State of the Art in Separation Processes for Alternative Working Fluids in Clean and Efficient Power Generation

Abstract

:1. Introduction

2. Carbon Capture and Storage (CCS)

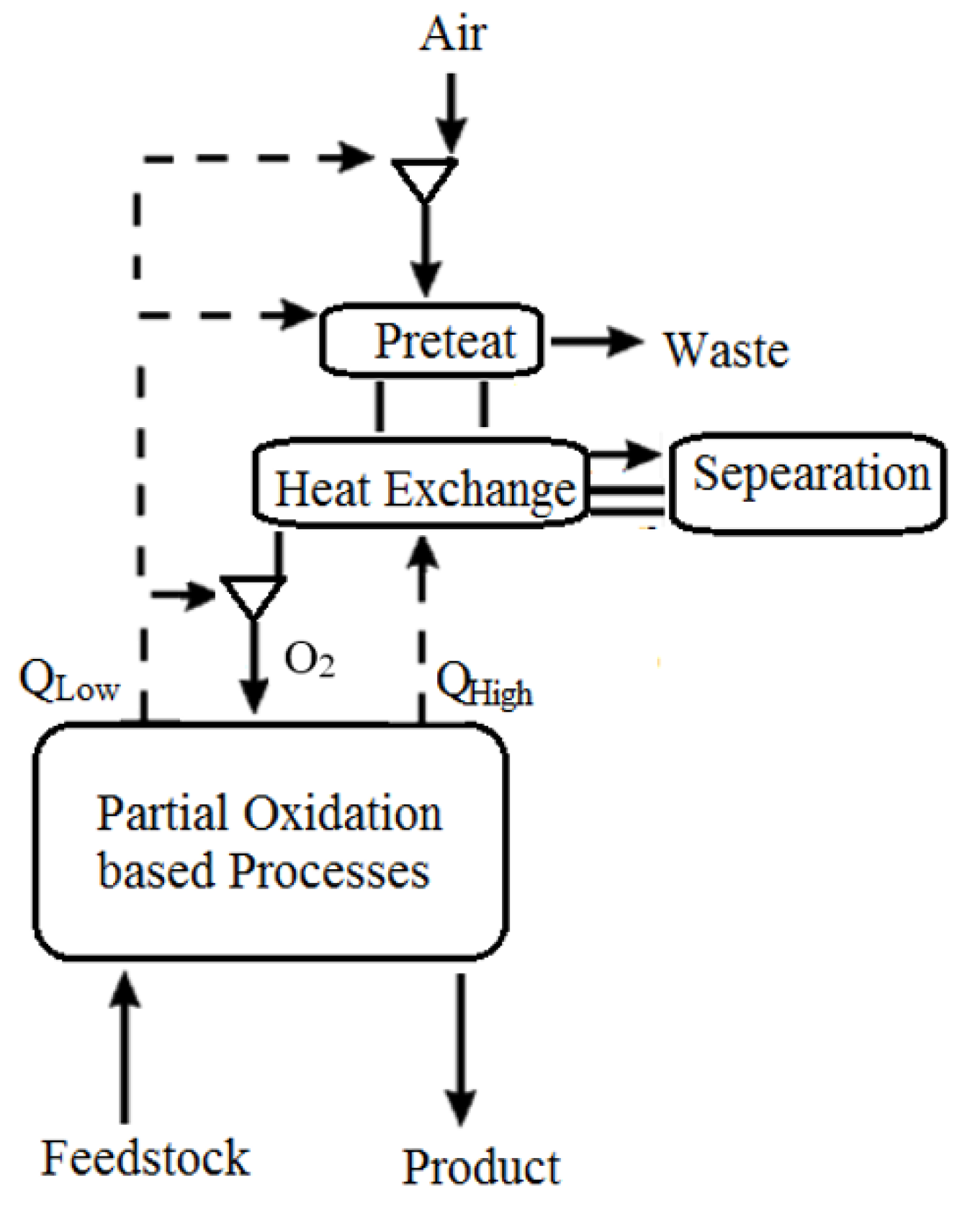

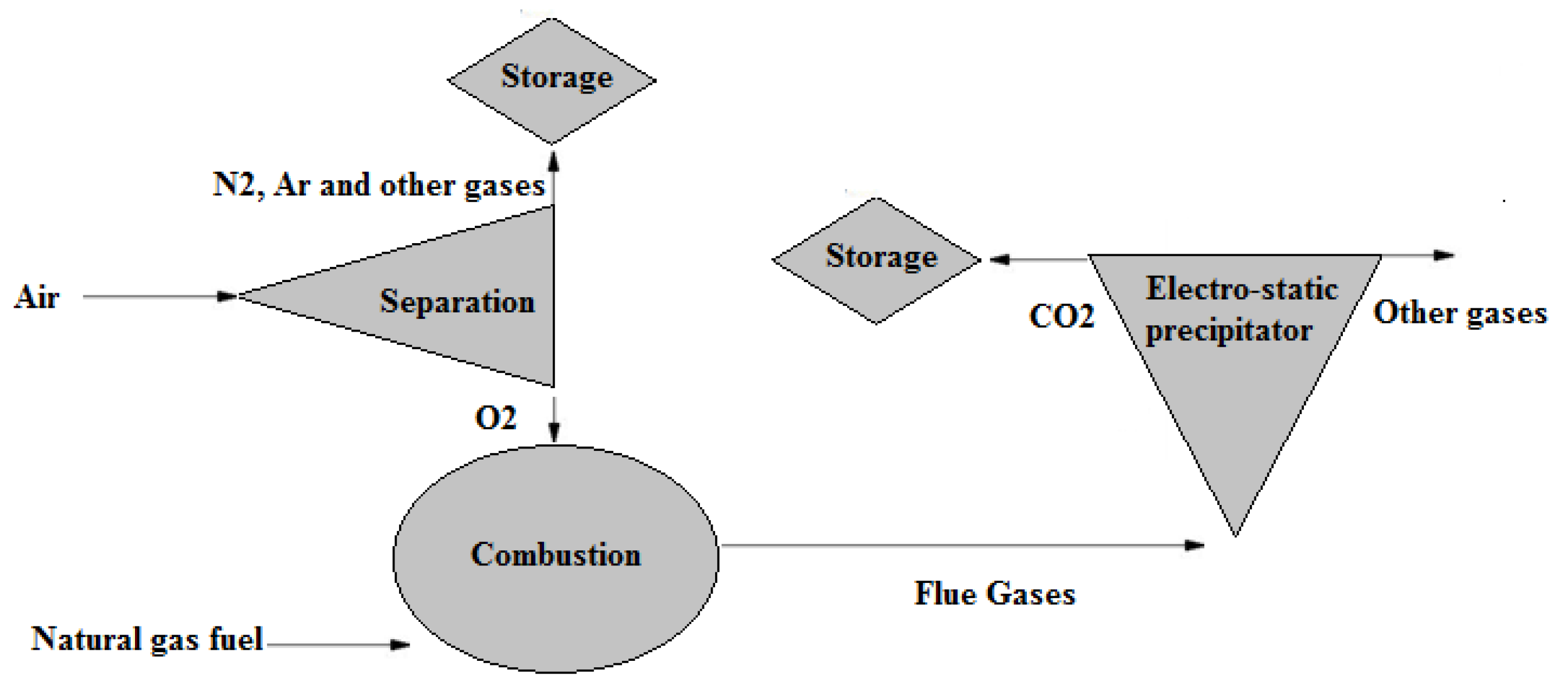

2.1. The Main Categories of the CCS

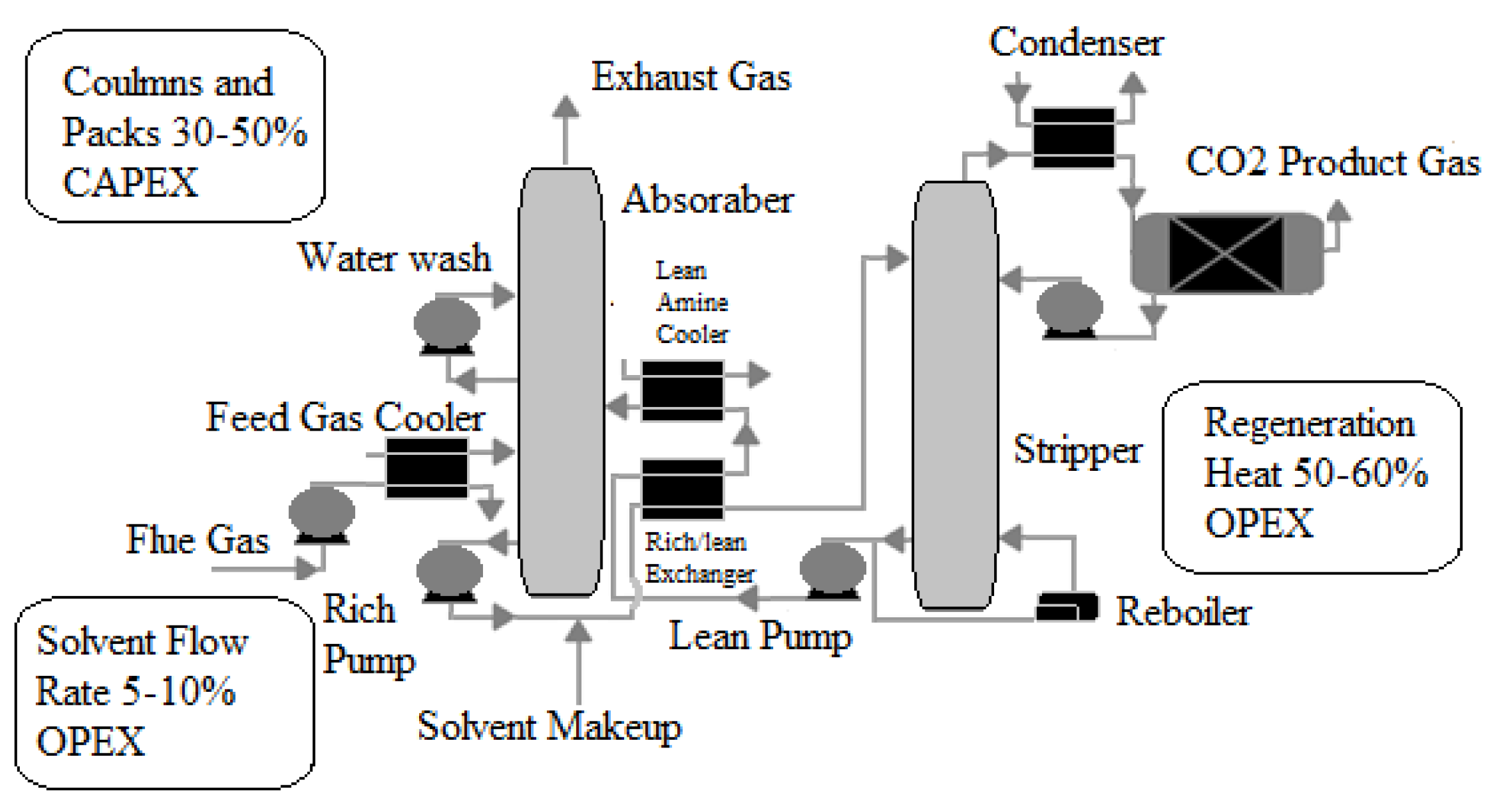

2.2. Methods for Separating Carbon Dioxide

2.3. CO2 Storage

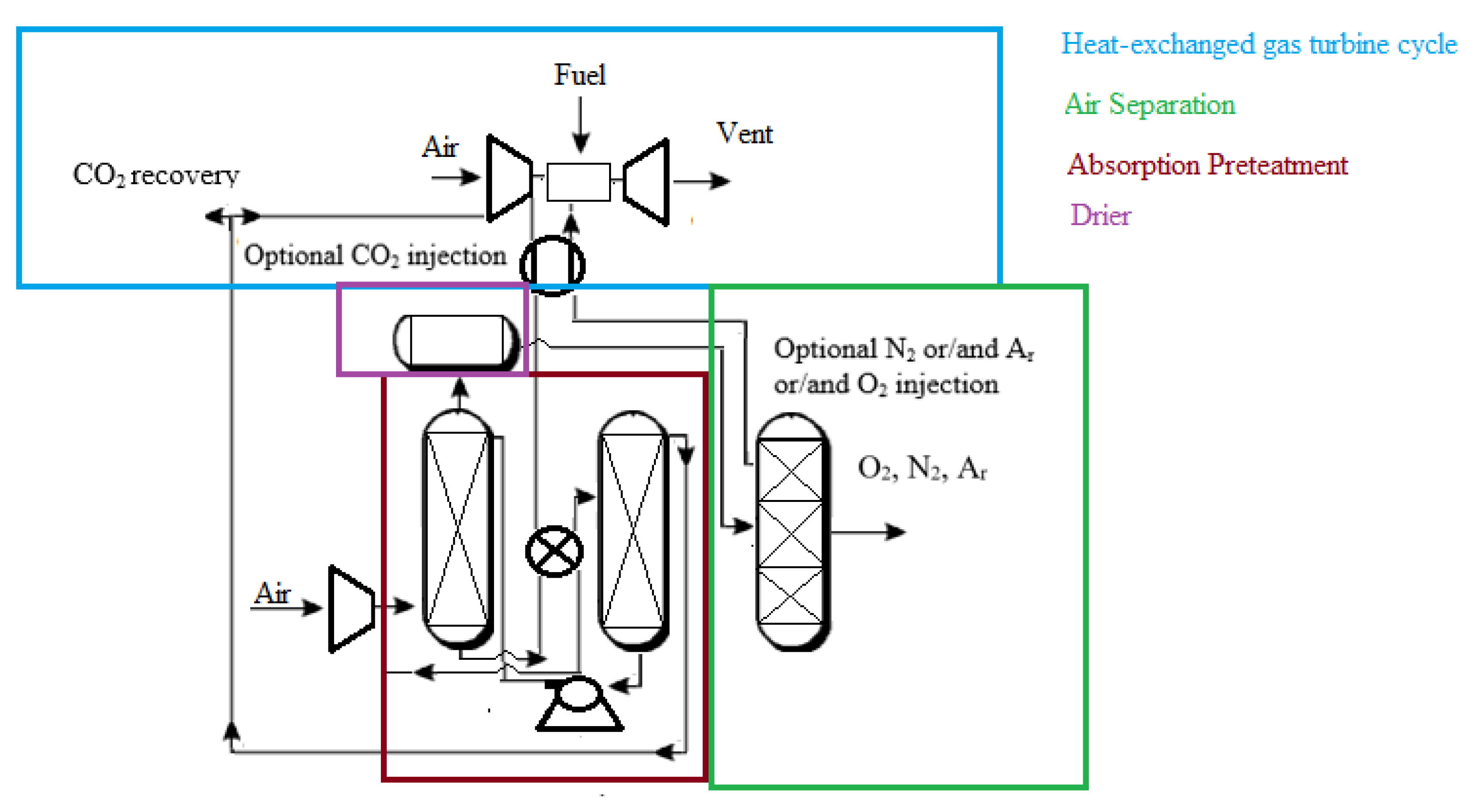

3. Air Separation Unit (ASU)

3.1. Types of Cryogenic Distillation

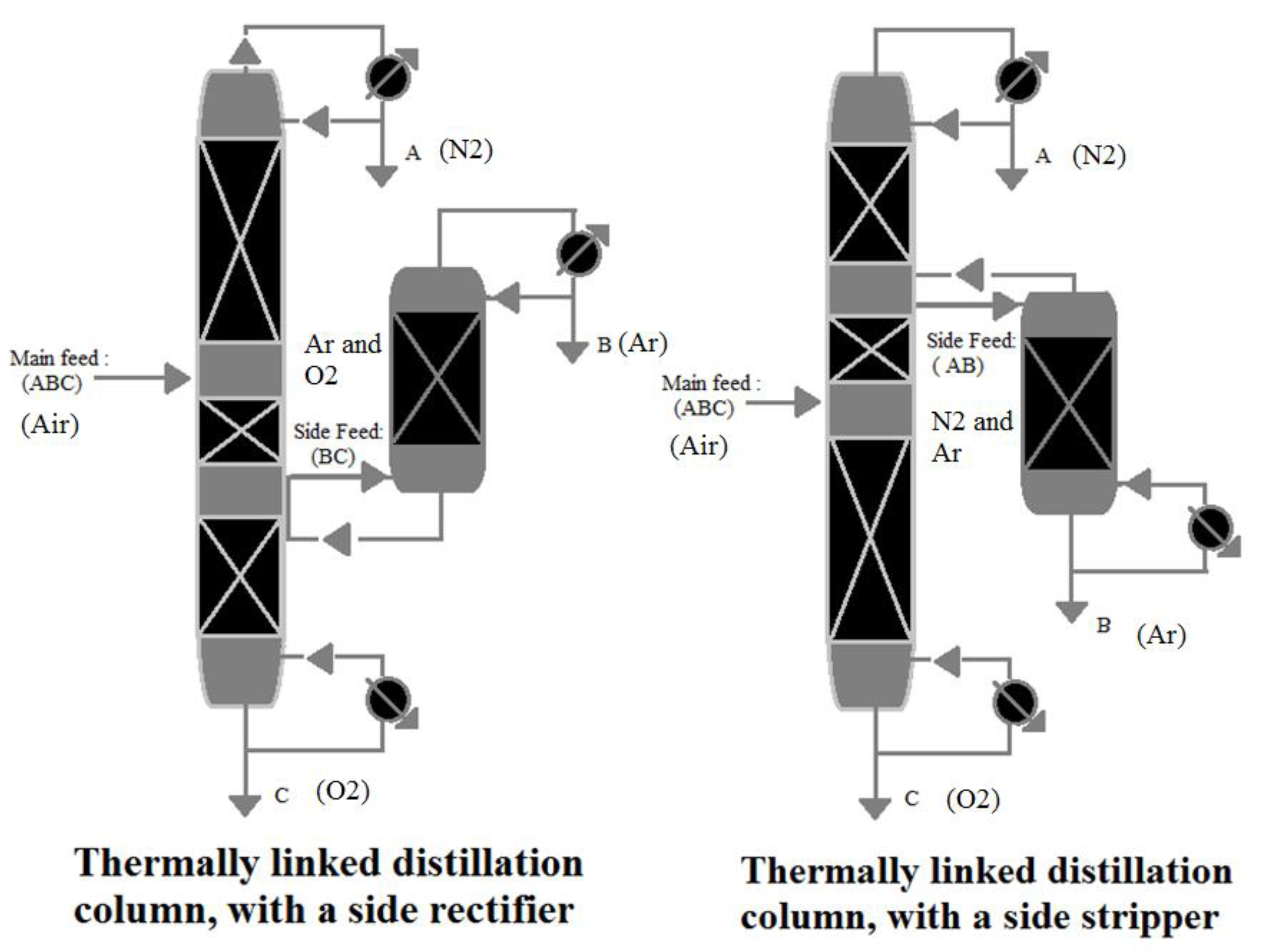

3.1.1. Thermally Linked Distillation Column, with a Side Rectifier

3.1.2. Thermally Linked Distillation Column, with a Side Stripper

3.1.3. Side Rectifier vs. Side Stripper

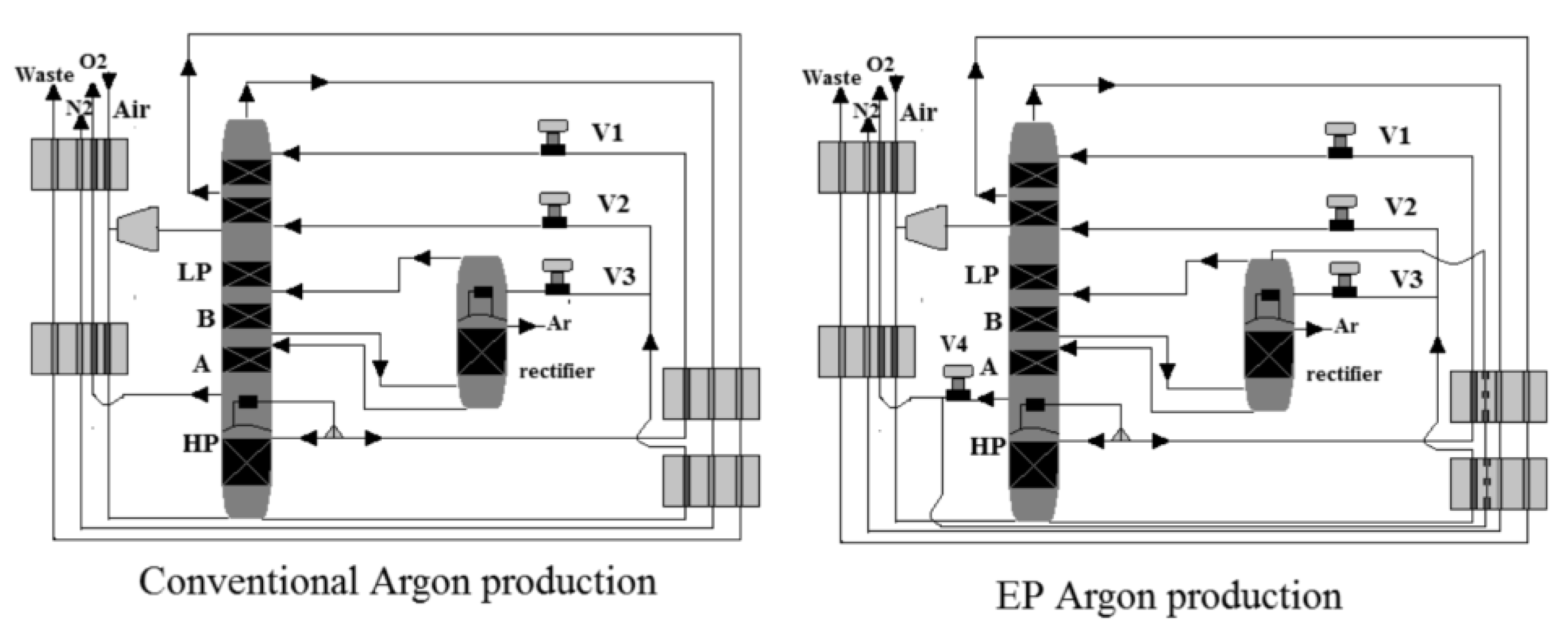

3.2. Low-Pressure (LP) Distillation Column vs. Elevated-Pressure (EP) Distillation Column

3.3. Single Distillation Column vs. Double Distillation Columns

3.3.1. Conventional Argon Production

3.3.2. EP Argon Production

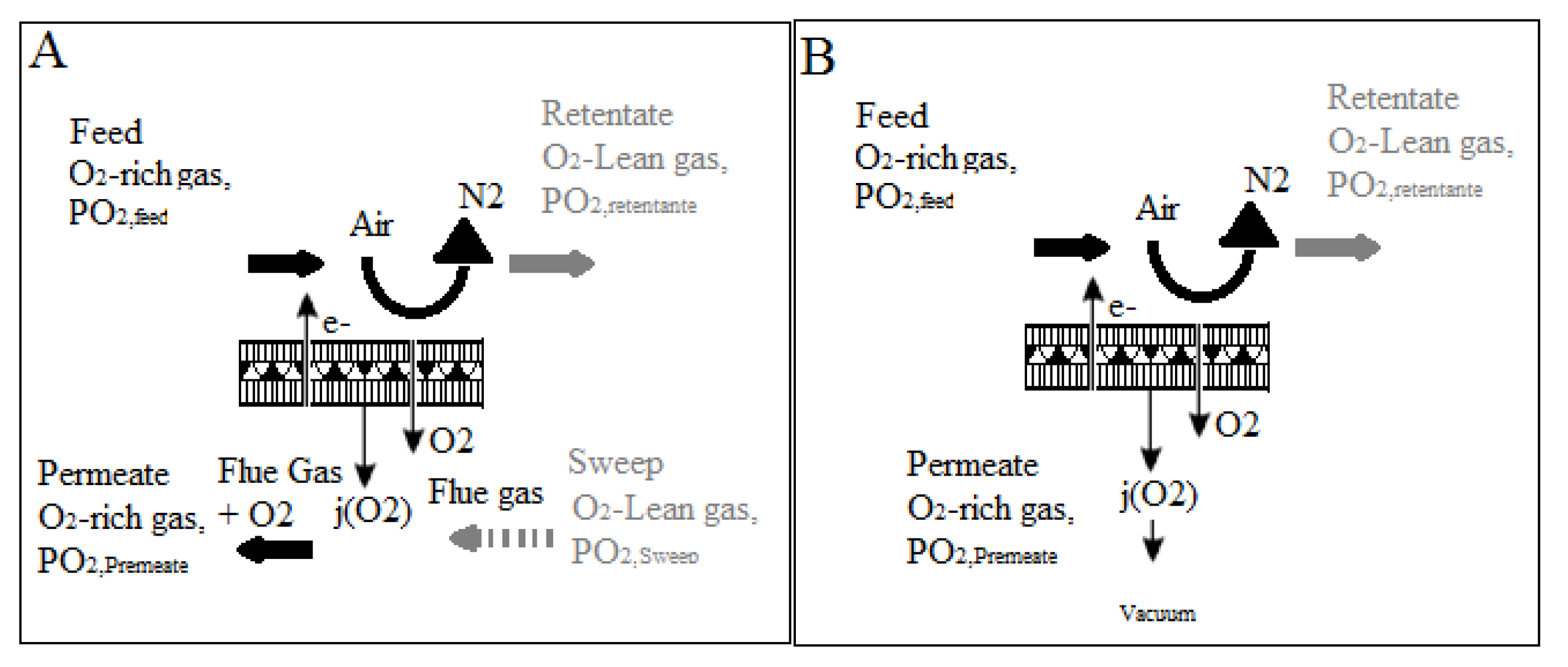

3.4. Membrane Air Separation

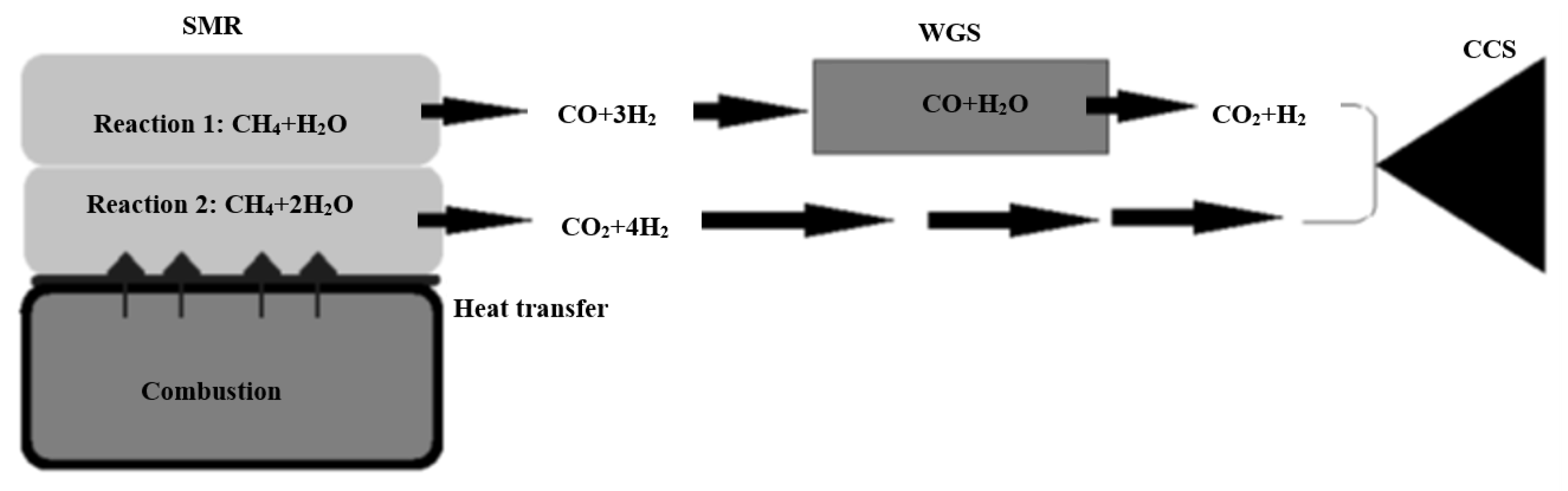

4. Steam Methane Reforming (SMR)

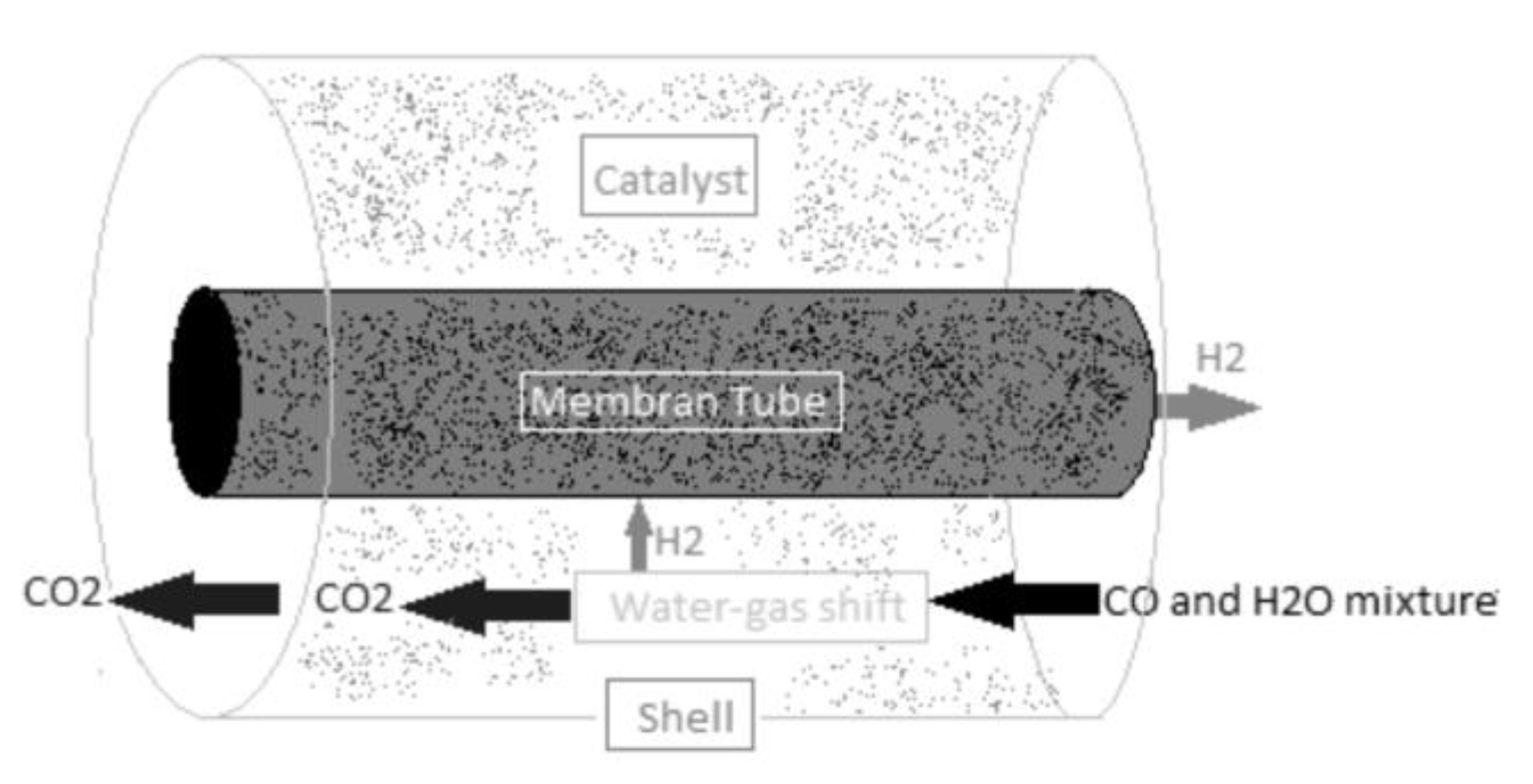

5. Water–Gas Shifting (WGS)

5.1. WGS Applications

5.2. WGS Catalyst

5.3. WGS Reactors

6. Helium as a Working Fluid

7. Conclusions

Author Contributions

Funding

Informed Consent Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CCS | Carbon Capture and Storage |

| ASU | Air separation units |

| HTGR | High-temperature gas-cooled nuclear reactors |

| HR | Heat recovery |

| CARSOXY | Carbon dioxide, argon, steam, and oxygen |

| POX | Partial oxidation process |

| SMR | Steam methane reformer |

| WGS | Water–gas shift |

| PSA | Pressure swing adsorption |

| MEA | Monoethanolamine |

| LP | Low pressure |

| EP | Elevated pressure |

| HP | high pressure |

| LOX | Liquid oxygen |

| MEIC | Mixed electronic ionic conducting |

| IGCC | Integrated gasification combined cycle |

| CBC | Closed Brayton cycle |

| NSPS | New source performance standards |

| BSCF | Ba0.5Sr0.5CO0.8Fe0.2O3I |

| HTWGS | High-temperature water–gas shift |

| LTWGS | Low-temperature water–gas shift |

References

- Scheffknecht, G.; Al-Makhadmeh, L.; Schnell, U.; Maier, J. Oxy-fuel coal combustion—A review of the current state-of-the-art. Int. J. Greenh. Gas Control 2011, 5, S16–S35. [Google Scholar] [CrossRef]

- Álvarez, J.F.G.; de Grado, J.G. Study of a modern industrial low pressure turbine for electricity production em-ployed in oxy-combustion cycles with CO2 capture purposes. Energy 2016, 107, 734–747. [Google Scholar] [CrossRef]

- Tuttle, S.G.; Chaudhuri, S.; Kostka, S., Jr.; Kopp-Vaughan, K.M.; Jensen, T.R.; Cetegen, B.M.; Renfro, M.W. Time-resolved blowoff transition measurements for two-dimensional bluff body-stabilized flames in vitiated flow. Combust. Flame 2012, 159, 291–305. [Google Scholar] [CrossRef]

- Nemitallah, M.A.; Rashwan, S.S.; Mansir, I.B.; Abdelhafez, A.A.; Habib, M.A.M. Review of Novel Combustion Techniques for Clean Power Production in Gas Turbines. Energy Fuels 2018, 32, 979–1004. [Google Scholar] [CrossRef]

- Fu, Q.; Kansha, Y.; Song, C.; Liu, Y.; Ishizuka, M.; Tsutsumi, A. A cryogenic air separation process based on self-heat recuperation for oxy-combustion plants. Appl. Energy 2016, 162, 1114–1121. [Google Scholar] [CrossRef]

- Rashwan, S.S.; Abouarab, T.W. Experimental Investigation of Oxy-fuel combustion of CNG Flames Stabilized over A Perforated Plate Burner. In Proceedings of the 18th IFRF Members’ Conference—Flexible and Clean Fuel Conversion to Industry, Freising, Germany, 1–3 June 2015; p. 25. [Google Scholar]

- Jonsson, M.; Yan, J. Humidified gas turbines—A review of proposed and implemented cycles. Energy 2005, 30, 1013–1078. [Google Scholar] [CrossRef]

- Giampaolo, T. The Gas Turbine Handbook: Principles and Practices; The Fairmont Press, Inc.: Gistrup, Denmark, 2003. [Google Scholar]

- He, Y.; Zou, C.; Song, Y.; Chen, W.; Jia, H.; Zheng, C. Experimental and Numerical Study of the Effect of High Steam Concentration on the Oxidation of Methane and Ammonia during Oxy-Steam Combustion. Energy Fuels 2016, 30, 6799–6807. [Google Scholar] [CrossRef]

- Richards, G.A.; Casleton, K.H.; Chorpening, B.T. CO2 and H2O diluted oxy-fuel combustion for zero-emission power. Proc. Inst. Mech. Eng. Part A J. Power Energy 2005, 219, 121–126. [Google Scholar] [CrossRef]

- Jin, B.; Zhao, H.; Zou, C.; Zheng, C. Comprehensive investigation of process characteristics for oxy-steam com-bustion power plants. Energy Convers. Manag. 2015, 99, 92–101. [Google Scholar] [CrossRef]

- Xiong, J.; Zhao, H.; Chen, M.; Zheng, C. Simulation Study of an 800 MWe Oxy-combustion Pulverized-Coal-Fired Power Plant. Energy Fuels 2011, 25, 2405–2415. [Google Scholar] [CrossRef]

- Xiong, J.; Zhao, H.; Zheng, C. Exergy Analysis of a 600 MWe Oxy-combustion Pulverized-Coal-Fired Power Plant. Energy Fuels 2011, 25, 3854–3864. [Google Scholar] [CrossRef]

- Xiong, J.; Zhao, H.; Zheng, C. Thermoeconomic cost analysis of a 600MWe oxy-combustion pulverized-coal-fired power plant. Int. J. Greenh. Gas Control 2012, 9, 469–483. [Google Scholar] [CrossRef]

- Jin, B.; Zhao, H.; Zheng, C. Dynamic modeling and control for pulverized-coal-fired oxy-combustion boiler island. Int. J. Greenh. Gas Control. 2014, 30, 97–117. [Google Scholar] [CrossRef]

- Singh, J. Sterling Dictionary of Physics; Sterling Publishers Pvt. Ltd.: New Delhi, India, 1999. [Google Scholar]

- Shahsavan, M.; Mack, J.H. The effect of heavy working fluids on hydrogen combustion. In Proceedings of the 10th U.S. National Combustion Meeting, College Park, MD, USA, 23–26 April 2017. [Google Scholar]

- No, H.-C.; Kim, J.-H.; Kim, H.-M. A review of helium gas turbine technology for high-temperature gas-cooled reactors. Nucl. Eng. Technol. 2007, 39, 21–30. [Google Scholar] [CrossRef] [Green Version]

- Nayagam, V.; Haggard, J.B., Jr.; Colantonio, R.O.; Marchese, A.J.; Dryer, F.L.; Zhang, B.L.; Williams, F.A. Mi-crogravity n-heptane droplet combustion in oxygen-helium mixtures at atmospheric pressure. AIAA J. 1998, 36, 1369–1378. [Google Scholar] [CrossRef]

- Li, H.; Yan, J.; Anheden, M. Impurity impacts on the purification process in oxy-fuel combustion based CO2 capture and storage system. Appl. Energy 2009, 86, 202–213. [Google Scholar] [CrossRef]

- Puebla, H.; Enrique, L.; Hurtado, J.I.L.; Soria, B.Y.M. Power cycle assessment of nuclear high temperature gas-cooled reactors. Appl. Therm. Eng. 2009, 29, 1759–1765. [Google Scholar]

- Rao, A.B.; Rubin, E.S. A Technical, Economic, and Environmental Assessment of Amine-Based CO2 Capture Technology for Power Plant Greenhouse Gas Control. Environ. Sci. Technol. 2002, 36, 4467–4475. [Google Scholar] [CrossRef] [Green Version]

- Prisyazhniuk, V.A. Alternative trends in development of thermal power plants. Appl. Therm. Eng. 2008, 28, 190–194. [Google Scholar] [CrossRef]

- Glarborg, P.; Bentzen, L.L.B. Chemical Effects of a High CO2 Concentration in Oxy-Fuel Combustion of Methane. Energy Fuels 2007, 22, 291–296. [Google Scholar] [CrossRef]

- Bibrzycki, J.; Poinsot, T. Reduced Chemical Kinetic Mechanisms for Methane Combustion in O2/N2 and O2/CO2 Atmosphere; Working note ECCOMET WN/CFD/10 17; CERFACT: Toulouse, France, 2010. [Google Scholar]

- Al-Tamreh, S.A.; Ibrahim, M.H.; El-Naas, M.H.; Vaes, J.; Pant, D.; Benamor, A.; Amhamed, A. Electroreduction of Carbon Dioxide into Formate: A Comprehensive Review. ChemElectroChem 2021, 8, 3207–3220. [Google Scholar] [CrossRef]

- Sa, D.A.; Al Zubaidy, S. Gas turbine performance at varying ambient temperature. Appl. Therm. Eng. 2011, 31, 2735–2739. [Google Scholar]

- Pilavachi, P. Mini- and micro-gas turbines for combined heat and power. Appl. Therm. Eng. 2002, 22, 2003–2014. [Google Scholar] [CrossRef]

- Heppenstall, T. Advanced gas turbine cycles for power generation: A critical review. Appl. Therm. Eng. 1998, 18, 837–846. [Google Scholar] [CrossRef]

- ASME COGEN-TURBO. A Study on Modified Gas Turbine Systems with Steam Injection or Evaporative Regeneration. Annerwall, K., Svedberg, G., Eds.; ASME Turbo Expo Conference, FLORIDA, USA. 1991. Available online: https://www.researchgate.net/publication/282387540_A_study_on_modified_gas_turbine_systems_with_steam_injection_or_evaporative_regeneration (accessed on 6 January 2022).

- Bhargava, R.; Meher-Homji, C.B. Parametric analysis of existing gas turbines with inlet evaporative and overspray fogging. In ASME Turbo Expo 2002: Power for Land, Sea, and Air; American Society of Mechanical Engineers: New York, NY, USA, 2002; Volume 36096, pp. 387–401. [Google Scholar]

- McDonald, C.F.; Wilson, D.G. The utilization of recuperated and regenerated engine cycles for high-efficiency gas turbines in the 21st century. Appl. Therm. Eng. 1996, 16, 635–653. [Google Scholar] [CrossRef]

- Al-Doboon, A.; Gutesa, M.; Valera-Medina, A.; Syred, N.; Ng, J.-H.; Chong, C.T. CO2-argon-steam oxy-fuel (CARSOXY) combustion for CCS inert gas atmospheres in gas turbines. Appl. Therm. Eng. 2017, 122, 350–358. [Google Scholar] [CrossRef]

- Luo, X.; Wang, M. Optimal operation of MEA-based post-combustion carbon capture for natural gas combined cycle power plants under different market conditions. Int. J. Greenh. Gas Control. 2016, 48, 312–320. [Google Scholar] [CrossRef]

- Kanniche, M.; Gros-Bonnivard, R.; Jaud, P.; Valle-Marcos, J.; Amann, J.M.; Bouallou, C. Pre-combustion, post-combustion and oxy-combustion in thermal power plant for CO2 capture. Appl. Therm. Eng. 2010, 30, 53–62. [Google Scholar] [CrossRef] [Green Version]

- Altamash, T.; Amhamed, A.; Aparicio, S.; Atilhan, M. Effect of hydrogen bond donors and acceptors on CO2 absorption by deep eutectic solvents. Processes 2020, 8, 1533. [Google Scholar] [CrossRef]

- Pugh, D.; Bowen, P.; Valera-Medina, A.; Giles, A.; Runyon, J.; Marsh, R. Influence of steam addition and elevated ambient conditions on NOx reduction in a staged premixed swirling NH3/H2 flame. Proc. Combust. Inst. 2019, 37, 5401–5409. [Google Scholar] [CrossRef]

- Hussein, N.A.; Valera-Medina, A.; Alsaegh, A.S. Ammonia- hydrogen combustion in a swirl burner with reduction of NOx emissions. Energy Procedia 2019, 158, 2305–2310. [Google Scholar] [CrossRef]

- Smith, A.R.; Klosek, J. A review of air separation technologies and their integration with energy conversion processes. Fuel Process. Technol. 2001, 70, 115–134. [Google Scholar] [CrossRef]

- Najjar, Y.S. Gas turbine cogeneration systems: A review of some novel cycles. Appl. Therm. Eng. 2000, 20, 179–197. [Google Scholar] [CrossRef]

- Terry, F.W. Combustion processes for carbon capture. Proc. Combust. Inst. 2007, 31, 31–47. [Google Scholar]

- Liang, Z.; Rongwong, W.; Liu, H.; Fu, K.; Gao, H.; Cao, F.; Zhang, R.; Sema, T.; Henni, A.; Sumon, K.Z.; et al. Recent progress and new developments in post-combustion carbon-capture technology with amine based solvents. Int. J. Greenh. Gas Control 2015, 40, 26–54. [Google Scholar] [CrossRef] [Green Version]

- Kaur, M. Carbon Capturing and Storage Technology & current CCS initiatives in India (Emerging Technology in the field of Environmental Engineering). Int. J. Adv. Res. Comput. Sci. 2017, 8, 52–55. [Google Scholar]

- Leung, D.Y.C.; Caramanna, G.; Maroto-Valer, M.M. An overview of current status of carbon dioxide capture and storage technologies. Renew. Sustain. Energy Rev. 2014, 39, 426–443. [Google Scholar] [CrossRef] [Green Version]

- Stanger, R.; Wall, T. Sulphur impacts during pulverised coal combustion in oxy-fuel technology for carbon capture and storage. Prog. Energy Combust. Sci. 2011, 37, 69–88. [Google Scholar] [CrossRef]

- Aaron, D.; Tsouris, C. Separation of CO2 from Flue Gas: A Review. Sep. Sci. Technol. 2005, 40, 321–348. [Google Scholar] [CrossRef]

- Knapik, E.; Chruszcz-Lipska, K. Chemistry of Reservoir Fluids in the Aspect of CO2 Injection for Selected Oil Reservoirs in Poland. Energies 2020, 13, 6456. [Google Scholar] [CrossRef]

- Rasmussen, L.; Fan, T.; Rinehart, A.; Luhmann, A.; Ampomah, W.; Dewers, T.; Heath, J.; Cather, M.; Grigg, R. Carbon Storage and Enhanced Oil Recovery in Pennsylvanian Morrow Formation Clastic Reservoirs: Controls on Oil–Brine and Oil–CO2 Relative Permeability from Diagenetic Heterogeneity and Evolving Wettability. Energies 2019, 12, 3663. [Google Scholar] [CrossRef] [Green Version]

- Cao, C.; Liu, H.; Hou, Z.; Mehmood, F.; Liao, J.; Feng, W. A Review of CO2 Storage in View of Safety and Cost-Effectiveness. Energies 2020, 13, 600. [Google Scholar] [CrossRef] [Green Version]

- Fawwaz Alrebei, O.; Al-Doboon, A.; Bowen, P.; Valera Medina, A. CO2-Argon-Steam Oxy-Fuel Production for (CARSOXY) Gas Turbines. Energies 2019, 12, 3580. [Google Scholar] [CrossRef] [Green Version]

- Amhamed, A.; Atilhan, M.; Berdiyorov, G. Permeabilities of CO2, H2S and CH4 through choline-based ionic liquids: Atomistic-scale simulations. Molecules 2019, 24, 2014. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Essehli, R.; Sabri, S.; El-Mellouhi, F.; Aïssa, B.; Yahia, H.B.; Altamash, T.; Khraisheh, M.; Amhamed, A.; El Bali, B. Single crystal structure, vibrational spectroscopy, gas sorption and antimicro-bial properties of a new inorganic acidic diphosphates material (NH4)2Mg(H2P2O7)2•2H2O. Sci. Rep. 2020, 10, 1–14. [Google Scholar] [CrossRef]

- Cheung, H. Moderate-pressure cryogenic air separation process. Gas Sep. Purif. 1991, 5, 25–28. [Google Scholar] [CrossRef]

- Khalel, Z.A.M.; Rabah, A.A.; Barakat, T.A.M. A New Cryogenic Air Separation Process with Flash Separator. ISRN Thermodyn. 2013, 2013, 1–4. [Google Scholar] [CrossRef] [Green Version]

- Leo, A.; Liu, S.; da Costa, J.C.D. Development of mixed conducting membranes for clean coal energy delivery. Int. J. Greenh. Gas Control 2009, 3, 357–367. [Google Scholar] [CrossRef]

- Kneer, R.; Toporov, D.; Förster, M.; Christ, D.; Broeckmann, C.; Pfaff, E.; Zwick, M.; Engels, S.; Modigell, M. OXYCOAL-AC: Towards an integrated coal-fired power plant process with ion transport membrane-based oxygen supply. Energy Environ. Sci. 2010, 3, 198–207. [Google Scholar] [CrossRef]

- Sundkvist, S.G.; Julsrud, S.; Vigeland, B.; Naas, T.; Budd, M.; Leistner, H.; Winkler, D. Development and testing of AZEP reactor components. Int. J. Greenh. Gas Control. 2007, 1, 180–187. [Google Scholar] [CrossRef]

- Wilson, J.; Christie, M.; Degenstein, N.; Shah, M.; Li, J. OTM based oxy-fuel combustion for CO2 capture. In Proceedings of the 34th International Technical Conference on Clean Coal & Fuel Systems, Clearwater, FL, USA, 31 May–4 June 2009; Volume 31. [Google Scholar]

- Holmes, M.J.; Ohrn, T.R.; Chen, C.M. Ion Transport Membrane Module and Vessel System with Directed Internal Gas Flow. U.S. Patent 7,658,788, 9 February 2010. [Google Scholar]

- Den Exter, M.J.; Haije, W.G.; Vente, J.F. Viability of ITM technology for oxygen production and oxidation processes: Material, system, and process aspects. In Inorganic Membranes for Energy and Environmental Applications; Springer: New York, NY, USA, 2009; pp. 27–51. [Google Scholar]

- Beggel, F.; Engels, S.; Modigell, M.; Nauels, N. Oxyfuel Combustion by Means of High Temperature Membranes for Air Separation; U.S. Department of Energy: Hyogo, Japan, 2009.

- Stadler, H.; Beggel, F.; Habermehl, M.; Persigehl, B.; Kneer, R.; Modigell, M.; Jeschke, P. Oxyfuel coal combustion by efficient integration of oxygen transport membranes. Int. J. Greenh. Gas Control 2011, 5, 7–15. [Google Scholar] [CrossRef]

- Christou, C.; Hadjipaschalis, I.; Poullikkas, A. Assessment of integrated gasification combined cycle technology competitiveness. Renew. Sustain. Energy Rev. 2008, 12, 2459–2471. [Google Scholar] [CrossRef]

- Ordorica-Garcia, G.; Douglas, P.; Croiset, E.; Zheng, L. Techno-Economic Evaluation of IGCC Power Plants with CO2 Capture; U.S. Department of Energy: Hyogo, Japan, 2005.

- Bohm, M.C.; Herzog, H.J.; Parsons, J.E.; Sekar, R.C. Capture-ready coal plants—Options, technologies and economics. Int. J. Greenh. Gas Control. 2007, 1, 113–120. [Google Scholar] [CrossRef]

- Guocai, T. Applications of green solvents in toxic gases removal. In Green Sustainable Process for Chemical and Environmental Engineering and Science; Elsevier: Amsterdam, The Netherlands, 2021; pp. 149–201. [Google Scholar]

- Song, Z.Y.; Wang, B.-W.; Song, K.; Zheng, C.-G. The performance research on new oxygen carrier CASO_4 used in chemical-looping combustion. J. Eng. Thermophys. 2006, 13, 3. [Google Scholar]

- Abad, A.; Mattisson, T.; Lyngfelt, A.; Rydèn, M. Chemical-looping combustion in a 300 W continuously operating reactor system using a manganese-based oxygen carrier. Fuel 2006, 85, 1174–1185. [Google Scholar] [CrossRef]

- Mattisson, T.; Johansson, M.; Lyngfelt, A. The use of NiO as an oxygen carrier in chemical-looping combustion. Fuel 2006, 85, 736–747. [Google Scholar] [CrossRef]

- Abad, A.; Adánez, J.; García-Labiano, F.; Luis, F.; Gayán, P.; Celaya, J. Mapping of the range of operational conditions for Cu-, Fe-, and Ni-based oxygen carriers in chemical-looping combustion. Chem. Eng. Sci. 2007, 62, 533–549. [Google Scholar] [CrossRef] [Green Version]

- Abad, A.; Mattisson, T.; Lyngfelt, A.; Johansson, M. The use of iron oxide as oxygen carrier in a chemical-looping reactor. Fuel 2007, 86, 1021–1035. [Google Scholar] [CrossRef]

- Agrawal, R.; Woodward, D.W.; Yee, T.F. Argon production from air distillation: Use of a heat pump in a ternary distillation with a side rectifier. Gas Sep. Purif. 1994, 8, 37–43. [Google Scholar] [CrossRef]

- Cornelissen, R.; Hirs, G. Exergy analysis of cryogenic air separation. Energy Convers. Manag. 1998, 39, 1821–1826. [Google Scholar] [CrossRef]

- Barelli, L.; Bidini, G.; Gallorini, F.; Servili, S. Hydrogen production through sorption-enhanced steam methane reforming and membrane technology: A review. Energy 2008, 33, 554–570. [Google Scholar] [CrossRef]

- LeValley, T.L.; Richard, A.R.; Fan, M. The progress in water gas shift and steam reforming hydrogen production technologies—A review. Int. J. Hydrog. Energy 2014, 39, 16983–17000. [Google Scholar] [CrossRef]

- Lee, F.B. A comparative study of fuels for on-board hydrogen production for fuel-cell-powered automo-biles. Int. J. Hydrog. Energy 2001, 26, 381–397. [Google Scholar]

- Sjardin, M.; Damen, K.J.; Faaij, A.P.C. Techno-economic prospects of small-scale membrane reactors in a future hydrogen-fuelled transportation sector. Energy 2006, 31, 2523–2555. [Google Scholar] [CrossRef] [Green Version]

- Khzouz, M.; Gkanas, E.I. Experimental and Numerical Study of Low Temperature Methane Steam Reforming for Hydrogen Production. Catalysts 2017, 8, 5. [Google Scholar] [CrossRef] [Green Version]

- Ballard. Available online: http://www.ballard.com/ (accessed on 30 April 2020).

- Martyn, V.T. Catalyst Handbook; Routledge: New York, NY, USA, 2018. [Google Scholar]

- Halabi, M.H.; de Croon, M.H.J.M.; van der Schaaf, J.; Cobden, P.D.; Schouten, J.C. Intrinsic kinetics of low tem-perature catalytic methane–steam reforming and water–gas shift over Rh/CeαZr1− αO2 catalyst. Appl. Catal. A Gen. 2010, 389, 80–91. [Google Scholar] [CrossRef]

- Angeli, S.; Monteleone, G.; Giaconia, A.; Lemonidou, A. State-of-the-art catalysts for CH4 steam reforming at low temperature. Int. J. Hydrog. Energy 2014, 39, 1979–1997. [Google Scholar] [CrossRef]

- Nieva, M.A.; Villaverde, M.M.; Monzón, A.; Garetto, T.F.; Marchi, A.J. Steam-methane reforming at low temperature on nickel-based catalysts. Chem. Eng. J. 2014, 235, 158–166. [Google Scholar] [CrossRef]

- Santo, V.D.; Gallo, A.; Naldoni, A.; Guidotti, M.; Psaro, R. Bimetallic heterogeneous catalysts for hydrogen production. Catal. Today 2012, 197, 190–205. [Google Scholar] [CrossRef]

- Andersson, M.; Paradis, H.; Yuan, J.; Sundén, B. Review of catalyst materials and catalytic steam reforming reactions in SOFC anodes. Int. J. Energy Res. 2011, 35, 1340–1350. [Google Scholar] [CrossRef] [Green Version]

- Li, D.; Nakagawa, Y.; Tomishige, K. Methane reforming to synthesis gas over Ni catalysts modified with noble metals. Appl. Catal. A Gen. 2011, 408, 1–24. [Google Scholar] [CrossRef]

- Sircar, S.; Golden, T.C. Pressure swing adsorption technology for hydrogen production. Hydrog. Syngas Prod. Purif. Technol. 2009, 10, 414–450. [Google Scholar]

- Smith, R.J.B.; Loganathan, M.; Shantha, M.S. A review of the water gas shift reaction kinetics. Int. J. Chem. React. Eng. 2010, 8, 11–44. [Google Scholar] [CrossRef]

- George, W.; Dresselhaus, M.S.; Buchanan, M.V. The hydrogen economy. Phys. Today 2004, 57, 39–44. [Google Scholar]

- Osvaldo, V.-Z.M.; Nicholas, S.; Agustín, V.-M.; Daniel, D.L.R.-U. Flashback Avoidance in Swirling Flow Burners. Ing. Investig. Tecnol. 2014, 15, 603–614. [Google Scholar] [CrossRef] [Green Version]

- Tian, Z.; Jiang, B.; Malik, A.; Zheng, Q. Axial helium compressor for high-temperature gas-cooled reactor: A review. Ann. Nucl. Energy 2019, 130, 54–68. [Google Scholar] [CrossRef]

- Kim, J.H.; No, H.C.; Kim, H.M.; Lim, H.S. Direct implementation of an axial-flow helium gas turbine tool in a system analysis tool for HTGRs. Nucl. Eng. Des. 2008, 238, 3379–3388. [Google Scholar] [CrossRef]

- Muto, Y.; Ishiyama, S.; Fukuyama, Y.; Okumoto, J.; Kishibe, T.; Yamada, S. Design Study of Helium Turbine for the 300 MW HTGR-GT Power Plant. In Turbo Expo: Power for Land, Sea, and Air; American Society of Mechanical Engineers: New York, NY, USA, 2000; Volume 78552, p. V002T04A010. [Google Scholar]

- Tian, Z.; Zheng, Q.; Malik, A.; Jiang, B. Numerical investigation of the effect of highly loaded design on the tip leakage in helium compressor rotors. Prog. Nucl. Energy 2018, 105, 263–270. [Google Scholar] [CrossRef]

- Elistratov, S.L.; Vitovskii, O.V.; Slesareva, E.Y. Experimental investigation of heat transfer of helium-xenon mixtures in cylindrical channels. J. Eng. Thermophys. 2015, 24, 33–35. [Google Scholar] [CrossRef]

- Vitovsky, O.; Nakoryakov, V.E.V.; Slesareva, E.Y. Heat transfer of helium–xenon mixture on the initial pipe section. J. Eng. Thermophys. 2015, 24, 338–341. [Google Scholar] [CrossRef]

- Nakoryakov, V.E.; Vitovsky, O.V. Study of heat transfer of a helium–xenon mixture in heated channels with different cross-sectional shapes. J. Appl. Mech. Tech. Phys. 2017, 58, 664–669. [Google Scholar] [CrossRef]

- Dragunov, Y.G.; Smetannikov, V.P.; Gabaraev, B.A.; Orlov, A.N.; Belyakov, M.S.; Derbenev, D.S. On calculation of the transport coefficients and thermodynamic properties of a helium-xenon gas mixture. J. Eng. Thermophys. 2013, 22, 21–29. [Google Scholar] [CrossRef]

- Haire, M.A.; Vargo, D.D. Review of Helium and Xenon Pure Component and Mixture Transport Properties and Recommendation of Estimating Approach for Project Prometheus (Viscosity and Thermal Conductivity). In AIP Conference Proceedings; American Institute of Physics: College Park, MD, USA, 2007; Volume 880, pp. 559–570. [Google Scholar] [CrossRef]

| Capturing Technology | Technology Status | Cost | CO2 Concentration | Thermal Efficiency | Pros | Cons |

|---|---|---|---|---|---|---|

| Post- combustion | Fully Developed | The lowest | The lowest | The highest | Easily integrated into existing power plants. | The electricity costs are increased by approximately 70% |

| Pre- combustion | Fully Developed | Medium | Medium | The lowest | The efficiency losses are significantly lower than those seen in post-combustion. Enables hydrogen production. The CO2 removal efficiency of natural gas fuel pre-combustion CCS can reach up to 80% | Difficult to integrate into existing power plants. Reduces the system’s compactness. |

| Oxyfuel combustion | Developed air separation | The highest | The highest | Medium | Eliminates NOx emission of the power plant. | Reduces plant efficiency by up to 10% |

| CO2 Separation Method | Pros | Cons |

|---|---|---|

| Absorption |

|

|

| Adsorption |

|

|

| Membrane separation |

|

|

| Hydrate-bases separation |

|

|

| Cryogenic distillation |

|

|

| Component | Volatility | Boiling Point | in Air | Relative Volatility |

|---|---|---|---|---|

| A | High | Low (−195.8 °C) | Nitrogen | The relative volatility of argon and oxygen (B and C) is lower than that of argon and nitrogen (B and A). |

| B | Intermediate | Intermediate (−185.8 °C) | Argon | |

| C | Low | High (−183 °C) | Oxygen |

| Air Separation Method. | Pros | Cons |

|---|---|---|

| Cryogenic distillation | Can be performed using a single distillation column or multiple distillation columns, depending on the specifications and requirements of the integrated power plant | The cost of multi-column distillation remains a challenge |

| Thermally linked distillation column, with a side rectifier | Used for alternative working fluids with high contents of oxygen and argon. | Excessive production of nitrogen for nitrogen-independent working fluid. |

| Thermally linked distillation column, with a side stripper | -- | Because argon and oxygen (B and C) have a lower relative volatility than argon and nitrogen (B and A) [54], a side rectifier is a more proper choice for air separation. |

| Low-pressure (LP) distillation | Less energy consumption compared to the EP distillation | Not suitable for gas turbines operating at high compression ratios |

| The elevated-pressure distillation column | Provides better matching between the ASU and the gas turbine unit compared to Low pressure (LP) distillation | High energy consumption |

| Single distillation column | In comparison to conventional double distillation columns, self-heat recuperation of a single distillation column saves 36% of energy consumption | Less popular, compared to the double distillation columns |

| Double distillation columns | More popular compared to the single distillation column | Liquefaction and air compression cause significant losses |

| Membrane Air Separation Method | Pros | Cons |

|---|---|---|

| MIEC membrane |

|

|

| Four-end approach |

|

|

| Three-end approach |

|

|

| Category | Temperature Range (°C) |

|---|---|

| nickel-based | 550–850 |

| carbon-based | 300–900 |

| zinc-based | 300–500 |

| aluminum-based | 750–800 |

| cerium-based | 300–800 |

| zirconium-based | 250–500 |

| Property | Composition | Stabilizer | Promoter |

|---|---|---|---|

| Iron-based catalyst | 74.2% Fe2O3, 10% Cr2O3, 0.2% MgO, and the remaining is to balance volatiles | Cr2O3 | --- |

| Copper-based catalyst | 24% ZnO, 24% Cr2O3, 3% Mn, Al, and Mg-oxides. The remaining is to balance volatiles | Cr2O3 | ZnO |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alrebei, O.F.; Amhamed, A.I.; El-Naas, M.H.; Hayajnh, M.; Orabi, Y.A.; Fawaz, W.; Al-tawaha, A.S.; Medina, A.V. State of the Art in Separation Processes for Alternative Working Fluids in Clean and Efficient Power Generation. Separations 2022, 9, 14. https://doi.org/10.3390/separations9010014

Alrebei OF, Amhamed AI, El-Naas MH, Hayajnh M, Orabi YA, Fawaz W, Al-tawaha AS, Medina AV. State of the Art in Separation Processes for Alternative Working Fluids in Clean and Efficient Power Generation. Separations. 2022; 9(1):14. https://doi.org/10.3390/separations9010014

Chicago/Turabian StyleAlrebei, Odi Fawwaz, Abdulkarem I. Amhamed, Muftah H. El-Naas, Mahmoud Hayajnh, Yasmeen A. Orabi, Ward Fawaz, Ahmad S. Al-tawaha, and Agustin Valera Medina. 2022. "State of the Art in Separation Processes for Alternative Working Fluids in Clean and Efficient Power Generation" Separations 9, no. 1: 14. https://doi.org/10.3390/separations9010014

APA StyleAlrebei, O. F., Amhamed, A. I., El-Naas, M. H., Hayajnh, M., Orabi, Y. A., Fawaz, W., Al-tawaha, A. S., & Medina, A. V. (2022). State of the Art in Separation Processes for Alternative Working Fluids in Clean and Efficient Power Generation. Separations, 9(1), 14. https://doi.org/10.3390/separations9010014