Sustainable Solutions: Reviewing the Future of Textile Dye Contaminant Removal with Emerging Biological Treatments

Abstract

:1. Introduction

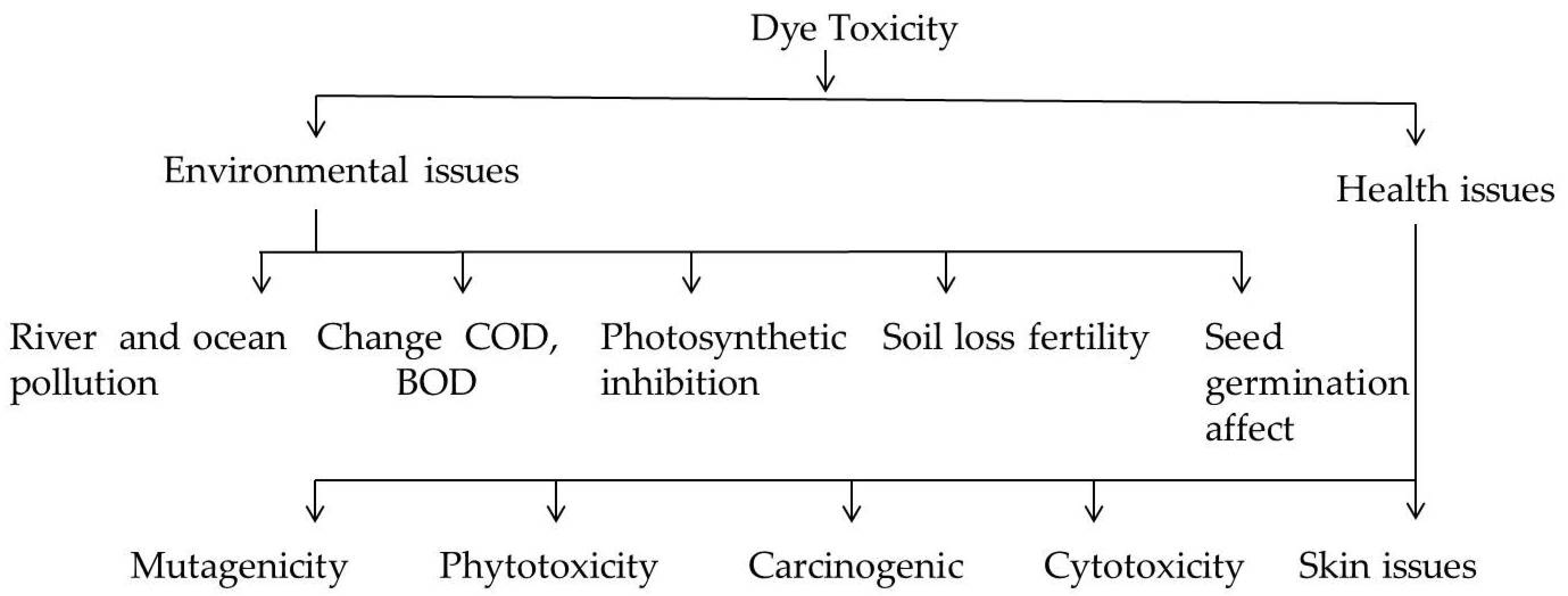

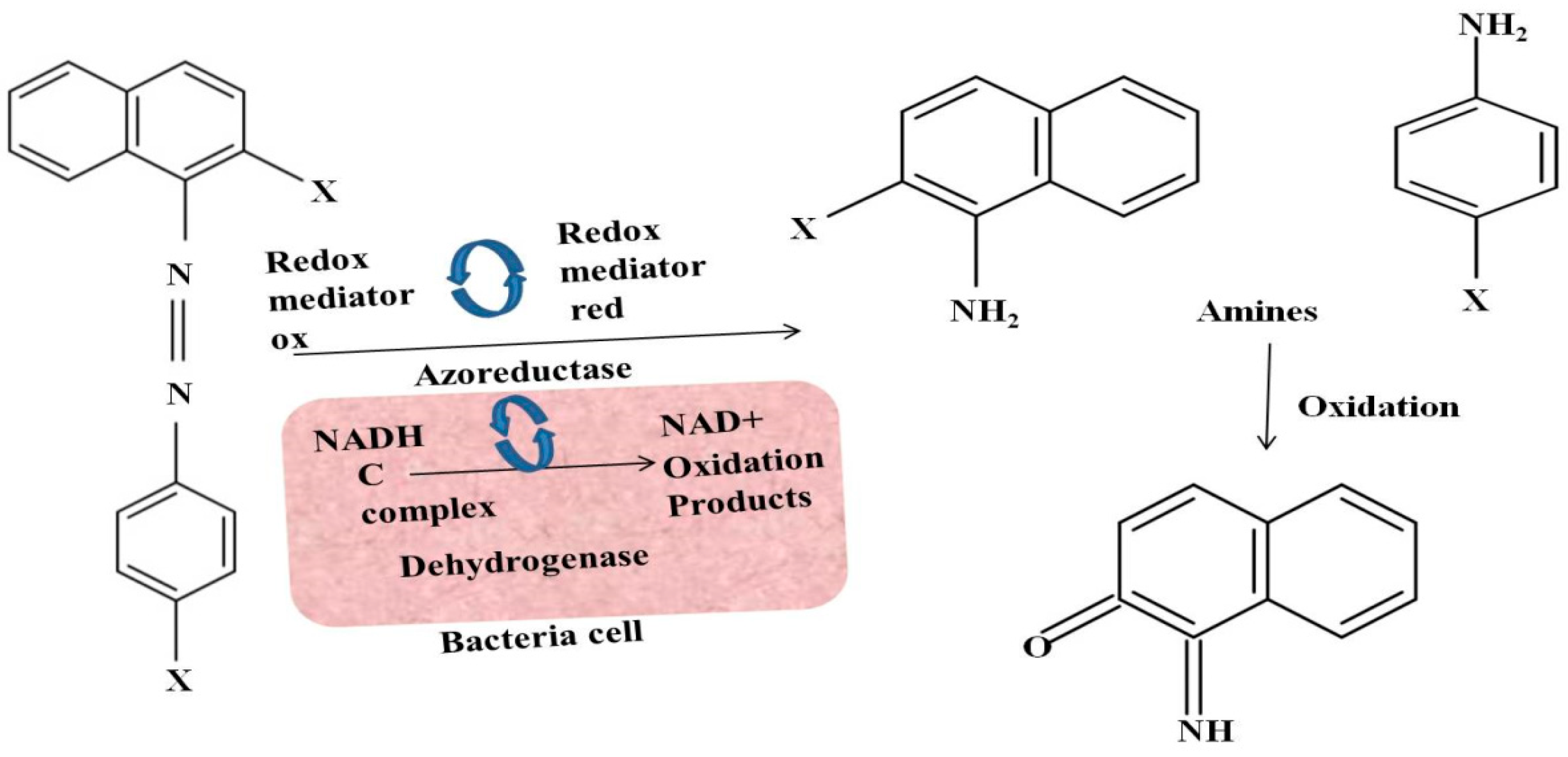

Environmental and Health Implications of Azo Dyes in Textile Industries

2. Dye Degradation Strategies

2.1. Challenges and Opportunities in Azo Dye Wastewater Treatment

2.2. Biosustainable Solutions for Synthetic Dye Degradation

3. Advanced Biological Approaches

3.1. Phytoremediation

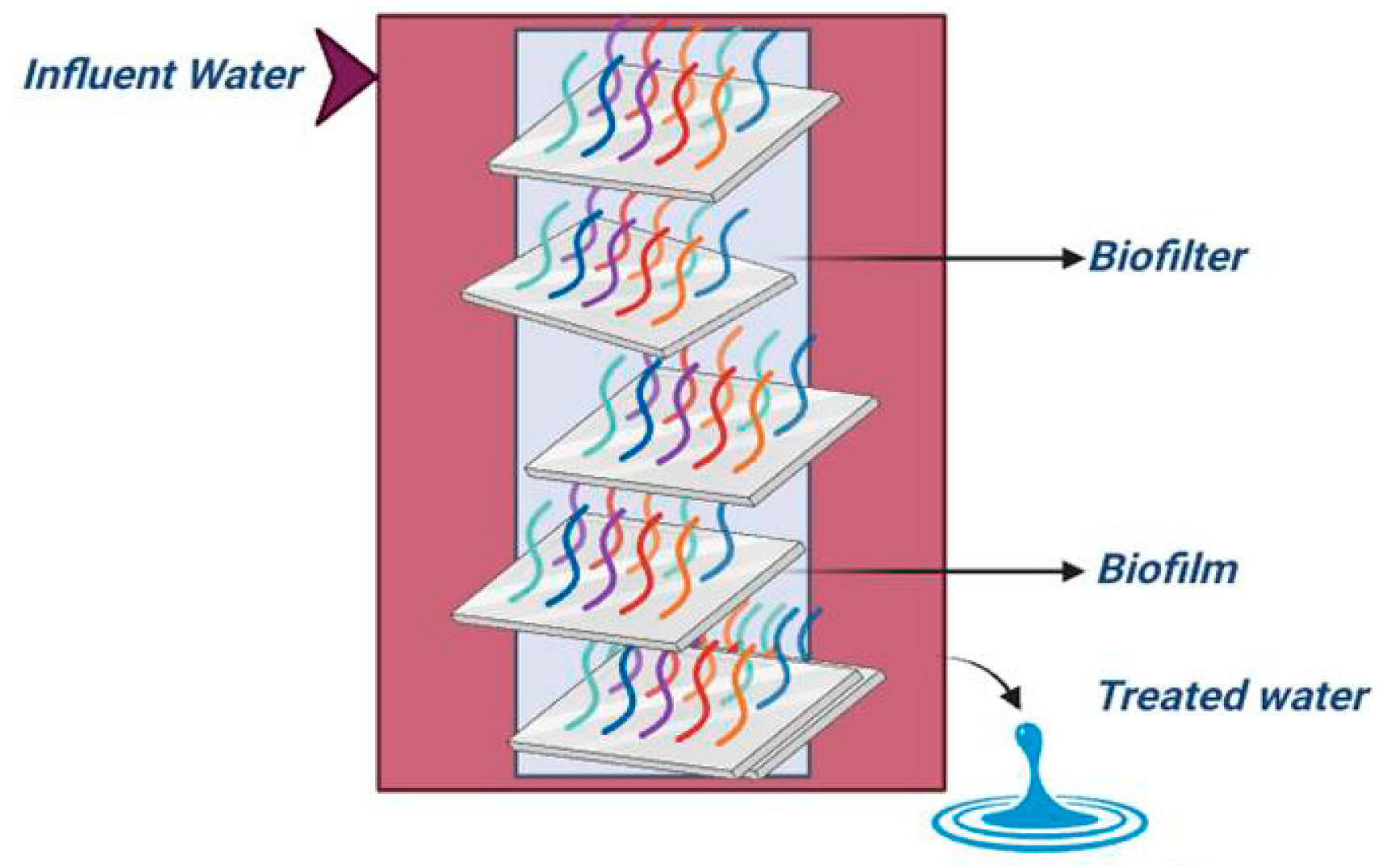

3.2. Biofilm Reactors

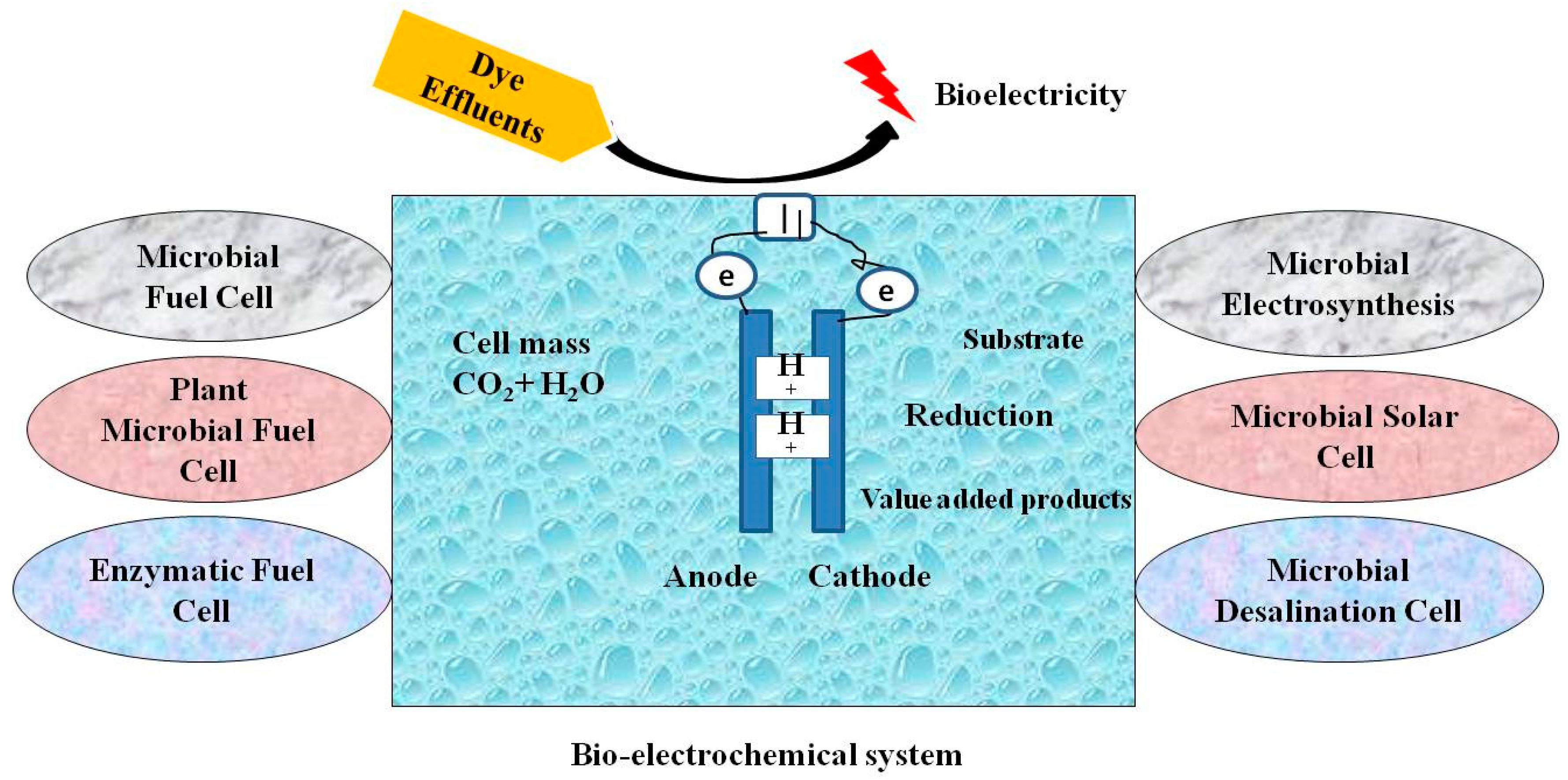

3.3. Microbial Fuel Cells (MFCs)

3.4. Microalgae through Dye Treatment and Biodiesel Production

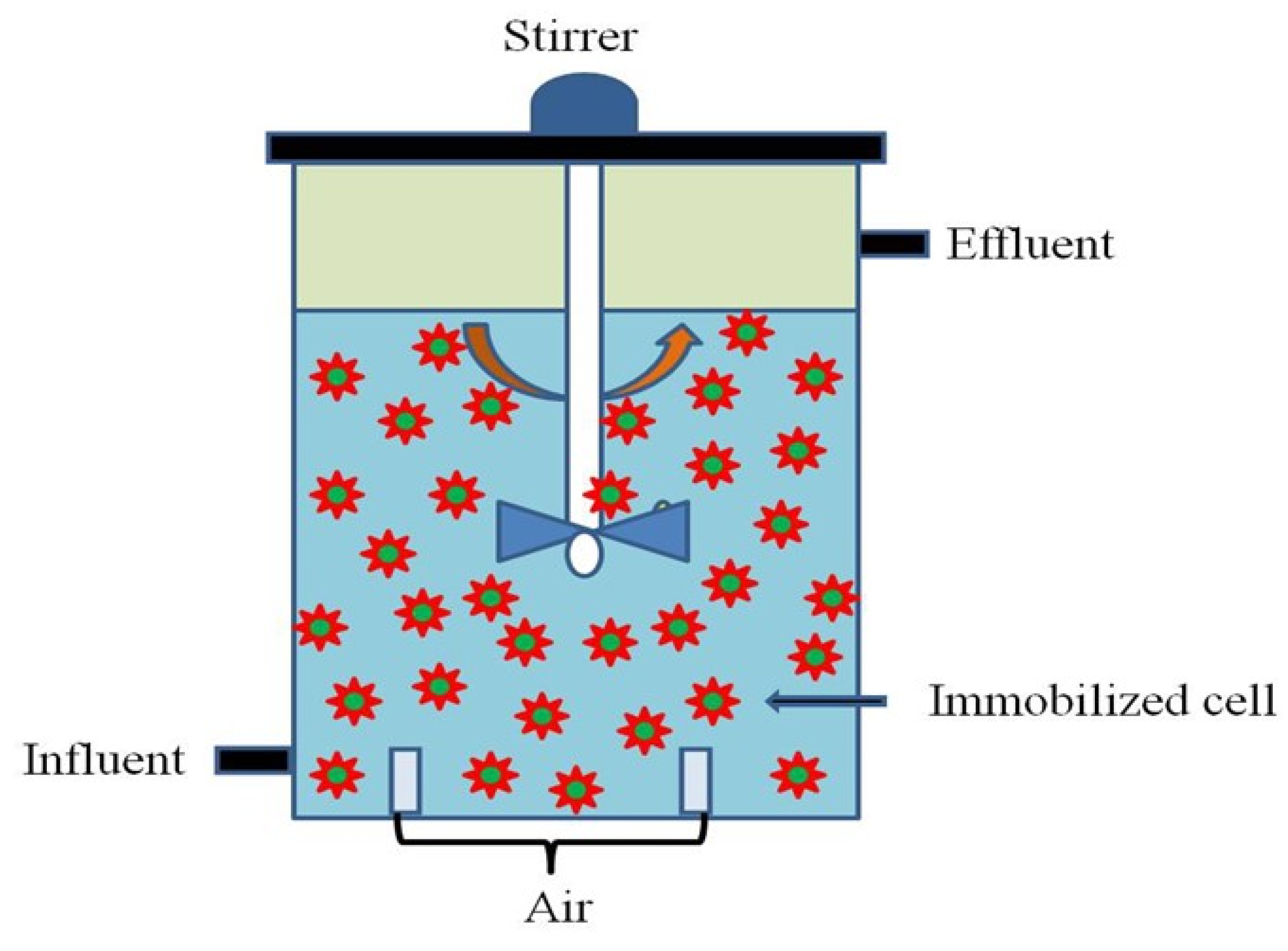

3.5. Bioreactors

| Type of Bioreactor | Microbial Strains | Dye | Efficiency, pH | Time/Temp | References |

|---|---|---|---|---|---|

| Anaerobic sequential batch reactor (An-SBR) and MBBR | Reactive Red, Reactive Black, and Reactive Brown 100 mg/L | 88% | 96 h | [73] | |

| MBSBBR and SBR | Black B 32.3 mg·L−1, Black WNN 64.5 mg·L−1 and Red 3BS 96.8 mg·L−1 | 79.9 ± 1.5%, | 15 and 25 days 30 °C | [76] | |

| Batch bioreactor | Enterobacter aerogenes ES014 | Acid orange, methyl orange and Congo red 100 mg/L | (82.3 ± 3.6%) (78.2 ± 3.3%) (81.5 ± 3.2%) pH 7.5 | 35 °C, 24 h | [75] |

| Anaerobic Membrane Bioreactor and downflow hanging sponge reactor | Euryarchaeota, Caldiserica, and Proteobacteria | Reactive Black 5 | 95.0 ± 1.6% | 12–24 h, pH 12, 30 °C | [77] |

| Immobilized batch and continuous packed-bed bioreactor | Brevibacillus parabrevis | Congo red dye 150 ppm | 95.71% | 30 °C, 6 days | [9] |

| Upflow fixed-film microaerophilic–aerobic bioreactor | Bacteroides, Sulfurospirillum, Pseudomonas, Macellibacteroides | Raw textile effluents | 73.08% | 25–30 °C | [78] |

| Airlift bioreactor | Ganoderma sp. KU-Alk4 | Indigo Carmine | 100% | 2 h | [79] |

| Packed-bed bioreactor | bacterial species | Acid orange 7 dye 300 mg/L | 7.5, 87.31% | 21.0 h | [80] |

| Pilot-scale aerobic reactor | Bacillus sp. | Acid orange 7 125 mg/L | 98.7%, (25.0–45.0 °C) pH (5.0–9.0) | 22 days | [81] |

| Moving-bed biofilm reactor | Congo red 25 to 300 mg/L | 99.2% 37 °C | 20 days | [81] | |

| Packed-bed bioreactor | Providencia stuartii | Congo red 100 mg/L | 85.3% | [81] | |

| Air-lift bioreactor | Bjerkandera adusta OBR105 | Red 120, blue 4, orange 16, and black 5) and acid dyes (red 114, blue 62, orange 7, and black 172) −200 mg L−1 | 91–99%, 28 °C, pH 5 | 10–15 h | [82] |

| Anaerobic–aerobic biological reactor system | Reactive Red, Reactive Black, and Reactive Brown 100 mg/L | 88% | 96 h | [73] | |

| Bench-scale bioreactors and lab-scale bioreactors | Bacillus, Pseudomonas, and E. coli | Reactive yellow 10 mg/L | 100% | 30 h | [73] |

| MBSBBR and SBR | Black B Black WNN Red 3BS 80 mg·L−1 | 85.7% 94.2% 91.4% | 60 days | [76] | |

| Fixed-film bioreactor | Alcaligenes sp. BAB3053, Bacillus sp. BAB2731 (BDN2, KF500594), Escherichia sp. BAB2734 (BDN3, KF500595), Pseudomonas sp. BAB3054 (BDN4, KF500596), Providencia sp. BAB2749 (BDN5, KF500597), Acinetobacter sp. BAB2750 (BDN6, KF500598), Bacillus sp. BAB2751 (BDN7, KF500599), Bacillus sp. BAB3055 (BDN8, KF500600) | Reactive Red 2, Reactive Red 198, Reactive Red 120, Reactive Blue 160, Reactive Blue 13 Reactive Blue 172, 300 mg/L | 99.5%, pH 7.0, 37 °C | 24 h | [83] |

| Packed-bed reactor | Bacillus cohnii RAPT1 | Reactive Red 120 200 ppm | pH 8.0, 35 °C, 100% | 36 h | [84] |

| Batch and column reactor | Bacillus subtilis | Methylene Blue 0.25 g | 30 °C, 96.17–90.11% | 3 h | [85] |

| Continuous upflow packed-bed bioreactor | Bacillus fexus TS8, Proteus mirabilis PMS, and Pseudomonas aeruginosa NCH | Indanthrene Blue RS dye 100 and 300 mg L−1 | 90%, pH-10.0, 30 °C | 20 days | [86] |

| Packed-bed reactor | Bacillus cohnii RAPT1 | Reactive Red 120 | 100% pH 8.0 and 35 °C | 4 h | [84] |

3.6. Enzyme Immobilization for Efficient Dye Decolorization

3.7. Genetically Modified Microorganisms and Their Products

- Natural microbial community acquisition of foreign genes;

- Survival efficiency and stability in natural ecosystems.

| Genetically Modified Microorganism | Dye | Gene Expressed from | Extracted Gene | Vector | Gene Extracted in | References |

|---|---|---|---|---|---|---|

| E. coli BL21 (DE3) | Azo dye wastewater | Halomonas sp. strain GT | AzoG gene | pET30a (+) | E. coli DH5α | [6] |

| Escherichia coli BL21 | Methyl Orange | K. pneumoniae MGH 78,578 | AzoK gene | Vector pGEM-T | E. coli DH5α | [117] |

| E. coli BL21 (DE3) | Methyl red and Remazol Black B | Halomonas elongata | Azoreductase gene | Vector pET21a | E. coli DH5 | [22] |

| Pichia pastoris | Amido Black 10B (62%), Remazol Brilliant Yellow (58%), Rhodamine 6 G (43%), crystal violet | M. mycetomatis | M. mycetomatis laccase-coding genes | pPICZαA and pPICZA | P. pastoris X33 | [12,118] |

| E. coli DH5 | Synthetic dyes | E. coli DH5 | Laccase CotA | pMD18-T | B. subtilis | |

| E. coli K12 | Malachite green | P. pastoris GS115 | Laccase CueO | pHBM905BDM | E. coli K12 | |

| Escherichia coli CY1 | Reactive red 22 | Rhodococcus sp. | Azo-dye-decolorizing genes | Plasmid pAZRS1 | Escherichia coli DH5a | [119] |

| Escherichia coli SS125 | Remazol red | Basillus latrasporus RRK1 | Azoreductase gene | Plasmid pAZR-SS125 | E. coli strain DH5a | [111] |

| Escherichia coli JM109 (pGEX-AZR) | Direct blue 71 | Rhodobacter sphaeoides AS1.1737 | Azoreductase gene | pGEX4T-1 | E. coli JM109 | [109] |

4. Futuristic Approaches to Dye Waste Water Treatment

5. Comprehensive Study of Advanced Biological Techniques

Challenges of Azo Dye Wastewater Treatment

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Munagapati, V.S.; Wen, H.Y.; Vijaya, Y.; Wen, J.C.; Wen, J.H.; Tian, Z.; Raul Garcia, J. Removal of anionic (Acid Yellow 17 and Amaranth) dyes using aminated avocado (Persea americana) seed powder: Adsorption/desorption, kinetics, isotherms, thermodynamics, and recycling studies. Int. J. Phytoremediat. 2021, 23, 911–923. [Google Scholar] [CrossRef] [PubMed]

- Mohamed, A.; Ghobara, M.M.; Abdelmaksoud, M.K.; Mohamed, G.G. A novel and highly efficient photocatalytic degradation of malachite green dye via surface-modified polyacrylonitrile nanofibers/biogenic silica composite nanofibers. Sep. Purif. Technol. 2019, 210, 935–942. [Google Scholar] [CrossRef]

- Ayele, A.; Getachew, D.; Kamaraj, M.; Suresh, A. Phycoremediation of synthetic dyes: An effective and eco-friendly algal technology for the dye abatement. J. Chem. 2021, 2021, 9923643. [Google Scholar] [CrossRef]

- Akansha, K.; Yadav, A.N.; Kumar, M.; Chakraborty, D.; Ghosh Sachan, S. Decolorization and degradation of reactive orange 16 by Bacillus stratosphericus SCA1007. Folia Microbiol. 2022, 67, 91–102. [Google Scholar] [CrossRef] [PubMed]

- Das, A.; Mishra, S. Decolorization of different textile azo dyes using an isolated bacterium Enterococcus durans GM13. Int. J. Curr. Microbiol. Appl. Sci. 2016, 5, 675–686. [Google Scholar] [CrossRef]

- Tian, F.; Wang, Y.; Guo, G.; Ding, K.; Yang, F.; Wang, H.; Liu, C. Enhanced azo dye biodegradation at high salinity by a halophilic bacterial consortium. Bioresour. Technol. 2021, 326, 124749. [Google Scholar] [CrossRef] [PubMed]

- Ajaz, M.; Shakeel, S.; Rehman, A. Microbial use for azo dye degradation—A strategy for dye bioremediation. Int. Microbiol. 2020, 23, 149–159. [Google Scholar] [CrossRef] [PubMed]

- El Awady, M.E.; Mohamed, G.E.; El-Shall, F.N.; Hassan, M.G. Screening and Optimization of Environmental Parameters for Maximum Decolorization of Reactive Orange 122 Azo-dye by Streptomyces sp. (A5). Egypt. Acad. J. Biol. Sci. G. Microbiol. 2021, 13, 49–60. [Google Scholar]

- Talha, M.A.; Goswami, M.; Giri, B.S.; Sharma, A.; Rai, B.N.; Singh, R.S. Bioremediation of Congo red dye in immobilized batch and continuous packed bed bioreactor by Brevibacillus parabrevis using coconut shell bio-char. Bioresour. Technol. 2018, 252, 37–43. [Google Scholar] [CrossRef]

- Thanavel, M.; Bankole, P.O.; Selvam, R.; Govindwar, S.P.; Sadasivam, S.K. Synergistic effect of biological and advanced oxidation process treatment in the biodegradation of Remazol yellow R.R. dye. Sci. Rep. 2020, 10, 20234. [Google Scholar] [CrossRef]

- Dwivedi, P.; Tomar, R.S. Bioremediation of textile effluent for degradation and decolourization of synthetic dyes: A review. Int. J. Curr. Res. Life Sci. 2018, 7, 1948–1951. [Google Scholar]

- Meerbergen, K.; Willems, K.A.; Dewil, R.; Van Impe, J.; Appels, L.; Lievens, B. Isolation and screening of bacterial isolates from wastewater treatment plants to decolorize azo dyes. J. Biosci. Bioeng. 2018, 125, 448–456. [Google Scholar] [CrossRef] [PubMed]

- Sreedharan, V.; Saha, P.; Rao, K.V.B. Dye degradation potential of Acinetobacter baumannii strain VITVB against commercial azo dyes. Bioremediat. J. 2021, 25, 347–368. [Google Scholar] [CrossRef]

- Kumar, N.; Sinha, S.; Mehrotra, T.; Singh, R.; Tandon, S.; Thakur, I.S. Biodecolorization of azo dye Acid Black 24 by Bacillus pseudomycoides: Process optimization using Box Behnken design model and toxicity assessment. Bioresour. Technol. Rep. 2019, 8, 100311. [Google Scholar] [CrossRef]

- Ayed, L.; Bekir, K.; Jabeur, C. Modelling and optimization of biodegradation of methylene blue by Staphylococcus aureus through a statistical optimization process: A sustainable approach for waste management. Water Sci. Technol. 2022, 86, 380–394. [Google Scholar] [CrossRef]

- Thangaraj, S.; Bankole, P.O.; Sadasivam, S.K. Microbial degradation of azo dyes by textile effluent adapted, Enterobacter hormaechei under microaerophilic condition. Microbiol. Res. 2021, 250, 126805. [Google Scholar] [CrossRef] [PubMed]

- Chung, K.T. Azo dyes and human health: A review. J. Environ. Sci. Health Part C 2016, 34, 233–261. [Google Scholar] [CrossRef]

- Prasad, S.S.; Aikat, K. Study of bio-degradation and bio-decolourization of azo dye by Enterobacter sp. SXCR. Environ. Technol. 2014, 35, 956–965. [Google Scholar] [CrossRef] [PubMed]

- Solís, M.; Solís, A.; Pérez, H.I.; Manjarrez, N.; Flores, M. Microbial decolouration of azo dyes: A review. Process Biochem. 2012, 47, 1723–1748. [Google Scholar] [CrossRef]

- El-Ahmady El-Naggar, N.; Rabei, N.H.; El-Malkey, S.E. Eco-friendly approach for biosorption of Pb2+ and carcinogenic Congo red dye from binary solution onto sustainable Ulva lactuca biomass. Sci. Rep. 2020, 10, 16021. [Google Scholar] [CrossRef]

- Saha, P.; Rao, K.V.B. Biotransformation of Reactive Orange 16 by alkaliphilic bacterium Bacillus flexus VITSP6 and toxicity assessment of biotransformed metabolites. Int. J. Environ. Sci. Technol. 2020, 17, 99–114. [Google Scholar] [CrossRef]

- Eslami, H.; Sedighi Khavidak, S.; Salehi, F.; Khosravi, R.; Fallahzadeh, R.A.; Peirovi, R.; Sadeghi, S. Biodegradation of methylene blue from aqueous solution by bacteria isolated from contaminated soil. J. Adv. Environ. Health Res. 2017, 5, 10–15. [Google Scholar]

- Shah, M. Effective treatment systems for azo dye degradation: A joint venture between physico-chemical & microbiological process. Int. J. Environ. Bioremediat. Biodegrad. 2014, 2, 231–242. [Google Scholar]

- Mabrouk, M.E.; Yusef, H.H. Decolorization of fast red by Bacillus subtilis H.M. J. Appl. Sci. Res. 2008, 4, 262–269. [Google Scholar]

- Carolin, C.F.; Kumar, P.S.; Joshiba, G.J. Sustainable approach to decolourize methyl orange dye from aqueous solution using novel bacterial strain and its metabolites characterization. Clean Technol. Environ. Policy 2021, 23, 173–181. [Google Scholar] [CrossRef]

- Khan, S.; Malik, A. Degradation of Reactive Black 5 dye by a newly isolated bacterium Pseudomonas entomophila BS1. Can. J. Microbiol. 2016, 62, 220–232. [Google Scholar] [CrossRef] [PubMed]

- Singh, P.K.; Singh, R.L. Bio-removal of azo dyes: A review. Int. J. Appl. Sci. Biotechnol. 2017, 5, 108–126. [Google Scholar] [CrossRef]

- Varjani, S.; Rakholiya, P.; Ng, H.Y.; You, S.; Teixeira, J.A. Microbial degradation of dyes: An overview. Bioresour. Technol. 2020, 314, 123728. [Google Scholar] [CrossRef]

- Zeng, Q.; Wang, Y.; Zan, F.; Khanal, S.K.; Hao, T. Biogenic sulfide for azo dye decolorization from textile dyeing wastewater. Chemosphere 2021, 283, 131158. [Google Scholar] [CrossRef]

- Gowri, R.S.; Vijayaraghavan, R.; Meenambigai, P. Microbial degradation of reactive dyes—A review. Int. J. Curr. Microbiol. Appl. Sci. 2014, 3, 421–436. [Google Scholar]

- Dave, S.R.; Patel, T.L.; Tipre, D.R. Bacterial degradation of azo dye containing wastes. In Microbial Degradation of Synthetic Dyes in Wastewaters; Springer: Cham, Switzerland, 2015; pp. 57–83. [Google Scholar]

- Legerská, B.; Chmelová, D.; Ondrejovič, M. Degradation of synthetic dyes by laccases—A mini-review. Nova Biotechnol. Chim. 2016, 15, 90–106. [Google Scholar] [CrossRef]

- Sen, S.K.; Raut, S.; Bandyopadhyay, P.; Raut, S. Fungal decolouration and degradation of azo dyes: A review. Fungal Biol. Rev. 2016, 30, 112–133. [Google Scholar] [CrossRef]

- Selvaraj, V.; Karthika, T.S.; Mansiya, C.; Alagar, M. An over review on recently developed techniques, mechanisms and intermediate involved in the advanced azo dye degradation for industrial applications. J. Mol. Struct. 2021, 1224, 129195. [Google Scholar] [CrossRef]

- Materac, M.; Wyrwicka, A.; Sobiecka, E. Phytoremediation techniques of wastewater treatment. Environ. Biotechnol. 2015, 11, 10–13. [Google Scholar] [CrossRef]

- Shindhal, T.; Rakholiya, P.; Varjani, S.; Pandey, A.; Ngo, H.H.; Guo, W.; Ng, H.Y.; Taherzadeh, M.J. A critical review on advances in the practices and perspectives for the treatment of dye industry wastewater. Bioengineered 2021, 12, 70–87. [Google Scholar] [CrossRef]

- Al-Hakkani, M.F.; Gouda, G.A.; Hassan, S.H. A review of green methods for phyto-fabrication of hematite (α-Fe2O3) nanoparticles and their characterization, properties, and applications. Heliyon 2021, 7, e05806. [Google Scholar] [CrossRef]

- Ahmad, A.; Mohd-Setapar, S.H.; Chuong, C.S.; Khatoon, A.; Wani, W.A.; Kumar, R.; Rafatullah, M. Recent advances in new generation dye removal technologies: Novel search for approaches to reprocess wastewater. RSC Adv. 2015, 5, 30801–30818. [Google Scholar] [CrossRef]

- Dutta, D.; Das, B.M. Scope of green nanotechnology towards amalgamation of green chemistry for cleaner environment: A review on synthesis and applications of green nanoparticles. Environ. Nanotechnol. Monit. Manag. 2021, 15, 100418. [Google Scholar] [CrossRef]

- Ullah, S.; Khalid, R.; Rehman, M.F.; Irfan, M.I.; Abbas, A.; Alhoshani, A.; Amin, H. Biosynthesis of phyto-functionalized silver nanoparticles using olive fruit extract and evaluation of their antibacterial and antioxidant properties. Front. Chem. 2023, 11, 1202252. [Google Scholar] [CrossRef]

- Barwal, A.; Chaudhary, R. To study the performance of biocarriers in moving bed biofilm reactor (MBBR) technology and kinetics of biofilm for retrofitting the existing aerobic treatment systems: A review. Rev. Environ. Sci. Bio/Technol. 2014, 13, 285–299. [Google Scholar] [CrossRef]

- Ercan, D.; Demirci, A. Current and future trends for biofilm reactors for fermentation processes. Crit. Rev. Biotechnol. 2015, 35, 1–14. [Google Scholar] [CrossRef] [PubMed]

- Nakul, S.; Kanwar, N. A review on biofilm mediated bioremediation. World J. Pharm. Res. 2018, 7, 458–465. [Google Scholar]

- Paździor, K.; Wrębiak, J.; Ledakowicz, S. Treatment of industrial textile wastewater in biological aerated filters–Microbial diversity analysis. Fibres Text. East. Eur. 2020, 1, 106–114. [Google Scholar] [CrossRef]

- Donkadokula, N.Y.; Kola, A.K.; Naz, I.; Saroj, D. A review on advanced physico-chemical and biological textile dye wastewater treatment techniques. Rev. Environ. Sci. Bio/Technol. 2020, 19, 543–560. [Google Scholar] [CrossRef]

- Haque, M.M.; Haque, M.A.; Mosharaf, M.K.; Marcus, P.K. Decolorization, degradation and detoxification of carcinogenic sulfonated azo dye methyl orange by newly developed biofilm consortia. Saudi J. Biol. Sci. 2021, 28, 793–804. [Google Scholar] [CrossRef] [PubMed]

- De Almeida, E.J.R.; Halfeld, G.G.; Reginatto, V.; de Andrade, A.R. Simultaneous energy generation, decolorization, and detoxification of the azo dye Procion Red MX-5B in a microbial fuel cell. J. Environ. Chem. Eng. 2021, 9, 106221. [Google Scholar] [CrossRef]

- Kalathil, S.; Lee, J.; Cho, M.H. Granular activated carbon based microbial fuel cell for simultaneous decolorization of real dye wastewater and electricity generation. New Biotechnol. 2011, 29, 32–37. [Google Scholar] [CrossRef]

- Srivastava, P.; Abbassi, R.; Yadav, A.K.; Garaniya, V.; Asadnia, M. A review on the contribution of electron flow in electroactive wetlands: Electricity generation and enhanced wastewater treatment. Chemosphere 2020, 254, 126926. [Google Scholar] [CrossRef]

- Sonu, K.; Syed, Z.; Sogani, M. Up-scaling microbial fuel cell systems for the treatment of real textile dye wastewater and bioelectricity recovery. Int. J. Environ. Stud. 2020, 77, 692–702. [Google Scholar] [CrossRef]

- Wang, W.; Zhang, Y.; Li, M.; Wei, X.; Wang, Y.; Liu, L.; Wang, H.; Shen, S. Operation mechanism of constructed wetland-microbial fuel cells for wastewater treatment and electricity generation: A review. Bioresour. Technol. 2020, 314, 123808. [Google Scholar] [CrossRef]

- Deng, D.; Aryal, N.; Ofori-Boadu, A.; Jha, M.K. Textiles Wastewater Treatment. Water Environ. Res. 2018, 90, 1648–1662. [Google Scholar] [CrossRef] [PubMed]

- Jadhav, D.A.; Carmona-Martínez, A.A.; Chendake, A.D.; Pandit, S.; Pant, D. Modelling and optimization strategies towards performance enhancement of microbial fuel cells. Bioresour. Technol. 2021, 320, 124256. [Google Scholar] [CrossRef]

- Ayyappan, C.S.; Bhalambaal, V.M.; Kumar, S. Effect of biochar on bio-electrochemical dye degradation and energy production. Bioresour. Technol. 2018, 251, 165–170. [Google Scholar] [CrossRef]

- Oon, Y.S.; Ong, S.A.; Ho, L.N.; Wong, Y.S.; Oon, Y.L.; Lehl, H.K.; Thung, W.E. Innovative baffled microbial fuel cells for azo dye degradation: Interactive mechanisms of electron transport and degradation pathway. J. Clean. Prod. 2021, 295, 126366. [Google Scholar] [CrossRef]

- Kishor, R.; Purchase, D.; Saratale, G.D.; Saratale, R.G.; Ferreira, L.F.R.; Bilal, M.; Chandra, R.; Bhargava, R.N. Ecotoxicological and health concerns of persistent coloring pollutants of textile industry wastewater and treatment approaches for environmental safety. J. Environ. Chem. Eng. 2021, 9, 105012. [Google Scholar] [CrossRef]

- Al-Fawwaz, A.T.; Abdullah, M. Decolorization of methylene blue and malachite green by immobilized Desmodesmus sp. isolated from North Jordan. Int. J. Environ. Sci. Dev. 2016, 7, 95. [Google Scholar] [CrossRef]

- Pathak, V.V.; Kothari, R.; Chopra, A.K.; Singh, D.P. Experimental and kinetic studies for phycoremediation and dye removal by Chlorella pyrenoidosa from textile wastewater. J. Environ. Manag. 2015, 163, 270–277. [Google Scholar] [CrossRef]

- Seo, Y.H.; Park, D.; Oh, Y.K.; Yoon, S.; Han, J.I. Harvesting of microalgae cells using oxidized dye wastewater. Bioresour. Technol. 2015, 192, 802–806. [Google Scholar] [CrossRef] [PubMed]

- Fazal, T.; Rehman, M.S.U.; Javed, F.; Akhtar, M.; Mushtaq, A.; Hafeez, A.; Din, A.A.; Iqbal, J.; Rashid, N.; Rehman, F. Integrating bioremediation of textile wastewater with biodiesel production using microalgae (Chlorella vulgaris). Chemosphere 2021, 281, 130758. [Google Scholar] [CrossRef]

- Waqas, M.R.; Nadeem, S.M.; Khan, M.Y.; Ahmad, Z.; Ali, L.; Asghar, H.N.; Khalid, A. Phycoremediation of textile effluents with enhanced efficacy of biodiesel production by algae and potential use of remediated effluent for improving growth of wheat. Environ. Sci. Pollut. Res. 2022, 29, 46118–46126. [Google Scholar] [CrossRef]

- Wu, J.Y.; Lay, C.H.; Chen, C.C.; Wu, S.Y. Lipid accumulating microalgae cultivation in textile wastewater: Environmental parameters optimization. J. Taiwan Inst. Chem. Eng. 2017, 79, 1–6. [Google Scholar] [CrossRef]

- Wu, J.Y.; Lay, C.H.; Chen, C.C.; Wu, S.Y.; Zhou, D.; Mohamed Abdula, P. Textile wastewater bioremediation using immobilized Chlorella sp. Wu-G23 with continuous culture. Clean Technol. Environ. Policy 2021, 23, 153–161. [Google Scholar] [CrossRef]

- Brahmbhatt, N.H.; Jasrai, R.T. Biodegradation of reactive dyes by two microalgal species. Int. J. Sci. Res. 2016, 4, 1697–1702. [Google Scholar]

- Vander Zee, F.P.; Villaverde, S. Combined anaerobic-aerobic treatment of azo dyes—A short review of bioreactor studies. Water Res. 2005, 39, 1425–1440. [Google Scholar] [CrossRef] [PubMed]

- Arslan, S.; Eyvaz, M.; Gürbulak, E.; Yüksel, E. A review of state-of-the-art technologies in dye-containing wastewater treatment–the textile industry case. In Textile Wastewater Treatment. 2016, pp. 1–29. Available online: https://www.intechopen.com/chapters/51191 (accessed on 9 January 2024).

- Khan, R.; Patel, V.; Khan, Z. Bioremediation of dyes from textile and dye manufacturing industry effluent. In Abatement of Environmental Pollutants; Elsevier: Amsterdam, The Netherlands, 2020; pp. 107–125. [Google Scholar]

- Dahiya, D.; Nigam, P.S. Waste management by biological approach employing natural substrates and microbial agents for the remediation of dyes’ wastewater. Appl. Sci. 2020, 10, 2958. [Google Scholar] [CrossRef]

- Tekere, M. Microbial Bioremediation and Different Bioreactors Designs Applied. In Biotechnology and Bioengineering; InTech: Rijeka, Croatia, 2019; pp. 1–19. [Google Scholar] [CrossRef]

- Samsami, S.; Mohamadi, M.; Sarrafzadeh, M.H.; Rene, E.R.; Firoozbahr, M. Recent advances in the treatment of dye-containing wastewater from textile industries: Overview and perspectives. Process Saf. Environ. Prot. 2020, 143, 138–163. [Google Scholar] [CrossRef]

- Pandey, A.K.; Singh, B.; Upadhyay, S.; Pandey, S.; Mishra, V.K.; Jain, P.A. Solution for sustainable development for developing countries: Waste water treatment by use of membranes—A review. Int. J. Curr. Microbiol. Appl. Sci. 2017, 6, 1212–1228. [Google Scholar] [CrossRef]

- Grilli, S.; Piscitelli, D.; Mattioli, D.; Casu, S.; Spagni, A. Textile wastewater treatment in a bench-scale anaerobic-biofilm anoxic-aerobic membrane bioreactor combined with nanofiltration. J. Environ. Sci. Health—Part A Toxic/Hazard. Subst. Environ. Eng. 2011, 46, 1512–1518. [Google Scholar] [CrossRef] [PubMed]

- Kathawala, T.M.; Gayathri, K.V.; Senthil Kumar, P. A Performance Comparison of Anaerobic and an Integrated Anaerobic-Aerobic Biological Reactor System for the Effective Treatment of Textile Wastewater. Int. J. Chem. Eng. 2021, 2021, 8894332. [Google Scholar] [CrossRef]

- Hameed, B.B.; Ismail, Z.Z. Biodegradation of reactive yellow dye using mixed cells immobilized in different biocarriers by sequential anaerobic/aerobic biotreatment: Experimental and modelling study. Environ. Technol. 2021, 42, 2991–3010. [Google Scholar] [CrossRef]

- Al-Ansari, M.M.; Li, Z.; Masood, A.; Rajaselvam, J. Decolourization of azo dye using a batch bioreactor by an indigenous bacterium Enterobacter aerogenes ES014 from the waste water dye effluent and toxicity analysis. Environ. Res. 2022, 205, 112189. [Google Scholar] [CrossRef]

- Azimi, B.; Abdollahzadeh-Sharghi, E.; Bonakdarpour, B. Anaerobic-aerobic processes for the treatment of textile dyeing wastewater containing three commercial reactive azo dyes: Effect of number of stages and bioreactor type. Chin. J. Chem. Eng. 2021, 39, 228–239. [Google Scholar] [CrossRef]

- Choerudin, C.; Arrahmah, F.I.; Daniel, J.K.; Watari, T.; Yamaguchi, T.; Setiadi, T. Evaluation of combined anaerobic membrane bioreactor and downflow hanging sponge reactor for treatment of synthetic textile wastewater. J. Environ. Chem. Eng. 2021, 9, 105276. [Google Scholar] [CrossRef]

- Rathour, R.; Jain, K.; Madamwar, D.; Desai, C. Performance and biofilm-associated bacterial community dynamics of an up-flow fixed-film microaerophilic-aerobic bioreactor system treating raw textile effluent. J. Clean. Prod. 2021, 295, 126380. [Google Scholar] [CrossRef]

- Teerapatsakul, C.; Parra, R.; Keshavarz, T.; Chitradon, L. Repeated batch for dye degradation in an airlift bioreactor by laccase entrapped in copper alginate. Int. Biodeterior. Biodegrad. 2017, 120, 52–57. [Google Scholar] [CrossRef]

- Swain, G.; Singh, S.; Sonwani, R.K.; Singh, R.S.; Jaiswal, R.P.; Rai, B.N. Removal of Acid Orange 7 dye in a packed bed bioreactor: Process optimization using response surface methodology and kinetic study. Bioresour. Technol. Rep. 2021, 13, 100620. [Google Scholar] [CrossRef]

- Sonwani, R.K.; Swain, G.; Jaiswal, R.P.; Singh, R.S.; Rai, B.N. Moving bed biofilm reactor with immobilized low-density polyethylene–polypropylene for Congo red dye removal. Environ. Technol. Innov. 2021, 23, 101558. [Google Scholar] [CrossRef]

- Sodaneath, H.; Lee, J.I.; Yang, S.O.; Jung, H.; Ryu, H.W.; Cho, K.S. Decolorization of textile dyes in an air-lift bioreactor inoculated with Bjerkandera adusta OBR105. J. Environ. Sci. Health Part A 2017, 52, 1099–1111. [Google Scholar] [CrossRef]

- Balapure, K.; Bhatt, N.; Madamwar, D. Mineralization of reactive azo dyes present in simulated textile waste water using down flow microaerophilic fixed film bioreactor. Bioresour. Technol. 2015, 175, 1–7. [Google Scholar] [CrossRef]

- Padmanaban, V.C.; Geed, S.R.R.; Achary, A.; Singh, R.S. Kinetic studies on degradation of Reactive Red 120 dye in immobilized packed bed reactor by Bacillus cohnii RAPT1. Bioresour. Technol. 2016, 213, 39–43. [Google Scholar] [CrossRef]

- Upendar, G.; Dutta, S.; Chakraborty, J.; Bhattacharyya, P. Removal of methylene blue dye using immobilized Bacillus subtilis in batch & column reactor. Mater. Today Proc. 2016, 3, 3467–3472. [Google Scholar] [CrossRef]

- Mohanty, S.S.; Kumar, A. Biodegradation of Indanthrene Blue R.S. dye in immobilized continuous up-flow packed bed bioreactor using corncob biochar. Sci. Rep. 2021, 11, 13390. [Google Scholar] [CrossRef] [PubMed]

- Routoula, E.; Patwardhan, S.V. Degradation of anthraquinone dyes from effluents: A review focusing on enzymatic dye degradation with industrial potential. Environ. Sci. Technol. 2020, 54, 647–664. [Google Scholar] [CrossRef] [PubMed]

- Ali, H. Biodegradation of synthetic dyes—A review. Water Air Soil Pollut. 2010, 213, 251–273. [Google Scholar] [CrossRef]

- Mani, A.; Hameed, S.A.S. Improved bacterial-fungal consortium as an alternative approach for enhanced decolourization and degradation of azo dyes: A review. Nat. Environ. Pollut. Technol. 2019, 18, 49–64. [Google Scholar]

- Chen, F.; Zhao, J.; Hidaka, H. Adsorption factor and photocatalytic degradation of dye-constituent aromatics on the surface of TiO2 in the presence of phosphate anions. Res. Chem. Intermed. 2003, 29, 733–748. [Google Scholar] [CrossRef]

- Bhatia, D.; Sharma, N.R.; Singh, J.; Kanwar, R.S. Biological methods for textile dye removal from wastewater: A review. Crit. Rev. Environ. Sci. Technol. 2017, 47, 1836–1876. [Google Scholar] [CrossRef]

- Bouabidi, Z.B.; El-Naas, M.H.; Zhang, Z. Immobilization of microbial cells for the biotreatment of wastewater: A review. Environ. Chem. Lett. 2019, 17, 241–257. [Google Scholar] [CrossRef]

- Datta, S.; Veena, R.; Samuel, M.S.; Selvarajan, E. Immobilization of laccases and applications for the detection and remediation of pollutants: A review. Environ. Chem. Lett. 2021, 19, 521–538. [Google Scholar] [CrossRef]

- Vijayaraghavan, J.; Basha, S.S.; Jegan, J. A review on efficacious methods to decolorize reactive azo dye. J. Urban Environ. Eng. 2013, 7, 30–47. [Google Scholar] [CrossRef]

- Bayramoglu, G.; Akbulut, A.; Arica, M.Y. Utilization of immobilized horseradish peroxidase for facilitated detoxification of a benzidine based azo dye. Chem. Eng. Res. Des. 2021, 165, 435–444. [Google Scholar] [CrossRef]

- Nguyen, T.A.; Fu, C.C.; Juang, R.S. Effective removal of sulfur dyes from water by biosorption and subsequent immobilized laccase degradation on crosslinked chitosan beads. Chem. Eng. J. 2016, 304, 313–324. [Google Scholar] [CrossRef]

- Bilal, M.; Asgher, M. Dye decolorization and detoxification potential of Ca-alginate beads immobilized manganese peroxidase. BMC Biotechnol. 2015, 15, 111. [Google Scholar] [CrossRef] [PubMed]

- Abd El Aty, A.A.; Mostafa, F.A.; Hassan, M.E.; Hamed, E.R.; Esawy, M.A. Covalent immobilization of Alternaria tenuissima KM651985 laccase and some applied aspects. Biocatal. Agric. Biotechnol. 2017, 9, 74–81. [Google Scholar] [CrossRef]

- Zheng, F.; Cui, B.K.; Wu, X.J.; Meng, G.; Liu, H.X.; Si, J. Immobilization of laccase onto chitosan beads to enhance its capability to degrade synthetic dyes. Int. Biodeterior. Biodegrad. 2016, 110, 69–78. [Google Scholar] [CrossRef]

- Noreen, S.; Asgher, M.; Hussain, F.; Iqbal, A. Performance improvement of Ca-alginate bead cross-linked laccase from Trametes versicolor IBL-04. BioResources 2016, 11, 558–572. [Google Scholar] [CrossRef]

- Ma, H.F.; Meng, G.; Cui, B.K.; Si, J.; Dai, Y.C. Chitosan crosslinked with genipin as supporting matrix for biodegradation of synthetic dyes: Laccase immobilization and characterization. Chem. Eng. Res. Des. 2018, 132, 664–676. [Google Scholar] [CrossRef]

- Gahlout, M.; Rudakiya, D.M.; Gupte, S.; Gupte, A. Laccase-conjugated amino-functionalized nanosilica for efficient degradation of Reactive Violet 1 dye. Int. Nano Lett. 2017, 7, 195–208. [Google Scholar] [CrossRef]

- Liu, Y.; Yan, M.; Geng, Y.; Huang, J. Laccase immobilization on poly (p-phenylenediamine)/Fe3O4 nanocomposite for reactive blue 19 dye removal. Appl. Sci. 2016, 6, 232. [Google Scholar] [CrossRef]

- Šekuljica, N.Ž.; Prlainović, N.Ž.; Jakovetić, S.M.; Grbavčić, S.Ž.; Ognjanović, N.D.; Knežević-Jugović, Z.D.; Mijin, D.Ž. Removal of Anthraquinone Dye by Cross-Linked Enzyme Aggregates from Fresh Horseradish Extract. CLEAN–Soil Air Water 2016, 44, 891–900. [Google Scholar] [CrossRef]

- Córdoba, A.; Alasino, N.; Asteasuain, M.; Magario, I.; Ferreira, M.L. Mechanistic evaluation of hematin action as a horseradish peroxidase biomimetic on the 4-amino antipyrine/phenol oxidation reaction. Chem. Eng. Sci. 2015, 129, 249–259. [Google Scholar] [CrossRef]

- Janović, B.S.; Mićić Vićovac, M.L.; Vujčić, Z.M.; Vujčić, M.T. Tailor-made biocatalysts based on scarcely studied acidic horseradish peroxidase for biodegradation of reactive dyes. Environ. Sci. Pollut. Res. 2017, 24, 3923–3933. [Google Scholar] [CrossRef]

- Goud, B.S.; Cha, H.L.; Koyyada, G.; Kim, J.H. Augmented Biodegradation of Textile Azo Dye Effluents by Plant Endophytes: A Sustainable, Eco-Friendly Alternative. Curr. Microbiol. 2020, 77, 3240–3255. [Google Scholar] [CrossRef]

- Biswas, R.; Mete, S.; Mandal, M.; Banerjee, B.; Singh, H.; Ahmed, I.; Haldar, K.K. Novel Green Approach for Fabrication of Ag2CrO4/TiO2/Au/r-GO Hybrid Biofilm for Visible Light-Driven Photocatalytic Performance. J. Phys. Chem. C 2020, 124, 3373–3388. [Google Scholar] [CrossRef]

- Jin, R.; Yang, H.; Zhang, A.; Wang, J.; Liu, G. Bioaugmentation on decolorization of CI Direct Blue 71 by using genetically engineered strain Escherichia coli JM109 (pGEX-AZR). J. Hazard. Mater. 2009, 163, 1123–1128. [Google Scholar] [CrossRef]

- Liu, G.F.; Zhou, J.T.; Qu, Y.Y.; Ma, X. Decolorization of sulfonated azo dyes with two photosynthetic bacterial strains and a genetically engineered Escherichia coli strain. World J. Microbiol. Biotechnol. 2007, 23, 931–937. [Google Scholar] [CrossRef]

- Sandhya, S.; Sarayu, K.; Uma, B.; Swaminathan, K. Decolorizing kinetics of a recombinant Escherichia coli SS125 strain harboring azoreductase gene from Bacillus latrosporus RRK1. Bioresour. Technol. 2008, 99, 2187–2191. [Google Scholar] [CrossRef]

- Bhandari, S.; Poudel, D.K.; Marahatha, R.; Dawadi, S.; Khadayat, K.; Phuyal, S.; Shrestha, S.; Gaire, S.; Basnet, K.; Khadka, U.; et al. Microbial Enzymes Used in Bioremediation. J. Chem. 2021, 2021, 8849512. [Google Scholar] [CrossRef]

- Roshan, V.; Vishal, M.; Sonika, S.; Jadhav, I. Microbial Enzymatic System in the Degradation of Textile Dyes. Int. J. Nat. Sci. 2020, 10, 18577–18589. [Google Scholar]

- Dafale, N.A. Exploration of genetic information from dynamic microbial populations for enhancing the efficiency of azo-dye-degrading systems. Environ. Rev. 2011, 19, 310–332. [Google Scholar] [CrossRef]

- Arora, P.K. Bacilli-Mediated Degradation of Xenobiotic Compounds and Heavy Metals. Front. Bioeng. Biotechnol. 2020, 8, 570307. [Google Scholar] [CrossRef]

- Rather, L.J.; Akhter, S.; Hassan, Q.P. Bioremediation: Green and Sustainable Technology for Textile Effluent Treatment. In Sustainable Innovations in Textile Chemistry and Dyes. Textile Science and Clothing Technology; Muthu, S., Ed.; Springer: Singapore, 2018; pp. 75–91. [Google Scholar] [CrossRef]

- Dixit, S.; Garg, S. Enzymatic degradation of sulphonated azo dye using purified azoreductase from facultative Klebsiella pneumoniae. Folia Microbiol. 2021, 66, 79–85. [Google Scholar] [CrossRef]

- Tülek, A.; Karataş, E.; Çakar, M.M.; Aydın, D.; Yılmazcan, Ö.; Binay, B. Optimization of the Production and Bleaching Process for a New Laccase from Madurella mycetomatis, Expressed in Pichia pastoris: From Secretion to Yielding Prominent. Mol. Biotechnol. 2021, 63, 24–39. [Google Scholar] [CrossRef]

- Chang, J.S.; Lin, C.Y. Decolorization kinetics of a recombinant Escherichia coli strain harboring azo-dye-decolorizing determinants from Rhodococcus sp. Biotechnol. Lett. 2001, 23, 631–636. [Google Scholar] [CrossRef]

- Yang, Z.; Pei, H.; Hou, Q.; Jiang, L.; Zhang, L.; Nie, C. Algal biofilm-assisted microbial fuel cell to enhance domestic wastewater treatment: Nutrient, organics removal and bioenergy production. Chem. Eng. J. 2018, 332, 277–285. [Google Scholar] [CrossRef]

- Moga, I.C.; Iordache, O.I.; Petrescu, G.; Pricop, F.; Dumitrescu, I. Polyethylene based materials for biofilm carriers used in wastewater treatment. IOP Conf. Ser. Mater. Sci. Eng. 2018, 374, 012080. [Google Scholar] [CrossRef]

- Murshid, S.; Antonysamy, A.; Dhakshinamoorthy, G.; Jayaseelan, A.; Arivalagan, P. A review on biofilm-based reactors for wastewater treatment: Recent advancements in biofilm carriers, kinetics, reactors, economics, and future perspectives. Sci. Total Environ. 2023, 892, 164796. [Google Scholar] [CrossRef]

- Neeti, K.; Gaurav, K.; Singh, R. The Potential of Algae Biofuel as a Renewable and Sustainable Bioresource. Eng. Proc. 2023, 37, 22. [Google Scholar] [CrossRef]

- Lam, M.K.; Lee, K.T. Immobilization as a feasible method to simplify the separation of microalgae from water for biodiesel production. Chem. Eng. J. 2012, 191, 263–268. [Google Scholar] [CrossRef]

- Mutamim, N.S.A.; Noor, Z.Z.; Hassan, M.A.A.; Yuniarto, A.; Olsson, G. Membrane bioreactor: Applications and limitations in treating high strength industrial wastewater. Chem. Eng. J. 2013, 225, 109–119. [Google Scholar] [CrossRef]

- Tischer, W.; Wedekind, F. Immobilized enzymes: Methods and applications. Biocatal. Discov. Appl. 1999, 200, 95–126. [Google Scholar]

| Physicochemical Methods | Advantages | Limitations |

|---|---|---|

| Flocculation/coagulation | Simple operation process | Sludge production |

| Adsorption | Excellent removal of various dyes | Transfer contaminants |

| Electrochemical oxidation | No consumption of chemical | Cast of electricity |

| Ozonation | Fast and effective dye removal method | Short half-life |

| Ion exchange | High cation exchange capacity | Not suitable for all dyes |

| Fenton oxidation | Suitable for soluble and insoluble dyes | Sludge production |

| Photochemical | No sludge production | Formations of byproducts |

| Membrane filtration | Low cast | Sludge disposal |

| Microalgae Species | Dyes | Decolonization % | References |

|---|---|---|---|

| CKW1 (Spirogyra sp.) and PKS33 (Cladophora sp.) | Textile effluent dyes | 90% | [61] |

| Chlorella vulgaris | Methylene Blue | 99.7% | [60] |

| Chroococcus minutes | Amido black 10B | 55% | [62] |

| Chlorella pyrenoidosa | Textile wastewater | 80% | [58] |

| Chlorella sp. Wu-G23 (G23) | Textile wastewater | 77.9% | [63] |

| Spirogyra sp. | Cr(IV) | 30% | [64] |

| Oscillatoria sp. | Textile wastewater | 76% | [57] |

| Desmodesmus sp. | Methylene Blue, Malachite Green, | 98% | [59] |

| Reactive Red-120 | 99% |

| Enzyme | Microbial Strains | Immobilization Matrices | Immobilization Technique | Dye | Decolorization % | Time | Reference |

|---|---|---|---|---|---|---|---|

| Horseradish peroxidase | C. vulgaris and D. magna | Cryogels | Direct Blue-6 | 99.6 to 7.3% 4.0–8.0 | 60 min | [95] | |

| Laccase | Trametes versicolor | Chitosan beads | Sulphur blue 15 200 mg/L | 81.6, 30 °C; 6.5; | 12 h | [96] | |

| Manganese peroxidase; | Ganoderma lucidum IBL-05 | Calcium alginate beads | Sandal-fx black CKF 100 mg/L | 60 °C; 4; 95.7 | 12 h | [97] | |

| Laccase | Alternia tenuissima | Calcium alginate beads with chitosan beads | Dye | 58% | [98] | ||

| Laccase | Trametes pubescens | Chitosan beads | Cross-linker glutaraldehyde | Acid Black 172 | 60%. | 4 h | [99] |

| Laccase | Trametes versicolor IBL-04 | Calcium alginate beads | Cross-linking | Reactive T Blue dye | 92% | 72 h | [100] |

| Laccase | Trametes pubescens | Genipin | Cross-linker | Synthetic dye | >55% | 14 h | [101] |

| Laccase | Ganoderma cupreum | Amino functionalized nanosilica | Cross-linking with nanosilica | Reactive violet dye | 96.76% | 12 h | [102] |

| Laccase | Magnetic polynano-composite | Reactive blue 19 | 80% | 1 h | [103] | ||

| Horseradish peroxidase | Activated kaolin | Adsorption | Acid red 109/40 mg/L | 87% | 40 min | [104] | |

| Horseradish peroxidase | Cross-linked enzyme aggregates | Cross-link | Acid violet 109/30 | 70–90% | 40 min | [104] | |

| Horseradish peroxidase | Chitosan and APTS | Covalent adsorption | Alizarin red 200 mg/L | 50% | 4 h | [105] | |

| Horseradish peroxidase | Adsorption | Hitosan | Reactive blue 19/100 mg/L | 70% | 4 h | [106] |

| Methods | Advantages | Limitations | References |

|---|---|---|---|

| Phytoremediation | No requirement for maintaining isolation and preparing culture media, cost-effective, stable, safe, non-toxic, ecologically friendly, laboratory setup is not necessary. | The short root structure of aquatic plants, which limits the depth of soil treatment by the rhizosphere, is a major drawback of phytoremediation. Time-consuming in the slow progress of the environmental remediation procedure. | [35] |

| Biofilm Reactors | Fast and cheap. The moving-bed biofilm reactor uses less electrical energy than the activated sludge process. Reducing the biological reactor’s volume or handling a higher organic load in the same reactor volume is one of the key advantages of the MBBR system. | The drawbacks of bacteria living in biofilms are as follows:

| [120,121] |

| Microbial Fuel Cells (MFCs) | High output. Produces valuable products, including biofuels. Applies to wastewater treatment. | Heterogeneous catalysts always require long reaction times because the presence of three immiscible phases at the beginning of the reaction significantly increases the mass transfer limitation within the system. | [122] |

| Microalgae through Dye Treatment and Biodiesel Production | Our dependence on non-renewable resources can be decreased and the fight against climate change increased by the use of this renewable energy source. Capable of growth in any kind of situation. Put in place a productive cycle for cycling nutrients. Reduce back on greenhouse gas emissions. | Open-pond farming activities are severely impacted by high temperatures. In order for algae biodiesel to be produced, transported, and used effectively, large financial investments must first be made. Challenges of stability and contamination. Requirements for using water and land. With the amount of cash and time it takes to cultivate, its manufacturing might become costly. | [123,124] |

| Bioreactors | The advantages of handling MBR include controlling the biofouling effect, reducing energy consumption during operation, and reducing water costs by reusing the treated water for other processes. It also helps to establish the ideal conditions for operating MBR for high-strength industrial wastewater and shock-loading rate. | Contamination chance. Concerning limitations are those related to pH, temperature, pressure, and some caustic chemicals. Excessive membrane cost, which raises the expense of operations and maintenance. The cost of the membrane includes cleaning procedures and replacement of severely fouled or corrupted membranes during maintenance. | [125] |

| Immobilization System | Simple retention, simple enzyme removal from the product. The enzyme can be reused. Prolonged durability. Enhanced tolerance to external stressors. Enhanced functionality efficiency. Enhanced degree of continuous operation. improved process control enhance the catalytic mechanism. | These limitations, which can be summed up as mass transfer effects, result in less effectiveness. High cost-to-income ratio. Limited application. Limits connected to carriers. System inactivation brought on by heat generation. | [126] |

| Genetically modified microorganisms or enzymes | The excellent capacity of GMOs to speeds up the colouring process is the real advantage. | Their disadvantages include decreased biodiversity, cross-pollination, unknown long-term health effects, and environmental harm from horizontal gene transfer. | [56] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kusumlata; Ambade, B.; Kumar, A.; Gautam, S. Sustainable Solutions: Reviewing the Future of Textile Dye Contaminant Removal with Emerging Biological Treatments. Limnol. Rev. 2024, 24, 126-149. https://doi.org/10.3390/limnolrev24020007

Kusumlata, Ambade B, Kumar A, Gautam S. Sustainable Solutions: Reviewing the Future of Textile Dye Contaminant Removal with Emerging Biological Treatments. Limnological Review. 2024; 24(2):126-149. https://doi.org/10.3390/limnolrev24020007

Chicago/Turabian StyleKusumlata, Balram Ambade, Ashish Kumar, and Sneha Gautam. 2024. "Sustainable Solutions: Reviewing the Future of Textile Dye Contaminant Removal with Emerging Biological Treatments" Limnological Review 24, no. 2: 126-149. https://doi.org/10.3390/limnolrev24020007

APA StyleKusumlata, Ambade, B., Kumar, A., & Gautam, S. (2024). Sustainable Solutions: Reviewing the Future of Textile Dye Contaminant Removal with Emerging Biological Treatments. Limnological Review, 24(2), 126-149. https://doi.org/10.3390/limnolrev24020007