Algorithm to Use Some Specific Lean Manufacturing Methods: Application in an Industrial Production Process

Abstract

:1. Introduction

- -

- change in the process, by applying all lean methods and tools;

- -

- changes in operation, coordination and control, through teamwork-building, cross-functional movement, network relationship with suppliers and customers, information transparency, participative management, and teamwork-rewarding;

- -

- changes in human values and behavior, through teamwork, open communication and information sharing, continuous improvement culture, knowledge learning, and sharing;

- -

- changes of power in the organization, through decentralized responsibilities and autonomous leadership [25].

- -

- the choice of the method of evaluating the performance of the production system recommended to be used, depending on the characteristics of the production system,

- -

- the choice of the improvement method to be implemented according to the results of the system evaluation, to allow efficient analysis and continuous increase of the performance of a production system.

2. Materials and Methods

2.1. Algorithm for Applying Lean Manufacturing Methods

- -

- data specific to the industrial system: layout, availability of energy sources (compressed air, electricity, etc.), and characteristics of the production environment;

- -

- data specific to the production process: technological process, production flow, and organizational elements of the process;

- -

- specific data of the products made: range of products made, packaging method, necessary raw materials, product specific requirements such as weight, quality, dimensions, fragility, etc.

- -

- Stability and standards: the stability and standardization of the processes within the production system are analyzed;

- -

- Operator efficiency: the aim is to evaluate the efficiency of the use of operators within the production system;

- -

- Flow: it is checked if the production system works in a pull flow, continuously and in small production batches, preferably piece by piece (one piece flow), desideratum specific to just-in-time production (JIT);

- -

- Quality system: evaluates the ability of the production system to prevent, detect, and reduce errors that may lead to defects;

- -

- The team: the degree of involvement in problem-solving of the team members and of capitalization of their knowledge by the management team is evaluated.

- -

- if the production system is not organized, there is wasted time (with movement and multi-handling), wasted space and inventory, and the safety and ergonomics norms for people are not met, 5S and TPM(Total Productive Maintenance) methods will be implemented;

- -

- if in the production system the wastes and the causes of these wastes are difficult to identify, teamwork is not encouraged and employees are not involved in the process of identifying and improving losses, 5S and Kaizen methods will be implemented;

- -

- if the production system is not operating in a pull flow, the Kanban method will be implemented;

- -

- if the production system does not have the capacity to prevent, detect, and reduce errors that may lead to defects, the Jidoka and Poka-Yoke methods will be implemented;

- -

- if the involvement of team members in solving problems is low and the knowledge of team members is not properly used, the Hoshin methods and Kaizen Circles will be implemented.

2.2. JobObservation Method

- -

- A form with general data of the system—Figure 3—contains general data about the production system, such as number of days worked per month, number of days worked per week, number of shifts worked per day, length of breaks, number of minutes per shift;

- -

- The SIPOC chart—Figure 4—the name SIPOC comes from every fundamental part of a process. Completing this questionnaire helps the analyst to better understand the entire operation of the production system;

- -

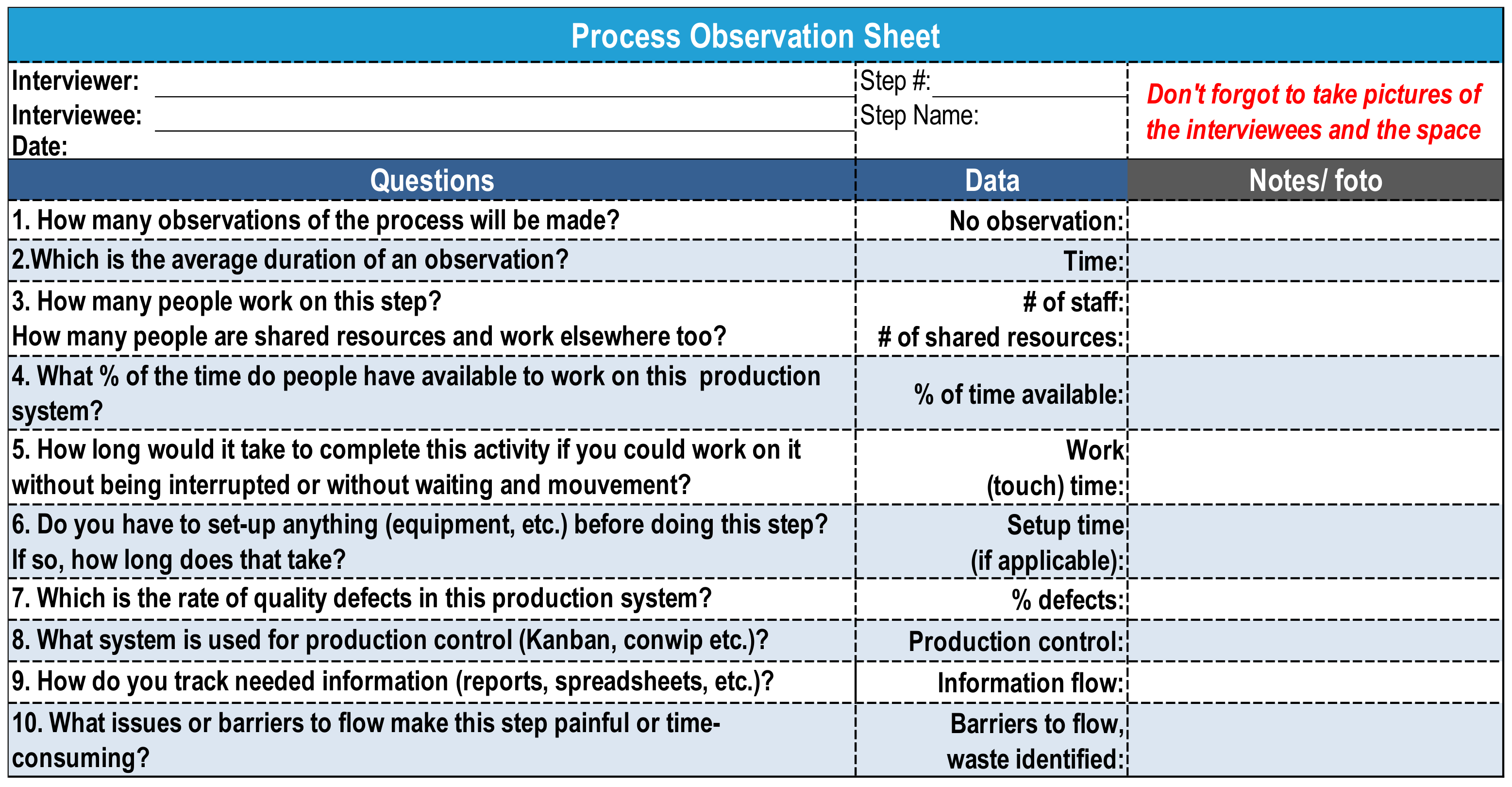

- A questionnaire for process observation—Figure 5—contains the names of the people who make the questionnaire, the name and number of the process, an image (photo) or graphic representation with of the analyzed process and a series of questions about the process, such as: how many people work at this stage, how much time is available to work at this stage etc.

2.3. 5S Method

3. Application in an Industrial Process: Case Study

3.1. Identification of the Characteristics of the Production System

- -

- the raw material in the form of granules is aspirated into the feed funnel.

- -

- the molten material is injected under pressure into the mold.

- -

- after the solidification of the material in the mold, the mold opens and a throwing system removes the product obtained from the mold, and the cycle can be resumed.

- -

- the products made in the injection machine fall through the collection pipe in a cardboard package.

- -

- Creation of the product kit. The kit is a set of products, configured according to customer requirements. To make the kit, the operator performs manual activities consisting of transfer of individual products from injection machines, visual control of each product, product counting, movement to the oven, vacuuming the kit in the oven and labeling the kit.

- -

- Final packaging, consisting of bringing kits to the packing table, counting kits, positioning kits in the box, closing and gluing the box, labeling the box, storing the box in the finished products area.

- -

- KPI system: movements, cycle time, No. operators, production capacity;

- -

- KPI qualitatively: Environment Management System, Efficiency Energy Consumption [kWh/prod.], No. item audit safety, No. item audit ergonomic, Quality defects.

3.2. Evaluation of the Production System

- -

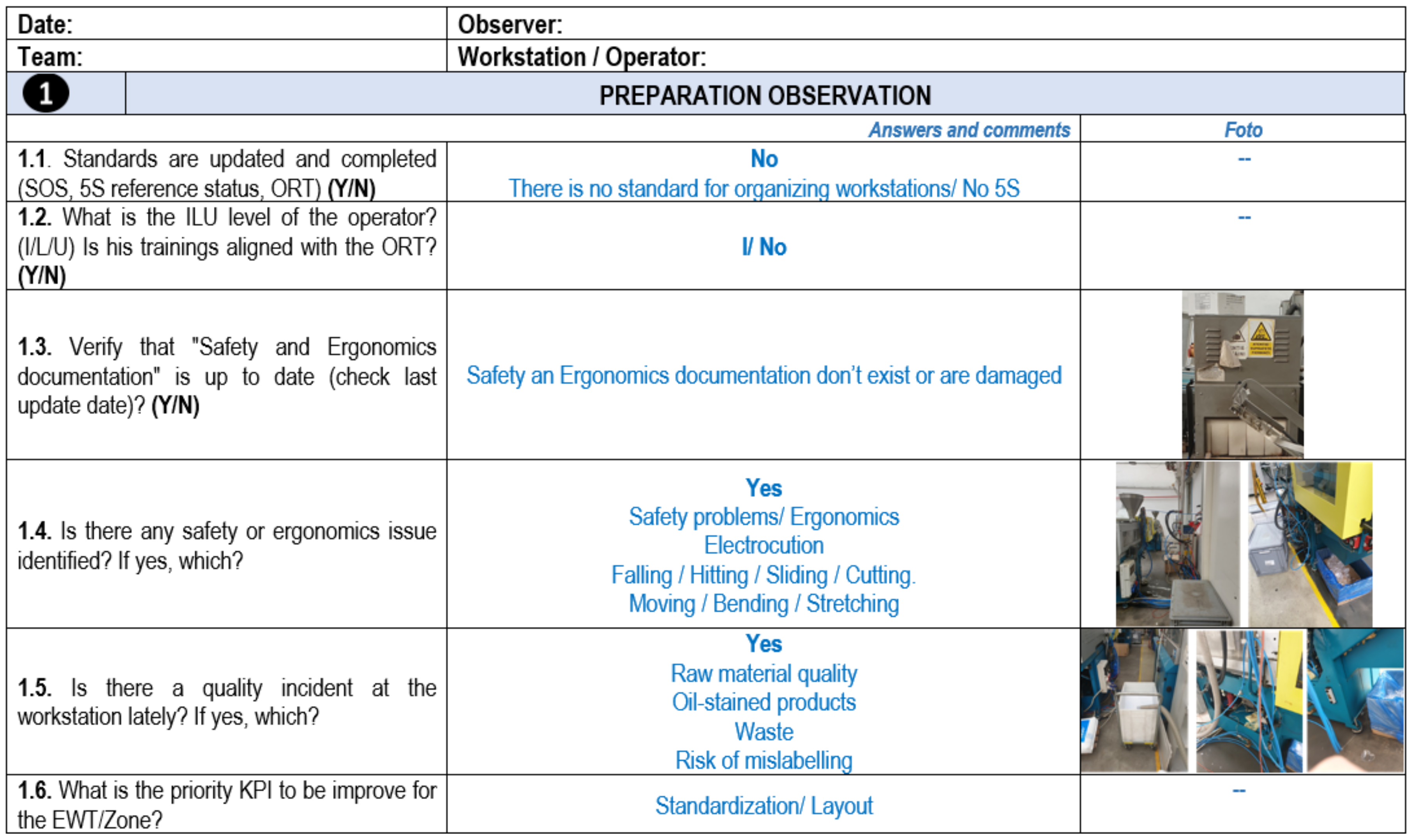

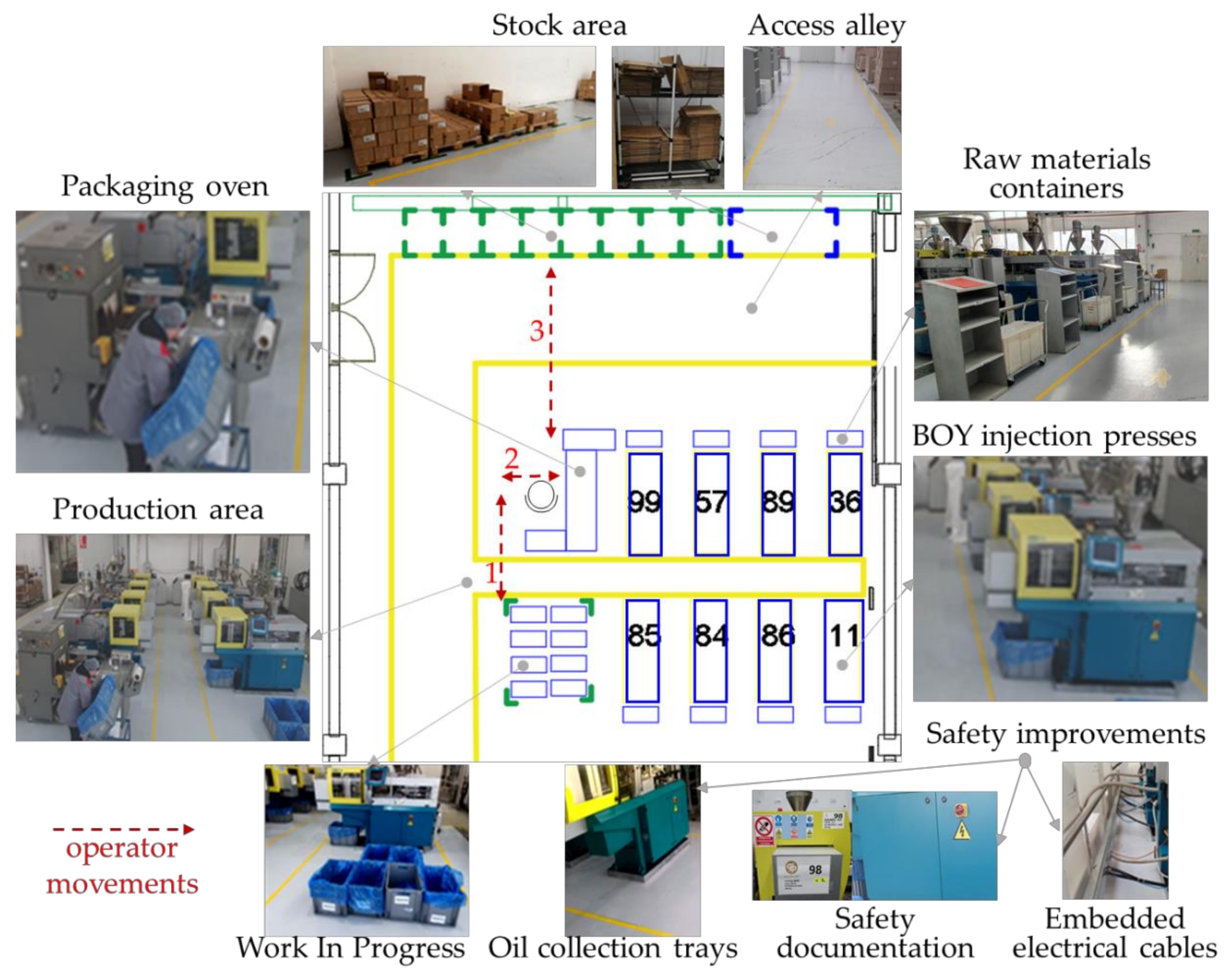

- the production flow was not organized: there was a loss of time due to multiple movements and manipulations performed by operators and loss of space due to the storage of unnecessary or defective objects in the production area (Figure 12);

- -

- the workstations were not ergonomically organized: the operator lifted the boxes, bent down, moved, stretched to grab a product;

- -

- the workstations were not standardized: the operators did not have explicit working procedures;

- -

- there were many quality incidents due to incorrect labeling of products, wrong packaging, destruction of products due to oil leaks, etc.;

- -

- the working environment was not safe for the operator: there was a risk of slipping, electric shock, fall.

3.2.1. Preparation for Observation

3.2.2. Workstation Observation/Filming/Photographing the Workstation

3.2.3. Filling JobObservation Questionnaire

3.2.4. Duration Analysis

3.2.5. Identifying Improvement Solutions

3.3. Analysis of Production System Evaluation Results

3.4. 5S Implementation

- -

- the workstations and the production flow in the injection machines by organizing the workstation so that the place of each element within the workstation is visible and well delimited and a working mode has been created in the production area (Figure 24);

- -

- the packing station and the packing flow, by designing some elements of the packing station to significantly improve the ergonomics of the station and to eliminate the losses due to the multiple movements and handling by the operators (Figure 25);

- -

- the operation of the entire production system, by creating a standard of the way of organizing the flows within the system (Figure 26).

4. Discussion

- -

- impact of automaton autonomy use had a significant impact by reducing the number of operators needed from 5 to 1 (that surveys the injection machines and dose the packaging activity) with minimal impact of the cycle time of packaging area;

- -

- by changing the layout and using reducing the frequency of movement (only when the raw material packaging was empty or the finished products box was full), the packaging operator could concentrate his activity in the packaging area and was possible a decrease of cycle time (from 180 to 30 s);

- -

- by optimization and standardization of the packaging cycle a further cycle time reduction was possible (from 30 to 13 s).

5. Conclusions

- -

- all unnecessary means of production have been eliminated and the workstations have been standardized;

- -

- the activities within the production system were reorganized and its operation mode was standardized.

- -

- significant reduction of movement waste, from 30 steps/kit, to 2 steps/kit,

- -

- significant decrease in cycle time, from 180 sec/kit to 13 sec/kit,

- -

- reducing the number of operators working in the production system from 5 to 1, all these with as general effect the increase of the production capacity, from 150 kits/shift to 1928 kits/shift and the reduction with 22% of the surface of the production system, the surplus being available for carrying out other activities.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Rosa, C.; Silva, F.J.G.; Ferreira, L.P.; Pereira, T.; Gouveia, R. Establishing Standard Methodologies To Improve The Production Rate Of Assembly Lines Used For Low Added-Value Products. In 28th International Conference on Flexible Automation and Intelligent Manufacturing; Sormaz, D., Suer, G., Chen, F.F., Eds.; Elsevier Science BV: Amsterdam, The Netherlands, 2018; Volume 17, pp. 555–562. [Google Scholar]

- Qun, Z.I.M.; Khattak, M.A.O.; Abbas, J.; Xiaoning, Z.; Shah, M.S. Critical Success Factors for Successful Lean Six Sigma Implementation in Pakistan. Interdiscip. J. Contemp. Res. Bus. 2012, 4, 117–124. [Google Scholar]

- Womack, J.P.; Jones, D.T. Lean thinking—banish waste and create wealth in your corporation. J. Oper. Res. Soc. 1997, 48, 1148. [Google Scholar] [CrossRef]

- Grycuk, A. Bariery w stosowaniu koncepcji Lean Management. Kwart. Nauk O Przedsiębiorstwie 2016, 40, 72–79. [Google Scholar]

- Näslund, D. Lean, six sigma and lean sigma: Fads or real process improvement methods? Bus. Process Manag. J. 2008, 14, 269–287. [Google Scholar] [CrossRef] [Green Version]

- Jon, C.Y.; Detty, R.B.; Sottile, J., Jr. Lean manufacturing principles and their applicability to the mining industry. Miner. Resour. Eng. 2000, 9, 215–238. [Google Scholar] [CrossRef]

- Kumar, R.; Kumar, P. Strategy development for lean manufacturing implementation in a selected Manufacturing company. Int. J. Eng. Sci. 2014, 3, 51–57. [Google Scholar]

- Mazur, M.; Momeni, H. LEAN Production issues in the organization of the company-results. Prod. Eng. Arch. 2019, 22, 50–53. [Google Scholar] [CrossRef] [Green Version]

- Tortorella, G.L.; Vergara, L.G.L.; Ferreira, E.P. Lean manufacturing implementation: An assessment method with regards to socio-technical and ergonomics practices adoption. Int. J. Adv. Manuf. Technol. 2017, 89, 3407–3418. [Google Scholar] [CrossRef]

- Chen, P.-K.; Lujan-Blanco, I.; Fortuny-Santos, J.; Ruiz-de-Arbulo-López, P. Lean Manufacturing and Environmental Sustainability: The Effects of Employee Involvement, Stakeholder Pressure and ISO 14001. Sustainability 2020, 12, 7258. [Google Scholar] [CrossRef]

- Azemi, F.; Lujić, R.; Šimunović, G.; Tokody, D. Selection the Basic Lean Manufacturing Techniques in Developing the Model for Industry 4.0 in Kosovo Manufacturing Industry. Proceedings 2020, 63, 62. [Google Scholar] [CrossRef]

- Frankowska, M. Implementation Barriers of Lean Manufacturing in the Production Sector. Eur. J. Serv. Manag. 2018, 28, 125–133. [Google Scholar] [CrossRef]

- Botti, L.; Mora, C.; Regattieri, A. Integrating ergonomics and lean manufacturing principles in a hybrid assembly line. Comput. Ind. Eng. 2017, 111, 481–491. [Google Scholar] [CrossRef]

- Venkat Jayanth, B.; Prathap, P.; Sivaraman, P.; Yogesh, S.; Madhu, S. Implementation of lean manufacturing in electronics industry. Mater. Today Proc. 2020, 33, 23–28. [Google Scholar] [CrossRef]

- Pena, R.; Ferreira, L.P.; Silva, F.J.G.; Sá, J.C.; Fernandes, N.O.; Pereira, T. Lean manufacturing applied to a wiring production process. Procedia Manuf. 2020, 51, 1387–1394. [Google Scholar] [CrossRef]

- Helleno, A.L.; de Moraes, A.J.I.; Simon, A.T. Integrating sustainability indicators and Lean Manufacturing to assess manufacturing processes: Application case studies in Brazilian industry. J. Clean. Prod. 2017, 153, 405–416. [Google Scholar] [CrossRef]

- Aziz, R.F.; Hafez, S.M. Applying lean thinking in construction and performance improvement. Alex. Eng. J. 2013, 52, 679–695. [Google Scholar] [CrossRef] [Green Version]

- Abu, F.; Gholami, H.; Mat Saman, M.Z.; Zakuan, N.; Streimikiene, D. The implementation of lean manufacturing in the furniture industry: A review and analysis on the motives, barriers, challenges, and the applications. J. Clean. Prod. 2019, 234, 660–680. [Google Scholar] [CrossRef]

- Alzubi, E.; Atieh, A.M.; Abu Shgair, K.; Damiani, J.; Sunna, S.; Madi, A. Hybrid Integrations of Value Stream Mapping, Theory of Constraints and Simulation: Application to Wooden Furniture Industry. Processes 2019, 7, 816. [Google Scholar] [CrossRef] [Green Version]

- Nassereddine, A.; Wehbe, A. Competition and resilience: Lean manufacturing in the plastic industry in Lebanon. Arab Econ. Bus. J. 2018, 13, 179–189. [Google Scholar] [CrossRef]

- Romero, V.J.; Sanchez, A. Methodology for multi-criteria design optimization of plastic products with a focus on highly competitive markets. Procedia Manuf. 2019, 41, 1087–1094. [Google Scholar] [CrossRef]

- Byrne, B.; McDermott, O.; Noonan, J. Applying Lean Six Sigma Methodology to a Pharmaceutical Manufacturing Facility: A Case Study. Processes 2021, 9, 550. [Google Scholar] [CrossRef]

- Roslin, E.N.; Shahadat, S.A.M.; Dawal, S.Z.M. Discovering Barriers of Lean Manufacturing System Implementation in Malaysian Automotive Industry. In Materials, Industrial, and Manufacturing Engineering Research Advances 1.1; Kurniawan, D., Ed.; Trans Tech Publications Ltd.: Johor Bahru, Malaysia, 2014; Volume 845, pp. 687–691. [Google Scholar]

- Narang, R.V. In Some issues to consider in lean production. In Proceedings of the 2008 First International Conference on Emerging Trends in Engineering and Technology, Nagpur, India, 16–18 July 2008; pp. 749–753. [Google Scholar]

- Nordin, N.; Deros, B.M.; Wahab, D.A.; Ab Rahman, M.N. Managing change in lean manufacturing implementation. In Advanced Manufacturing Technology; Gao, J., Ed.; Trans Tech Publications Ltd.: Guangzhou, China, 2011; Volume 314–316, pp. 2105–2111. [Google Scholar]

- Moradlou, H.; Perera, T. Identification of the barriers in implementation of lean principles in Iranian SMEs: Case study approach. Glob. J. Manag. Bus. Res. 2017. Available online: https://journalofbusiness.org/index.php/GJMBR/article/view/2252 (accessed on 5 April 2021).

- Elkhairi, A.; Fedouaki, F.; Alami, S.E. Barriers and Critical Success Factors for Implementing Lean Manufacturing in SMEs. IFAC Pap. 2019, 52, 565–570. [Google Scholar] [CrossRef]

- Kleszcz, D.; Zasadzień, M.; Ulewicz, R. Lean Manufacturing in the ceramic industry. Multidiscip. Asp. Prod. Eng. 2019, 2, 457–466. [Google Scholar] [CrossRef] [Green Version]

- Pampanelli, A.B.; Found, P.; Bernardes, A.M. A Lean & Green Model for a production cell. J. Clean. Prod. 2014, 85, 19–30. [Google Scholar]

- Brito, M.; Vale, M.; Leão, J.; Ferreira, L.P.; Silva, F.J.G.; Gonçalves, M.A. Lean and Ergonomics decision support tool assessment in a plastic packaging company. Procedia Manuf. 2020, 51, 613–619. [Google Scholar] [CrossRef]

- Benkarim, A.; Imbeau, D. Organizational Commitment and Lean Sustainability: Literature Review and Directions for Future Research. Sustainability 2021, 13, 3357. [Google Scholar] [CrossRef]

- Vinoth Kumar, H.; Annamalai, S.; Bagathsingh, N. Impact of lean implementation from the ergonomics view: A research article. Mater. Proc. 2020. [Google Scholar] [CrossRef]

- Dighe, S.B.; Kakirde, A. Lean manufacturing implementation using value stream mapping: A case study of pumps manufacturing company. Int. J. Sci. Res. 2014, 3, 2492–2498. [Google Scholar]

- Gavriluţă, A.; Niţu, E.; Belu, N.; Anghel, D.; Neacşu, C.; Pascu, I. In Lean manufacturing methodology for improving production flows on an assembly line. In Proceedings of the RMEE International Management Conference, Cluj Napoca, Romania, 17–19 September 2020; pp. 52–65. [Google Scholar]

- Nitu, E.; Gavriluta, A.; Belu, N.; Gavriluta, C. Methodology for improving production flows on an assembly line. In Proceedings of the 6th International Conference on Advanced Manufacturing Engineering and Technologies, Galati, Romania, 9–11 September 2020; IOP Conference Series: Materials Science and Engineering. Volume 968. [Google Scholar] [CrossRef]

- Nitu, E.L.; Gavriluta, A.C. Lean Learning Factory at the University of Pitesti. In Proceedings of the Modern Technologies in Industrial Engineering VII (ModTech2019), Iasi, Romania, 19–22 June 2019; IOP Conference Series: Materials Science and Engineering. Volume 591. [Google Scholar] [CrossRef]

- Carey, P.; Farrel, J.; Hui, M.; Sullivan, B. Heyde’s MODAPTS: A Language of Work; Heyde Dynamics Pty. Ltd.: Brighton, VIC, Australia, 2001. [Google Scholar]

| KPI | Before | After |

|---|---|---|

| Operator/shift | 5 | 1 |

| Movement [steps/kit] | 30 | 2 |

| Cycle time [sec/kit] | 180 | 13 |

| Capacity production [kits/shift] | 150 | 1928 |

| Before | The Contribution of Improvement Actions | After | ||

|---|---|---|---|---|

| Automation Autonomy | Movement Reduction | Workstation Standardization | ||

| 30 [kits/operator] | (120) 6.32% | (870) 39.52% | (1028) 54.16% | 1928 [kits/operator] |

| TOTAL GAIN: 1898 [kits/shift] | ||||

| KPI Qualitative Indicators | Before | After |

|---|---|---|

| Environment Management System | 0 | 100% |

| Efficiency energy consumption [kWh/prod] | 3.2 | 0.25 |

| No. item audit safety—observed in the system | 5 | 0 |

| No item audit ergonomic—observed in the system | 4 | 0 |

| Quality defects rate | 27% | 11% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gavriluţă, A.C.; Niţu, E.L.; Gavriluţă, C.A. Algorithm to Use Some Specific Lean Manufacturing Methods: Application in an Industrial Production Process. Processes 2021, 9, 641. https://doi.org/10.3390/pr9040641

Gavriluţă AC, Niţu EL, Gavriluţă CA. Algorithm to Use Some Specific Lean Manufacturing Methods: Application in an Industrial Production Process. Processes. 2021; 9(4):641. https://doi.org/10.3390/pr9040641

Chicago/Turabian StyleGavriluţă, Ana Cornelia, Eduard Laurenţiu Niţu, and Constantin Alin Gavriluţă. 2021. "Algorithm to Use Some Specific Lean Manufacturing Methods: Application in an Industrial Production Process" Processes 9, no. 4: 641. https://doi.org/10.3390/pr9040641

APA StyleGavriluţă, A. C., Niţu, E. L., & Gavriluţă, C. A. (2021). Algorithm to Use Some Specific Lean Manufacturing Methods: Application in an Industrial Production Process. Processes, 9(4), 641. https://doi.org/10.3390/pr9040641