Electrothermal Desiccant Regeneration Technique for Air Dehumidification

Abstract

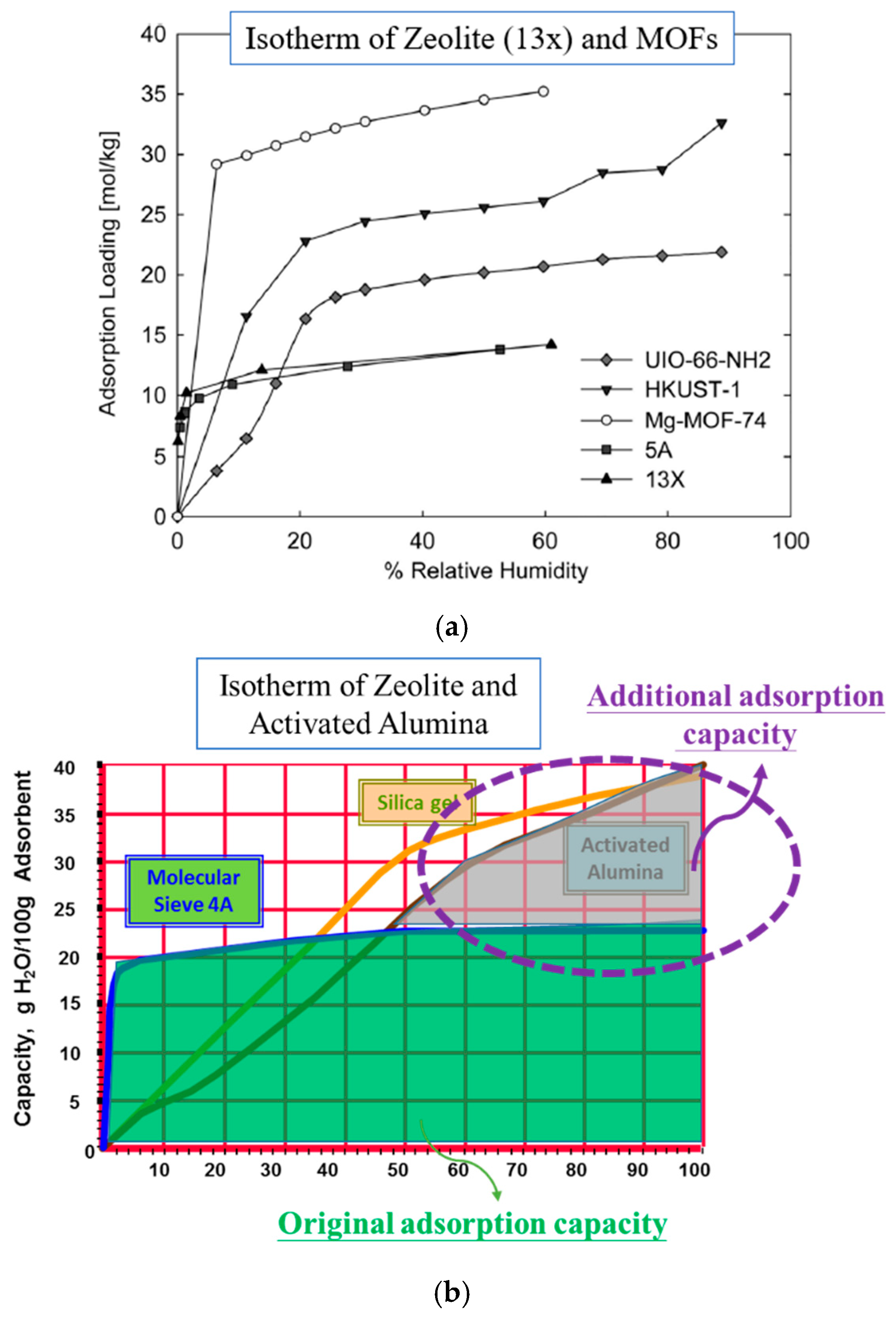

:1. Introduction

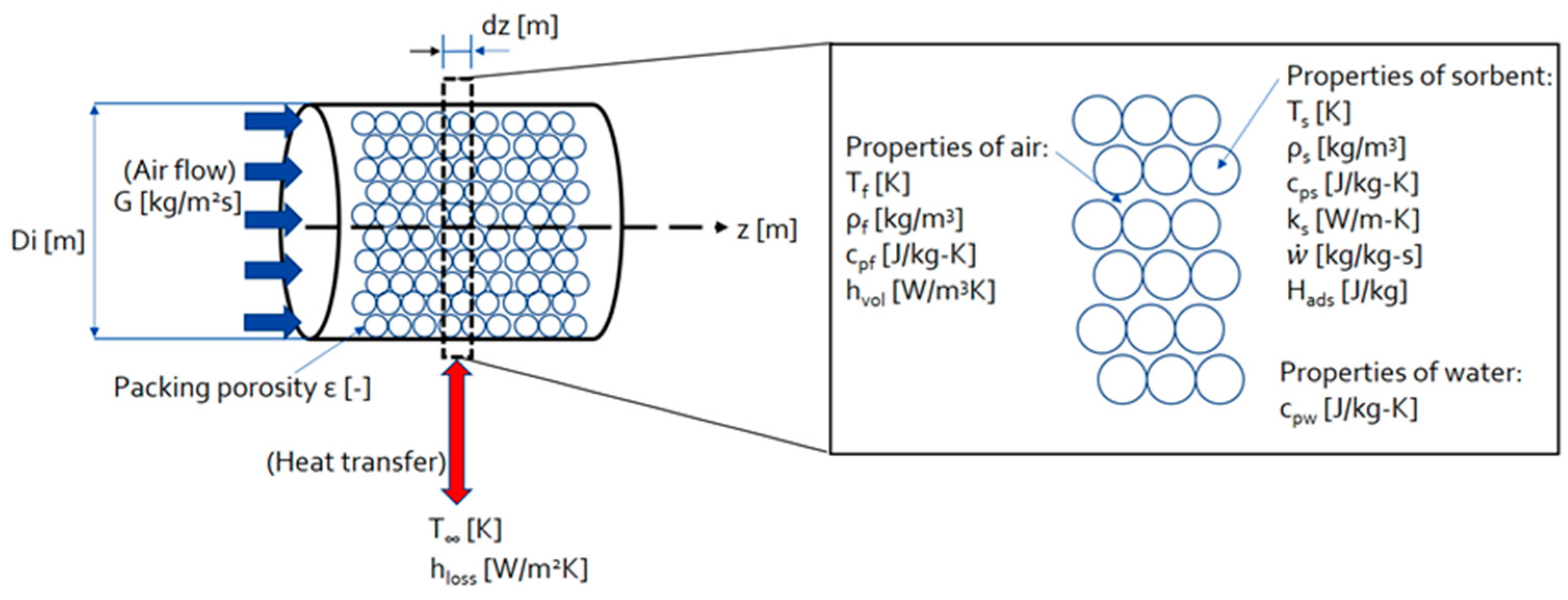

2. Theoretical Analysis

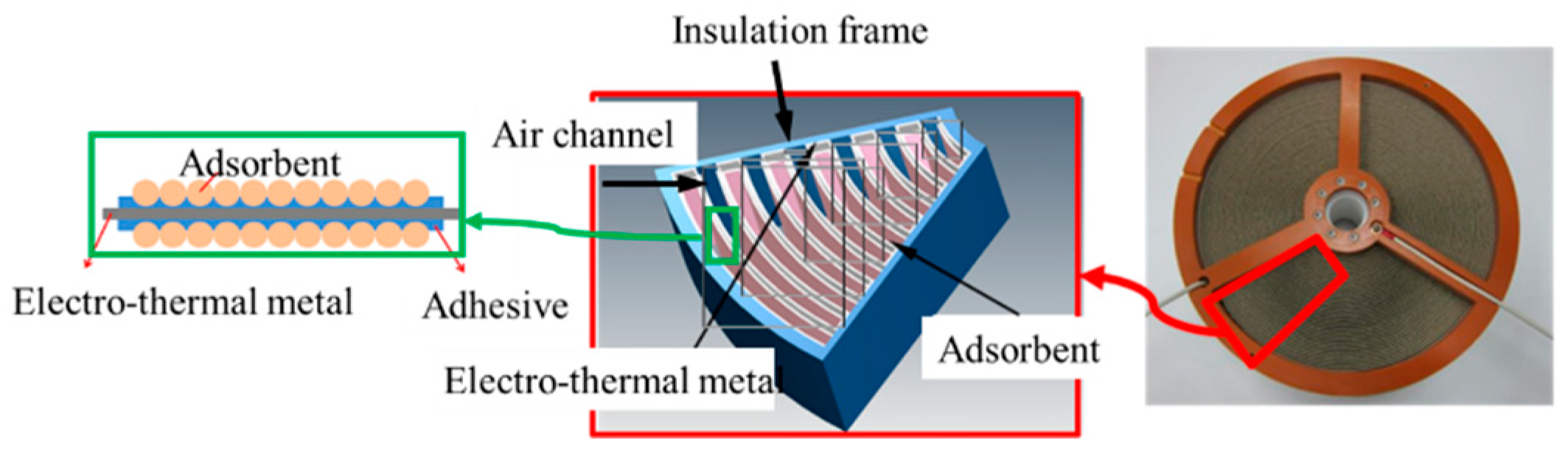

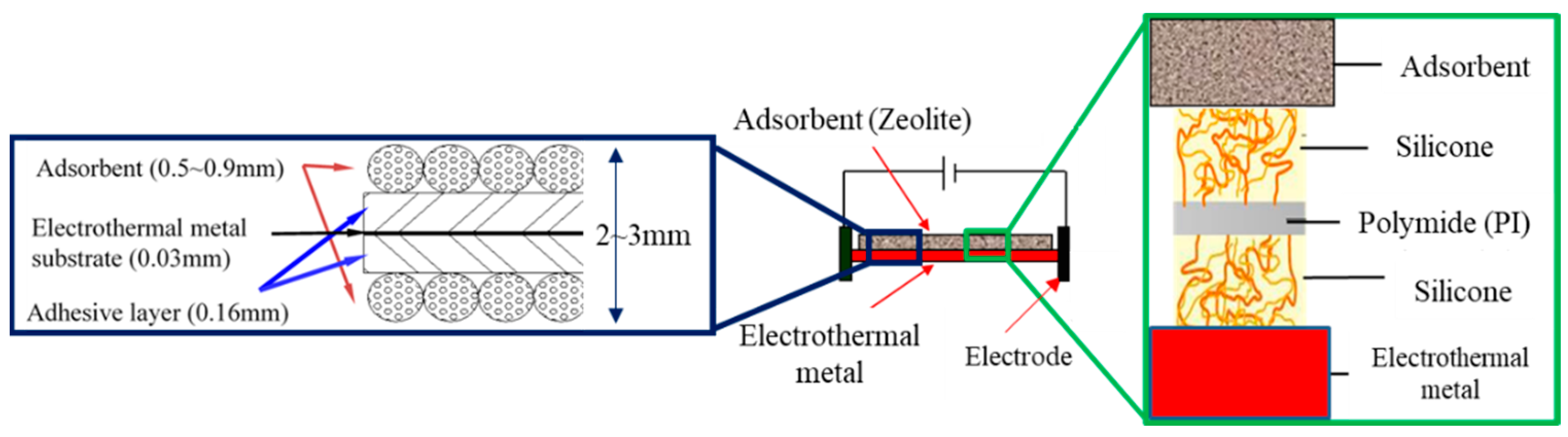

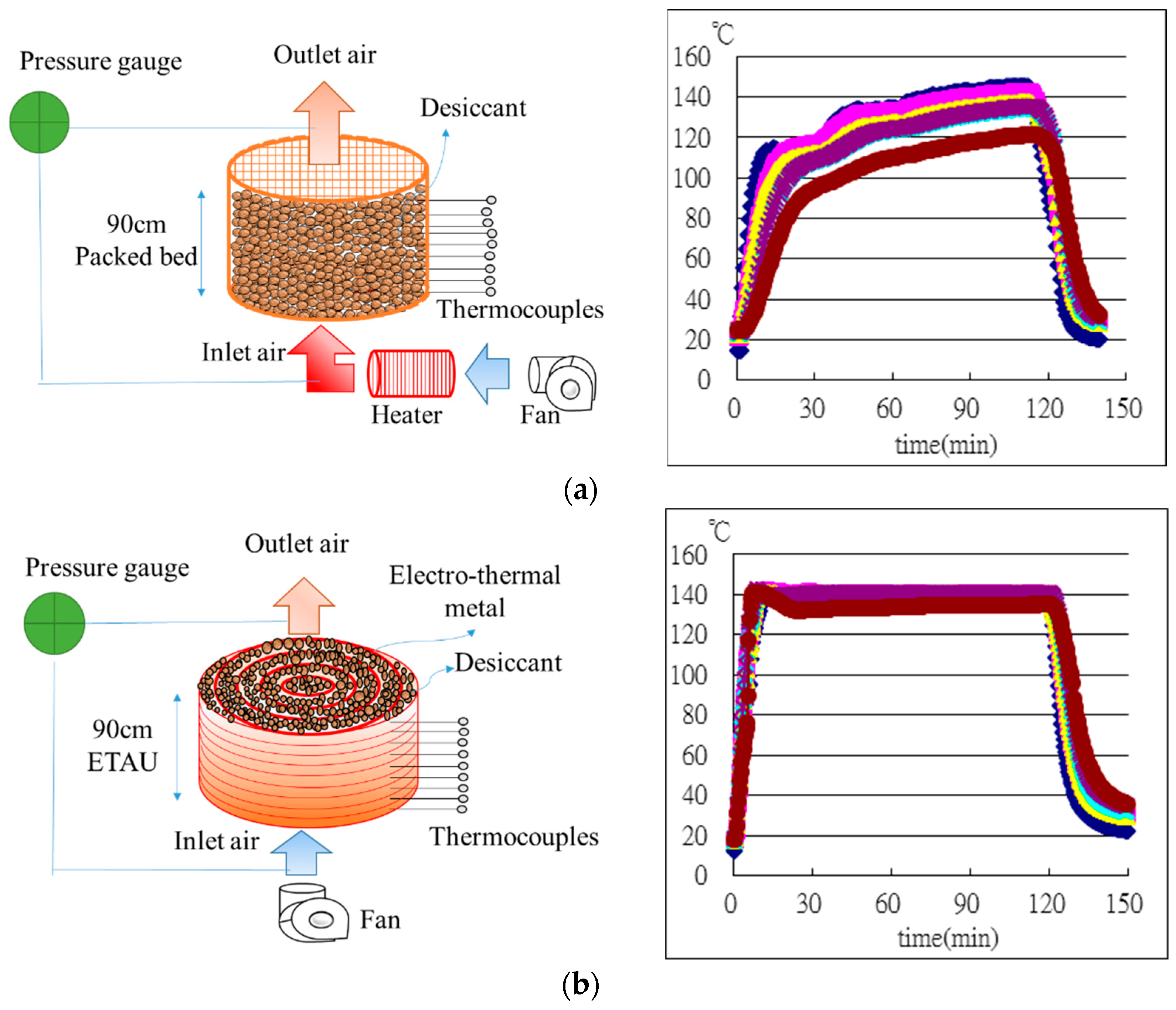

2.1. Electrothermal Adsorbent Unit (ETAU) Regeneration Method

- (1)

- The adsorbent is zeolite with d = 3 mm and kad = 0.20 W⁄mK.

- (2)

- In the indirect heating method, the plate heats the air through one of its surfaces (Asurface = 5d2), whereas the adsorbent granules are completely exposed to air (Agrain = 5d2 π). The forced convective coefficient for the low-speed airflow over a solid surface [18] is used: hconv ≅ 10 W⁄(m2 K).

- (3)

- The thick of the adhesive layer is 0.16~0.2 mm, and the adsorbent’s diameter is 0.5~0.9 mm. Therefore In the direct heating method, the granules are in contact with the plate through the adhesive across 1/10 of the surface area of the adsorbent: Acontact = 1/10 Agrain.

- (4)

- The desiccant conducts a pressed procession after it adheres to the electrothermal metal, so the thermal resistance between the two is minimal and can be ignored.

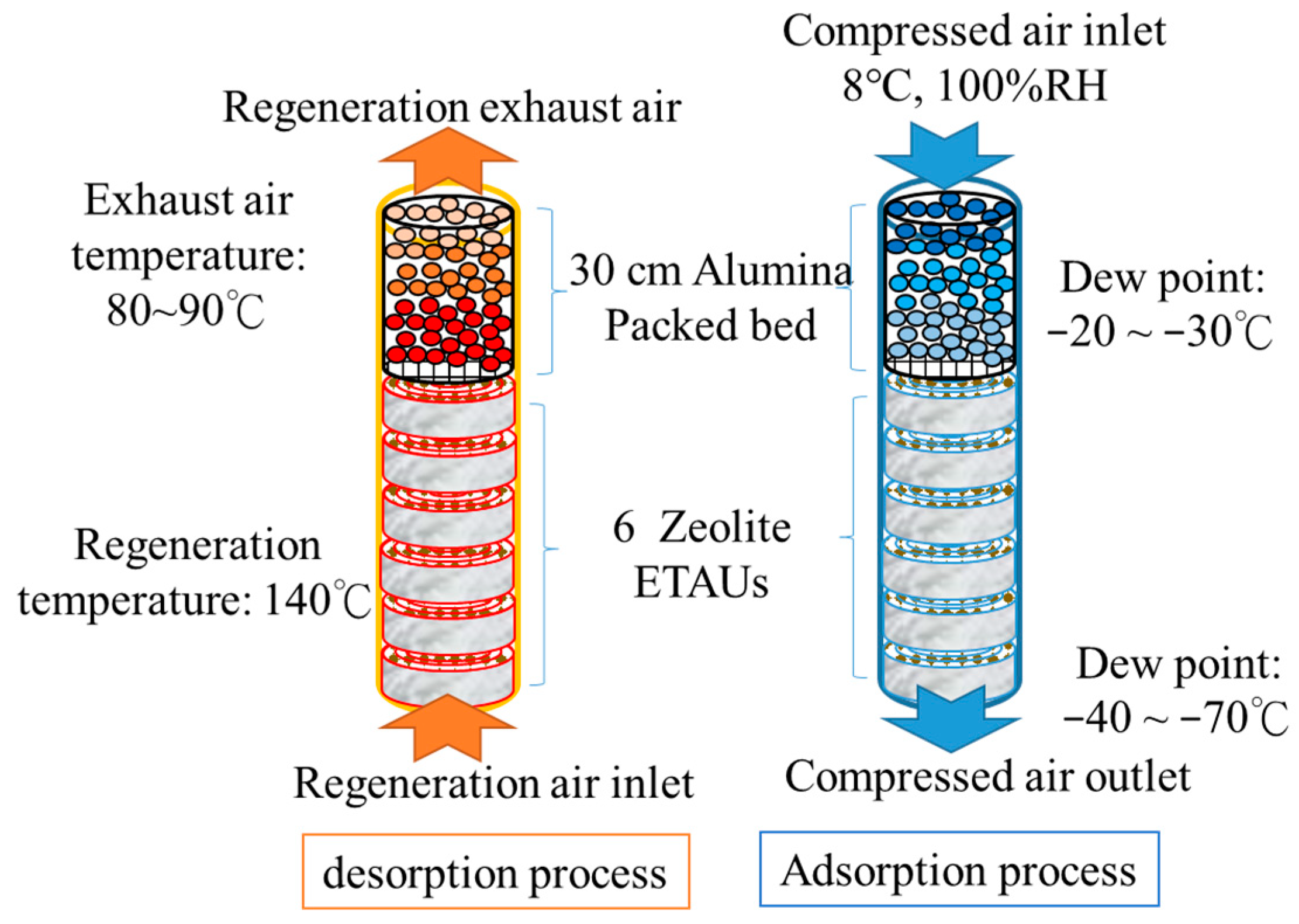

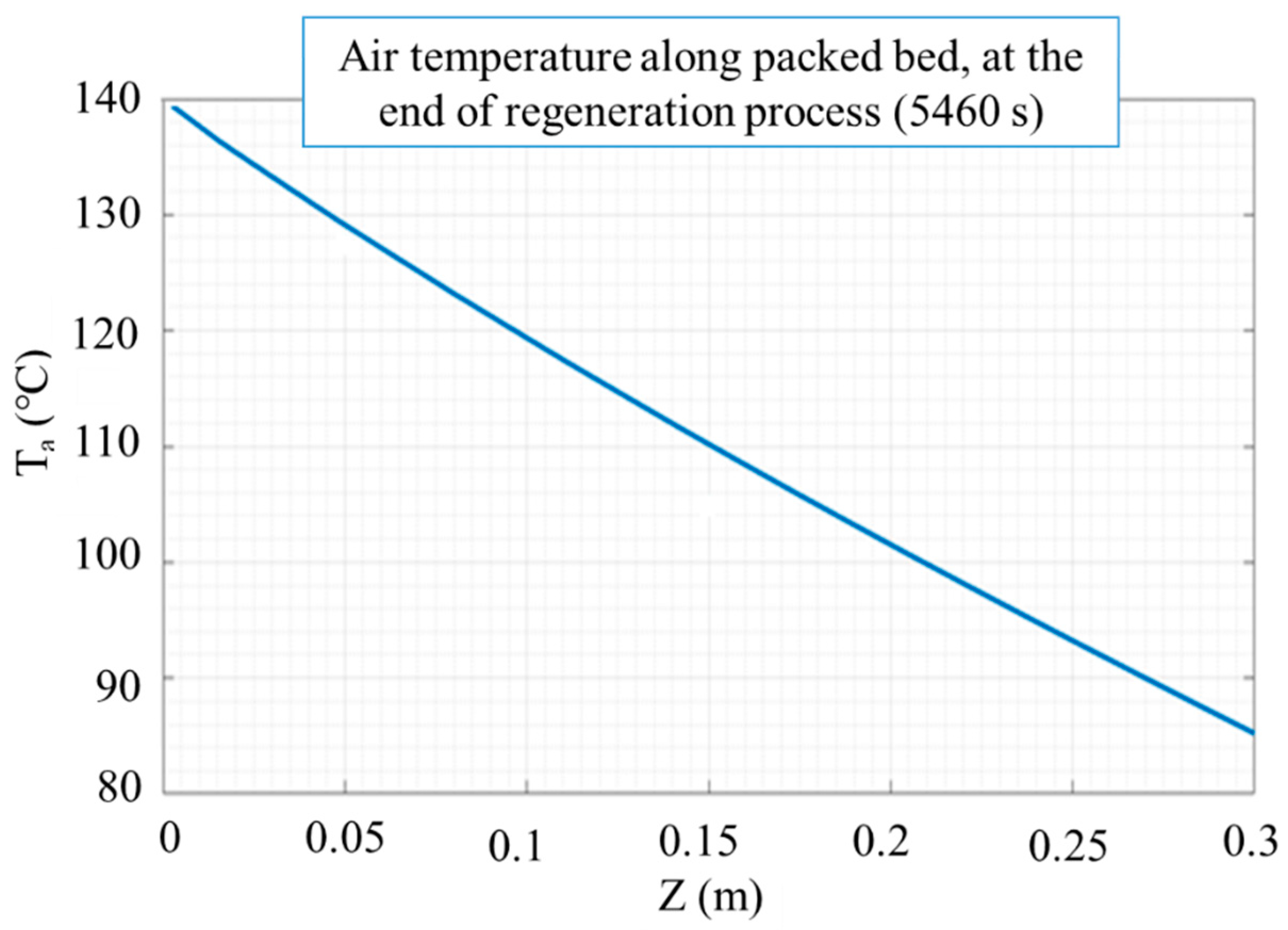

2.2. The Length of the Alumina Packed-Bed in Composite System

3. Electrothermal Adsorbent Unit (ETAU) Manufacture

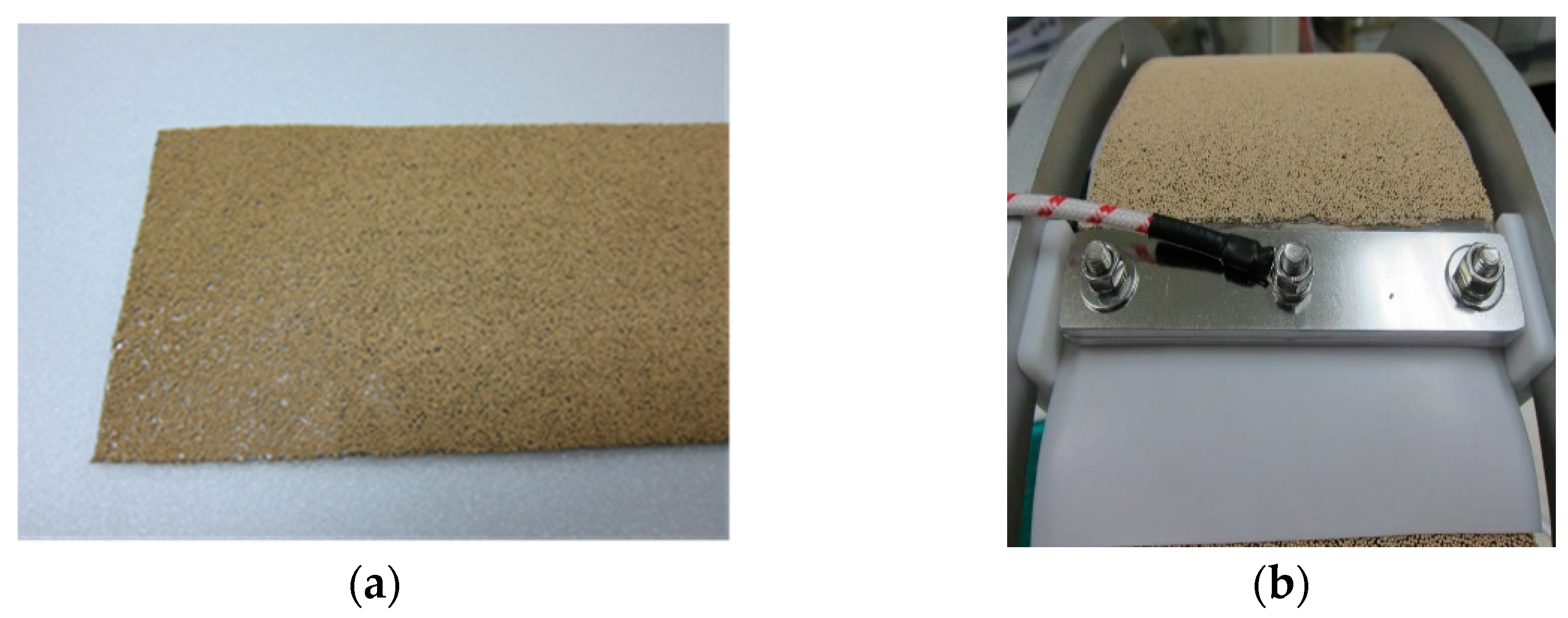

3.1. Desiccant Coating Method

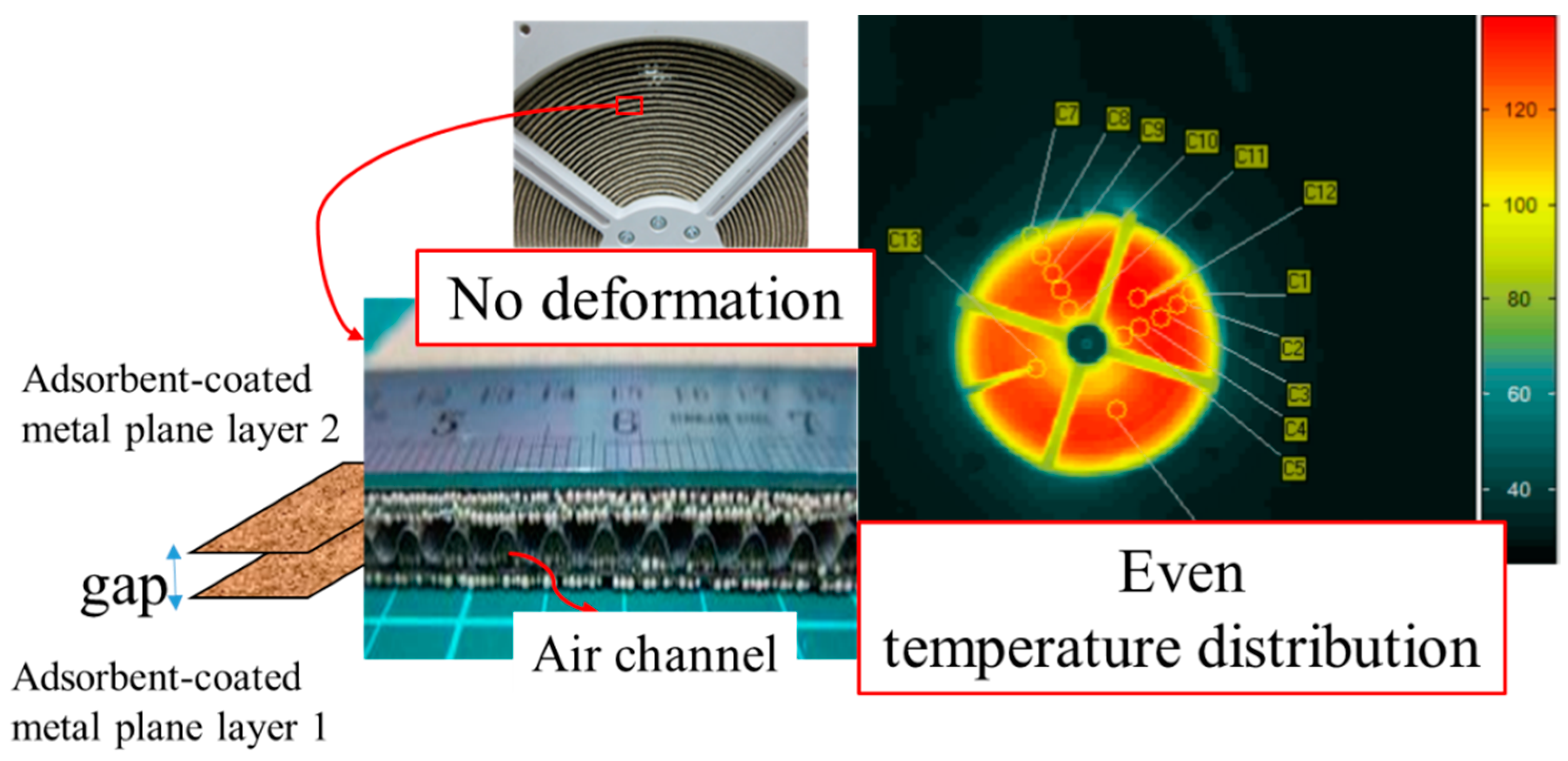

3.2. Air Channel

3.3. Continuous and Rapid Roll-to-Roll Production

4. Performance Test Result and Discussion

4.1. ETAU Basic Test

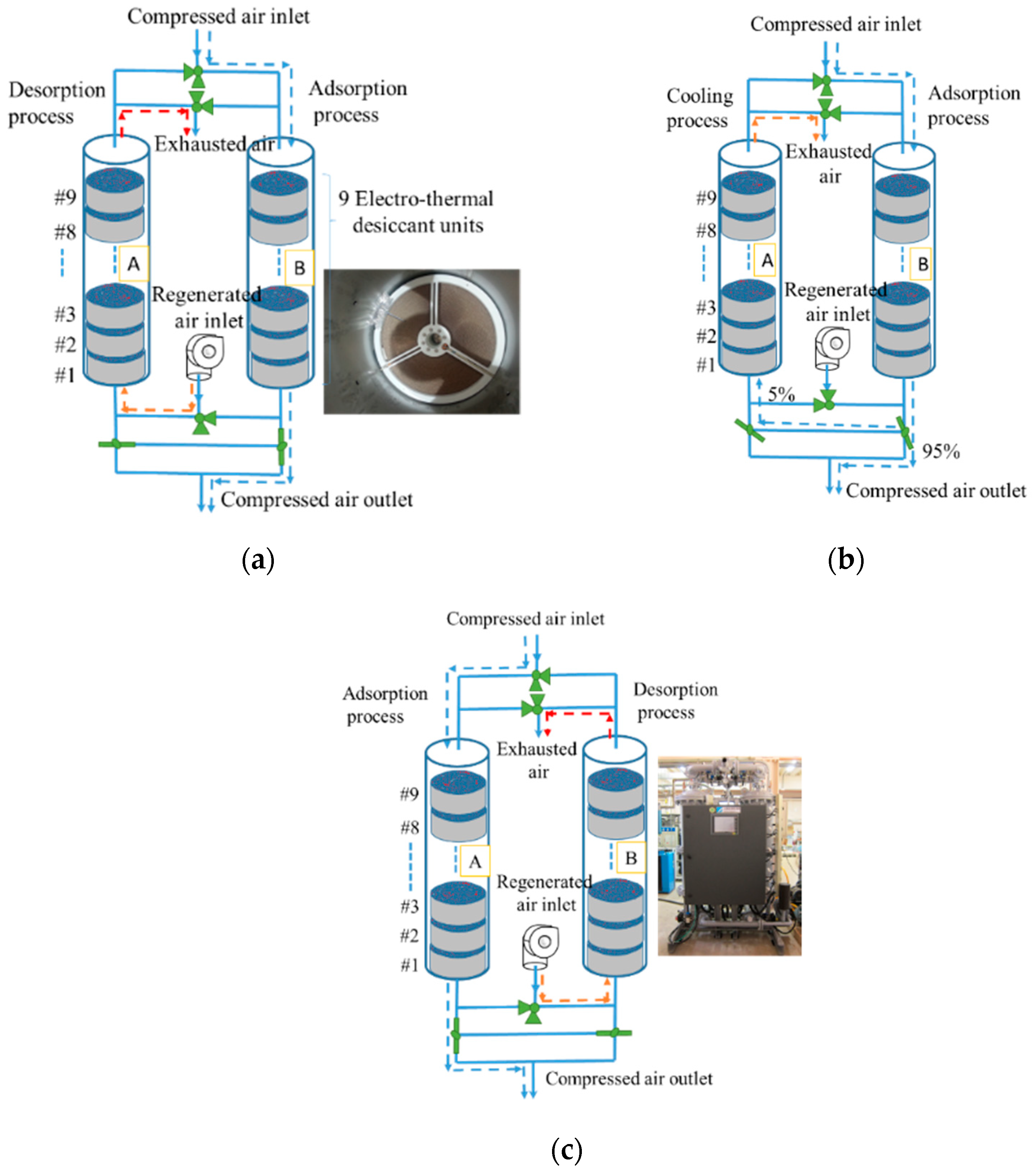

4.2. ETAUs Compressed Air Dryer

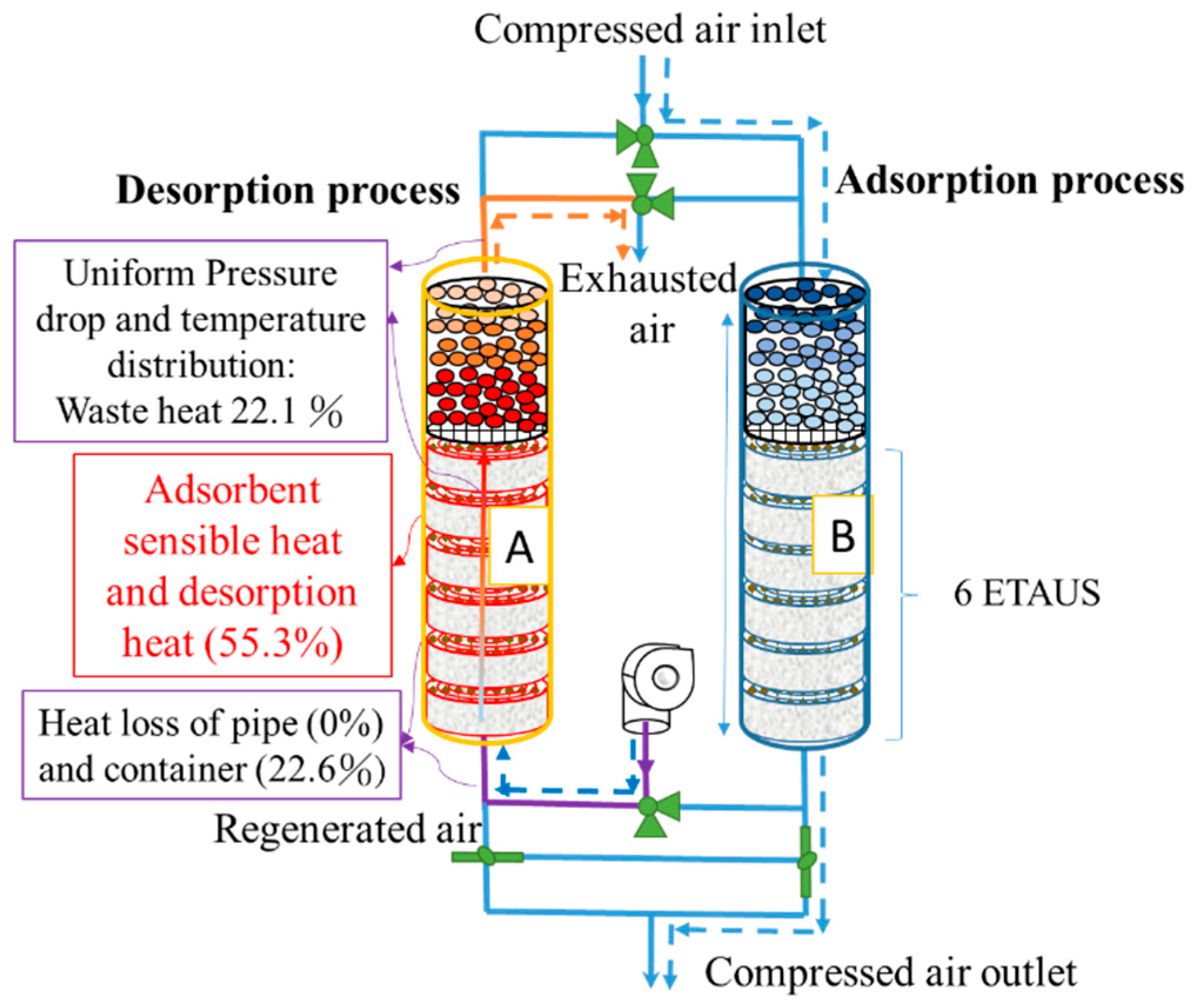

4.3. Composite ETAUs Compressed Air Dryer

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Nehler, T. Linking energy efficiency measures in industrial compressed air systems with non-energy benefits—A review. Renew. Sustain. Energy Rev. 2018, 89, 72–87. [Google Scholar] [CrossRef]

- Zhan, C.; Yin, Y.; Guo, X.; Jin, X.; Zhang, X. Investigation on drying performance and alternative analysis of different liquid desiccants in compressed air drying system. Energy 2018, 165, 1–9. [Google Scholar] [CrossRef]

- Sun, H.; Luo, X.; Wang, J. Feasibility study of a hybrid wind turbine system—Integration with compressed air energy storage. Appl. Energy 2015, 137, 617–628. [Google Scholar] [CrossRef] [Green Version]

- Barbour, E.; Mignard, D.; Ding, Y.; Li, Y. Adiabatic Compressed Air Energy Storage with packed bed thermal energy storage. Appl. Energy 2015, 155, 804–815. [Google Scholar] [CrossRef] [Green Version]

- Yin, Y.; Zheng, B.; Yang, C.; Zhang, X. A proposed compressed air drying method using pressurized liquid desiccant and experimental verification. Appl. Energy 2015, 141, 80–89. [Google Scholar] [CrossRef]

- Senanayake, N.S.; Dissanayake, D. Activated carbon for drying compressed air for low pressure applications. Int. Rev. Mech. Eng. 2011, 5, 818–821. [Google Scholar]

- Guo, P.; Wong-Foy, A.G.; Matzger, A.J. Microporous Coordination Polymers as Efficient Sorbents for Air Dehumidification. Langmuir 2014, 30, 1921–1925. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.-H.; Huang, P.-C.; Yang, T.-H.; Chiang, Y.-C.; Chen, S.-L. Polymer/alumina composite desic-cant combined with periodic total heat exchangers for air-conditioning systems. Int. J. Refrig. 2016, 67, 10–21. [Google Scholar] [CrossRef]

- Fu, H.-X.; Zhang, L.-Z.; Xu, J.-C.; Cai, R.-R. A dual-scale analysis of a desiccant wheel with a novel organic–inorganic hybrid adsorbent for energy recovery. Appl. Energy 2016, 163, 167–179. [Google Scholar] [CrossRef]

- Chua, K.J.; Chou, S.; Yang, W.; Yan, J. Achieving better energy-efficient air conditioning—A review of technologies and strategies. Appl. Energy 2013, 104, 87–104. [Google Scholar] [CrossRef]

- Angrisani, G.; Roselli, C.; Sasso, M. Effect of rotational speed on the performances of a desiccant wheel. Appl. Energy 2013, 104, 268–275. [Google Scholar] [CrossRef]

- Chen, C.-H.; Ma, S.-S.; Wu, P.-H.; Chiang, Y.-C.; Chen, S.-L. Adsorption and desorption of silica gel circulating fluidized beds for air conditioning systems. Appl. Energy 2015, 155, 708–718. [Google Scholar] [CrossRef]

- Enteria, N.; Yoshino, H.; Satake, A.; Mochida, A.; Takaki, R.; Yoshie, R.; Baba, S. Development and construction of the novel solar thermal desiccant cooling system incorporating hot water production. Appl. Energy 2010, 87, 478–486. [Google Scholar] [CrossRef]

- Eicker, U.; Schneider, D.; Schumacher, J.; Ge, T.; Dai, Y. Operational experiences with solar air collector driven desiccant cooling systems. Appl. Energy 2010, 87, 3735–3747. [Google Scholar] [CrossRef]

- Chen, C.-H.; Hsu, C.-Y.; Chiang, Y.-C.; Chen, S.-L. Silica gel/polymer composite desiccant wheel combined with heat pump for air-conditioning systems. Energy 2016, 94, 87–99. [Google Scholar] [CrossRef]

- Hao, W.; Björkman, E.; Lilliestråle, M.; Hedin, N. Activated carbons prepared from hydrothermally car-bonized waste biomass used as adsorbents for CO2. Appl. Energy 2013, 112, 526–532. [Google Scholar] [CrossRef]

- Karmakar, A.; Prabakaran, V.; Zhao, D.; Chua, K.J. A review of metal-organic frameworks (MOFs) as energy-efficient desiccants for adsorption driven heat-transformation applications. Appl. Energy 2020, 269, 115070. [Google Scholar] [CrossRef]

- Whitelaw, J.H. Convective Heat Transfer. 2011. Available online: http://dx.doi.org/10.1615/AtoZ.c.convective_heat_transfer (accessed on 14 January 2017).

- Coutier, J.; Farber, E. Two applications of a numerical approach of heat transfer process within rock beds. Sol. Energy 1982, 29, 451–462. [Google Scholar] [CrossRef]

- Niu, J.; Zhang, L. Heat transfer and friction coefficients in corrugated ducts confined by sinusoidal and arc curves. Int. J. Heat Mass Transf. 2002, 45, 571–578. [Google Scholar] [CrossRef]

- Zhang, L.Z.; Niu, J.L. A Numerical Study of Laminar Forced Convection in Sinusoidal Ducts with Arc Lower Boundaries under Uniform Wall Temperature. Numer. Heat Transf. Part A Appl. 2001, 40, 55–72. [Google Scholar] [CrossRef]

- Zhang, L.Z. Conjugate Heat and Mass Transfer in Heat Mass Exchanger Ducts; Academic Press: Cambridge, MA, USA, 2014; pp. 21–74. [Google Scholar]

- Edwin, M. Talbott, Compressed Air Systems: A Guidebook on Energy and Cost Savings, 2nd ed.; The Fairmont Press: Lilburn, GA, USA, 1993. [Google Scholar]

| Packing Bed | |

|---|---|

| Diameter (mm) | 610 |

| Length (mm) | 300 |

| Packing porosity | 0.27 |

| Initial temperature (°C) | 40 |

| Activated alumina adsorbent | |

| Particle diameter (mm) | 4 |

| Density (kg/m3) | 1053 |

| Specific heat capacity (J/kgK) | 880 |

| Step | 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|

| Duration (s) | 0–60 | 60–160 | 160–4160 | 4160–4260 | 4260–5460 |

| Inlet temperature (°C) | 140 | ||||

| Velocity (10−3 m/s) | 39.6 | 34.2 | 78.4 | 22.9 | 34.2 |

| Equipment | Range | Error |

|---|---|---|

| K-type thermocouples | 0~260 °C | ±0.5 °C |

| Inlet mirror dew point meters | −35 to −10 °C | ±0.2 °C |

| Outlet mirror dew point meters | −65 to −25 °C | ±0.2 °C |

| Vortex Flowmeter | 8 to 80 m/s | ±1% |

| Pressure gauge | −101 to 2944 kPa | ±2 kPa |

| Electricity meter | Maximum current 80 A | ±0.1% |

| Atmosphere | After Compressed | Air Storage Barrel | Refrigeration Dryer | Adsorption Dryer | |

|---|---|---|---|---|---|

| Pressure (kPa) | 101 | 885 | 876 | 865 | 836 |

| Temperature (°C) | 30 | 43 | 25 | 8 | 25 |

| Relative humidity (%RH) (High pressure) | - | 100% | 100% | 100% | 2.6% |

| Relative humidity (%RH) (Atmosphere) | 80% | 12% | 11.5% | 11.3% | 0.3% |

| Pressure dew point (°C) | - | 43 | 25 | 8 | −22.2 |

| Dew point (°C) | 26.1 | 7.5 | −6.1 | −18.3 | −42 |

| Supply Air (m3/min., CMM) | The Adsorption Time (Before the Dew Point of Outlet Air Was Higher Than −40 °C) | |

|---|---|---|

| The Dew Point of Inlet Compressed Air: −8~−10 °C | The Dew Point of Inlet Compressed Air: −18~−20 °C | |

| 3 | 3 hours | 4 hours |

| 1.8 | 3.5 hours | 5 hours |

| Adsorption Dryer Type | Heatless | Heat-Air-Flow | ETAU | Composite ETAU |

|---|---|---|---|---|

| Outlet dew point (°C) | −40 | −40 | −40 | −40 |

| Inlet air flow (m3/min.,CMM) | 3.11 | 2.86 | 3.01 | 3.00 |

| Outlet air flow (m3/min., CMM) | 2.17 | 2.62 | 2.79 | 2.78 |

| Compressed air consumption ratio in cooling step (%) | 30.1 | 8.1 | 7.3 | 7.3 |

| Compressed air consumption energy index (kW/CMMcompressed air) | 2.31 | 0.62 | 0.56 | 0.56 |

| Regeneration energy index (kW/CMMcompressed air) | --- | 0.57 | 0.41 | 0.32 |

| Total energy efficiency index (kW/CMMcompressed air) | 2.31 | 1.19 | 0.97 | 0.86 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, C.-H.; Kang, Y.-H.; Lu, J.-H.; Hung, M.-L.; Perng, J.-C.; Chen, J.-J. Electrothermal Desiccant Regeneration Technique for Air Dehumidification. Processes 2021, 9, 1082. https://doi.org/10.3390/pr9071082

Chen C-H, Kang Y-H, Lu J-H, Hung M-L, Perng J-C, Chen J-J. Electrothermal Desiccant Regeneration Technique for Air Dehumidification. Processes. 2021; 9(7):1082. https://doi.org/10.3390/pr9071082

Chicago/Turabian StyleChen, Chih-Hao, Yu-Hao Kang, Jing-Hung Lu, Ming-Lang Hung, Jyi-Ching Perng, and Jiun-Jen Chen. 2021. "Electrothermal Desiccant Regeneration Technique for Air Dehumidification" Processes 9, no. 7: 1082. https://doi.org/10.3390/pr9071082