Development and Commissioning of a Small-Scale, Modular and Integrated Plant for the Quasi-Continuous Production of Crystalline Particles

Abstract

1. Introduction

2. Materials and Methods

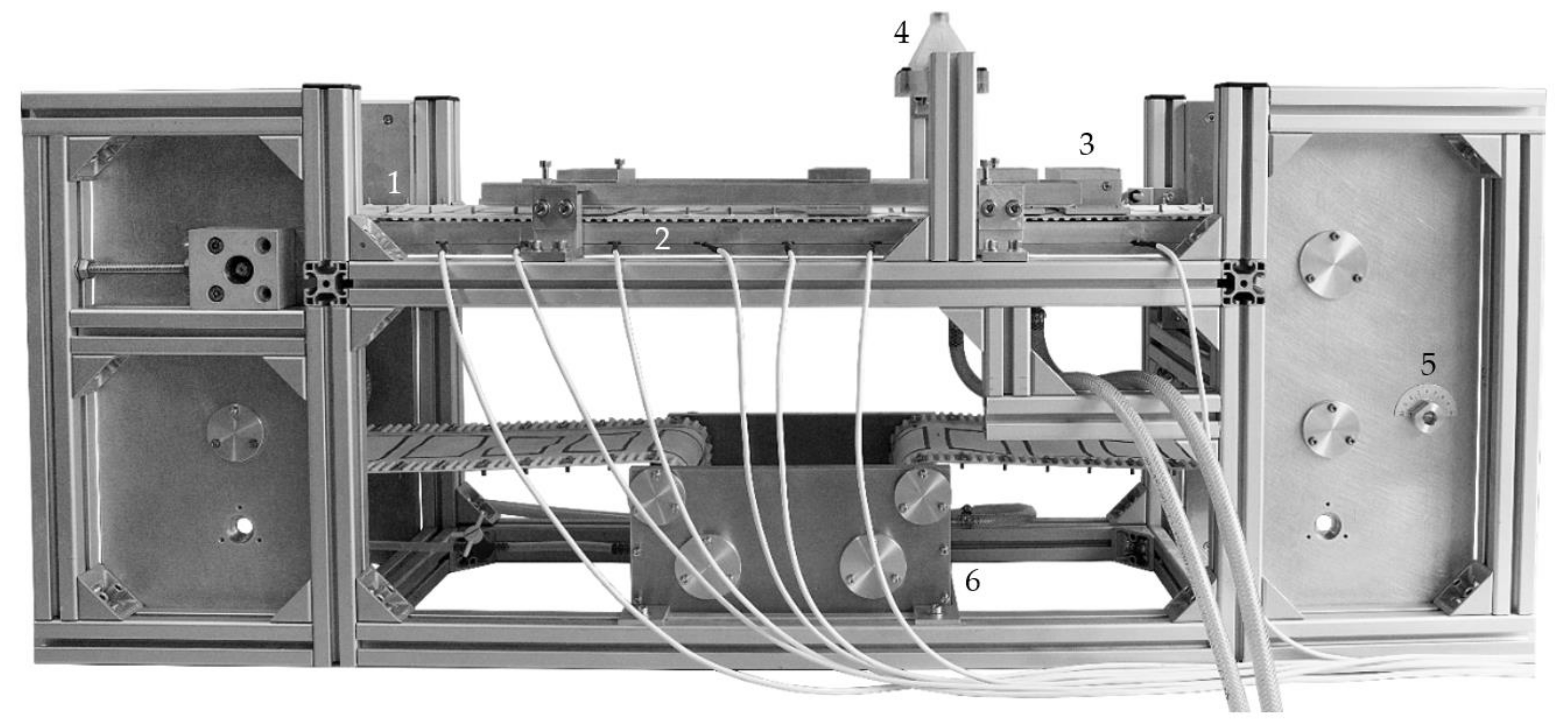

2.1. Belt Crystallizer

2.1.1. Apparatus Concept and Process Procedure

2.1.2. Apparatus Implementation

2.2. Particle System

2.3. Centrifugation Experiments

2.4. Filtration Experiments

3. Results and Discussion

3.1. Commissioning of the Temperature Control Units in the Crystallization Zone

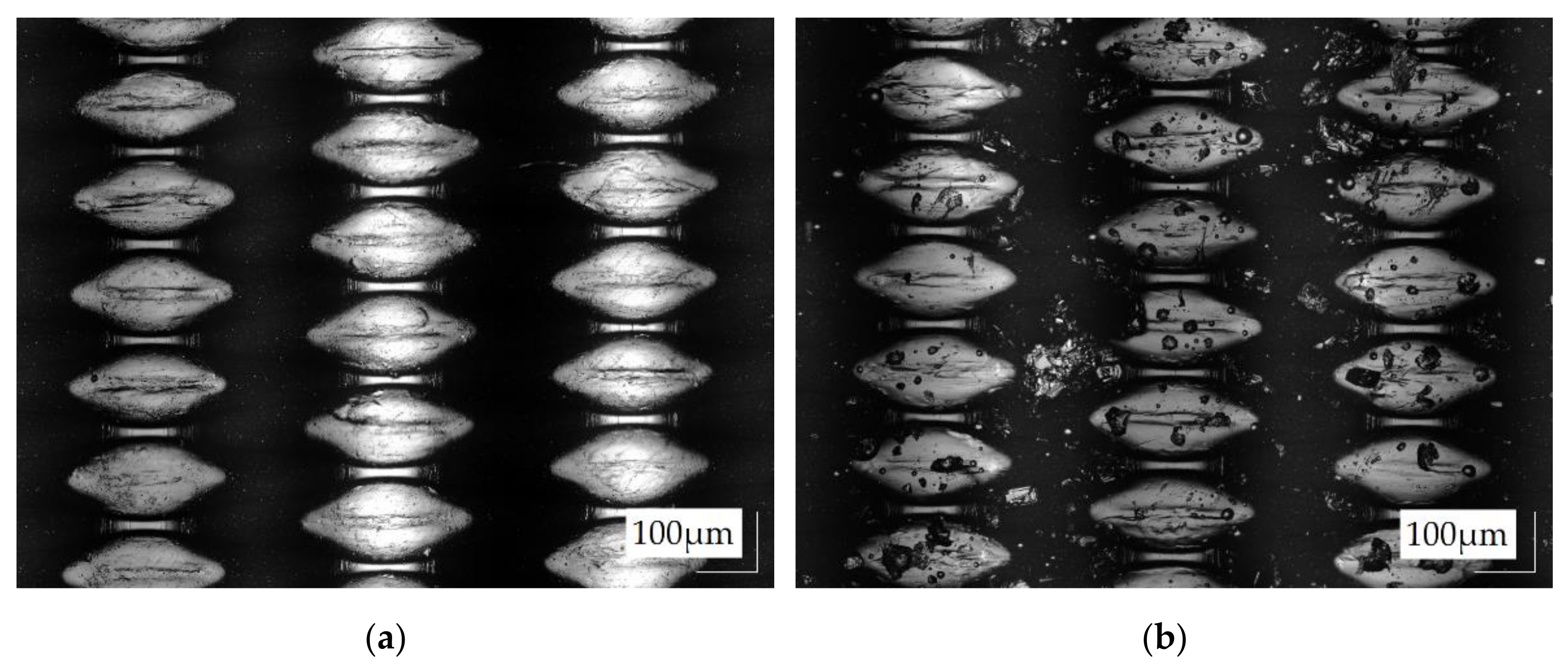

3.2. Influence of the Temperature Profile on the Crystal Properties

3.3. Influence of Residence Time on the Crystal Properties

3.4. Influence of the Crystallization Process on the Filter Medium

3.5. Influence of the Desaturation Time on Filter Cake Properties

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lier, S.; Wörsdörfer, D.; Grünewald, M. Wandlungsfähige Produktionskonzepte: Flexibel, Mobil, Dezentral, Modular, Beschleunigt. Chem. Ing. Tech. 2015, 87, 1147–1158. [Google Scholar] [CrossRef]

- Bieringer, T.; Buchholz, S.; Kockmann, N. Future Production Concepts in the Chemical Industry: Modular—Small-Scale—Continuous. Chem. Eng. Technol. 2013, 36, 900–910. [Google Scholar] [CrossRef]

- Lang, J.; Stenger, F.; Schütte, R. Chemieanlagen der Zukunft—Unikate und/oder Module. Chem. Ing. Tech. 2012, 883–884. [Google Scholar] [CrossRef]

- Lier, S.; Paul, S.; Ferdinand, D.; Grünewald, M. Modulare Verfahrenstechnik: Apparateentwicklung für wandlungsfähige Produktionssysteme. Chem. Ing. Tech. 2016, 88, 1444–1454. [Google Scholar] [CrossRef]

- Seifert, T.; Sievers, S.; Bramsiepe, C.; Schembecker, G. Small scale, modular and continuous: A new approach in plant design. Chem. Eng. Process. Process. Intensif. 2012, 52, 140–150. [Google Scholar] [CrossRef]

- Fleischer, C.; Wittmann, J.; Kockmann, N.; Bieringer, T.; Bramsiepe, C. Sicherheitstechnische Aspekte bei Planung und Bau modularer Produktionsanlagen. Chem. Ing. Tech. 2015, 87, 1258–1269. [Google Scholar] [CrossRef]

- Reitze, A.; Jürgensmeyer, N.; Lier, S.; Kohnke, M.; Riese, J.; Grünewald, M. Auf dem Weg zur Smart Factory: Modulare, intelligente Konzepte für die Produktion von Spezialchemikalien der Zukunft. Angew. Chem. 2018, 130, 4318–4324. [Google Scholar] [CrossRef]

- VDI-Gesellschaft Verfahrenstechnik und Chemieingenieurwesen. Process Engineering Plants—Modular Plants—Fundamentals and Planning Modular Plants; Beuth Verlag GmbH: Berlin, Germany, 2020. [Google Scholar]

- Hohmann, L.; Kössl, K.; Kockmann, N.; Schembecker, G.; Bramsiepe, C. Modules in process industry—A life cycle definition. Chem. Eng. Process. Process. Intensif. 2017, 111, 115–126. [Google Scholar] [CrossRef]

- Baldea, M.; Edgar, T.F.; Stanley, B.L.; Kiss, A.A. Modular manufacturing processes: Status, challenges, and opportunities. AIChE J. 2017, 63, 4262–4272. [Google Scholar] [CrossRef]

- Bieringer, T.; Bramsiepe, C.; Brand, S.; Brodhagen, A.; Dreiser, C.; Fleischer-Trebes, C.; Kockmann, N.; Lier, S.; Schmalz, D.; Schwede, C.; et al. Modulare Anlagen: Flexible Chemische Produktion durch Modularisierung und Standardisierung—Status quo und zukünftige Trends; DECHEMA e.V.: Frankfurt, Germany, 2017. [Google Scholar]

- Löbnitz, L. Auslegung des Separationsprozesses und Entwicklung Neuer Verfahrenskonzepte zur Integrierten Produktion und Separation Kristalliner Aminosäuren; Karlsruher Institut für Technologie: Karlsruhe, Germany, 2020. [Google Scholar]

- Gehrmann, D.; Schweigler, N. Device for Continuous Filtration and Drying of a Solid Suspension. U.S. Patent No. 5,527,458, 18 June 1996. [Google Scholar]

- Schweigler, N.; Gehrmann, D.; Bamberger, T.; Tichy, J. Kontinuierliche Filtration und Trocknung auf einem neuartigen Filtertrockner (Konfiltro). Chem. Ing. Tech. 1995, 67, 1186–1187. [Google Scholar] [CrossRef]

- Thurner, F. Der Titus-Nutsch-Trockner—Neue Wege der Produktisolierung. Chem. Ing. Tech. 1990, 62, 753–755. [Google Scholar] [CrossRef]

- Capellades, G.; Neurohr, C.; Azad, M.; Brancazio, D.; Rapp, K.; Hammersmith, G.; Myerson, A.S. A Compact Device for the Integrated Filtration, Drying, and Mechanical Processing of Active Pharmaceutical Ingredients. J. Pharm. Sci. 2020, 109, 1365–1372. [Google Scholar] [CrossRef] [PubMed]

- Mathlouthi, M.; Reiser, P. Sucrose: Properties and Applications; Springer US: Boston, MA, USA, 1995. [Google Scholar]

- Pot, A. Industrial Sucrose Crystallisation: A Study on the Development of Crystal Size Distributions in Continuous and Batch Sucrose Suspension Crystallisers; Technische Universität Delft: Delft, The Netherlands, 1983. [Google Scholar]

- Detloff, T.; Sobisch, T.; Lerche, D. Particle Size Distribution by Space or Time Dependent Extinction Profiles obtained by Analytical Centrifugation. Part. Part. Syst. Charact. 2006, 23, 184–187. [Google Scholar] [CrossRef]

- Anlauf, H. Wet Cake Filtration: Fundamentals, Equipment, Strategies; WILEY VCH: Weinheim, Germany, 2020. [Google Scholar]

- VDI-Gesellschaft Verfahrenstechnik und Chemieingenieurwesen. Mechanical Solid-Liquid Separation by Cake Filtration—Determination of Filter Cake Resistance; Beuth Verlag GmbH: Berlin, Germany, 2010. [Google Scholar]

- Elahi, M. Untersuchungen zur Optimierung der Kühlrate der Kühlungskristallisation von Nachprodukt-Kristallsuspensionen bei der Saccharosegewinnung; Technische Universität Berlin: Berlin, Germany, 2004. [Google Scholar]

| Cooling Curve | Median Particle Size in | Span |

|---|---|---|

| Progressive | 35.7 ± 3.0 | 1.1 ± 0.1 |

| Linear | 31.0 ± 1.3 | 0.9 ± 0.1 |

| Degressive | 26.2 ± 1.0 | 0.6 ± 0.2 |

| Condition | Medium Resistance in | Total Resistance in | Ratio |

|---|---|---|---|

| Unused | 1.04 ± 0.36 | 10.05 ± 4.67 | 0.10 |

| Used | 1.97 ± 0.76 | 16.45 ± 5.00 | 0.12 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dobler, T.; Buchheiser, S.; Gleiß, M.; Nirschl, H. Development and Commissioning of a Small-Scale, Modular and Integrated Plant for the Quasi-Continuous Production of Crystalline Particles. Processes 2021, 9, 663. https://doi.org/10.3390/pr9040663

Dobler T, Buchheiser S, Gleiß M, Nirschl H. Development and Commissioning of a Small-Scale, Modular and Integrated Plant for the Quasi-Continuous Production of Crystalline Particles. Processes. 2021; 9(4):663. https://doi.org/10.3390/pr9040663

Chicago/Turabian StyleDobler, Timo, Simon Buchheiser, Marco Gleiß, and Hermann Nirschl. 2021. "Development and Commissioning of a Small-Scale, Modular and Integrated Plant for the Quasi-Continuous Production of Crystalline Particles" Processes 9, no. 4: 663. https://doi.org/10.3390/pr9040663

APA StyleDobler, T., Buchheiser, S., Gleiß, M., & Nirschl, H. (2021). Development and Commissioning of a Small-Scale, Modular and Integrated Plant for the Quasi-Continuous Production of Crystalline Particles. Processes, 9(4), 663. https://doi.org/10.3390/pr9040663