Solution Doping of PMMA-Based Step-Index Polymer Optical Fibers by Rhodamine B Near Glass Transition Temperature of PMMA

Abstract

1. Introduction

2. Experimental

2.1. Materials and Reagents

2.2. Doping and Characterization of POFs

2.3. Measurement of Doping Concentration

3. Results and Discussion

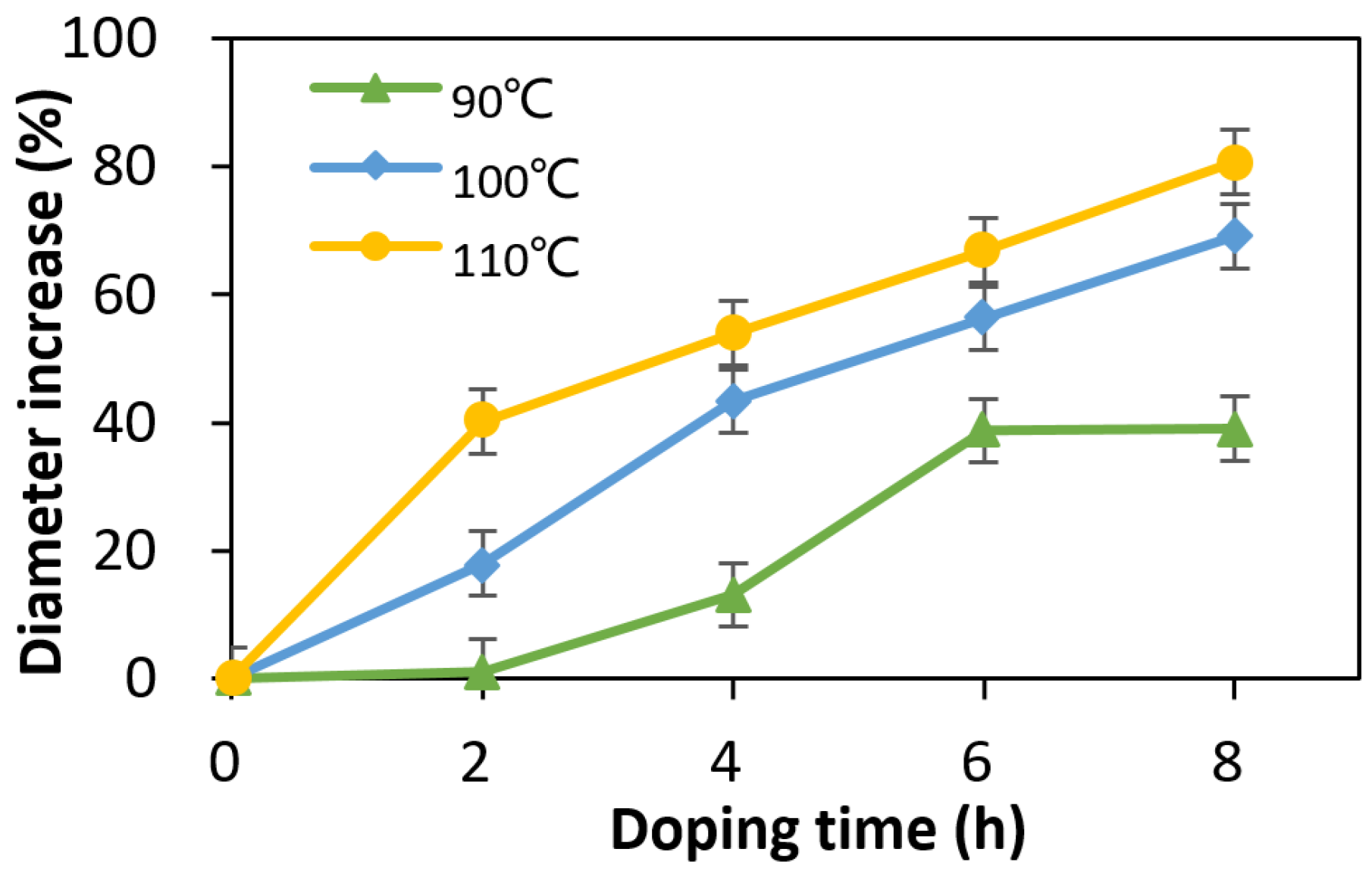

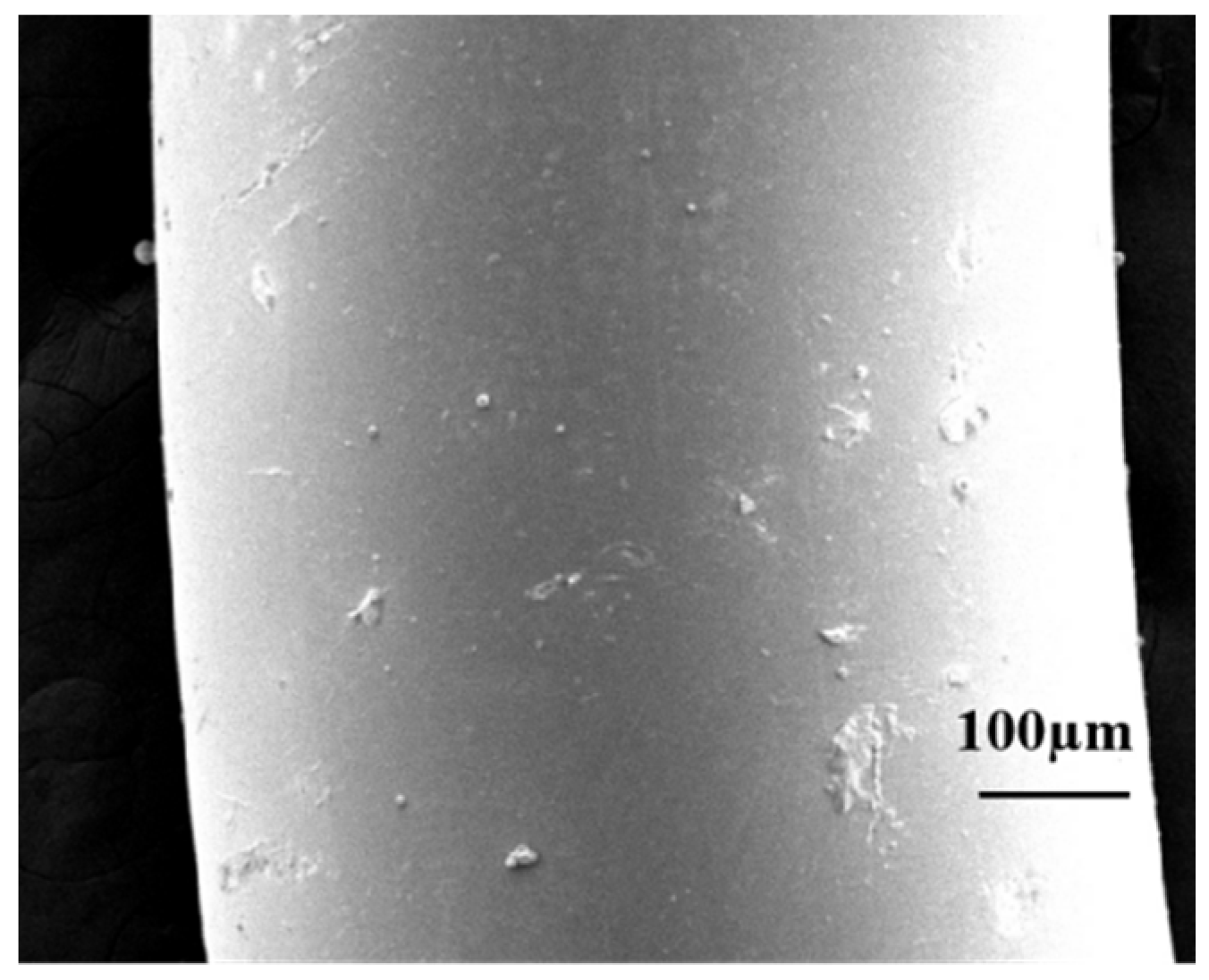

3.1. Macroscopic and Microscopic Changes in POFs

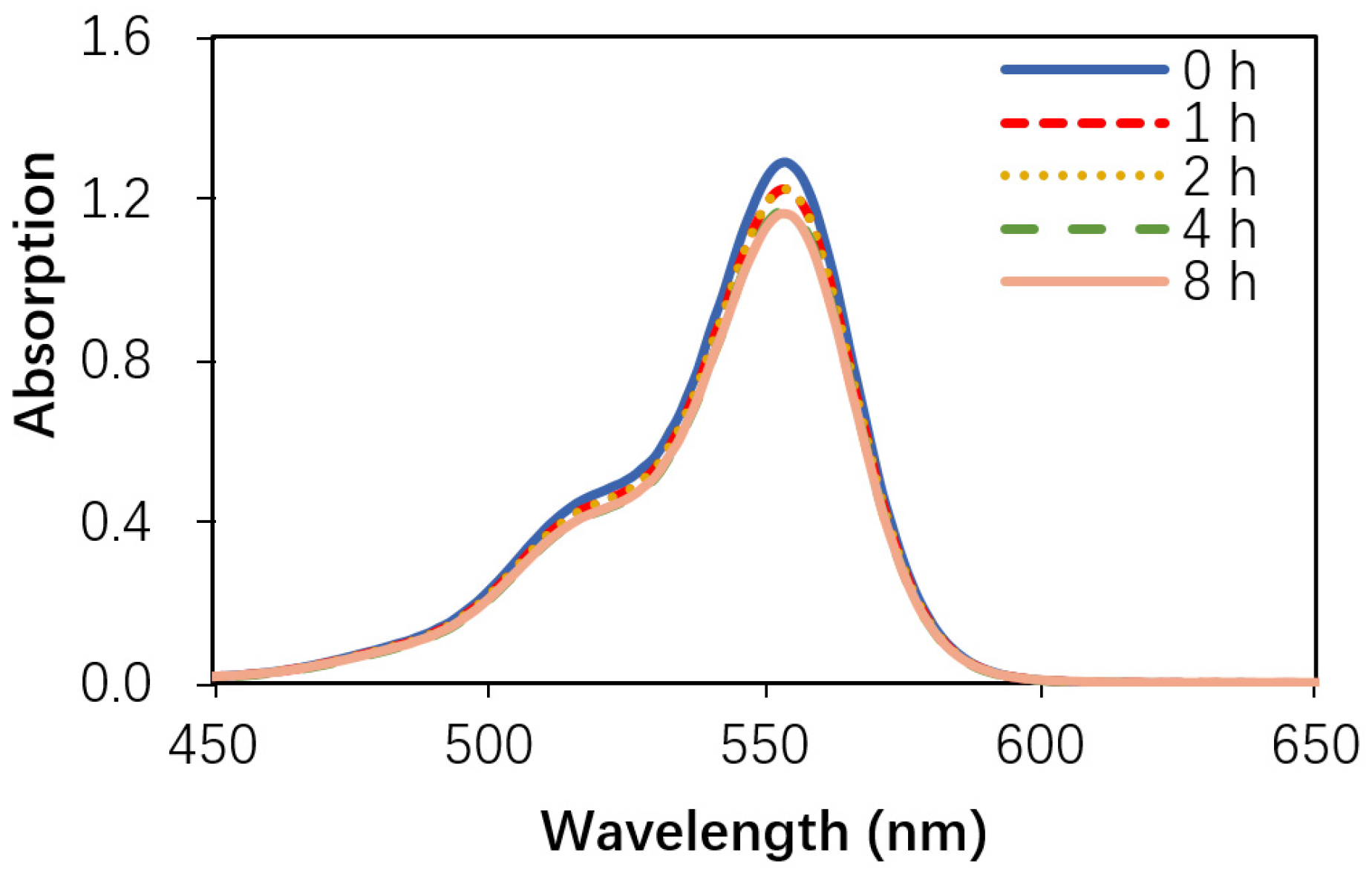

3.2. Dopant Concentration in the Fiber

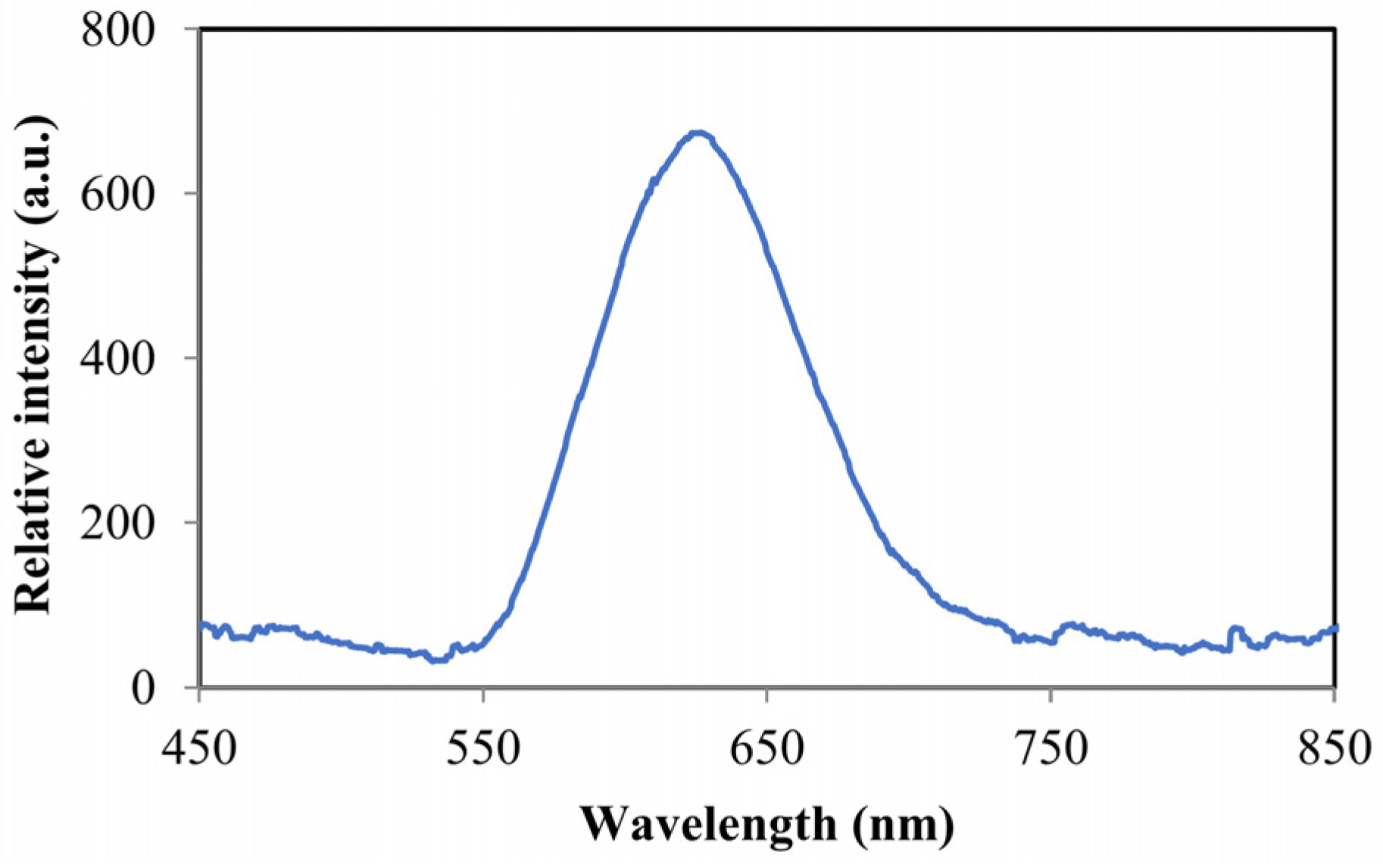

3.3. Effect of Doping on the Fiber Loss

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhao, Y.; Lin, Z.; Dong, S.; Chen, M. Review of Wearable Optical Fiber Sensors: Drawing a Blueprint for Human Health Monitoring. Opt. Laser Technol. 2023, 161, 109227. [Google Scholar] [CrossRef]

- Sadeque, M.S.B.; Chowdhury, H.K.; Rafique, M.; Durmuş, M.A.; Ahmed, M.K.; Hasan, M.M.; Erbaş, A.; Sarpkaya, İ.; Inci, F.; Ordu, M. Hydrogel-Integrated Optical Fiber Sensors and Their Applications: A Comprehensive Review. J. Mater. Chem. C 2023, 11, 9383–9424. [Google Scholar] [CrossRef]

- Kuang, R.; Wang, Z.; Ma, L.; Wang, H.; Chen, Q.; Junior, A.L.; Kumar, S.; Li, X.; Marques, C.; Min, R. Smart Photonic Wristband for Pulse Wave Monitoring. Opto-Electron. Sci. 2024, 3, 240009. [Google Scholar] [CrossRef]

- Ngiejungbwen, L.A.; Hamdaoui, H.; Chen, M.-Y. Polymer Optical Fiber and Fiber Bragg Grating Sensors for Biomedical Engineering Applications: A Comprehensive Review. Opt. Laser Technol. 2024, 170, 110187. [Google Scholar] [CrossRef]

- Zhu, Z.; Sun, S.; Chai, X.; Gao, J.; Lu, M.; Wu, Z.; Gao, Y.; Feng, T.; Bai, X.; Zhang, Y.; et al. Quantum Dot-Doped Optical Fibers. Laser Photonics Rev. 2024, 18, 2301388. [Google Scholar] [CrossRef]

- Hemming, A.; Simakov, N.; Haub, J.; Carter, A. A Review of Recent Progress in Holmium-Doped Silica Fibre Sources. Opt. Fiber Technol. 2014, 20, 621–630. [Google Scholar] [CrossRef]

- Bradley, D.A.; Hugtenburg, R.P.; Nisbet, A.; Abdul Rahman, A.T.; Issa, F.; Mohd Noor, N.; Alalawi, A. Review of Doped Silica Glass Optical Fibre: Their TL Properties and Potential Applications in Radiation Therapy Dosimetry. Appl. Radiat. Isot. 2012, 71, 2–11. [Google Scholar] [CrossRef]

- Large, M.C.J.; Ponrathnam, S.; Argyros, A.; Pujari, N.S.; Cox, F. Solution Doping of Microstructured Polymer Optical Fibres. Opt. Express 2004, 12, 1966–1971. [Google Scholar] [CrossRef]

- Ayesta, I.; Azkune, M.; Arrospide, E.; Arrue, J.; Illarramendi, M.; Durana, G.; Zubia, J. Fabrication of Active Polymer Optical Fibers by Solution Doping and Their Characterization. Polymers 2018, 11, 52. [Google Scholar] [CrossRef]

- Ma, C.; Tian, C.; Zhang, Z.F. Doping of Polymer Optical Fiber Cladding in the Solution of Water and Methanol at Elevated Temperature. Polym. Bull. 2024, 81, 4307–4317. [Google Scholar] [CrossRef]

- Yu, H.C.Y.; Argyros, A.; Leon-Saval, S.G.; Fuerbach, A.; Efimov, A.; Barton, G.W. Emission Properties of Quantum Dots in Polymer Optical Fibres. Opt. Express 2009, 17, 21344–21349. [Google Scholar] [CrossRef]

- Whittaker, C.A.; Perret, A.; Fortier, C.W.; Tardif, O.-M.; Lamarre, S.A.; Morency, S.; Larivière, D.; Beaulieu, L.; Messaddeq, Y.; Allen, C.N. Light-Generating CdSe/CdS Colloidal Quantum Dot-Doped Plastic Optical Fibers. ACS Appl. Nano Mater. 2020, 3, 6478–6488. [Google Scholar] [CrossRef]

- Arrue, J.; García-Ramiro, B.; Jiménez, F.; Illarramendi, M.A.; Ayesta, I.; Zubia, J.; Evert, R.; Zaremba, D. Gain in Europium-Chelate-Doped Polymer-Optical-Fiber Amplifiers. J. Opt. Soc. Am. B 2018, 35, 2770. [Google Scholar] [CrossRef]

- Vieira, A.; Arrue, J.; García-Ramiro, B.; Jiménez, F.; Illarramendi, M.A.; Zubia, J. POF-Based Solar Concentrators Incorporating Dyes and Europium Chelates. Materials 2021, 14, 2667. [Google Scholar] [CrossRef]

- Arrue, J.; Jiménez, F.; Ayesta, I.; Illarramendi, M.A.; Zubia, J. Polymer-Optical-Fiber Lasers and Amplifiers Doped with Organic Dyes. Polymers 2011, 3, 1162–1180. [Google Scholar] [CrossRef]

- Sheeba, M.; Thomas, K.J.; Rajesh, M.; Nampoori, V.P.N.; Vallabhan, C.P.G.; Radhakrishnan, P. Multimode Laser Emission from Dye Doped Polymer Optical Fiber. Appl. Opt. 2007, 46, 8089–8094. [Google Scholar] [CrossRef]

- Jaramillo-Ochoa, L.; Narro-García, R.; Ocampo, M.A.; Quintero-Torres, R. High Stability of Polymer Optical Fiber with Dye Doped Cladding for Illumination Systems. J. Lumin. 2017, 184, 205–210. [Google Scholar] [CrossRef]

- Jiang, N.; Ahmed, R.; Rifat, A.A.; Guo, J.; Yin, Y.; Montelongo, Y.; Butt, H.; Yetisen, A.K. Functionalized Flexible Soft Polymer Optical Fibers for Laser Photomedicine. Adv. Opt. Mater. 2018, 6, 1701118. [Google Scholar] [CrossRef]

- Hu, X.; Woyessa, G.; Kinet, D.; Janting, J.; Nielsen, K.; Bang, O.; Caucheteur, C. BDK-Doped Core Microstructured PMMA Optical Fiber for Effective Bragg Grating Photo-Inscription. Opt. Lett. 2017, 42, 2209–2212. [Google Scholar] [CrossRef]

- He, J.; Chan, W.-K.; Cheng, X.; Tse, M.-L.; Lu, C.; Wai, P.-K.; Savovic, S.; Tam, H.-Y. Experimental and Theoretical Investigation of the Polymer Optical Fiber Random Laser with Resonant Feedback. Adv. Opt. Mater. 2018, 6, 1701187. [Google Scholar] [CrossRef]

- Shukla, S.K.; Kushwaha, C.S.; Guner, T.; Demir, M.M. Chemically Modified Optical Fibers in Advanced Technology: An Overview. Opt. Laser Technol. 2019, 115, 404–432. [Google Scholar] [CrossRef]

- Parola, I.; Arrospide, E.; Recart, F.; Illarramendi, M.; Durana, G.; Guarrotxena, N.; García, O.; Zubia, J. Fabrication and Characterization of Polymer Optical Fibers Doped with Perylene-Derivatives for Fluorescent Lighting Applications. Fibers 2017, 5, 28. [Google Scholar] [CrossRef]

- Liang, H.; Zheng, Z.; Li, Z.; Xu, J.; Chen, B.; Zhao, H.; Zhang, Q.; Ming, H. Fabrication and Amplified Spontaneous Emission of Eu(DBM) 3Phen Doped Step-Index Polymer Optical Fiber. Opt. Quantum Electron. 2004, 36, 1313–1322. [Google Scholar] [CrossRef]

- Jiang, C.; Kuzyk, M.G.; Ding, J.-L.; Johns, W.E.; Welker, D.J. Fabrication and Mechanical Behavior of Dye-Doped Polymer Optical Fiber. J. Appl. Phys. 2002, 92, 4–12. [Google Scholar] [CrossRef]

- Qiu, S.; Chu, H.; Zou, Y.; Xiang, C.; Zhang, H.; Sun, L.; Xu, F. Thermochemical Studies of Rhodamine B and Rhodamine 6G by Modulated Differential Scanning Calorimetry and Thermogravimetric Analysis. J. Therm. Anal. Calorim. 2016, 123, 1611–1618. [Google Scholar] [CrossRef]

- Fasano, A.; Woyessa, G.; Janting, J.; Rasmussen, H.K.; Bang, O. Solution-Mediated Annealing of Polymer Optical Fiber Bragg Gratings at Room Temperature. IEEE Photonics Technol. Lett. 2017, 29, 687–690. [Google Scholar] [CrossRef]

- Tian, C.; Ma, C.; Han, X.; Zhang, Z.F. Doping of Polymer Optical Fiber Cladding by Rhodamine 6G in Aqueous Solution at Elevated Temperature. Polym. Bull. 2023, 80, 3395–3403. [Google Scholar] [CrossRef]

- Ayesta, I.; Azkune, M.; Illarramendi, M.A.; Arrospide, E.; Zubia, J.; Durana, G. Fabrication and Characterization of Active Polymer Optical Fibers with a Ring-Doped Structure. Opt. Fiber Technol. 2023, 75, 103209. [Google Scholar] [CrossRef]

- Stajanca, P.; Cetinkaya, O.; Schukar, M.; Mergo, P.; Webb, D.J.; Krebber, K. Molecular Alignment Relaxation in Polymer Optical Fibers for Sensing Applications. Opt. Fiber Technol. 2016, 28, 11–17. [Google Scholar] [CrossRef]

- de la Rosa-Cruz, E.; Dirk, C.W.; RodrÍguez, O.; CastaÑo, V.M. Characterization of Fluorescence Induced by Side Illumination of Rhodamine B Doped Plastic Optical Fibers. Fiber Integr. Opt. 2001, 20, 457–464. [Google Scholar] [CrossRef]

| Doping Temperature (°C) | RhB Concentration of the Cladding (mg/g) | RhB Concentration of the Core (mg/g) | ||||

|---|---|---|---|---|---|---|

| H2O | H2O + 10% MeOH | H2O + 20% MeOH | H2O | H2O + 10% MeOH | H2O + 20% MeOH | |

| 90 | 7.90 | 4.71 | 0.489 | 0.305 | 0.278 | 0.043 |

| 100 | 10.3 | 7.21 | 0.294 | 0.389 | 0.116 | 0.029 |

| 110 | 11.5 | 8.70 | 0.305 | 0.479 | 0.222 | 0.031 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, Y.; Fu, D.; Zhang, Z.-F. Solution Doping of PMMA-Based Step-Index Polymer Optical Fibers by Rhodamine B Near Glass Transition Temperature of PMMA. Photonics 2024, 11, 966. https://doi.org/10.3390/photonics11100966

Ma Y, Fu D, Zhang Z-F. Solution Doping of PMMA-Based Step-Index Polymer Optical Fibers by Rhodamine B Near Glass Transition Temperature of PMMA. Photonics. 2024; 11(10):966. https://doi.org/10.3390/photonics11100966

Chicago/Turabian StyleMa, Yinhua, Dewen Fu, and Zhi-Feng Zhang. 2024. "Solution Doping of PMMA-Based Step-Index Polymer Optical Fibers by Rhodamine B Near Glass Transition Temperature of PMMA" Photonics 11, no. 10: 966. https://doi.org/10.3390/photonics11100966

APA StyleMa, Y., Fu, D., & Zhang, Z.-F. (2024). Solution Doping of PMMA-Based Step-Index Polymer Optical Fibers by Rhodamine B Near Glass Transition Temperature of PMMA. Photonics, 11(10), 966. https://doi.org/10.3390/photonics11100966