Control of Sunroof Buffeting Noise by Optimizing the Flow Field Characteristics of a Commercial Vehicle

Abstract

1. Introduction

2. Mathematical Methods

2.1. Large Eddy Simulation

2.2. Ffowcs Williams and Hawkings (FW-H) Equation

2.3. Acoustic Post Processing

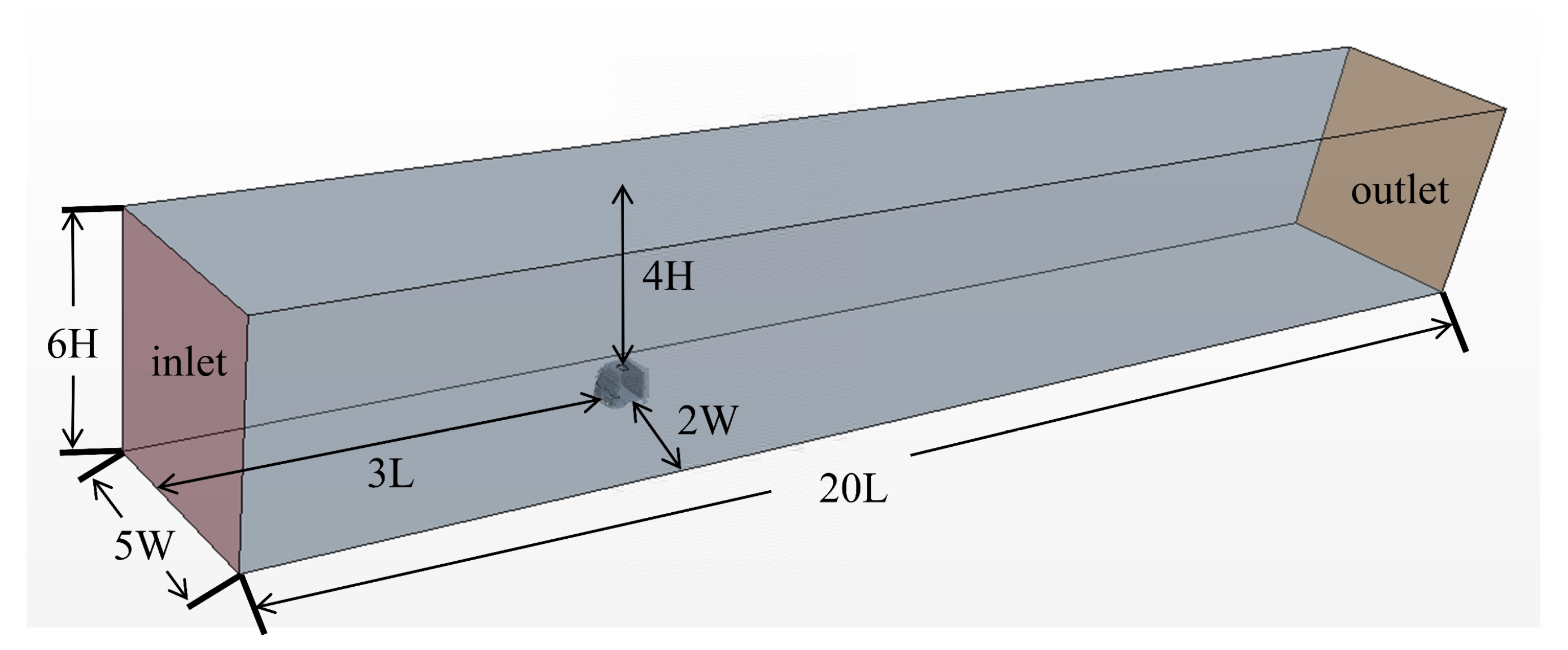

3. Simulation Model

3.1. Geometric Modeling

3.2. Boundary Condition Setting

- (1)

- The virtual wind tunnel inlet speed was set according to different working conditions.

- (2)

- The outlet pressure of the virtual wind tunnel was 0 Pa. At this time, the outlet pressure was equal to the atmospheric pressure.

- (3)

- The cab and computing domain ground was a non-slip wall.

- (4)

- The upper and the sidewall in the virtual wind tunnel were the free slip walls.

4. Simulation Results and Analysis of Sunroof Buffeting Noise

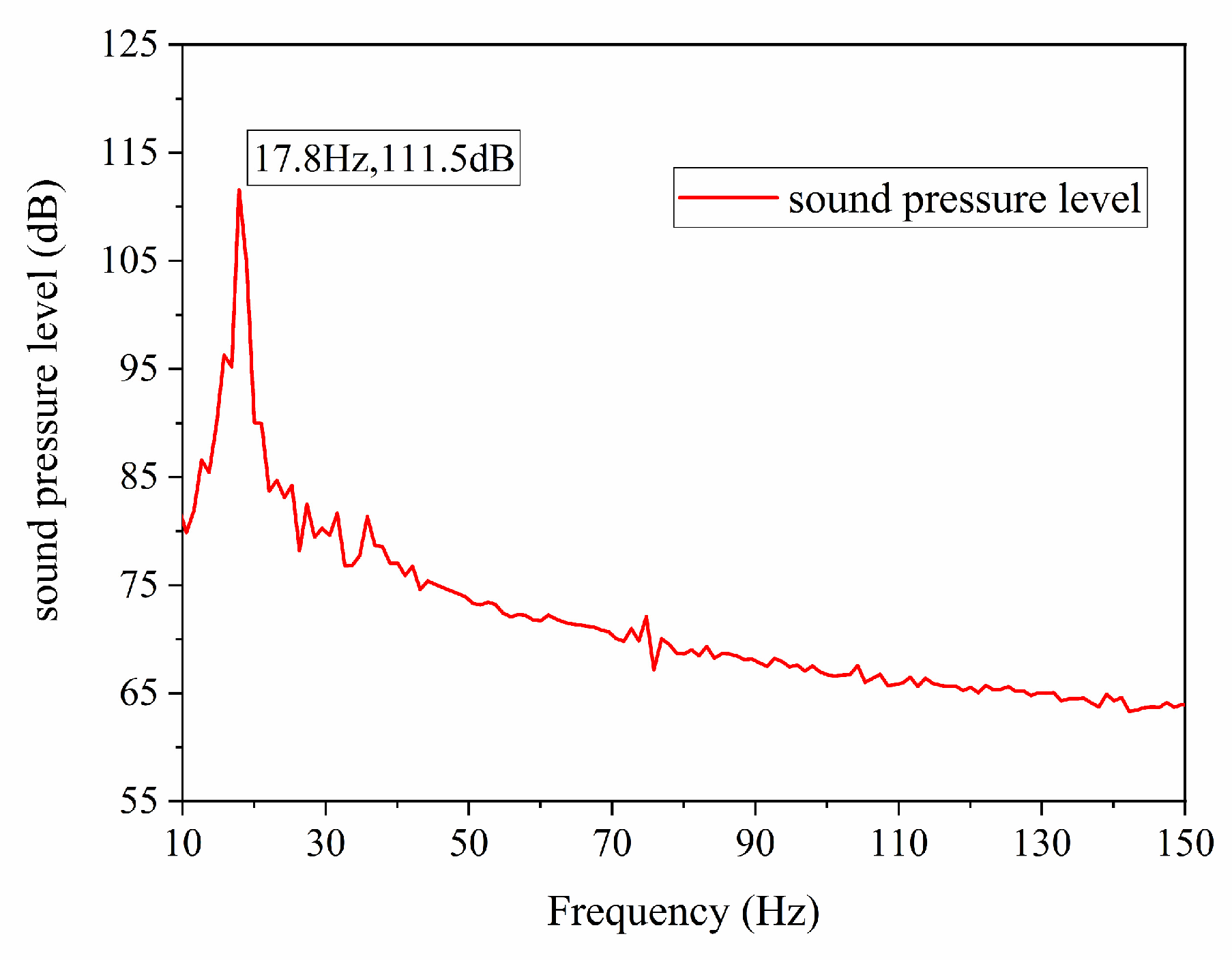

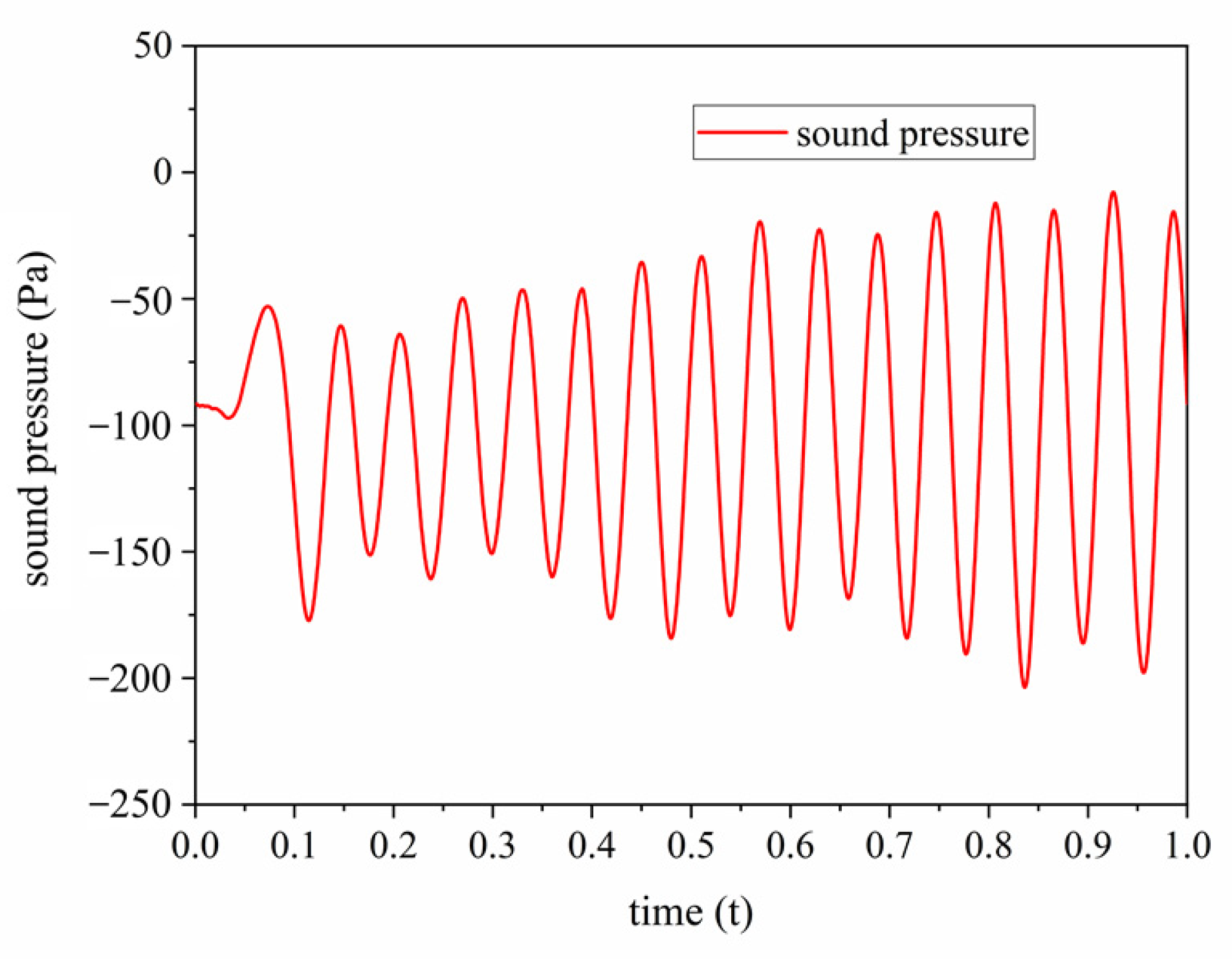

4.1. Working Condition One

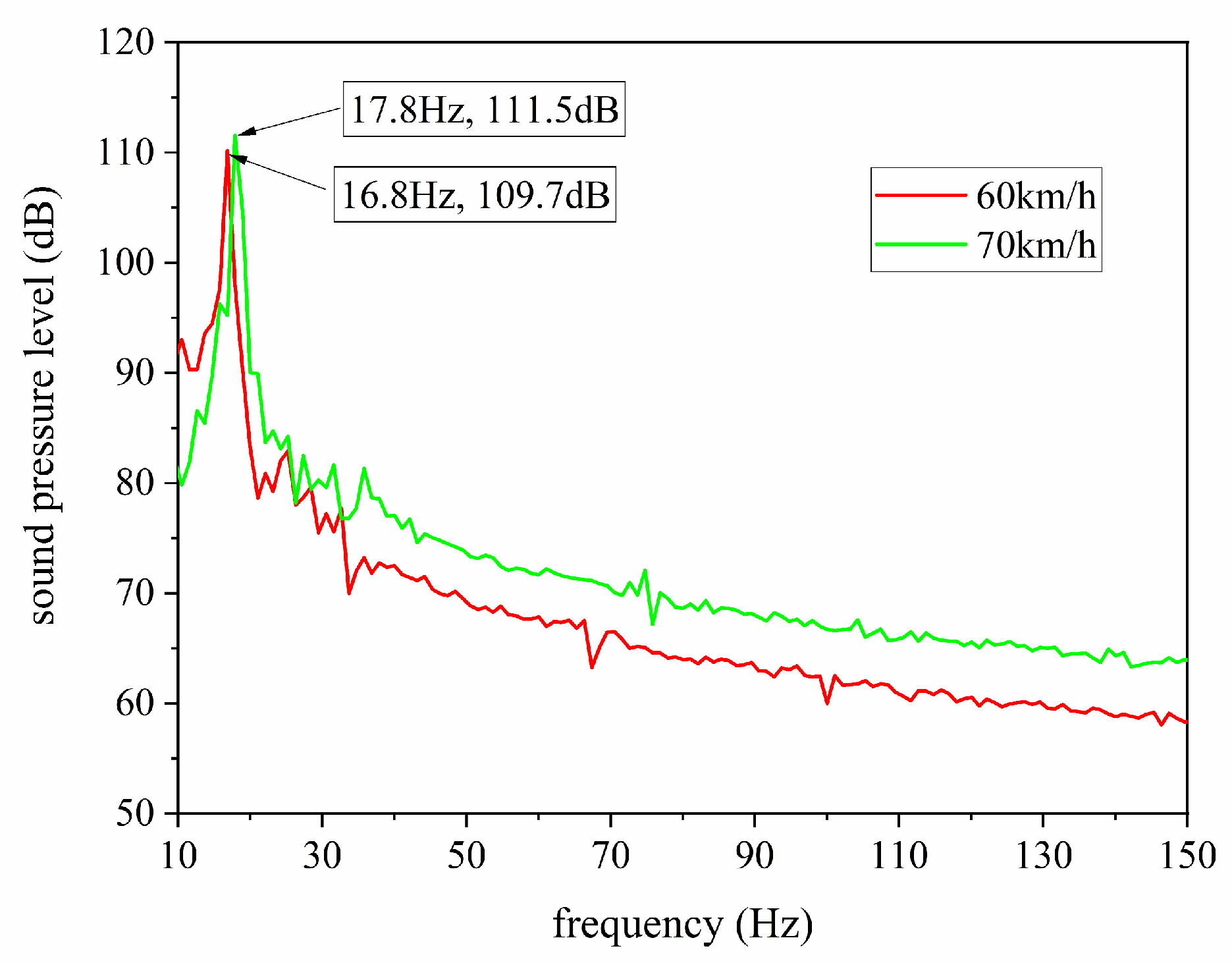

4.2. Working Condition Two

5. Sunroof Buffeting Noise Control

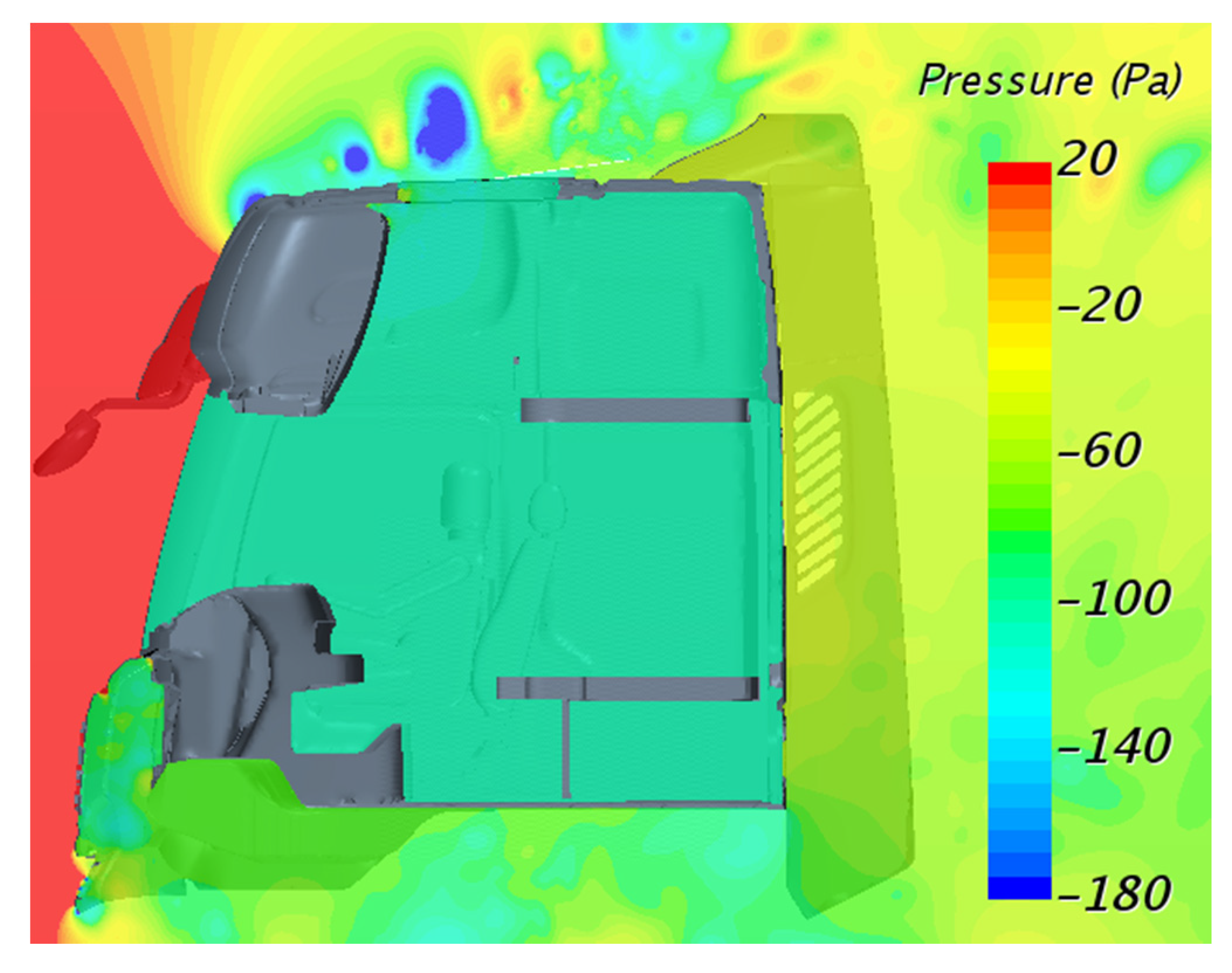

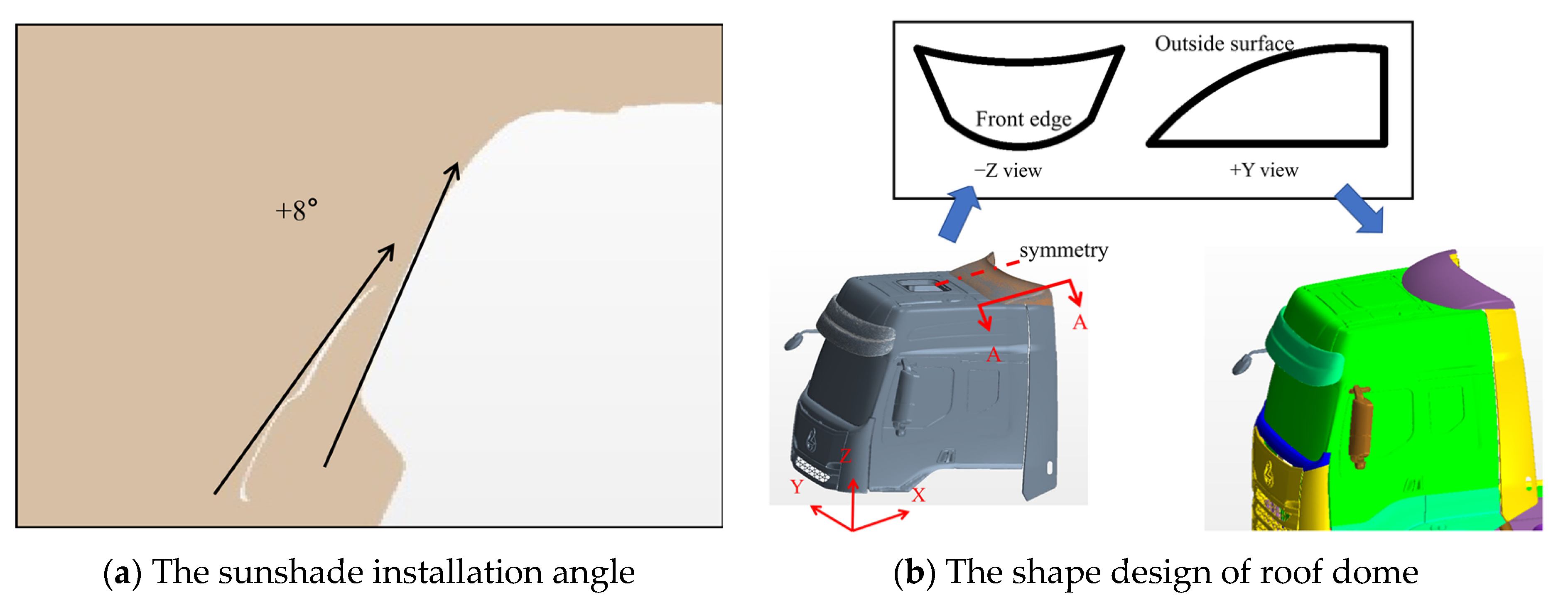

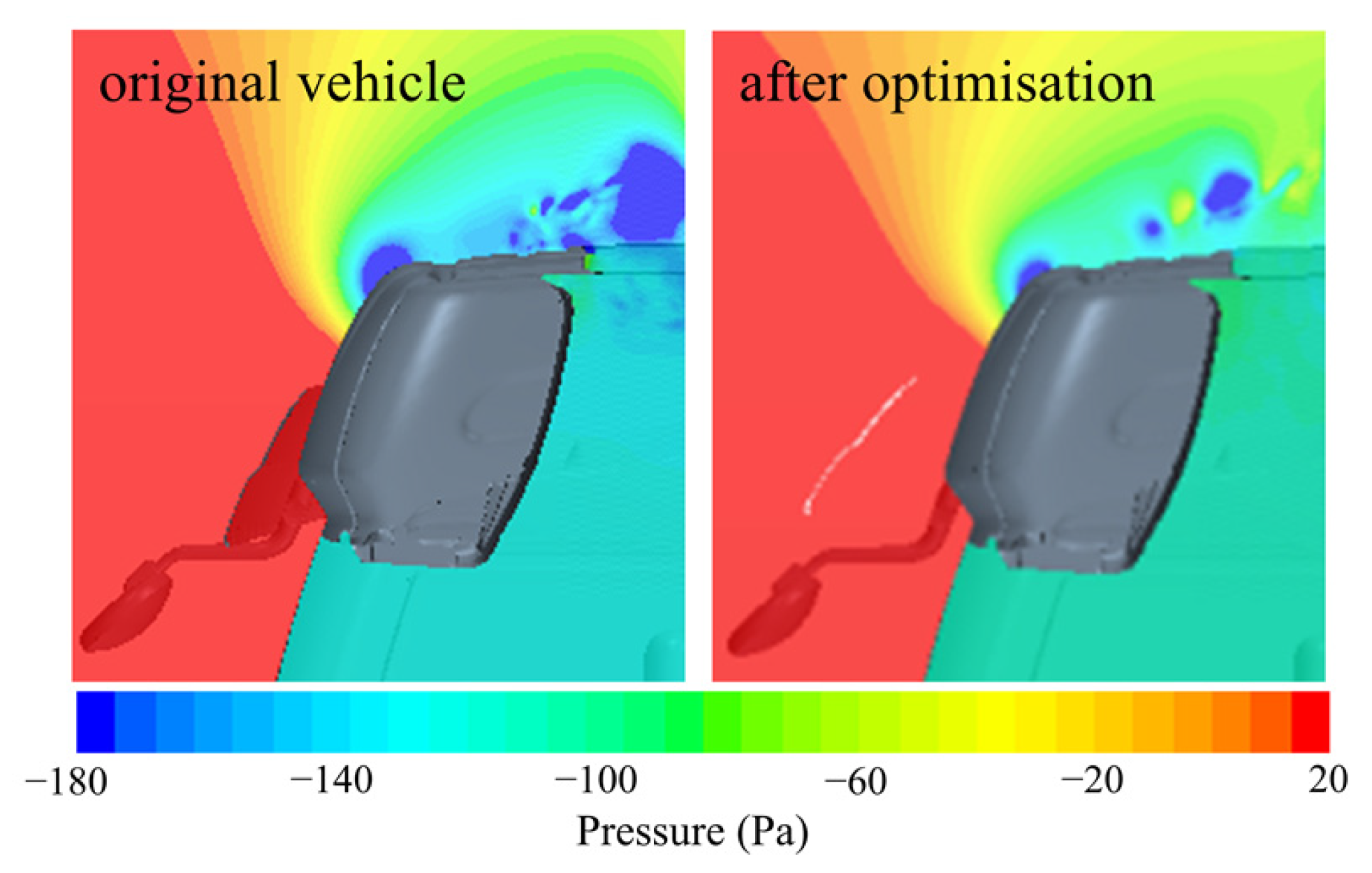

5.1. Optimization Scheme

5.2. Buffeting Noise Simulation of the Optimized Scheme

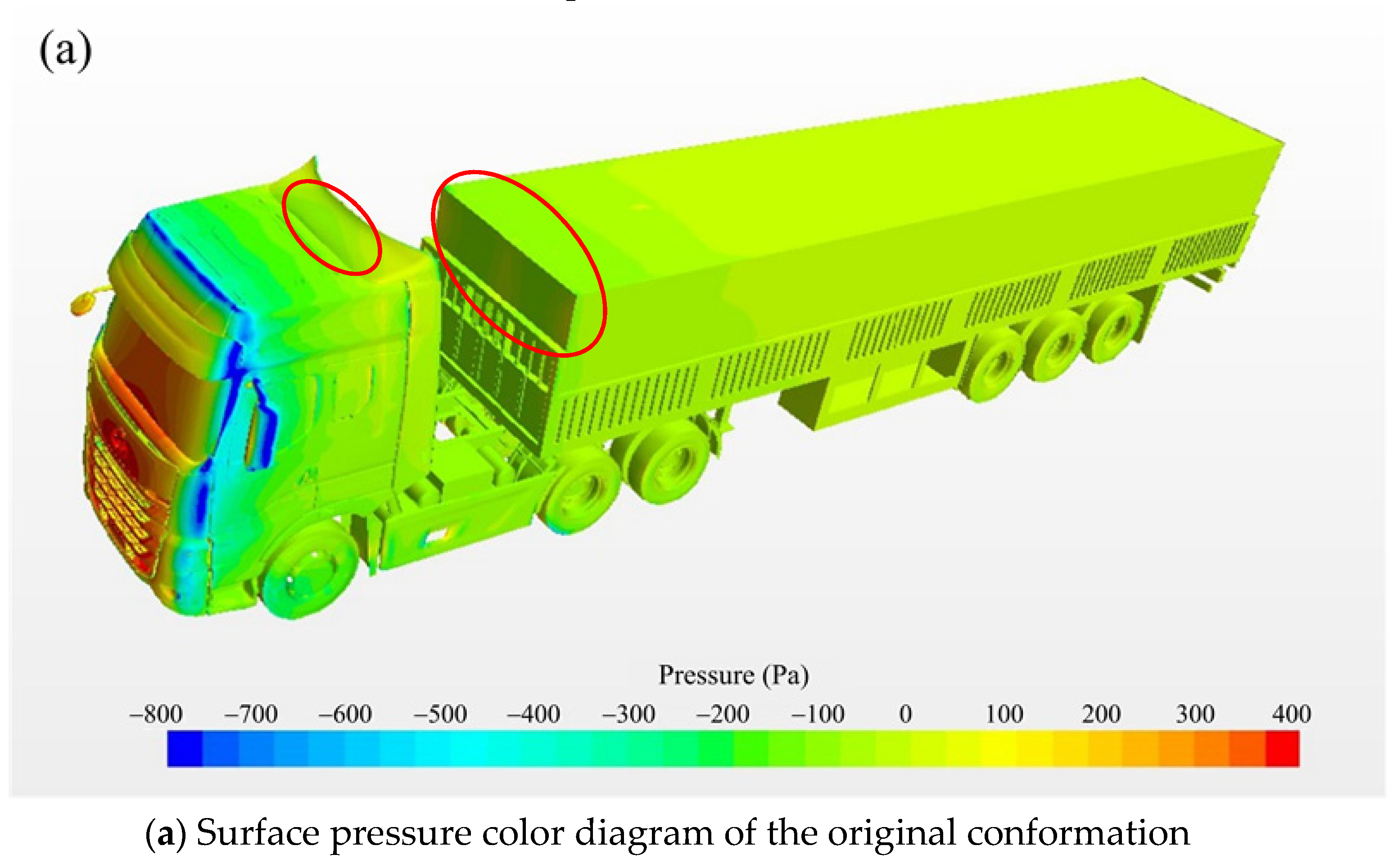

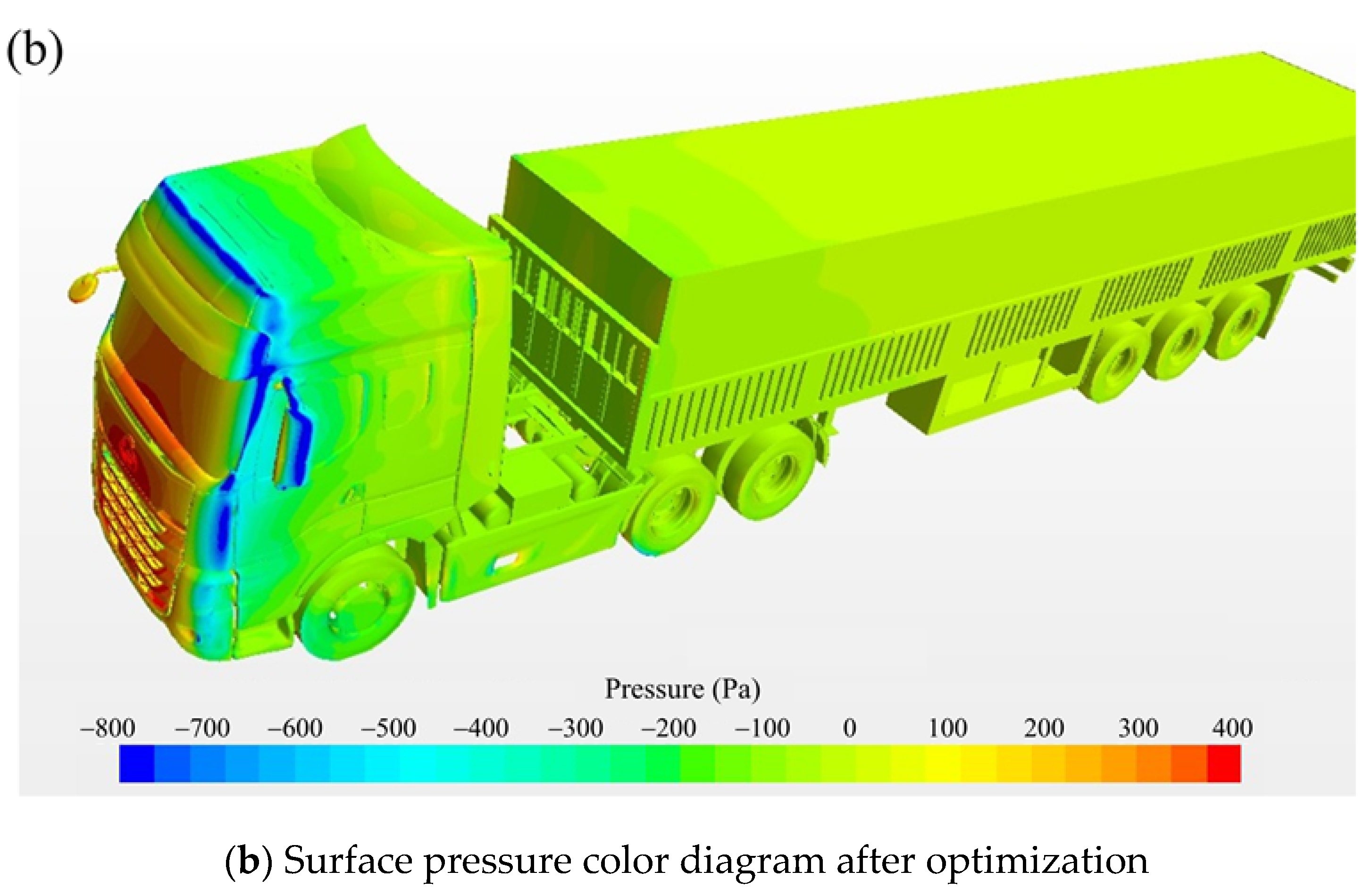

5.3. Wind Resistance Analysis

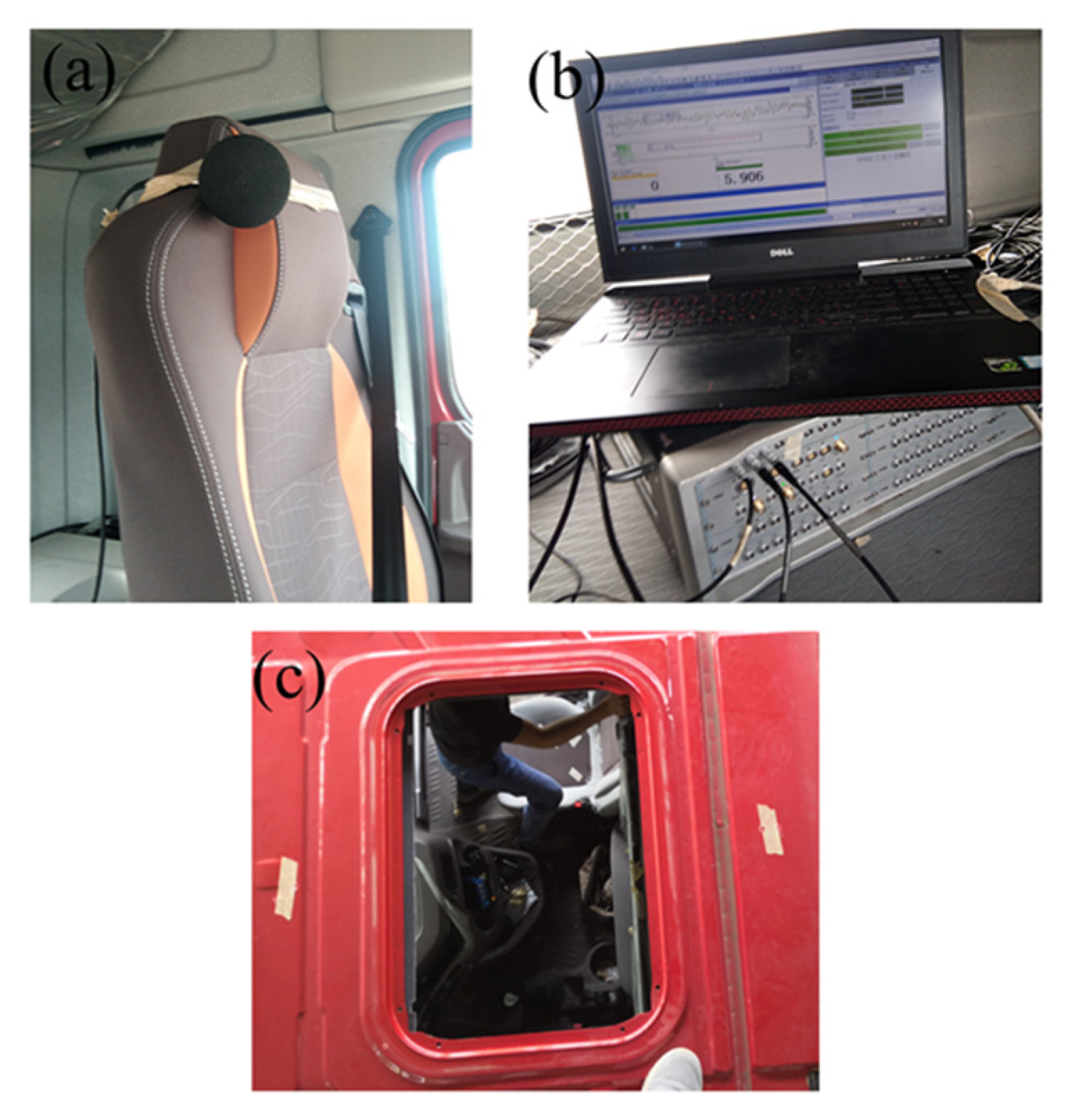

5.4. Sunroof Buffeting Noise Test

6. Conclusions

- (1)

- Based on numerical simulations, the airflow separates on the forehead of the cab to produce turbulent vortices. These vortices gradually become larger during the backward movement and fall off into the cab at the sunroof. The pressure wave generated by the turbulent vortex breaks causing the pressure in the cab to drop sharply. Turbulent vortices have periodic characteristics.

- (2)

- After analyzing the sunroof buffeting noise for two-speed conditions, it was evidenced that reducing the speed can improve the flow field characteristics above the roof and reduce the number of the small turbulent vortices.

- (3)

- Optimizing the sun visor and roof dome accessories of the cab can reduce the sunroof buffeting noise. The validity of the simulation results was verified through experiments.

- (4)

- The optimization scheme of the sun visor and roof dome improves the flow field characteristics of the commercial vehicles. This scheme reduces the impact of airflow on the roof dome and the local pressure drag and reduces the aerodynamic drag coefficient of the commercial vehicle, improving fuel economy, and the design cost is also reduced.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, Q.; He, Y.; Wang, Y.; Xu, Z.; Zhang, Z. Computational study on the passive control of sunroof buffeting using a sub-cavity. Appl. Acoust. 2020, 159, 1–9. [Google Scholar] [CrossRef]

- Chen, S.; Wang, D.; Liang, J. Sound quality analysis and prediction of vehicle interior noise based on grey system theory. Fluct. Noise Lett. 2012, 11, 1–22. [Google Scholar] [CrossRef]

- Lemaitre, G.; Vartanian, C.; Lambourg, C.; Boussard, P. A psychoacoustical study of wind buffeting noise. Appl. Acoust. 2015, 95, 1–12. [Google Scholar] [CrossRef]

- He, Y.; Long, L.; Yang, Z. A study on wind tunnel test on side window buffeting characteristics of a sedan. Automot. Eng. 2017, 39, 1011–1017. [Google Scholar]

- Yang, Z.; Gu, Z.; Tu, J.; Dong, G.; Wang, Y. Numerical analysis and passive control of a car side window buffeting noise based on scale-adaptive simulation. Appl. Acoust. 2014, 79, 23–34. [Google Scholar] [CrossRef]

- Oettle, N.; Meskine, M.; Senthooran, S.; Bissell, A.; Balasubramanian, G.; Powell, R. A computational approach to assess buffeting and broadband noise generated by a vehicle sunroof. SAE Int. J. Passeng. Cars Mech. Syst. 2015, 8, 196–204. [Google Scholar] [CrossRef]

- Wang, Y.; Deng, Y.; Yang, Z.; Jiang, T.; Su, C.; Yang, X. Numerical study of the flow-induced sunroof buffeting noise of a simplified cavity model based on the slightly compressible model. Proc. Inst. Mech. Eng. Part D 2013, 227, 1187–1199. [Google Scholar] [CrossRef]

- Wang, Z.; Zhuang, M. A numerical study of trailing edge serrations on sunroof buffeting noise reduction. SAE Int. J. Veh. Dyn. Stab. NVH 2017, 1, 112–118. [Google Scholar] [CrossRef]

- Gu, Z.; Zong, Y.; Luo, Z.; Yang, Z.; Jiang, C.; Chen, Z. Numerical simulation of automobile side-window buffeting noise based on fluid–structure interaction. Appl. Acoust. 2015, 90, 126–137. [Google Scholar] [CrossRef]

- Gong, X.; Wang, J.; Deng, C.; Wei, P.; Liu, B.; Li, L. Optimization and simulation of SUV sunroof buffeting noise. In Proceedings of the Society of Automotive Engineers (SAE)—China Congress, Shanghai, China, 26–28 October 2016; Springer: Singapore, 2016; pp. 365–373. [Google Scholar]

- He, Y.; Zhang, Q.; An, C.; Wang, Y.; Xu, Z.; Zhang, Z. Computational investigation and passive control of vehicle sunroof buffeting. J. Vib. Control 2020, 26, 747–756. [Google Scholar] [CrossRef]

- He, Y.; Zhang, Q.; Xu, Z.; Zhang, Z. Study on the sunroof buffeting suppression with a notched flat deflector. In Proceedings of the INTER-NOISE and NOISE-CON Congress and Conference Proceedings, Madrid, Spain, 16–19 June 2019; Institute of Noise Control Engineering: Reston, VA, USA, 2019; Volume 259, pp. 1677–1683. [Google Scholar]

- He, Y.Z.; Long, L.H.; Yang, Z.G. Reduction and optimization of a vehicle’s rear side window buffeting. Noise Control Eng. J. 2018, 66, 298–307. [Google Scholar] [CrossRef]

- Hu, X.J.; Peng, G.; Zhang, Y.H.; Mao, J.M.; Sun, X.Z.; Sang, T.; Lan, W.; Wang, J.Y. Buffeting noise characteristics and control of automobile side window. SAE Int. J. Veh. Dyn. Stab. NVH 2021, 5, 65–79. [Google Scholar] [CrossRef]

- Gu, Z.Q.; Liu, Z.Z.; Yang, Z.D.; Zheng, L.D.; Yin, S.B. Optimization of air-jet structure for automobile wind buffeting noises. China Mech. Eng. 2021, 32, 681–733. [Google Scholar]

- Chen, Z.; Wen, G.; Li, W. Influence of stream velocity on the buffeting characteristic of vehicle sunroof. Automot. Eng. 2013, 35, 654–659. [Google Scholar]

- Zhang, Y.; Zhang, J.; Li, T.; Zhang, L. Investigation of the aeroacoustic behavior and aerodynamic noise of a high-speed train pantograph. Sci. China Technol. Sci. 2017, 60, 561–575. [Google Scholar] [CrossRef]

- Slaboch, P.; Ma, R.; Shannon, D.; Gleason, M.; Puskarz, M. Window buffeting measurements of a full scale vehicle and simplified small scale models. SAE Int. J. Passeng. Cars 2009, 2, 410–418. [Google Scholar] [CrossRef]

- Wu, H.; Zhou, J.; Chen, Q.; Liu, G.; Qian, C. A study on rear window wind vibration of a sedan. Automob. Technol. 2016, 9–25. [Google Scholar]

- Kook, H.-S.; Shin, S.-R.; Cho, J.; Ih, K.-D. Development of an active deflector system for sunroof buffeting noise control. J. Vib. Control. 2014, 20, 2521–2529. [Google Scholar] [CrossRef]

- Wang, Y.; Lee, H.C.; Li, K.M.; Gu, Z.; Chen, J. Experimental and numerical study of flow over a cavity for reduction of buffeting noise. Acta Acust. United Acust. 2012, 98, 600–610. [Google Scholar] [CrossRef]

| Wind Resistance Coefficient (Cd) | Change Rate | |

|---|---|---|

| Original car | 0.581 | - |

| After optimization | 0.572 | −1.55% |

| Before Optimization | Optimized | |||

|---|---|---|---|---|

| Frequency (Hz) | Sound Pressure Level (dB) | Frequency (Hz) | Sound Pressure Level (dB) | |

| Simulation | 17.8 | 111.5 | 17.0 | 104.8 |

| Test | 16.5 | 116.3 | 16.1 | 109.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, R.; He, H.; Lu, Z.; Li, S.; Xu, E.; Xiao, F.; Núñez-Delgado, A. Control of Sunroof Buffeting Noise by Optimizing the Flow Field Characteristics of a Commercial Vehicle. Processes 2021, 9, 1052. https://doi.org/10.3390/pr9061052

Tang R, He H, Lu Z, Li S, Xu E, Xiao F, Núñez-Delgado A. Control of Sunroof Buffeting Noise by Optimizing the Flow Field Characteristics of a Commercial Vehicle. Processes. 2021; 9(6):1052. https://doi.org/10.3390/pr9061052

Chicago/Turabian StyleTang, Rongjiang, Hongbin He, Zengjun Lu, Shenfang Li, Enyong Xu, Fei Xiao, and Avelino Núñez-Delgado. 2021. "Control of Sunroof Buffeting Noise by Optimizing the Flow Field Characteristics of a Commercial Vehicle" Processes 9, no. 6: 1052. https://doi.org/10.3390/pr9061052

APA StyleTang, R., He, H., Lu, Z., Li, S., Xu, E., Xiao, F., & Núñez-Delgado, A. (2021). Control of Sunroof Buffeting Noise by Optimizing the Flow Field Characteristics of a Commercial Vehicle. Processes, 9(6), 1052. https://doi.org/10.3390/pr9061052