The Structure and Applications of Fused Tapered Fiber Optic Sensing: A Review

Abstract

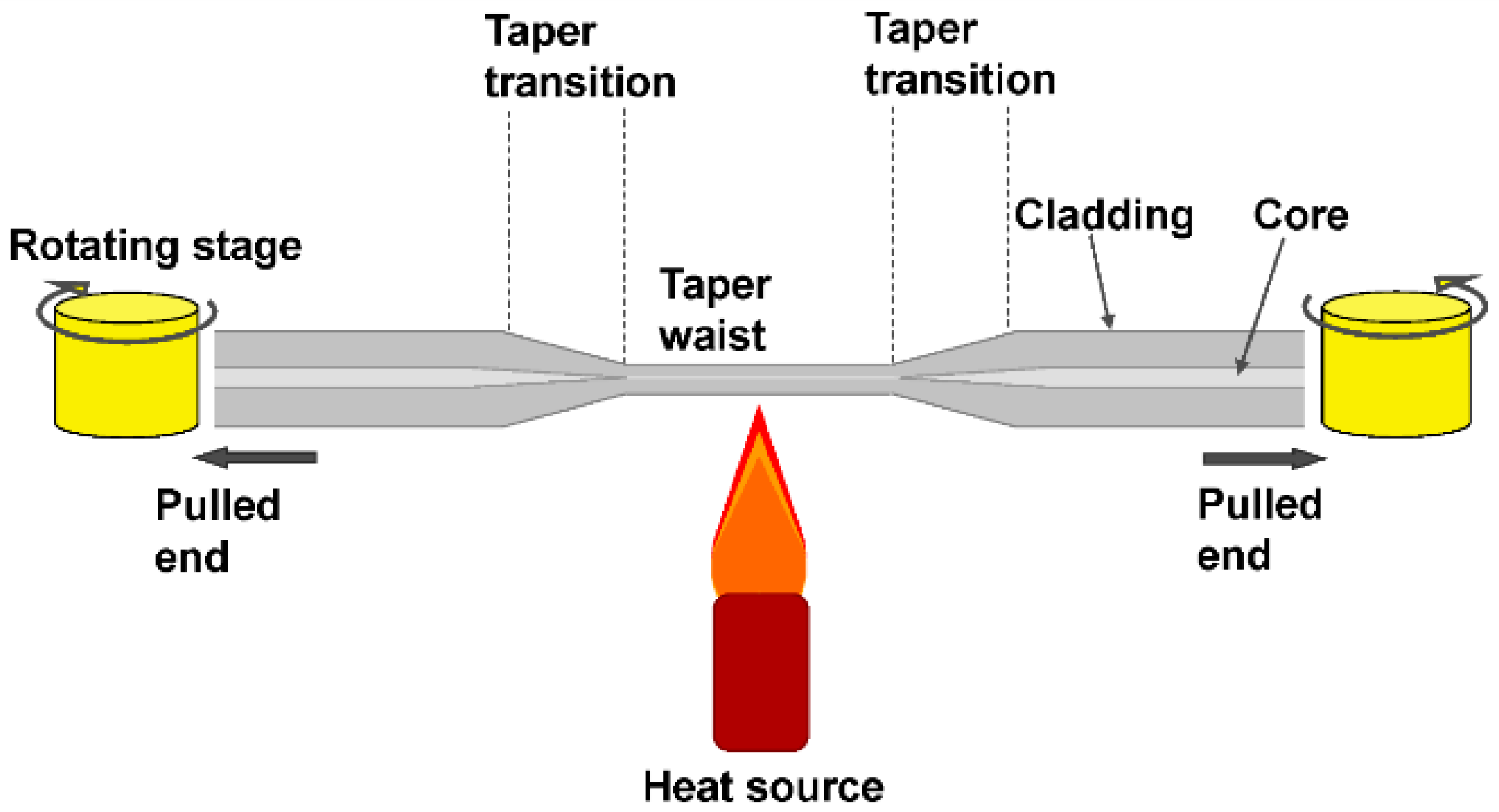

1. Introduction

2. Different Sensor Structures

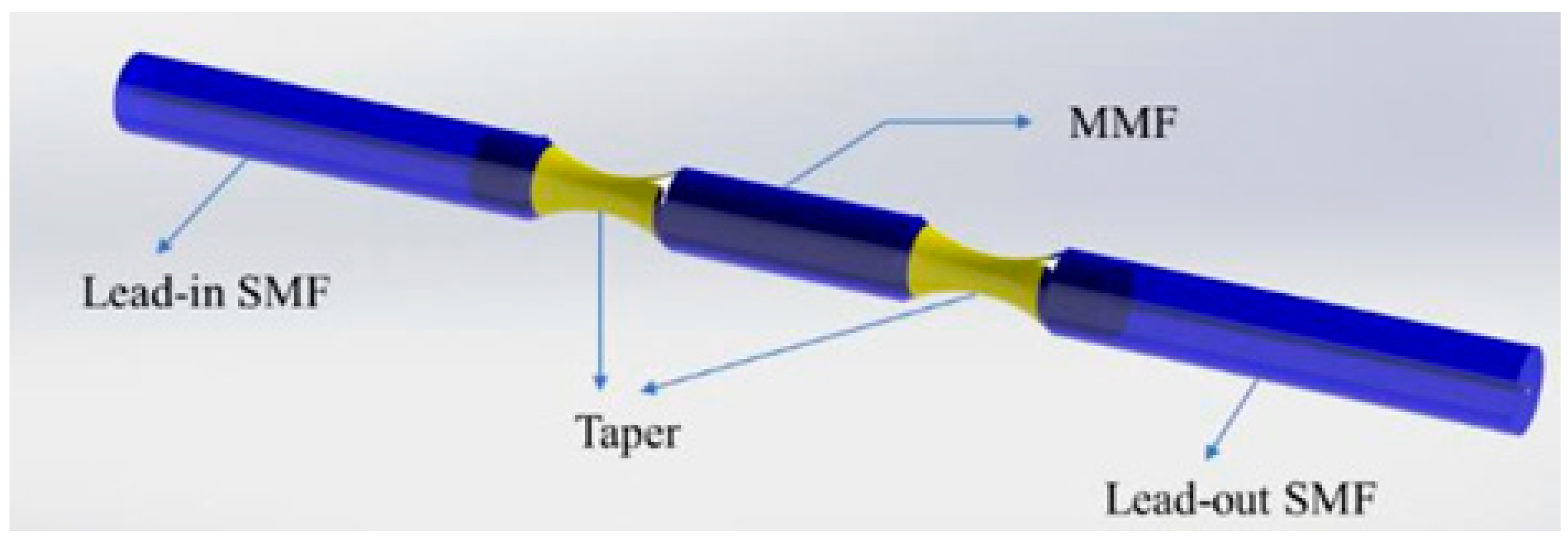

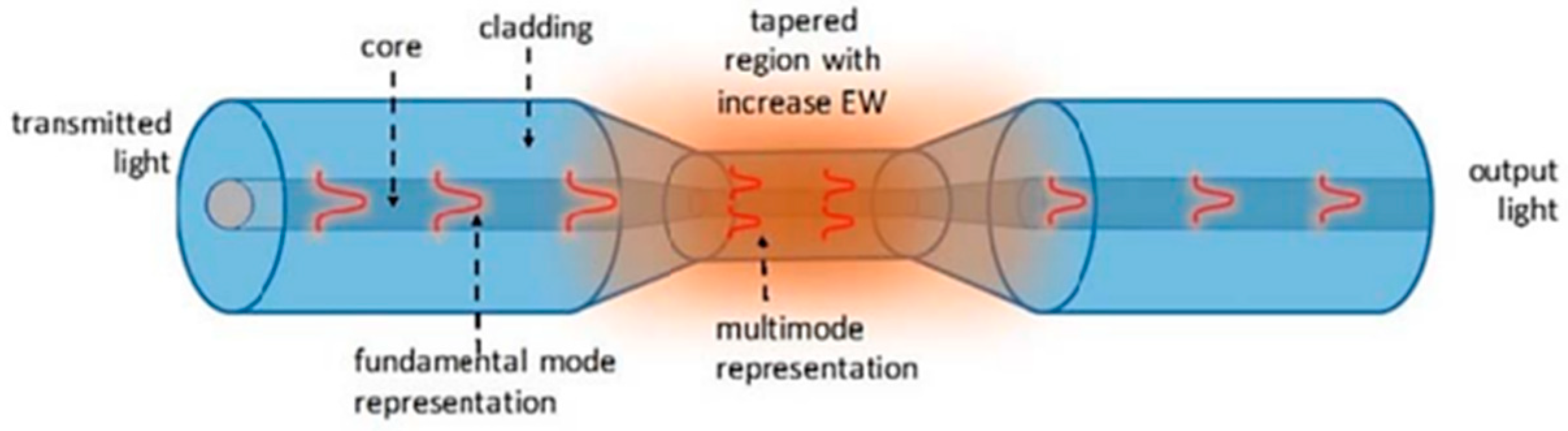

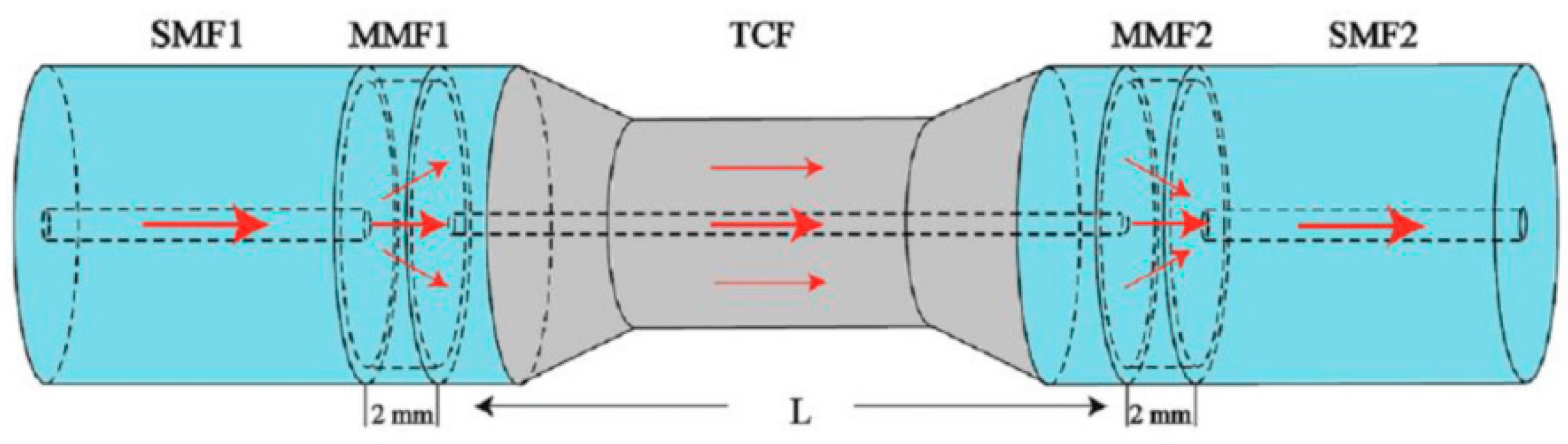

2.1. Multimode Fiber

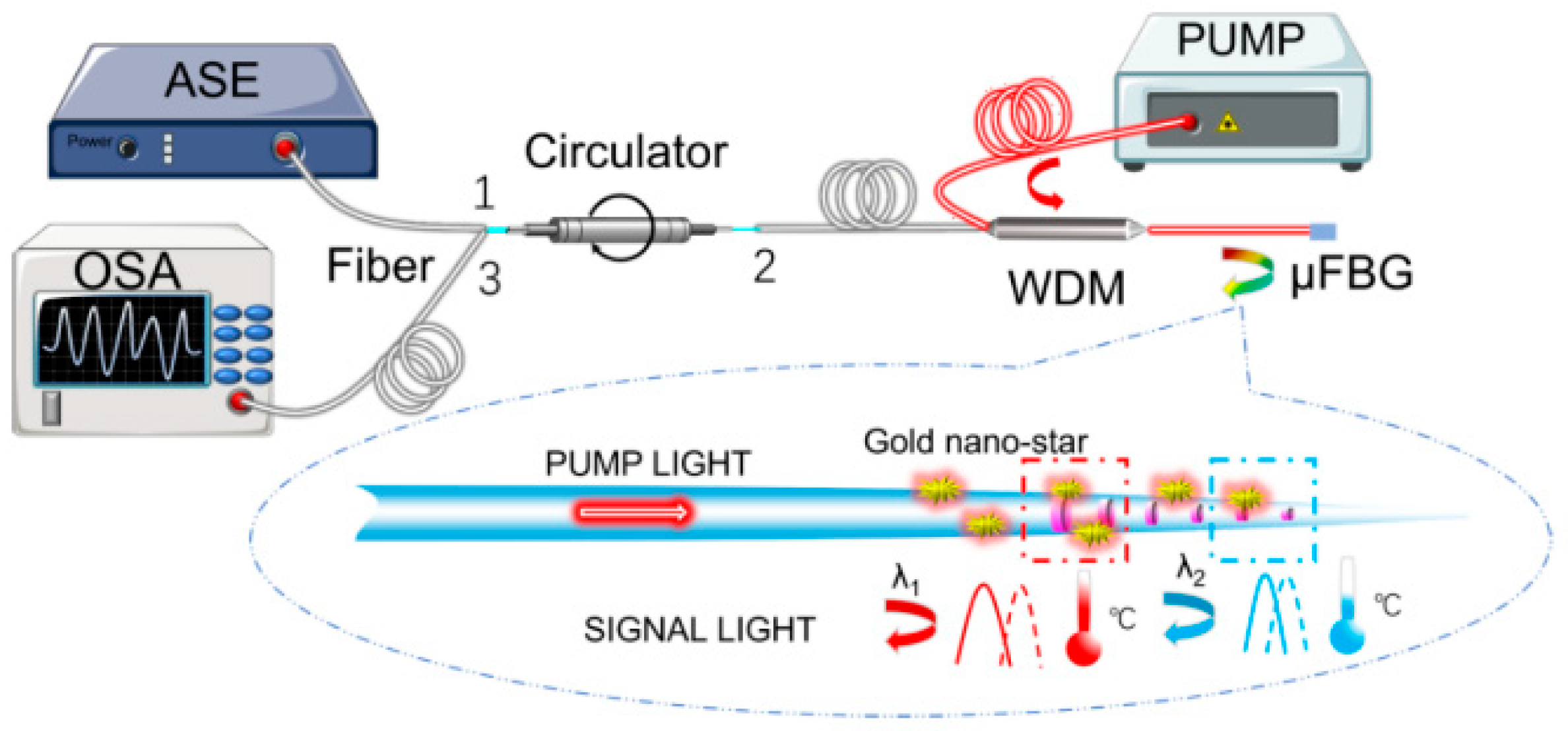

2.2. Fiber Bragg Grating

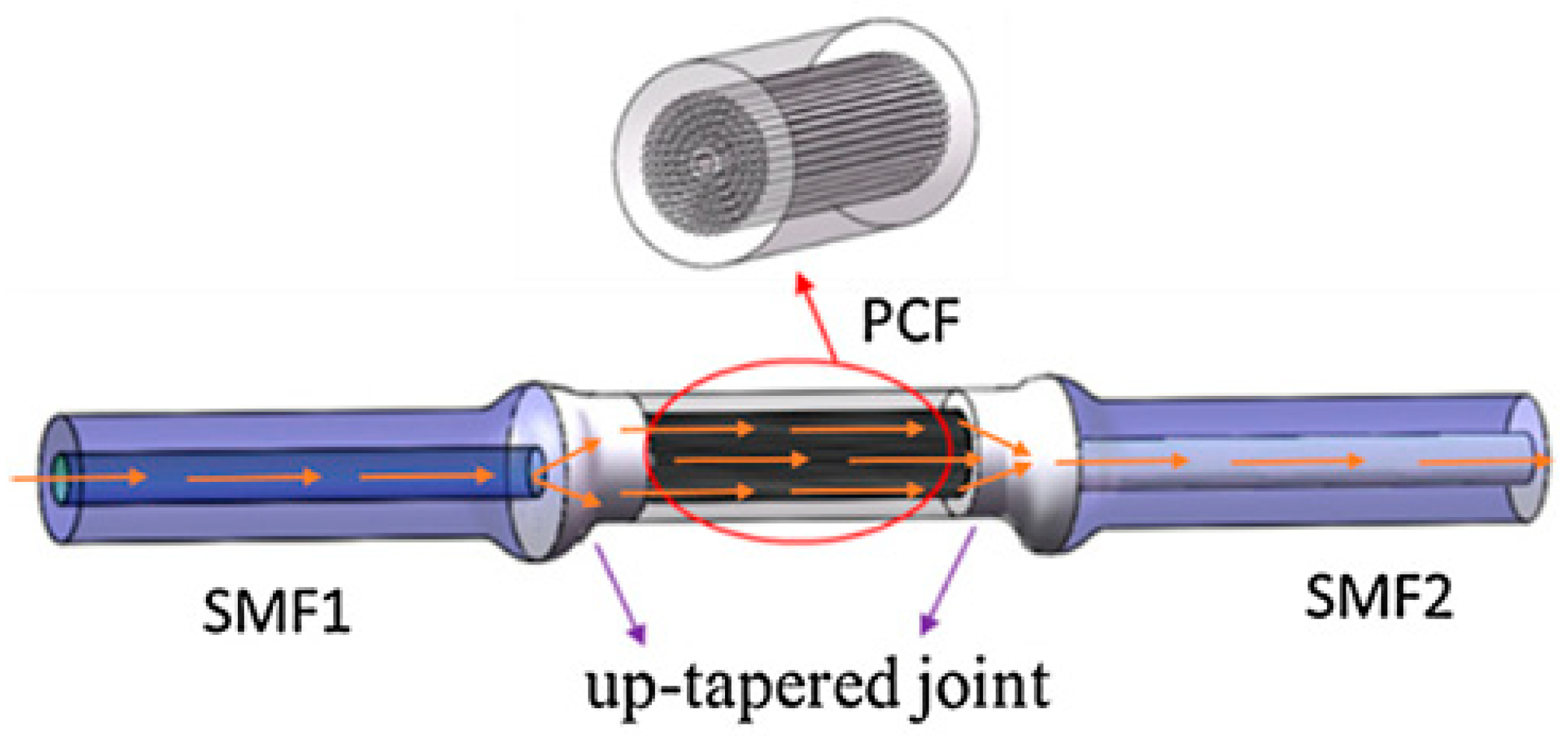

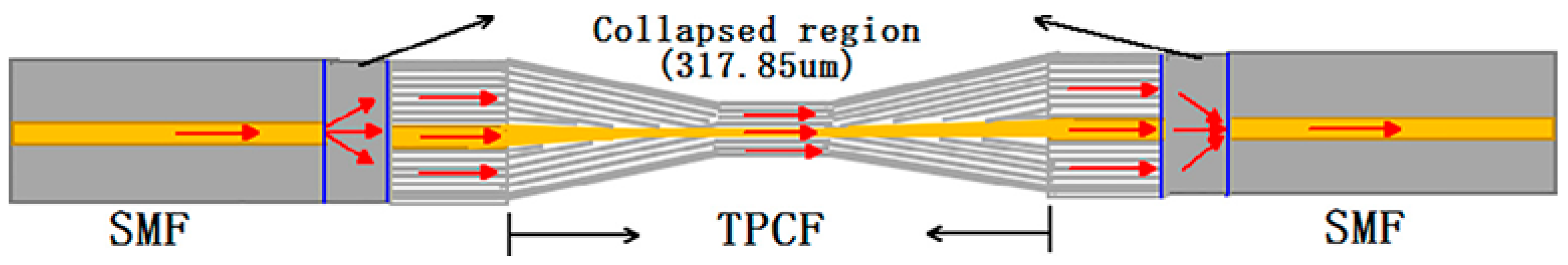

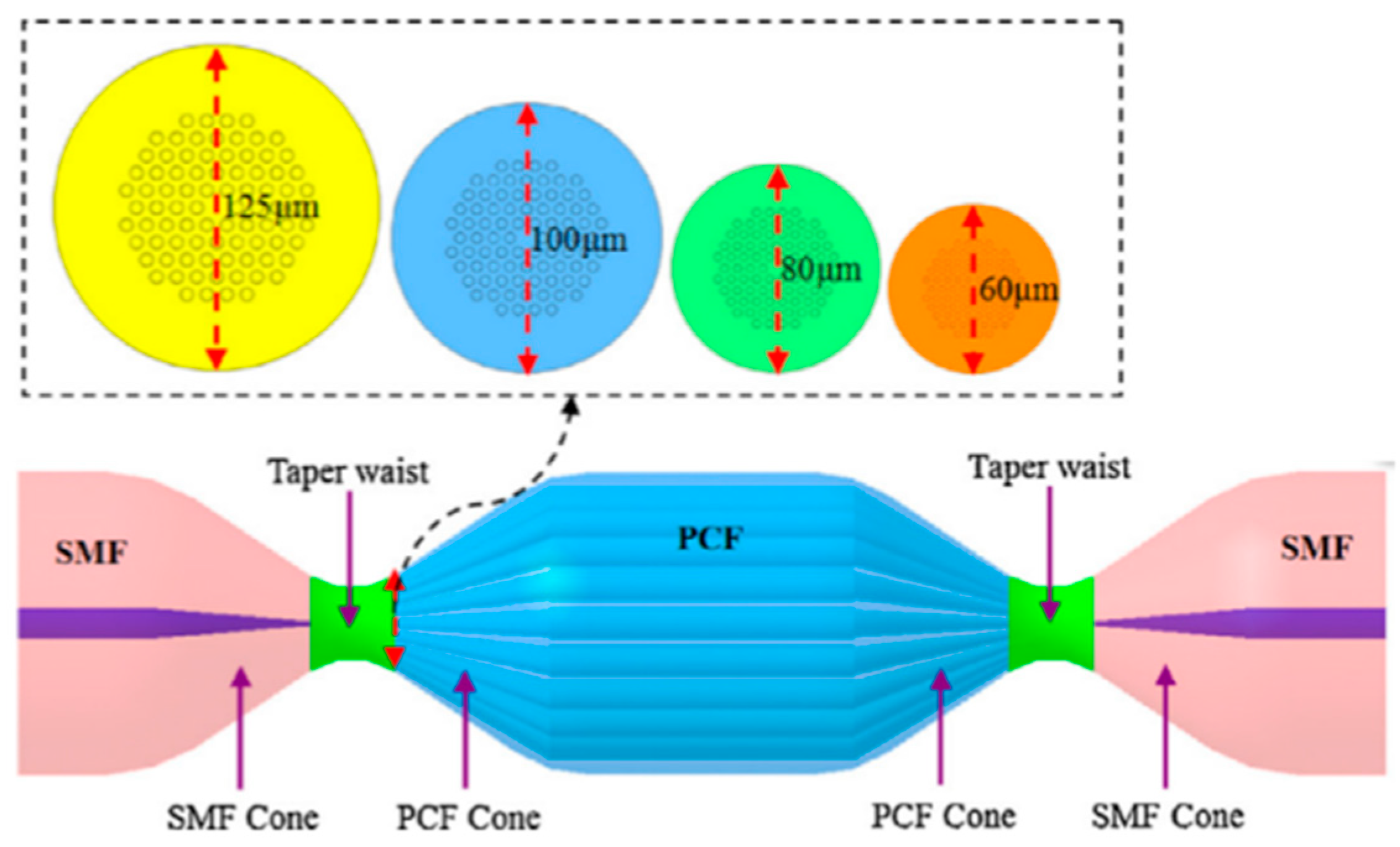

2.3. Photonic Crystal Fiber

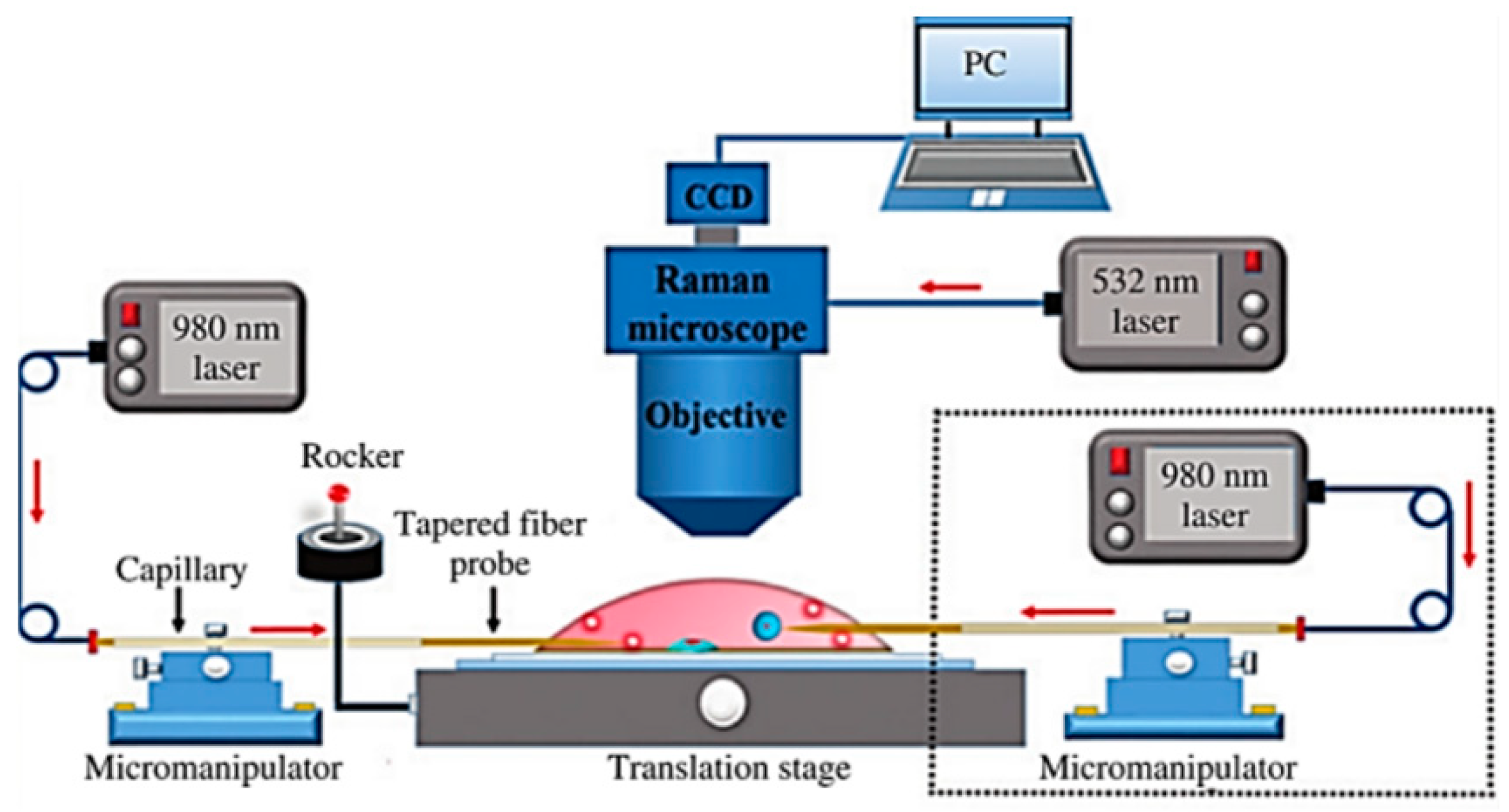

2.4. Optical Tweezers

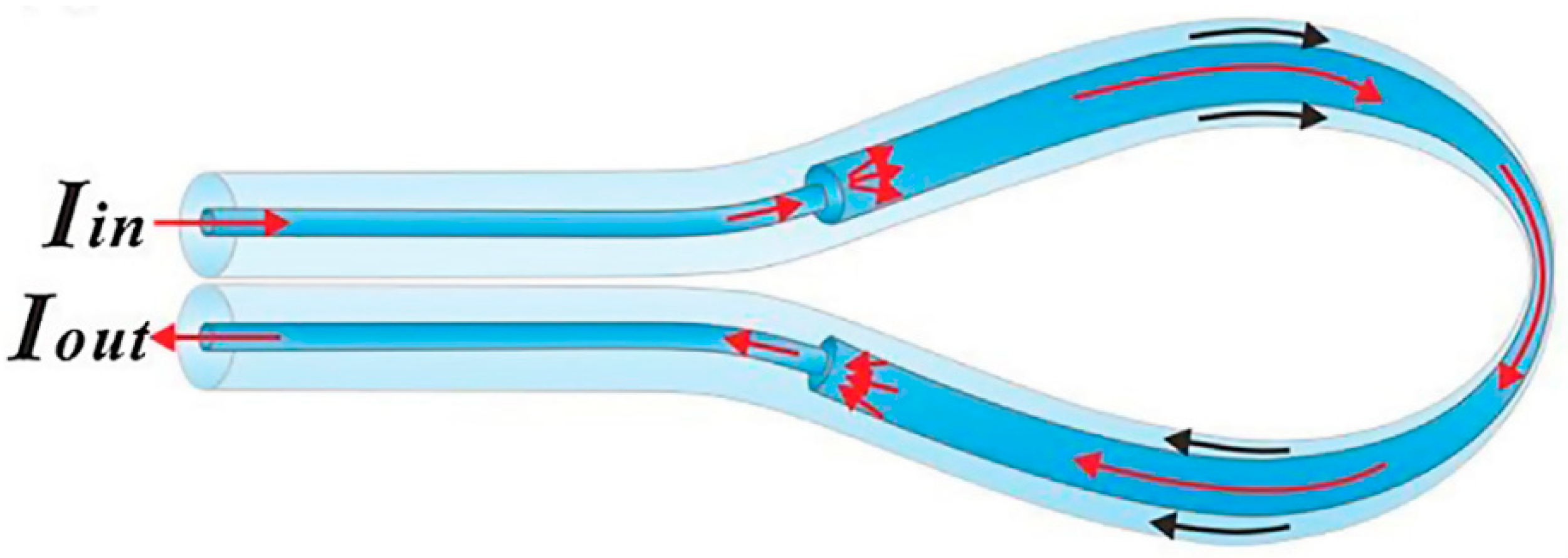

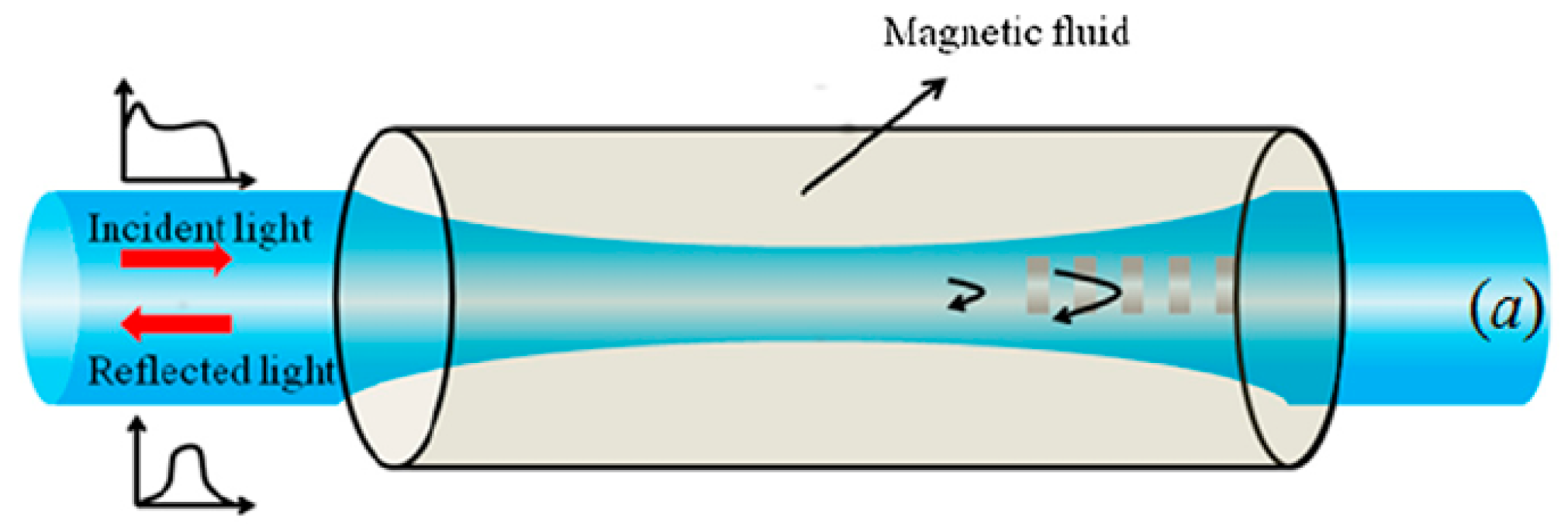

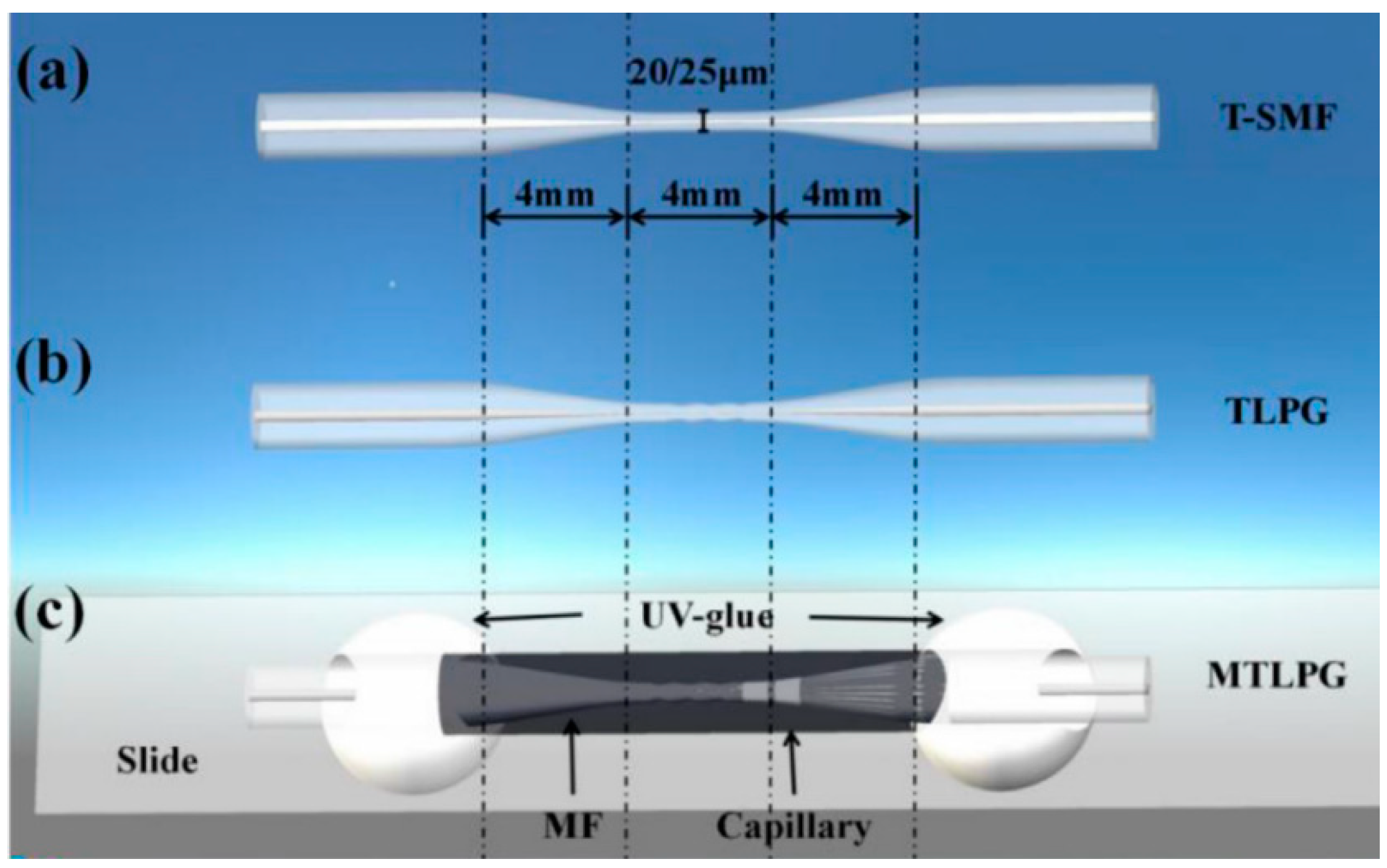

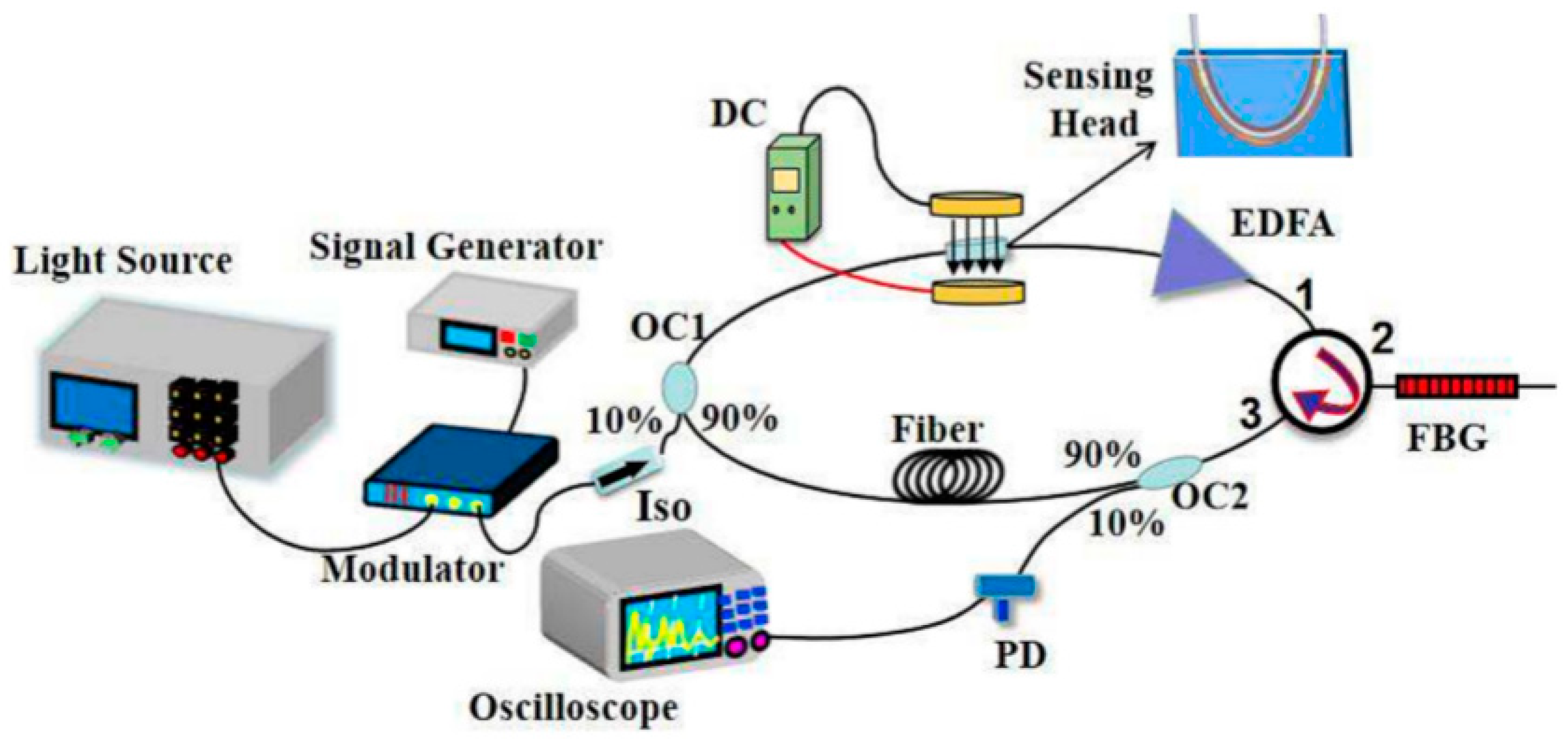

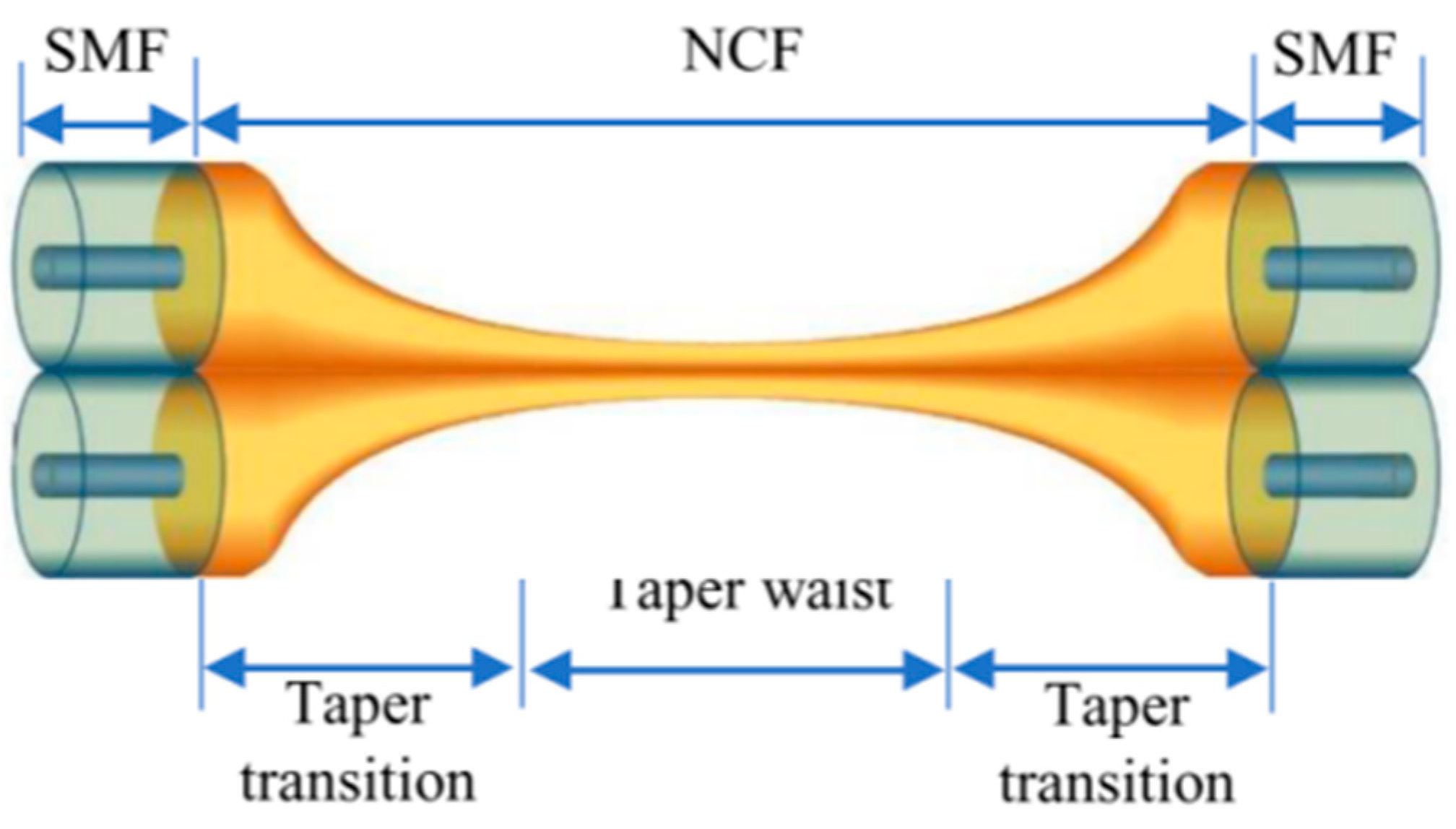

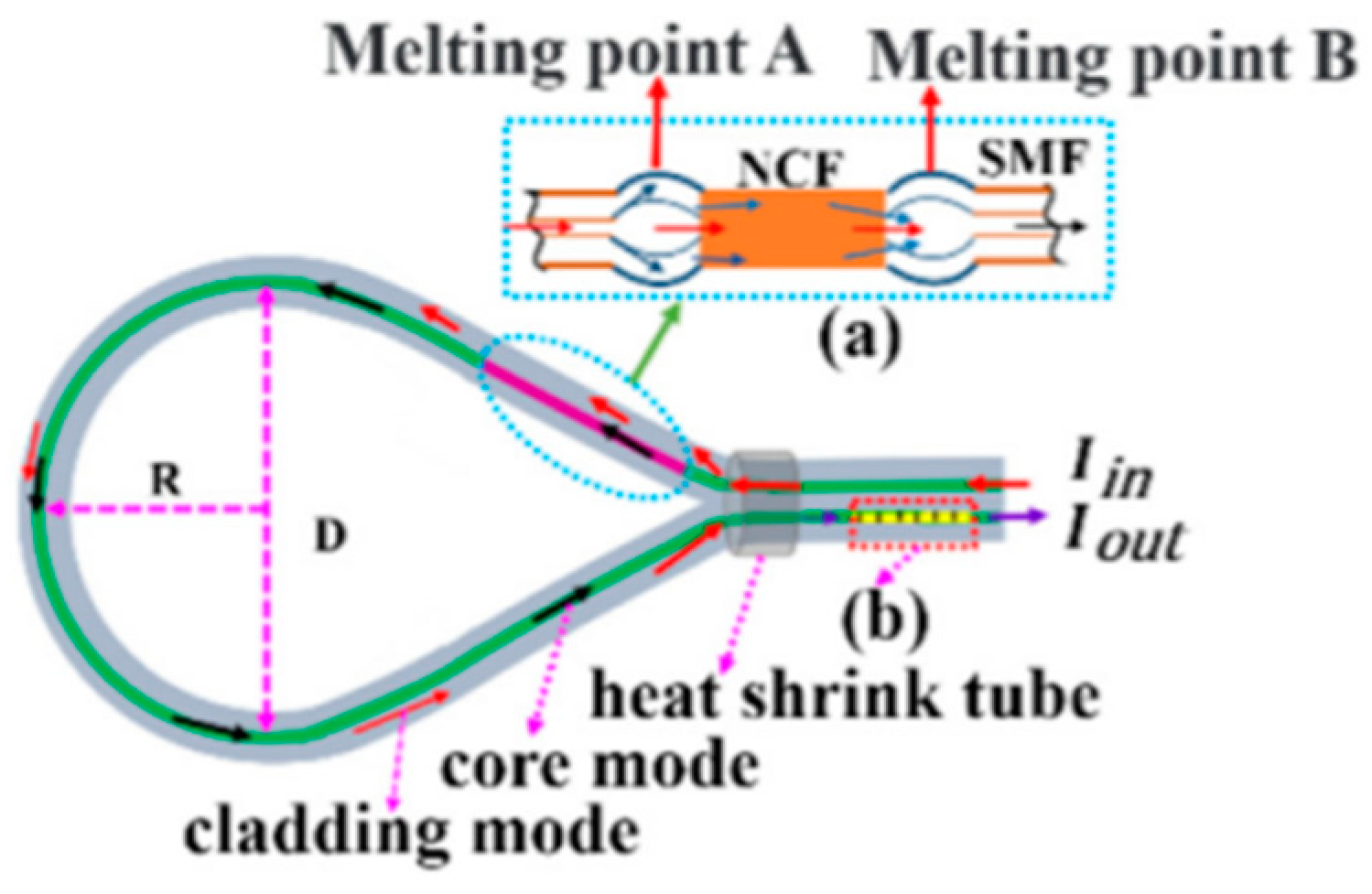

2.5. Fiber Interferometer

2.6. Summary

3. Applications

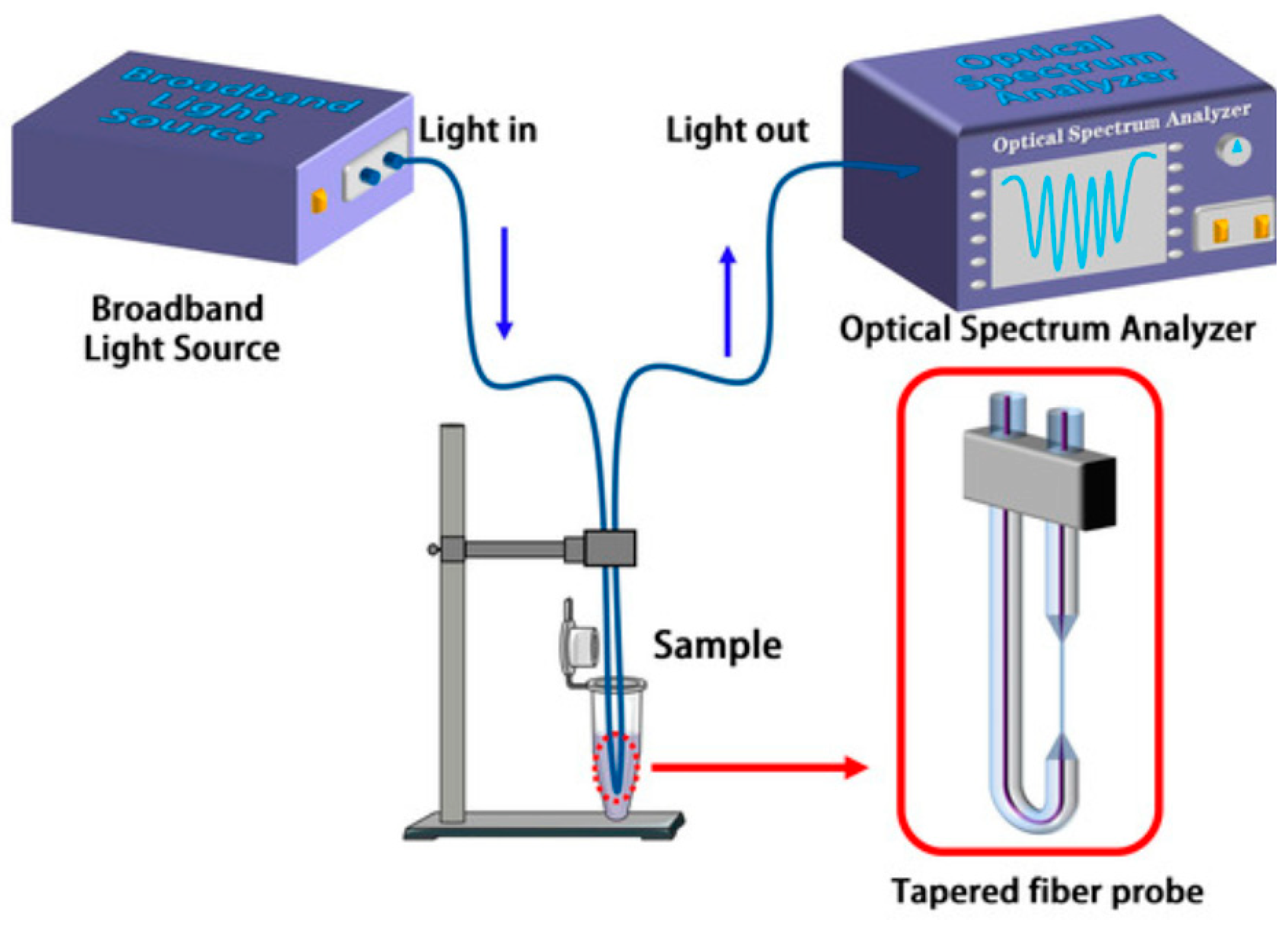

3.1. Biosensing

3.1.1. Biomolecule Concentration Detection

3.1.2. Cellular Realization of Targeted Drug Delivery (Cancer)

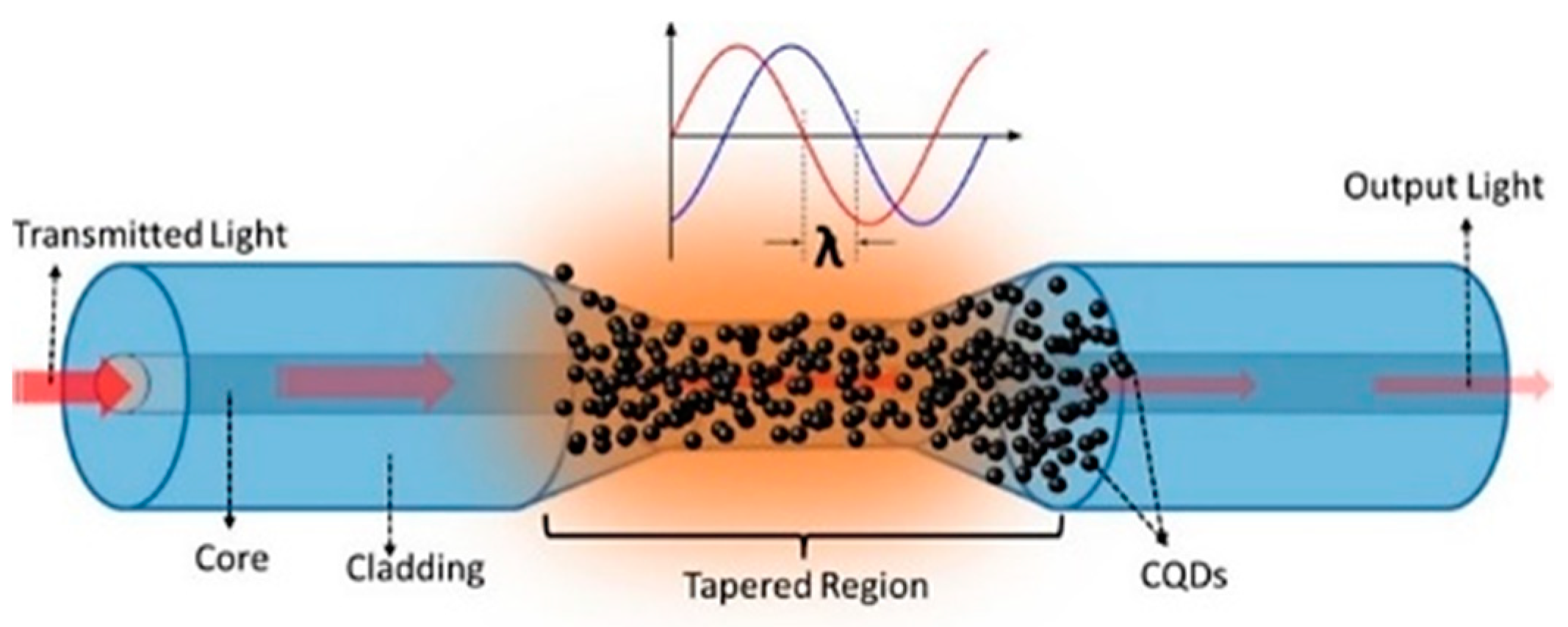

3.1.3. DNA Hybridization

3.2. Environmental Monitoring

3.2.1. Ambient Temperature and Humidity Sensing

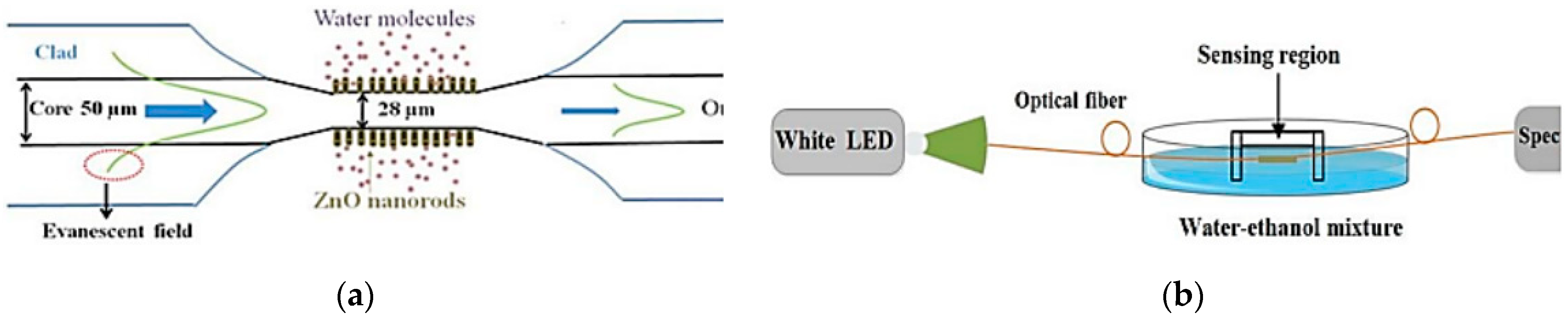

3.2.2. Detection of Ethanol Concentration in Water

3.3. Industrial Monitoring

3.3.1. Radiation Dosimetry

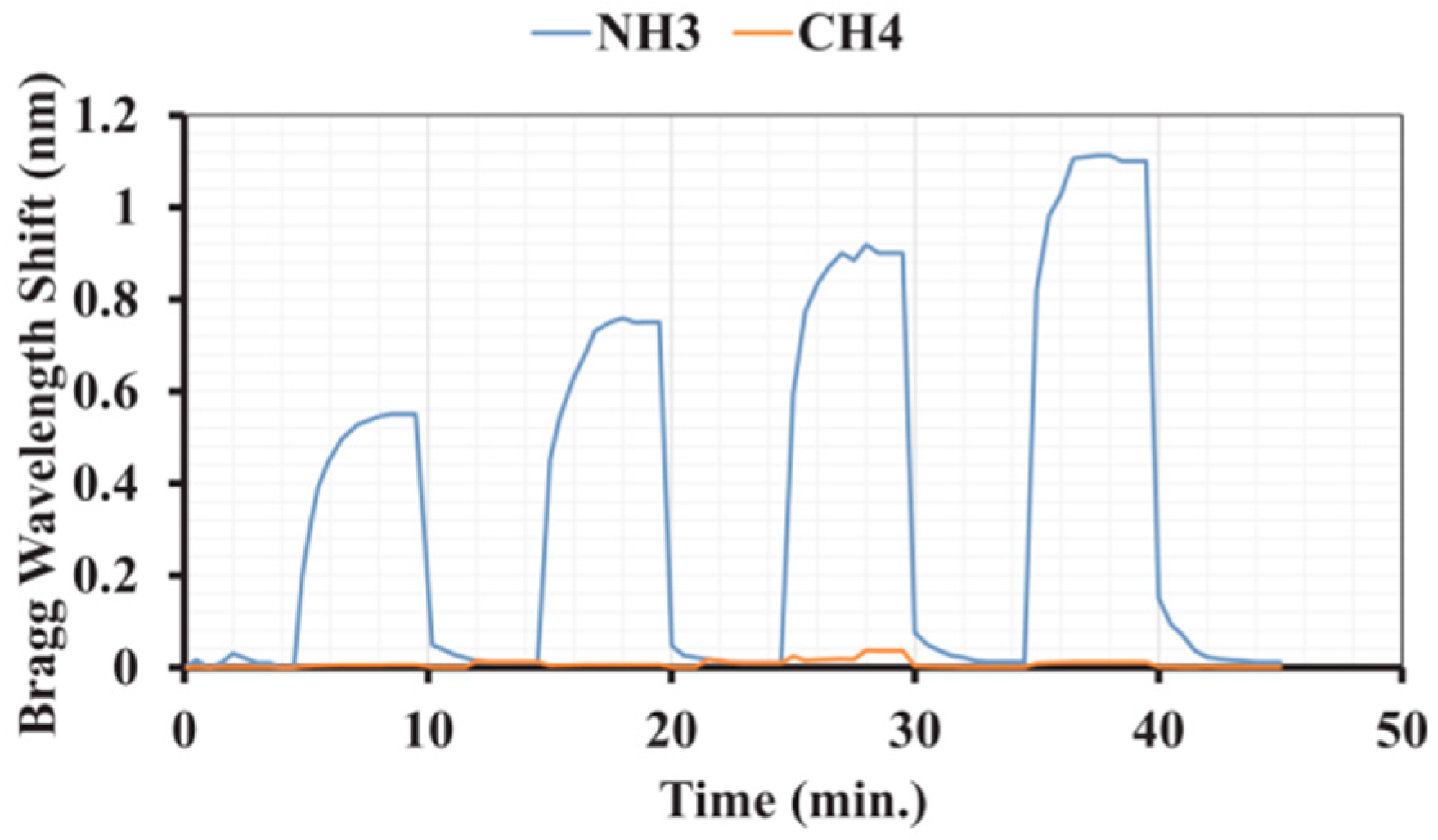

3.3.2. Gas (Ammonia) Leak Detection

3.4. Summary

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Birks, T.A.; Li, Y.W. The shape of fiber tapers. J. Light. Technol. 1992, 10, 432–438. [Google Scholar] [CrossRef]

- Xiong, Y.; Xu, F. Multifunctional integration on optical fiber tips: Challenges and opportunities. Adv. Photonics 2020, 2, 064001. [Google Scholar] [CrossRef]

- Li, G.; Liu, Z.; Feng, J.; Zhou, G.; Huang, X. Pb2+ fiber optic sensor based on smart hydrogel coated Mach–Zehnder interferometer. Opt. Laser Technol. 2022, 145, 107453. [Google Scholar] [CrossRef]

- Liu, Y.; Lin, W.; Zhao, F.; Hu, J.; Chen, J.; Liu, H.; Shum, P.P.; Zhang, X.; Shao, L.-Y. Adaptive Fiber Ring Laser Based on Tapered Polarization Maintaining Fiber in Sagnac Loop for Temperature and Salinity Sensing. Photonics 2023, 10, 599. [Google Scholar] [CrossRef]

- Kumari, A.; Vyas, V.; Kumar, S. Synthesis, characterization, and applications of gold nanoparticles in development of plasmonic optical fiber-based sensors. Nanotechnology 2022, 34, 042001. [Google Scholar] [CrossRef] [PubMed]

- Zhou, H.; Suo, L.; Peng, Y.-P.; Yang, F.; Ren, S.; Chen, N.-K.; Lu, X.; Rahman, B.; Grattan, K. Micro-tapered fiber few-mode interferometers incorporated by molecule self-assembly fiber grating for temperature sensing applications. Photonics 2022, 9, 96. [Google Scholar] [CrossRef]

- Zainuddin, N.H.; Chee, H.Y.; Rashid, S.A.; Ahmad, M.Z.; Zan, Z.; Bakar, M.H.A.; Alresheedi, M.T.; Mahdi, M.A.; Yaacob, M.H. Enhanced detection sensitivity of Leptospira DNA using a post-deposition annealed carbon quantum dots integrated tapered optical fiber biosensor. Opt. Mater. 2023, 141, 113926. [Google Scholar] [CrossRef]

- Roriz, P.; Carvalho, L.; Frazão, O.; Santos, J.L.; Simões, J.A. From conventional sensors to fibre optic sensors for strain and force measurements in biomechanics applications: A review. J. Biomech. 2014, 47, 1251–1261. [Google Scholar] [CrossRef]

- Golden, J.P.; Anderson, G.P.; Rabbany, S.; Ligler, F. An evanescent wave biosensor. II. Fluorescent signal acquisition from tapered fiber optic probes. IEEE Trans. Biomed. Eng. 1994, 41, 585–591. [Google Scholar] [CrossRef]

- Correia, R.; James, S.; Lee, S.; Morgan, S.; Korposh, S. Biomedical application of optical fibre sensors. J. Opt. 2018, 20, 073003. [Google Scholar] [CrossRef]

- Soria, S.; Berneschi, S.; Brenci, M.; Cosi, F.; Conti, G.N.; Pelli, S.; Righini, G.C. Optical microspherical resonators for biomedical sensing. Sensors 2011, 11, 785–805. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Miao, Y.; Liu, B.; Lin, W.; Zhang, H.; Song, B.; Huang, M.; Lin, L. Relative humidity sensor based on S-taper fiber coated with SiO 2 nanoparticles. IEEE Sens. J. 2015, 15, 3424–3428. [Google Scholar] [CrossRef]

- Yu, Y.; Bian, Q.; Lu, Y.; Zhang, X.; Yang, J.; Liang, L. High sensitivity all optical fiber conductivity-temperature-depth (CTD) sensing based on an optical microfiber coupler (OMC). J. Light. Technol. 2018, 37, 2739–2747. [Google Scholar] [CrossRef]

- Bariain, C.; Matías, I.R.; Arregui, F.J.; Lopez-Amo, M. Optical fiber humidity sensor based on a tapered fiber coated with agarose gel. Sens. Actuators B Chem. 2000, 69, 127–131. [Google Scholar] [CrossRef]

- Zhang, W.; Zhuang, W.; Dong, M.; Zhu, L.; Meng, F. Dual-parameter optical fiber sensor for temperature and pressure discrimination featuring cascaded tapered-FBG and ball-EFPI. IEEE Sens. J. 2019, 19, 5645–5652. [Google Scholar] [CrossRef]

- Kim, Y.-C.; Peng, W.; Banerji, S.; Booksh, K.S. Tapered fiber optic surface plasmon resonance sensor for analyses of vapor and liquid phases. Opt. Lett. 2005, 30, 2218–2220. [Google Scholar] [CrossRef]

- Jin, B.; Wang, D. Multimode fiber surface plasmon resonance sensor based on a down–up taper. Opt. Lett. 2022, 47, 5329–5332. [Google Scholar] [CrossRef] [PubMed]

- Sun, G.; Wu, G.; Wang, F.; Tang, R.; Qiu, G. High-stress resistance fiber refractometer based on MMF sandwiched between two SMF half-tapers. IEEE Photonics Technol. Lett. 2016, 28, 1336–1339. [Google Scholar] [CrossRef]

- Fu, X.; Zhang, Y.; Zhou, J.; Li, Q.; Fu, G.; Jin, W.; Bi, W.; Hu, Q. A temperature and strain dual-parameter sensor based on conical four-core fiber combined with a multimode fiber. IEEE Sens. J. 2022, 22, 23990–23996. [Google Scholar] [CrossRef]

- Shen, T.; Gong, A.; Chen, J.; Liu, C.; Liu, X.; Feng, Y.; Duan, S. An investigation on temperature sensor of SDTMS structure with Ag-ZnO/graphene cladding. Opt. Laser Technol. 2022, 153, 108275. [Google Scholar] [CrossRef]

- Deng, L.; Jiang, C.; Hu, C.; Li, L.; Gao, J.; Li, H.; Sun, S.; Liu, C.; Shu, Y. Highly Sensitive Temperature and Gas Pressure Sensor Based on Long-Period Fiber Grating Inscribed in Tapered Two-Mode Fiber and PDMS. IEEE Sens. J. 2023, 23, 15578–15585. [Google Scholar] [CrossRef]

- Liu, Y.; Xie, S.; Zheng, Y.; Yang, X. Simultaneous measurement of refractive index and temperature based on tapered no-core fiber cascaded with a fiber Bragg grating. Results Opt. 2022, 9, 100300. [Google Scholar] [CrossRef]

- Zhu, C.; Huang, S.; Meng, X.; Zhao, Y.; Li, H. Deeply-Tapered Ultrashort Long-Period Fiber Grating and Its Application to Ultrasensitive Transverse-Load Sensor. J. Light. Technol. 2023, 41, 6108–6115. [Google Scholar] [CrossRef]

- Kang, X.; Wang, R.; Jiang, M.; Li, E.; Li, Y.; Yan, X.; Wang, T.; Ren, Z. Polydopamine functionalized graphene oxide for high sensitivity micro-tapered long period fiber grating sensor and its application in detection Co2+ ions. Opt. Fiber Technol. 2022, 68, 102807. [Google Scholar] [CrossRef]

- Fan, R.; Ma, Q.; Li, L.; Zhuo, Y.; Shen, J.; Ren, Z.; Chen, H.; Peng, B. Liquid level and refractive index double-parameter sensor based on tapered photonic crystal fiber. J. Light. Technol. 2020, 38, 3717–3722. [Google Scholar] [CrossRef]

- Abbas, S.K.; Ahmed, S.S. Refractive index sensor based on tapered photonic crystal fiber to determine the performance of different carbonated liquids. J. Opt. 2023. [Google Scholar] [CrossRef]

- Gao, B.; Zhong, H.; Yan, B.; Yue, L.; Dang, Y.; Chen, P.; Jiang, C.; Wang, Z. Combined single/dual fiber optical trapping for flexible particle manipulation. Opt. Lasers Eng. 2023, 161, 107373. [Google Scholar] [CrossRef]

- Deng, H.; Chen, D.; Wang, R.; Li, F.; Luo, Z.; Deng, S.; Yin, J.; Yu, L.; Zhang, W.; Yuan, L. Fiber-integrated optical tweezers for ballistic transport and trapping yeast cells. Nanoscale 2022, 14, 6941–6948. [Google Scholar] [CrossRef]

- Li, X.; Chen, N.; Zhou, X.; Zhang, Y.; Zhao, Y.; Nguyen, L.V.; Ebendorff-Heidepriem, H.; Warren-Smith, S.C. In-situ DNA detection with an interferometric-type optical sensor based on tapered exposed core microstructured optical fiber. Sens. Actuators B Chem. 2022, 351, 130942. [Google Scholar] [CrossRef]

- Zhao, F.; Lin, W.; Hu, J.; Liu, S.; Yu, F.; Chen, X.; Wang, G.; Shum, P.P.; Shao, L. Highly sensitive salinity and temperature measurement based on tapered-SHF MZI fiber laser structure. Meas. Sci. Technol. 2023, 34, 064002. [Google Scholar] [CrossRef]

- Yang, J.; Lv, Y.; Li, P.; Zhang, G.; Lv, M.; Meng, L. Highly sensitive current sensor based on fiber loop Ring-Down spectroscopy and Bent-Annealed taper No-Core fiber surrounded by magnetic fluid. Opt. Laser Technol. 2023, 162, 109260. [Google Scholar] [CrossRef]

- Bai, P.; Gao, Y.; Zhang, H.; Jin, B. A high-sensitivity magnetic field sensor using spindly optical fiber taper. Opt. Fiber Technol. 2023, 78, 103332. [Google Scholar] [CrossRef]

- Zakariyah, S.S.; Conway, P.P.; Hutt, D.A.; Selviah, D.R.; Wang, K.; Baghsiahi, H.; Rygate, J.; Calver, J.; Kandulski, W. Polymer optical waveguide fabrication using laser ablation. In Proceedings of the 2009 11th Electronics Packaging Technology Conference, Singapore, 9–11 December 2009; pp. 936–941. [Google Scholar]

- Xu, Y.; Geng, Y.; Wang, L.; Kumar, A.G.; Fang, L.; Du, Y.; Li, X. Femtosecond laser ablated pyramidal fiber taper-SERS probe with laser-induced silver nanostructures. J. Phys. D Appl. Phys. 2018, 51, 285104. [Google Scholar] [CrossRef]

- Brambilla, G.; Xu, F.; Horak, P.; Jung, Y.; Koizumi, F.; Sessions, N.P.; Koukharenko, E.; Feng, X.; Murugan, G.S.; Wilkinson, J.S. Optical fiber nanowires and microwires: Fabrication and applications. Adv. Opt. Photonics 2009, 1, 107–161. [Google Scholar] [CrossRef]

- Pang, S.; Shao, X.; Li, W.; Chen, X.; Gong, S. Dynamic characteristics and mechanisms of compressible metallic vapor plume behaviors in transient keyhole during deep penetration fiber laser welding. Appl. Phys. A 2016, 122, 702. [Google Scholar] [CrossRef]

- Pricking, S.; Giessen, H. Tapering fibers with complex shape. Opt. Express 2010, 18, 3426–3437. [Google Scholar] [CrossRef]

- Felipe, A.; Espíndola, G.; Kalinowski, H.J.; Lima, J.A.; Paterno, A.S. Stepwise fabrication of arbitrary fiber optic tapers. Opt. Express 2012, 20, 19893–19904. [Google Scholar] [CrossRef] [PubMed]

- Harun, S.W.; Lim, K.; Tio, C.; Dimyati, K.; Ahmad, H. Theoretical analysis and fabrication of tapered fiber. Optik 2013, 124, 538–543. [Google Scholar] [CrossRef]

- Korposh, S.; James, S.W.; Lee, S.-W.; Tatam, R.P. Tapered optical fibre sensors: Current trends and future perspectives. Sensors 2019, 19, 2294. [Google Scholar] [CrossRef]

- Shabaneh, A.; Girei, S.; Arasu, P.; Rahman, W.; Bakar, A.; Sadek, A.; Lim, H.; Huang, N.; Yaacob, M. Reflectance response of tapered optical fiber coated with graphene oxide nanostructured thin film for aqueous ethanol sensing. Opt. Commun. 2014, 331, 320–324. [Google Scholar] [CrossRef]

- Ibrahim, S.; Rahman, N.; Bakar, M.A.; Girei, S.; Yaacob, M.; Ahmad, H.; Mahdi, M. Room temperature ammonia sensing using tapered multimode fiber coated with polyaniline nanofibers. Opt. Express 2015, 23, 2837–2845. [Google Scholar] [CrossRef] [PubMed]

- Qiu, H.; Gao, S.; Chen, P.; Li, Z.; Liu, X.; Zhang, C.; Xu, Y.; Jiang, S.; Yang, C.; Huo, Y. Evanescent wave absorption sensor based on tapered multimode fiber coated with monolayer graphene film. Opt. Commun. 2016, 366, 275–281. [Google Scholar] [CrossRef]

- Chauhan, M.; Singh, V.K. Tapered MMF sensor fabrication using SnO2-NPs for alcohol sensing application. Opt. Fiber Technol. 2023, 75, 103167. [Google Scholar] [CrossRef]

- Gao, R.; Wang, H.; Zhu, D.; Fan, G.; Yan, H.; Wang, P.; Liu, Y.; Wang, Y.; Liu, W.; Song, L. Acoustic frequency vibration sensor based on tapered SMS fiber structure. Sens. Actuators A Phys. 2018, 271, 243–250. [Google Scholar] [CrossRef]

- Wang, P.; Brambilla, G.; Ding, M.; Semenova, Y.; Wu, Q.; Farrell, G. High-sensitivity, evanescent field refractometric sensor based on a tapered, multimode fiber interference. Opt. Lett. 2011, 36, 2233–2235. [Google Scholar] [CrossRef]

- André, R.M.; Biazoli, C.R.; Silva, S.O.; Marques, M.B.; Cordeiro, C.M.; Frazão, O. Multimode interference in tapered single mode-multimode-single mode fiber structures for strain sensing applications. In Proceedings of the OFS2012 22nd International Conference on Optical Fiber Sensors, Beijing, China, 15–19 October 2012; pp. 576–579. [Google Scholar]

- Zhao, Y.; Cai, L.; Hu, H.-F. Fiber-optic refractive index sensor based on multi-tapered SMS fiber structure. IEEE Sens. J. 2015, 15, 6348–6353. [Google Scholar] [CrossRef]

- Yang, B.; Niu, Y.; Yang, B.; Hu, Y.; Dai, L.; Yin, Y.; Ding, M. High sensitivity balloon-like refractometric sensor based on singlemode-tapered multimode-singlemode fiber. Sens. Actuators A Phys. 2018, 281, 42–47. [Google Scholar] [CrossRef]

- Song, D.; Chai, Q.; Liu, Y.; Jiang, Y.; Zhang, J.; Sun, W.; Yuan, L.; Canning, J.; Peng, G.-D. A simultaneous strain and temperature sensing module based on FBG-in-SMS. Meas. Sci. Technol. 2014, 25, 055205. [Google Scholar] [CrossRef]

- Wang, J.; Wang, L.; Su, X.; Xiao, R.; Cheng, H. Temperature, stress, refractive index and humidity multi parameter highly integrated optical fiber sensor. Opt. Laser Technol. 2022, 152, 108086. [Google Scholar] [CrossRef]

- Tian, K.; Xin, Y.; Yang, W.; Geng, T.; Ren, J.; Fan, Y.-X.; Farrell, G.; Lewis, E.; Wang, P. A curvature sensor based on twisted single-mode–multimode–single-mode hybrid optical fiber structure. J. Light. Technol. 2017, 35, 1725–1731. [Google Scholar] [CrossRef]

- Li, S.; Nezami, M.S.; Mishra, S.; Liboiron-Ladouceur, O. Spectral-dependent electronic-photonic modeling of high-speed VCSEL-MMF links for optimized launch conditions. Opt. Express 2021, 29, 2738–2756. [Google Scholar] [CrossRef]

- Yang, Q.; Hu, D.; Li, Z.; Xu, Z.; Ran, Y.; Guan, B.-o. Assembly tapered fiber Bragg grating tip with gold nanostars for heat generation and gradient temperature sensing. Opt. Laser Technol. 2024, 175, 110759. [Google Scholar] [CrossRef]

- Zhao, X.; Zhang, Y.; Zhang, W.; Li, Z.; Kong, L.; Yu, L.; Ge, J.; Yan, T. Ultra-high sensitivity and temperature-compensated Fabry–Perot strain sensor based on tapered FBG. Opt. Laser Technol. 2020, 124, 105997. [Google Scholar] [CrossRef]

- Li, P.; Yan, H.; Xie, Z.; Li, Y.; Zhao, X. An intensity-modulated and large bandwidth magnetic field sensor based on a tapered fiber Bragg grating. Opt. Laser Technol. 2020, 125, 105996. [Google Scholar] [CrossRef]

- Mishra, V.; Singh, N.; Tiwari, U.; Kapur, P. Fiber grating sensors in medicine: Current and emerging applications. Sens. Actuators A Phys. 2011, 167, 279–290. [Google Scholar] [CrossRef]

- Bock, W.J.; Chen, J.; Mikulic, P.; Eftimov, T. A novel fiber-optic tapered long-period grating sensor for pressure monitoring. IEEE Trans. Instrum. Meas. 2007, 56, 1176–1180. [Google Scholar] [CrossRef]

- Lee, C.-L.; Weng, Z.-Y.; Lin, C.-J.; Lin, Y. Leakage coupling of ultrasensitive periodical silica thin-film long-period grating coated on tapered fiber. Opt. Lett. 2010, 35, 4172–4174. [Google Scholar] [CrossRef] [PubMed]

- Shao, F.; Li, S.; Lu, L.; Kuai, Y.; Cao, Z.; Xu, F.; Liu, Y.; Xie, F.; Xie, K.; Yu, B. High sensitivity and dual parameters micro-tapered-LPG sensor. Opt. Lasers Eng. 2023, 164, 107498. [Google Scholar] [CrossRef]

- Lee, S.-L.; Kim, J.; Choi, S.; Han, J.; Seo, G.; Lee, Y.W. Fiber-optic label-free biosensor for SARS-CoV-2 spike protein detection using biofunctionalized long-period fiber grating. Talanta 2021, 235, 122801. [Google Scholar] [CrossRef]

- Dudley, J.M.; Taylor, J.R. Ten years of nonlinear optics in photonic crystal fibre. Nat. Photonics 2009, 3, 85–90. [Google Scholar] [CrossRef]

- Frazao, O.; Santos, J.L.; Araujo, F.M.; Ferreira, L.A. Optical sensing with photonic crystal fibers. Laser Photonics Rev. 2008, 2, 449–459. [Google Scholar] [CrossRef]

- Wang, H.; Tong, K.; Cui, W.; Li, Z. Study of temperature measurement with one-dimensional photonic crystal. In Proceedings of the Lasers in Material Processing and Manufacturing III, Beijing, China, 11–15 November 2007; pp. 348–353. [Google Scholar]

- Zhao, Y.; Li, X.-G.; Cai, L.; Yang, Y. Refractive index sensing based on photonic crystal fiber interferometer structure with up-tapered joints. Sens. Actuators B Chem. 2015, 221, 406–410. [Google Scholar] [CrossRef]

- Fan, R.; Li, L.; Zhuo, Y.; Lv, X.; Ren, Z.; Shen, J.; Peng, B. Practical research on photonic crystal fiber micro-strain sensor. Opt. Fiber Technol. 2019, 52, 101959. [Google Scholar] [CrossRef]

- Dass, S.; Dash, J.N.; Jha, R. Intensity modulated SMF cascaded tapers with a hollow core PCF based microcavity for curvature sensing. J. Opt. 2016, 18, 035006. [Google Scholar] [CrossRef]

- Tu, T.; Pang, F.; Zhu, S.; Cheng, J.; Liu, H.; Wen, J.; Wang, T. Excitation of Bloch surface wave on tapered fiber coated with one-dimensional photonic crystal for refractive index sensing. Opt. Express 2017, 25, 9019–9027. [Google Scholar] [CrossRef]

- Li, X.; Yu, Q.; Zhou, X.; Zhang, Y.; Lv, R.; Zhao, Y. Magnetic sensing technology of fiber optic interferometer based on magnetic fluid: A review. Measurement 2023, 216, 112929. [Google Scholar] [CrossRef]

- Benazza, A.; Beffara, F.; Auguste, J.-L.; Olivo, M.; Dinish, U.; Humbert, G. Reliable and easy-to-use SERS spectroscopy probe using a tapered opto-fluidic photonic crystal fiber. Opt. Express 2024, 32, 3440–3450. [Google Scholar] [CrossRef] [PubMed]

- Zhao, X.; Zhao, N.; Shi, Y.; Xin, H.; Li, B. Optical fiber tweezers: A versatile tool for optical trapping and manipulation. Micromachines 2020, 11, 114. [Google Scholar] [CrossRef]

- Taha, B.A.; Ali, N.; Sapiee, N.M.; Fadhel, M.M.; Mat Yeh, R.M.; Bachok, N.N.; Al Mashhadany, Y.; Arsad, N. Comprehensive review tapered optical fiber configurations for sensing application: Trend and challenges. Biosensors 2021, 11, 253. [Google Scholar] [CrossRef]

- Huang, J.; Liu, X.; Zhang, Y.; Li, B. Optical trapping and orientation of Escherichia coli cells using two tapered fiber probes. Photonics Res. 2015, 3, 308–312. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, T.; Zhang, Y.; Tang, X.; Liu, P.; Zhang, Y.; Yang, X.; Zhang, J.; Yang, J.; Yuan, L. Single fiber dual-functionality optical tweezers based on graded-index multimode fiber. Chin. Opt. Lett. 2018, 16, 053501. [Google Scholar]

- Wang, T.; Jiang, J.; Liu, K.; Wang, S.; Zhang, Y.; Niu, P.; Liu, T. Pendulum-style adjustment of captured particles with fiber tweezers based on asymmetrical fiber tip for CARS system. In Proceedings of the Advanced Sensor Systems and Applications X, Online, 11–16 October 2020; pp. 24–29. [Google Scholar]

- Rong, Q.; Wang, Y.; Shao, Z.; Qiao, X. Large diameter fiber-optics tweezers for escherichia coli bacteria manipulation. IEEE J. Sel. Top. Quantum Electron. 2018, 25, 1–7. [Google Scholar] [CrossRef]

- Asadollahbaik, A.; Thiele, S.; Weber, K.; Kumar, A.; Drozella, J.; Sterl, F.; Herkommer, A.M.; Giessen, H.; Fick, J. Highly efficient dual-fiber optical trapping with 3D printed diffractive fresnel lenses. Acs Photonics 2019, 7, 88–97. [Google Scholar] [CrossRef]

- Fooladi, E.; Sadeghi, M.; Adelpour, Z.; Bahadori-Jahromi, F. Performance improvement of a plasmonic tapered twin–core fiber optical tweezers. Optik 2021, 245, 167656. [Google Scholar] [CrossRef]

- Novotny, L.; Bian, R.X.; Xie, X.S. Theory of nanometric optical tweezers. Phys. Rev. Lett. 1997, 79, 645. [Google Scholar] [CrossRef]

- Kaya, M.; Sahay, P.; Wang, C. Reproducibly reversible fiber loop ringdown water sensor embedded in concrete and grout for water monitoring. Sens. Actuators B Chem. 2013, 176, 803–810. [Google Scholar] [CrossRef]

- Wang, C. Fiber loop ringdown—A time-domain sensing technique for multi-function fiber optic sensor platforms: Current status and design perspectives. Sensors 2009, 9, 7595–7621. [Google Scholar] [CrossRef] [PubMed]

- Yu, D.; Humar, M.; Meserve, K.; Bailey, R.C.; Chormaic, S.N.; Vollmer, F. Whispering-gallery-mode sensors for biological and physical sensing. Nat. Rev. Methods Primers 2021, 1, 83. [Google Scholar] [CrossRef]

- Li, X.; Wang, X.; Niu, P.; Zhao, J.; Zhang, C.; Gu, E. Refractive index measurement using OTDR-based ring-down technique with S fiber taper. Opt. Commun. 2019, 446, 186–190. [Google Scholar] [CrossRef]

- Tian, J.; Yang, L.; Qin, C.; Wu, T.; Wang, J.; Zhang, Z.; Li, K.; Copner, N.J. Refractive index sensing based on chaotic correlation fiber loop ring down system using tapered fiber. IEEE Sens. J. 2019, 20, 4215–4220. [Google Scholar] [CrossRef]

- Wang, F.; Li, H.; Wang, X.; Ma, T.; Yu, K.; Lu, Y.; Zhang, L.; Liu, Y. Temperature and curvature measurement based on low cavity loss FLRD technology. IEEE Sens. J. 2021, 22, 2221–2228. [Google Scholar] [CrossRef]

- Cheng, C.; Chen, J.; Chen, Z.; Ou, Y. Large-dynamic-range fiber loop ringdown strain sensor using Frequency-shifted Interferometry. Opt. Quantum Electron. 2021, 53, 318. [Google Scholar] [CrossRef]

- Chen, Z.; Cheng, C.; Ou, Y.; Yang, Z.; Chen, J.; Lv, H. Multipoint strain sensing system based on fiber loop ringdown and frequency-shifted interferometry. In Proceedings of the AOPC 2019: Optical Sensing and Imaging Technology, Beijing, China, 7–9 July 2019; pp. 177–182. [Google Scholar]

- Jiang, Q.; Yang, L.; Guo, Y.; Wang, J.; Xue, P.; Liu, J. Multi-channel chaotic cross-correlation fiber loop ring down sensing. Opt. Commun. 2023, 540, 129502. [Google Scholar] [CrossRef]

- Lechuga, L.M. Optical biosensors. Compr. Anal. Chem. 2005, 44, 209–250. [Google Scholar]

- Wang, Q.; Kong, L.; Dang, Y.; Xia, F.; Zhang, Y.; Zhao, Y.; Hu, H.; Li, J. High sensitivity refractive index sensor based on splicing points tapered SMF-PCF-SMF structure Mach–Zehnder mode interferometer. Sens. Actuators B Chem. 2016, 225, 213–220. [Google Scholar] [CrossRef]

- Pawar, D.; Kale, S. Birefringence manipulation in tapered polarization-maintaining photonic crystal fiber Mach–Zehnder interferometer for refractive index sensing. Sens. Actuators A Phys. 2016, 252, 180–184. [Google Scholar] [CrossRef]

- Yang, J.; Jiang, L.; Wang, S.; Li, B.; Wang, M.; Xiao, H.; Lu, Y.; Tsai, H. High sensitivity of taper-based Mach–Zehnder interferometer embedded in a thinned optical fiber for refractive index sensing. Appl. Opt. 2011, 50, 5503–5507. [Google Scholar] [CrossRef] [PubMed]

- Wang, F.; Pang, K.; Ma, T.; Wang, X.; Liu, Y. Folded-tapered multimode-no-core fiber sensor for simultaneous measurement of refractive index and temperature. Opt. Laser Technol. 2020, 130, 106333. [Google Scholar] [CrossRef]

- Su, H.; Zhang, Y.; Ma, K.; Yi, G.; Zhao, Y.; Yu, C. Slight-offset tapered multimode fiber with high sensitivity for low refractive index range. IEEE Sens. J. 2020, 20, 9849–9855. [Google Scholar] [CrossRef]

- Hu, H.; Song, X.; Han, Q.; Chang, P.; Zhang, J.; Liu, K.; Du, Y.; Wang, H.; Liu, T. High sensitivity fiber optic SPR refractive index sensor based on multimode-no-core-multimode structure. IEEE Sens. J. 2019, 20, 2967–2975. [Google Scholar] [CrossRef]

- Ayupova, T.; Shaimerdenova, M.; Tosi, D. Shallow-tapered chirped fiber Bragg grating sensors for dual refractive index and temperature sensing. Sensors 2021, 21, 3635. [Google Scholar] [CrossRef]

- Jin, X.; Sun, C.; Duan, S.; Liu, W.; Li, G.; Zhang, S.; Chen, X.; Zhao, L.; Lu, C.; Yang, X. High strain sensitivity temperature sensor based on a secondary modulated tapered long period fiber grating. IEEE Photonics J. 2019, 11, 1–8. [Google Scholar] [CrossRef]

- Song, B.; Jin, C.; Wang, B.; Wu, J.; Liu, B.; Lin, W.; Huang, W.; Duan, S.; Qiao, M. Hydrophobin HGFI assisted immunobiologic sensor based on a cascaded taper integrated ultra-long-period fiber grating. Biomed. Opt. Express 2021, 12, 2790–2799. [Google Scholar] [CrossRef] [PubMed]

- Minkovich, V.P.; Sotsky, A.B. Tapered photonic crystal fibers coated with ultra-thin films for highly sensitive bio-chemical sensing. J. Eur. Opt. Soc. -Rapid Publ. 2019, 15, 7. [Google Scholar] [CrossRef]

- Wu, Y.; Liu, B.; Wang, J.; Wu, J.; Mao, Y.; Ren, J.; Zhao, L.; Sun, T.; Nan, T.; Han, Y. A novel temperature insensitive refractive index sensor based on dual photonic crystal fiber. Optik 2021, 226, 165495. [Google Scholar] [CrossRef]

- Chen, W.W.; Zhao, C.L.; Wang, Z.K.; Mao, B.N. Curvature sensor based on SMF taper in fiber loop ring down system. Opt. Fiber Technol. 2019, 52, 101977. [Google Scholar] [CrossRef]

- Ma, J.; Wu, S.; Cheng, H.; Yang, X.; Wang, S.; Lu, P. Sensitivity-enhanced temperature sensor based on encapsulated S-taper fiber Modal interferometer. Opt. Laser Technol. 2021, 139, 106933. [Google Scholar] [CrossRef]

- Mumtaz, F.; Cheng, P.; Li, C.; Cheng, S.; Du, C.; Yang, M.; Dai, Y.; Hu, W. A design of taper-like etched multicore fiber refractive index-insensitive a temperature highly sensitive Mach–Zehnder interferometer. IEEE Sens. J. 2020, 20, 7074–7081. [Google Scholar] [CrossRef]

- Liao, Y.-C.; Liu, B.; Liu, J.; Wan, S.-P.; He, X.-D.; Yuan, J.; Fan, X.; Wu, Q. High temperature (Up to 950 °C) sensor based on micro taper in-line fiber Mach–Zehnder interferometer. Appl. Sci. 2019, 9, 2394. [Google Scholar] [CrossRef]

- Ahsani, V.; Ahmed, F.; Jun, M.B.; Bradley, C. Tapered fiber-optic Mach–Zehnder interferometer for ultra-high sensitivity measurement of refractive index. Sensors 2019, 19, 1652. [Google Scholar] [CrossRef]

- Verma, R.K.; Sharma, A.K.; Gupta, B. Surface plasmon resonance based tapered fiber optic sensor with different taper profiles. Opt. Commun. 2008, 281, 1486–1491. [Google Scholar] [CrossRef]

- Stokes, D.L.; Chi, Z.; Vo-Dinh, T. Surface-enhanced-Raman-scattering-inducing nanoprobe for spectrochemical analysis. Appl. Spectrosc. 2004, 58, 292–298. [Google Scholar] [CrossRef]

- Zheng, D.; Wang, M.; Wang, M.; Zhai, M.; Wang, W. Measurement of droplet size and velocity based on a single tapered fiber optical reflectometer. Measurement 2022, 189, 110487. [Google Scholar] [CrossRef]

- Ogert, R.A.; Brown, J.E.; Singh, B.R.; Shriver-Lake, L.C.; Ligler, F.S. Detection of Clostridium botulinum toxin A using a fiber optic-based biosensor. Anal. Biochem. 1992, 205, 306–312. [Google Scholar] [CrossRef] [PubMed]

- Duan, S.; Wang, B.; Qiao, M.; Zhang, X.; Liu, B.; Zhang, H.; Song, B.; Wu, J. Hydrophobin HGFI–based fibre-optic biosensor for detection of antigen–antibody interaction. Nanophotonics 2019, 9, 177–186. [Google Scholar] [CrossRef]

- Chen, X.; Xiao, L.; Li, X.; Yi, D.; Zhang, J.; Yuan, H.; Ning, Z.; Hong, X.; Chen, Y. Tapered Fiber Bioprobe Based on U-Shaped Fiber Transmission for Immunoassay. Biosensors 2023, 13, 940. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.; Leng, Y.-K.; Liu, B.; Liu, J.; Wan, S.-P.; Wu, T.; Yuan, J.; Shao, L.; Gu, G.; Fu, Y.Q. Ultrahigh-sensitivity label-free optical fiber biosensor based on a tapered singlemode-no core-singlemode coupler for Staphylococcus aureus detection. Sens. Actuators B Chem. 2020, 320, 128283. [Google Scholar] [CrossRef]

- Cui, J.; Zhou, M.; Li, Y.; Liang, Z.; Li, Y.; Yu, L.; Liu, Y.; Liang, Y.; Chen, L.; Yang, C. A new optical fiber probe-based quantum dots immunofluorescence biosensors in the detection of Staphylococcus aureus. Front. Cell. Infect. Microbiol. 2021, 11, 665241. [Google Scholar] [CrossRef]

- Li, H.-C.; Leng, Y.-K.; Liao, Y.-C.; Liu, B.; Luo, W.; Liu, J.; Shi, J.-L.; Yuan, J.; Xu, H.-Y.; Xiong, Y.-H. Tapered microfiber MZI Biosensor for highly sensitive detection of Staphylococcus aureus. IEEE Sens. J. 2022, 22, 5531–5539. [Google Scholar] [CrossRef]

- Gupta, B.D. Fiber Optic Sensors: Principles and Applications; New India Publishing: New Delhi, India, 2006. [Google Scholar]

- Liu, X.; Yuan, J.; Wu, D.; Zou, X.; Zheng, Q.; Zhang, W.; Lei, H. All-optical targeted drug delivery and real-time detection of a single cancer cell. Nanophotonics 2019, 9, 611–622. [Google Scholar] [CrossRef]

- Vikas; Saccomandi, P. Antimonene-Coated Uniform-Waist Tapered Fiber Optic Surface Plasmon Resonance Biosensor for the Detection of Cancerous Cells: Design and Optimization. ACS Omega 2023, 8, 4627–4638. [Google Scholar] [CrossRef] [PubMed]

- Pan, J.; Sun, X.; Feng, J.; Zeng, H. Tapered Fiber Based Infrared DNA Molecule Sensor. In Proceedings of the 2019 IEEE 4th Optoelectronics Global Conference (OGC), Shenzhen, China, 3–6 September 2019; pp. 81–84. [Google Scholar]

- Sun, D.; Guo, T.; Ran, Y.; Huang, Y.; Guan, B.-O. In-situ DNA hybridization detection with a reflective microfiber grating biosensor. Biosens. Bioelectron. 2014, 61, 541–546. [Google Scholar] [CrossRef] [PubMed]

- Song, B.; Zhang, H.; Liu, B.; Lin, W.; Wu, J. Label-free in-situ real-time DNA hybridization kinetics detection employing microfiber-assisted Mach–Zehnder interferometer. Biosens. Bioelectron. 2016, 81, 151–158. [Google Scholar] [CrossRef]

- Zainuddin, N.H.; Chee, H.Y.; Ahmad, M.Z.; Mahdi, M.A.; Abu Bakar, M.H.; Yaacob, M.H. Sensitive Leptospira DNA detection using tapered optical fiber sensor. J. Biophotonics 2018, 11, e201700363. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Liu, B.; Zhang, H.; Song, B.; Wu, J.; Duan, S. Label-free detection of DNA hybridization utilizing dual S-tapered thin-core fiber interferometer. J. Light. Technol. 2019, 37, 2762–2767. [Google Scholar] [CrossRef]

- Zainuddin, N.H.; Chee, H.Y.; Rashid, S.A.; Ahmad, M.Z.; Bakar, M.H.A.; Mahdi, M.A.; Yaacob, M.H. Carbon quantum dots functionalized tapered optical fiber for highly sensitive and specific detection of Leptospira DNA. Opt. Laser Technol. 2023, 157, 108696. [Google Scholar] [CrossRef]

- Bariain, C.; Matias, I.R.; Arregui, F.J.; Lopez-Amo, M. Experimental results toward development of humidity sensors by using a hygroscopic material on biconically tapered optical fiber. In Proceedings of the Optical and Fiber Optic Sensor Systems, Beijing, China, 16–19 September 1998; pp. 95–105. [Google Scholar]

- Li, L.; Wang, Z.; Ma, Q.; Wang, M.; Wu, Q.; Chen, H.; Peng, B. Sagnac ring humidity sensor with a melting cone based on graphene properties. IEEE Sens. J. 2021, 21, 16061–16065. [Google Scholar] [CrossRef]

- Quiñones-Flores, A.A.; Guzman-Sepulveda, J.R.; Castillo-Guzman, A.A. Relative Humidity Measurement Based on a Tapered, PVA-Coated Fiber Optics Multimode Interference Sensor. Optics 2023, 4, 473–481. [Google Scholar] [CrossRef]

- Le, D.D.A.; Yoo, K.-W.; Lee, S.M.; Chung, H.; Cha, K.J.; Han, Y.-G. Few-mode microfiber knot resonator for measurement of relative humidity by considering group index difference (Conference Presentation). In Proceedings of the Optical Components and Materials XV, San Francisco, CA, USA, 27 January–1 February 2018; p. 105280I. [Google Scholar]

- Kou, J.-l.; Feng, J.; Ye, L.; Xu, F.; Lu, Y.-q. Miniaturized fiber taper reflective interferometer for high temperature measurement. Opt. Express 2010, 18, 14245–14250. [Google Scholar] [CrossRef]

- Tong, R.-j.; Zhao, Y.; Chen, M.-q.; Hu, X.-g.; Yang, Y. Simultaneous measurement of RH and temperature based on FBG and balloon-like sensing structure with inner embedded up-tapered MZI. Measurement 2019, 146, 1–8. [Google Scholar] [CrossRef]

- Yang, H.-Z.; Qiao, X.-G.; Ali, M.M.; Islam, M.R.; Lim, K.-S. Optimized Tapered Optical Fiber for Ethanol (C2H5OH) Concentration Sensing. J. Light. Technol. 2014, 32, 1777–1783. [Google Scholar] [CrossRef]

- Semwal, V.; Gupta, B. Localized Surface Plasmon Resonance Based Tapered Fiber Optic Ethanol Sensor. In Proceedings of the The European Conference on Lasers and Electro-Optics, Munich Germany, 23–27 June 2019; p. ch_p_10. [Google Scholar]

- Azad, S.; Parvizi, R.; Sadeghi, E. Tapered optical fiber coated with ZnO nanorods for detection of ethanol concentration in water. Int. J. Opt. Photonics 2018, 12, 109–118. [Google Scholar] [CrossRef]

- Khalaf, A.L.; Shabaneh, A.A.A.; Yaacob, M.H. Carbon Nanotubes and Graphene Oxide Applications in Optochemical Sensors. In Synthesis, Technology and Applications of Carbon Nanomaterials; Elsevier: Amsterdam, The Netherlands, 2019; pp. 223–246. [Google Scholar]

- Jia, M.; Wen, J.; Pan, X.; Xin, Z.; Pang, F.; He, L.; Wang, T. Tapered fiber radiation sensor based on Ce/Tb: YAG crystals for remote γ-ray dosimetry. Opt. Express 2021, 29, 1210–1220. [Google Scholar] [CrossRef]

- Rajbhar, M.K.; Maharana, B.; Patra, S.; Chatterjee, S. Tapered Optical Fiber-based Detection of Charged Particle Irradiation in Space Exploration and Nuclear Reactors. arXiv 2022, arXiv:2210.13226. [Google Scholar]

- Pakdeevanich, P. Tapered optical fiber ammonia sensor coated with phenol red and tetraethyl ortho silicate (TEOS). In Proceedings of the 2017 2nd International Conference on Frontiers of Sensors Technologies (ICFST), Shenzhen, China, 14–16 April 2017; pp. 78–81. [Google Scholar]

- Riahi, A.; Vahedi, M.; Khalilzadeh, J.; Dastjerdi, V. Investigation of the effect of the taper geometry on the sensitivity of tapered-fibre gas sensors. J. Mod. Opt. 2020, 67, 1259–1266. [Google Scholar] [CrossRef]

- Fan, X.; Deng, S.; Wei, Z.; Wang, F.; Tan, C.; Meng, H. Ammonia gas sensor based on graphene oxide-coated Mach–Zehnder interferometer with hybrid fiber structure. Sensors 2021, 21, 3886. [Google Scholar] [CrossRef]

- Mohammed, H.; Yaacob, M. A novel modified fiber Bragg grating (FBG) based ammonia sensor coated with polyaniline/graphite nanofibers nanocomposites. Opt. Fiber Technol. 2020, 58, 102282. [Google Scholar] [CrossRef]

- Peng, Y.; Zhao, Y.; Hu, X.-g.; Yang, Y. Optical fiber quantum biosensor based on surface plasmon polaritons for the label-free measurement of protein. Sens. Actuators B Chem. 2020, 316, 128097. [Google Scholar] [CrossRef]

- Maiti, S.; Prakash, S.; Singh, V. Enhanced sensing performance of tapered profile in the apodized fiber Bragg grating for detection of cancerous cells utilizing their refractive index. J. Biophotonics 2023, 16, e202300237. [Google Scholar] [CrossRef]

- Chauhan, M.; Singh, V.K. TiO2 coated tapered optical fiber SPR sensor for alcohol sensing application. J. Opt. 2023, 52, 2285–2295. [Google Scholar] [CrossRef]

- Wang, S.; Miao, Y.; Fei, C.; Zhang, H.; Li, B. A high-sensitivity temperature sensor based on a liquid cladding tapered microfiber. IEEE Sens. J. 2020, 21, 6152–6157. [Google Scholar] [CrossRef]

- Fu, X.; Zhang, Y.; Wang, Y.; Fu, G.; Jin, W.; Bi, W. A temperature sensor based on tapered few mode fiber long-period grating induced by CO2 laser and fusion tapering. Opt. Laser Technol. 2020, 121, 105825. [Google Scholar] [CrossRef]

- Lu, J.; Yu, Y.; Qin, S.; Li, M.; Bian, Q.; Lu, Y.; Hu, X.; Yang, J.; Meng, Z.; Zhang, Z. High-performance temperature and pressure dual-parameter sensor based on a polymer-coated tapered optical fiber. Opt. Express 2022, 30, 9714–9726. [Google Scholar] [CrossRef] [PubMed]

- Wang, F.; Zhang, L.; Ma, T.; Wang, X.; Yu, K.; Liu, Y. A high-sensitivity sensor based on tapered dispersion compensation fiber for curvature and temperature measurement. Opt. Commun. 2021, 481, 126534. [Google Scholar] [CrossRef]

- Chen, N.; Zhou, X.; Li, X. Highly sensitive humidity sensor with low-temperature cross-sensitivity based on a polyvinyl alcohol coating tapered fiber. IEEE Trans. Instrum. Meas. 2020, 70, 1–8. [Google Scholar] [CrossRef]

- Syuhada, A.; Shamsudin, M.S.; Daud, S.; Krishnan, G.; Harun, S.W.; Aziz, M.S.A. Single-mode modified tapered fiber structure functionalized with GO-PVA composite layer for relative humidity sensing. Photonic Sens. 2021, 11, 314–324. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, M.; Zhang, Y.; Xu, Y.; Zhang, Y.; Yang, X.; Zhang, J.; Yang, J.; Yuan, L. Spider silk-based tapered optical fiber for humidity sensing based on multimode interference. Sens. Actuators A Phys. 2020, 313, 112179. [Google Scholar] [CrossRef]

- Cheng, J. In-fiber Mach–Zehnder interferometer based on multi-core microfiber for humidity and temperature sensing. Appl. Opt. 2020, 59, 756–763. [Google Scholar] [CrossRef] [PubMed]

- Arjmand, M.; Saghafifar, H.; Alijanianzadeh, M.; Soltanolkotabi, M. A sensitive tapered-fiber optic biosensor for the label-free detection of organophosphate pesticides. Sens. Actuators B Chem. 2017, 249, 523–532. [Google Scholar] [CrossRef]

- López-Higuera, J.M.; Cobo, L.R.; Incera, A.Q.; Cobo, A. Fiber optic sensors in structural health monitoring. J. Light. Technol. 2011, 29, 587–608. [Google Scholar] [CrossRef]

- Kuang, K.S.; Cantwell, W.J.; Scully, P.J. An evaluation of a novel plastic optical fibre sensor for axial strain and bend measurements. Meas. Sci. Technol. 2002, 13, 1523. [Google Scholar] [CrossRef]

- Willberry, J.O.; Papaelias, M.; Franklyn Fernando, G. Structural health monitoring using fibre optic acoustic emission sensors. Sensors 2020, 20, 6369. [Google Scholar] [CrossRef] [PubMed]

- Di Sante, R. Fibre optic sensors for structural health monitoring of aircraft composite structures: Recent advances and applications. Sensors 2015, 15, 18666–18713. [Google Scholar] [CrossRef] [PubMed]

- Binu, S.; Pillai, V.M.; Chandrasekaran, N. Fibre optic displacement sensor for the measurement of amplitude and frequency of vibration. Opt. Laser Technol. 2007, 39, 1537–1543. [Google Scholar] [CrossRef]

| Tapered Method | Taper Length | Sensitivity | RI Scale OR Wavelength Scale | Waist Diameter | Application | Ref |

|---|---|---|---|---|---|---|

| MMF | 2500 μm | 3264.01 nm/RIU | 1.345–1.375 | 40 μm | Biological and chemical | [17] |

| MMF | —— | 12145 nm/RIU | 1.3345–1.339 | 4.2 μm | Biological and chemical | [94] |

| MMF | 160 µm | 11792 nm/RIU | 1.3330–1.4102 | —— | Biological and chemical | [95] |

| FBG | 7.29 mm | 382.83 dB/RIU and 9.893 pm/°C | 1.34974–1.35845 | 39 μm | Biological and chemical | [96] |

| LPBG | 2.3 mm | Peak A 1.82 pm/μϵ, 47.9 pm/°C, Peak B 8.17 pm/μϵ, 65 pm/°C | Peak A: 1540.3–1543.2 nm, Peak B: 1571.4–1575.3 nm | 62.5 μm | Temperature and strain | [97] |

| LPBG | 1 mm | 1246.594 nm/(N/mm) | 1480–1640 nm | 100 μm, 90 μm, 80 μm | Lateral Load | [23] |

| LPBG | 690 μm | 4.5 nm/(μg/mL) | 1300–1620 nm | 45.51 μm | Biomedical | [98] |

| PCF | 10 mm | 722.3 nm/RIU | 1.30864–1.32014 | 18.1 μm | Biological | [99] |

| PCF | —— | 152.97 nm/RIU | 1.330–1.383 | 40 μm | RI | [100] |

| FLRD | 785 μm | 2646.307 dB/(km RIU) | 1.3330–1.3518 | 70 μm | RI | [83] |

| FLRD | 340 μm | 0.725 μs/m−1 | —— | 44.1 μm | Curvature | [101] |

| MZI | 690–850 μm | −15.66 nm/μC | —— | 28–40 μm | Temperature | [102] |

| MZI | —— | 103.2 pm/°C | 1.34–1.38 | 84.70 μm | Temperature | [103] |

| MZI | 500 μm | 0.116 nm/°C | —— | 80 μm | Temperature | [104] |

| MZI | —— | 4234 nm/RIU | 1.4204–1.4408 | 35.5 μm | Biological and chemical | [105] |

| Analyte | Taper Length/ Waist Diameter | Sensitivity/Limit of Detection | Coating Material | Response/ Recovery Times | Ref |

|---|---|---|---|---|---|

| Bovine serum albumin (BSA) | Length 10 mm Waist 18.1 μm | LoD 125 pg/mL | BSA antigen | —— | [99] |

| Length 1 mm Waist 37 mm | 0.0342/(mg/mL) LoD 0.971 μg/mL | Gold | Response 5 s | [140] | |

| Staphylococcus aureus | Waist 10 μm | LoD 3.1 CFU/mL | porcine IgG antibody | Response <30 min | [112] |

| Length 379 μm Waist 83.3 μm | 2731.1 nm/RIU LoD 11 CFU/mL | Porcine IgG | Response <30 min | [114] | |

| Cancer cell | —— | adrenal cancer 15.2414 μm/RIU LoD 7.2 × 10−5 RIU | Graphene-Antimonene | —— | [117] |

| —— | 682.5 nm/RIU | —— | —— | [141] | |

| Ethanol concentration (in water) | Waist 28 μm | 14.9 (count/%) | ZnO | Response 0.6 s | [132] |

| Waist 7 μm | 0.886 nm/% | TiO2 | —— | [142] | |

| Ammonia (gas) | Length 2 mm Waist 15 μm | 0.72 nm/vol% | PANI \GNF Composite | Response 80 s recovery 36 s | [139] |

| Length 30 mm Waist 80 μm | 4.97 pm/ppm | GO | Response 5 min recovery 7.5 min | [138] |

| Measurand | Taper Length/ Waist Diameter | Sensitivity | Dynamic Range | Ref |

|---|---|---|---|---|

| Temperature | Length 2.5 mm Waist 4.9 μm | −415 pm/°C | 30–50 °C | [143] |

| Length 5 mm | −0.0393 nm/°C | 30–90 °C | [144] | |

| Length 8 mm Waist 3 μm | −2.283 nm/°C | 21.5–28 °C | [145] | |

| Length 370 μm Waist 90 μm | 79.8 pm/°C | 25–60 °C | [146] | |

| Humidity | Waist 9 μm | 0.1194 nm/%RH | 30–90%RH | [147] |

| Length 28 mm Waist 9.03 μm | 0.5290 RH (%) | 20–99.9%RH | [148] | |

| Length 1.3 mm Waist 7.82 μm | 0.789 nm/%RH | 70–89%RH | [149] | |

| Waist 8.52 µm | 59.8 pm/(%RH) | 35–95%RH | [150] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ban, S.; Lian, Y. The Structure and Applications of Fused Tapered Fiber Optic Sensing: A Review. Photonics 2024, 11, 414. https://doi.org/10.3390/photonics11050414

Ban S, Lian Y. The Structure and Applications of Fused Tapered Fiber Optic Sensing: A Review. Photonics. 2024; 11(5):414. https://doi.org/10.3390/photonics11050414

Chicago/Turabian StyleBan, Siqi, and Yudong Lian. 2024. "The Structure and Applications of Fused Tapered Fiber Optic Sensing: A Review" Photonics 11, no. 5: 414. https://doi.org/10.3390/photonics11050414

APA StyleBan, S., & Lian, Y. (2024). The Structure and Applications of Fused Tapered Fiber Optic Sensing: A Review. Photonics, 11(5), 414. https://doi.org/10.3390/photonics11050414