Tailoring Wavelength-Selective Diffraction Efficiency Using Triple-Layer Double-Relief Blazed Gratings Incorporating Materials with Intersecting Dispersion Curves

Abstract

:1. Introduction

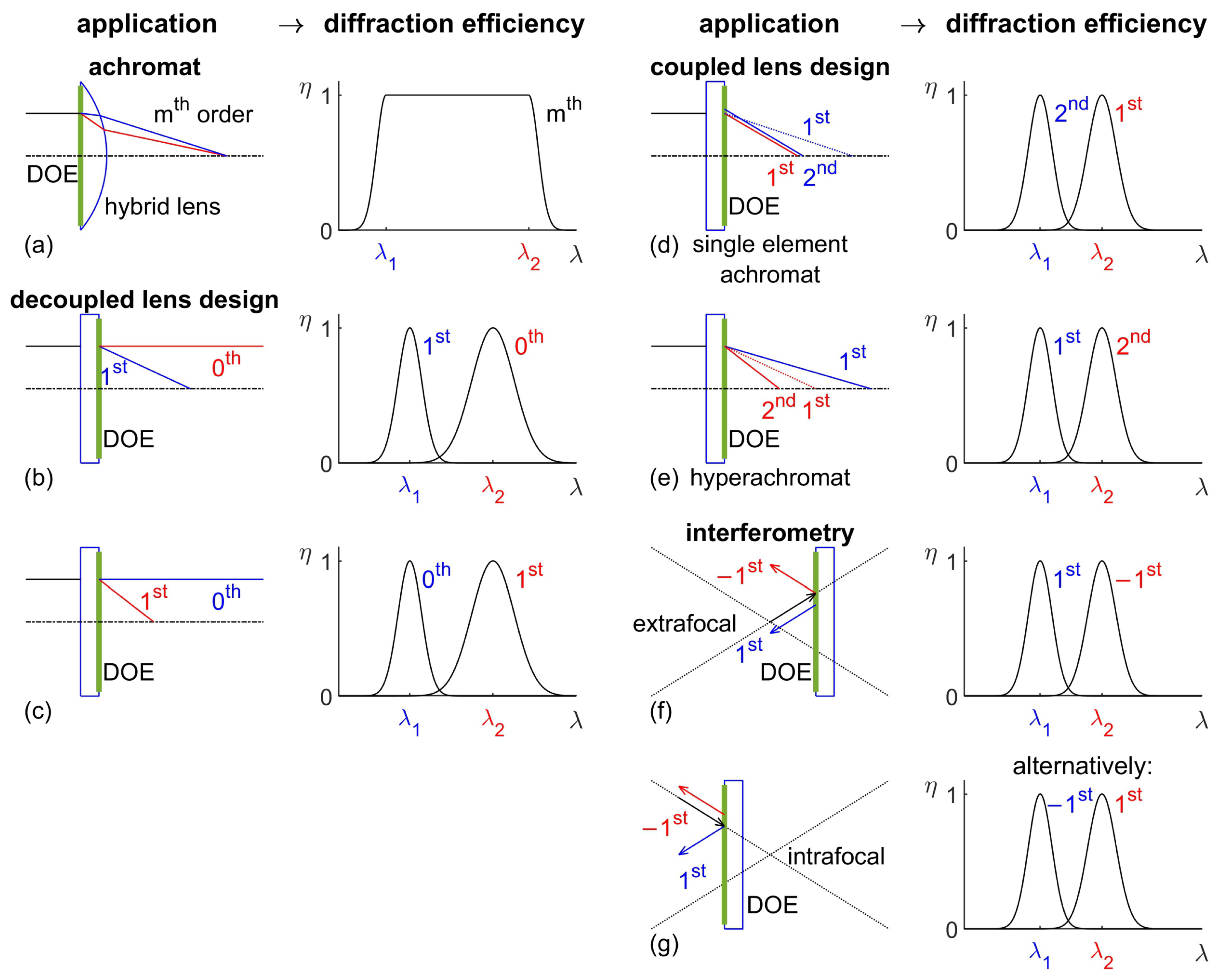

2. Basic Application Concepts for Wavelength-Selective DOEs

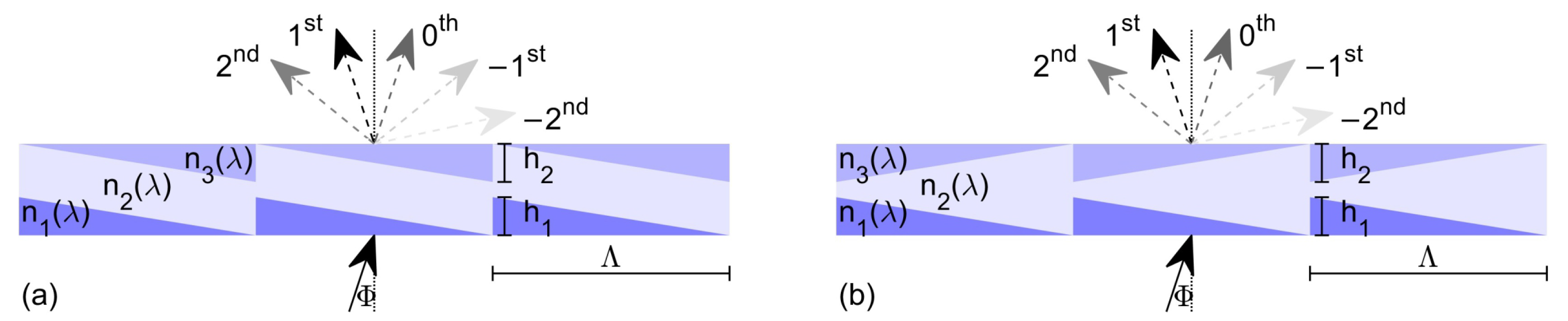

3. Fundamentals of the Diffraction Behavior of TLDOEs

4. Selected Material Combinations for Varying the Efficiency of TLDOEs

4.1. PS-ITO/N-PSK53/PMMA-ITO TLDOE Type 1 Orientation

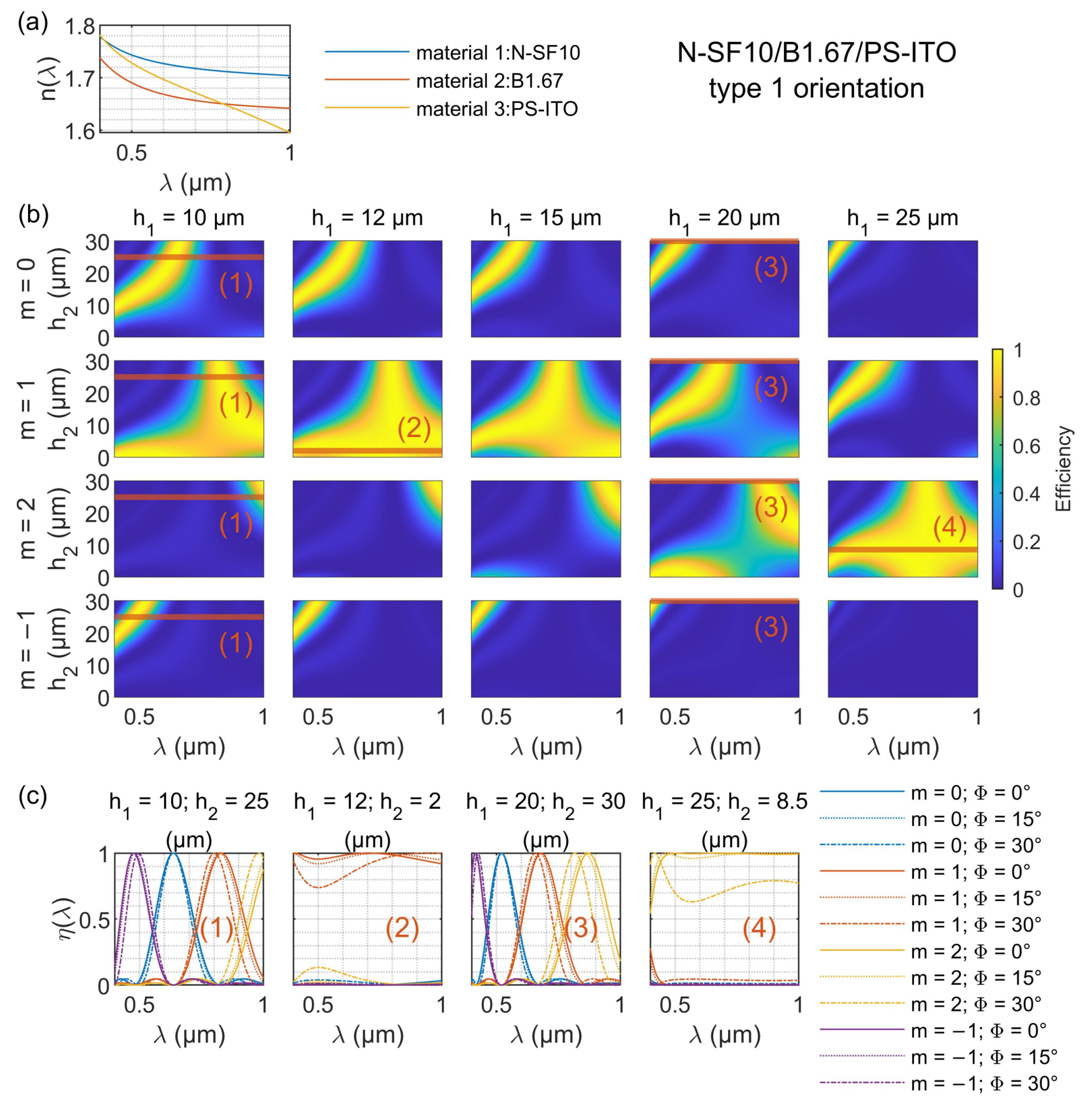

4.2. N-SF10/B1.67/PS-ITO TLDOE Type 1 Orientation

4.3. Al2O3/N-SF10/CsBr TLDOE Type 2 Orientation

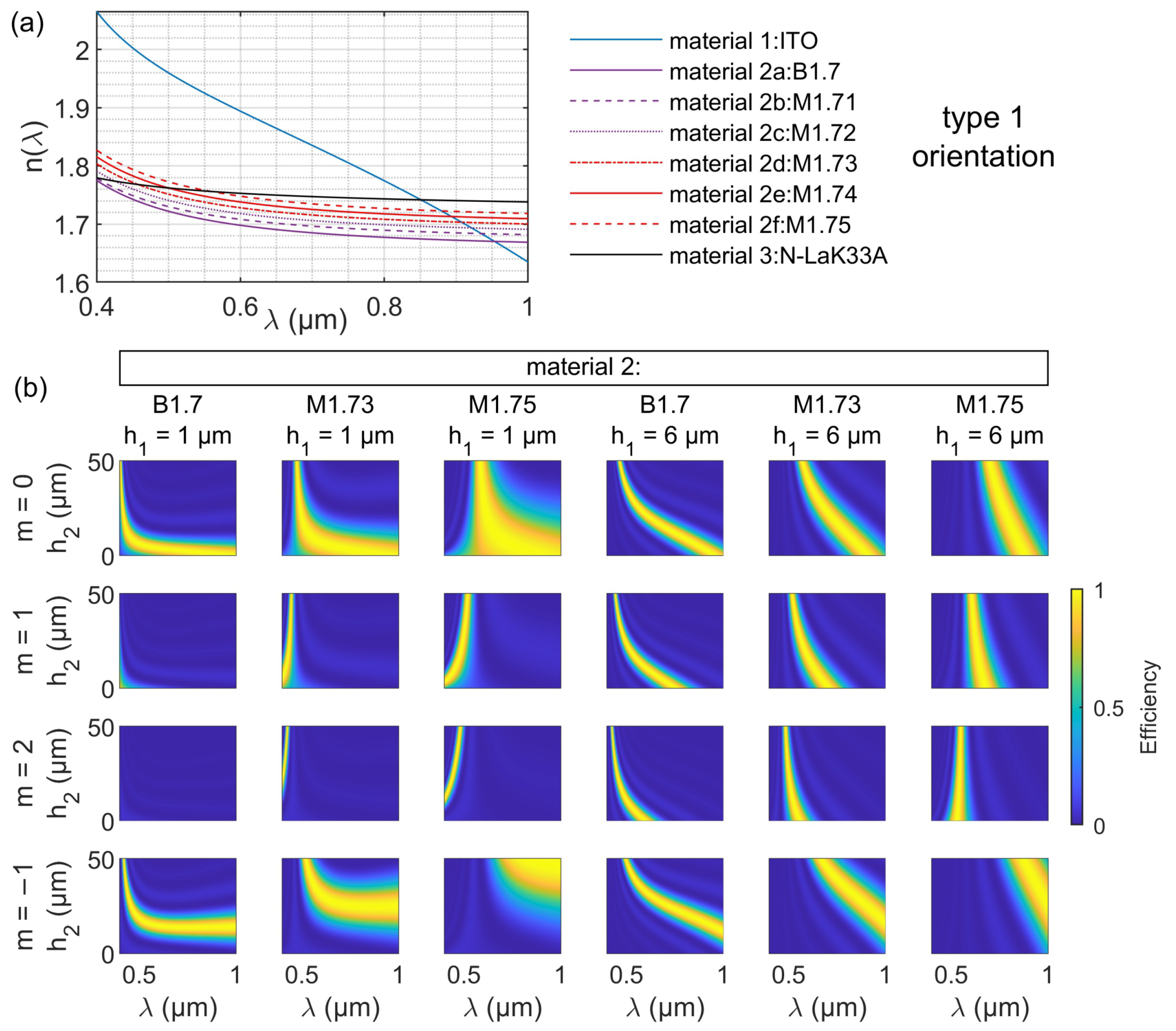

4.4. ITO/N-LaK33A/M1.75 TLDOE Type 1 Orientation

4.5. M1.73/N-LaK34/PS-ITO TLDOE Type 1 Orientation

5. Adaptation of the Wavelength Selectivity of a TLDOE Structure by Variation of an Intermediate Liquid Layer

6. Discussion

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| DOE | diffractive optical element |

| HW | spectral half-width |

| ITO | indium tin oxide |

| MLDOE | multilayer diffractive optical element |

| PMMA | polymethyl methacrylate |

| PS | polystyrene |

| TLDOE | triple-layer double-relief diffractive optical element |

References

- Davidson, N.; Friesem, A.A.; Hasman, E. Analytic design of hybrid diffractive-refractive achromats. Appl. Opt. 1993, 32, 4770–4774. [Google Scholar] [CrossRef]

- Meyer, M.M. Hybrid Refractive/Diffractive Achromatic Camera Lens. U.S. Patent 5,543,966, 6 August 1996. [Google Scholar]

- Evdokimova, V.; Podlipnov, V.; Ivliev, N.; Petrov, M.; Ganchevskaya, S.; Fursov, V.; Yuzifovich, Y.; Stepanenko, S.; Kazanskiy, N.; Nikonorov, A.; et al. Hybrid refractive-diffractive lens with reduced chromatic and geometric aberrations and learned image reconstruction. Sensors 2023, 23, 415. [Google Scholar] [CrossRef]

- Zhao, Y.H.; Fan, C.J.; Ying, C.F.; Liu, S.H. The investigation of triple-layer diffraction optical element with wide field of view and high diffraction efficiency. Opt. Commun. 2013, 295, 104–107. [Google Scholar] [CrossRef]

- Xie, H.; Ren, D.; Wang, C.; Mao, C.; Yang, L. Design of high-efficiency diffractive optical elements towards ultrafast mid-infrared time-stretched imaging and spectroscopy. J. Mod. Opt. 2018, 65, 255–261. [Google Scholar] [CrossRef]

- Yang, H.; Xue, C.; Xiao, J.; Chen, J. Glued diffraction optical elements with broadband and a large field of view. Appl. Opt. 2020, 59, 10217–10223. [Google Scholar] [CrossRef]

- Zhang, B.; Cui, Q.; Piaoi, M. Effect of substrate material selection on polychromatic integral diffraction efficiency for multilayer diffractive optics in oblique incident situation. Opt. Commun. 2018, 415, 156–163. [Google Scholar] [CrossRef]

- Mao, S.; Zhao, L.; Zhao, J. Integral diffraction efficiency model for multilayer diffractive optical elements with wide angles of incidence in case of polychromatic light. Opt. Express 2019, 27, 21497–21507. [Google Scholar] [CrossRef] [PubMed]

- Laborde, V.; Loicq, J.; Hastanin, J.; Habraken, S. Multilayer diffractive optical element material selection method based on transmission, total internal reflection, and thickness. Appl. Opt. 2022, 61, 7415–7423. [Google Scholar] [CrossRef] [PubMed]

- Zhang, B.; Song, Y.; Dong, K.; Piao, M.; Wang, J.; Jia, R.; Chang, S.; Jiang, L.; Jiang, H. Substrate material selection model for dual-band multilayer diffractive optical elements with wide angle of incidence. Optik 2022, 255, 168701. [Google Scholar] [CrossRef]

- Greisukh, G.I.; Danilov, V.A.; Ezhov, E.G.; Stepanov, S.A.; Usievich, B.A. Spectral and angular dependences of the efficiency of relief-phase diffractive lenses with two- and three-layer microstructures. Opt. Spectrosc. 2015, 118, 964–970. [Google Scholar] [CrossRef]

- Greisukh, G.I.; Danilov, V.A.; Ezhov, E.G.; Stepanov, S.A.; Usievich, B.A. Comparism of electromagnetic and scalar methods for evaluation of efficiency of diffractive lenses for wide spectral bandwidth. Opt. Commun. 2015, 338, 54–57. [Google Scholar] [CrossRef]

- Greisukh, G.I.; Danilov, V.A.; Stepanov, S.A.; Antonov, A.I.; Usievich, B.A. Spectral and angular dependences of the efficiency of three-layer relief-phase diffraction elements of the IR range. Opt. Spectrosc. 2018, 125, 60–64. [Google Scholar] [CrossRef]

- Brunner, R.; Steiner, R.; Dobschal, H.J.; Martin, D.; Burkhardt, M.; Helgert, M. New solutions to realize complex optical systems by a combination of diffractive and refractive optical components. In Lithographic and Micromachining Techniques for Optical Component Fabrication II; SPIE: Bellingham, WA, USA, 2003; Volume 5183, pp. 47–55. [Google Scholar] [CrossRef]

- Brunner, R.; Dobschal, H.J. Diffractive Optical Lenses in Imaging Systems—High-Resolution Microscopy and Diffractive Solid Immersion Systems. In Optical Imaging and Microscopy: Techniques and Advanced Systems; Török, P., Kao, F.J., Eds.; Springer: Berlin/Heidelberg, Germany, 2007; pp. 45–70. [Google Scholar] [CrossRef]

- Ori, Y.; Takada, K.; Hashimura, J.; Mushiake, N. Diffractive/refractive hybrids for blue LD optical storage. In Frontiers in Optics 2004/Laser Science XXII/Diffractive Optics and Micro-Optics/Optical Fabrication and Testing; Optica Publishing Group: Washington, DC, USA, 2004; paper DTuA1. [Google Scholar] [CrossRef]

- Engelhardt, L.; Stumpf, D.; Brunner, R. Tailored chromatic diffraction efficiency of double-layer single-relief blazed gratings. J. Opt. Soc. Am. A 2023, 40, 703–713. [Google Scholar] [CrossRef]

- Förster, E.; Stumpf, D.; Werner, L.; Hillmer, H.; Brunner, R. Hyperchromatic lens doublets with an extremely small equivalent Abbe number employing diffractive elements and refractive materials with exceptional dispersion properties. J. Opt. Soc. Am. A 2022, 39, 1992–2000. [Google Scholar] [CrossRef] [PubMed]

- Werner, L.; Förster, E.; Kraus, M.; Hillmer, H.; Brunner, R. Extreme refractive-, diffractive- and hybrid-hyperchromats: Minimizing the equivalent Abbe number of a two-lens system. Photonics 2023, 10, 556. [Google Scholar] [CrossRef]

- Reichelt, S.; Pruss, C.; Tizianii, H.J. Absolute Testing of aspheric surfaces. Proc. SPIE Opt. Fabr. Testing Metrol. 2004, 5252, 252–263. [Google Scholar] [CrossRef]

- Swanson, G.J. Binary Optics Technology: Theoretical Limits on the Diffraction Efficiency of Multilevel Diffractive Optical Elements; Lincoln Laboratory, Massachusetts Institute of Technology: Lexington, MA, USA, 1991; Volume 1, Technical Report 914. [Google Scholar]

- Werdehausen, D. Nanocomposites as Next-Generation Optical Materials: Fundamentals, Design and Advanced Applications; Springer: Cham, Switzerland, 2021; Volume 316. [Google Scholar]

- Polyanskiy, M.N. Refractive Index Database. Available online: https://refractiveindex.info. (accessed on 12 April 2023).

- Cargille-Sacher Laboratories Inc. Available Refractive Indices, SDS and Datasheets—Refractive Index Liquids. Available online: https://www.cargille.com/available-refractive-indices-sds-datasheets/ (accessed on 12 April 2023).

- The Mathworks Inc. Matlab. Available online: https://matlab.mathworks.com/ (accessed on 1 August 2023).

- Antonov, A.; Greisukh, G.; Ezhov, E.; Stepanov, S. Diffractive elements for imaging optical systems. Optoelectron. Instrum. Data Process. 2017, 53, 421–430. [Google Scholar] [CrossRef]

- Rudolf, P.G.; Tollet, J.J.; MacGowan, R.R. Computer modeling wave propagation with a variation of the Helmholtz-Kirchhoff relation. Appl. Opt. 1990, 90, 998–1003. [Google Scholar] [CrossRef]

- Grushina, A. Direct-write grayscale lithography. Adv. Opt. Technol. 2019, 8, 163–169. [Google Scholar] [CrossRef]

- Schindler, A.; Haensel, T.; Flamm, D.; Frank, W.; Boehm, G.; Frost, F.; Fechner, R.; Bigl, F.; Rauschenbach, B. Ion beam and plasma jet etching for optical component fabrication. In Lithographic and Micromachining Techniques for Optical Component Fabrication; Kley, E.B., Herzig, H.P., Eds.; International Society for Optics and Photonics, SPIE: Bellingham, WA, USA, 2001; Volume 4440, pp. 217–227. [Google Scholar] [CrossRef]

- Zhang, Y.; Liang, R.; Spires, O.J.; Yin, S.; Yi, A.; Milster, T.D. Precision glass molding of diffractive optical elements with high surface quality. Opt. Lett. 2020, 45, 6438–6441. [Google Scholar] [CrossRef]

- Dannberg, P.; Mann, G.; Wagner, L.; Braeuer, A.H. Polymer UV-molding for micro-optical systems and O/E-integration. In Micromachining Technology for Micro-Optics; Lee, S.H., Johnson, E.G., Eds.; International Society for Optics and Photonics, SPIE: Bellingham, WA, USA, 2000; Volume 4179, pp. 137–145. [Google Scholar] [CrossRef]

- Au, A.K.; Huynh, W.; Horowitz, L.F.; Folch, A. 3D-Printed Microfluidics. Angew. Chem. Int. Ed. 2016, 55, 3862–3881. [Google Scholar] [CrossRef] [PubMed]

| Material | Material | ||||

|---|---|---|---|---|---|

| ITO | 1.9016 | 8.21 | B1.7 | 1.7 | 18.8 |

| PS-ITO | 1.7001 | 13.6 | M1.71 | 1.71 | 21.0 |

| PMMA-ITO | 1.6357 | 14.5 | M1.72 | 1.72 | 20.6 |

| N-LaK33A | 1.7539 | 52.27 | M1.73 | 1.73 | 20.3 |

| N-LaK34 | 1.7292 | 54.5 | M1.74 | 1.74 | 19.9 |

| N-PSK53 | 1.6201 | 63.48 | M1.75 | 1.75 | 19.7 |

| N-SF10 | 1.7283 | 28.53 | Al2O3 | 1.7682 | 72.31 |

| B1.67 | 1.67 | 19.8 | CsBr | 1.6976 | 34.19 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schmidt, L.; Hillmer, H.; Brunner, R. Tailoring Wavelength-Selective Diffraction Efficiency Using Triple-Layer Double-Relief Blazed Gratings Incorporating Materials with Intersecting Dispersion Curves. Photonics 2023, 10, 1116. https://doi.org/10.3390/photonics10101116

Schmidt L, Hillmer H, Brunner R. Tailoring Wavelength-Selective Diffraction Efficiency Using Triple-Layer Double-Relief Blazed Gratings Incorporating Materials with Intersecting Dispersion Curves. Photonics. 2023; 10(10):1116. https://doi.org/10.3390/photonics10101116

Chicago/Turabian StyleSchmidt, Lia, Hartmut Hillmer, and Robert Brunner. 2023. "Tailoring Wavelength-Selective Diffraction Efficiency Using Triple-Layer Double-Relief Blazed Gratings Incorporating Materials with Intersecting Dispersion Curves" Photonics 10, no. 10: 1116. https://doi.org/10.3390/photonics10101116