Geometric Modeling and 3D Printing Using Recursively Generated Point Cloud

Abstract

:1. Introduction

- What are the characteristics and roles of the variables and constants used in the recursive process that deterministically creates a point cloud?

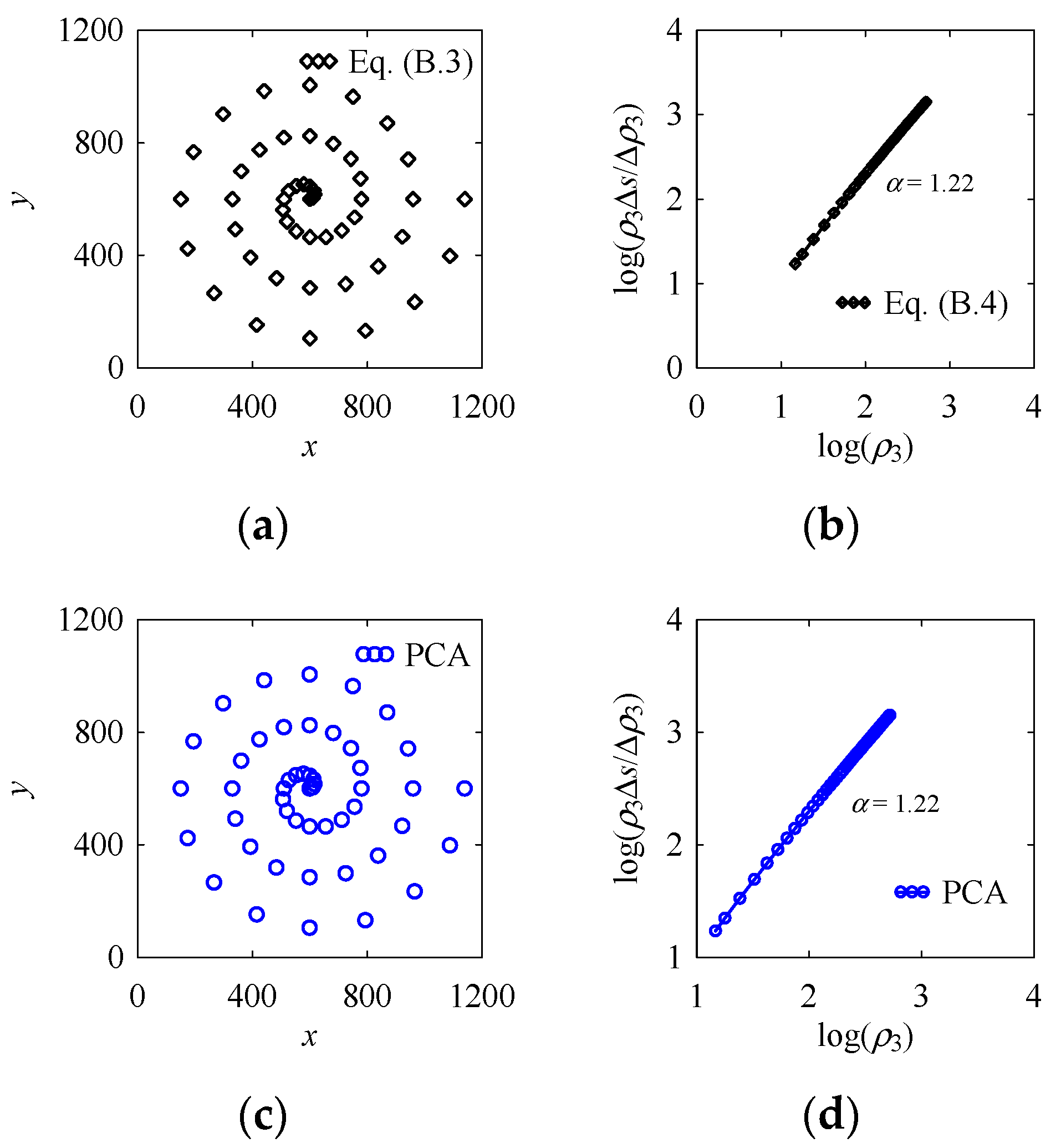

- How do we quantify the shape information modeled by a set of a point cloud?

- Does the recursive process that deterministically creates a point cloud correctly model a given shape?

- Does the deterministically created point cloud help create 3D solid models of some given objects?

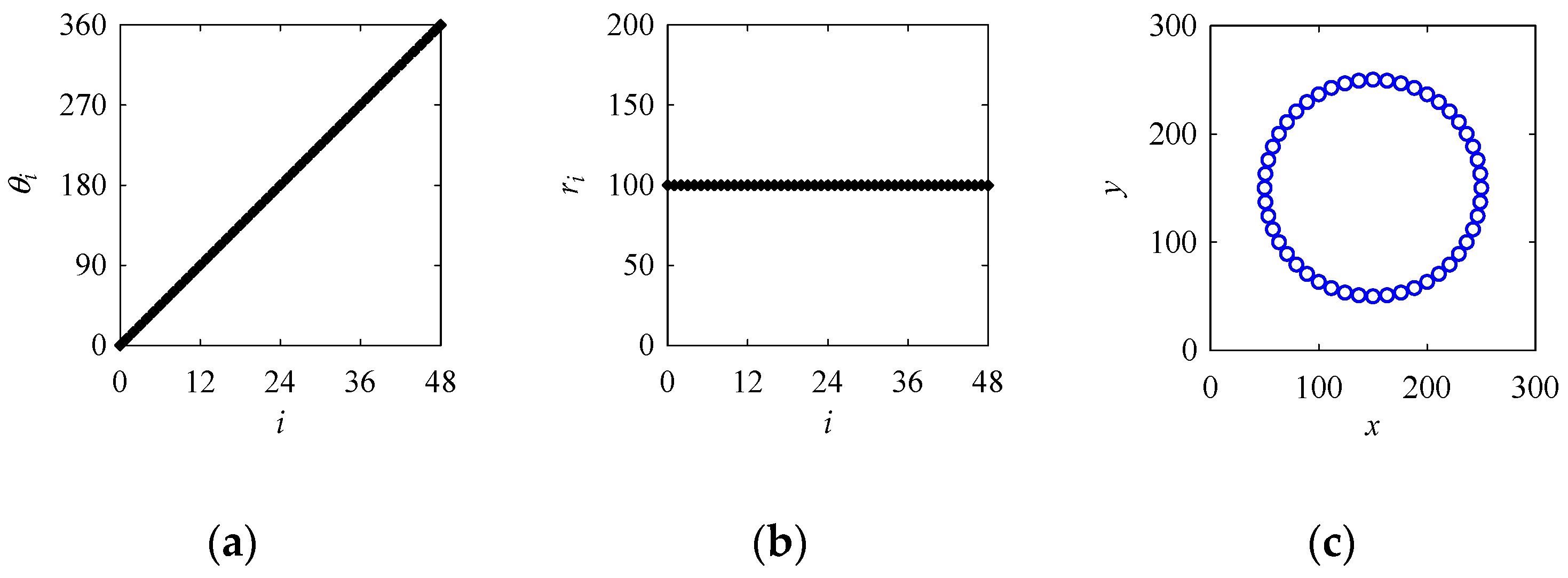

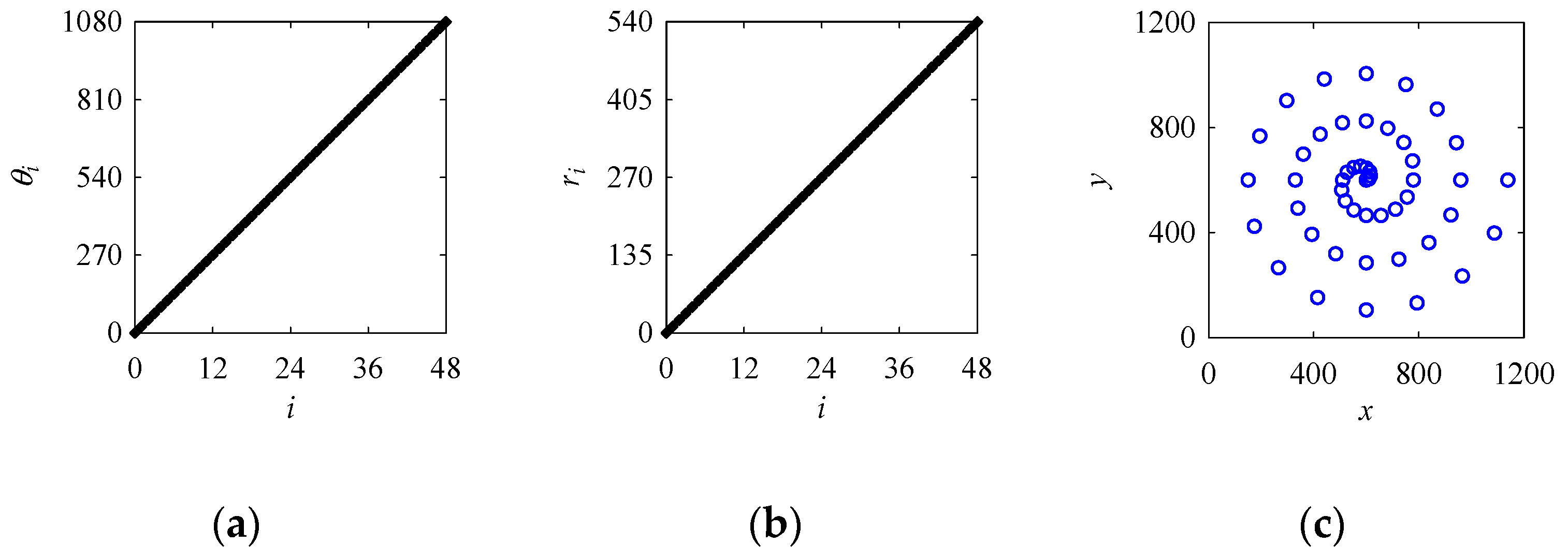

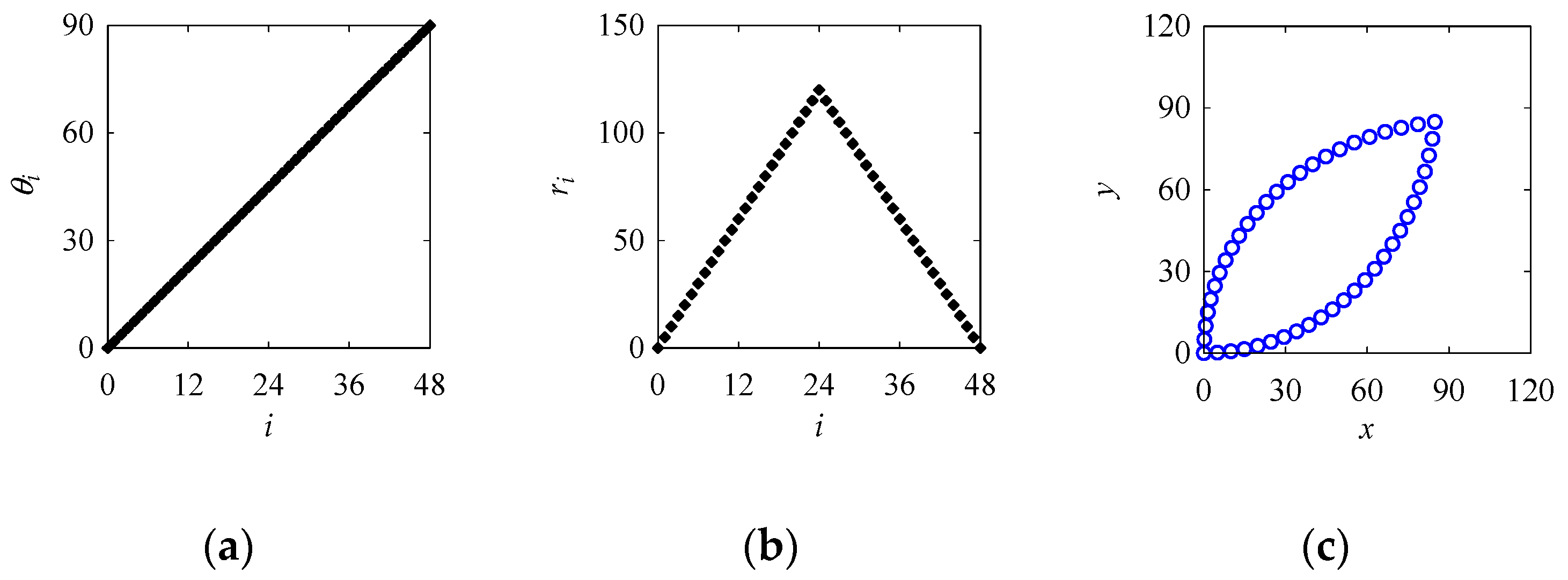

2. Characteristics of the Point-Cloud-Creating Algorithm

3. Quantification of Point Clouds

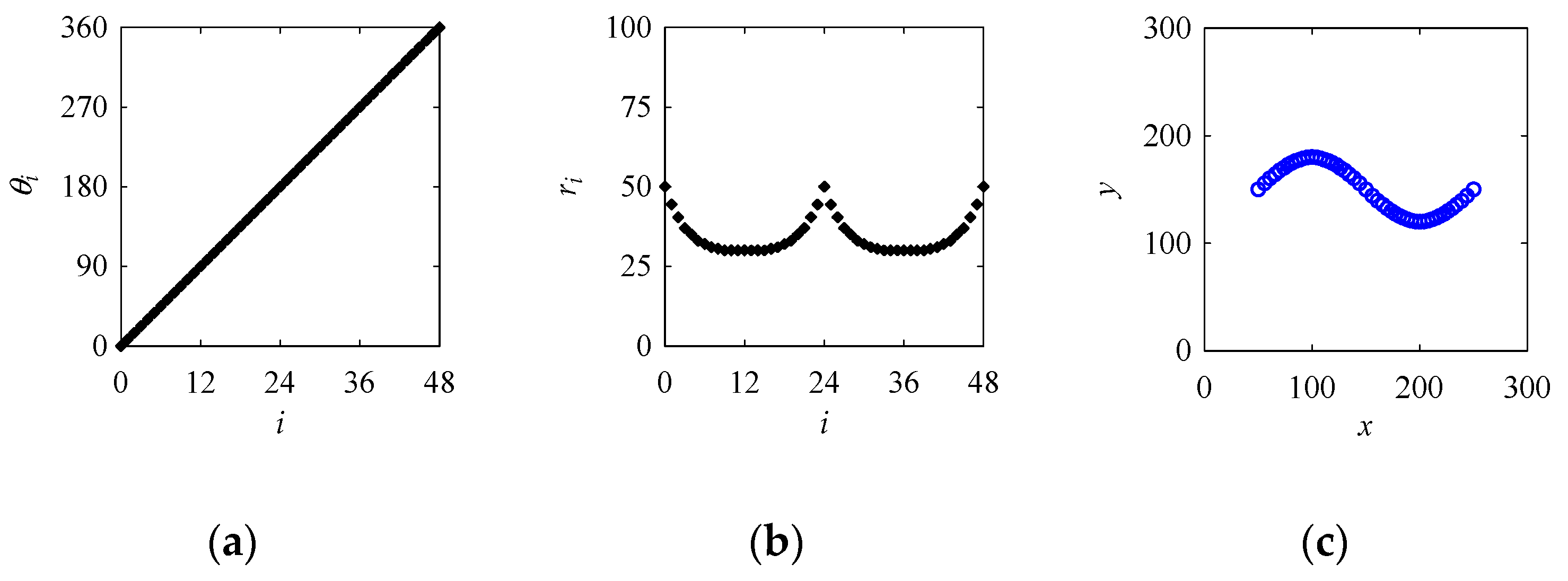

3.1. Quantification Based on Radius of Curvature

3.2. Quantification Based on Aesthetic Value

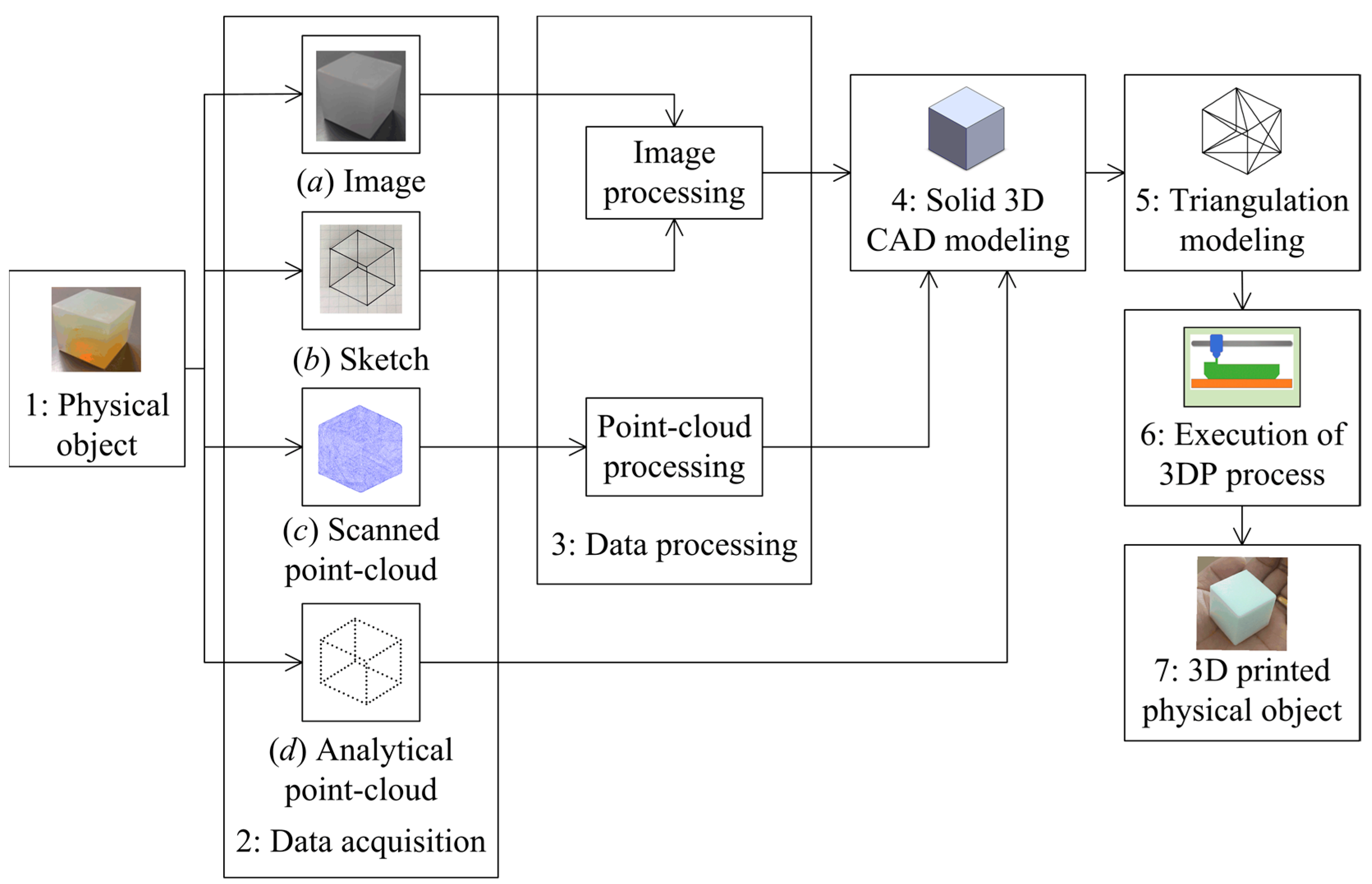

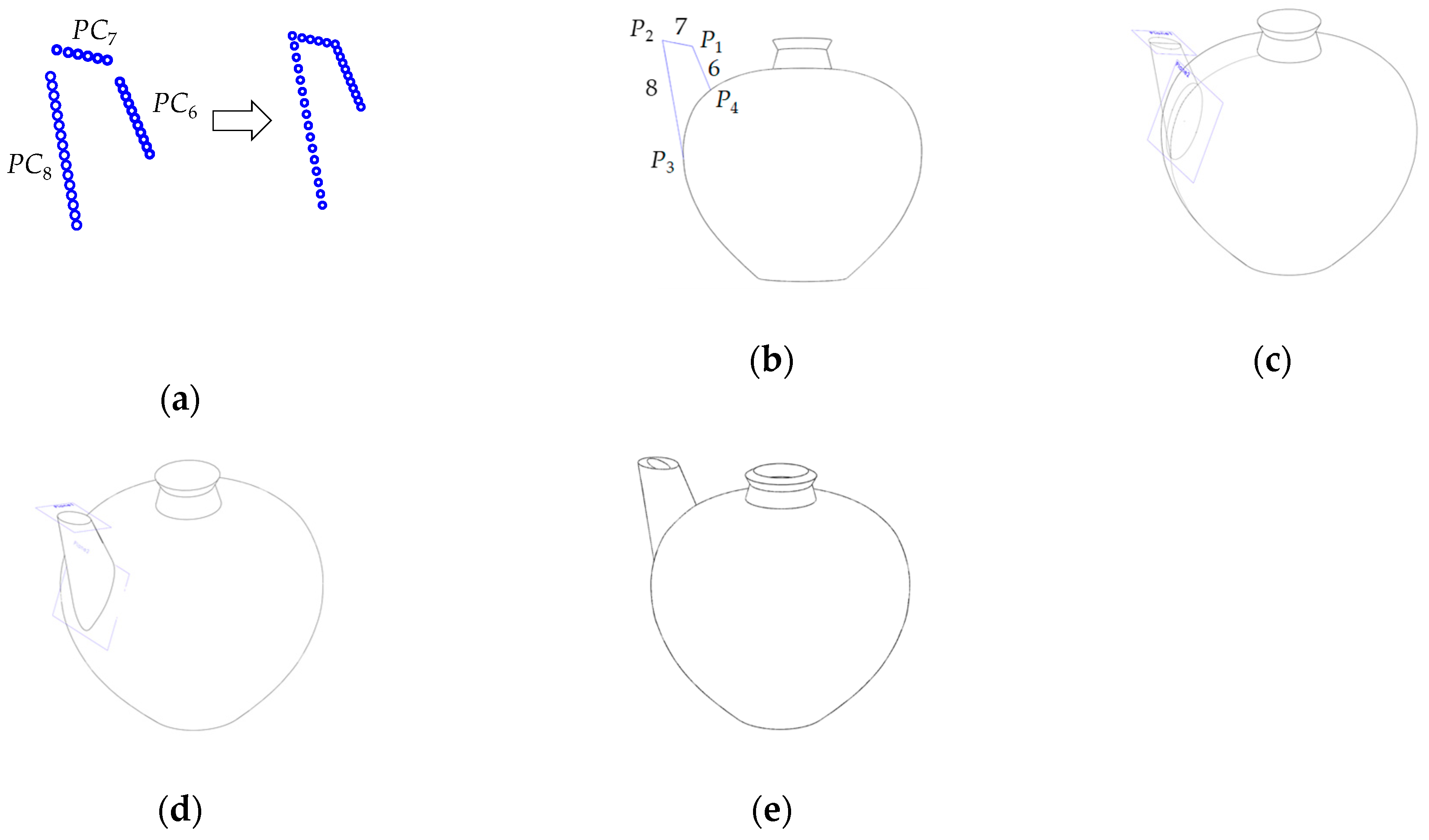

4. 3D Solid Modeling and Physical Prototyping

5. Discussions

6. Concluding Remarks

Author Contributions

Acknowledgments

Conflicts of Interest

Appendix A. Point Cloud Creation Algorithm

| Point Cloud Creation Algorithm (PCA): | ||

| 1 | Define: | Center Point Pc = (Pcx, Pcy) ∈ 2, Initial Length d > 0, Initial Angle φ ∈ Instantaneous Distance (ri ∈ | i = 0, 1, ..., n) Instantaneous Rotational Angle (θi ∈ | i = 0, 1, ..., n) |

| 2 | Calculate: | P0 = (P0x, P0y) so that and |

| 3 | Iterate: | For i = 0, 1, ..., n

|

| 4 | Output: | PC = (Pei | i = 0, 1, ..., n) |

Appendix B. Definition of Relevant Shapes and Parameters

B.1. Relevant Shapes

B.2. Radius of Curvature

B.3. Aesthetic Value

References

- Thompson, M.K.; Moroni, G.; Vaneker, T.; Fadel, G.; Campbell, R.I.; Gibson, I.; Bernard, A.; Schulz, J.; Graf, P.; Ahuja, B.; et al. Design for Additive Manufacturing: Trends, opportunities, considerations, and constraints. CIRP Ann. 2016, 65, 737–760. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.; Stucker, B. Additive Manufacturing Technologies: 3D Printing, Rapid Prototyping, and Direct Digital Manufacturing, 2nd ed.; Springer-Verlag: New York, NY, USA, 2015. [Google Scholar]

- Gao, W.; Zhang, Y.; Ramanujan, D.; Ramani, K.; Chen, Y.; Williams, C.B.; Wang, C.C.L.; Shin, Y.C.; Zhang, S.; Zavattieri, P.D. The status, challenges, and future of additive manufacturing in engineering. Comput. Aided Des. 2015, 69, 65–89. [Google Scholar] [CrossRef]

- Tofail, S.A.M.; Koumoulos, E.P.; Bandyopadhyay, A.; Bose, S.; O’Donoghue, L.; Charitidis, C. Additive manufacturing: scientific and technological challenges, market uptake and opportunities. Mater. Today 2018, 21, 22–37. [Google Scholar] [CrossRef]

- Nooran, R. 3D Printing: Technology, Applications, and Selection, 1st ed.; CRC Press: Boca Raton, FL, USA, 2018. [Google Scholar]

- Camille, B. What are you printing? Ambivalent emancipation by 3D printing. Rapid Prototyp. J. 2015, 21, 572–581. [Google Scholar]

- Bourell, D.L.; Rosen, D.W.; Leu, M.C. The Roadmap for Additive Manufacturing and Its Impact. 3D Print. Addit. Manuf. 2014, 1, 6–9. [Google Scholar] [CrossRef]

- Hirz, M.; Rossbacher, P.; Gulanová, J. Future trends in CAD—From the perspective of automotive industry. Comput. Aided Des. Appl. 2017, 14, 734–741. [Google Scholar] [CrossRef]

- Yap, Y.L.; Tan, Y.S.E.; Tan, H.K.J.; Peh, Z.K.; Low, X.Y.; Yeong, W.Y.; Tan, C.S.H.; Laude, A. 3D printed bio-models for medical applications. Rapid Prototyp. J. 2017, 23, 227–235. [Google Scholar] [CrossRef]

- Hieu, L.C.; Zlatov, N.; Vander Sloten, J.; Bohez, E.; Khanh, L.; Binh, P.H.; Oris, P.; Toshev, Y. Medical rapid prototyping applications and methods. Assembly Autom. 2005, 25, 284–292. [Google Scholar] [CrossRef]

- Sun, W.; Starly, B.; Nam, J.; Darling, A. Bio-CAD modeling and its applications in computer-aided tissue engineering. Comput. Aided Des. 2005, 37, 1097–1114. [Google Scholar] [CrossRef]

- Mannoor, M.S.; Jiang, Z.; James, T.; Kong, Y.L.; Malatesta, K.A.; Soboyejo, W.O.; Verma, N.; Gracias, D.H.; McAlpine, M.C. 3D Printed Bionic Ears. Nano Lett. 2013, 13, 2634–2639. [Google Scholar] [CrossRef] [Green Version]

- Steffan, D.; Dominic, E. A CAD and AM process for maxillofacial prostheses bar-clip retention. Rapid Prototyp. J. 2016, 22, 170–177. [Google Scholar]

- Luximon, Y.; Ball, R.M.; Chow, E.H.C. A design and evaluation tool using 3D head templates. Comput. Aided Des. Appl. 2016, 13, 153–161. [Google Scholar] [CrossRef]

- Jung, W.; Park, S.; Shin, H. Combining volumetric dental CT and optical scan data for teeth modeling. Comput. Aided Des. 2015, 67, 24–37. [Google Scholar] [CrossRef]

- Urbanic, R.J. From thought to thing: using the fused deposition modeling and 3D printing processes for undergraduate design projects. Comput. Aided Des. Appl. 2016, 13, 768–785. [Google Scholar] [CrossRef]

- Galina, L.; Na, X. Academic library innovation through 3D printing services. Libr. Manag. 2017, 38, 208–218. [Google Scholar] [Green Version]

- Heather, M.M.L. Makers in the library: case studies of 3D printers and maker spaces in library settings. Libr. Hi Tech 2014, 32, 583–593. [Google Scholar]

- Wannarumon, S.; Bohez, E.L.J. A New Aesthetic Evolutionary Approach for Jewelry Design. Comput. Aided Des. Appl. 2006, 3, 385–394. [Google Scholar] [CrossRef]

- 3D Printed Clothing. Available online: https://3dprint.com/tag/3d-printed-clothing/ (accessed on 13 September 2019).

- The Future of Running is Here. Available online: https://www.newbalance.com/article?id=4041 (accessed on 13 September 2019).

- 3D Printed Fashion: 10 Amazing 3D Printed Dresses. Available online: https://i.materialise.com/blog/3d-printed-fashion-dresses/ (accessed on 13 September 2019).

- Nike. Nike Debuts First-ever Football Cleat Built Using 3D Printing Technology. Available online: https://news.nike.com/news/nike-debuts-first-ever-football-cleat-built-using-3d-printing-technology (accessed on 13 September 2019).

- Sun, J.; Zhou, W.; Yan, L.; Huang, D.; Lin, L.Y. Extrusion-based food printing for digitalized food design and nutrition control. J. Food Eng. 2018, 220, 1–11. [Google Scholar] [CrossRef]

- Lin, C. 3D Food Printing: A Taste of the Future. J. Food Sci. Educ. 2015, 14, 86–87. [Google Scholar] [CrossRef] [Green Version]

- Ferreira, I.A.; Alves, J.L. Low-cost 3D food printing. Ciência Tecnologia dos Materiais 2017, 29, e265–e269. [Google Scholar] [CrossRef]

- Jiang, H.; Zheng, L.; Zou, Y.; Tong, Z.; Han, S.; Wang, S. 3D food printing: Main components selection by considering rheological properties. Crit. Rev. Food Sci. Nutr. 2019, 59, 2335–2347. [Google Scholar] [CrossRef] [PubMed]

- Lupton, D.; Turner, B. Food of the Future? Consumer Responses to the Idea of 3D-Printed Meat and Insect-Based Foods. Food Foodways 2018, 26, 269–289. [Google Scholar] [CrossRef]

- Sakin, M.; Kiroglu, Y.C. 3D Printing of Buildings: Construction of the Sustainable Houses of the Future by BIM. Energy Procedia 2017, 134, 702–711. [Google Scholar] [CrossRef]

- Hager, I.; Golonka, A.; Putanowicz, R. 3D Printing of Buildings and Building Components as the Future of Sustainable Construction? Procedia Eng. 2016, 151, 292–299. [Google Scholar] [CrossRef] [Green Version]

- Lim, S.; Buswell, R.A.; Le, T.T.; Austin, S.A.; Gibb, A.G.F.; Thorpe, T. Developments in construction-scale additive manufacturing processes. Autom. Constr. 2012, 21, 262–268. [Google Scholar] [CrossRef] [Green Version]

- Tay, Y.W.D.; Panda, B.; Paul, S.C.; Noor Mohamed, N.A.; Tan, M.J.; Leong, K.F. 3D printing trends in building and construction industry: A review. Virtual Phys. Prototyp. 2017, 12, 261–276. [Google Scholar] [CrossRef]

- Scopigno, R.; Cignoni, P.; Pietroni, N.; Callieri, M.; Dellepiane, M. Digital Fabrication Techniques for Cultural Heritage: A Survey. Comput. Graph. Forum 2017, 36, 6–21. [Google Scholar] [CrossRef]

- Sharif Ullah, A.M.M.; Sato, Y.; Kubo, A.; Tamaki, J.i. Design for Manufacturing of IFS Fractals from the Perspective of Barnsley’s Fern-leaf. Comput. Aided Des. Appl. 2015, 12, 241–255. [Google Scholar] [CrossRef]

- Várady, T.; Martin, R.R.; Cox, J. Reverse engineering of geometric models—An introduction. Comput. Aided Des. 1997, 29, 255–268. [Google Scholar] [CrossRef]

- James, D.W.; Belblidia, F.; Eckermann, J.E.; Sienz, J. An innovative photogrammetry color segmentation based technique as an alternative approach to 3D scanning for reverse engineering design. Comput. Aided Des. Appl. 2017, 14, 1–16. [Google Scholar] [CrossRef]

- Paulic, M.; Irgolic, T.; Balic, J.; Cus, F.; Cupar, A.; Brajlih, T.; Drstvensek, I. Reverse Engineering of Parts with Optical Scanning and Additive Manufacturing. Procedia Eng. 2014, 69, 795–803. [Google Scholar] [CrossRef] [Green Version]

- Ullah, A.M.M.; Watanabe, M.; Kubo, A. Analytical Point-Cloud Based Geometric Modeling for Additive Manufacturing and Its Application to Cultural Heritage Preservation. Appl. Sci. 2018, 8, 656. [Google Scholar] [Green Version]

- Furferi, R.; Governi, L.; Volpe, Y.; Puggelli, L.; Vanni, N.; Carfagni, M. From 2D to 2.5D i.e. from painting to tactile model. Graph. Models 2014, 76, 706–723. [Google Scholar] [CrossRef]

- Rojas-Sola, J.I.; Galán-Moral, B.; De la Morena-De la Fuente, E. Agustín de Betancourt’s Double-Acting Steam Engine: Geometric Modeling and Virtual Reconstruction. Symmetry 2018, 10, 351. [Google Scholar] [CrossRef]

- Chen, Z.; Chen, W.; Guo, J.; Cao, J.; Zhang, Y.J. Orientation field guided line abstraction for 3D printing. Comput. Aided Geom. Des. 2018, 62, 253–262. [Google Scholar] [CrossRef]

- Schwartz, A.; Schneor, R.; Molcho, G.; Weiss Cohen, M. Surface detection and modeling of an arbitrary point cloud from 3D sketching. Comput. Aided Des. Appl. 2018, 15, 227–237. [Google Scholar] [CrossRef]

- Company, P.; Contero, M.; Conesa, J.; Piquer, A. An optimisation-based reconstruction engine for 3D modelling by sketching. Comput. Graph. 2004, 28, 955–979. [Google Scholar] [CrossRef]

- Naya, F.; Conesa, J.; Contero, M.; Company, P.; Jorge, J. Smart Sketch System for 3D Reconstruction Based Modeling. In Proceedings of the Third International Symposium on Smart Graphics, Heidelberg, Germany, 2–4 July 2003; pp. 58–68. [Google Scholar]

- Yang, J.; Cao, Z.; Zhang, Q. A fast and robust local descriptor for 3D point cloud registration. Inf. Sci. 2016, 346–347, 163–179. [Google Scholar] [CrossRef]

- Li, W.; Song, P. A modified ICP algorithm based on dynamic adjustment factor for registration of point cloud and CAD model. Pattern Recognit. Lett. 2015, 65, 88–94. [Google Scholar] [CrossRef]

- Jung, S.; Song, S.; Chang, M.; Park, S. Range image registration based on 2D synthetic images. Comput. Aided Des. 2018, 94, 16–27. [Google Scholar] [CrossRef]

- Chen, Z.; Zhang, T.; Cao, J.; Zhang, Y.J.; Wang, C. Point cloud resampling using centroidal Voronoi tessellation methods. Comput. Aided Des. 2018, 102, 12–21. [Google Scholar] [CrossRef]

- Skrodzki, M.; Jansen, J.; Polthier, K. Directional density measure to intrinsically estimate and counteract non-uniformity in point clouds. Comput. Aided Geom. Des. 2018, 64, 73–89. [Google Scholar] [CrossRef]

- Lee, K.H.; Woo, H. Direct integration of reverse engineering and rapid prototyping. Comput. Ind. Eng. 2000, 38, 21–38. [Google Scholar] [CrossRef]

- Budak, I.; Vukelić, D.; Bračun, D.; Hodolič, J.; Soković, M. Pre-Processing of Point-Data from Contact and Optical 3D Digitization Sensors. Sensors 2012, 12, 1100–1126. [Google Scholar] [CrossRef] [Green Version]

- Masuda, H.; Niwa, T.; Tanaka, I.; Matsuoka, R. Reconstruction of Polygonal Faces from Large-Scale Point-Clouds of Engineering Plants. Comput. Aided Des. Appl. 2015, 12, 555–563. [Google Scholar] [CrossRef]

- Williams, R.M.; Ilieş, H.T. Practical shape analysis and segmentation methods for point cloud models. Comput. Aided Geom. Des. 2018, 67, 97–120. [Google Scholar] [CrossRef] [Green Version]

- Fayolle, P.-A.; Pasko, A. An evolutionary approach to the extraction of object construction trees from 3D point clouds. Comput. Aided Des. 2016, 74, 1–17. [Google Scholar] [CrossRef] [Green Version]

- Pan, M.; Tong, W.; Chen, F. Phase-field guided surface reconstruction based on implicit hierarchical B-splines. Comput. Aided Geom. Des. 2017, 52–53, 154–169. [Google Scholar] [CrossRef]

- Feng, C.; Taguchi, Y. FasTFit: A fast T-spline fitting algorithm. Comput. Aided Des. 2017, 92, 11–21. [Google Scholar] [CrossRef]

- Peternell, M.; Steiner, T. Reconstruction of piecewise planar objects from point clouds. Comput. Aided Des. 2004, 36, 333–342. [Google Scholar] [CrossRef] [Green Version]

- Toll, B.; Cheng, F. Surface Reconstruction from Point Clouds. In Proceedings of the International Conference on Sculptured Surface Machining (SSM98), Chrysler Technology Center, MI, USA, 9–11 November 1998; Olling, G.J., Choi, B.K., Jerard, R.B., Eds.; Springer US: Boston, MA, USA, 1999; pp. 173–178. [Google Scholar] [Green Version]

- Pralay, P. An easy rapid prototyping technique with point cloud data. Rapid Prototyp. J. 2001, 7, 82–90. [Google Scholar]

- Ma, J.; Chen, J.S.-S.; Feng, H.-Y.; Wang, L. Automatic construction of watertight manifold triangle meshes from scanned point clouds using matched umbrella facets. Comput. Aided Des. Appl. 2017, 14, 742–750. [Google Scholar] [CrossRef] [Green Version]

- Zhong, S.; Yang, Y.; Huang, Y. Data Slicing Processing Method for RE/RP System Based on Spatial Point Cloud Data. Comput. Aided Des. Appl. 2014, 11, 20–31. [Google Scholar] [CrossRef]

- Chang, M.C.; Leymarie, F.F.; Kimia, B.B. Surface reconstruction from point clouds by transforming the medial scaffold. Comput. Vis. Image Underst. 2009, 113, 1130–1146. [Google Scholar] [CrossRef]

- Remil, O.; Xie, Q.; Xie, X.; Xu, K.; Wang, J. Surface reconstruction with data-driven exemplar priors. Comput. Aided Des. 2017, 88, 31–41. [Google Scholar] [CrossRef] [Green Version]

- Percoco, G.; Galantucci, L.M. Local-genetic slicing of point clouds for rapid prototyping. Rapid Prototyp. J. 2008, 14, 161–166. [Google Scholar] [CrossRef]

- Wang, X.; Hu, J.; Guo, L.; Zhang, D.; Qin, H.; Hao, A. Feature-preserving, mesh-free empirical mode decomposition for point clouds and its applications. Comput. Aided Geom. Des. 2018, 59, 1–16. [Google Scholar] [CrossRef]

- Yang, P.; Schmidt, T.; Qian, X. Direct Digital Design and Manufacturing from Massive Point-Cloud Data. Comput. Aided Des. Appl. 2009, 6, 685–699. [Google Scholar] [CrossRef]

- Oropallo, W.; Piegl, L.A.; Rosen, P.; Rajab, K. Point cloud slicing for 3-D printing. Comput. Aided Des. Appl. 2018, 15, 90–97. [Google Scholar] [CrossRef]

- Oropallo, W.; Piegl, L.A.; Rosen, P.; Rajab, K. Generating point clouds for slicing free-form objects for 3-D printing. Comput. Aided Des. Appl. 2017, 14, 242–249. [Google Scholar] [CrossRef]

- Ullah, A.M.M. Symmetrical Patterns of Ainu Heritage and Their Virtual and Physical Prototyping. Symmetry 2019, 11, 985. [Google Scholar] [Green Version]

- Ullah, A.M.M.S.; Omori, R.; Nagara, Y.; Kubo, A.; Tamaki, J. Toward Error-free Manufacturing of Fractals. Procedia CIRP 2013, 12, 43–48. [Google Scholar] [CrossRef]

- Ullah, A.M.M.S.; D’Addona, D.M.; Harib, K.H.; Kin, T. Fractals and Additive Manufacturing. Int. J. Autom. Technol. 2016, 10, 222–230. [Google Scholar] [CrossRef]

- Sharif Ullah, A.M.M. Design for additive manufacturing of porous structures using stochastic point-cloud: a pragmatic approach. Comput. Aided Des. Appl. 2018, 15, 138–146. [Google Scholar] [CrossRef]

- Kishan, H. Diffrential Calculus; Atlantic Publishers & Distributors Pvt. Ltd.: New Delhi, India, 2007. [Google Scholar]

- Ujiie, Y.; Matsuoka, Y. Macro-informatics of cognition and its application for design. Adv. Eng. Inform. 2009, 23, 184–190. [Google Scholar] [CrossRef]

- Harada, T. Study of Quantitative Analysis of the Characteristics of a Curve. Forma 1997, 12, 55–63. [Google Scholar]

- Miura, K.T.; Sone, J.; Yamashita, A.; Kaneko, T. Derivation of a General Formula of Aesthetic Curves. In Proceedings of the 8th International Conference on Humans and Computer (HC2005), Aizu-Wakamutsu, Japan, 31 August–2 September 2005; pp. 166–171. [Google Scholar]

- Yoshida, N.; Saito, T. Interactive aesthetic curve segments. Vis. Comput. 2006, 22, 896–905. [Google Scholar] [CrossRef]

- Japanese Pottery and Porcelain. Available online: https://en.wikipedia.org/w/index.php?title=Japanese_pottery_and_porcelain&oldid=875182192 (accessed on 13 September 2019).

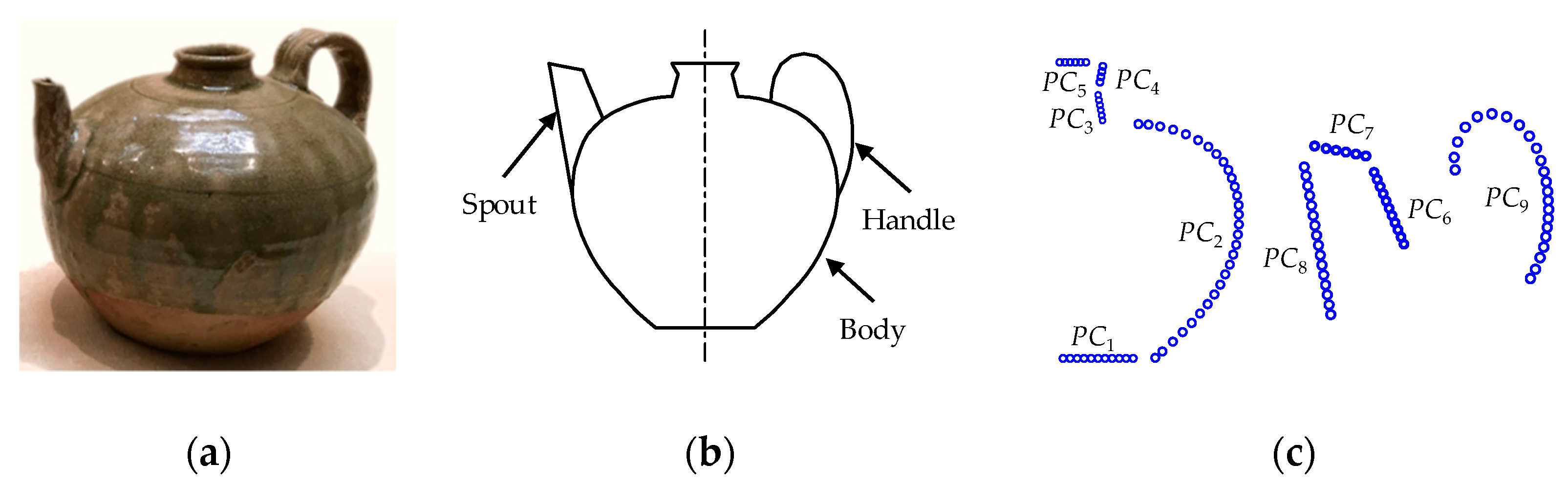

| Instantaneous Rotational Angle, θi | Instantaneous Distance, ri | Point Cloud, PC |

|---|---|---|

| Constant | Increase or decrease linearly | Straight-line |

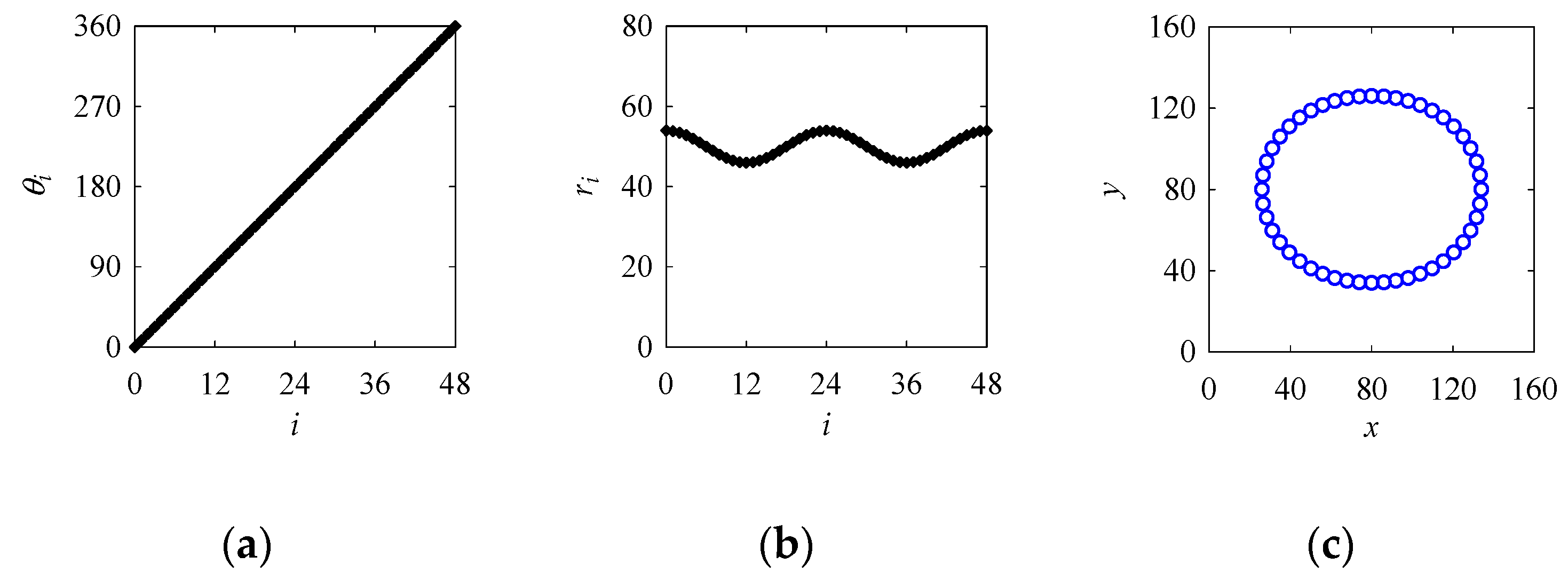

| Increase or decrease linearly | Constant | Circle |

| Increases linearly | Spiral | |

| Increase and decrease linearly like a tent function | Leaf-shape | |

| Decrease and increase gradually like a sine/cosine for two cycles | Ellipse | |

| Decrease and increase gradually like a U-shape function for four cycles | Astroid | |

| Decrease and increase gradually like a bathtub function for two cycles | S-shape | |

| Center point, Pc | Translate a shape | |

| Initial angle, φ | Rotate shape | |

| Initial distance, d | No effect on a shape | |

| Models | Model without Texture | Model with Texture | 3D Scanned Model |

|---|---|---|---|

| Number of points | 109 | 789 | 52,1404 |

| Number of facets | 25,336 | 51,244 | 271,803 |

| Number of vertices | 76,008 | 153,732 | 815,409 |

| Printing time without support | 7 h, 50 min, 38 s | 8 h, 6 min, 58 s | - |

| Printing time with support | 12 h, 20 min, 28 s | 13 h, 14 min, 56 s | - |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tashi; Ullah, A.S.; Kubo, A. Geometric Modeling and 3D Printing Using Recursively Generated Point Cloud. Math. Comput. Appl. 2019, 24, 83. https://doi.org/10.3390/mca24030083

Tashi, Ullah AS, Kubo A. Geometric Modeling and 3D Printing Using Recursively Generated Point Cloud. Mathematical and Computational Applications. 2019; 24(3):83. https://doi.org/10.3390/mca24030083

Chicago/Turabian StyleTashi, AMM Sharif Ullah, and Akihiko Kubo. 2019. "Geometric Modeling and 3D Printing Using Recursively Generated Point Cloud" Mathematical and Computational Applications 24, no. 3: 83. https://doi.org/10.3390/mca24030083