Degradation- and Thermal-Related Changes in Selected Electro-Optical Parameters of High-Power 270–280 nm LEDs

Abstract

:1. Introduction

| LP-Hg | MP-Hg | Excimer Lamp | UVC LED | |

|---|---|---|---|---|

| WPE [%] | 30–40 | 5–15 | <2 | 1–6 |

| Wavelength (nm) | 253.7 | 200–600 | 100–350 | 255, 260, 265, 270, 275, 280 |

| FWHM (nm) | 1 | – | 2–15 | 10–15 |

| OP of UVC per device (W) | 1–20 | >10 | 0.1–0.3 | 0.005–0.1 |

| Cost per watt of UVC output (USD/W) | 2 | 3 | >1000 | 50–600 |

| Lifetime (h) | 9000–18,000 | 10,000 | 4000 | 1000–12,000 |

| Wavelength | OP | Electrical Conditions | Heat Sink Temperature | Degradation Period | Change in OP | Data from | ||

|---|---|---|---|---|---|---|---|---|

| (nm) | (mW) | I (mA) | J (A/cm2) | V (V) | (°C) | (h) | (%) | |

| 262 | 4.0 | 100 | 67 | 14.5 | 20 | 25 | −20 | [37] |

| 250 | −42 | |||||||

| 271 | 12 | 100 | 40 | 5.8 | 25 | 24 | −21 | [33] |

| 48 | −32 | |||||||

| 96 | −37 | |||||||

| 500 | −50 | |||||||

| 265 | N/A | 78 | N/A | N/A | 25 | 333 | −31 (Mg 1%) | [34] |

| 95 | N/A | N/A | 25.5 | 333 | −55 (Mg 0.5%) | |||

| 100 | N/A | N/A | 26.5 | 333 | −74 (Mg 0.15%) | |||

| 265 | 12 | N/A | 60 | N/A | 25 | 333 | −11 | [27] |

| N/A | 120 | N/A | −19 | |||||

| N/A | 180 | N/A | −38 | |||||

| 265 | N/A | 100 | 100 | 7.2 | 40 | 202 | −50 | [39] |

| 265 | N/A | 100 | 100 | 7.0 | 25 | 317 | N/A | [40] |

| 275 | N/A | 250 | 33 | 6.3 | 25 | 5000 | −25 | [21] |

| 350 | 46 | 6.7 | −28 | |||||

| 268 | 199 | 250 | 33 | 6.3 | 60 (ambient) | 2500 | −36 | |

| 350 | 46 | 6.7 | 25 (ambient) | −6 | ||||

| 278 | N/A | 100 | N/A | N/A | 25 | 10,000 | −16.5 | |

| 277 | 12 | 150 | 60 | 7.3 | 25 | 333 | −11 | [22] |

| 300 | 120 | −19 | ||||||

| 450 | 180 | −39 | ||||||

| 278 | 18@200 mA | 350 | N/A | 6.6 | 25 | 90 | N/A | [23] |

| 500 | N/A | 7.3 | N/A | |||||

| 275 | 37.5@350 mA | 800 | 50 | 8 | 25 | 333 | −31 | [20] |

| 277 | 12@100 mA | 300 | 25 | 7.2 | −13 | |||

| 278 | 5@50 mA | 100 | 24 | 5.8 | −31 | |||

| 278 | 10@150 mA | 150 | 33 | 5.8 | −22 | |||

| 275 | 37.5@350 mA | N/A | 40 | N/A | −92 | |||

| 277 | 12@100 mA | N/A | 40 | N/A | −76 | |||

| 278 | 5@50 mA | N/A | 40 | N/A | −76 | |||

| 278 | 10@150 mA | N/A | 40 | N/A | −91 | |||

| 260 | N/A | 20 | 32 | 7.2 | 25 | 150 | −37 | [41] |

| 265 | N/A | 20 | N/A | 6.5 | 25 | 50 | −50 | [42] |

| 275 | 60 | 350 | N/A | 6 | N/A | 250 | −65 | [36] |

| 275 | 40 | 350 | 66 | 7.5 | 150 (junction) | 102 | −20 | [35] |

| 484 | −40 | |||||||

2. Materials and Methods

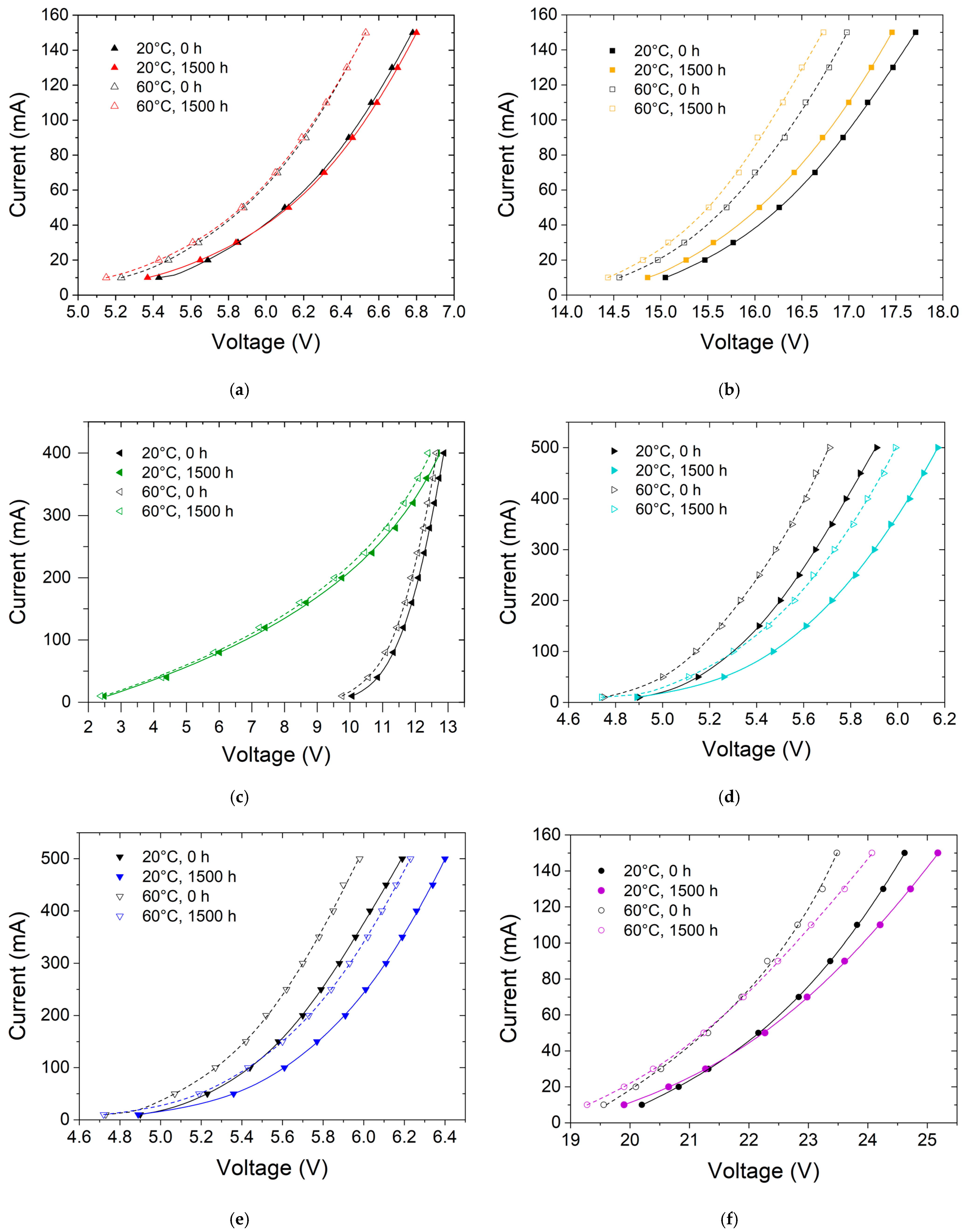

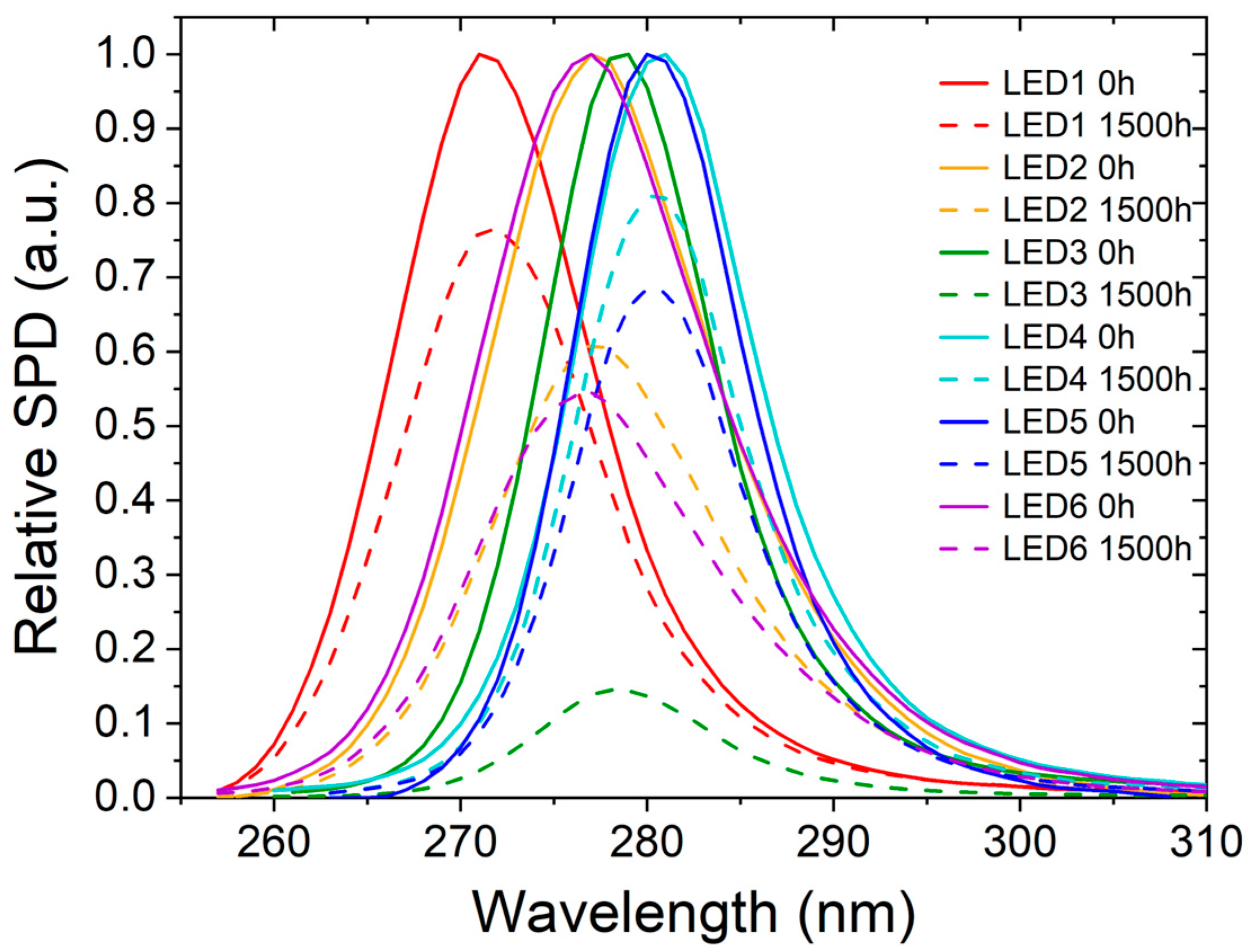

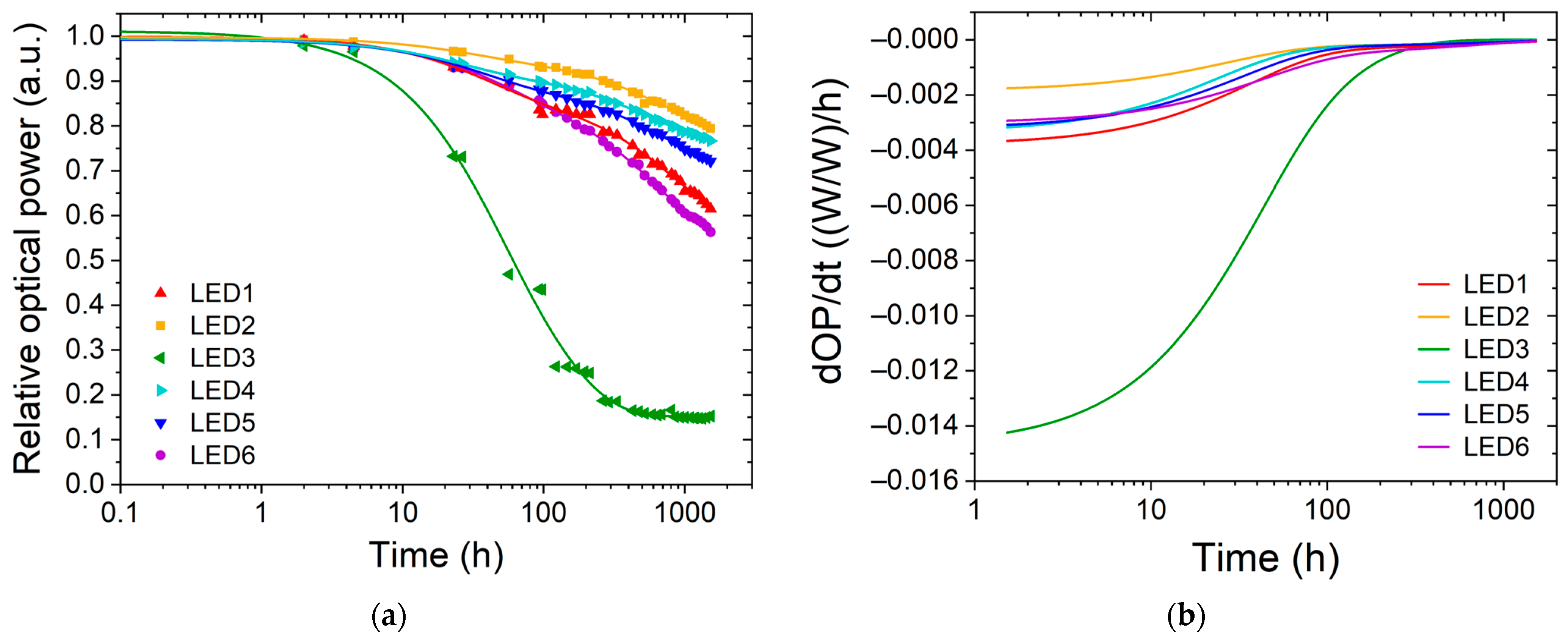

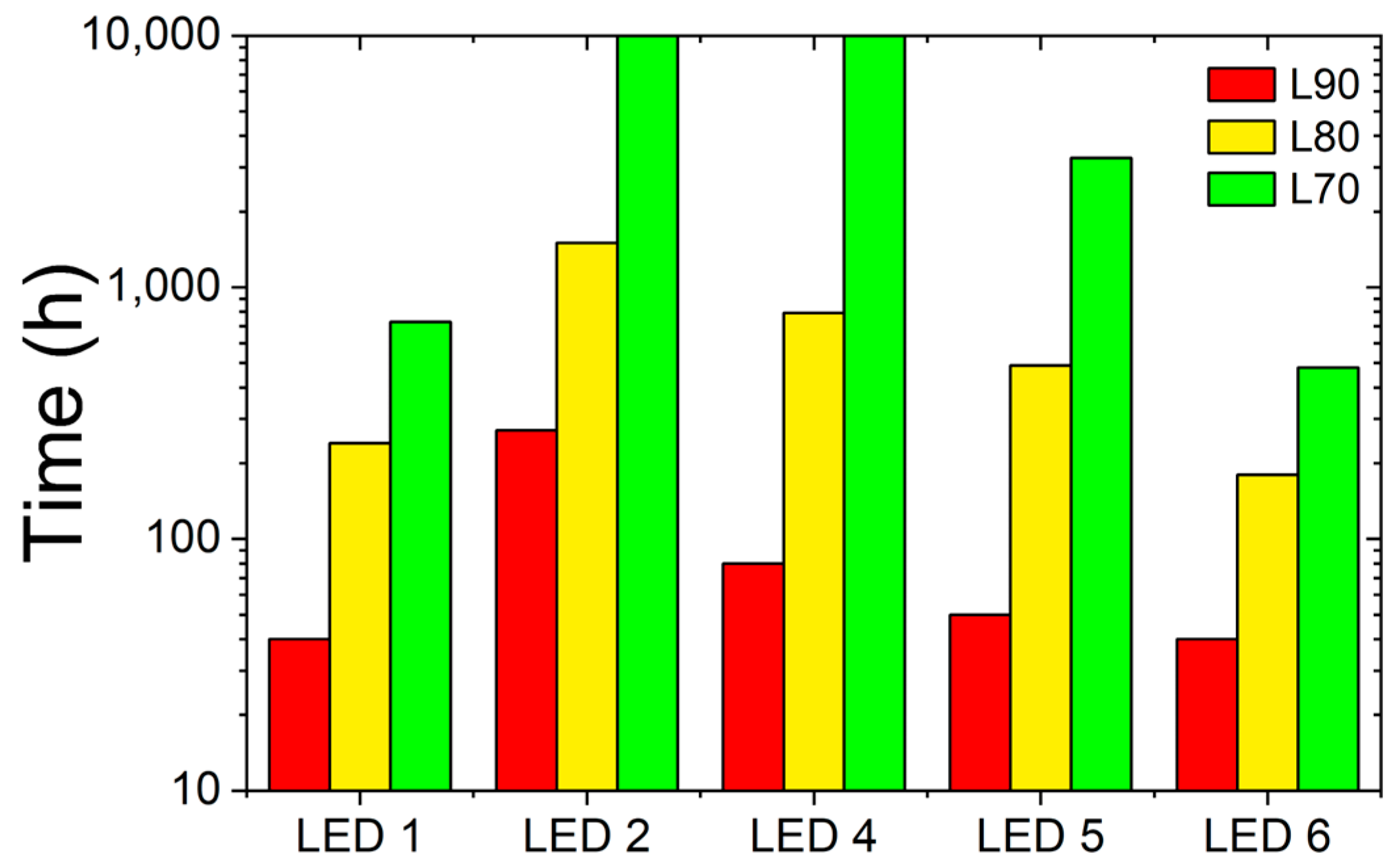

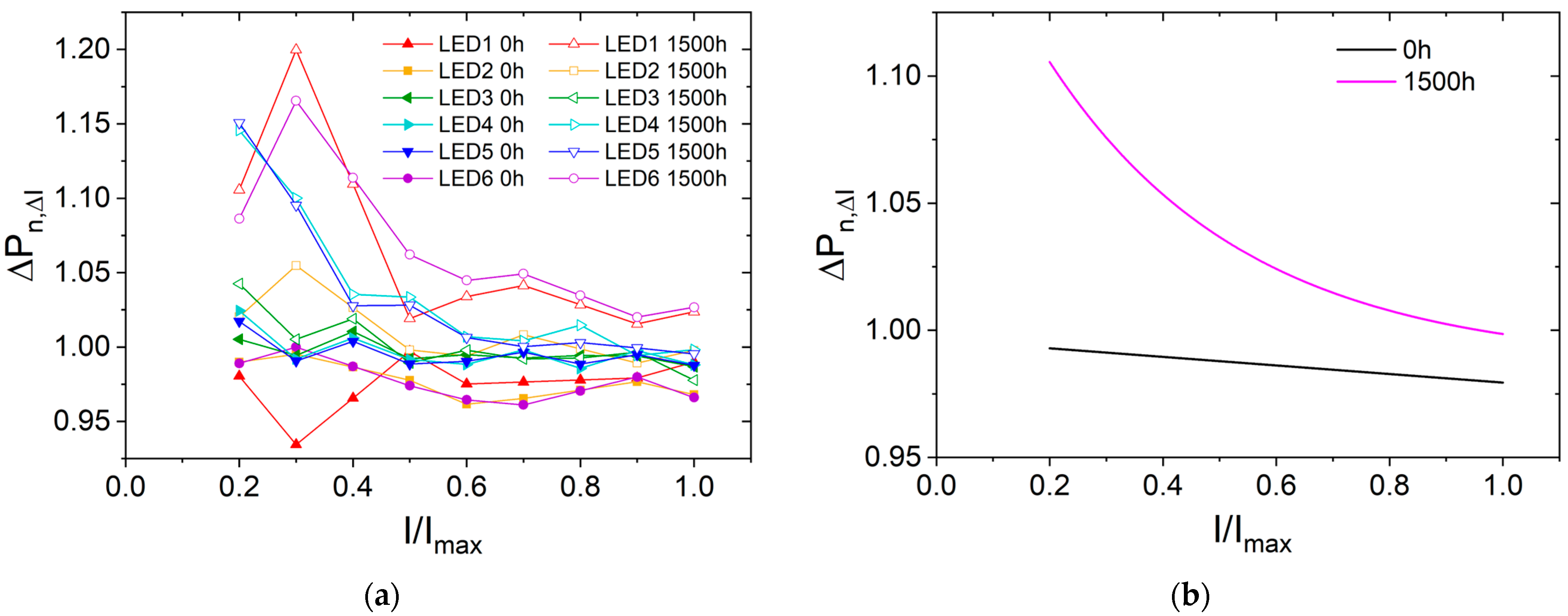

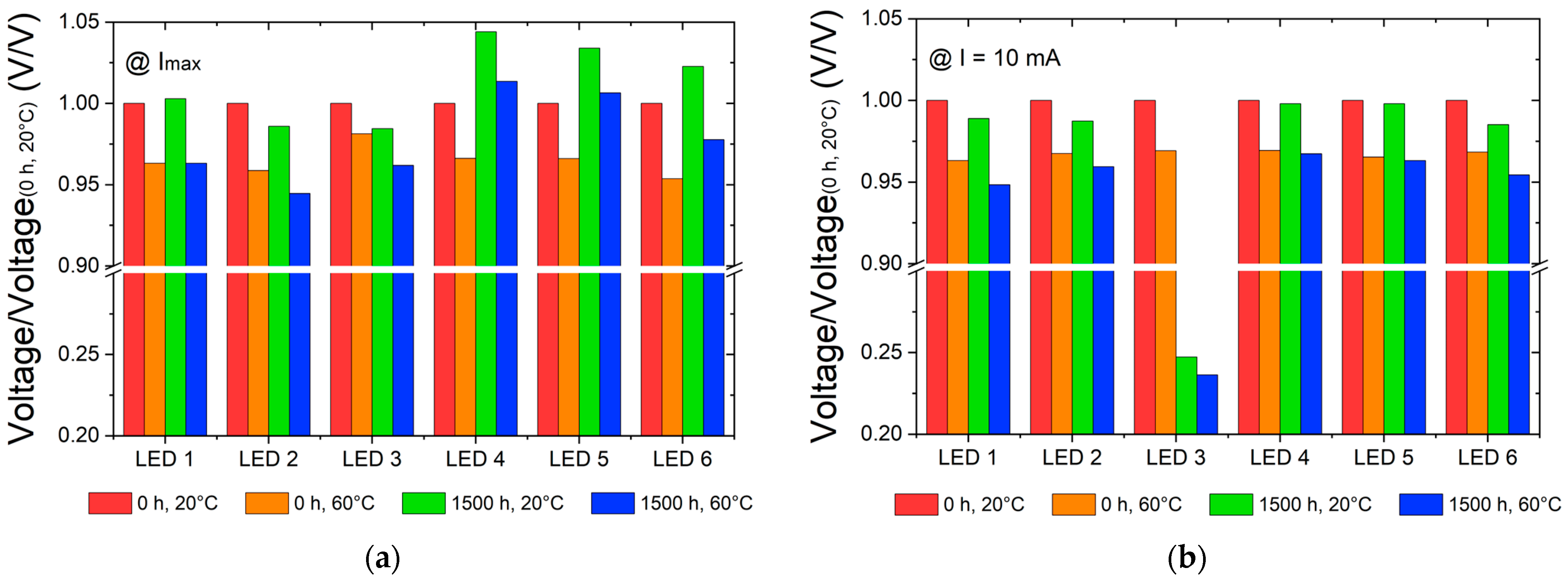

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

Appendix B

References

- Amano, H.; Collazo, R.; De Santi, C.; Einfeldt, S.; Funato, M.; Glaab, J.; Hagedorn, S.; Hirano, A.; Hirayama, H.; Ishii, R.; et al. The 2020 UV Emitter Roadmap. J. Phys. D Appl. Phys 2020, 53, 503001. [Google Scholar] [CrossRef]

- Zollner, C.J.; DenBaars, S.P.; Speck, J.S.; Nakamura, S. Germicidal Ultraviolet LEDs: A Review of Applications and Semiconductor Technologies. Semicond. Sci. Technol. 2021, 36, 123001. [Google Scholar] [CrossRef]

- Jarvis, P.; Autin, O.; Goslan, E.H.; Hassard, F. Application of Ultraviolet Light-Emitting Diodes (UV-LED) to Full-Scale Drinking-Water Disinfection. Water 2019, 11, 1894. [Google Scholar] [CrossRef]

- Song, K.; Mohseni, M.; Taghipour, F. Application of Ultraviolet Light-Emitting Diodes (UV-LEDs) for Water Disinfection: A Review. Water Res. 2016, 94, 341–349. [Google Scholar] [CrossRef] [PubMed]

- Kim, D.-K.; Kang, D.-H. UVC LED Irradiation Effectively Inactivates Aerosolized Viruses, Bacteria, and Fungi in a Chamber-Type Air Disinfection System. Appl. Environ. Microbiol. 2018, 84, e00944-18. [Google Scholar] [CrossRef] [PubMed]

- Sellera, F.P.; Sabino, C.P.; Cabral, F.V.; Ribeiro, M.S. A Systematic Scoping Review of Ultraviolet C (UVC) Light Systems for SARS-CoV-2 Inactivation. J. Photochem. Photobiol. 2021, 8, 100068. [Google Scholar] [CrossRef]

- Osintseva, D.; Osintsev, E.; Rebezov, M.; Prokhasko, L.; Seilgazina, S.; Kurmanbayev, S.; Nurzhumanova, Z.; Yessimbekov, Z.; Voytsekhovskiy, V.; Maksimiuk, N.; et al. Ozonation and Microwave Treatments as New Pest Management Methods for Grain Crop Cleaning and Disinfection. Annu. Res. Rev. Biol. 2017, 20, 1–6. [Google Scholar] [CrossRef]

- Dombrovsky, A.; Mor, N.; Gantz, S.; Lachman, O.; Smith, E. Disinfection Efficacy of Tobamovirus-Contaminated Soil in Greenhouse-Grown Crops. Horticulturae 2022, 8, 563. [Google Scholar] [CrossRef]

- Kowalski, W. Ultraviolet Germicidal Irradiation Handbook; Springer: Berlin/Heidelberg, Germany, 2009; ISBN 978-3-642-01998-2. [Google Scholar]

- Matsukura, Y.; Inazu, T.; Pernot, C.; Shibata, N.; Kushimoto, M.; Deki, M.; Honda, Y.; Amano, H. Improving Light Output Power of AlGaN-Based Deep-Ultraviolet Light-Emitting Diodes by Optimizing the Optical Thickness of p-Layers. Appl. Phys. Express 2021, 14, 084004. [Google Scholar] [CrossRef]

- Wilm, A.; Leirer, C.; Lugauer, H.-J.; Hoffmann, M.P. UV-C LEDs and Their Use in Disinfection Applications. In Light-Emitting Devices, Materials, and Applications XXVI; Strassburg, M., Kim, J.K., Krames, M.R., Eds.; SPIE: Bellingham, WA, USA, 2022; p. 15. [Google Scholar]

- Kneissl, M.; Seong, T.-Y.; Han, J.; Amano, H. The Emergence and Prospects of Deep-Ultraviolet Light-Emitting Diode Technologies. Nat. Photonics 2019, 13, 233–244. [Google Scholar] [CrossRef]

- Ruschel, J.; Glaab, J.; Susilo, N.; Hagedorn, S.; Walde, S.; Ziffer, E.; Cho, H.K.; Ploch, N.L.; Wernicke, T.; Weyers, M.; et al. Reliability of UVC LEDs Fabricated on AlN/Sapphire Templates with Different Threading Dislocation Densities. Appl. Phys. Lett. 2020, 117, 241104. [Google Scholar] [CrossRef]

- Available online: https://bolb.co (accessed on 1 October 2023).

- Hsu, T.-C.; Teng, Y.-T.; Yeh, Y.-W.; Fan, X.; Chu, K.-H.; Lin, S.-H.; Yeh, K.-K.; Lee, P.-T.; Lin, Y.; Chen, Z.; et al. Perspectives on UVC LED: Its Progress and Application. Photonics 2021, 8, 196. [Google Scholar] [CrossRef]

- Tucciarone, C.M.; Cecchinato, M.; Vianello, L.; Simi, G.; Borsato, E.; Silvestrin, L.; Giorato, M.; Salata, C.; Morandin, M.; Greggio, E.; et al. Evaluation of UVC Excimer Lamp (222 Nm) Efficacy for Coronavirus Inactivation in an Animal Model. Viruses 2022, 14, 2038. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, S.I. (Ed.) Ultraviolet Light in Human Health, Diseases and Environment; Springer International Publishing: Cham, Switzerland, 2017; Volume 996, ISBN 978-3-319-56016-8. [Google Scholar]

- Ramos, C.C.R.; Roque, J.L.A.; Sarmiento, D.B.; Suarez, L.E.G.; Sunio, J.T.P.; Tabungar, K.I.B.; Tengco, G.S.C.; Rio, P.C.; Hilario, A.L. Use of Ultraviolet-C in Environmental Sterilization in Hospitals: A Systematic Review on Efficacy and Safety. Int. J. Health Sci. 2020, 14, 52–65. [Google Scholar]

- Letson, B.; Conklin, J.W.; Wass, P.; Barke, S.; Mueller, G.; Rasel, M.A.J.; Haque, A.; Pearton, S.J.; Ren, F. Review—Reliability and Degradation Mechanisms of Deep UV AlGaN LEDs. ECS J. Solid. State Sci. Technol. 2023, 12, 066002. [Google Scholar] [CrossRef]

- Trivellin, N.; Fiorimonte, D.; Piva, F.; Buffolo, M.; De Santi, C.; Meneghesso, G.; Zanoni, E.; Meneghini, M. Reliability of Commercial UVC LEDs: 2022 State-of-the-Art. Electronics 2022, 11, 728. [Google Scholar] [CrossRef]

- Zhang, J.; Zhou, L.; Gao, Y.; Lunev, A.; Zhang, B.; Wu, S. Defect Dynamics and Internal Quantum Efficiency Decay Resultant Ultraviolet C-Band Light-Emitting Diode Lifetime Performance. Phys. Status Solidi 2022, 220, 2200433. [Google Scholar] [CrossRef]

- Trivellin, N.; Piva, F.; Fiorimonte, D.; Buffolo, M.; De Santi, C.; Zanoni, E.; Meneghesso, G.; Meneghini, M. Performance and Degradation of Commercial UV-C LEDs for Disinfection Purposes. Phys. Status Solidi 2023, 220, 2200900. [Google Scholar] [CrossRef]

- Trivellin, N.; Monti, D.; Piva, F.; Buffolo, M.; De Santi, C.; Zanoni, E.; Meneghesso, G.; Meneghini, M. Degradation Processes of 280 Nm High Power DUV LEDs: Impact on Parasitic Luminescence. Jpn. J. Appl. Phys. 2019, 58, SCCC19. [Google Scholar] [CrossRef]

- Buffolo, M.; Caria, A.; Piva, F.; Roccato, N.; Casu, C.; De Santi, C.; Trivellin, N.; Meneghesso, G.; Zanoni, E.; Meneghini, M. Defects and Reliability of GaN-Based LEDs: Review and Perspectives. Phys. Status Solidi 2022, 219, 2100727. [Google Scholar] [CrossRef]

- Trivellin, N.; Piva, F.; Fiorimonte, D.; Buffolo, M.; De Santi, C.; Orlandi, V.T.; Dughiero, F.; Meneghesso, G.; Zanoni, E.; Meneghini, M. UV-Based Technologies for SARS-CoV2 Inactivation: Status and Perspectives. Electronics 2021, 10, 1703. [Google Scholar] [CrossRef]

- Yoshikawa, A.; Hasegawa, R.; Morishita, T.; Nagase, K.; Yamada, S.; Grandusky, J.; Mann, J.; Miller, A.; Schowalter, L.J. Improve Efficiency and Long Lifetime UVC LEDs with Wavelengths between 230 and 237 Nm. Appl. Phys. Express 2020, 13, 022001. [Google Scholar] [CrossRef]

- Trivellin, N.; Piva, F.; Buffolo, M.; De Santi, C.; Zanoni, E.; Meneghesso, G.; Meneghini, M. UVC LED Reliability and Its Effect on Disinfection Systems Design. In Light-Emitting Devices, Materials, and Applications XXVII; Strassburg, M., Kim, J.K., Krames, M.R., Eds.; SPIE: Bellingham, WA, USA, 2023; p. 8. [Google Scholar]

- Glaab, J.; Ploch, C.; Kelz, R.; Stölmacker, C.; Lapeyrade, M.; Ploch, N.L.; Rass, J.; Kolbe, T.; Einfeldt, S.; Mehnke, F.; et al. Degradation of (InAlGa)N-Based UV-B Light Emitting Diodes Stressed by Current and Temperature. J. Appl. Phys. 2015, 118, 094504. [Google Scholar] [CrossRef]

- Piva, F.; De Santi, C.; Deki, M.; Kushimoto, M.; Amano, H.; Tomozawa, H.; Shibata, N.; Meneghesso, G.; Zanoni, E.; Meneghini, M. Stability and Degradation of AlGaN-Based UV-B LEDs: Role of Doping and Semiconductor Defects. Microelectron. Reliab. 2019, 100–101, 113418. [Google Scholar] [CrossRef]

- Buffolo, M.; de Santi, C.; Meneghini, M.; Rigon, D.; Meneghesso, G.; Zanoni, E. Long-Term Degradation Mechanisms of Mid-Power LEDs for Lighting Applications. Microelectron. Reliab. 2015, 55, 1754–1758. [Google Scholar] [CrossRef]

- Dalapati, P.; Yamamoto, K.; Egawa, T.; Miyoshi, M. Current-Induced Degradation Process in (In)AlGaN-Based Deep-UV Light-Emitting Diode Fabricated on AlN/Sapphire Template. Opt. Mater. 2020, 109, 110352. [Google Scholar] [CrossRef]

- Arques-Orobon, F.J.; Nuñez, N.; Vazquez, M.; González-Posadas, V. UV LEDs Reliability Tests for Fluoro-Sensing Sensor Application. Microelectron. Reliab. 2014, 54, 2154–2158. [Google Scholar] [CrossRef]

- Shen, C.-H.; Yang, R.-L.; Gong, H.-L.; Zhu, L.-H.; Gao, Y.-L.; Chen, G.-L.; Chen, Z.; Lu, Y. Optical Power Degradation Mechanisms in 271 Nm AlGaN-Based Deep Ultraviolet Light-Emitting Diodes. Opt. Express 2023, 31, 20265. [Google Scholar] [CrossRef]

- Meneghini, M.; Piva, F.; De Santi, C.; Trivellin, N.; Buffolo, M.; Roccato, N.; Brescancin, R.; Grigoletto, M.; Fiorimonte, D.; Einfeldt, S.; et al. UV LED Reliability: Degradation Mechanisms and Challenges. In Gallium Nitride Materials and Devices XVII; Morkoç, H., Fujioka, H., Schwarz, U.T., Eds.; SPIE: Bellingham, WA, USA, 2022; p. 43. [Google Scholar]

- Chichibu, S.F.; Nagata, K.; Oya, M.; Kasuya, T.; Okuno, K.; Ishiguro, H.; Saito, Y.; Takeuchi, T.; Shima, K. Operation-Induced Degradation Mechanisms of 275-Nm-Band AlGaN-Based Deep-Ultraviolet Light-Emitting Diodes Fabricated on a Sapphire Substrate. Appl. Phys. Lett. 2023, 122, 201105. [Google Scholar] [CrossRef]

- Huang, C.-Y.; Hsieh, W.-H.; Shao, T.-L.; Wu, C.-H.; Lu, T.-C. Degradation of High-Power UVC Light-Emitting Diodes via Emission-Activated Nitrogen Vacancy Generation. IEEE Trans. Electron. Devices 2023, 70, 3166–3171. [Google Scholar] [CrossRef]

- Glaab, J.; Haefke, J.; Ruschel, J.; Brendel, M.; Rass, J.; Kolbe, T.; Knauer, A.; Weyers, M.; Einfeldt, S.; Guttmann, M.; et al. Degradation Effects of the Active Region in UV-C Light-Emitting Diodes. J. Appl. Phys. 2018, 123, 104502. [Google Scholar] [CrossRef]

- Ruschel, J.; Glaab, J.; Beidoun, B.; Ploch, N.L.; Rass, J.; Kolbe, T.; Knauer, A.; Weyers, M.; Einfeldt, S.; Kneissl, M. Current-Induced Degradation and Lifetime Prediction of 310 Nm Ultraviolet Light-Emitting Diodes. Photonics Res. 2019, 7, B36. [Google Scholar] [CrossRef]

- Piva, F.; Pilati, M.; Buffolo, M.; Roccato, N.; Susilo, N.; Hauer Vidal, D.; Muhin, A.; Sulmoni, L.; Wernicke, T.; Kneissl, M.; et al. Degradation of AlGaN-Based UV-C SQW LEDs Analyzed by Means of Capacitance Deep-Level Transient Spectroscopy and Numerical Simulations. Appl. Phys. Lett. 2023, 122, 18. [Google Scholar] [CrossRef]

- Roccato, N.; Piva, F.; De Santi, C.; Buffolo, M.; Fregolent, M.; Pilati, M.; Susilo, N.; Vidal, D.H.; Muhin, A.; Sulmoni, L.; et al. Modeling the Electrical Degradation of AlGaN-Based UV-C LEDs by Combined Deep-Level Optical Spectroscopy and TCAD Simulations. Appl. Phys. Lett. 2023, 122, 16. [Google Scholar] [CrossRef]

- Ma, Z.; Cao, H.; Lin, S.; Li, X.; Zhao, L. Degradation and Failure Mechanism of AlGaN-Based UVC-LEDs. Solid. State Electron. 2019, 156, 92–96. [Google Scholar] [CrossRef]

- Xiu, H.; Zhang, Y.; Fu, J.; Ma, Z.; Zhao, L.; Feng, J. Degradation Behavior of Deep UV-LEDs Studied by Electro-Optical Methods and Transmission Electron Microscopy. Curr. Appl. Phys. 2019, 19, 20–24. [Google Scholar] [CrossRef]

- IESNA TM-21-11; Projecting Long Term Lumen Maintenance of LED Light Sources. Illuminating Engineering Society: New York, NY, USA, 2011.

- IESNA, TM-28-14; Projecting Long-Term Luminous Flux Maintenance of LED Lamps and Luminaries. Illuminating Engineering Society: New York, NY, USA, 2014.

- Arques-Orobon, F.J.; Vazquez, M.; Nuñez, N. Lifetime Analysis of Commercial 3 W UV-A LED. Crystals 2020, 10, 1083. [Google Scholar] [CrossRef]

- Tan, K.-Z.; Lee, S.-K.; Low, H.-C. LED Lifetime Prediction Under Thermal-Electrical Stress. IEEE Trans. Device Mater. Reliab. 2021, 21, 310–319. [Google Scholar] [CrossRef]

- Kochanowicz, M.; Zmojda, J.; Baranowska, A.; Kuwik, M.; Starzyk, B.; Lesniak, M.; Miluski, P.; Pisarski, W.A.; Pisarska, J.; Dorosz, J.; et al. Fluoroindate Glass Co-Doped with Yb3+/Ho3+ as a 2.85 Μm Luminescent Source for MID-IR Sensing. Sensors 2021, 21, 2155. [Google Scholar] [CrossRef]

- Kochanowicz, M.; Zmojda, J.; Miluski, P.; Baranowska, A.; Leich, M.; Schwuchow, A.; Jäger, M.; Kuwik, M.; Pisarska, J.; Pisarski, W.A.; et al. Tm 3+ /Ho 3+ Co-Doped Germanate Glass and Double-Clad Optical Fiber for Broadband Emission and Lasing above 2 Μm. Opt. Mater. Express 2019, 9, 1450. [Google Scholar] [CrossRef]

- Meneghini, M.; De Santi, C.; Tibaldi, A.; Vallone, M.; Bertazzi, F.; Meneghesso, G.; Zanoni, E.; Goano, M. Thermal Droop in III-Nitride Based Light-Emitting Diodes: Physical Origin and Perspectives. J. Appl. Phys. 2020, 127, 21. [Google Scholar] [CrossRef]

- Piva, F.; De Santi, C.; Deki, M.; Kushimoto, M.; Amano, H.; Tomozawa, H.; Shibata, N.; Meneghesso, G.; Zanoni, E.; Meneghini, M. Modeling the Degradation Mechanisms of AlGaN-Based UV-C LEDs: From Injection Efficiency to Mid-Gap State Generation. Photonics Res. 2020, 8, 1786. [Google Scholar] [CrossRef]

- Buffolo, M.; Magri, A.; De Santi, C.; Meneghesso, G.; Zanoni, E.; Meneghini, M. Gradual Degradation of InGaAs LEDs: Impact on Non-Radiative Lifetime and Extraction of Defect Characteristics. Materials 2021, 14, 1114. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Zhou, L.; Gao, Y.; Lunev, A.; Zhang, B.; Götz, W. Performance and Analysis of an Ultraviolet C-Band Light Emitting Diode with an Emission Wavelength of 268 Nm. Semicond. Sci. Technol. 2022, 37, 07LT01. [Google Scholar] [CrossRef]

- Chen, J.; Loeb, S.; Kim, J.-H. LED Revolution: Fundamentals and Prospects for UV Disinfection Applications. Environ. Sci. 2017, 3, 188–202. [Google Scholar] [CrossRef]

- Reed, N.G. The History of Ultraviolet Germicidal Irradiation for Air Disinfection. Public. Health Rep. 2010, 125, 15–27. [Google Scholar] [CrossRef]

- Liang, S.; Sun, W. Recent Advances in Packaging Technologies of AlGaN-Based Deep Ultraviolet Light-Emitting Diodes. Adv. Mater. Technol. 2022, 7, 2101502. [Google Scholar] [CrossRef]

| LED | Absolute Maximum Current Imax (mA) * | OP at Current (mW@mA) * | Current During Degradation Procedure (mA) ** | Peak Wavelength (nm) ** | FWHM (nm) ** | Package Size/ Total Pad Area * | Maximum Junction Temperature (°C) * |

|---|---|---|---|---|---|---|---|

| 1 | 150 | 10.5@100 | 90 | 271 | 13 | SMD 3.5 × 3.5 mm TP (4.29 mm2) Contacts (4.29 mm2) | 85 |

| 2 | 150 | 32@100 | 105 | 277 | 14 | SMD 5 × 5 mm TP (13.29 mm2) Contacts (4 mm2) | 85 |

| 3 | 400 | 100@450 | 350 | 278 | 11 | SMD 6.5 × 6.5 mm TP (18.9 mm2) Contacts (13.86 mm2) | 85 |

| 4 | 500 | 50@350 | 350 | 280 | 11 | SMD 3.5 × 3.5 mm TP (4.88 mm2) Contacts (3.15 mm2) | 85 |

| 5 | 500 | 55@350 | 350 | 280 | 11 | SMD 3.5 × 3.5 mm no TP Contacts (10.5 mm2) | 85 |

| 6 | 150 | 52–72@150 | 150 | 277 | 14 | SMD STAR 20 mm no data no data | no data |

| Coefficient | LED1 | LED2 | LED3 * | LED4 | LED5 | LED6 |

|---|---|---|---|---|---|---|

| OP0 | 0.565 | 0.776 | 0.152 | 0.759 | 0.697 | 0.535 |

| A1 | 0.125 | 0.044 | 0.414 | 0.073 | 0.097 | 0.108 |

| τ1 | 36.07 | 27.154 | 37.67 | 23.66 | 32.63 | 43.48 |

| A2 | 0.309 | 0.178 | 0.445 | 0.162 | 0.199 | 0.349 |

| τ2 | 888.9 | 754.2 | 118.4 | 579.7 | 755.0 | 647.1 |

| R2 | 0.995 | 0.997 | 0.993 | 0.999 | 0.999 | 0.999 |

| τ (h) | 875 | 748 | 100 | 570 | 740 | 635 |

| Optical Power Temperature Coefficient | Unit | LED1 | LED2 | LED4 | LED5 | LED6 | Average |

|---|---|---|---|---|---|---|---|

| ∆OP/∆T0h | (%/°C) | −0.11 | −0.18 | −0.21 | −0.10 | −0.18 | −0.15 |

| ∆OP/∆T1500h | (%/°C) | −0.03 | −0.15 | −0.22 | −0.17 | −0.04 | −0.12 |

| LED1 | LED2 | LED3 | LED4 | LED5 | LED6 | |

|---|---|---|---|---|---|---|

| EQE (%) | 2.3 | 7.1 | 5.0 | 3.2 | 3.5 | 7.7 |

| WPE (%) | 1.6 | 1.9 | 1.7 | 2.5 | 2.6 | 1.4 |

| EE (%) | 70 | 26 | 34 | 77 | 74 | 18 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gryko, Ł.; Błaszczak, U.J.; Kochanowicz, M. Degradation- and Thermal-Related Changes in Selected Electro-Optical Parameters of High-Power 270–280 nm LEDs. Photonics 2023, 10, 1326. https://doi.org/10.3390/photonics10121326

Gryko Ł, Błaszczak UJ, Kochanowicz M. Degradation- and Thermal-Related Changes in Selected Electro-Optical Parameters of High-Power 270–280 nm LEDs. Photonics. 2023; 10(12):1326. https://doi.org/10.3390/photonics10121326

Chicago/Turabian StyleGryko, Łukasz, Urszula Joanna Błaszczak, and Marcin Kochanowicz. 2023. "Degradation- and Thermal-Related Changes in Selected Electro-Optical Parameters of High-Power 270–280 nm LEDs" Photonics 10, no. 12: 1326. https://doi.org/10.3390/photonics10121326