A 30 mW Laser Oscillator at 2.72 μm and 2.8 μm Wavelengths Based on Er3+-Doped Tungsten–Tellurite Fibers

Abstract

1. Introduction

2. Materials and Methods

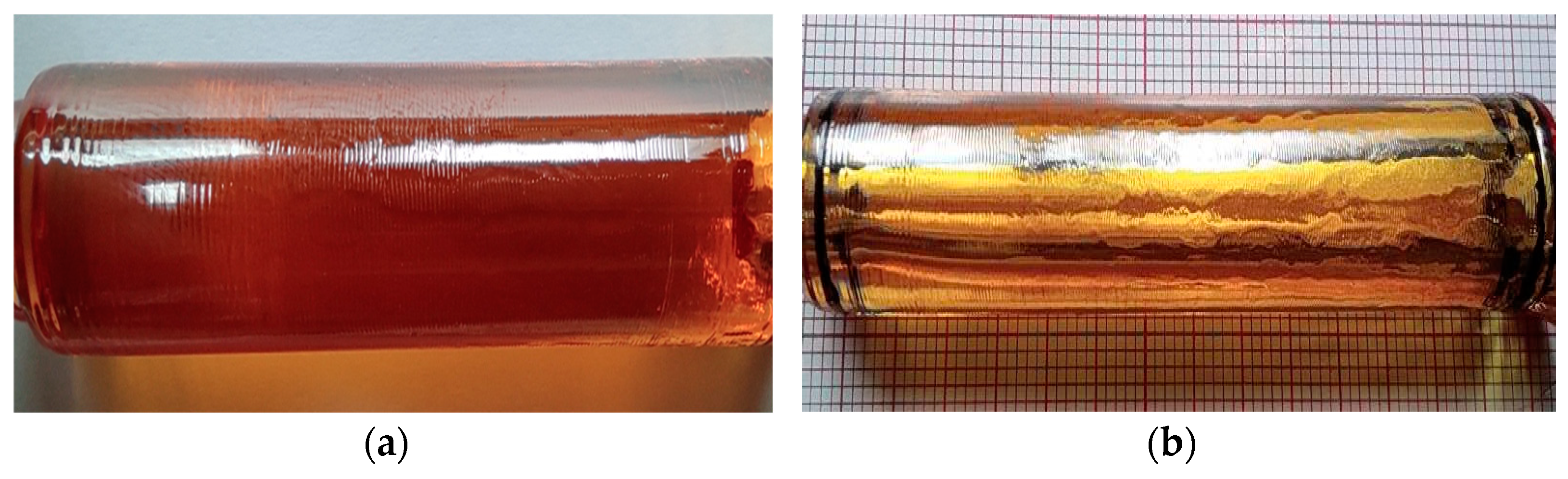

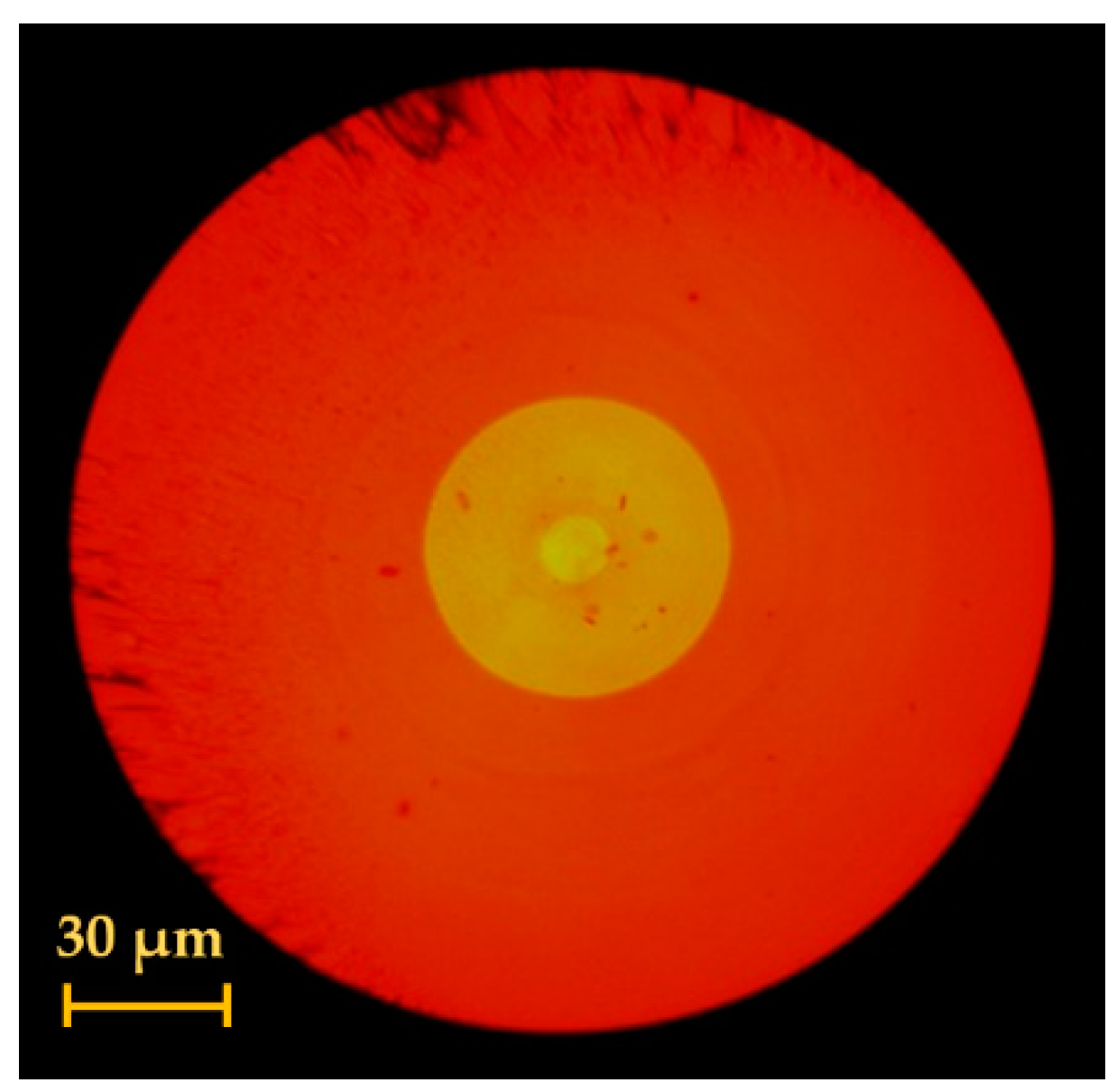

2.1. Tungsten–Tellurite Erbium-Doped Fiber

2.1.1. Glasses and Preform Preparation

2.1.2. TWL Fiber Production and Its Properties

2.2. Experimental Setup

3. Results and Discussion

3.1. Luminescent Properties

3.2. Lasing in the TWL Fiber

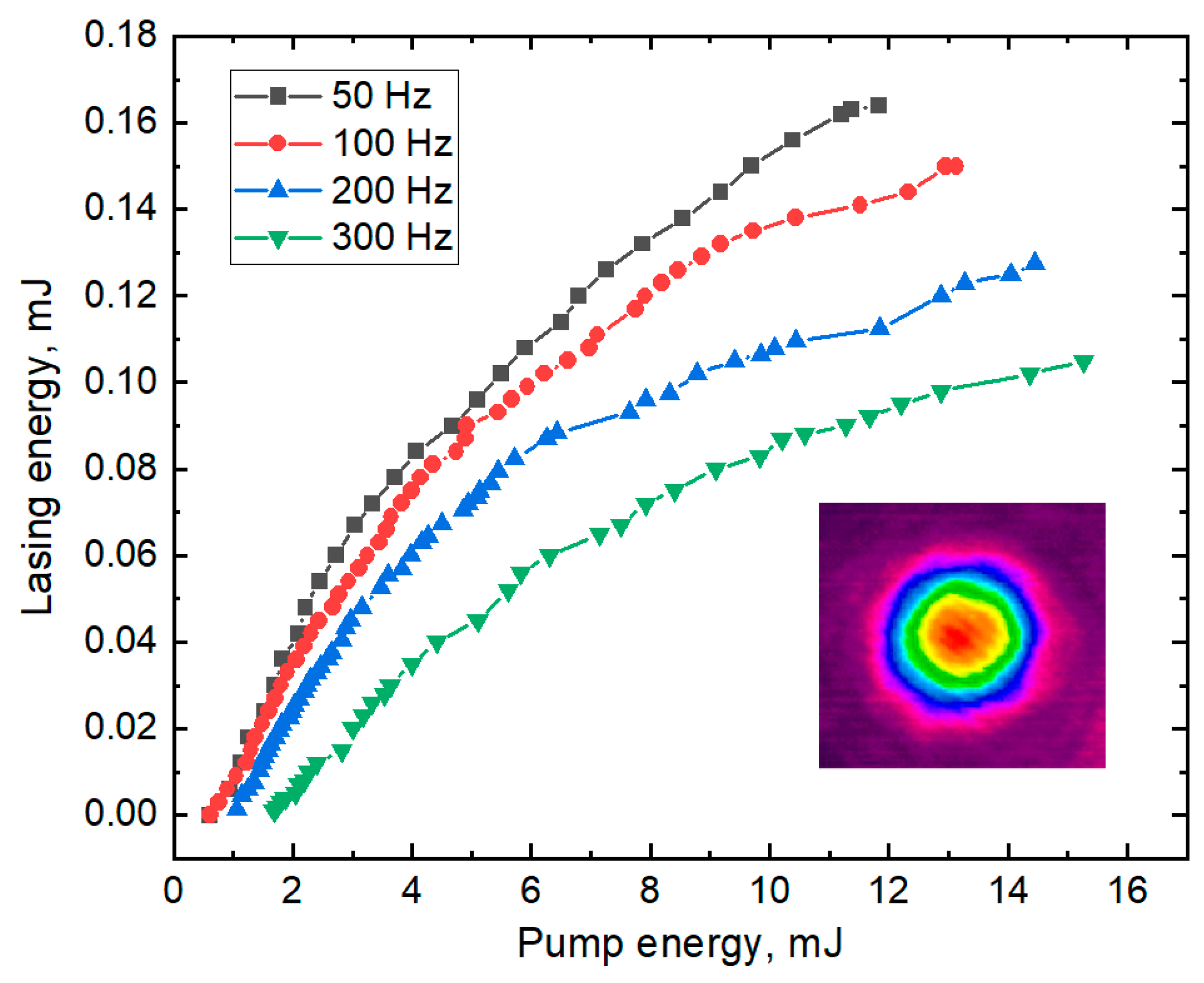

3.2.1. Lasing Efficiency

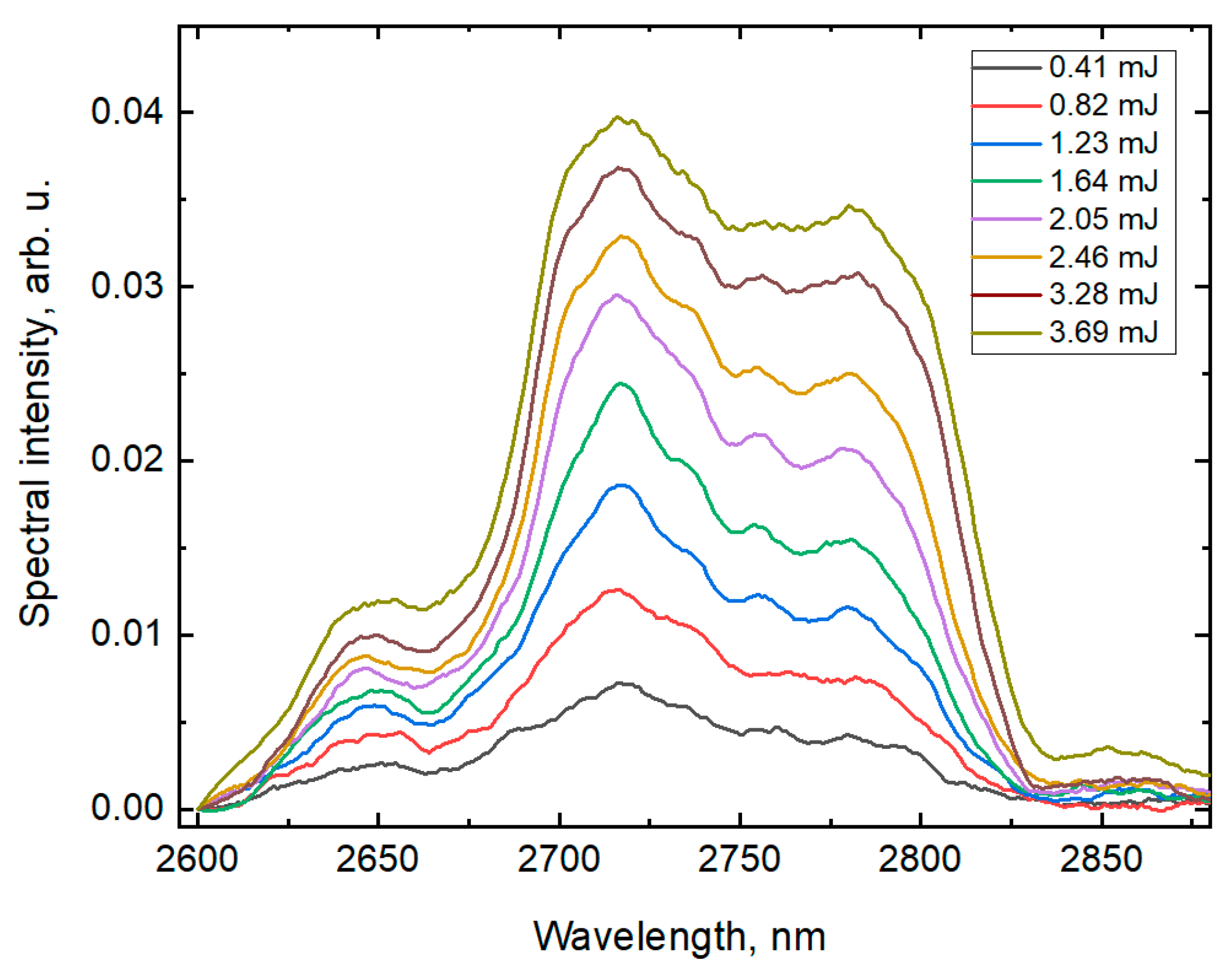

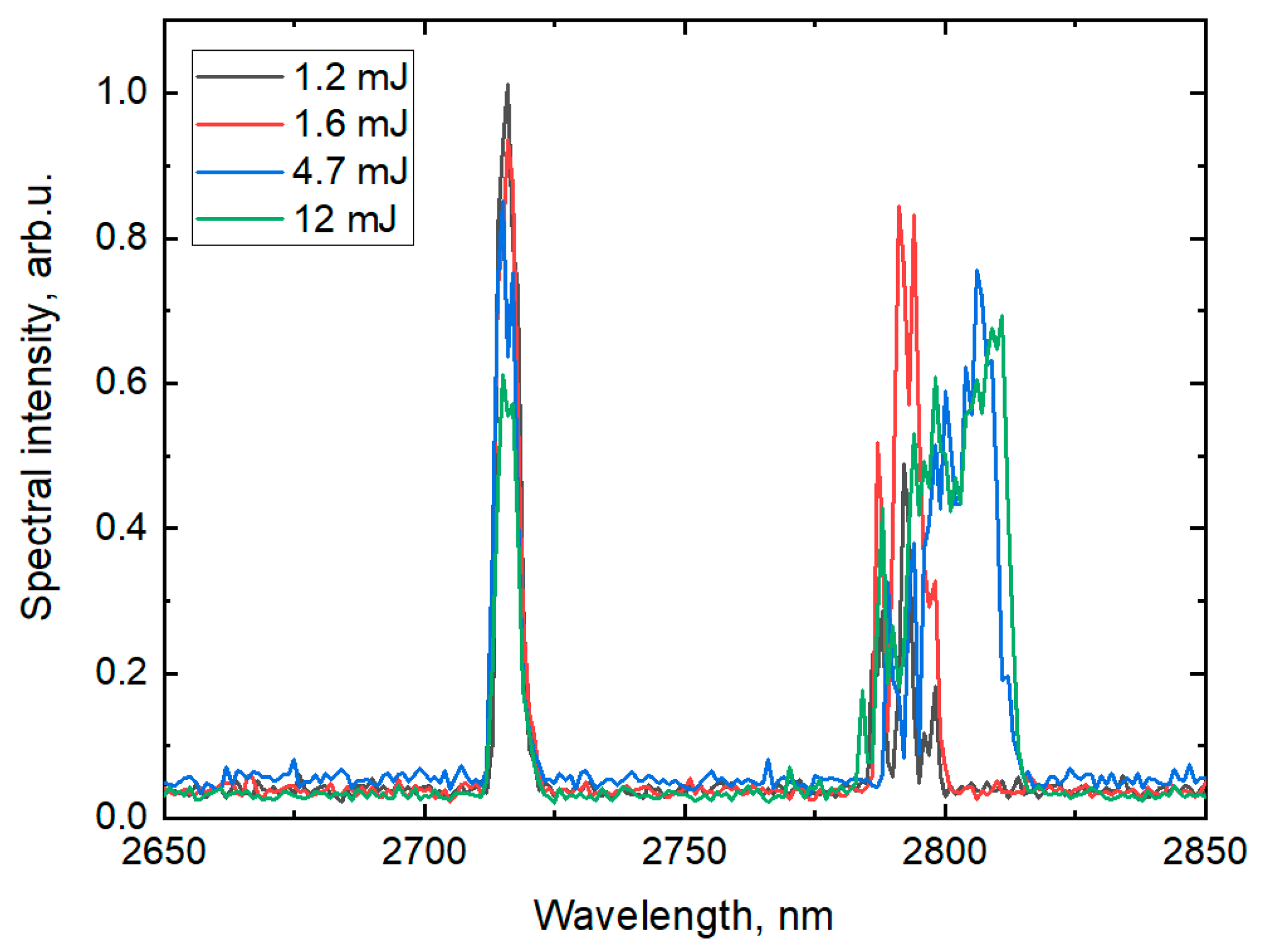

3.2.2. Lasing Spectra

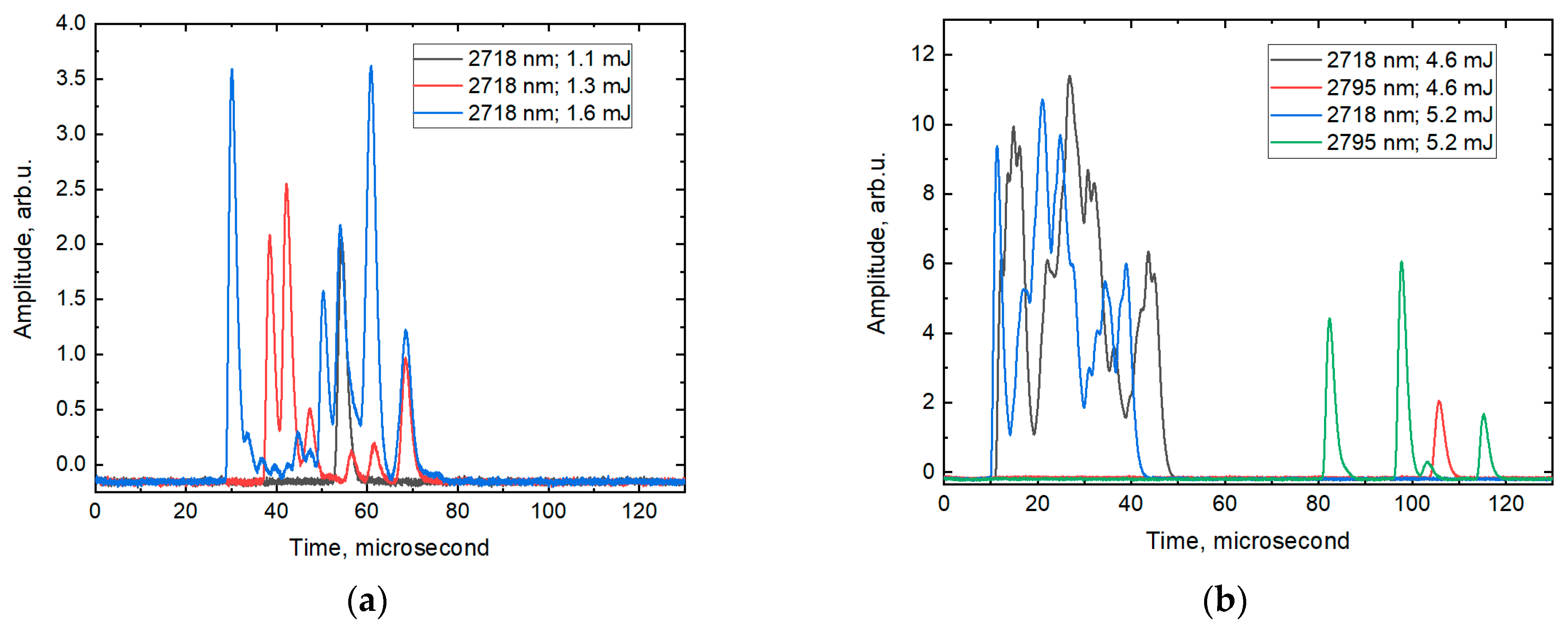

3.2.3. Temporal Profile of Laser Pulses

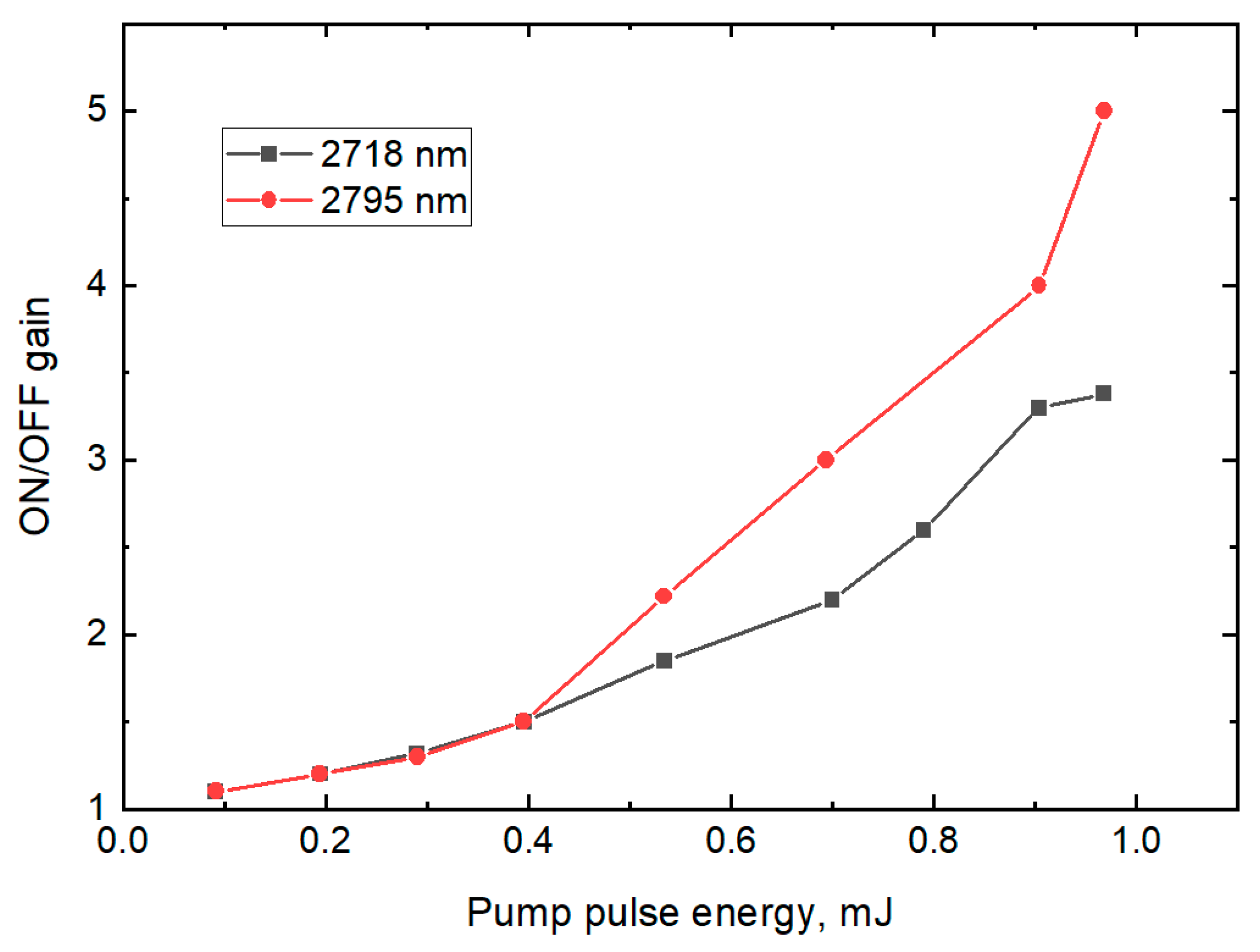

3.3. On/Off Gain

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ebrahim-Zadeh, M.; Sorokina, I.T. Mid-Infrared Coherent Sources and Applications; Springer: Dordrecht, The Netherlands, 2008. [Google Scholar]

- Jackson, S.D. Towards High-Power Mid-Infrared Emission from a Fibre Laser. Nat. Photon 2012, 6, 423–431. [Google Scholar] [CrossRef]

- Aydın, Y.O.; Fortin, V.; Maes, F.; Jobin, F.; Jackson, S.D.; Vallée, R.; Bernier, M. Diode-Pumped Mid-Infrared Fiber Laser with 50% Slope Efficiency. Optica 2017, 4, 235–238. [Google Scholar] [CrossRef]

- Aydin, Y.O.; Fortin, V.; Vallée, R.; Bernier, M. Towards Power Scaling of 28 µm Fiber Lasers. Opt. Lett. 2018, 43, 4542–4545. [Google Scholar] [CrossRef] [PubMed]

- Shen, Y.; Wang, Y.; Zhu, F.; Ma, L.; Zhao, L.; Chen, Z.; Wang, H.; Huang, C.; Huang, K.; Feng, G. 200 ΜJ, 13 ns Er:ZBLAN Mid-Infrared Fiber Laser Actively Q-Switched by an Electro-Optic Modulator. Opt. Lett. 2021, 46, 1141–1144. [Google Scholar] [CrossRef]

- Luo, H.; Yang, J.; Li, J.; Liu, Y. Tunable Sub-300 Fs Soliton and Switchable Dual-Wavelength Pulse Generation from a Mode-Locked Fiber Oscillator around 2.8 µm. Opt. Lett. 2021, 46, 841–844. [Google Scholar] [CrossRef] [PubMed]

- Jackson, S.D.; Jain, R.K. Fiber-Based Sources of Coherent MIR Radiation: Key Advances and Future Prospects (Invited). Opt. Express 2020, 28, 30964–31019. [Google Scholar] [CrossRef]

- El-Mallawany, R.A.H. Tellurite Glasses Handbook: Physical Properties and Data; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- Wang, W.C.; Yuan, J.; Li, L.X.; Chen, D.D.; Qian, Q.; Zhang, Q.Y. Broadband 2.7 μm amplified spontaneous emission of Er3+-doped tellurite fibers for mid-infrared laser applications. Opt. Mater. Express 2015, 5, 2964–2977. [Google Scholar] [CrossRef]

- Tian, Y.; Jing, X.; Li, B.; Li, P.; Li, Y.; Lei, R.; Zhang, J.; Xu, S. Synthesis, theoretical analysis, and characterization of highly Er3+ doped fluoroaluminate–tellurite glass with 2.7 μm emission. Opt. Mater. Express 2016, 6, 3274–3285. [Google Scholar] [CrossRef]

- AbouDeif, Y.M.; Yousef, E.S.; Marzouk, S.Y. Investigation of luminescence para meters of novel glasses with composition TeO2-ZnO-NaF-MoO2-Er2O3 as laser material. J. Non-Cryst. Solids 2018, 498, 72–81. [Google Scholar] [CrossRef]

- Fu, S.; Zhu, X.; Wang, J.; Wu, J.; Tong, M.; Zong, J.; Li, M.; Wiersma, K.; Chavez-Pirson, A.; Peyghambarian, N. L-Band Wavelength-Tunable Er3+ -Doped Tellurite Fiber Lasers. J. Lightwave Technol. 2020, 38, 1435–1438. [Google Scholar] [CrossRef]

- Wang, J.; Jia, Z.; Ren, Y.; Zhang, C.; Ohishi, Y.; Qin, W.; Qin, G. Watt-Level 815 nm Lasing from Tm3+ -Doped Fluorotellurite Glass Fibers. Opt. Lett. 2023, 48, 6476–6479. [Google Scholar] [CrossRef] [PubMed]

- Cui, L.; Jia, Z.; Wang, J.; Zhang, C.; Tian, F.; Meng, F.; Ohishi, Y.; Qin, W.; Qin, G. Widely Tunable S-Band Ring-Cavity Tm3+-Doped Fluorotellurite Fiber Laser. Opt. Lett. 2024, 49, 2333–2336. [Google Scholar] [CrossRef]

- Ma, Y.; Guo, Y.; Huang, F.; Hu, L.; Zhang, J. Spectroscopic Properties in Er3+-Doped Zinc- and Tungsten-Modified Tellurite Glasses for 2.7 µm Laser Materials. J. Lumin. 2014, 147, 372–377. [Google Scholar] [CrossRef]

- Muraviev, S.V.; Dorofeev, V.V.; Koptev, M.Y.; Kim, A.V. Experimental insights into increasing laser output at 2.8 μm in Er3+-doped zinc-tellurite fibers. Opt. Lett. 2024, 49, 5555–5558. [Google Scholar] [CrossRef] [PubMed]

- Muraviev, S.V.; Dorofeev, V.V.; Kuznechikov, P.A.; Sharafeev, A.R.; Koptev, M.Y.; Kim, A.V. 2.8 µm Er3+-Doped Zinc-Tellurite Fiber Lasers Pumped by 976 Laser Diode. IEEE Photon. Technol. Lett. 2023, 35, 1435–1438. [Google Scholar] [CrossRef]

- Gomes, L.; Oermann, M.; Ebendorff-Heidepriem, H.; Ottaway, D.; Monro, T.; Librantz, A.F.; Jackson, S.D. Energy Level Decay and Excited State Absorption Processes in Erbium-Doped Tellurite Glass. Appl. Phys. 2011, 110, 083111. [Google Scholar] [CrossRef]

- Muraviev, S.V.; Dorofeev, V.V.; Motorin, S.E.; Koltashev, V.V.; Koptev, M.Y.; Kim, A.V. Lasing at 2.72 µm in an Er3+-Doped High-Purity Tungsten–Tellurite Glass Fiber Laser. Opt. Lett. 2022, 47, 5821–5824. [Google Scholar] [CrossRef]

- Dorofeev, V.V.; Koltashev, V.V.; Motorin, S.E.; Plekhovich, A.D.; Kim, A.V. Thermal, Optical, and IR-Emission Properties of Extremely Low Hydroxyl TeO2-WO3-Bi2O3-La2O3-xEr2O3 Glasses for Mid-Infrared Photonics. Photonics 2021, 8, 320. [Google Scholar] [CrossRef]

- Oermann, M.R.; Ebendor-Heidepriem, H.; Li, Y.; Foo, T.C.; Monro, T.M. Index Matching between Passive and Active Tellurite Glasses for Use in Microstructured Fiber Lasers: Erbium Doped Lanthanum-Tellurite Glass. Opt. Express 2009, 17, 15578–15584. [Google Scholar] [CrossRef]

- Zhan, H.; Zhou, Z.; He, J. Intense 2.7 μm Emission of Er3+-Doped Water-Free Fluorotellurite Glasses. Opt. Lett. 2012, 37, 3408–3410. [Google Scholar] [CrossRef]

- Muraviev, S.V.; Dorofeev, V.V.; Motorin, S.E.; Koptev, M.Y.; Kim, A.V. Broadband Gain Performance in the Mid-IR Using Supercontinuum: 2.7 µm Gain in High-Purity Er 3+ Doped Tungsten Tellurite Glass Fibers. Appl. Opt. 2022, 61, 9701–9707. [Google Scholar] [CrossRef] [PubMed]

| Fiber Parameter | Parameter Value |

|---|---|

| Er2O3 concentration | 1.6 mol.% |

| Core diameter | 12 µm |

| First cladding diameter | 60 µm |

| Second cladding diameter | 190 µm |

| Core numerical aperture | 0.12 |

| First cladding numerical aperture | 0.16 |

| Core OH absorption coefficient near 3 µm | 0.01 cm−1 |

| Cladding OH absorption coefficient near 3 µm | 0.006 cm−1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Muraviev, S.; Dorofeev, V.; Motorin, S.; Koptev, M.; Kim, A. A 30 mW Laser Oscillator at 2.72 μm and 2.8 μm Wavelengths Based on Er3+-Doped Tungsten–Tellurite Fibers. Photonics 2024, 11, 1159. https://doi.org/10.3390/photonics11121159

Muraviev S, Dorofeev V, Motorin S, Koptev M, Kim A. A 30 mW Laser Oscillator at 2.72 μm and 2.8 μm Wavelengths Based on Er3+-Doped Tungsten–Tellurite Fibers. Photonics. 2024; 11(12):1159. https://doi.org/10.3390/photonics11121159

Chicago/Turabian StyleMuraviev, Sergei, Vitaly Dorofeev, Sergei Motorin, Maxim Koptev, and Arkady Kim. 2024. "A 30 mW Laser Oscillator at 2.72 μm and 2.8 μm Wavelengths Based on Er3+-Doped Tungsten–Tellurite Fibers" Photonics 11, no. 12: 1159. https://doi.org/10.3390/photonics11121159

APA StyleMuraviev, S., Dorofeev, V., Motorin, S., Koptev, M., & Kim, A. (2024). A 30 mW Laser Oscillator at 2.72 μm and 2.8 μm Wavelengths Based on Er3+-Doped Tungsten–Tellurite Fibers. Photonics, 11(12), 1159. https://doi.org/10.3390/photonics11121159