Hazard-Free Treatment of Electrolytic Manganese Residue and Recovery of High-Concentration SO2 Using High-Temperature Reduction Roasting Process

Abstract

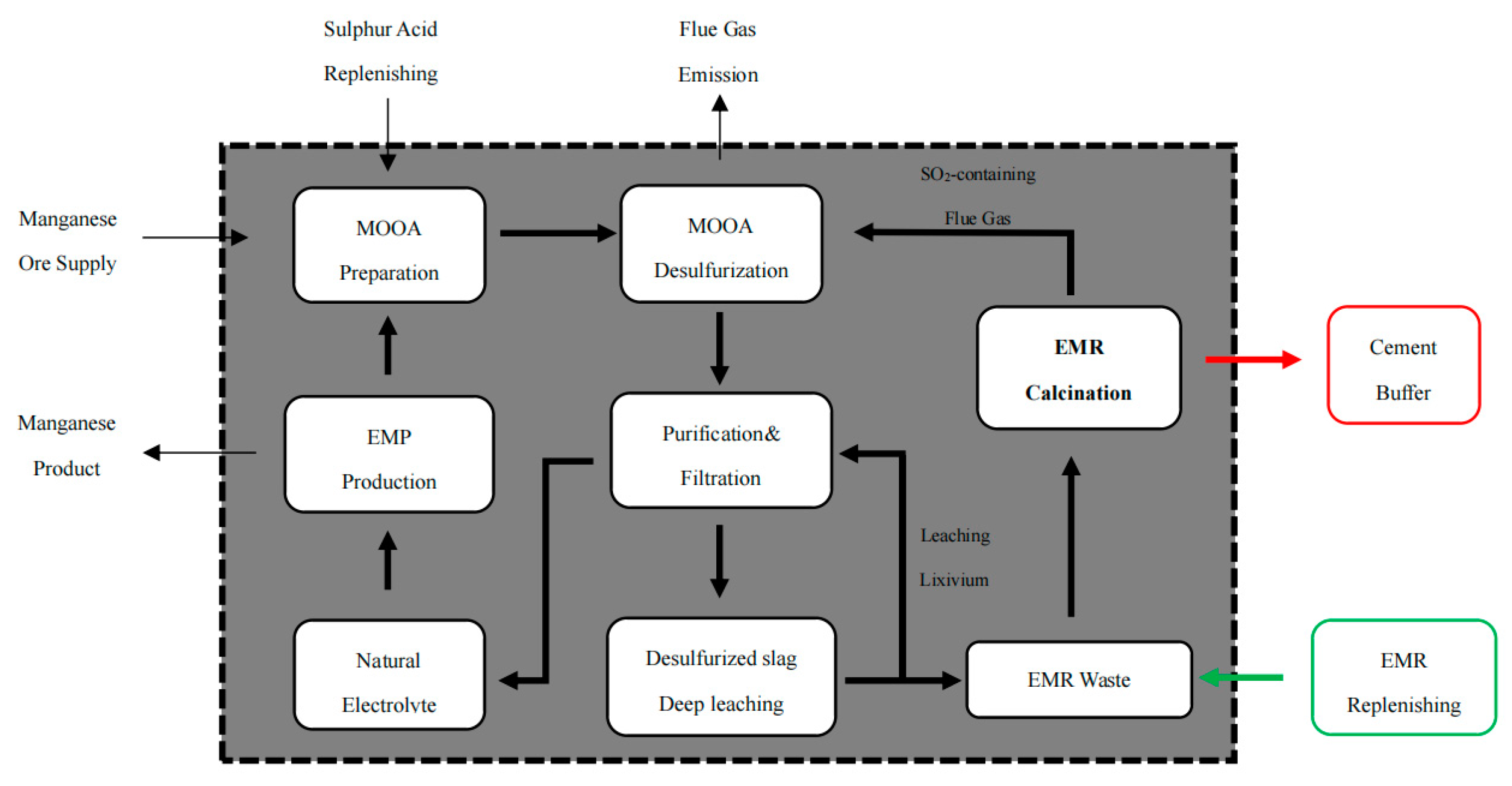

:1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Experiment Method

2.3. SO3 Analysis Method

2.4. Methods of Analysis

3. Results and Discussion

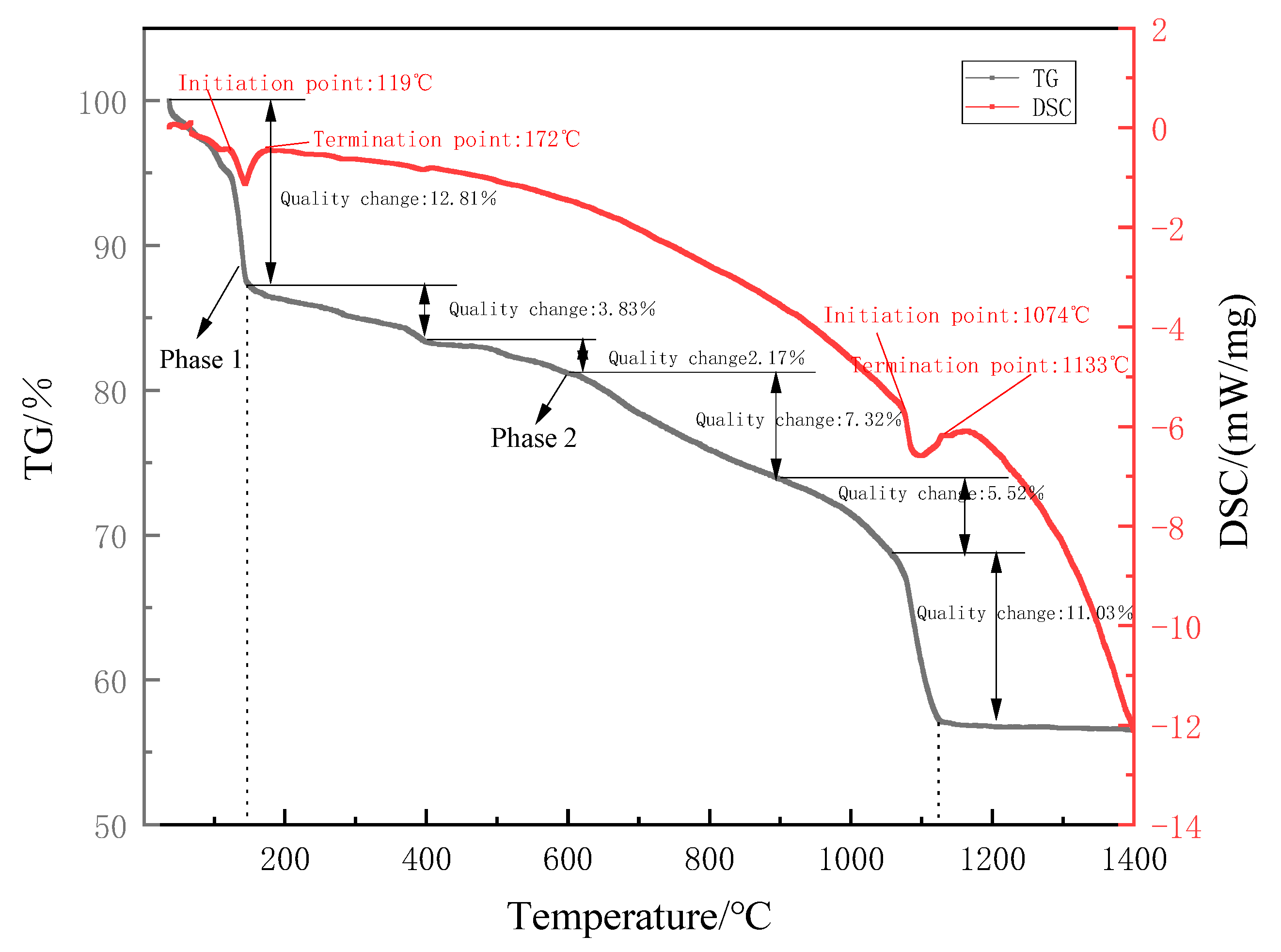

3.1. Properties of Raw Materials

3.2. EMR Calcination

3.2.1. Response Surface Prediction Model of Flue Gas from EMR

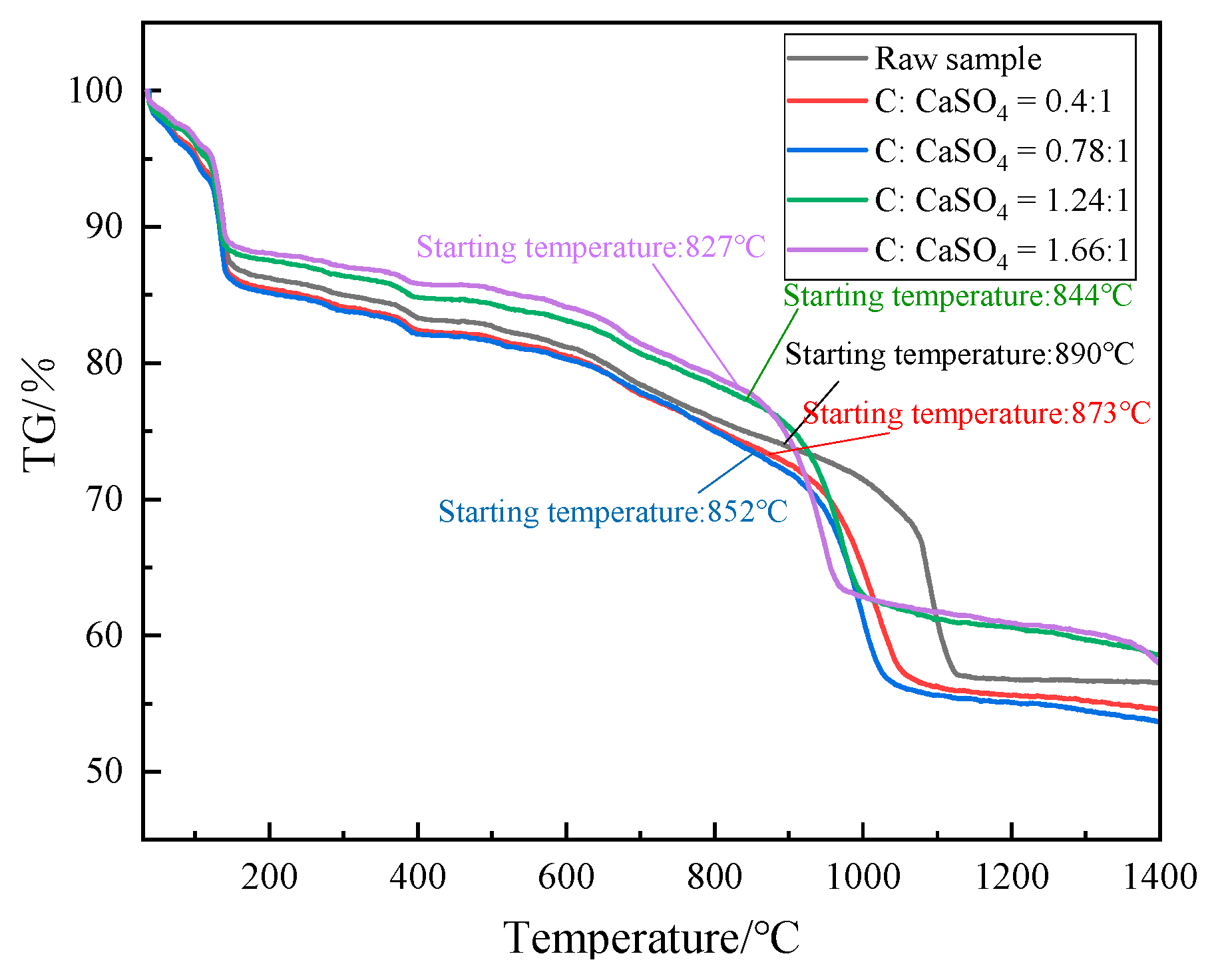

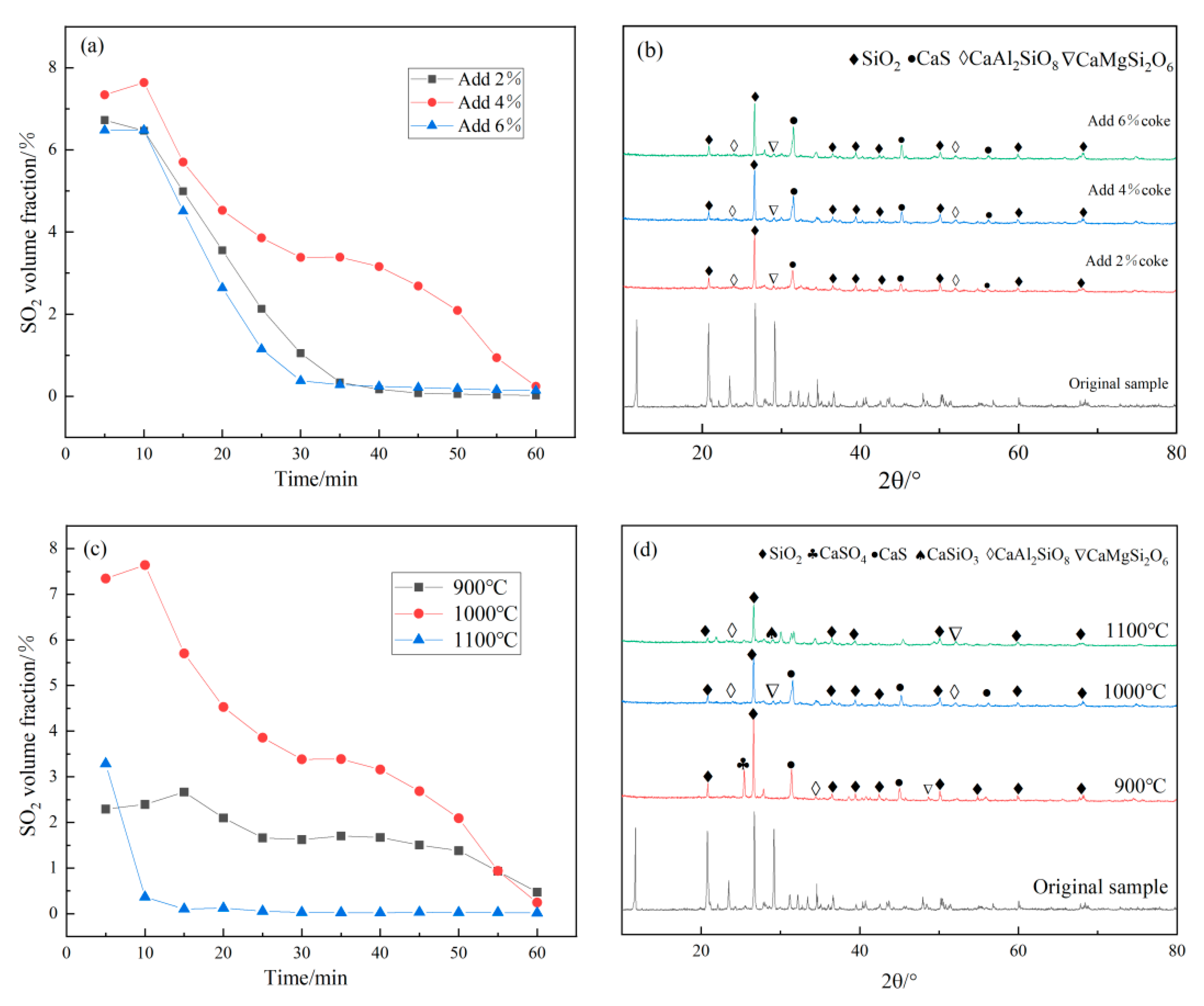

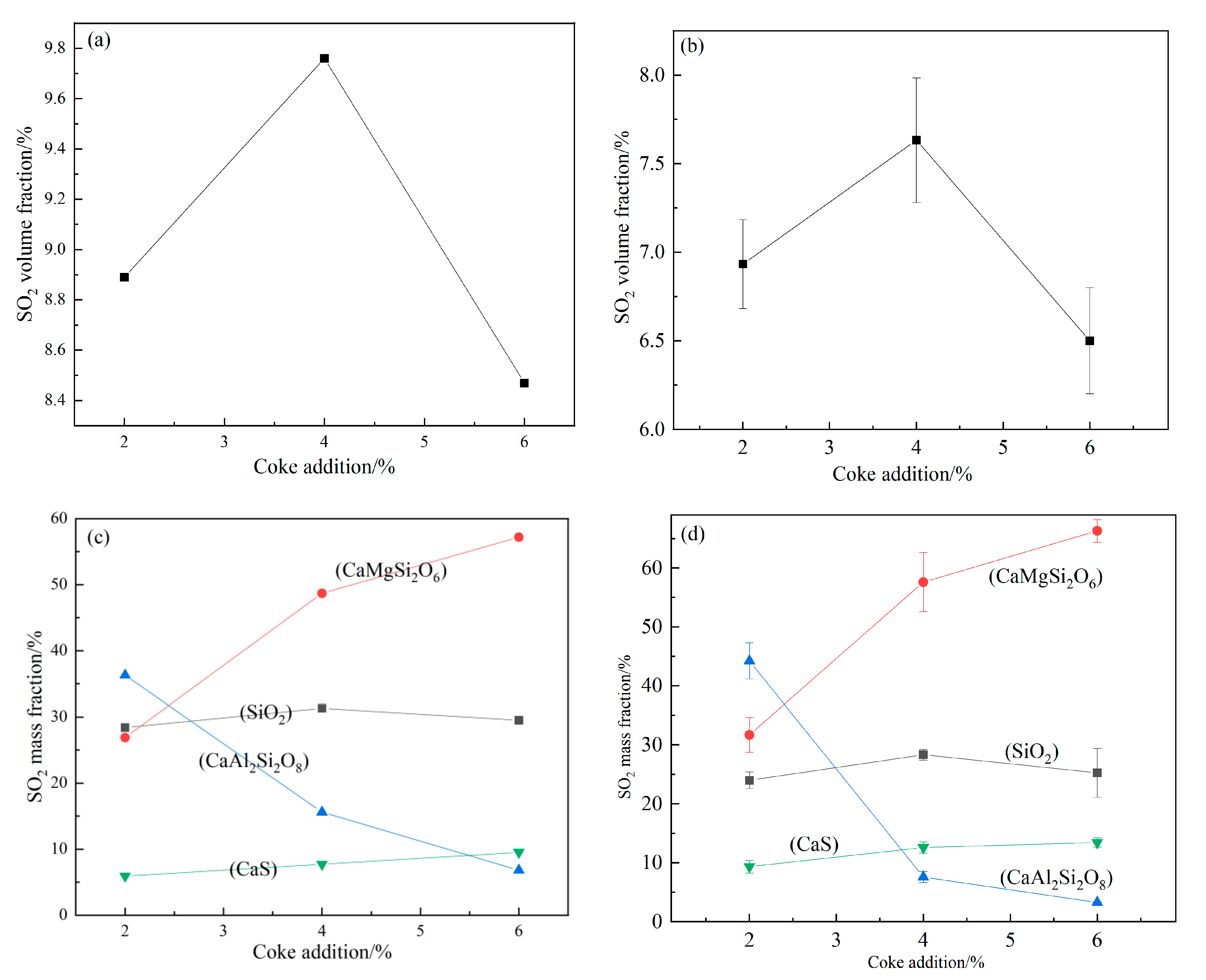

3.2.2. Effect of the Mole Ratio of EMR to Coke

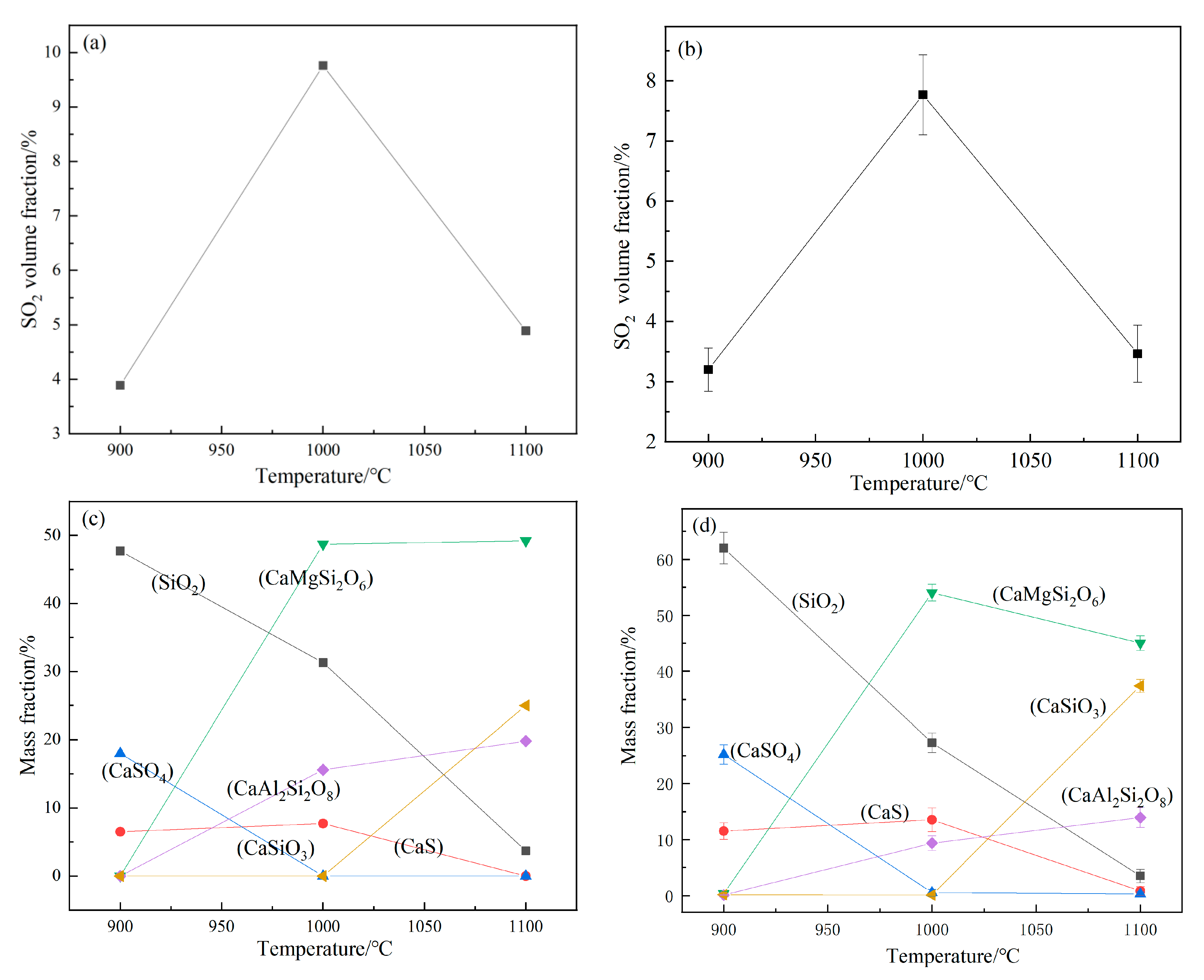

3.2.3. Effect of the Reaction Temperature

3.3. Study on the Solid Product of EMR Calcination as Cement Raw Material

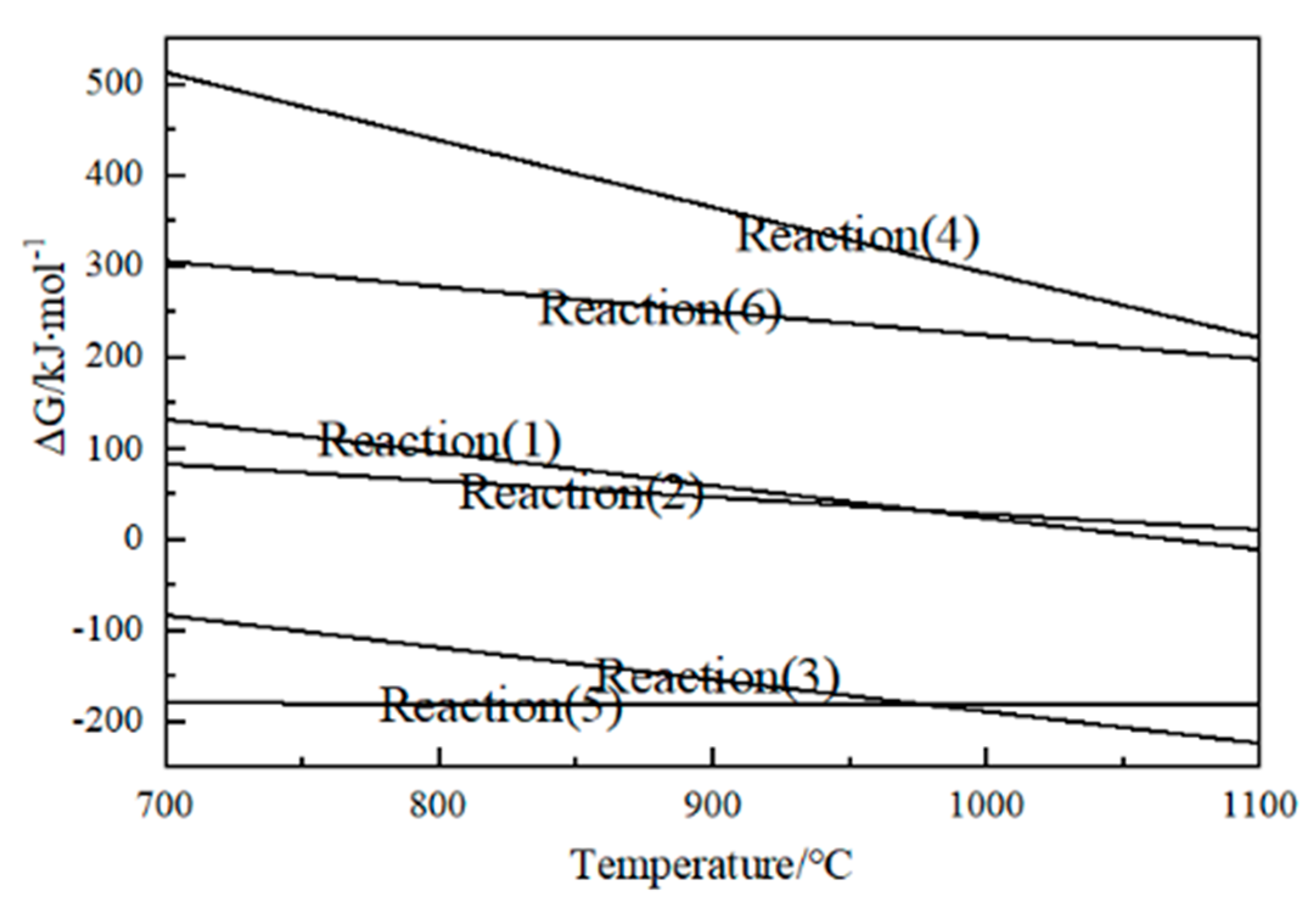

3.4. Calculation and Simulation of Gas–Solid Product Formation during Calcination of EMR

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hagelstein, K. Globally sustainable manganese metal production and use. J. Environ. Manag. 2009, 90, 3736–3740. [Google Scholar] [CrossRef] [PubMed]

- Xu, F.Y.; Jiang, L.H.; Dan, Z. Water balance analysis and wastewater recycling investigation in electrolytic manganese industry of China—A case study. Hydrometallurgy 2014, 149, 12–22. [Google Scholar] [CrossRef]

- Shu, J.; Lin, F.; Chen, M.; Li, B. An innovative method to enhance manganese and ammonia nitrogen leaching from electrolytic manganese residue by surfactant and anode iron plate. Hydrometallurgy 2020, 193, 105311. [Google Scholar] [CrossRef]

- Wang, D.; Wang, Q.; Xue, J. Reuse of hazardous electrolytic manganese residue: Detailed leaching characterization and novel application as a cementitious material. Resour. Conserv. Recycl. 2020, 154, 104645. [Google Scholar] [CrossRef]

- He, S.; Wilson, B.; Lundstrom, M. Hazard-free treatment of electrolytic manganese residue and recovery of manganese using low temperature roasting-water washing process. J. Hazard. Mater. 2021, 402, 11223561. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, X.; Xu, Y. Preparation of road base material by utilizing electrolytic manganese residue based on Si-Al structure: Mechanical properties and Mn2+ stabilization/solidification characterization. J. Hazard. Mater. 2020, 390, 122188. [Google Scholar] [CrossRef]

- Wang, Y.; Gao, S.; Liu, X. Preparation of non-sintered permeable bricks using electrolytic manganese residue: Environmental and NH3-N recovery benefits. J. Hazard. Mater. 2019, 378, 120768. [Google Scholar] [CrossRef]

- Zhan, X.; Wang, L.; Wang, L. Co-sintering MSWI fly ash with electrolytic manganese residue and coal fly ash for lightweight ceramisite. Chemosphere 2021, 263, 127914. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, X.; Xu, Y. Synergic effects of electrolytic manganese residue-red mud-carbide slag on the road base strength and durability properties. Constr. Build. Mater. 2019, 220, 364–374. [Google Scholar] [CrossRef]

- Wang, Z.; Guo, Q.; Jiang, X. Sulphate activating of electrolytic manganese residue to fly ash. Non−met. Ore 2011, 4, 5–8. (In Chinese) [Google Scholar]

- Zhou, C.; Wang, J.; Wang, N. Treating electrolytic manganese residue with alkaline additives for stabilizing manganese and removing ammonia. Korean J. Chem. Eng. 2013, 30, 2037–2042. [Google Scholar] [CrossRef]

- Wang, J.; Peng, B.; Chai, L. Preparation of electrolytic manganese residue–ground granulated blastfurnace slag cement. Powder Technol. 2013, 241, 12–18. [Google Scholar] [CrossRef]

- Du, B.; Zhou, C.; Dan, Z.; Luan, Z.; Duan, N. Preparation and characteristics of steam-autoclaved bricks produced from electrolytic manganese solid waste. Constr. Build. Mater. 2014, 50, 291–299. [Google Scholar] [CrossRef]

- Arezoumandi, M.; Volz, J.S.; Ortega, C.A.; Myers, J.J. Effect of total cementitious content on shear strength of high-volume fly ash concrete beams. Mater. Des. 2013, 46, 301–309. [Google Scholar] [CrossRef]

- Lo, T.Y.; Cui, H.Z.; Li, Z.G. Influence of aggregate pre-wetting and fly ash on mechanical properties of lightweight concrete. Waste Manag. 2004, 24, 333–338. [Google Scholar] [CrossRef]

- Chen, S.; Shuo, Z.; Shi, X. Study on application of manganese slag as cement mixture. China Build. Mater. Sci. Technol. 2019, 28, 48–49. (In Chinese) [Google Scholar]

- Van der Merwe, E.M.; Strydom, C.A.; Potgieter, J.H. Thermogravimetric analysis of the reaction between carbon and CaSO4·2H2O, gypsum and phosphogypsum in an inert atmosphere. Thermochim. Acta 1999, 340, 431–437. [Google Scholar] [CrossRef]

- Yao, L.; Xin, G.; Pu, P.; Yang, L.; Jiang, X.; Jiang, Z.; Jiang, W. Promotion of manganese extraction and flue gas desulfurization with manganese ore by iron in the anodic solution of electrolytic manganese. Hydrometallurgy 2021, 199, 105542. [Google Scholar] [CrossRef]

- GB/T176-2017; The State General Administration of the People’s Republic of China for Quality Supervision and Inspection and Quarantine, Methods for Chemical Analysis of Cement, The State Standard of the People’s Republic of China. Standards Press of China: Beijing, China, 2017. (In Chinese)

- Xu, R. Study on the Influence of Coke and Its Impurities on Pyrolysis Process of Calcium Sulfate; East China University of Science and Technology: Shanghai, China, 2011. [Google Scholar]

- Tagawa, H. Thermal decomposition temperatures of metal sulfates. Thermochim. Acta 1984, 80, 23–33. [Google Scholar] [CrossRef]

- Kato, T.; Murakami, K.; Sugawara, K. Carbon reduction of gypsum produced from flue gas desulfurization. Chem. Eng. Trans. 2012, 29, 805–810. [Google Scholar]

- Zheng, S.; Ning, P.; Ma, L.; Niu, X.; Zhang, W.; Chen, Y. Reductive decomposition of phosphogypsum with high-sulfur-concentration coal to SO2 in an inert atmosphere. Chem. Eng. Res. Des. 2011, 89, 2736–2741. [Google Scholar] [CrossRef]

- Li, C.; Zhong, H.; Wang, S.; Xue, J.; Wang, H. Reaction process and mechanism analysis for CaS generation in the process of reductive decomposition of CaSO3 with coal. J. Taiwan Inst. Chem. Eng. 2015, 50, 173–181. [Google Scholar] [CrossRef]

- Jia, X.; Wang, Q.; Cen, K.; Chen, L. An experimental study of CaSO4 decomposition during coal pyrolysis. Fuel 2016, 163, 157–165. [Google Scholar] [CrossRef]

- Li, X.; Zhang, Y.; Shen, X.D. Kinetics of calcium sulfoaluminate formation from tricalcium aluminate, calcium sulfate and calcium oxide. Cem. Concr. Res. 2014, 55, 79–87. [Google Scholar] [CrossRef]

- Yan, Z.Q.; Wang, Z.A.; Wang, X.F. Kinetic model for calcium sulfate decomposition at high temperature. Trans. Nonferrous Met. Soc. China 2015, 25, 3490–3497. [Google Scholar] [CrossRef]

- Zheng, D.; Lu, H.; Sun, X.; Liu, X.; Han, W.; Wang, L. Reaction mechanism of reductive decomposition of FGD gypsum with anthracite. Thermochim. Acta 2013, 559, 23–31. [Google Scholar] [CrossRef]

- GB175-2020; The State General Administration of the People’s Republic of China for Quality Supervision and Inspection and Quarantine, Common Portland Cement, The State Standard of the People’s Republic of China. Standards Press of China: Beijing, China, 2020. (In Chinese)

- GB50295-2016; The State General Administration of the People’s Republic of China for Quality Supervision and Inspection and Quarantine, Code for Design of Cement Plant, The State Standard of the People’s Republic of China. Standards Press of China: Beijing, China, 2016. (In Chinese)

| Square Difference Source | Sum of Squares | Free Degree | Mean Square | F | p | Significance |

|---|---|---|---|---|---|---|

| Model | 117.5 | 9 | 13.06 | 6.49 | 0.011 | * |

| x1 | 35.28 | 1 | 35.28 | 17.54 | 0.0041 | ** |

| x2 | 32 | 1 | 32 | 15.91 | 0.0053 | ** |

| x3 | 0.72 | 1 | 0.72 | 0.36 | 0.5685 | |

| x1 x2 | 10.89 | 1 | 10.89 | 5.41 | 0.0529 | |

| x1 x3 | 12.96 | 1 | 12.96 | 6.44 | 0.0388 | * |

| x2 x3 | 1.96 | 1 | 1.96 | 0.97 | 0.3565 | |

| x12 | 3.22 | 1 | 3.22 | 1.6 | 0.246 | |

| x22 | 18.13 | 1 | 18.13 | 9.01 | 0.0199 | * |

| x32 | 0.76 | 1 | 0.76 | 0.38 | 0.5581 | |

| Residual | 14.08 | 7 | 2.01 | |||

| Spurious term | 14.08 | 3 | 4.69 | |||

| Error term | 0 | 4 | 0 | |||

| Sum | 131.58 | 16 |

| Type | F-CaO (%) | Density (g/cm3) | Specific Surface Area (cm3/g) | 3 Days Intensity (Mpa) | 7 Days Intensity (Mpa) | 28 Days Intensity (Mpa) | |||

|---|---|---|---|---|---|---|---|---|---|

| Compressive Strength | Flexural Strength | Compressive Strength | Flexural Strength | Compressive Strength | Flexural Strength | ||||

| Clinker | 2.79 | 3.11 | 4550 | 21.3 | 3.8 | 35.7 | 5.7 | 56.3 | 8.2 |

| Type | Stability | Water Demand/% | Initial Setting Time /Min | Final Setting Time /Min |

|---|---|---|---|---|

| Cement made of clinker | qualified | 24.5 | 105 | 181 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, L.; Xiong, Y.; Liu, H.; Li, Y.; Chen, S.; Tian, S. Hazard-Free Treatment of Electrolytic Manganese Residue and Recovery of High-Concentration SO2 Using High-Temperature Reduction Roasting Process. Separations 2023, 10, 288. https://doi.org/10.3390/separations10050288

Zhang L, Xiong Y, Liu H, Li Y, Chen S, Tian S. Hazard-Free Treatment of Electrolytic Manganese Residue and Recovery of High-Concentration SO2 Using High-Temperature Reduction Roasting Process. Separations. 2023; 10(5):288. https://doi.org/10.3390/separations10050288

Chicago/Turabian StyleZhang, Linfeng, Yulu Xiong, Huaying Liu, Yingjie Li, Shouyue Chen, and Senlin Tian. 2023. "Hazard-Free Treatment of Electrolytic Manganese Residue and Recovery of High-Concentration SO2 Using High-Temperature Reduction Roasting Process" Separations 10, no. 5: 288. https://doi.org/10.3390/separations10050288