A Numerical Analysis of the Effects of Equivalence Ratio Measurement Accuracy on the Engine Efficiency and Emissions at Varied Compression Ratios

Abstract

:1. Introduction

2. Numerical Simulation Methodology

3. Results and Discussions

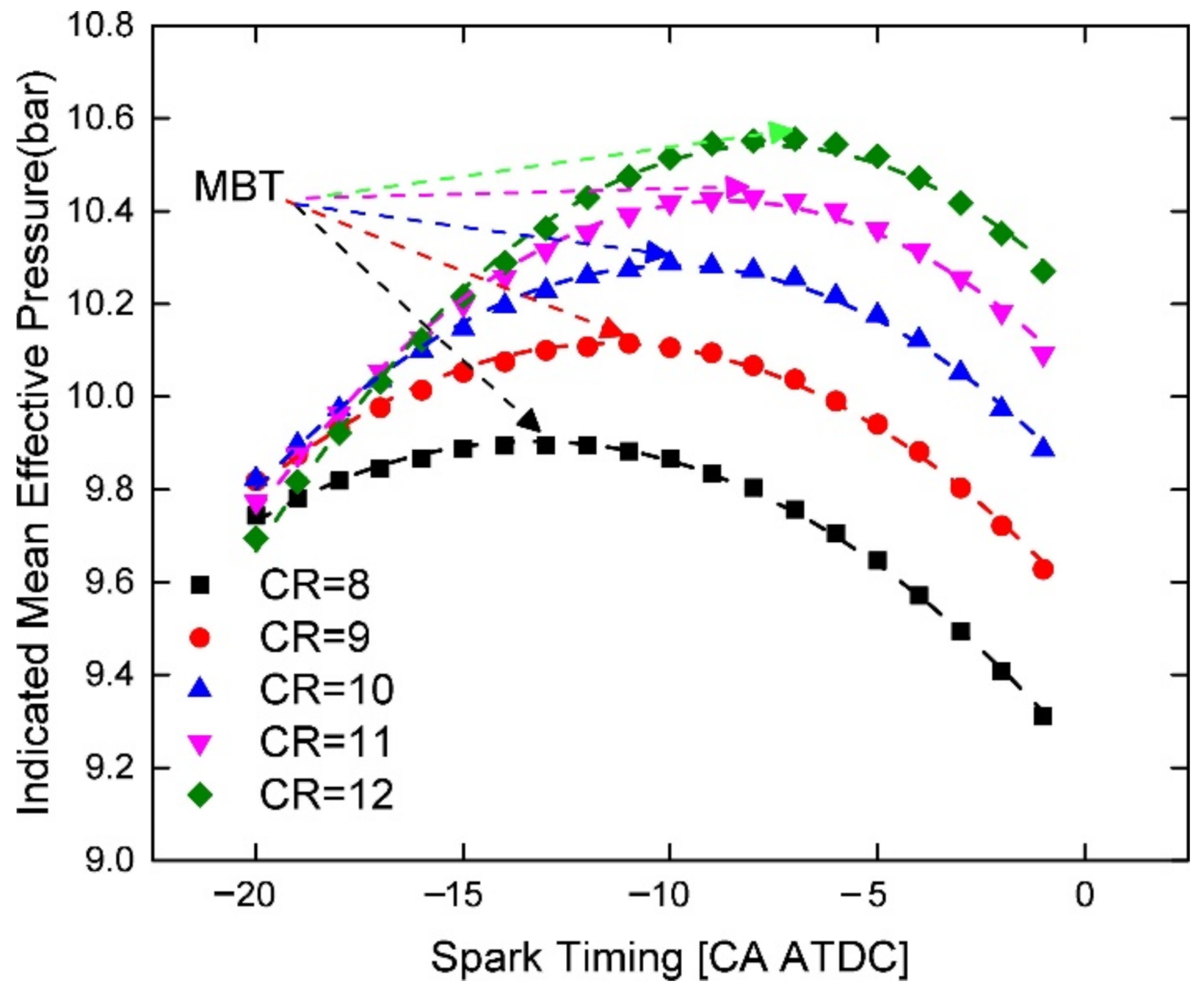

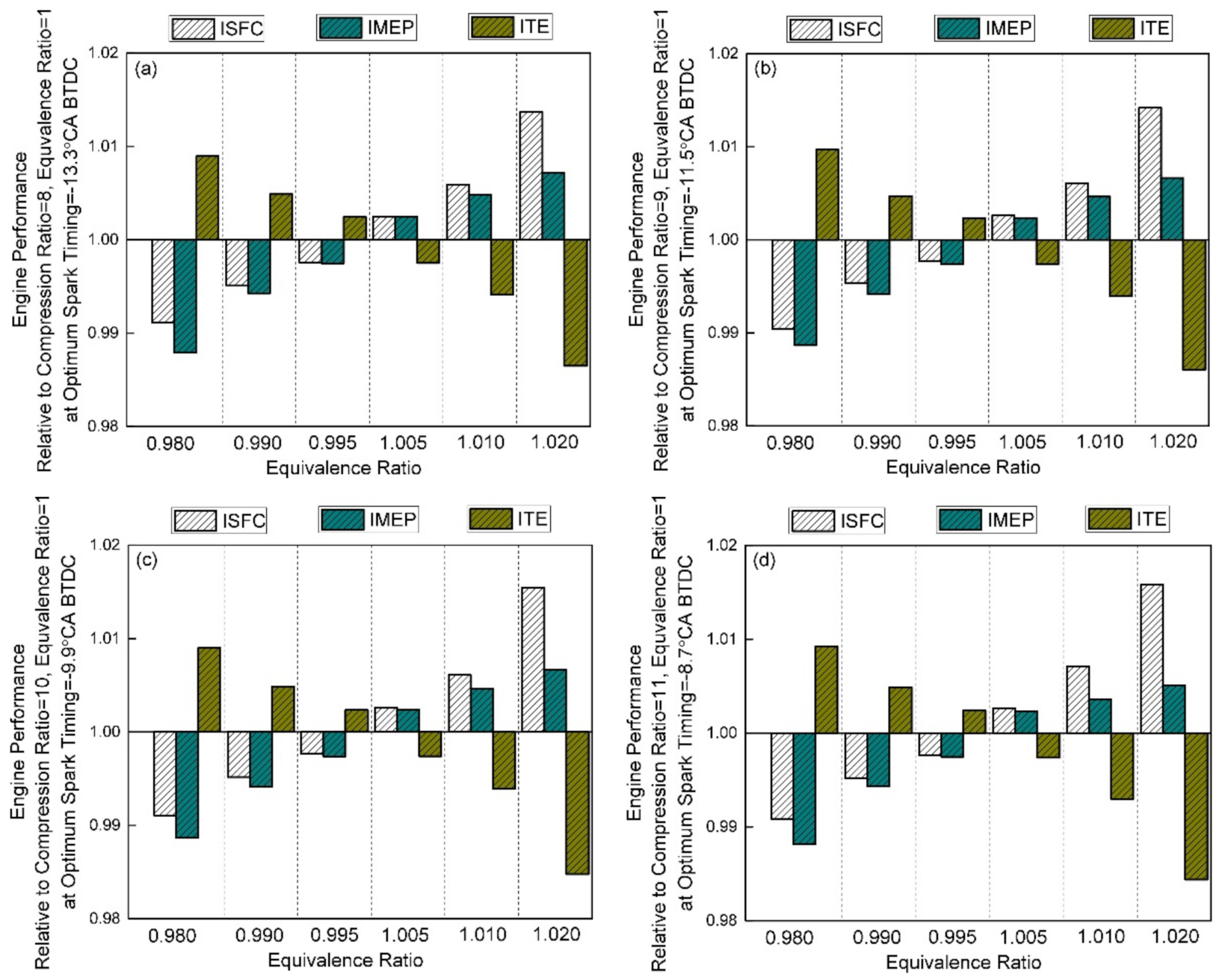

3.1. Compression Ratios Effects on Performance

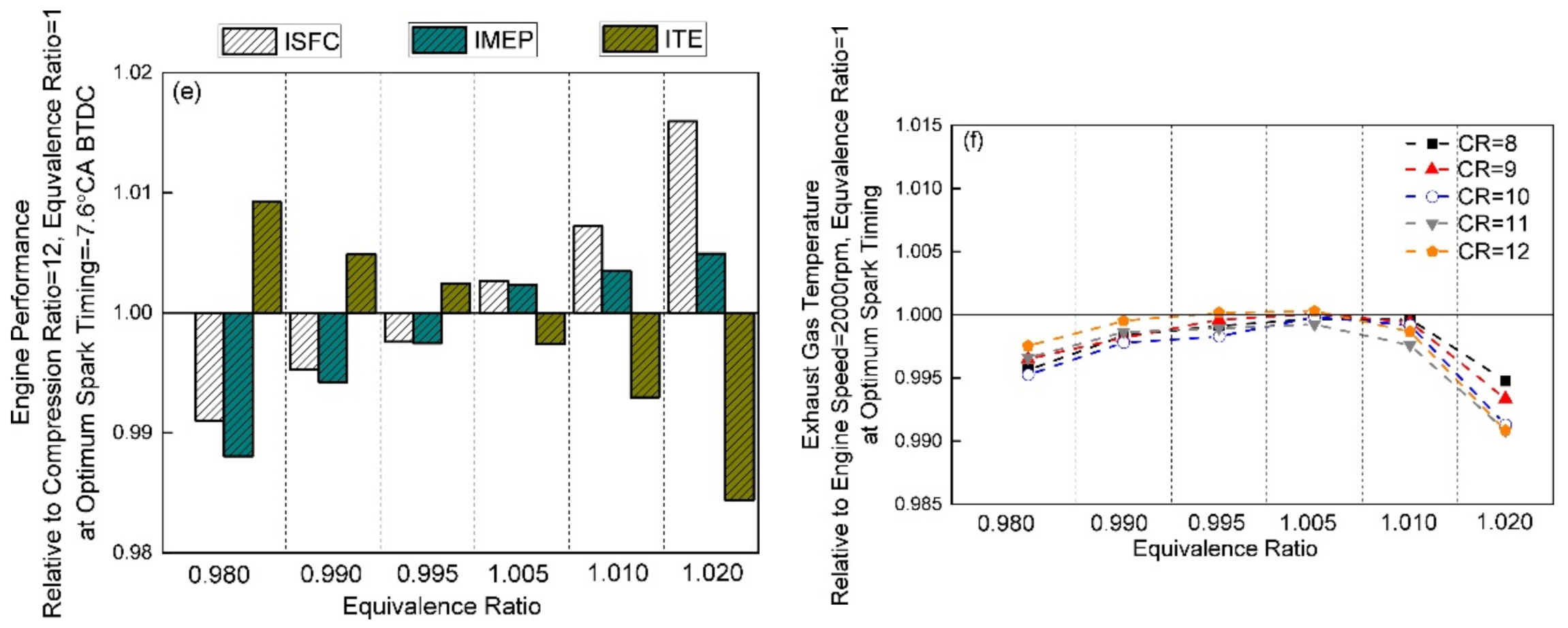

3.2. Compression Ratios Effects on Emissions

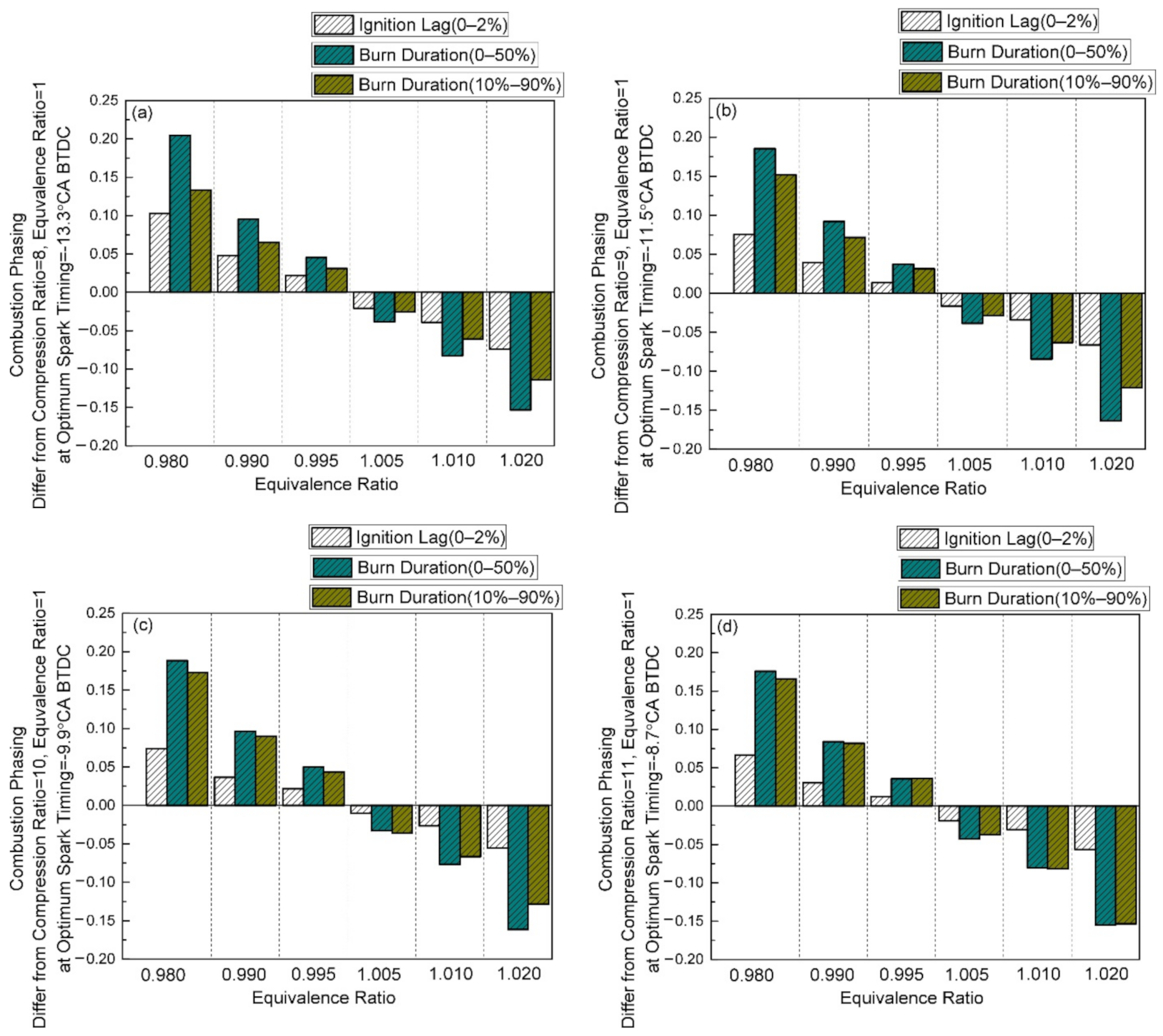

3.3. Compression Ratios Effects on Combustion Phasing

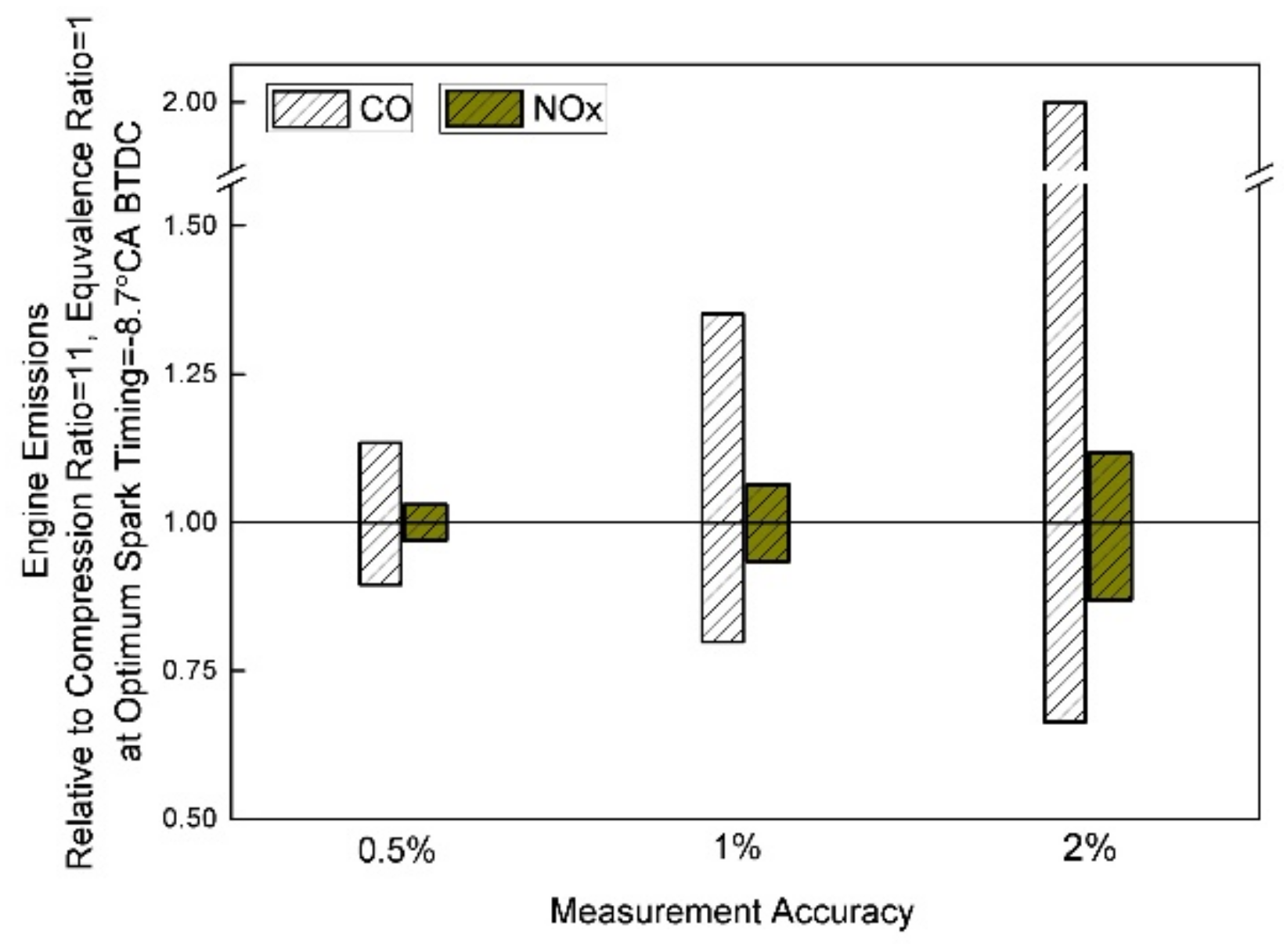

3.4. Measurement Accuracy Discussions

4. Future Work

5. Summary and Conclusions

- With small changes in equivalence ratio measurement accuracy at different compression ratios, the performance indicators changed very little. Therefore, indicated specific fuel consumption (ISFC), indicated mean effective pressure (IMEP), and indicated thermal efficiency (ITE) were not sensitive to the air-fuel ratio measurement accuracy, at least within the operating conditions investigated here.

- The air-fuel ratio measurement accuracy had a significant impact on carbon monoxide (CO) and nitrogen oxides production. In contrast, the variation of the air-fuel ratio at different compression ratios (CR = 8~11) did not have a significant effect on other engine efficiency indicators and unburned hydrocarbons (UHC).

- At the same air-fuel ratio, the variation of CO decreased with increasing CR value in the range of compression ratio 8~12. Additionally, the varied compression ratio, within the range of 8~12, had little effect on the variation of NOx.

- The compression ratio of the engine could not be increased indefinitely due to the knock presence limit, and too high CR was not beneficial for emission control. Therefore, the compression ratio should be increased, and the recommended value is 11.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| 1D | One-dimensional |

| AFR | Air-fuel Ratio |

| ATDC | After Top Dead Center |

| BTDC | Before Top Dead Center |

| CAD | Crank Angle Degree |

| CFD | Computational Fluid Dynamics |

| CO | Carbon Monoxide |

| CR | Compression Ratio |

| ICE | Internal Combustion Engine |

| IMEP | Indicated Mean Effective Pressure |

| ISFC | Indicated Specific Fuel Consumption |

| ITE | Indicated Thermal Efficiency |

| LPG | Liquefied Petroleum Gas |

| MBT | Maximum Brake Torque |

| NOx | Nitrogen Oxides |

| PFI | Port Fuel Injection |

| RPM | Revolutions per minute |

| SI | Spark Ignition |

| ST | Spark Timing |

| TDC | Top Dead Center |

| TWC | Three-way Catalyst |

| UHC | Unburned Hydrocarbon |

References

- Dehhaghi, M.; Kazemi Shariat Panahi, H.; Aghbashlo, M.; Lam, S.S.; Tabatabaei, M. The effects of nanoadditives on the performance and emission characteristics of spark-ignition gasoline engines: A critical review with a focus on health impacts. Energy 2021, 225, 120259. [Google Scholar] [CrossRef]

- Liu, J.; Dumitrescu, C.E. Single and double Wiebe function combustion model for a heavy-duty diesel engine retrofitted to natural-gas spark-ignition. Appl. Energy 2019, 248, 95–103. [Google Scholar] [CrossRef]

- Liu, J.; Dumitrescu, C.E. Analysis of two-stage natural-gas lean combustion inside a diesel geometry. Appl. Therm. Eng. 2019, 160, 114116. [Google Scholar] [CrossRef]

- Liu, J.; Dumitrescu, C.E. Methodology to separate the two burn stages of natural-gas lean premixed-combustion inside a diesel geometry. Energy Convers. Manag. 2019, 195, 21–31. [Google Scholar] [CrossRef]

- Liu, Z.; Sun, M.; Huang, Y.; Li, K.; Wang, C. Investigation of heat transfer characteristics of high-altitude intercooler for piston aero-engine based on multi-scale coupling method. Int. J. Heat Mass Transf. 2020, 156, 119898. [Google Scholar] [CrossRef]

- Huang, Y.; Liu, Z.; Lu, G.; Yu, X. Multi-scale thermal analysis approach for the typical heat exchanger in automotive cooling systems. Int. Commun. Heat Mass Transf. 2014, 59, 75–87. [Google Scholar] [CrossRef]

- Fu, J.; Liu, Z.; Han, S.; Zhao, J.; Huang, Y. Comparison of temperature difference measurement technologies used in vehicular heat exchangers. Exp. Therm. Fluid Sci. 2017, 82, 94–101. [Google Scholar] [CrossRef]

- Mashadi, B.; Kakaee, A.; Horestani, A.J. Low-temperature Rankine cycle to increase waste heat recovery from the internal combustion engine cooling system. Energy Convers. Manag. 2019, 182, 451–460. [Google Scholar] [CrossRef]

- Kaleli, A. Development of the predictive based control of an autonomous engine cooling system for variable engine operating conditions in SI engines: Design, modeling and real-time application. Control. Eng. Pract. 2020, 100, 104424. [Google Scholar] [CrossRef]

- Balakheli, M.M.; Chahartaghi, M.; Sheykhi, M.; Hashemian, S.M.; Rafiee, N. Analysis of different arrangements of combined cooling, heating and power systems with internal combustion engine from energy, economic and environmental viewpoints. Energy Convers. Manag. 2020, 203, 112253. [Google Scholar] [CrossRef]

- Szmytka, F.; Salem, M.; Rézaï-Aria, F.; Oudin, A. Thermal fatigue analysis of automotive Diesel piston: Experimental procedure and numerical protocol. Int. J. Fatigue 2014, 73, 48–57. [Google Scholar] [CrossRef] [Green Version]

- Liu, J.; Huang, Q.; Ulishney, C.; Dumitrescu, C. A Support-Vector Machine Model to Predict the Dynamic Performance of a Heavy-Duty Natural Gas Spark Ignition Engine. SAE Tech. Pap. 2021. [Google Scholar] [CrossRef]

- Yang, R.; Sun, X.; Liu, Z.; Zhang, Y.; Fu, J. A Numerical Study into the Importance of Equivalence Ratio Measurement Accuracy for Spark Ignition Engines. In Proceedings of the ASME 2021 International Mechanical Engineering Congress and Exposition, American Society of Mechanical Engineers, Virtual Conference, Online, 1–5 November 2021. [Google Scholar]

- Huang, Q.; Paul, P.; Bhattacharyya, D.; Pillai, R.C.; Sabolsky, K.; Sabolsky, E.M. Estimations of Gasifier Wall Temperature and Extent of Slag Penetration Using a Refractory Brick with Embedded Sensors. Ind. Eng. Chem. Res. 2017, 56, 9858–9867. [Google Scholar] [CrossRef]

- Huang, Q.; Bhattacharyya, D. Optimal sensor network design for multi-scale, time-varying differential algebraic equation systems: Application to an entrained-flow gasifier refractory brick. Comput. Chem. Eng. 2020, 141, 106985. [Google Scholar] [CrossRef]

- Wang, J.; Shuai, S. Principles of Automobile Engines; Tsinghua University Press: Beijing, China, 2011. [Google Scholar]

- Liu, J.; Dumitrescu, C.E. Combustion partitioning inside a natural gas spark ignition engine with a bowl-in-piston geometry. Energy Convers. Manag. 2019, 183, 73–83. [Google Scholar] [CrossRef]

- Podevin, P.; Clenci, A.; Descombes, G. Influence of the lubricating oil pressure and temperature on the performance at low speeds of a centrifugal compressor for an automotive engine. Appl. Therm. Eng. 2011, 31, 194–201. [Google Scholar] [CrossRef] [Green Version]

- Kaminaga, T.; Yamaguchi, K.; Ratnak, S.; Kusaka, J.; Youso, T.; Fujikawa, T.; Yamakawa, M. A Study on Combustion Characteristics of a High Compression Ratio SI Engine with High Pressure Gasoline Injection. SAE Tech. Paper 2019. [Google Scholar] [CrossRef]

- Liu, J.; Dumitrescu, C.E. 3D CFD simulation of a CI engine converted to SI natural gas operation using the G-equation. Fuel 2018, 232, 833–844. [Google Scholar] [CrossRef]

- Ng, E.C.Y.; Huang, Y.; Hong, G.; Zhou, J.L.; Surawski, N.C. Reducing vehicle fuel consumption and exhaust emissions from the application of a green-safety device under real driving. Sci. Total Enbiron. 2021, 793, 148602. [Google Scholar] [CrossRef]

- Xu, Z. Study on Characteristics and Control Strategy of Emissions in a Natural Gas Engine; Shandong University: Jinan, China, 2017. [Google Scholar]

- Wu, H.-M.; Tafreshi, R. Observer-based internal model air–fuel ratio control of lean-burn SI engines. IFAC J. Syst. Control. 2019, 9, 100065. [Google Scholar] [CrossRef]

- Khajorntraidet, C.; Shen, T. Adaptive Lean Air-Fuel Ratio Control and Analysis of Commercial Gasoline Engines. IFAC-PapersOnLine 2018, 51, 423–428. [Google Scholar] [CrossRef]

- Trimboli, S.; Di Cairano, S.; Bemporad, A.; Kolmanovsky, I.V. Model predictive control for automotive time-delay processes: An application to air-to-fuel ratio control*. IFAC Proc. Vol. 2009, 42, 90–95. [Google Scholar] [CrossRef] [Green Version]

- Han, Y.; Young, P. Model-Based Precise Air-Fuel Ratio Control for Gaseous Fueled Engines. SAE Int. J. Commer. Veh. 2020, 13, 221–231. [Google Scholar] [CrossRef]

- GAMMA TECHNOLOGIES. GT-SUITE Engine Performance Tutorials; Gamma Technologies LLC: Westmont, IL, USA, 2016. [Google Scholar]

- Caton, J.A. Combustion phasing for maximum efficiency for conventional and high efficiency engines. Energy Convers. Manag. 2014, 77, 564–576. [Google Scholar] [CrossRef]

- Heywood, J.B. Internal Combustion Engine Fundamentals; McGraw-Hill: New York, NY, USA, 1988. [Google Scholar]

- Lavoie, G.A. Correlations of Combustion Data for S.I. Engine Calculations: Laminar Flame Speed, Quench Distance, and Global Reaction Rates. SAE Trans. 1978, 87, 1015–1033. [Google Scholar]

- Wang, Y.; Chen, Y.; Liang, X.; Tan, P.; Deng, S. Impacts of lubricating oil and its formulations on diesel engine particle characteristics. Combust. Flame 2020, 225, 48–56. [Google Scholar] [CrossRef]

- Wu, H.-M.; Tafreshi, R. Fuzzy Sliding-mode Strategy for Air-fuel Ratio Control of Lean-burn Spark Ignition Engines. Asian J. Control. 2017, 20, 149–158. [Google Scholar] [CrossRef]

- Wu, C.-W.; Chen, R.-H.; Pu, J.-Y.; Lin, T.-H. The influence of air–fuel ratio on engine performance and pollutant emission of an SI engine using ethanol–gasoline-blended fuels. Atmos. Environ. 2004, 38, 7093–7100. [Google Scholar] [CrossRef]

- Yontar, A.A.; Doğu, Y. Effects of equivalence ratio and CNG addition on engine performance and emissions in a dual sequential ignition engine. Int. J. Engine Res. 2019, 21, 1067–1082. [Google Scholar] [CrossRef]

- Topgül, T.; Yücesu, H.S.; Çinar, C.; Koca, A. The effects of ethanol–unleaded gasoline blends and ignition timing on engine performance and exhaust emissions. Renew. Energy 2006, 31, 2534–2542. [Google Scholar] [CrossRef]

- Liu, J.; Dumitrescu, C. Experimental Investigation of Combustion Characteristics in a Heavy-Duty Compression-Ignition Engine Retrofitted to Natural-Gas Spark-Ignition Operation. SAE Tech. Pap. 2019. [Google Scholar] [CrossRef]

- Gasbarro, L.; Liu, J.; Dumitrescu, C.; Ulishney, C.; Battistoni, M.; Ambrogi, L. Heavy-Duty Compression-Ignition Engines Retrofitted to Spark-Ignition Operation Fueled with Natural Gas. SAE Tech. Pap. 2019. [Google Scholar] [CrossRef]

- Ambrogi, L.; Liu, J.; Battistoni, M.; Dumitrescu, C.; Gasbarro, L. CFD Investigation of the Effects of Gas’ Methane Number on the Performance of a Heavy-Duty Natural-Gas Spark-Ignition Engine. SAE Tech. Pap. 2019. [Google Scholar] [CrossRef]

- Ouyang, T.; Wang, Z.; Wang, G.; Zhao, Z.; Xie, S.; Li, X. Advanced thermo-economic scheme and multi-objective optimization for exploiting the waste heat potentiality of marine natural gas engine. Energy 2021, 236, 121440. [Google Scholar] [CrossRef]

- Li, M.; Wu, H.; Liu, X.; Wei, Z.; Tian, H.; Zhang, Q.; Li, Z. Numerical investigations on pilot ignited high pressure direct injection natural gas engines: A review. Renew. Sustain. Energy Rev. 2021, 150, 111390. [Google Scholar] [CrossRef]

- Zareei, J.; Rohani, A.; Mazari, F.; Mikkhailova, M.V. Numerical investigation of the effect of two-step injection (direct and port injection) of hydrogen blending and natural gas on engine performance and exhaust gas emissions. Energy 2021, 231, 120957. [Google Scholar] [CrossRef]

- Zhou, D.; Li, T.; Huang, D.; Wu, Y.; Huang, Z.; Xiao, W.; Wang, Q.; Wang, X. The experiment study to assess the impact of hydrogen blended natural gas on the tensile properties and damage mechanism of X80 pipeline steel. Int. J. Hydrog. Energy 2020, 46, 7402–7414. [Google Scholar] [CrossRef]

- Quiros, E.N.; Vergel, K.B.; Abaya, E.B.; Mercado, J.G.; Encarnacion, J.I.; Santos, E. A Consolidated Investigation on LPG as an Alternative Fuel for Public Utility Jeepneys. SAE Tech. Pap. 2018. [Google Scholar] [CrossRef]

- Lee, S.; Park, S.; Bae, C. Particle Reduction in LPG Lean Stratified Combustion by Intake Strategies. SAE Tech. Pap. 2019. [Google Scholar] [CrossRef]

- Fiore, M.; Magi, V.; Viggiano, A. Internal combustion engines powered by syngas: A review. Appl. Energy 2020, 276, 115415. [Google Scholar] [CrossRef]

- Karthikeyan, S.; Periyasamy, M.; Mahendran, G. Assessment of engine performance using syngas. Mater. Today Proc. 2020, 33, 4142–4144. [Google Scholar] [CrossRef]

- Gürbüz, H.; Demirtürk, S. Investigation of Dual-Fuel Combustion by Different Port Injection Fuels (Neat Ethanol and E85) in a DE95 Diesel/Ethanol Blend Fueled Compression Ignition Engine. J. Energy Resour. Technol. 2020, 142, 122306. [Google Scholar] [CrossRef]

- Maurya, R.K.; Agarwal, A.K. Experimental Investigations of Particulate Size and Number Distribution in an Ethanol and Methanol Fueled HCCI Engine. J. Energy Resour. Technol. 2014, 137, 012201. [Google Scholar] [CrossRef]

- Amine, M.; Barakat, Y. Effect of cyclohexanol on phase stability and volatility behavior of hydrous ethanol-gasoline blends. Egypt. J. Pet. 2021. [Google Scholar] [CrossRef]

- Zhang, L.; Qi, Q. A reduced mechanism for the combustion of gasoline-ethanol blend on advanced engine combustion modes. Fuel 2021, 300, 120951. [Google Scholar] [CrossRef]

| Research Type | Single-Cylinder |

| Cycle | 4-stroke SI PFI |

| Valves per cylinder | 2 |

| Bore [mm] × Stoke [mm] | 86 × 86.07 |

| Intake valve opens | 9 CAD BTDC Exhaust |

| Intake valve closes | 96 CAD BTDC Compression |

| Exhaust valve opens | 125 CAD ATDC Compression |

| Exhaust valve closes | 38 CAD ATDC Exhaust |

| Connecting rod length [mm] | 175 |

| Piston cup diameter [mm] | 80 |

| Piston cup depth [mm] | 5 |

| Wrist pin to crank offset [mm] | 1 |

| TDC clearance height [mm] | 1 |

| Compression Ratio (−) | 8 | 9 | 10 | 11 | 12 |

| Intake pressure (bar) | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 |

| Spark timing, ST (CAD ATDC) | −13.3 | −11.5 | −9.9 | −8.7 | −7.6 |

| Injector delivery rate(g/s) | 6.0 | 6.0 | 6.0 | 6.0 | 6.0 |

| Intake air temperature (K) | 300 | 300 | 300 | 300 | 300 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, R.; Sun, X.; Liu, Z.; Zhang, Y.; Fu, J. A Numerical Analysis of the Effects of Equivalence Ratio Measurement Accuracy on the Engine Efficiency and Emissions at Varied Compression Ratios. Processes 2021, 9, 1413. https://doi.org/10.3390/pr9081413

Yang R, Sun X, Liu Z, Zhang Y, Fu J. A Numerical Analysis of the Effects of Equivalence Ratio Measurement Accuracy on the Engine Efficiency and Emissions at Varied Compression Ratios. Processes. 2021; 9(8):1413. https://doi.org/10.3390/pr9081413

Chicago/Turabian StyleYang, Ruomiao, Xiaoxia Sun, Zhentao Liu, Yu Zhang, and Jiahong Fu. 2021. "A Numerical Analysis of the Effects of Equivalence Ratio Measurement Accuracy on the Engine Efficiency and Emissions at Varied Compression Ratios" Processes 9, no. 8: 1413. https://doi.org/10.3390/pr9081413

APA StyleYang, R., Sun, X., Liu, Z., Zhang, Y., & Fu, J. (2021). A Numerical Analysis of the Effects of Equivalence Ratio Measurement Accuracy on the Engine Efficiency and Emissions at Varied Compression Ratios. Processes, 9(8), 1413. https://doi.org/10.3390/pr9081413