Semi-Quantitative and Qualitative Distinction of Aromatic and Flavour Compounds in Charcoal Grilled, Electric Barbecue Grilled, Infrared Grilled and Superheated-Steam Roasted Lamb Meat Patties Using GC/MC, E-nose and E-tongue

Abstract

:1. Introduction

2. Material and Methods

2.1. Preparation of Lamb Patties

2.2. Cooking of Patties

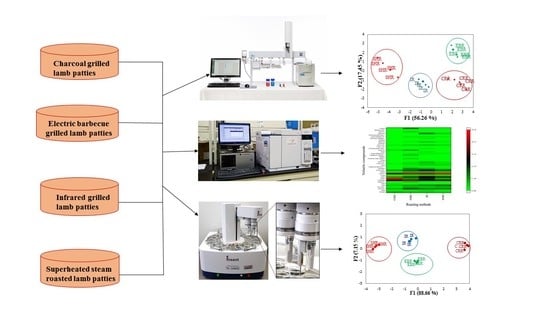

2.3. Volatile Compound Profiling by Electronic Nose

2.4. Analysis of Electric Tongue

2.5. Analysis by Gas Chromatography–Mass Spectrometry (GC–MS/MS)

2.6. Statistical Analysis

3. Results and Discussion

3.1. GC-MS/MS Analysis of Volatile Compounds in Lamb Patties

3.2. Volatile Analysis of Lamb Patties by E-Nose

3.3. Flavour Analysis of Lamb Patties by E-Tongue

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Ni, Q.; Khomenko, I.; Gallo, L.; Biasioli, F.; Bittante, G. Rapid profiling of the volatilome of cooked meat by PTR-ToF-MS: Characterization of chicken, turkey, ork, Veal and Beef Meat. Foods 2020, 9, 1776. [Google Scholar] [CrossRef]

- Mao, Y.; Hopkins, D.L.; Zhang, Y.; Luo, X. Consumption patterns and consumer attitudes to beef and sheep meat in China. Am. J. Food Nutr. 2016, 4, 30–39. [Google Scholar]

- Krishtafovich, V.; Krishtafovich, D.; Surzhanskaya, I.; Marakova, A.; Vorobieva, D. The value of the lamb meat in human nutrition. Int. Food Res. J. 2016, 23, 2540–2544. [Google Scholar]

- Binnie, M.A.; Barlow, K.; Johnson, V.; Harrison, C. Red meats: Time for a paradigm shift in dietary advice. Meat Sci. 2014, 98, 445–451. [Google Scholar] [CrossRef] [PubMed]

- De Andrade, J.C.; de Aguiar Sobral, L.; Ares, G.; Deliza, R. Understanding consumers’ perception of lamb meat using free word association. Meat Sci. 2016, 117, 68–74. [Google Scholar] [CrossRef]

- Sañudo, C.; Alfonso, M.; Sanchez, A.; Berge, P.; Dransfield, E.; Zygoyiannis, D.; Stamataris, C.; Thorkelsson, G.; Valdimarsdottir, T.; Piasentier, E.; et al. Meat texture of lambs from different European production systems. Aust. J. Agric. Res. 2003, 54, 551–560. [Google Scholar] [CrossRef]

- Khan, M.I.; Jo, C.; Tariq, M.R. Meat flavor precursors and factors influencing flavor precursors-A systematic review. Meat Sci. 2015, 110, 278–284. [Google Scholar] [CrossRef]

- Mottram, D.S.; Whitfield, F.B. Aroma volatiles from meat like maillard systems. In ACS Symposium Series; ACS Publications: Washington, DC, USA, 1994; pp. 180–191. [Google Scholar]

- Roldán, M.; Ruiz, J.; del Pulgar, J.S.; Pérez-Palacios, T.; Antequera, T. Volatile compound profile of sous-vide cooked lamb loins at different temperature–time combinations. Meat Sci. 2015, 100, 52–57. [Google Scholar] [CrossRef]

- Xiao, X.; Hou, C.; Zhang, D.; Li, X.; Ren, C.; Ijaz, M.; Liu, D. Effect of pre-and post-rigor on texture, flavor, heterocyclic aromatic amines and sensory evaluation of roasted lamb. Meat Sci. 2020, 169, 108220. [Google Scholar] [CrossRef]

- Obuz, E.; Dikeman, M.E.; Loughin, T.M. Effects of cooking method, reheating, holding time, and holding temperature on beef longissimus lumborum and biceps femoris tenderness. Meat Sci. 2003, 65, 841–851. [Google Scholar] [CrossRef]

- Elmore, J.S.; Mottram, D.S. The role of lipid in the flavour of cooked beef. In Developments in Food Science; Elsevier: Amsterdam, The Netherlands, 2006; Volume 43, pp. 375–378. [Google Scholar]

- Bravo-Lamas, L.; Barron, L.J.; Farmer, L.; Aldai, N. Fatty acid composition of intramuscular fat and odour-active compounds of lamb commercialized in northern Spain. Meat Sci. 2018, 139, 231–238. [Google Scholar] [CrossRef] [PubMed]

- Vasta, V.; D’Alessandro, A.G.; Priolo, A.; Petrotos, K.; Martemucci, G. Volatile compound profile of ewe’s milk and meat of their suckling lambs in relation to pasture vs. indoor feeding system. Small Rumin. Res. 2012, 105, 16–21. [Google Scholar] [CrossRef]

- Ortuño, J.; Mateo, L.; Rodríguez-Estrada, M.T.; Bañón, S. Effects of sousvide vs grilling methods on lamb meat colour and lipid stability during cooking and heated display. Meat Sci. 2020, 171, 108287. [Google Scholar] [CrossRef]

- Ye, Y.; Eyres, G.T.; Reis, M.G.; Schreurs, N.M.; Silcock, P.; Agnew, M.P.; Johnson, P.L.; MacLean, P.; Realini, C.E. Fatty Acid Composition and Volatile Profile of M. longissimus thoracis from Commercial Lambs Reared in Different Forage Systems. Foods 2020, 9, 1885. [Google Scholar] [CrossRef]

- Yang, Y.; Li, J.; Jia, X.; Zhao, Q.; Ma, Q.; Yu, Y.; Tang, C.; Zhang, J. Characterization of the Flavor Precursors and Flavor Fingerprints in Grazing Lambs by Foodomics. Foods 2022, 11, 191. [Google Scholar] [CrossRef] [PubMed]

- Zou, Y.; Kang, D.; Liu, R.; Qi, J.; Zhou, G.; Zhang, W. Effects of ultrasonic assisted cooking on the chemical profiles of taste and flavor of spiced beef. Ultrason. Sonochem. 2018, 46, 36–45. [Google Scholar] [CrossRef]

- Zhang, K.; Li, D.; Zang, M.; Zhang, Z.; Li, X.; Wang, S.; Zhang, S.; Zhao, B. Comparative characterization of fatty acids, reheating volatile compounds, and warmed-over flavor (WOF) of Chinese indigenous pork and hybrid pork. LWT—Food Sci. Technol. 2021, 155, 112981. [Google Scholar] [CrossRef]

- Karpiński, P.; Łątkowska, M.; Kruszewski, B.; Kuźma, P.; Obiedziński, M.W. Profile of volatile compounds in european dry-cured hams as indicator of their quality and authenticity (in Polish, with English summary). Żywność Nauka Technol. Jakość (Food Sci. Technol. Qual.) 2015, 2, 47–61. [Google Scholar]

- Calik, J.; Krawczyk, J.; Świątkiewicz, S.; Gąsior, R.; Wojtycza, K.; Potowicz, K.; Obrzut, J.; Puchała, M. Comparison of the physicochemical and sensory characteristics of Rhode Island Red (R-11) capons and cockerels. Ann. Anim. Sci. 2017, 17, 903–917. [Google Scholar] [CrossRef] [Green Version]

- Gong, H.; Yang, Z.; Liu, M.; Shi, Z.; Li, J.; Chen, W.; Qiao, X. Time-dependent categorization of volatile aroma compound formation in stewed Chinese spicy beef using electron nose profile coupled with thermal desorption GC–MS detection. Food Sci. Hum. Wellness 2013, 6, 137–146. [Google Scholar] [CrossRef]

- Mottram, D.S. Flavor formation in meat and meat products: A review. Food Chem. 1998, 62, 415–424. [Google Scholar] [CrossRef]

- Sivadier, G.; Ratel, J.; Engel, E. Persistence of pasture feeding volatile biomarkers in lamb fats. Food Chem. 2010, 118, 418–425. [Google Scholar] [CrossRef]

- Nieto, G.; Estrada, M.; Jordán, M.J.; Garrido, M.D.; Bañón, S. Effects in ewe diet of rosemary by-product on lipid oxidation and the eating quality of cooked lamb under retail display conditions. Food Chem. 2011, 124, 1423–1429. [Google Scholar] [CrossRef]

- Bai, S.; Wang, Y.; Luo, R.; Ding, D.; Bai, H.; Shen, F. Characterization of flavor volatile compounds in industrial stir-frying mutton sao zi by GC-MS, E-nose, and physicochemical analysis. Food Sci. Nutr. 2021, 9, 499–513. [Google Scholar] [CrossRef] [PubMed]

- Karpiński, P.; Kruszewski, B.; Stachelska, M.A.; Szabłowska, E. Development of volatile profile of Kumpiak podlaski dry-cured ham during traditional ripening. Int. J. Food Sci. Technol. 2020, 55, 3630–3638. [Google Scholar] [CrossRef]

- Ji, J.R.; Park, K.M.; Choe, H.S.; Hwang, I.H. Objective meat quality and volatile components as a function of cooking temperature in beef Longissimus lumborum. Korean J. Food Sci. Anim. Resour. 2010, 30, 373–384. [Google Scholar] [CrossRef] [Green Version]

- Giri, A.; Osako, K.; Ohshima, T. Identification and characterisation of head space volatiles of fish miso, a Japanese fish meat based fermented paste, with special emphasis on effect of fish species and meat washing. Food Chem. 2010, 120, 621–631. [Google Scholar] [CrossRef]

- Bueno, M.; Campo, M.M.; Cacho, J.; Ferreira, V.; Escudero, A. A model explaining and predicting lamb flavour from the aroma-active chemical compounds released upon grilling light lamb loins. Meat Sci. 2014, 98, 622–628. [Google Scholar] [CrossRef]

- Wang, Q.; Li, L.; Ding, W.; Zhang, D.; Wang, J.; Reed, K.; Zhang, B. Adulterant identification in mutton by electronic nose and gas chromatography-mass spectrometer. Food Control 2019, 98, 431–438. [Google Scholar] [CrossRef]

- Campo, M.M.; Nute, G.R.; Wood, J.D.; Elmore, S.J.; Mottram, D.S.; Enser, M. Modelling the effect of fatty acids in odour development of cooked meat in vitro: Part I—Sensory perception. Meat Sci. 2003, 63, 367–375. [Google Scholar] [CrossRef]

- Nieto, G.; Bañón, S.; Garrido, M.D. Effect of supplementing ewes’ diet with thyme (Thymus zygis ssp. gracilis) leaves on the lipid oxidation of cooked lamb meat. Food Chem. 2011, 125, 1147–1152. [Google Scholar]

- Elmore, J.S.; Cooper, S.L.; Enser, M.; Mottram, D.S.; Sinclair, L.A.; Wilkinson, R.G. Dietary manipulation of fatty acid composition in lamb meat and its effect on the volatile aroma compounds of grilled lamb. Meat Sci. 2005, 69, 233–242. [Google Scholar] [CrossRef] [PubMed]

- Cai, L.; Li, D.; Dong, Z.; Cao, A.; Lin, H.; Li, J. Change regularity of the characteristics of Maillard reaction products derived from xylose and Chinese shrimp waste hydrolysates. LWT—Food Sci. Technol. 2016, 65, 908–916. [Google Scholar] [CrossRef]

- Roldan, M.; Antequera, T.; Armenteros, M.; Ruiz, J. Effect of different temperature-time combinations on lipid and protein oxidation of sous-vide cooked lamb loins. Food Chem. 2014, 149, 129–136. [Google Scholar] [CrossRef] [PubMed]

- Karabagias, I. Volatile Profile of Raw Lamb Meat Stored at 4 ± 1 °C: The potential of specific aldehyde ratios as indicators of lamb meat quality. Foods 2018, 7, 40. [Google Scholar] [CrossRef] [Green Version]

- Farmer, L.; Hagan, T.D.J.; Paraskevas, O. Role of selected precursors in meat flavor formation. In Quality Attributes of Muscle Foods; Xiong, Y.L., Ho, C.T., Shahidi, F., Eds.; Springer: Boston, MA, USA, 1999; pp. 159–172. [Google Scholar]

- Vasta, V.; Priolo, A. Ruminant fat volatiles as affected by diet. A review. Meat Sci. 2006, 73, 218–228. [Google Scholar] [CrossRef] [PubMed]

- Bueno, M.; Resconi, V.C.; Campo, M.M.; Cacho, J.; Ferreira, V.; Escudero, A. Effect of freezing method and frozen storage duration on odor-active compounds and sensory perception of lamb. Food Res. Int. 2013, 54, 772–780. [Google Scholar] [CrossRef]

- Du, W.; Zhen, D.; Wang, Y.; Cheng, J.; Xie, J. Characterization of the key odorants in grilled mutton shashlik with or without suet brushing during grilling. Flavour Fragr. J. 2021, 36, 111–120. [Google Scholar] [CrossRef]

- Resconi, V.C.; Campo, M.M.; Montossi, F.; Ferreira, V.; Sañudo, C.; Escudero, A. Relationship between odour-active compounds and flavour perception in meat from lambs fed different diets. Meat Sci. 2010, 85, 700–706. [Google Scholar] [CrossRef]

- Insausti, K.; Murillo-Arbizu, M.T.; Urrutia, O.; Mendizabal, J.A.; Beriain, M.J.; Colle, M.J.; Bass, P.D.; Arana, A. Volatile Compounds, Odour and Flavour Attributes of Lamb Meat from the Navarra Breed as Affected by Ageing. Foods 2021, 10, 493. [Google Scholar] [CrossRef]

- Watkins, P.J.; Kearney, G.; Rose, G.; Allen, D.; Ball, A.J.; Pethick, D.W.; Warner, R.D. Effect of branched-chain fatty acids, 3-methylindole and 4-methylphenol on consumer sensory scores of grilled lamb meat. Meat Sci. 2014, 96, 1088–1094. [Google Scholar] [CrossRef] [PubMed]

- Tian, H.; Zhan, P.; Li, W.; Zhang, X.; He, X.; Ma, Y.; Zhang, D. Contribution to the aroma characteristics of mutton process flavor from oxidized suet evaluated by descriptive sensory analysis, gas chromatography, and electronic nose through partial least squares regression. Eur. J. Lipid Sci. Technol. 2014, 116, 1522–1533. [Google Scholar] [CrossRef]

- Amaral, A.B.; da Silva, M.V.; da Silva Lannes, S.C. Lipid oxidation in meat: Mechanisms and protective factors a review. Food Sci. Technol. 2018, 38, 1–5. [Google Scholar] [CrossRef] [Green Version]

- Oltra, O.R.; Farmer, L.J.; Gordon, A.W.; Moss, B.W.; Birnie, J.; Devlin, D.J.; Farrell, D. Identification of sensory attributes, instrumental and chemical measurements important for consumer acceptability of grilled lamb Longissimus lumborum. Meat Sci. 2015, 100, 97–109. [Google Scholar] [CrossRef]

- Arshad, M.S.; Sohaib, M.; Ahmad, R.S.; Nadeem, M.T.; Imran, A.; Arshad, M.U.; Amjad, Z. Ruminant meat flavor influenced by different factors with special reference to fatty acids. Lipids Health Dis. 2018, 17, 223. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Discrimination Power | ||||

|---|---|---|---|---|

| Header Cooking Treaments | Charcoal-Grilled | Electric Barbecue | Infrared-Grilled | Superheated-Steam-Roasted |

| Charcoal-grilled | 0.461 | 0.628 * | 0.765 * | |

| Electric barbecue | 0.753 * | 0.794 * | ||

| Infrared-grilled | 0.613 * | |||

| Superheated- steam-roasted | ||||

| Cooking Method | AHS-Sourness | PKS | CTS-Saltiness | NMS-Umami | CPS | ANS | SCS |

|---|---|---|---|---|---|---|---|

| Charcoal grill | 2.9 | 8.7 * | 3.6 | 3.1 | 9.0 ** | 8.7 * | 9.0 ** |

| Electric barbecue | 6.0 | 6.3 | 5.0 | 6.0 | 5.9 | 4.0 | 6.1 |

| Infrared grill | 6.6 | 5.7 | 6.7 | 6.4 | 5.4 | 7.2 | 5.4 |

| Superheated steam roast | 8.5 ** | 3.3 | 8.7 ** | 8.6 ** | 3.7 | 4.2 | 3.5 |

| Sample Names | Comparative Sample | Distance | p-Value | Finger Print Identity Index (%) |

|---|---|---|---|---|

| Charcoal grill | Electric barbecue | 436.09 * | 0.00 | 94.46 ** |

| Charcoal grill | Infrared grill | 491.29 * | 0.00 | 95.55 ** |

| Charcoal grill | Superheated steam | 798.21 ** | 0.00 | 98.29 ** |

| Electric barbecue | Infrared grill | 149.41 | 0.00 | 62.39 |

| Electric barbecue | Superheated steam | 385.20 * | 0.00 | 91.36 * |

| Infrared grill | Superheated steam | 313.71 * | 0.00 | 88.01 * |

| (I) Cooking Method | (J) Cooking Method | Mean Difference (I-J) | Standard Error | Significance. |

|---|---|---|---|---|

| CRR | EBR | 130.91 * | 6.46 | 0.00 |

| IR | 128.49 * | 6.46 | 0.00 | |

| SHR | 215.32 * | 6.46 | 0.00 | |

| EBR | CRR | −130.91 * | 6.46 | 0.00 |

| IR | −2.41 | 6.46 | 0.70 | |

| SHR | 84.41 * | 6.46 | 0.00 | |

| IR | CRR | −128.49 * | 6.46 | 0.00 |

| EBR | 2.4182 | 6.46 | 0.70 | |

| SHR | 86.83 * | 6.46 | 0.00 | |

| SHR | CRR | −215.32 * | 6.46 | 0.00 |

| EBR | −84.41 * | 6.46 | 0.00 | |

| IR | −86.83 * | 6.46 | 0.00 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Suleman, R.; Hui, T.; Wang, Z.; Alarcon-Rojo, A.D.; Liu, H.; Zhang, D. Semi-Quantitative and Qualitative Distinction of Aromatic and Flavour Compounds in Charcoal Grilled, Electric Barbecue Grilled, Infrared Grilled and Superheated-Steam Roasted Lamb Meat Patties Using GC/MC, E-nose and E-tongue. Separations 2022, 9, 71. https://doi.org/10.3390/separations9030071

Suleman R, Hui T, Wang Z, Alarcon-Rojo AD, Liu H, Zhang D. Semi-Quantitative and Qualitative Distinction of Aromatic and Flavour Compounds in Charcoal Grilled, Electric Barbecue Grilled, Infrared Grilled and Superheated-Steam Roasted Lamb Meat Patties Using GC/MC, E-nose and E-tongue. Separations. 2022; 9(3):71. https://doi.org/10.3390/separations9030071

Chicago/Turabian StyleSuleman, Raheel, Teng Hui, Zhenyu Wang, Alma Delia Alarcon-Rojo, Huan Liu, and Dequan Zhang. 2022. "Semi-Quantitative and Qualitative Distinction of Aromatic and Flavour Compounds in Charcoal Grilled, Electric Barbecue Grilled, Infrared Grilled and Superheated-Steam Roasted Lamb Meat Patties Using GC/MC, E-nose and E-tongue" Separations 9, no. 3: 71. https://doi.org/10.3390/separations9030071

APA StyleSuleman, R., Hui, T., Wang, Z., Alarcon-Rojo, A. D., Liu, H., & Zhang, D. (2022). Semi-Quantitative and Qualitative Distinction of Aromatic and Flavour Compounds in Charcoal Grilled, Electric Barbecue Grilled, Infrared Grilled and Superheated-Steam Roasted Lamb Meat Patties Using GC/MC, E-nose and E-tongue. Separations, 9(3), 71. https://doi.org/10.3390/separations9030071