Removal Mechanisms and Microstructure Characteristics of Laser Paint Stripping on Aircraft Skin Surface

Abstract

:1. Introduction

2. Experimental Procedure

2.1. Materials

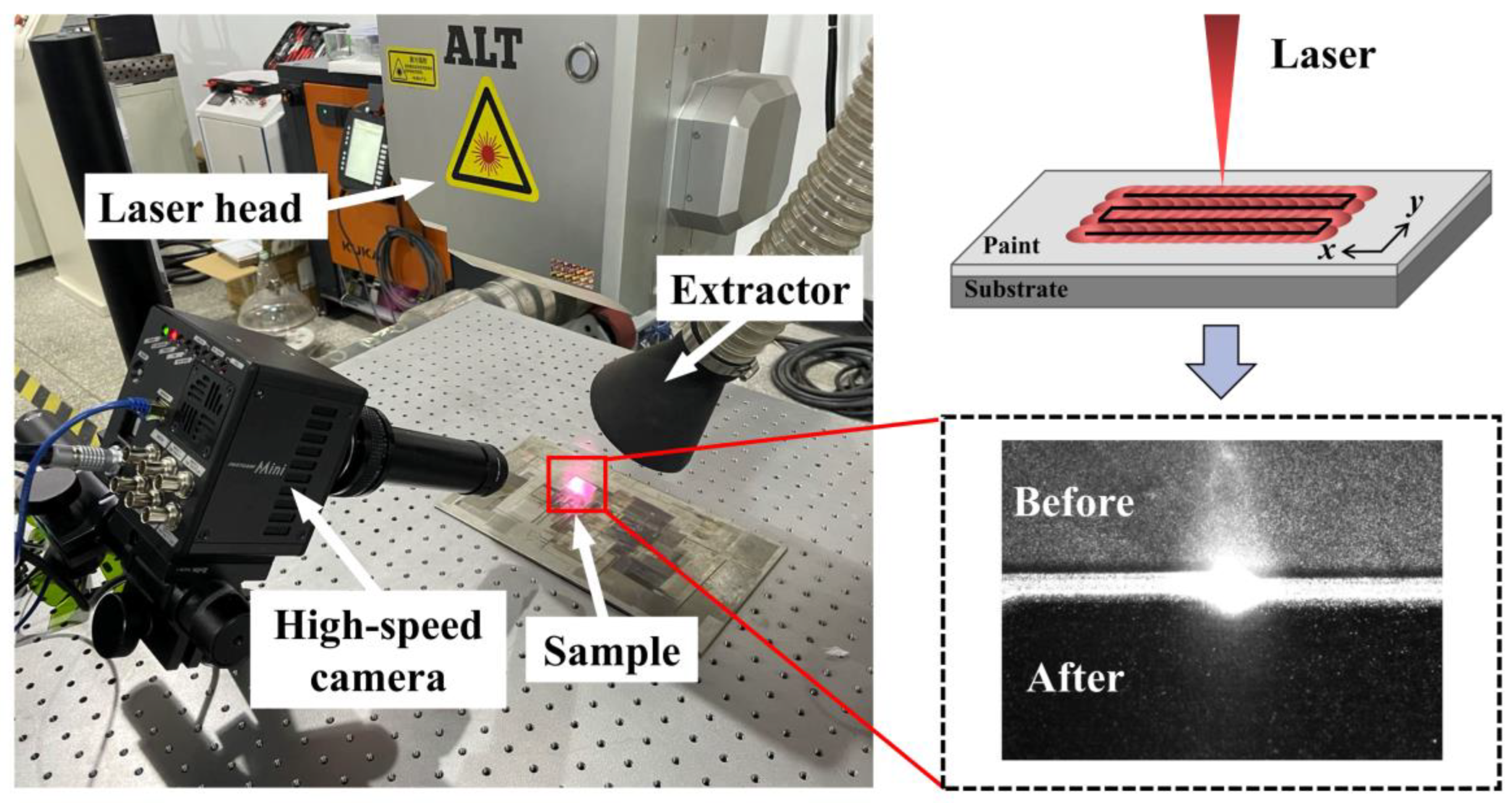

2.2. Laser-Cleaning Experiment

2.3. Surface Characterization

3. Results

3.1. Macroscopic Observation

3.2. Microscopic Characterization

3.3. Energy Spectroscopy Analysis

3.4. Fourier Transform Infrared Spectroscopy Analysis

3.5. Nanoindentation Hardness Analysis

4. Discussion

4.1. Influence of the Process Parameters on the Cleaning Effect

4.2. Mechanisms of Laser Paint Stripping from Aircraft Al Alloy Skin

4.3. Enhancement Mechanism of Microhardness Induced by Laser

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Starke, E.A.; Staley, J.T. Application of Modern Aluminum Alloys to Aircraft. Prog. Aerosp. Sci. 1996, 32, 131–172. [Google Scholar] [CrossRef]

- Molina-Viedma, Á.; López-Alba, E.; Felipe-Sesé, L.; Díaz, F. Full-Field Operational Modal Analysis of an Aircraft Composite Panel from the Dynamic Response in Multi-Impact Test. Sensors 2021, 21, 1602. [Google Scholar] [CrossRef] [PubMed]

- Moupfouma, F. Aircraft Structure Paint Thickness and Lightning Swept Stroke Damages. SAE Int. J. Aerosp. 2013, 6, 392–398. [Google Scholar] [CrossRef]

- Merati, A.; Yanishevsky, M.; Despinic, T.; Lo, P. The Effect of Atmospheric Plasma Paint Stripping on the Fatigue Crack Growth Properties of Aluminium Substrates. JMMCE 2017, 5, 161–173. [Google Scholar] [CrossRef] [Green Version]

- Merati, A.; Yanishevsky, M.; Despinic, T.; Lo, P.; Pankov, V. Alternate Environmentally Friendly De-Painting Process for Aircraft Structures-Atmospheric Plasma. JMMCE 2017, 5, 223–235. [Google Scholar] [CrossRef] [Green Version]

- Yanishevsky, M.; Merati, A.; Bombardier, Y. Effect of Atmospheric Plasma Paint Removal on the Fatigue Performance of 2024-T3 Aluminium Alloy Sheet. J. Miner. Mater. Charact. Eng. 2017, 6, 15–24. [Google Scholar] [CrossRef] [Green Version]

- Shan, T.; Yin, F.; Wang, S.; Qiao, Y.; Liu, P. Surface Integrity Control of Laser Cleaning of an Aluminum Alloy Surface Paint Layer. Appl. Opt. 2020, 59, 9313–9319. [Google Scholar] [CrossRef]

- Morelli, U.; Dalla Vedova, M.D.L.; Maggiore, P. Automatic Painting and Paint Removal System: A Preliminary Design for Aircraft Applications. In Proceedings of the Advances in Service and Industrial Robotics, Patras, Greece, 19–21 June 2018; Springer: Cham, Switzerland, 2019; pp. 640–650. [Google Scholar]

- Li, X.; Wang, H.; Yu, W.; Wang, L.; Wang, D.; Cheng, H.; Wang, L. Laser Paint Stripping Strategy in Engineering Application: A Systematic Review. Optik 2021, 241, 167036. [Google Scholar] [CrossRef]

- Uang, S.-N.; Shih, T.-S.; Chang, C.-H.; Chang, S.-M.; Tsai, C.-J.; Deshpande, C.G. Exposure Assessment of Organic Solvents for Aircraft Paint Stripping and Spraying Workers. Sci. Total Environ. 2006, 356, 38–44. [Google Scholar] [CrossRef]

- Yang, W.; Qian, Z.; Cao, Y.; Wei, Y.; Fu, C.; Li, T.; Lin, D.; Li, S. LIBS Monitoring and Analysis of Laser-Based Layered Controlled Paint Removal from Aircraft Skin. J. Spectrosc. 2021, 2021, 1–12. [Google Scholar] [CrossRef]

- Sun, X.; Yu, Q.; Bai, X.; Jin, G.; Cai, J.; Yuan, B. Substrate Cleaning Threshold for Various Coated Al Alloys Using a Continuous-Wave Laser. Photonics 2021, 8, 395. [Google Scholar] [CrossRef]

- Tam, A.C.; Leung, W.P.; Zapka, W.; Ziemlich, W. Laser-cleaning Techniques for Removal of Surface Particulates. J. Appl. Phys. 1992, 71, 3515–3523. [Google Scholar] [CrossRef]

- Steen, W.M. Laser Material Processing—An Overview. J. Opt. A Pure Appl. Opt. 2003, 5, S3. [Google Scholar] [CrossRef]

- Kane, D.M. Laser Cleaning II; World Scientific: Singapore, 2007; ISBN 978-981-270-372-9. [Google Scholar]

- Steen, W.M.; Mazumder, J. Laser Material Processing; Springer: London, UK, 2010; ISBN 978-1-84996-061-8. [Google Scholar]

- Bertasa, M.; Korenberg, C. Successes and Challenges in Laser Cleaning Metal Artefacts: A Review. J. Cult. Herit. 2022, 53, 100–117. [Google Scholar] [CrossRef]

- Zhu, G.; Xu, Z.; Jin, Y.; Chen, X.; Yang, L.; Xu, J.; Shan, D.; Chen, Y.; Guo, B. Mechanism and Application of Laser Cleaning: A Review. Opt. Lasers Eng. 2022, 157, 107130. [Google Scholar] [CrossRef]

- Genna, S.; Lambiase, F.; Leone, C. Effect of Laser Cleaning in Laser Assisted Joining of CFRP and PC Sheets. Compos. Part B Eng. 2018, 145, 206–214. [Google Scholar] [CrossRef]

- Lu, Y.; Ding, Y.; Wang, M.; Yang, L.; Wang, Y. An Environmentally Friendly Laser Cleaning Method to Remove Oceanic Micro-Biofoulings from AH36 Steel Substrate and Corrosion Protection. J. Clean. Prod. 2021, 314, 127961. [Google Scholar] [CrossRef]

- Zhang, D.; Wu, L.-C.; Ueki, M.; Ito, Y.; Sugioka, K. Femtosecond Laser Shockwave Peening Ablation in Liquids for Hierarchical Micro/Nanostructuring of Brittle Silicon and Its Biological Application. Int. J. Extrem. Manuf. 2020, 2, 045001. [Google Scholar] [CrossRef]

- Zhang, D.; Ranjan, B.; Tanaka, T.; Sugioka, K. Underwater Persistent Bubble-Assisted Femtosecond Laser Ablation for Hierarchical Micro/Nanostructuring. Int. J. Extrem. Manuf. 2020, 2, 015001. [Google Scholar] [CrossRef]

- Schaiwlow, A.L. Lasers. Science 1965, 149, 13–22. [Google Scholar] [CrossRef]

- Bedair, S.M.; Smith, H.P. Atomically Clean Surfaces by Pulsed Laser Bombardment. J. Appl. Phys. 1969, 40, 4776–4781. [Google Scholar] [CrossRef]

- Pozo-Antonio, J.S.; Ramil, A.; Rivas, T.; López, A.J.; Fiorucci, M.P. Effectiveness of Chemical, Mechanical and Laser Cleaning Methods of Sulphated Black Crusts Developed on Granite. Constr. Build. Mater. 2016, 112, 682–690. [Google Scholar] [CrossRef]

- Yang, J.; Zhou, J.; Sun, Q.; Meng, X.; Guo, Z.; Zhu, M. Digital Analysis and Prediction of the Topography after Pulsed Laser Paint Stripping. J. Manuf. Process. 2021, 62, 685–694. [Google Scholar] [CrossRef]

- Ouyang, J.; Mativenga, P.T.; Liu, Z.; Li, L. Energy Consumption and Process Characteristics of Picosecond Laser De-Coating of Cutting Tools. J. Clean. Prod. 2021, 290, 125815. [Google Scholar] [CrossRef]

- Zhuang, S.; Kainuma, S.; Yang, M.; Haraguchi, M.; Asano, T. Characterizing Corrosion Properties of Carbon Steel Affected by High-Power Laser Cleaning. Constr. Build. Mater. 2021, 274, 122085. [Google Scholar] [CrossRef]

- Kumar, A.; Biswas, D.J. Particulate Size and Shape Effects in Laser Cleaning of Heavy Metal Oxide Loose Contamination off Clad Surface. Opt. Laser Technol. 2018, 106, 286–293. [Google Scholar] [CrossRef]

- Palomar, T.; Oujja, M.; Llorente, I.; Ramírez Barat, B.; Cañamares, M.V.; Cano, E.; Castillejo, M. Evaluation of Laser Cleaning for the Restoration of Tarnished Silver Artifacts. Appl. Surf. Sci. 2016, 387, 118–127. [Google Scholar] [CrossRef] [Green Version]

- Yoo, H.J.; Baek, S.; Kim, J.H.; Choi, J.; Kim, Y.-J.; Park, C. Effect of Laser Surface Cleaning of Corroded 304L Stainless Steel on Microstructure and Mechanical Properties. J. Mater. Res. Technol. 2022, 16, 373–385. [Google Scholar] [CrossRef]

- Li, Z.; Chen, X.; Yang, S.; Zhang, D.; Xu, J.; Ma, R.; Shan, D.; Guo, B. Removal Mechanism of Liquid-Assisted Nanosecond Pulsed Laser Cleaning TA15 Titanium Alloy Oxide Film. J. Mater. Res. Technol. 2022, 19, 4986–4997. [Google Scholar] [CrossRef]

- Tian, Z.; Lei, Z.; Chen, X.; Chen, Y.; Zhang, L.-C.; Bi, J.; Liang, J. Nanosecond Pulsed Fiber Laser Cleaning of Natural Marine Micro-Biofoulings from the Surface of Aluminum Alloy. J. Clean. Prod. 2020, 244, 118724. [Google Scholar] [CrossRef]

- Tsunemi, A.; Endo, A.; Ichishima, D. Paint Removal from Aluminum and Composite Substrate of Aircraft by Laser Ablation Using TEA CO2 Lasers; Proc. SPIE, High-Power Laser Ablation, Santa Fe, NM, United States, 26–30 April 1998; Phipps, C.R., Ed.; SPIE: Bellingham, WA, USA, 1998; pp. 1018–1022. [Google Scholar]

- Arthur, J. Robotic Laser System to Strip Paint from Aircraft. Adv. Coat. Surf. Technol. 2013, 26, 2–3. [Google Scholar]

- Wang, F.; Wang, Q.; Huang, H.; Cheng, Y.; Wang, L.; Ai, S.; Cai, C.; Chen, H. Effects of Laser Paint Stripping on Oxide Film Damage of 2024 Aluminium Alloy Aircraft Skin. Opt. Express OE 2021, 29, 35516–35531. [Google Scholar] [CrossRef] [PubMed]

- Zhu, G.; Wang, S.; Cheng, W.; Ren, Y.; Wen, D. Corrosion and Wear Performance of Aircraft Skin after Laser Cleaning. Opt. Laser Technol. 2020, 132, 106475. [Google Scholar] [CrossRef]

- Dutta Majumdar, J.; Manna, I. Laser Material Processing. Int. Mater. Rev. 2011, 56, 341–388. [Google Scholar] [CrossRef]

- Razab, M.K.A.A.; Mohamed Noor, A.; Suhaimi Jaafar, M.; Abdullah, N.H.; Suhaimi, F.M.; Mohamed, M.; Adam, N.; Auli Nik Yusuf, N.A. A Review of Incorporating Nd: YAG Laser Cleaning Principal in Automotive Industry. J. Radiat. Res. Appl. Sci. 2018, 11, 393–402. [Google Scholar] [CrossRef] [Green Version]

- Kuang, Z.; Guo, W.; Li, J.; Jin, Y.; Qian, D.; Ouyang, J.; Fu, L.; Fearon, E.; Hardacre, R.; Liu, Z.; et al. Nanosecond Fibre Laser Paint Stripping with Suppression of Flames and Sparks. J. Mater. Process. Technol. 2019, 266, 474–483. [Google Scholar] [CrossRef]

- Shi, T.; Wang, C.; Mi, G.; Yan, F. A Study of Microstructure and Mechanical Properties of Aluminum Alloy Using Laser Cleaning. J. Manuf. Process. 2019, 42, 60–66. [Google Scholar] [CrossRef]

- Wang, Z.; Zeng, X.; Huang, W. Parameters and Surface Performance of Laser Removal of Rust Layer on A3 Steel. Surf. Coat. Technol. 2003, 166, 10–16. [Google Scholar] [CrossRef]

- Zhu, G.; Wang, S.; Cheng, W.; Wang, G.; Liu, W.; Ren, Y. Investigation on the Surface Properties of 5A12 Aluminum Alloy after Nd: YAG Laser Cleaning. Coatings 2019, 9, 578. [Google Scholar] [CrossRef] [Green Version]

- Mahanty, S. Gouthama Surface Modification of Al–Si Alloy by Excimer Laser Pulse Processing. Mater. Chem. Phys. 2016, 173, 192–199. [Google Scholar] [CrossRef]

- Saklakoglu, N.; Gencalp Irizalp, S.; Akman, E.; Demir, A. Near Surface Modification of Aluminum Alloy Induced by Laser Shock Processing. Opt. Laser Technol. 2014, 64, 235–241. [Google Scholar] [CrossRef]

- Ge, J.; Liu, H.; Yang, S.; Lan, J. Laser Cleaning Surface Roughness Estimation Using Enhanced GLCM Feature and IPSO-SVR. Photonics 2022, 9, 510. [Google Scholar] [CrossRef]

- Khorasani, A.M.; Yazdi, M.R.S.; Safizadeh, M.S. Analysis of Machining Parameters Effects on Surface Roughness: A Review. IJCMSSE 2012, 5, 68. [Google Scholar] [CrossRef]

- Li, Z.; Xu, J.; Zhang, D.; Xu, Z.; Su, X.; Jin, Y.; Shan, D.; Chen, Y.; Guo, B. Nanosecond Pulsed Laser Cleaning of Titanium Alloy Oxide Films: Modeling and Experiments. J. Manuf. Process. 2022, 82, 665–677. [Google Scholar] [CrossRef]

- Larson, M.G. Analysis of Variance. Circulation 2008, 117, 115–121. [Google Scholar] [CrossRef] [Green Version]

- Gelman, A. Analysis of Variance—Why It Is More Important than Ever. Ann. Stat. 2005, 33, 1–53. [Google Scholar] [CrossRef] [Green Version]

- Finney, D.J. Main Effects and Interactions. J. Am. Stat. Assoc. 1948, 43, 566–571. [Google Scholar] [CrossRef]

- Zhang, D.; Xu, J.; Li, Z.; Li, K.; Wang, C.; Shan, D.; Guo, B. Removal Mechanism of Blue Paint on Aluminum Alloy Substrate during Surface Cleaning Using Nanosecond Pulsed Laser. Opt. Laser Technol. 2022, 149, 107882. [Google Scholar] [CrossRef]

- Zhang, D.; Xu, J.; Li, Z.; Jin, Y.; Su, X.; Shan, D.; Guo, B. Removal Mechanisms of Nanosecond Pulsed Laser Cleaning of Blue and Red Polyurethane Paint. Appl. Phys. A 2022, 128, 170. [Google Scholar] [CrossRef]

- Liu, K.K.; Hill, M.R. The Effects of Laser Peening and Shot Peening on Fretting Fatigue in Ti–6Al–4V Coupons. Tribol. Int. 2009, 42, 1250–1262. [Google Scholar] [CrossRef]

- Jing, Y.; Fang, X.; Xi, N.; Feng, X.; Huang, K. Investigation of Microstructure and Mechanical Properties Evolution in 7050 Aluminum Alloy and 316L Stainless Steel Treated by Laser Shock Peening. Mater. Charact. 2021, 182, 111571. [Google Scholar] [CrossRef]

| Parameter | Symbol | Value | Unit |

|---|---|---|---|

| Wavelength | λ | 1064 | nm |

| Maximum average power | P | 1000 | W |

| Pulse duration | τ | 30, 40, 60, 100 | ns |

| Repetition rate | f | 2–50 | kHz |

| Laser spot diameter | D | 1 | mm |

| Maximum scanning speed | v | 10,000 | mm/s |

| Level | F (J/cm2) | v (mm/s) |

|---|---|---|

| 1 | 2.55 | 500 |

| 2 | 3.82 | 600 |

| 3 | 5.09 | 700 |

| 4 | 6.37 | 800 |

| 5 | 7.64 | 900 |

| 6 | 8.91 | 1000 |

| Sample Number | F (J/cm2) | v (mm/s) |

|---|---|---|

| 1 | 0 | 0 |

| 2 | 2.55 | 500 |

| 3 | 5.09 | 800 |

| 4 | 6.37 | 900 |

| 5 | 5.09 | 700 |

| 6 | 8.91 | 700 |

| Response | Source | DF | Adj SS | Adj MS | p-Value |

|---|---|---|---|---|---|

| Ra | F | 5 | 7.109 | 1.4218 | 0.046 |

| Ra | v | 5 | 2.725 | 0.5450 | 0.425 |

| H | F | 5 | 145,158 | 29,031.5 | <0.001 |

| H | v | 5 | 4717 | 943.3 | 0.019 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, W.; Su, X.; Gu, J.; Jin, Y.; Xu, J.; Guo, B. Removal Mechanisms and Microstructure Characteristics of Laser Paint Stripping on Aircraft Skin Surface. Photonics 2023, 10, 96. https://doi.org/10.3390/photonics10010096

Li W, Su X, Gu J, Jin Y, Xu J, Guo B. Removal Mechanisms and Microstructure Characteristics of Laser Paint Stripping on Aircraft Skin Surface. Photonics. 2023; 10(1):96. https://doi.org/10.3390/photonics10010096

Chicago/Turabian StyleLi, Wenqin, Xuan Su, Junyi Gu, Yang Jin, Jie Xu, and Bin Guo. 2023. "Removal Mechanisms and Microstructure Characteristics of Laser Paint Stripping on Aircraft Skin Surface" Photonics 10, no. 1: 96. https://doi.org/10.3390/photonics10010096

APA StyleLi, W., Su, X., Gu, J., Jin, Y., Xu, J., & Guo, B. (2023). Removal Mechanisms and Microstructure Characteristics of Laser Paint Stripping on Aircraft Skin Surface. Photonics, 10(1), 96. https://doi.org/10.3390/photonics10010096