Fractional Modeling and Characteristic Analysis of Hydro-Pneumatic Suspension for Construction Vehicles

Abstract

:1. Introduction

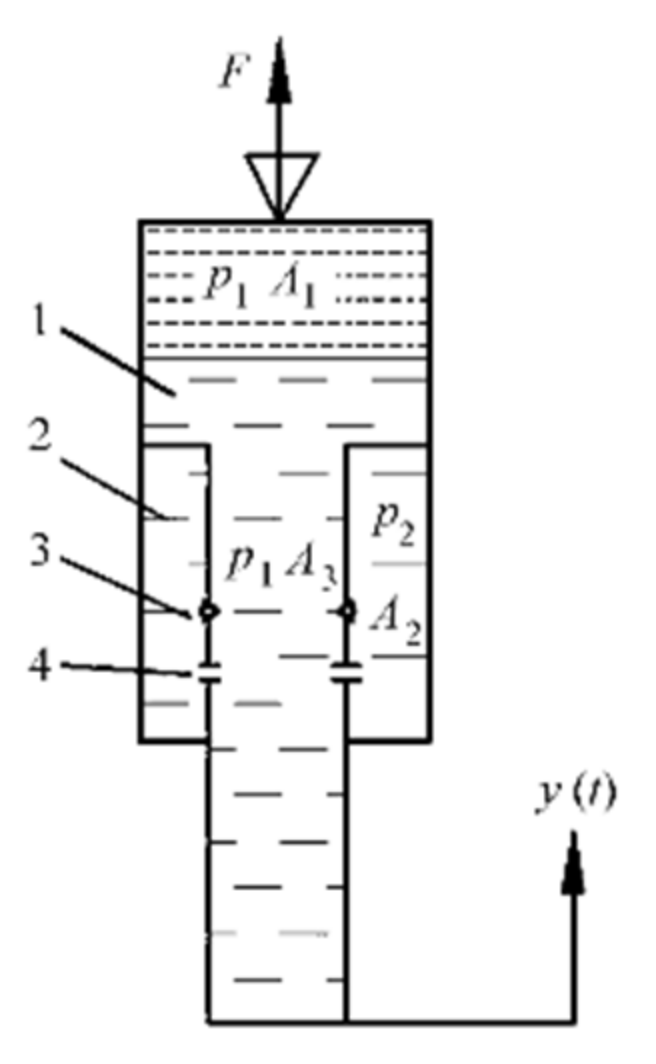

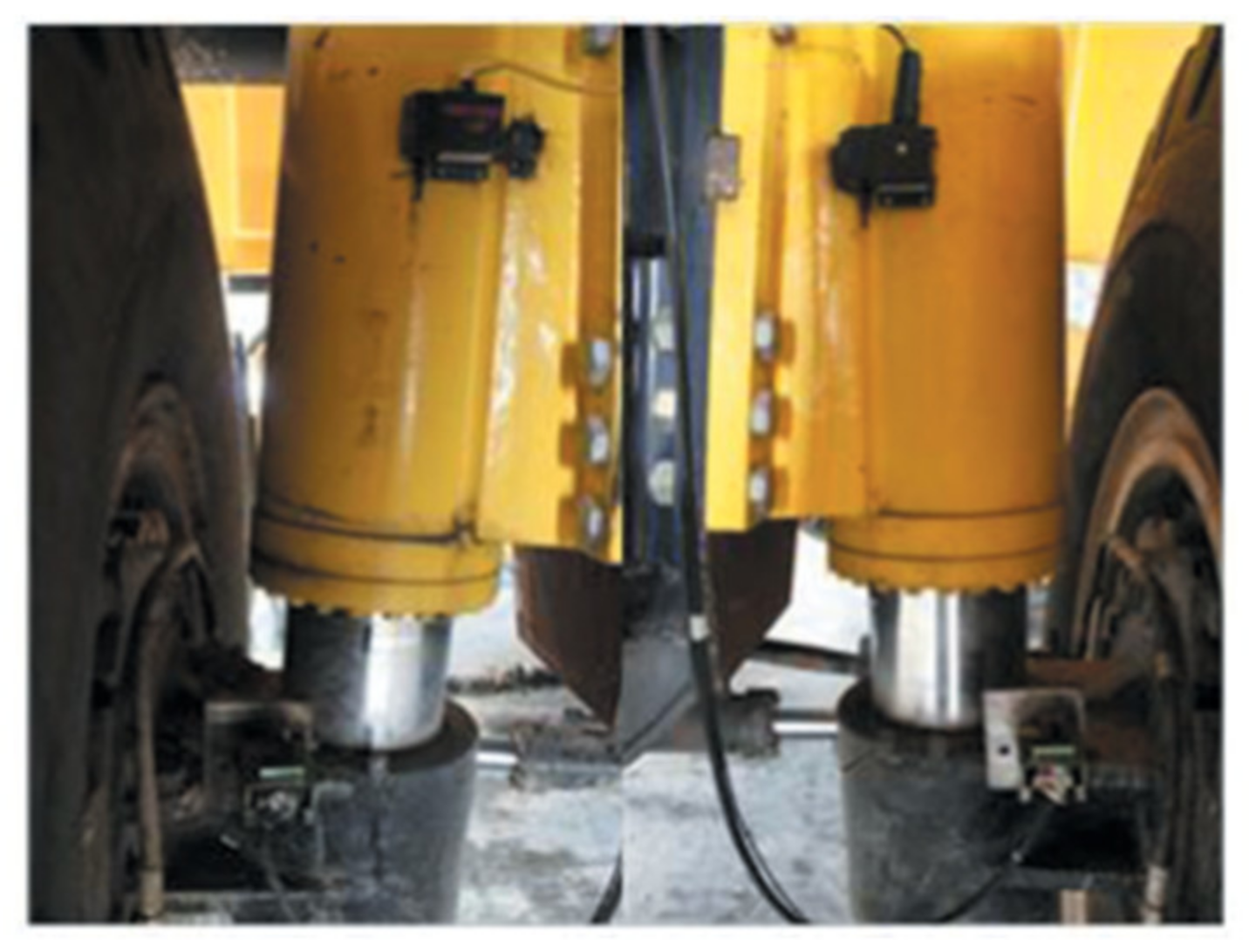

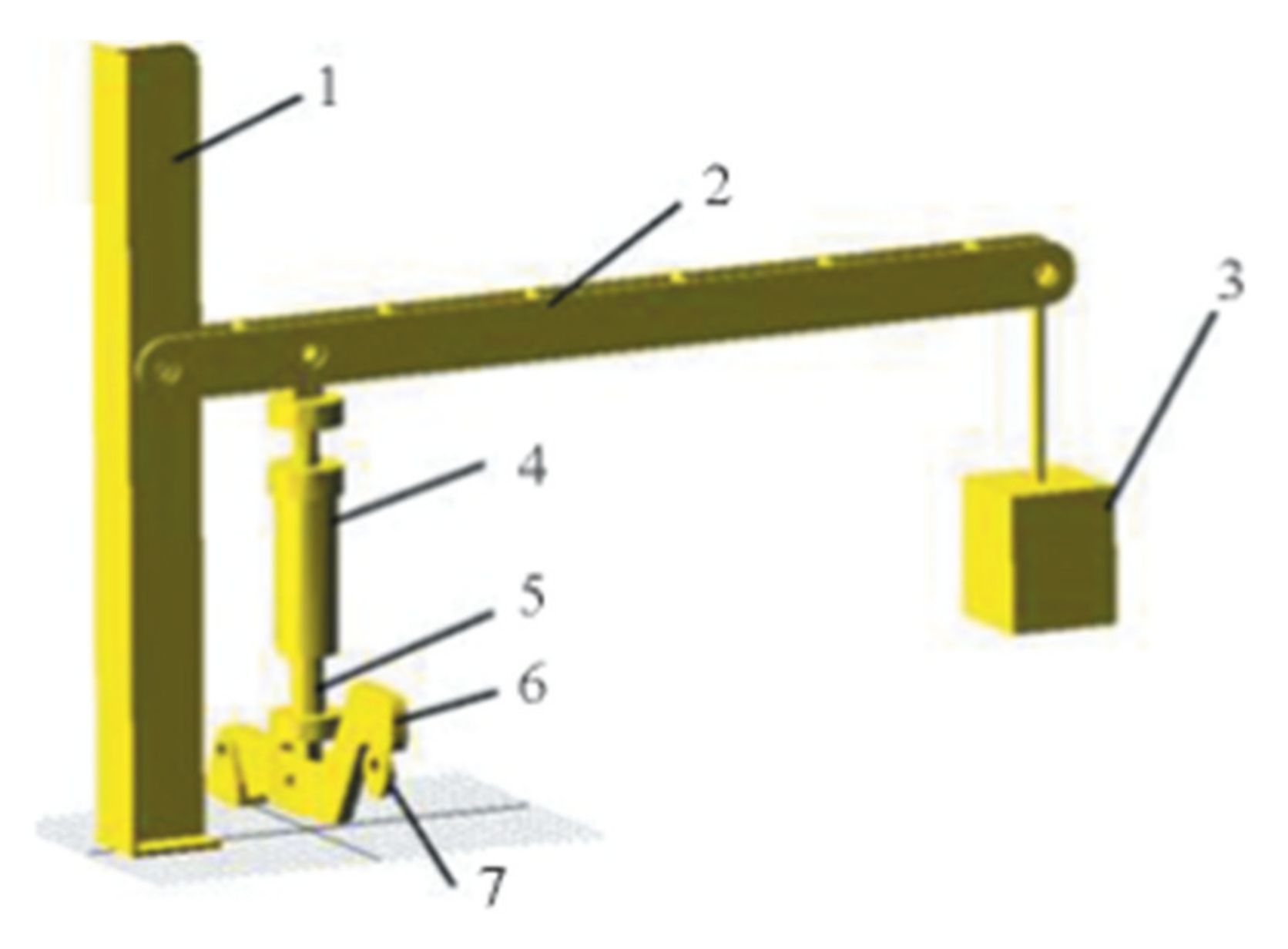

2. Hydro-Pneumatic Suspension Structure and Working Principle

3. Establishment of Fractional Model of Hydro-Pneumatic Suspension

3.1. Definition of Fractional Derivative

- D is the differential operator, the upper right corner q represents the order, the lower left corner a indicates the lower limit of the integral, and the lower right corner t indicates the upper limit of the integral.

- Γ (n − q) is the gamma function, n is any integer.

- q is the fractional order, is the integral variable.

3.2. Fractional Model of Hydro-Pneumatic Suspension

- F is the output force of the hydro-pneumatic suspension.

- is the gas elastic force, is the oil damping force.

- is the friction between the piston and the cylinder.

- p is the gas pressure in the working chamber.

- is the gas multivariable index, the thermodynamic process can be regarded as an adiabatic process during rapid loading, taking 1.4.

- A3 is the piston rod area, Mis the fluid density.

- V0 is the gas volume at a static equilibrium position.

- x is the relative displacement of piston and cylinder.

- Cz, Az is the flow coefficient and flow area of the orifice.

- Cd, Ad is the flow coefficient and flow area of the one-way valve.

- Ρ is the oil density.

- is the sign function, which takes positive and negative values according to the speed direction of the input signal. The compression stroke is 1, and the extension stroke is −1. In order to facilitate calculation and description, only compression was considered.

- μ is the friction factor of the seal ring.

- Δp is the pressure difference on both sides of the hydraulic cylinder sealing ring.

- D is the inner diameter of hydraulic cylinder.

- d is the outer diameter of piston rod.

- bD, bd are the piston, and piston rod seal ring width.

- kD, kd is the friction correction coefficient of the sealing ring.

- z(t) is the output displacement at the upper end of the suspension.

- y(t) is the input excitation displacement under the suspension.

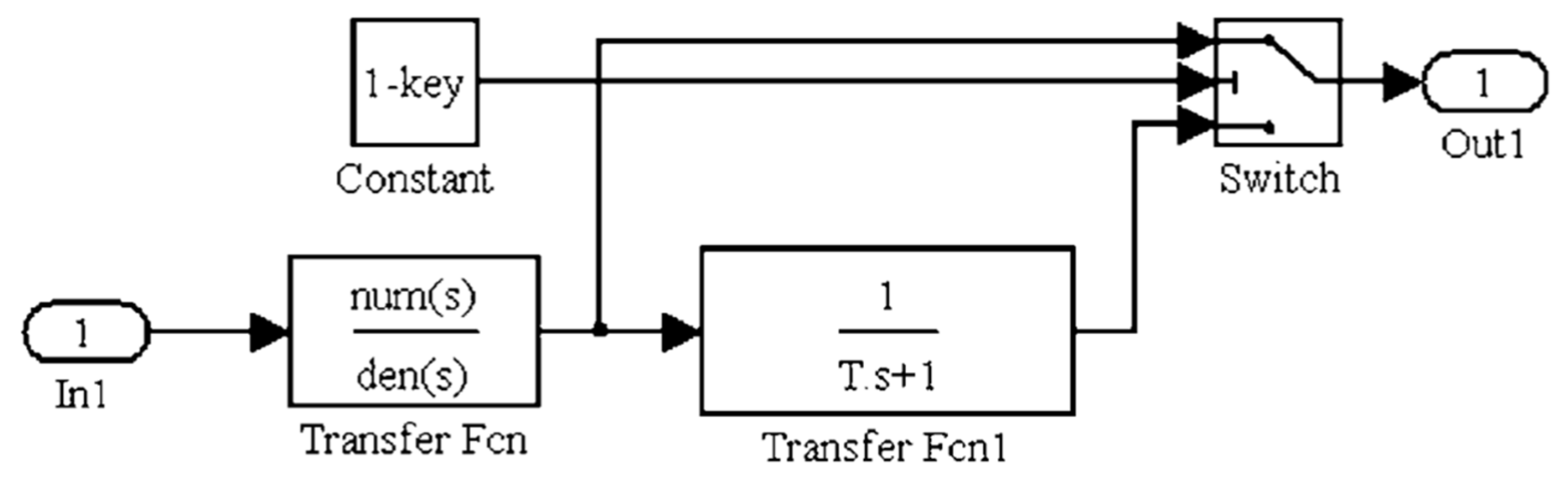

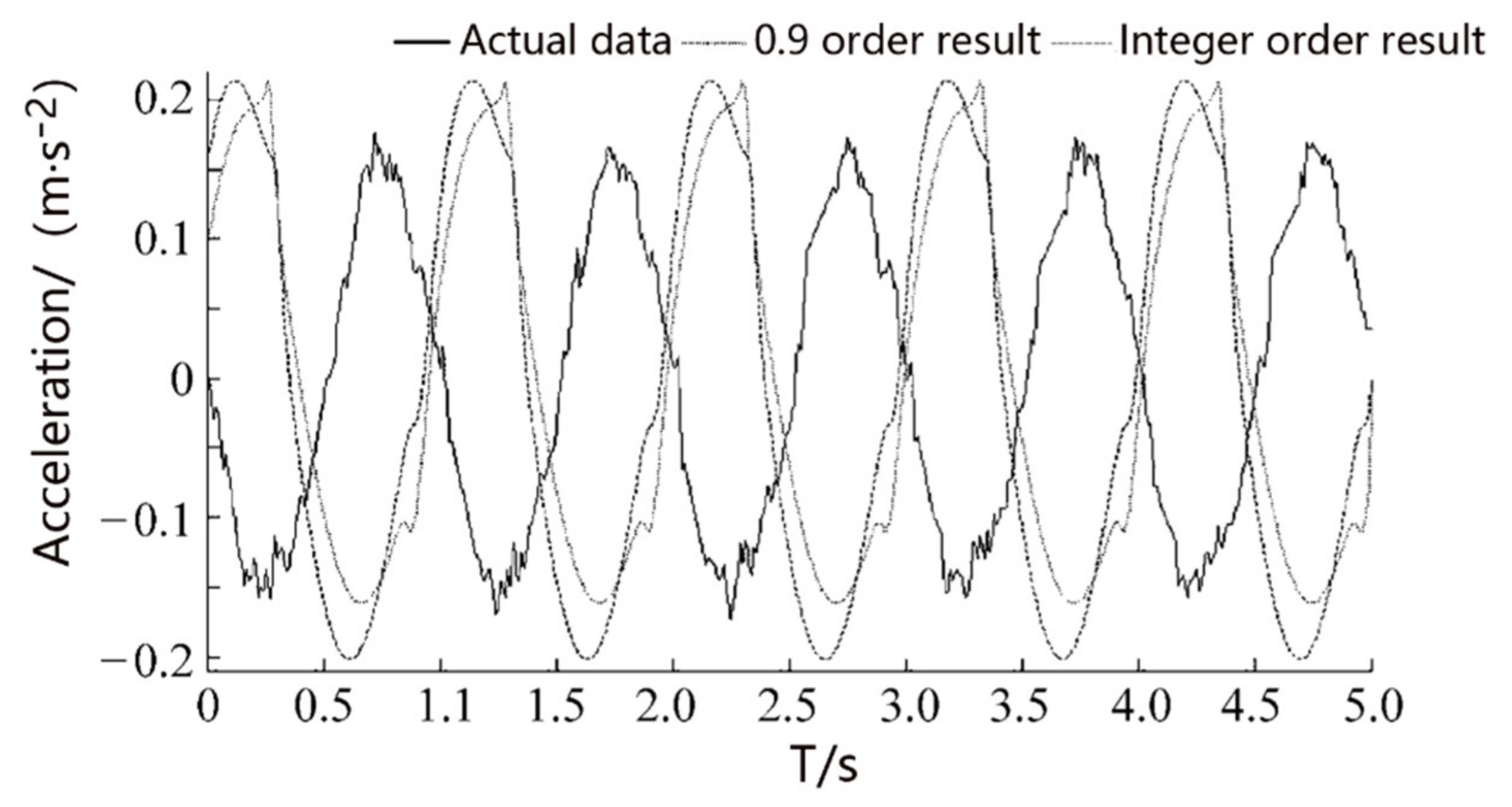

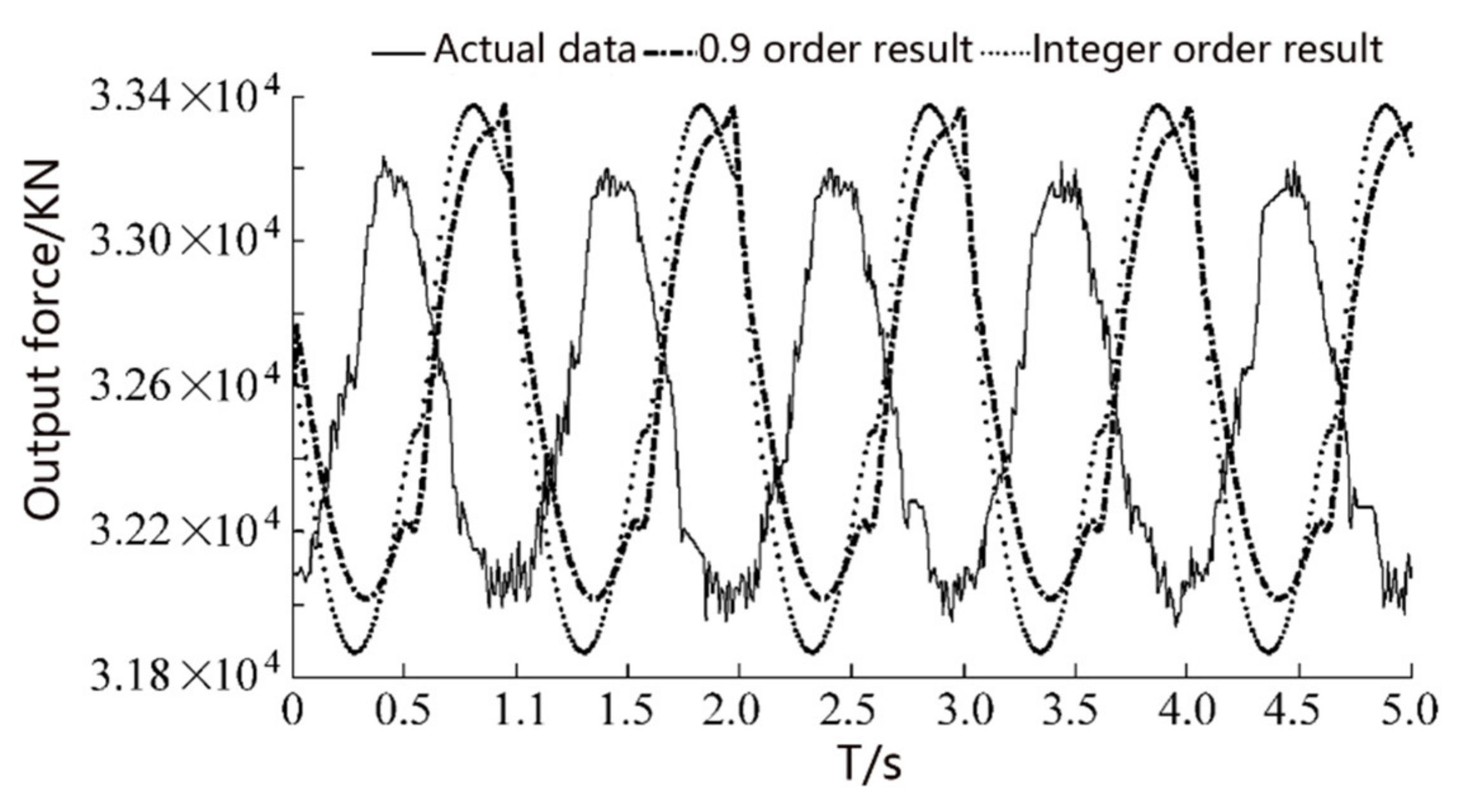

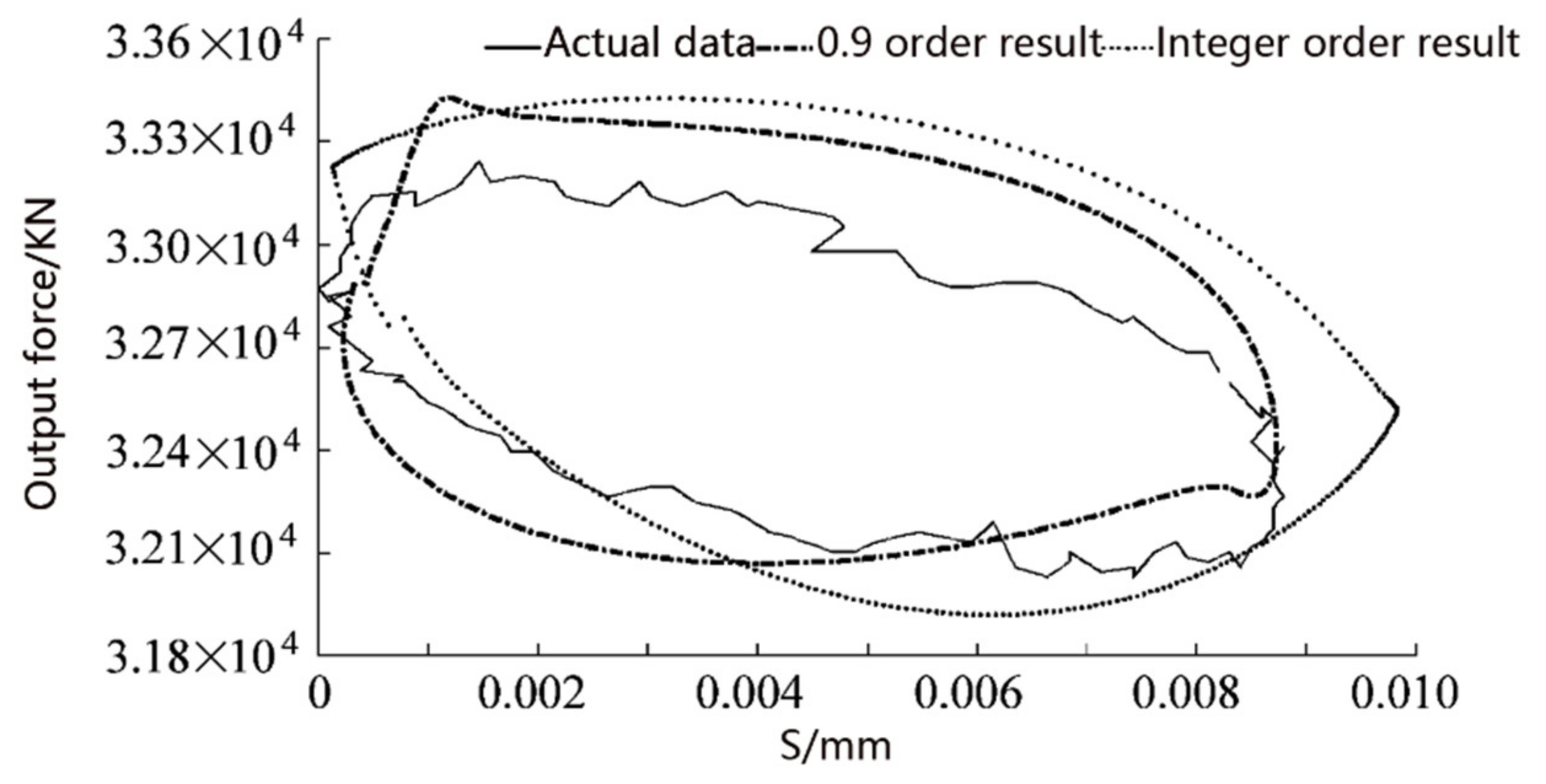

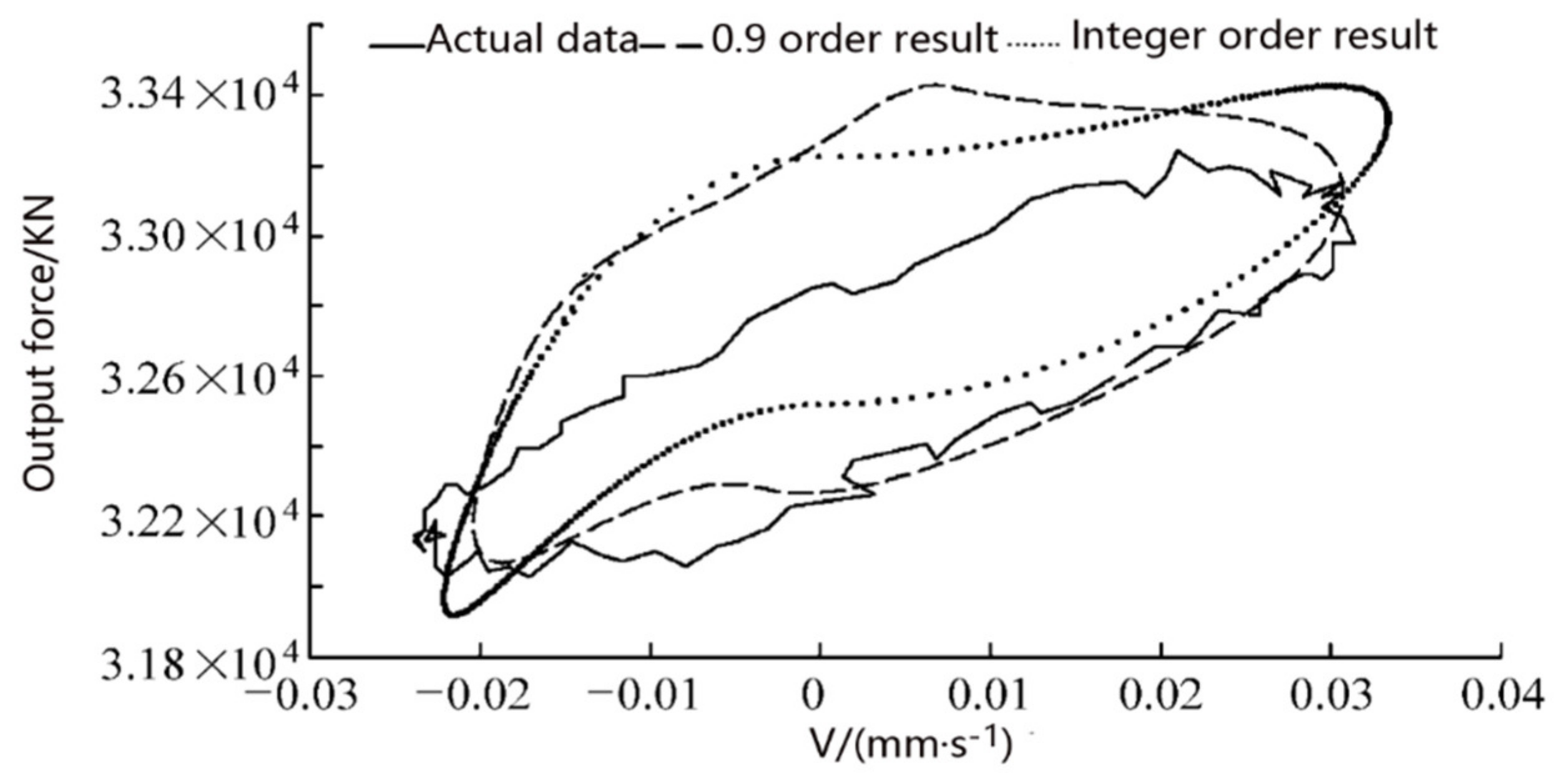

4. Numerical Solution and Test of the Fractional Characteristics of Suspension

5. Conclusions

- (1)

- According to the working principle of the hydro-pneumatic suspension, highlighting the characteristics of the multi-phase medium of the hydro-pneumatic suspension, using the equivalent viscoelastic damping analysis method, introducing the fractional derivative to describe, and establish the Bagley–Torvik equation of the hydro-pneumatic suspension;

- (2)

- According to the definition of the fractional-order model, the Oustaloup algorithm is used to numerically solve the fractional-order nonlinear differential equation, and the mechanical properties are described from the constitutive equation, and multiple numerical results such as the fractional output force, displacement, and velocity of the hydro-pneumatic suspension are obtained;

- (3)

- The fractional-order and integer-order simulation and test results are compared to verify the correctness of the fractional-order model. The results show that the fractional order of 0.9 is the closest to the test results. This concise model can describe the characteristics of the hydro-pneumatic suspension more accurately, which is of great significance to the improvement of design and precise control.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ieluzzi, M.; Turco, P.; Montiglio, M. Development of a heavy truck semi-active suspension control. Control Eng. Pract. 2006, 14, 305–312. [Google Scholar] [CrossRef]

- Gao, B.; Darling, J.; Tilley, D.G.; Williams, R.A.; Bean, A.; Donahue, J. Control of a hydro pneumatic active suspension based on a non-linear quarter-car model. J. Syst. Control Eng. 2006, 220, 15–31. [Google Scholar]

- Sun, T.; Yu, F.; Zhang, Z. Uncertainty analysis for a hydro-pneumatic suspension system of heavy duty vehicles and H∞ controller design. J. Vib. Shock 2007, 26, 51–54. (In Chinese) [Google Scholar]

- Wang, H.; Zhang, P.; Shao, Z. The viberation Characteristics of the Heavy Vehicle with Composite Interconnecting Oi-Air Suspension. Missles Space Vehic. 2003, 4, 7–11. [Google Scholar]

- Tian, J.; Di, Y.; Xiang, H. Study on rigid property and damping capacity of HPS with isolated single-chamber. Trans. Chin. Soc. Agric. Mach. 2007, 38, 35–38. (In Chinese) [Google Scholar]

- Yang, J.; Chen, S.; Wu, Z. Design and testing on the hydro-pneumatic suspensions with controllable stiffness and damping. Trans. Chin. Soc. Agric. Mach. 2008, 39, 20–24. (In Chinese) [Google Scholar]

- Ma, G.; Tan, R.; Wu, R. Non-linear mathematic model of hydro-pneumatic suspension crane vehicles and its simulation. Chin. J. Mech. Eng. 2002, 38, 95–98. (In Chinese) [Google Scholar] [CrossRef]

- Li, Z.; Tong, J.; Wei, L. Optimal design of asingle chamber hydro-pneumatic spring. J. Vib. Shock 2011, 30, 166–171. (In Chinese) [Google Scholar]

- Longxin, Z.; Wenming, Z. Research on simulation and experiment of hydro-pneumatic suspension with single gas cell. Chin. J. Mech. Eng. 2009, 45, 290–294. (In Chinese) [Google Scholar]

- Hang, X.; Yang, J.; Shen, Y.; Feng, Y. Characteristics Analysis of Hydro Pneumatic suspension based on gas dissolution and oil compressibility. Transact. Chin. Soc. Agric. Mach. 2013, 44, 14–18. (In Chinese) [Google Scholar]

- Adolfsson, K.; Enelund, M.; Olsson, P. On the Fractional Order Model of Viscoelasticity. Mech. Time-Depend. Mater. 2005, 9, 15–34. [Google Scholar] [CrossRef]

- Friedrich, C. Relaxation and retardation functions of the Maxwell model with fractional derivatives. Rheol. Acta 1991, 30, 151–158. [Google Scholar] [CrossRef]

- Song, D.Y.; Jiang, T. Study on the constitutive equation with fractional derivative for viscoelastic fluids-modified Jeffreys models and its application. Rheol. Acta 1998, 37, 512–517. [Google Scholar] [CrossRef]

- Yong, C.; Zhonghao, H. Study and review on the resistance specificity of automobile hydraulic damper. J. Liaoning Inst. Technol. 2001, 21, 8–11. (In Chinese) [Google Scholar]

- Lei, T. The Second Volume of The New Hydraulic Engineering Manual; Beijing Institute of Technology Press: Beijing, China, 1998; Volume 12, p. 1389. [Google Scholar]

- Shujun, S.; Fawang, L. A computational efficient numerical method of solving fractional Bagley-Torvik equation. J. Xiamen Univ. Nat. Sci. 2004, 3, 306–311. [Google Scholar]

- Xue, D. MATLAB Solution to Higher Applied Mathematics Problems; Tsinghua University Press: Beijing, China, 2008; pp. 398–399. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, H.; Li, R.; Xu, J.; Xu, F.; Zhang, B.; Dong, X. Fractional Modeling and Characteristic Analysis of Hydro-Pneumatic Suspension for Construction Vehicles. Processes 2021, 9, 1414. https://doi.org/10.3390/pr9081414

Sun H, Li R, Xu J, Xu F, Zhang B, Dong X. Fractional Modeling and Characteristic Analysis of Hydro-Pneumatic Suspension for Construction Vehicles. Processes. 2021; 9(8):1414. https://doi.org/10.3390/pr9081414

Chicago/Turabian StyleSun, Huilai, Ruichuan Li, Jikang Xu, Funing Xu, Bo Zhang, and Xinyuan Dong. 2021. "Fractional Modeling and Characteristic Analysis of Hydro-Pneumatic Suspension for Construction Vehicles" Processes 9, no. 8: 1414. https://doi.org/10.3390/pr9081414

APA StyleSun, H., Li, R., Xu, J., Xu, F., Zhang, B., & Dong, X. (2021). Fractional Modeling and Characteristic Analysis of Hydro-Pneumatic Suspension for Construction Vehicles. Processes, 9(8), 1414. https://doi.org/10.3390/pr9081414