; Zhang, W.-H. Effect of additives on the microwave-assisted pyrolysis of sawdust. Fuel Process. Technol. 2015, 131, 167–174. [Google Scholar] [CrossRef]

- Chitnis, G.K.; Herbst, J.A. Cracking Catalysts Containing Phosphate Treated Zeolites, and Method of Preparing the Same. U.S. Patent No 5,110,776, 5 May 1992. [Google Scholar]

- Emig, G.; Hofmann, H. Action of zirconium phosphate as a catalyst for the oxydehydrogenation of ethylbenzene to styrene. J. Catal. 1983, 84, 15–26. [Google Scholar] [CrossRef]

- Swift, H.E.; Stanulonis, J.J.; Reynolds, E.H. Alumina-aluminum phosphate-silica-zeolite catalyst. U.S. Patent No. 4,228, 036, 14 October 1980. [Google Scholar]

- Vitolo, S.; Seggiani, M.; Frediani, P.; Ambrosini, G.; Politi, L. Catalytic upgrading of pyrolytic oils to fuel over different zeolites. Fuel 1999, 78, 1147–1159. [Google Scholar] [CrossRef]

- Zhang, B.; Zhong, Z.; Xie, Q.; Liu, S.; Ruan, R. Two-step fast microwave-assisted pyrolysis of biomass for bio-oil production using microwave absorbent and HZSM-5 catalyst. J. Environ. Sci. 2016, 45, 240–247. [Google Scholar] [CrossRef] [Green Version]

- Zhang, B.; Zhong, Z.; Li, T.; Xue, Z.; Wang, X.; Ruan, R. Biofuel production from distillers dried grains with solubles (DDGS) co-fed with waste agricultural plastic mulching films via microwave-assisted catalytic fast pyrolysis using microwave absorbent and hierarchical ZSM-5/MCM-41 catalyst. J. Anal. Appl. Pyrolysis 2018, 130, 1–7. [Google Scholar] [CrossRef]

- Zhang, B.; Zhong, Z.; Chen, P.; Ruan, R. Microwave-assisted catalytic fast co-pyrolysis of Ageratina adenophora and kerogen with CaO and ZSM-5. J. Anal. Appl. Pyrolysis 2017, 127, 246–257. [Google Scholar] [CrossRef]

- Zhang, B.; Zhong, Z.; Chen, P.; Ruan, R. Microwave-assisted catalytic fast pyrolysis of biomass for bio-oil production using chemical vapor deposition modified HZSM-5 catalyst. Bioresour. Technol. 2015, 197, 79–84. [Google Scholar] [CrossRef] [Green Version]

- Zhang, B.; Zhang, J.; Zhong, Z.; Zhang, Y.; Song, M.; Wang, X.; Ding, K.; Ruan, R. Conversion of poultry litter into bio-oil by microwave-assisted catalytic fast pyrolysis using microwave absorbent and hierarchical ZSM-5/MCM-41 catalyst. J. Anal. Appl. Pyrolysis 2018, 130, 233–240. [Google Scholar] [CrossRef]

- Zhang, B.; Tan, G.; Zhong, Z.; Ruan, R. Microwave-assisted catalytic fast pyrolysis of spent edible mushroom substrate for bio-oil production using surface modified zeolite catalyst. J. Anal. Appl. Pyrolysis 2017, 123, 92–98. [Google Scholar] [CrossRef] [Green Version]

- Wang, J.; Zhong, Z.; Song, Z.; Ding, K.; Deng, A. Modification and regeneration of HZSM-5 catalyst in microwave assisted catalytic fast pyrolysis of mushroom waste. Energy Convers. Manag. 2016, 123, 29–34. [Google Scholar] [CrossRef]

- Sun, J.; Wang, K.; Song, Z.; Lv, Y.; Chen, S. Enhancement of bio-oil quality: Metal-induced microwave-assisted pyrolysis coupled with ex-situ catalytic upgrading over HZSM-5. J. Anal. Appl. Pyrolysis 2019, 137, 276–284. [Google Scholar] [CrossRef]

- Liu, S.; Xie, Q.; Zhang, B.; Cheng, Y.; Liu, Y.; Chen, P.; Ruan, R. Fast microwave-assisted catalytic co-pyrolysis of corn stover and scum for bio-oil production with CaO and HZSM-5 as the catalyst. Bioresour. Technol. 2016, 204, 164–170. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dai, L.; Fan, L.; Duan, D.; Ruan, R.; Wang, Y.; Liu, Y.; Zhou, Y.; Yu, Z.; Liu, Y.; Jiang, L. Production of hydrocarbon-rich bio-oil from soapstock via fast microwave-assisted catalytic pyrolysis. J. Anal. Appl. Pyrolysis 2017, 125, 356–362. [Google Scholar] [CrossRef]

- Zhang, B.; Zhong, Z.; Li, T.; Xue, Z.; Ruan, R. Bio-oil production from sequential two-step microwave-assisted catalytic fast pyrolysis of water hyacinth using Ce-doped γ-Al2O3/ZrO2 composite mesoporous catalyst. J. Anal. Appl. Pyrolysis 2018, 132, 143–150. [Google Scholar] [CrossRef]

- Mortensen, P.M.; Grunwaldt, J.-D.; Jensen, P.A.; Knudsen, K.; Jensen, A.D. A review of catalytic upgrading of bio-oil to engine fuels. Appl. Catal. A Gen. 2011, 407, 1–19. [Google Scholar] [CrossRef]

- Gooty, A.T.; Li, D.; Briens, C.; Berruti, F. Fractional condensation of bio-oil vapors produced from birch bark pyrolysis. Sep. Purif. Technol. 2014, 124, 81–88. [Google Scholar] [CrossRef]

- Westerhof, R.J.; Brilman, D.W.F.; Garcia-Perez, M.; Wang, Z.; Oudenhoven, S.R.; van Swaaij, W.P.; Kersten, S.R. Fractional condensation of biomass pyrolysis vapors. Energy Fuels 2011, 25, 1817–1829. [Google Scholar] [CrossRef]

- Dai, L.; Wang, Y.; Liu, Y.; Ruan, R.; Yu, Z.; Jiang, L. Comparative study on characteristics of the bio-oil from microwave-assisted pyrolysis of lignocellulose and triacylglycerol. Sci. Total Environ. 2019, 659, 95–100. [Google Scholar] [CrossRef]

- Omidghane, M.; Bartoli, M.; Asomaning, J.; Xia, L.; Chae, M.; Bressler, D.C. Pyrolysis of fatty acids derived from hydrolysis of brown grease with biosolids. Env. Sci. Pollut. Res. 2020. [Google Scholar] [CrossRef]

- Wang, Y.; Dai, L.; Shan, S.; Zeng, Q.; Fan, L.; Liu, Y.; Ruan, R.; Zhao, Y.; Zhou, Y. Effect of unsaturation degree on microwave-assisted pyrolysis of fatty acid salts. J. Anal. Appl. Pyrolysis 2016, 120, 247–251. [Google Scholar] [CrossRef]

- Ng, J.-H.; Leong, S.K.; Lam, S.S.; Ani, F.N.; Chong, C.T. Microwave-assisted and carbonaceous catalytic pyrolysis of crude glycerol from biodiesel waste for energy production. Energy Convers. Manag. 2017, 143, 399–409. [Google Scholar] [CrossRef]

- Omar, R.; Robinson, J.P. Conventional and microwave-assisted pyrolysis of rapeseed oil for bio-fuel production. J. Anal. Appl. Pyrolysis 2014, 105, 131–142. [Google Scholar] [CrossRef]

- Du, Z.; Li, Y.; Wang, X.; Wan, Y.; Chen, Q.; Wang, C.; Lin, X.; Liu, Y.; Chen, P.; Ruan, R. Microwave-assisted pyrolysis of microalgae for biofuel production. Bioresour. Technol. 2011, 102, 4890–4896. [Google Scholar] [CrossRef]

- Zhang, R.; Li, L.; Tong, D.; Hu, C. Microwave-enhanced pyrolysis of natural algae from water blooms. Bioresour. Technol. 2016, 212, 311–317. [Google Scholar] [CrossRef]

- Hu, Z.; Ma, X.; Chen, C. A study on experimental characteristic of microwave-assisted pyrolysis of microalgae. Bioresour. Technol. 2012, 107, 487–493. [Google Scholar] [CrossRef]

- Budarin, V.L.; Zhao, Y.; Gronnow, M.J.; Shuttleworth, P.S.; Breeden, S.W.; Macquarrie, D.J.; Clark, J.H. Microwave-mediated pyrolysis of macro-algae. Green Chem. 2011, 13, 2330–2333. [Google Scholar] [CrossRef]

- Xie, Q.; Addy, M.; Liu, S.; Zhang, B.; Cheng, Y.; Wan, Y.; Li, Y.; Liu, Y.; Lin, X.; Chen, P.; et al. Fast microwave-assisted catalytic co-pyrolysis of microalgae and scum for bio-oil production. Fuel 2015, 160, 577–582. [Google Scholar] [CrossRef]

- Dai, M.; Xu, H.; Yu, Z.; Fang, S.; Chen, L.; Gu, W.; Ma, X. Microwave-assisted fast co-pyrolysis behaviors and products between microalgae and polyvinyl chloride. Appl. Therm. Eng. 2018, 136, 9–15. [Google Scholar] [CrossRef]

- Duan, D.; Ruan, R.; Lei, H.; Liu, Y.; Wang, Y.; Zhang, Y.; Zhao, Y.; Dai, L.; Wu, Q.; Zhang, S. Microwave-assisted co-pyrolysis of pretreated lignin and soapstock for upgrading liquid oil: Effect of pretreatment parameters on pyrolysis behavior. Bioresour. Technol. 2018, 258, 98–104. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, Q.; Duan, D.; Ruan, R.; Liu, Y.; Dai, L.; Zhou, Y.; Zhao, Y.; Zhang, S.; Zeng, Z. Ex-situ catalytic upgrading of vapors from fast microwave-assisted co-pyrolysis of Chromolaena odorata and soybean soapstock. Bioresour. Technol. 2018, 261, 306–312. [Google Scholar] [CrossRef]

- Wang, Y.; Tian, X.; Zeng, Z.; Dai, L.; Zhang, S.; Jiang, L.; Wu, Q.; Yang, X.; Liu, Y.; Zhang, B.; et al. Catalytic co-pyrolysis of Alternanthera philoxeroides and peanut soapstock via a new continuous fast microwave pyrolysis system. Waste Manag. 2019, 88, 102–109. [Google Scholar] [CrossRef]

- Borges, F.C.; Xie, Q.; Min, M.; Muniz, L.A.R.; Farenzena, M.; Trierweiler, J.O.; Chen, P.; Ruan, R. Fast microwave-assisted pyrolysis of microalgae using microwave absorbent and HZSM-5 catalyst. Bioresour. Technol. 2014, 166, 518–526. [Google Scholar] [CrossRef]

- Kadlimatti, H.M.; Raj Mohan, B.; Saidutta, M.B. Bio-oil from microwave assisted pyrolysis of food waste-optimization using response surface methodology. Biomass Bioenergy 2019, 123, 25–33. [Google Scholar] [CrossRef]

- Chen, W.; Shi, S.; Zhang, J.; Chen, M.; Zhou, X. Co-pyrolysis of waste newspaper with high-density polyethylene: Synergistic effect and oil characterization. Energy Convers. Manag. 2016, 112, 41–48. [Google Scholar] [CrossRef]

- Zhao, Y.; Wang, Y.; Duan, D.; Ruan, R.; Fan, L.; Zhou, Y.; Dai, L.; Lv, J.; Liu, Y. Fast microwave-assisted ex-catalytic co-pyrolysis of bamboo and polypropylene for bio-oil production. Bioresour. Technol. 2018, 249, 69–75. [Google Scholar] [CrossRef]

- Suriapparao, D.V.; Boruah, B.; Raja, D.; Vinu, R. Microwave assisted co-pyrolysis of biomasses with polypropylene and polystyrene for high quality bio-oil production. Fuel Process. Technol. 2018, 175, 64–75. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Giorcelli, M.; Das, O.; Sas, G.; Försth, M.; Bartoli, M. A Review of Bio-Oil Production through Microwave-Assisted Pyrolysis. Processes 2021, 9, 561. https://doi.org/10.3390/pr9030561

Giorcelli M, Das O, Sas G, Försth M, Bartoli M. A Review of Bio-Oil Production through Microwave-Assisted Pyrolysis. Processes. 2021; 9(3):561. https://doi.org/10.3390/pr9030561

Chicago/Turabian StyleGiorcelli, Mauro, Oisik Das, Gabriel Sas, Michael Försth, and Mattia Bartoli. 2021. "A Review of Bio-Oil Production through Microwave-Assisted Pyrolysis" Processes 9, no. 3: 561. https://doi.org/10.3390/pr9030561

APA StyleGiorcelli, M., Das, O., Sas, G., Försth, M., & Bartoli, M. (2021). A Review of Bio-Oil Production through Microwave-Assisted Pyrolysis. Processes, 9(3), 561. https://doi.org/10.3390/pr9030561