A Sustainable Approach for Enhancing Stability and Bioactivity of Allium ursinum Extract for Food Additive Applications

Abstract

:1. Introduction

2. Material and Methods

2.1. Chemicals and Reagents

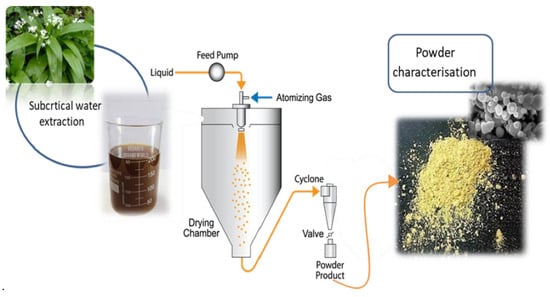

2.2. Extraction Process

2.3. Encapsulation Process

2.4. Powder Characterization

2.4.1. Bulk Density

2.4.2. Moisture Content

2.4.3. Hygroscopicity

2.4.4. Rehydration

2.4.5. Water Solubility Index and Water Absorption Index

2.4.6. Color

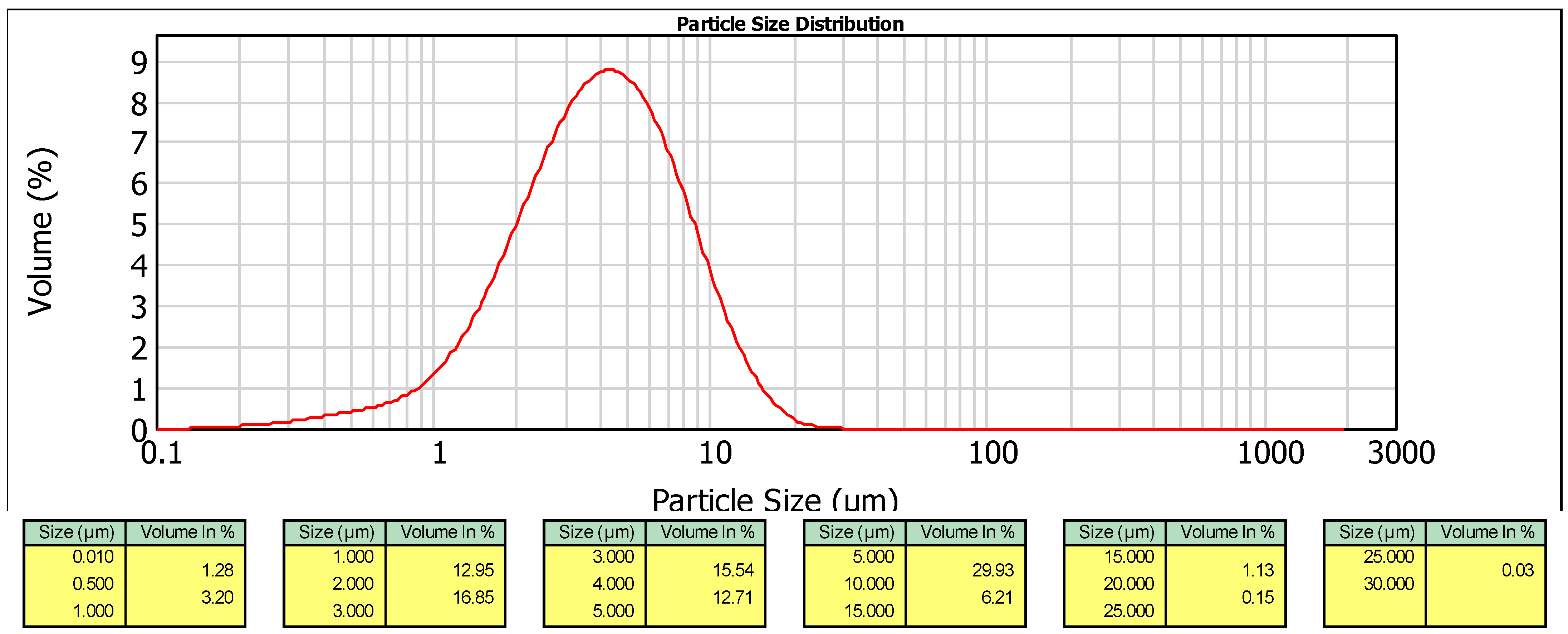

2.4.7. Particle Size Distribution

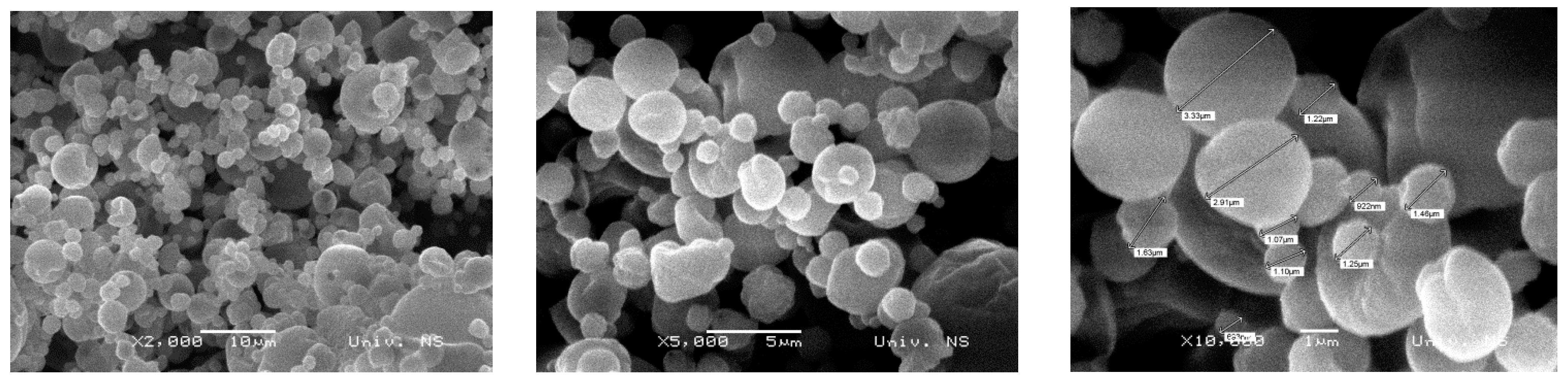

2.5. Scanning Electron Microscopy (SEM)

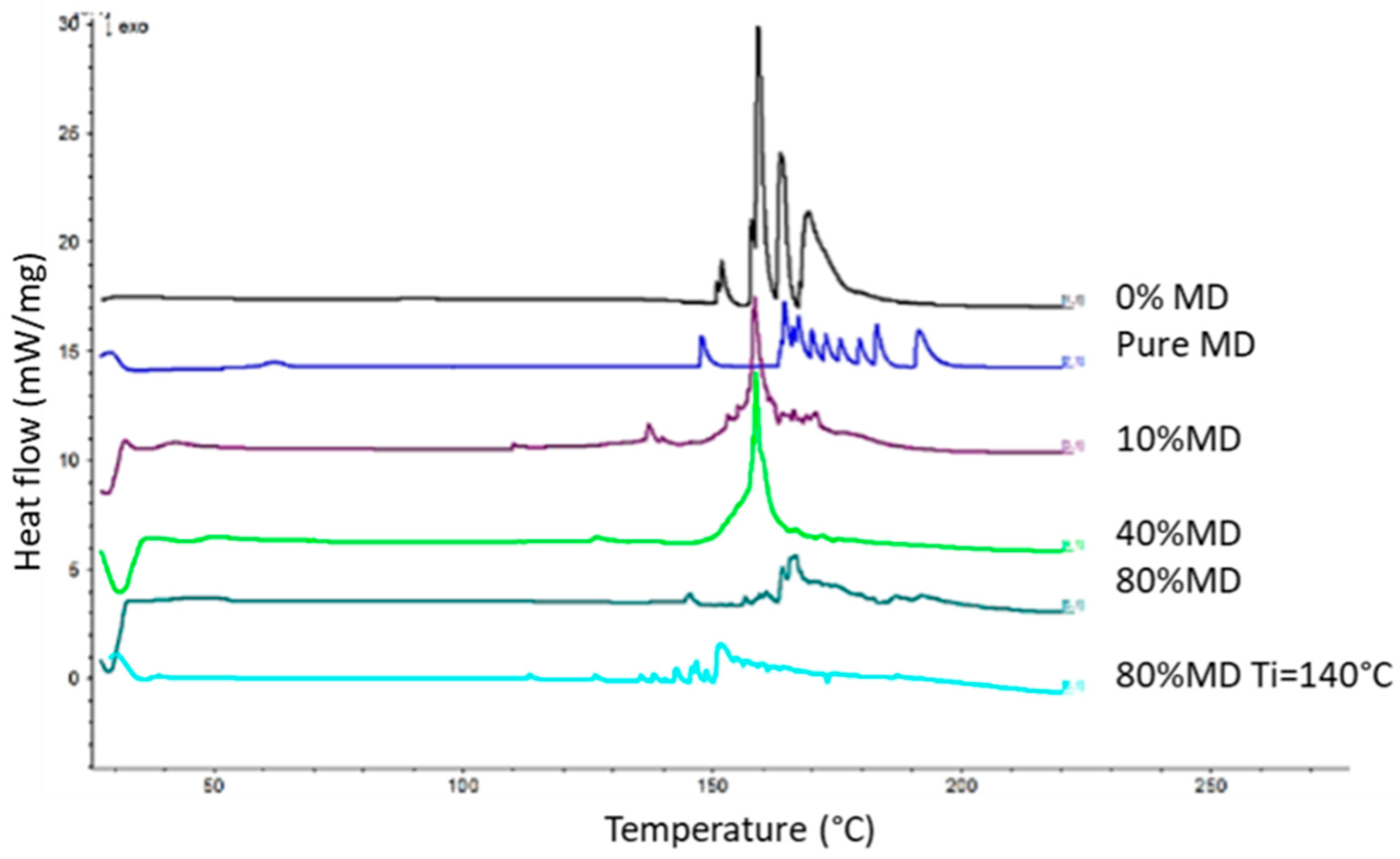

2.6. Differential Scanning Calorimetry Analysis (DSC)

2.7. Analysis of Bioactive Compounds

2.7.1. Total Phenolic Content (TPC)

2.7.2. Total Flavonoid Content (TFC)

2.7.3. Radical Scavenging Activity Assay

2.8. Storage Stability

2.9. Statistical Analysis

3. Results and Discussion

3.1. Physical Characteristics of Obtained Extract Powders

3.2. Polyphenol Content and Antioxidant Capacity of the Produced Encapsulates

3.3. Storages Stability

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Xu, D.-P.; Li, Y.; Meng, X.; Zhou, T.; Zhou, Y.; Zheng, J.; Zhang, J.-J.; Li, H.-B. Natural Antioxidants in Foods and Medicinal Plants: Extraction, Assessment and Resources. Int. J. Mol. Sci. 2017, 18, 96. [Google Scholar] [CrossRef]

- Elsorady, M.E.; Elgindy, A.A. Effect of Ginger Extract (Zingiber Officinale) as a Natural Antioxidant on Sunflower Oil Oxidation. Food Feed Res. 2022, 49, 173–182. [Google Scholar] [CrossRef]

- Vrgović, P.; Pojić, M.; Teslić, N.; Mandić, A.; Kljakić, A.C.; Pavlić, B.; Stupar, A.; Pestorić, M.; Škrobot, D.; Mišan, A. Communicating Function and Co-Creating Healthy Food: Designing a Functional Food Product Together with Consumers. Foods 2022, 11, 961. [Google Scholar] [CrossRef]

- de Souza Simões, L.; Madalena, D.A.; Pinheiro, A.C.; Teixeira, J.A.; Vicente, A.A.; Ramos, Ó.L. Micro- and Nano Bio-Based Delivery Systems for Food Applications: In Vitro Behavior. Adv. Colloid Interface Sci. 2017, 243, 23–45. [Google Scholar] [CrossRef]

- Vidović, S.; Tomšik, A.; Vladić, J.; Jokić, S.; Aladić, K.; Pastor, K.; Jerković, I. Supercritical Carbon Dioxide Extraction of Allium Ursinum: Impact of Temperature and Pressure on the Extracts Chemical Profile. Chem. Biodivers. 2021, 18, e2100058. [Google Scholar] [CrossRef] [PubMed]

- Krivokapic, M.; Jakovljević, V.; Sovilić, M.; Bradić, J.; Petković, A.; Radojević, I.; Branković, S.; Čomić, L.; Anđić, M.; Kcović, A.; et al. Biological Activities of Different Extracts from Allium Ursinum Leaves. Acta Pol. Pharm.-Drug Res. 2020, 77, 121–129. [Google Scholar] [CrossRef]

- Stupar, A.; Šarić, L.; Vidović, S.; Bajić, A.; Kolarov, V.; Šarić, B. Antibacterial Potential of Allium Ursinum Extract Prepared by the Green Extraction Method. Microorganisms 2022, 10, 1358. [Google Scholar] [CrossRef]

- Mašková, L.; Janská, P.; Klimša, V.; Knejzlík, Z.; Tokárová, V.; Kašpar, O. Development of Compartmentalized Antibacterial Systems Based on Encapsulated Alliinase. Adv. Powder Technol. 2021, 32, 2720–2732. [Google Scholar] [CrossRef]

- Daglia, M. Polyphenols as Antimicrobial Agents. Curr. Opin. Biotechnol. 2011, 23, 174–181. [Google Scholar] [CrossRef] [PubMed]

- Lu, W.; Yang, X.; Shen, J.; Li, Z.; Tan, S.; Liu, W.; Cheng, Z. Choosing the Appropriate Wall Materials for Spray-Drying Microencapsulation of Natural Bioactive Ingredients: Taking Phenolic Compounds as Examples. Powder Technol. 2021, 394, 562–574. [Google Scholar] [CrossRef]

- Buljeta, I.; Pichler, A.; Šimunovi´c, J.Š.; Kopjar, M. Polysaccharides as Carriers of Polyphenols: Comparison of Freeze-Drying and Spray-Drying as Encapsulation Techniques. Molecules 2022, 27, 5069. [Google Scholar] [CrossRef] [PubMed]

- Šeregelj, V.; Ćetković, G.; Čanadanović-Brunet, J.; Šaponjac, V.T.; Vulić, J.; Stajčić, S. Encapsulation and Degradation Kinetics of Bioactive Compounds from Sweet Potato Peel During Storage Running Title: Encapsulation of Sweet Potato Peel Bioactive Compounds. Food Technol. Biotechnol. 2020, 58, 2020. [Google Scholar] [CrossRef]

- Wang, Y.; Selomulya, C. Spray Drying Strategy for Encapsulation of Bioactive Peptide Powders for Food Applications. Adv. Powder Technol. 2020, 31, 409–415. [Google Scholar] [CrossRef]

- Tan, S.P.; Kha, T.C.; Parks, S.E.; Stathopoulos, C.E.; Roach, P.D. Effects of the Spray-Drying Temperatures on the Physiochemical Properties of an Encapsulated Bitter Melon Aqueous Extract Powder. Powder Technol. 2015, 281, 65–75. [Google Scholar] [CrossRef]

- Mousavi Kalajahi, S.E.; Ghandiha, S. Optimization of Spray Drying Parameters for Encapsulation of Nettle (Urtica dioica L.) Extract. LWT 2022, 158, 113149. [Google Scholar] [CrossRef]

- Filipčev, B.; Kojić, J.; Miljanić, J.; Šimurina, O.; Stupar, A.; Škrobot, D.; Travičić, V.; Pojić, M.; Kojić, J.; Miljanić, J.; et al. Wild Garlic (Allium ursinum) Preparations in the Design of Novel Functional Pasta. Foods 2023, 12, 4376. [Google Scholar] [CrossRef] [PubMed]

- Tomšik, A.; Pavlić, B.; Vladić, J.; Cindrić, M.; Jovanov, P.; Sakač, M.; Mandić, A.; Vidović, S. Subcritical Water Extraction of Wild Garlic (Allium ursinum L.) and Process Optimization by Response Surface Methodology. J. Supercrit. Fluids 2017, 128, 79–88. [Google Scholar] [CrossRef]

- Gavarić, A.; Vladić, J.; Ambrus, R.; Jokić, S.; Szabó-Révész, P.; Tomić, M.; Blažić, M.; Vidović, S. Spray Drying of a Subcritical Extract Using Marrubium Vulgare as a Method of Choice for Obtaining High Quality Powder. Pharmaceutics 2019, 11, 523. [Google Scholar] [CrossRef]

- Vladić, J.; Ambrus, R.; Szabó-Révész, P.; Vasić, A.; Cvejin, A.; Pavlić, B.; Vidović, S. Recycling of Filter Tea Industry By-Products: Production of A. Millefolium Powder Using Spray Drying Technique. Ind. Crops Prod. 2016, 80, 197–206. [Google Scholar] [CrossRef]

- Hogekamp, S.; Schubert, H. Rehydration of Food Powders. Food Sci. Technol. Int. 2003, 9, 223–235. [Google Scholar] [CrossRef]

- Šavikin, K.; Nastić, N.; Janković, T.; Bigović, D.; Miličević, B.; Vidović, S.; Menković, N.; Vladić, J. Effect of Type and Concentration of Carrier Material on the Encapsulation of Pomegranate Peel Using Spray Drying Method. Foods 2021, 10, 1968. [Google Scholar] [CrossRef]

- Lončarević, I.; Pajin, B.; Tumbas Šaponjac, V.; Petrović, J.; Vulić, J.; Fišteš, A.; Jovanović, P. Physical, Sensorial and Bioactive Characteristics of White Chocolate with Encapsulated Green Tea Extract. J. Sci. Food Agric. 2019, 99, 5834–5841. [Google Scholar] [CrossRef] [PubMed]

- Tomšik, A.; Šarić, L.; Bertoni, S.; Protti, M.; Albertini, B.; Mercolini, L.; Passerini, N. Encapsulations of Wild Garlic (Allium ursinum L.) Extract Using Spray Congealing Technology. Food Res. Int. 2019, 119, 941–950. [Google Scholar] [CrossRef] [PubMed]

- Zannou, O.; Koca, I. Optimization and Stabilization of the Antioxidant Properties from Alkanet (Alkanna tinctoria) with Natural Deep Eutectic Solvents. Arab. J. Chem. 2020, 13, 6437–6450. [Google Scholar] [CrossRef]

- Todorović, A.; Šturm, L.; Salević-Jelić, A.; Lević, S.; Osojnik Črnivec, I.G.; Prislan, I.; Skrt, M.; Bjeković, A.; Poklar Ulrih, N.; Nedović, V. Encapsulation of Bilberry Extract with Maltodextrin and Gum Arabic by Freeze-Drying: Formulation, Characterisation, and Storage Stability. Processes 2022, 10, 1991. [Google Scholar] [CrossRef]

- Jovanović, M.; Ćujić-Nikolić, N.; Drinić, Z.; Janković, T.; Marković, S.; Petrović, P.; Šavikin, K. Spray Drying of Gentiana asclepiadea L. Root Extract: Successful Encapsulation into Powders with Preserved Stability of Bioactive Compounds. Ind. Crops Prod. 2021, 172, 114044. [Google Scholar] [CrossRef]

- Pavlić, B.; Teslić, N.; Vidaković, A.; Vidović, S.; Velićanski, A.; Versari, A.; Radosavljević, R.; Zeković, Z. Sage Processing from By-Product to High Quality Powder: I. Bioactive Potential. Ind. Crops Prod. 2017, 107, 81–89. [Google Scholar] [CrossRef]

- Vidović, S.; Ramić, M.; Ambrus, R.; Vladić, J.; Szabó-Révész, P.; Gavarić, A. Aronia Berry Processing by Spray Drying: From Byproduct to High Quality Functional Powder. Food Technol. Biotechnol. 2019, 57, 513. [Google Scholar] [CrossRef]

- Vidović, S.S.; Vladić, J.Z.; Vaštag, Ž.G.; Zeković, Z.P.; Popović, L.M. Maltodextrin as a Carrier of Health Benefit Compounds in Satureja Montana Dry Powder Extract Obtained by Spray Drying Technique. Powder Technol. 2014, 258, 209–215. [Google Scholar] [CrossRef]

- Celli, G.B.; Dibazar, R.; Ghanem, A.; Brooks, M.S.-L. Degradation Kinetics of Anthocyanins in Freeze-Dried Microencapsulates from Lowbush Blueberries (Vaccinium angustifolium Aiton) and Prediction of Shelf-Life. Dry. Technol. 2016, 34, 1175–1184. [Google Scholar] [CrossRef]

- Caliskan, G.; Nur Dirim, S. The Effects of the Different Drying Conditions and the Amounts of Maltodextrin Addition during Spray Drying of Sumac Extract. Food Bioprod. Process. 2013, 91, 539–548. [Google Scholar] [CrossRef]

- Fernandes, F.H.A.; Santana, C.P.; Santos, R.L.; Correia, L.P.; Conceição, M.M.; Macêdo, R.O.; Medeiros, A.C.D. Thermal Characterization of Dried Extract of Medicinal Plant by DSC and Analytical Techniques. J. Therm. Anal. Calorim. 2013, 113, 443–447. [Google Scholar] [CrossRef]

- Gallo, L.; Ramírez-Rigo, M.V.; Piña, J.; Bucalá, V. A Comparative Study of Spray-Dried Medicinal Plant Aqueous Extracts. Drying Performance and Product Quality. Chem. Eng. Res. Des. 2015, 104, 681–694. [Google Scholar] [CrossRef]

- de Souza, V.B.; Thomazini, M.; de Carvalho Balieiro, J.C.; Fávaro-Trindade, C.S. Effect of Spray Drying on the Physicochemical Properties and Color Stability of the Powdered Pigment Obtained from Vinification Byproducts of the Bordo Grape (Vitis labrusca). Food Bioprod. Process. 2015, 93, 39–50. [Google Scholar] [CrossRef]

- Aliakbarian, B.; Sampaio, F.C.; de Faria, J.T.; Pitangui, C.G.; Lovaglio, F.; Casazza, A.A.; Converti, A.; Perego, P. Optimization of Spray Drying Microencapsulation of Olive Pomace Polyphenols Using Response Surface Methodology and Artificial Neural Network. LWT 2018, 93, 220–228. [Google Scholar] [CrossRef]

- Kurek, M.A.; Pratap-Singh, A. Plant-Based (Hemp, Pea and Rice) Protein–Maltodextrin Combinations as Wall Material for Spray-Drying Microencapsulation of Hempseed (Cannabis sativa) Oil. Foods 2020, 9, 1707. [Google Scholar] [CrossRef] [PubMed]

- Kanakidi, L.-D.; Tsimogiannis, D.; Kiokias, S.; Oreopoulou, V. Formulation of Rosemary Extracts through Spray-Drying Encapsulation or Emulsification. Nutraceuticals 2022, 2, 1–21. [Google Scholar] [CrossRef]

| MD (%) | Inlet Drying Temperature (°C) | Encapsulation Yield (%) | Colors Parameters | Moisture Content (%) | Bulk Density (mg/mL) | Tg (°C) | WSI (%) | WAI (%) | Rehydration | Hygroscopicity (%) | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L* | a* | b* | (s) | after 24 h | after 2 Days | after 7 Days | ||||||||

| 0 | 120 | 25.86 c ± 2.24 | 64.95 c ± 3.24 | 10.61 a ± 0.61 | 40.51 a ± 2.21 | 15.83 a ± 0.51 | 250 b ± 5.21 | >20 a | 77.13 a ± 1.92 | 7.61 a ± 0.39 | 137 a ± 4.21 | 9.26 b ± 0.48 | 12.90 b ± 0.45 | 21.43 a ± 0.69 |

| 10 | 120 | 26.45 c ± 2.64 | 63.43 c ± 2.81 | 10.13 b ± 0.52 | 38.82 b ± 1.89 | 13.07 b ± 0.42 | 250 b ± 5.23 | 42.3 b ± 2.26 | 82.04 b ± 1.52 | 7.13 b ± 0.27 | 114 b ± 3.82 | 8.85 b,c ± 0.42 | 12.32 b ± 0.39 | 18.67 b ± 0.53 |

| 40 | 120 | 62.3 a ± 2.13 | 67.82 b ± 2.85 | 8.78 c ± 0.49 | 35.46 c ± 1.92 | 11.13 c ± 0.58 | 230 a ± 5.92 | 51.6 c ± 2.98 | 83.81 b ± 2.01 | 5.78 c ± 0.38 | 105 c ± 2.02 | 8.55 c ± 0.56 | 11.08 c ± 0.43 | 17.79 b ± 0.96 |

| 80 | 120 | 76.3 a ± 1.64 | 79.11 a ± 3.11 | 4.78 d ± 0.12 | 34.45 d ± 1.56 | 7.65 d ± 0.25 | 620 d ± 2.82 | 52.5 c ± 3.12 | 85.05 b ± 2.11 | 1.78 d ± 0.24 | 68 d ± 2.21 | 8.53 c ± 0.56 | 10.48 c ± 0.48 | 17.69 b ± 0.75 |

| 80 | 140 | 73.3 a ± 1.54 | 79.76 a ± 3.86 | 3.78 e ± 0.19 | 29.03 e ± 0.1.30 | 5.02 e ± 0.12 | 570 c ± 3.29 | 52.4 c ± 0.3.10 | 80.30 b ± 1.69 | 0.78 e ± 0.26 | 62 e ± 3.03 | 13.46 a ± 0.71 | 17.26 a ± 0.48 | 21.18 a ± 0.092 |

| Maltodextrin Content (%) | Inlet Drying Temperature (°C) | Total Phenolics (mg GAE/g) | Total Flavonoids (mg CE/g) | IC50 (mg/mL) |

|---|---|---|---|---|

| 0 | 120 | 28.21 a ± 1.26 | 6.22 a ± 0.42 | 0.25 b ± 0.014 |

| 10 | 120 | 26.02 b ± 1.32 | 6.33 a ± 0.29 | 0.31 a ± 0.015 |

| 40 | 120 | 22.98 d ± 1.31 | 5.47 a,b ± 0.39 | 0.24 b,c ± 0.013 |

| 80 | 120 | 23.10 c ± 1.42 | 4.92 b ± 0.48 | 0.21 b,c ± 0.014 |

| 80 | 140 | 23.44 c ± 1.20 | 4.89 b ± 0.51 | 0.21 b,c ± 0.015 |

| Maltodextrin Content (%) | Inlet Drying Temperature (°C) | Total Phenolics (mg GAE/g) | Total Flavonoids (mg CE/g SE) | IC50 (mg/mL) | Moisture Content (%) | WSI (%) | WAI (%) |

|---|---|---|---|---|---|---|---|

| 80 | 120 | 20.180 c ± 0.51 | 4.02 b ± 0.52 | 0.18 b,c ± 0.014 | 7.87 d ± 0.35 | 82.95 b ± 2.16 | 2.18 d ± 0.44 |

| 80 | 140 | 20.44 d ± 0.44 | 4.29 b ± 0.64 | 0.19 b,c ± 0.017 | 5.62 e ± 0.32 | 82.35 b ± 2.69 | 0.98 e ± 0.56 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stupar, A.; Vidović, S.; Vladić, J.; Radusin, T.; Mišan, A. A Sustainable Approach for Enhancing Stability and Bioactivity of Allium ursinum Extract for Food Additive Applications. Separations 2024, 11, 81. https://doi.org/10.3390/separations11030081

Stupar A, Vidović S, Vladić J, Radusin T, Mišan A. A Sustainable Approach for Enhancing Stability and Bioactivity of Allium ursinum Extract for Food Additive Applications. Separations. 2024; 11(3):81. https://doi.org/10.3390/separations11030081

Chicago/Turabian StyleStupar, Alena, Senka Vidović, Jelena Vladić, Tanja Radusin, and Aleksandra Mišan. 2024. "A Sustainable Approach for Enhancing Stability and Bioactivity of Allium ursinum Extract for Food Additive Applications" Separations 11, no. 3: 81. https://doi.org/10.3390/separations11030081

APA StyleStupar, A., Vidović, S., Vladić, J., Radusin, T., & Mišan, A. (2024). A Sustainable Approach for Enhancing Stability and Bioactivity of Allium ursinum Extract for Food Additive Applications. Separations, 11(3), 81. https://doi.org/10.3390/separations11030081