Green Ag/AgCl as an Effective Plasmonic Photocatalyst for Degradation and Mineralization of Methylthioninium Chloride

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Synthesis of Ag/AgCl Catalyst

2.3. Material Characterization

2.4. Photocatalytic Activities of Ag/AgCl Nanoparticles

3. Results and Discussion

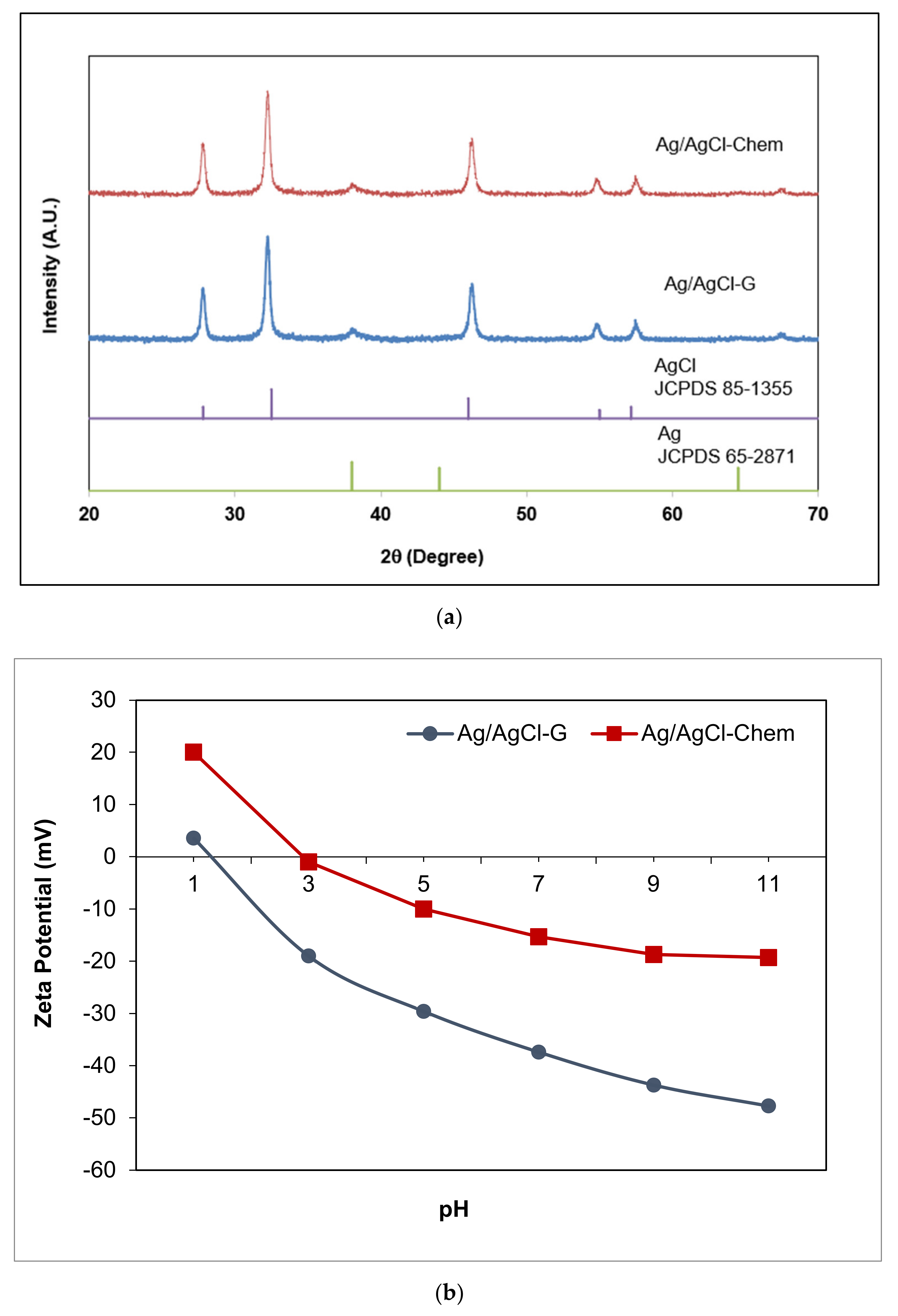

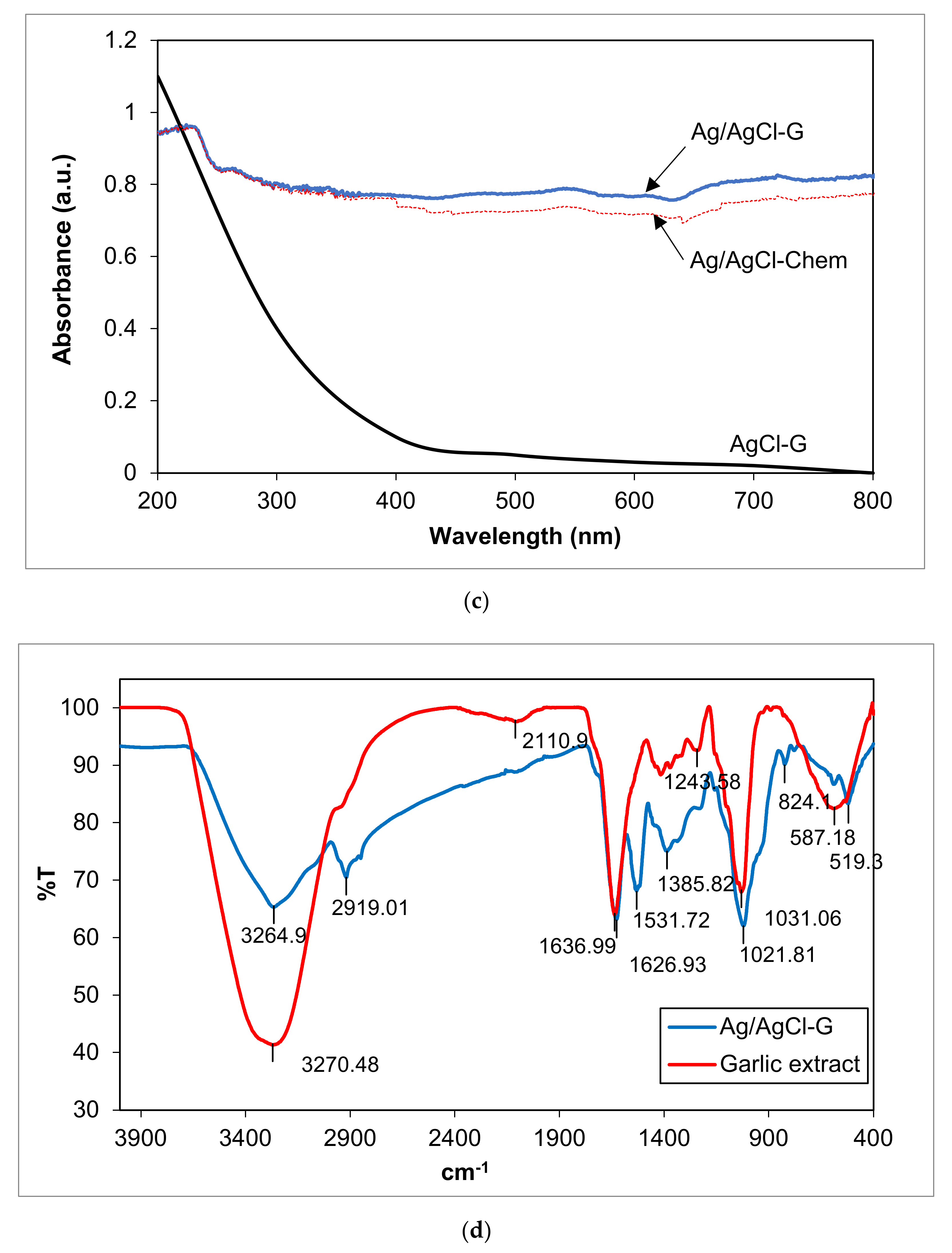

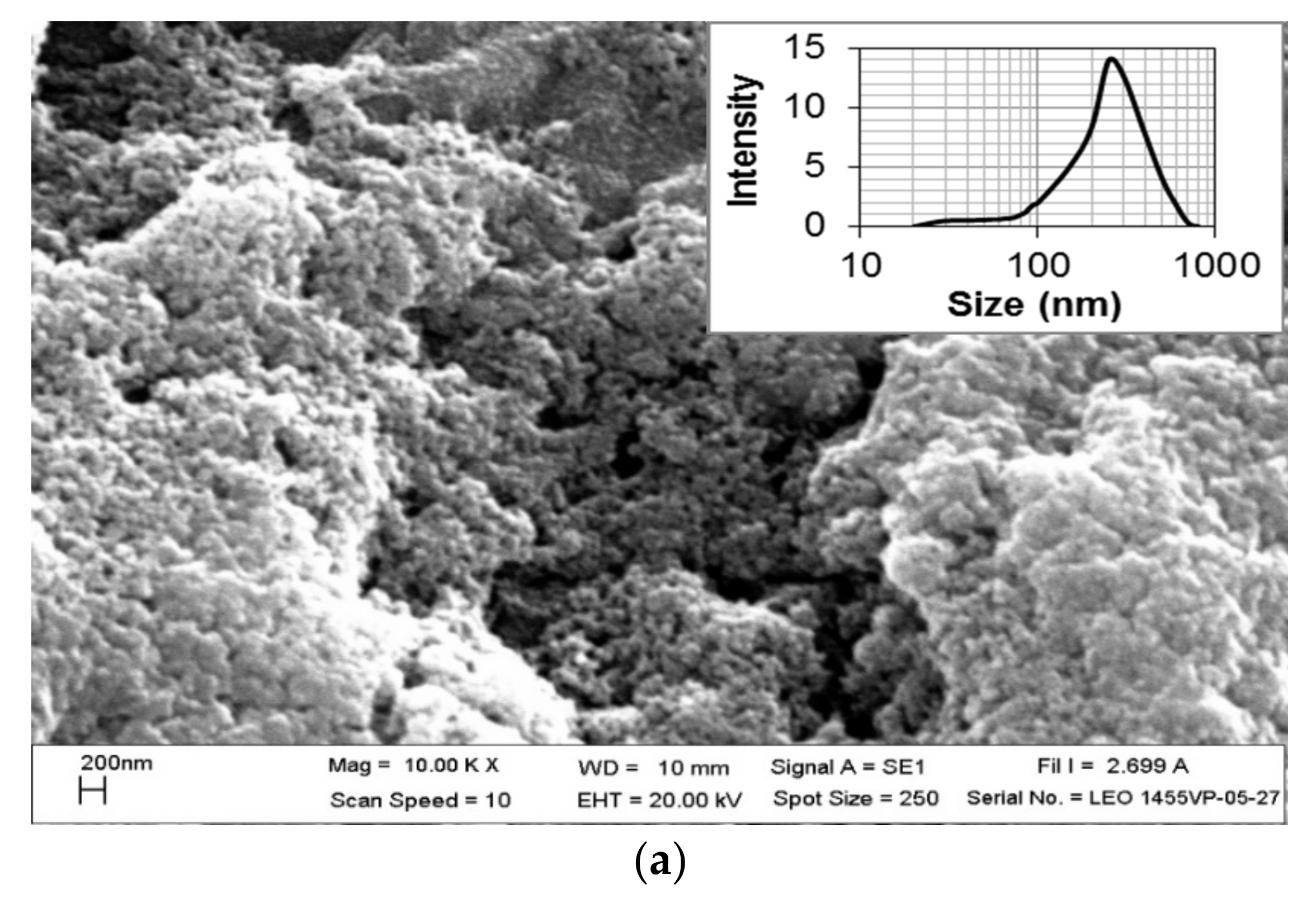

3.1. Characteristics of Ag/AgCl-G Nanoparticles

3.2. Plasmonic Photocatalytic Activity of Ag/AgCl in MC Removal under Visible Light and Sunlight

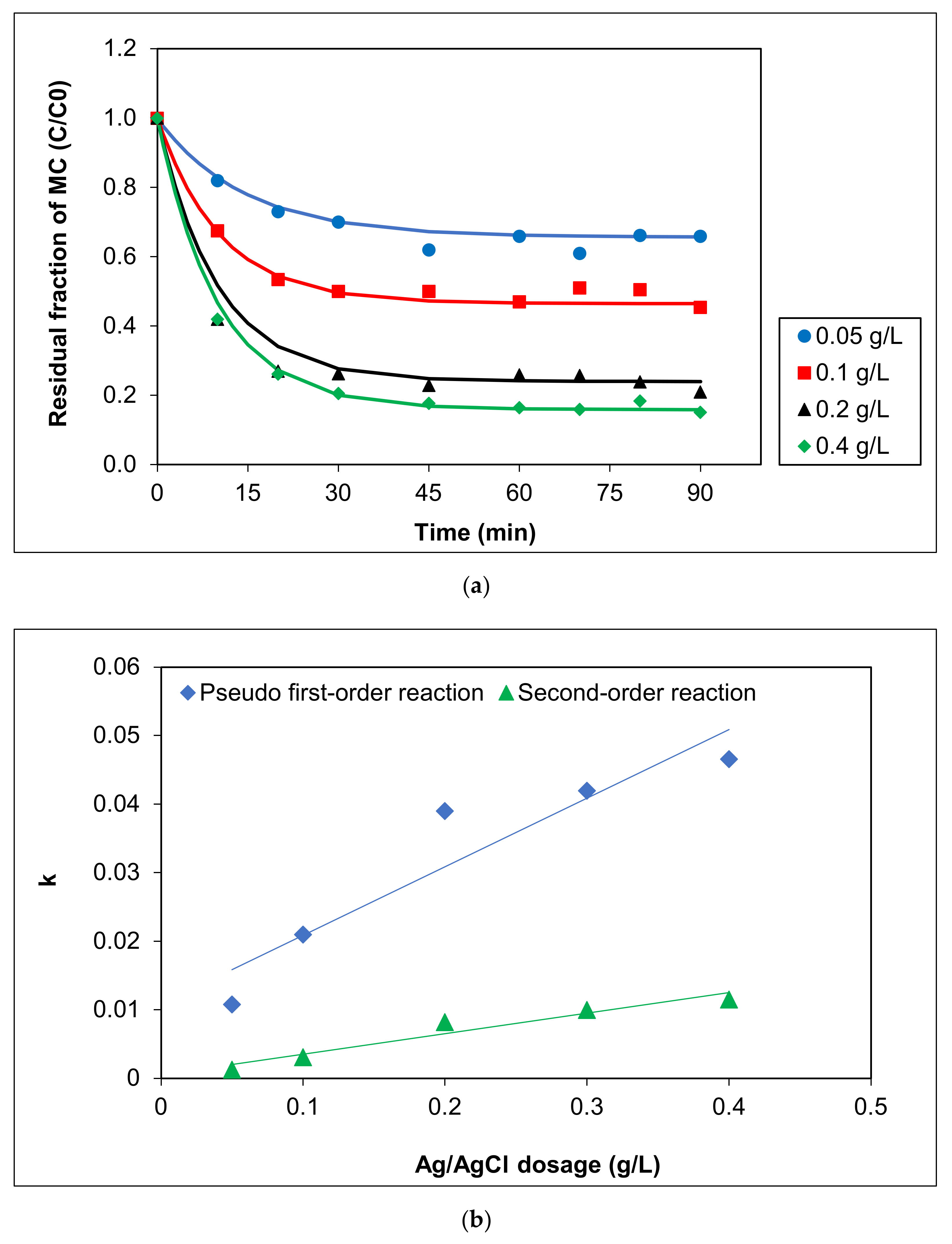

3.2.1. Effect of Ag/AgCl-G Dosages on MC Removal and Kinetics

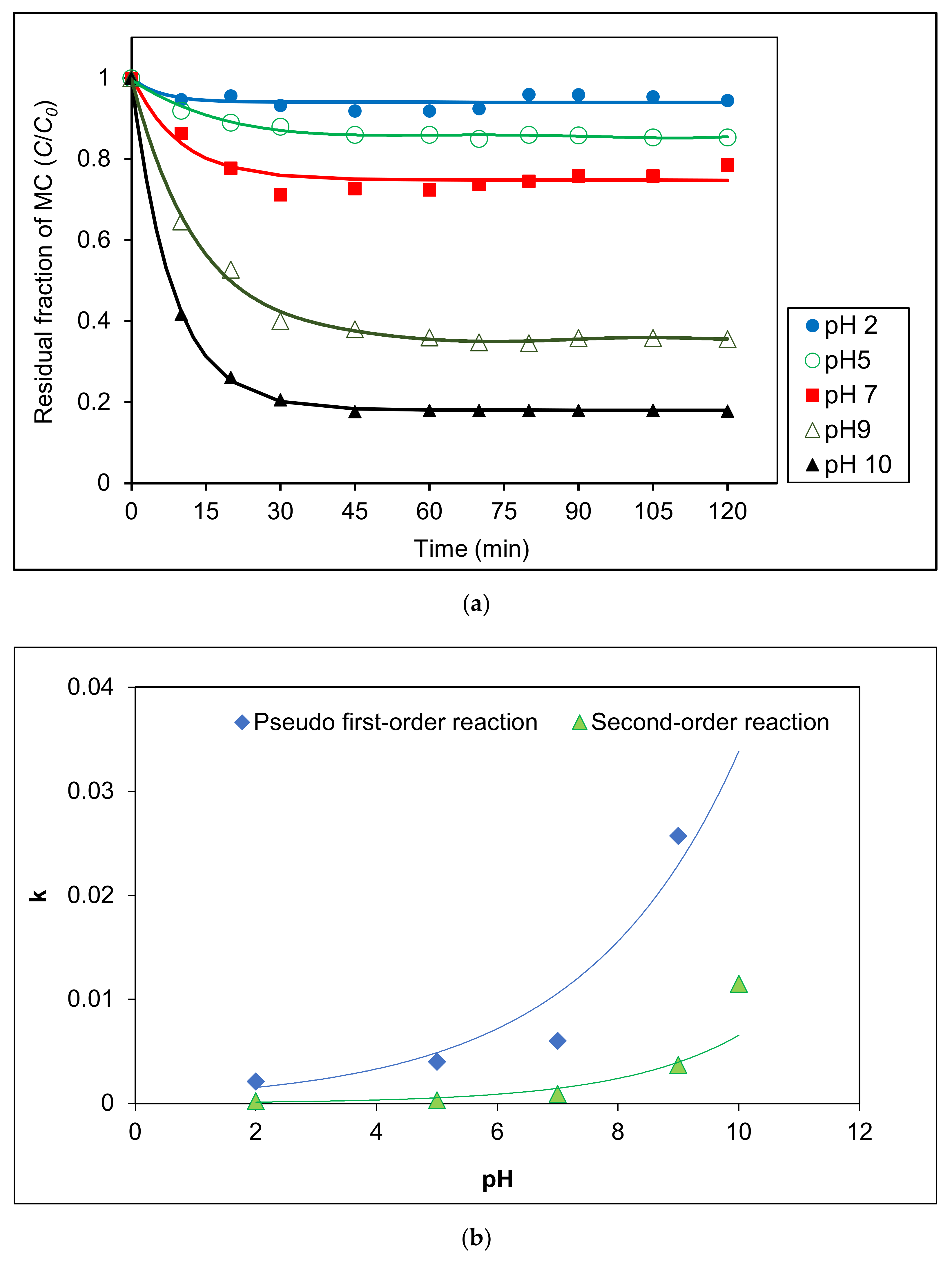

3.2.2. Effect of pH on the Degradation of MC by a Photocatalytic Process under Visible Light

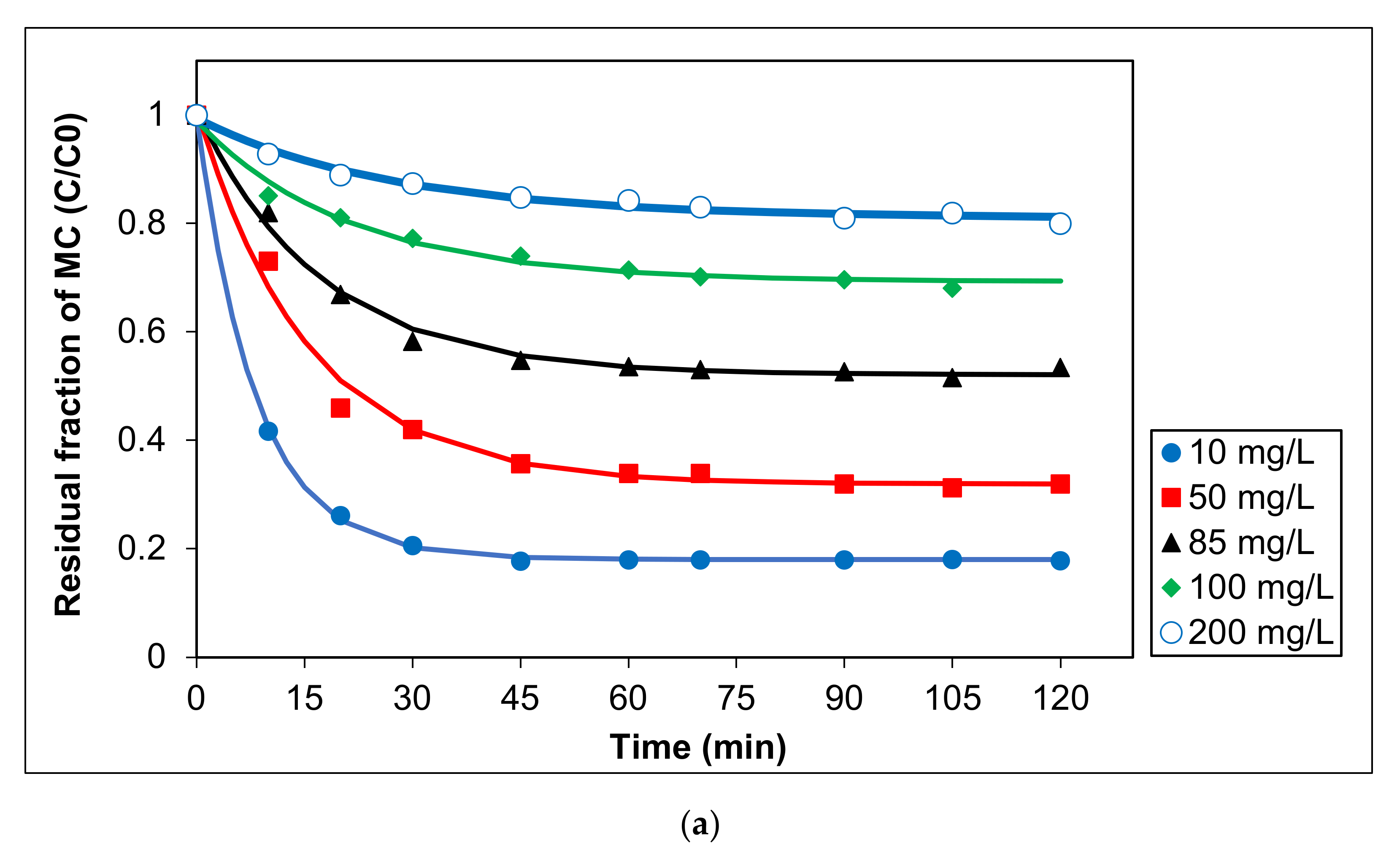

3.2.3. Influence of Initial MC Concentration on the Photocatalytic Activity of Ag/AgCl-G under Visible Light

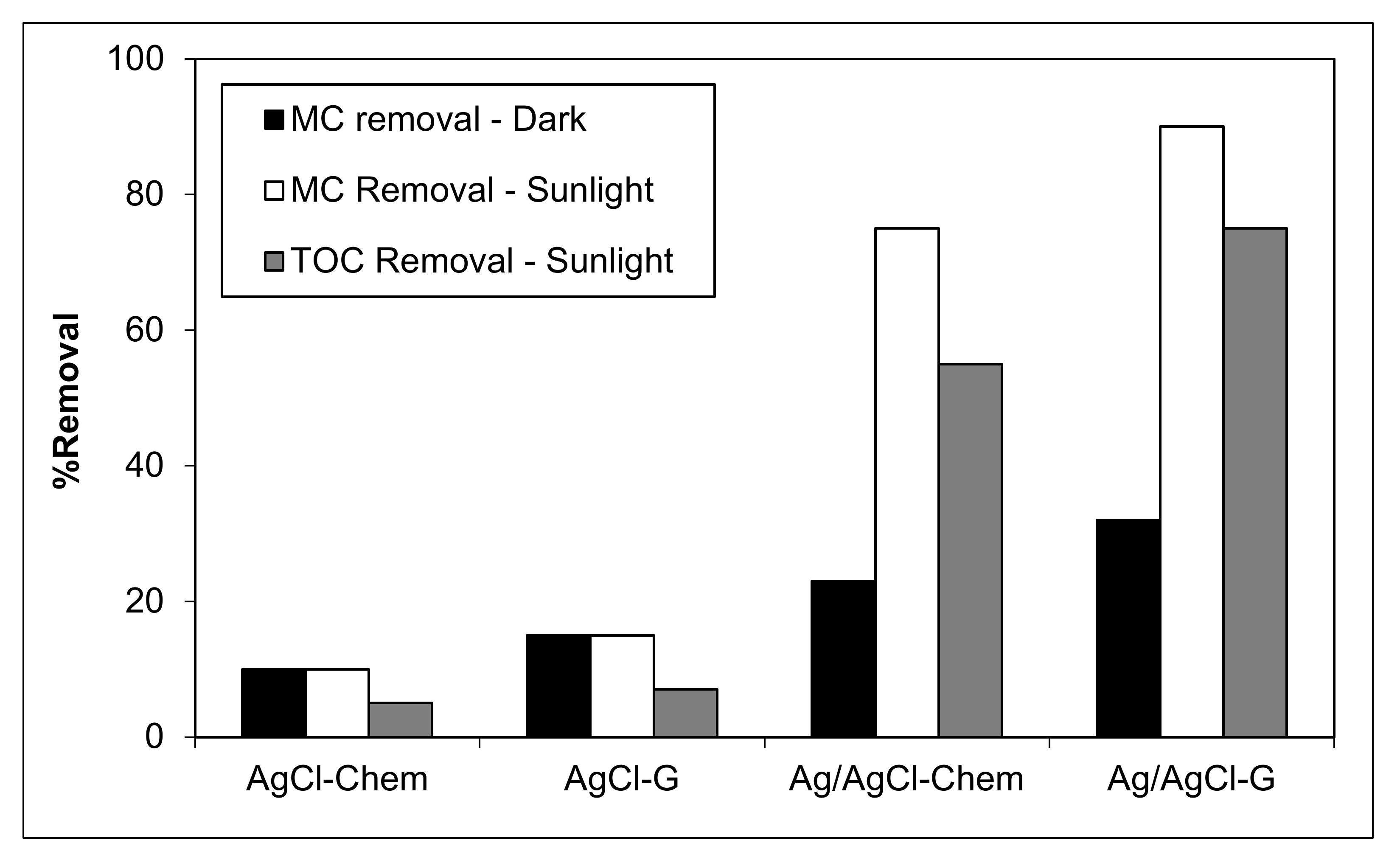

3.2.4. Plasmonic Photocatalytic Activity of Ag/AgCl-G for MC Removal under Sunlight

3.3. Mechanism and Degradation Pathway of MC Removal Using Ag/AgCl-G

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tao, A.; Sinsermsuksakul, P.; Yang, P. Polyhedral silver nanocrystals with distinct scattering signatures. Angew. Chem. Int. Ed. Engl. 2006, 45, 4597–4601. [Google Scholar] [CrossRef] [PubMed]

- Mock, J.J.; Barbic, M.; Smith, D.R.; Schultz, D.A.; Schultz, S. Shape effects in plasmon resonance of individual colloidal silver nanoparticles. J. Chem. Phys. 2002, 116, 6755–6759. [Google Scholar] [CrossRef]

- Zhang, Q.; Ge, J.; Pham, T.; Goebl, J.; Hu, Y.; Lu, Z.; Yin, Y. Reconstruction of silver nanoplates by UV irradiation: Tailored optical properties and enhanced stability. Angew. Chem. Int. Ed. Engl. 2009, 48, 3516–3519. [Google Scholar] [CrossRef] [PubMed]

- Awazu, K.; Fujimaki, M.; Rockstuhl, C.; Tominaga, J.; Murakami, H.; Ohki, Y.; Yoshida, N.; Watanabe, T. A plasmonic photocatalyst consisting of silver nanoparticles embedded in titanium dioxide. J. Am. Chem. Soc. 2008, 130, 1676–1680. [Google Scholar] [CrossRef] [PubMed]

- Bi, Y.; Ye, J. Heteroepitaxial growth of platinum nanocrystals on AgCl nanotubes via galvanic replacement reaction. Chem. Commun. 2010, 46, 1532–1534. [Google Scholar] [CrossRef] [PubMed]

- Wang, P.; Huang, B.; Qin, X.; Zhang, X.; Dai, Y.; Wei, J.; Whangbo, M.H. Ag@AgCl: A highly efficient and stable photocatalyst active under visible light. Angew. Chem. Int. Ed. 2008, 47, 7931–7933. [Google Scholar] [CrossRef] [PubMed]

- Xu, H.; Li, H.; Xia, J.; Yin, S.; Luo, Z.; Liu, L.; Xu, L. One-pot synthesis of visible-light-driven plasmonic photocatalyst Ag/AgCl in ionic liquid. ACS Appl. Mater. Interfaces 2011, 3, 22–29. [Google Scholar] [CrossRef]

- Li, Y.; Ding, Y. Porous AgCl/Ag nanocomposites with enhanced visible light photocatalytic properties. J. Phys. Chem. C 2010, 114, 3175–3179. [Google Scholar] [CrossRef]

- Jiang, J.; Zhang, L. Rapid microwave-assisted nonaqueous synthesis and growth mechanism of AgCl/Ag, and its daylight-driven plasmonic photocatalysis. Chem. Eur. J. 2011, 17, 3710–3717. [Google Scholar] [CrossRef]

- Philip, D. Honey mediated green synthesis of gold nanoparticles. Spectrochim. Acta A Mol. Biomol. Spectrosc. 2009, 73, 650–653. [Google Scholar] [CrossRef]

- Shukla, R.; Nune, S.K.; Chanda, N.; Katti, K.; Mekapothula, S.; Kulkarni, R.R.; Welshons, W.V.; Kannan, R.; Katti, K.V. Soybeans as a phytochemical reservoir for the production and stabilization of biocompatible gold nanoparticles. Small 2008, 4, 1425–1436. [Google Scholar] [CrossRef]

- Smuleac, V.; Varma, R.; Sikdar, S.; Bhattacharyya, D. Green synthesis of Fe and Fe/Pd bimetallic nanoparticles in membranes for reductive degradation of chlorinated organics. J. Membr. Sci. 2011, 379, 131–137. [Google Scholar] [CrossRef] [Green Version]

- Phuinthiang, P.; Kajitvichyanukul, P. Degradation of paraquat from contaminated water using green TiO2 nanoparticles synthesized from Coffea arabica L. In photocatalytic process. Water Sci. Technol. 2019, 79, 905–910. [Google Scholar] [CrossRef]

- Wang, W.; Lin, F.; Yan, B.; Cheng, Z.; Chen, G.; Kuang, M.; Yang, C.; Hou, L. The role of seashell wastes in TiO2/Seashell composites: Photocatalytic degradation of methylene blue dye under sunlight. Environ. Res. 2020, 188, 109831. [Google Scholar] [CrossRef]

- Boonupara, T.; Kajitvichyanukul, P. Facile synthesis of plasmonic Ag/AgCl nanoparticles with aqueous garlic extract (Allium sativum L.) for visible-light triggered antibacterial activity. Mater. Lett. 2020, 277, 128362. [Google Scholar] [CrossRef]

- Lan, L.; Wang, F.; Zeng, G. Staining with methylthioninium chloride for the diagnosis of fungal keratitis. Exp. Ther. Med. 2013, 6, 1229–1232. [Google Scholar] [CrossRef] [Green Version]

- Ginimuge, P.R.; Jyothi, S.D. Methylene Blue: Revisited. J. Anaesthesiol. Clin. Pharmacol. 2010, 26, 517–520. [Google Scholar] [CrossRef]

- Chou, K.S.; Ren, C.Y. Synthesis of nanosized silver particles by chemical reduction method. Mater. Chem. Phys. 2000, 64, 241–246. [Google Scholar] [CrossRef]

- Wang, H.; Qiao, X.; Chen, J.; Ding, S. Preparation of silver nanoparticles by chemical reduction method. Colloids Surf. A Physicochem. Eng. Asp. 2005, 256, 111–115. [Google Scholar] [CrossRef]

- Shu, J.; Wang, Z.; Xia, G.; Zheng, Y.; Yang, L.; Zhang, W. One-pot synthesis of AgCl at Ag hybrid photocatalyst with high photocatalytic activity and photostability under visible light and sunlight irradiation. Chem. Eng. J. 2014, 252, 374–381. [Google Scholar] [CrossRef]

- Von White, G.; Kerscher, P.; Brown, R.M.; Morella, J.D.; McAllister, W.; Dean, D.; Kitchens, C.L. Green synthesis of robust, biocompatible silver nanoparticles using garlic extract. J. Nanomater. 2012, 2012, 730746. [Google Scholar] [CrossRef]

- Kittler, S.; Greulich, C.; Diendorf, J.; Köller, M.; Epple, M. Toxicity of silver nanoparticles increases during storage because of slow dissolution under release of silver ions. Chem. Mater. 2010, 22, 4548–4554. [Google Scholar] [CrossRef]

- Massich, M.D.; Giljohann, D.A.; Schmucker, A.L.; Patel, P.C.; Mirkin, C.A. Cellular response of polyvalent oligonucleotide—Gold nanoparticle conjugates. ACS Nano 2010, 4, 5641–5646. [Google Scholar] [CrossRef]

- Köth, A.; Joachim, K.; Appelhans, D.; Voit, B. “Sweet” gold nanoparticles with oligosaccharide-modified poly(ethyleneimine). Colloid Polym. Sci. 2008, 286, 1317–1327. [Google Scholar] [CrossRef]

- Rao, Y.N.; Banerjee, D.; Datta, A.; Das, S.K.; Guin, R.; Saha, A. Gamma irradiation route to synthesis of highly re-dispersible natural polymer capped silver nanoparticles. Radiat. Phys. Chem. 2010, 79, 1240–1246. [Google Scholar] [CrossRef]

- Sur, I.; Cam, D.; Kahraman, M.; Baysal, A.; Culha, M. Interaction of multi-functional silver nanoparticles with living cells. Nanotechnology 2010, 21, 175104. [Google Scholar] [CrossRef]

- Losso, J.N.; Nakai, S. Molecular size of garlic fructooligosaccharides and fructopolysaccharides by matrix-assisted laser desorption ionization mass spectrometry. J. Agric. Food Chem. 1997, 45, 4342–4346. [Google Scholar] [CrossRef]

- Zheng, Y.; Shu, J.; Wang, Z. AgCl@Ag composites with rough surfaces as bifunctional catalyst for the photooxidation and catalytic reduction of 4-nitrophenol. Mater. Lett. 2015, 158, 339–342. [Google Scholar] [CrossRef]

- Wang, S.; Tang, S.; Gao, H.; Chen, X.; Liu, H.; Yu, C.; Yin, Z.; Zhao, X.; Pan, X.; Yang, H. Microstructure, optical, photoluminescence properties and the intrinsic mechanism of photoluminescence and photocatalysis for the BaTiO3, BaTiO3/TiO2 and BaTiO3/TiO2/CeC2 smart composites. Opt. Mater. 2021, 118, 111273. [Google Scholar] [CrossRef]

- Valenti, L.E.; Giacomelli, C.E. Stability of silver nanoparticles: Agglomeration and oxidation in biological relevant conditions. J. Nanopart. Res. 2017, 19, 156. [Google Scholar] [CrossRef]

- Tian, J.; Liu, R.; Wang, G.; Xu, Y.; Wang, X.; Yu, H. Dependence of metallic Ag on the photocatalytic activity and photoinduced stability of Ag/AgCl photocatalyst. Appl. Surf. Sci. 2014, 319, 324–331. [Google Scholar] [CrossRef]

- Epling, G.A.; Lin, C. Photoassisted bleaching of dyes utilizing TiO2 and visible light. Chemosphere 2002, 46, 561–570. [Google Scholar] [CrossRef]

- An, C.; Peng, S.; Sun, Y. Facile synthesis of sunlight-driven AgCl: Ag plasmonic nanophotocatalyst. Adv. Mater. 2010, 22, 2570–2574. [Google Scholar] [CrossRef] [PubMed]

- Madhu, G.M.; Raj, M.A.L.A.; Pai, K.V.K.; Rao, S. Photodegradation of methylene blue dye using UV/BaTiO3, UV/H2O2 and UV/H2O2/BaTiO3 oxidation processes. Indian J. Chem. Technol. 2007, 14, 139–144. [Google Scholar]

- Sriskandakumar, T.; Opembe, N.; Chen, C.H.; Morey, A.; King’ondu, C.; Suib, S.L. Green decomposition of organic dyes using octahedral molecular sieve manganese oxide catalysts. J. Phys. Chem. A. 2009, 113, 1523–1530. [Google Scholar] [CrossRef]

- Oliveira, L.C.A.; Gonçalves, M.; Guerreiro, M.C.; Ramalho, T.C.; Fabris, J.D.; Pereira, M.C.; Sapag, K. A new catalyst material based on niobia/iron oxide composite on the oxidation of organic contaminants in water via heterogeneous Fenton mechanisms. Appl. Catal. A Gen. 2007, 316, 117–124. [Google Scholar] [CrossRef]

- Liu, T.; Yang, G.; Wang, W.; Wang, C.; Wang, M.; Sun, X.; Xu, P.; Zhang, J. Preparation of C3N5 nanosheets with enhanced performance in photocatalytic methylene blue (MB) degradation and H2-evolution from water splitting. Environ. Res. 2020, 188, 109741. [Google Scholar] [CrossRef]

| Dosage (g L−1) | r (mg L−1 min−1) | Pseudo-First Order Reaction | Second Order Reaction | ||||

|---|---|---|---|---|---|---|---|

| k1 (min−1) | t1/2 (min) | R2 | k2 (mg L−1 min−1) | t1/2 (min) | R2 | ||

| 0.05 | 0.1799 | 0.0108 | 64.18 | 0.8121 | 0.0013 | 76.93 | 0.9726 |

| 0.1 | 0.3248 | 0.021 | 33.01 | 0.7189 | 0.0031 | 32.26 | 0.9304 |

| 0.2 | 0.4874 | 0.039 | 17.77 | 0.8218 | 0.0082 | 12.19 | 0.9628 |

| 0.4 | 0.5291 | 0.0466 | 14.87 | 0.7927 | 0.0115 | 8.70 | 0.9508 |

| pH | Initial Rate, r (mg L−1 min−1) | Pseudo-First Order Reaction | Second Order Reaction | ||||

|---|---|---|---|---|---|---|---|

| k1 (min−1) | t1/2 (min) | R2 | k2 (mg L−1 min−1) | t1/2 (min) | R2 | ||

| pH 2 | 0.0530 | 0.0021 | 330.07 | 0.9263 | 0.0002 | 500.00 | 0.8414 |

| pH 5 | 0.0800 | 0.004 | 173.29 | 0.9308 | 0.0003 | 351.99 | 0.8434 |

| pH 7 | 0.1360 | 0.006 | 115.52 | 0.8649 | 0.0009 | 116.24 | 0.8283 |

| pH 9 | 0.3540 | 0.0257 | 26.97 | 0.9559 | 0.0037 | 28.97 | 0.9379 |

| pH 10 | 0.5829 | 0.047 | 14.75 | 0.9378 | 0.0115 | 9.47 | 0.9359 |

| Initial Concentration, C0 (mg L−1) | Initial Rate, r (mg L−1 min−1) | Pseudo-First Order Reaction | Second Order Reaction | ||||

|---|---|---|---|---|---|---|---|

| k1 (min−1) | t1/2 (min) | R2 | k2 (mg L−1 min−1) | t1/2 (min) | R2 | ||

| 10 | 0.5829 | 0.0593 | 11.69 | 0.9718 | 0.013 | 7.69 | 0.9949 |

| 50 | 1.3475 | 0.0266 | 26.06 | 0.9622 | 0.0009 | 22.22 | 0.9469 |

| 85 | 1.5309 | 0.0156 | 44.43 | 0.9707 | 0.0002 | 58.82 | 0.9522 |

| 100 | 1.4890 | 0.0079 | 87.74 | 0.9431 | 0.00009 | 111.11 | 0.8937 |

| 200 | 1.4340 | 0.0042 | 165.04 | 0.9569 | 0.00002 | 250.00 | 0.9134 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Udomkun, P.; Boonupara, T.; Smith, S.M.; Kajitvichyanukul, P. Green Ag/AgCl as an Effective Plasmonic Photocatalyst for Degradation and Mineralization of Methylthioninium Chloride. Separations 2022, 9, 191. https://doi.org/10.3390/separations9080191

Udomkun P, Boonupara T, Smith SM, Kajitvichyanukul P. Green Ag/AgCl as an Effective Plasmonic Photocatalyst for Degradation and Mineralization of Methylthioninium Chloride. Separations. 2022; 9(8):191. https://doi.org/10.3390/separations9080191

Chicago/Turabian StyleUdomkun, Patchimaporn, Thirasant Boonupara, Siwaporn M. Smith, and Puangrat Kajitvichyanukul. 2022. "Green Ag/AgCl as an Effective Plasmonic Photocatalyst for Degradation and Mineralization of Methylthioninium Chloride" Separations 9, no. 8: 191. https://doi.org/10.3390/separations9080191