Laser Machining at High ∼PW/cm2 Intensity and High Throughput

Abstract

1. Introduction

2. Experimental Section: Setup and Materials

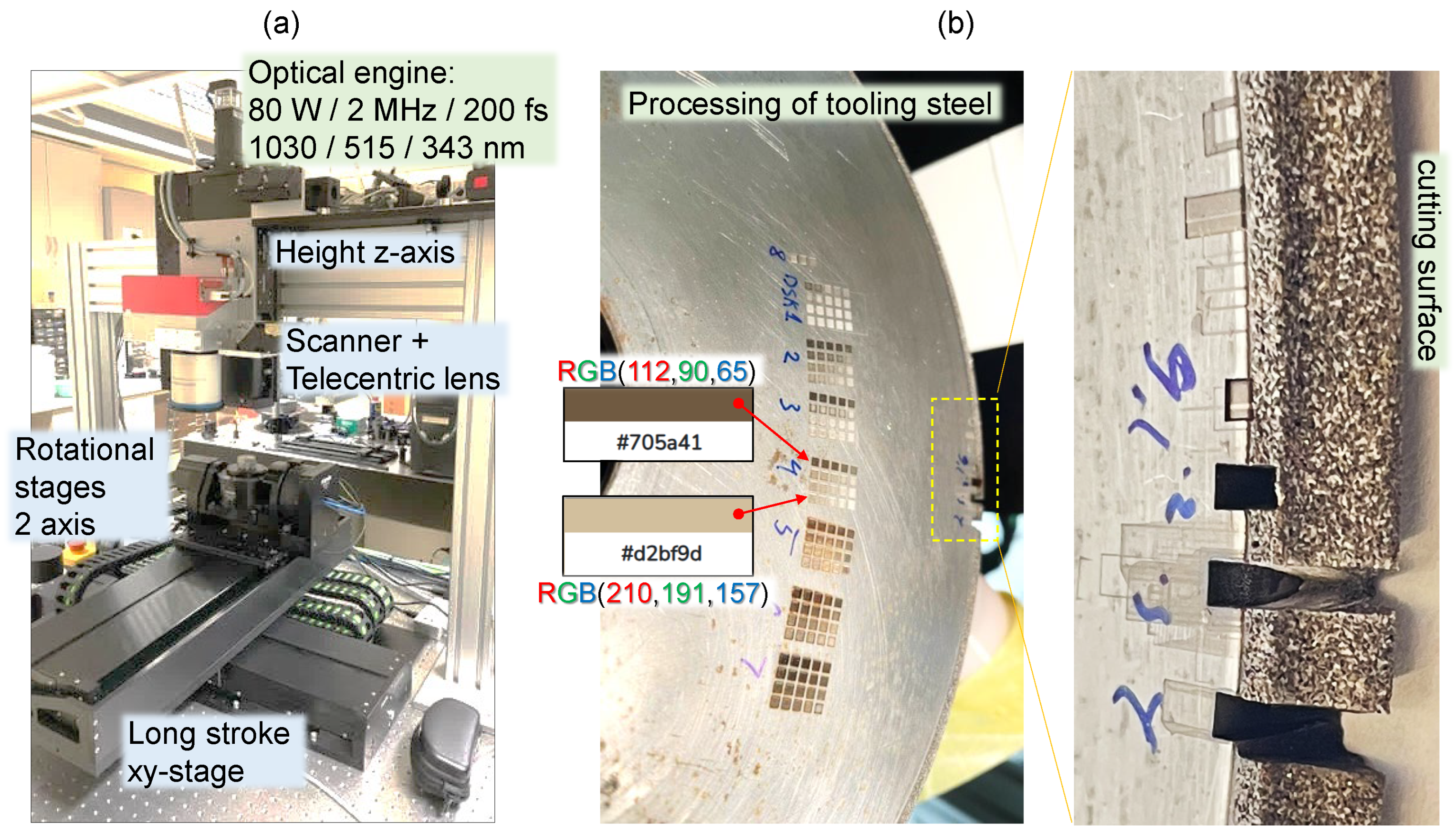

2.1. Assembly of fs-Laser Machining Setup

2.2. Ablation and Structural Characterization

2.3. Material Properties

3. Framework for Analysis and Bench-Marking of Ablation Efficiency

3.1. Energy Deposition Depth: Localization Mechanism

3.2. Ablation Rate

3.3. Power Scaling of Direct Energy Deposition per Volume

4. Results

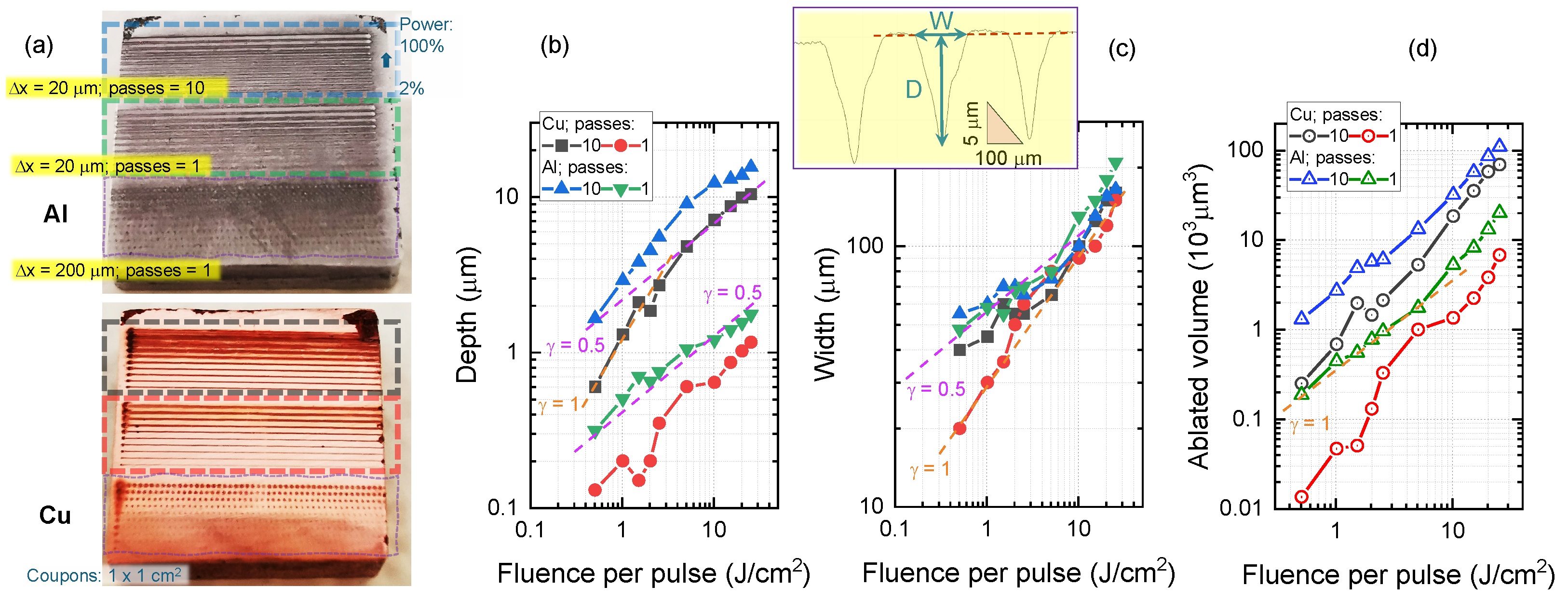

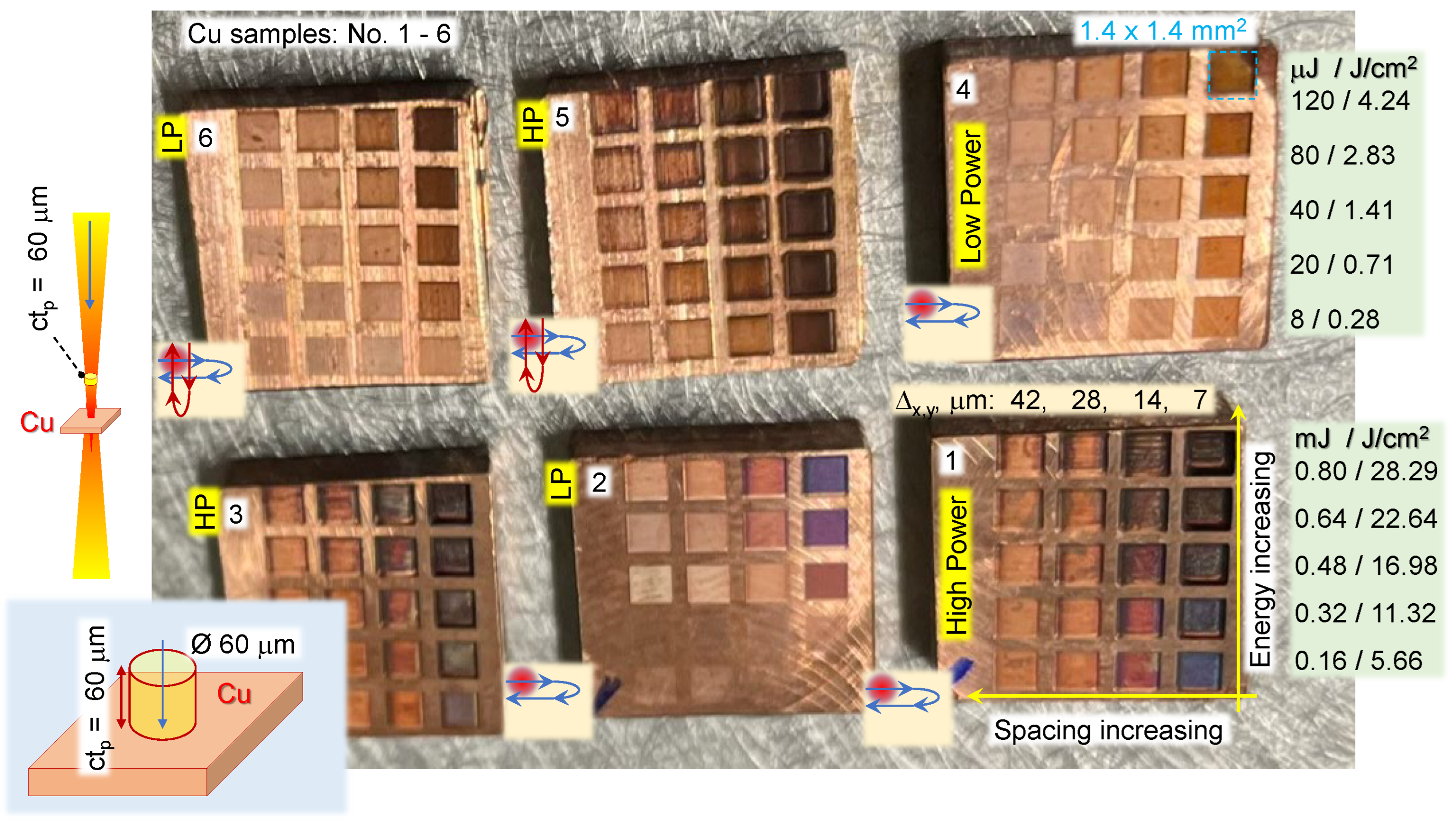

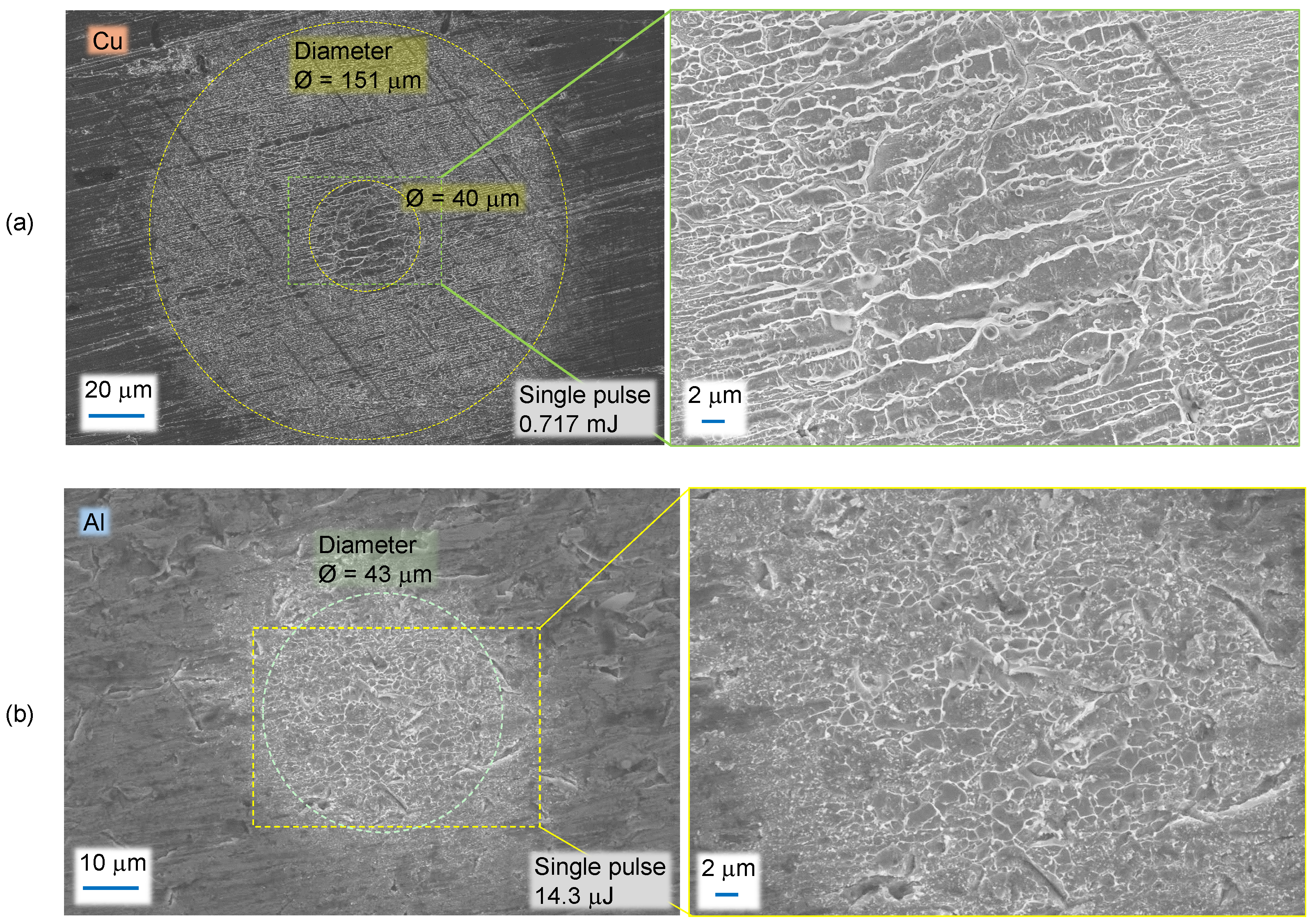

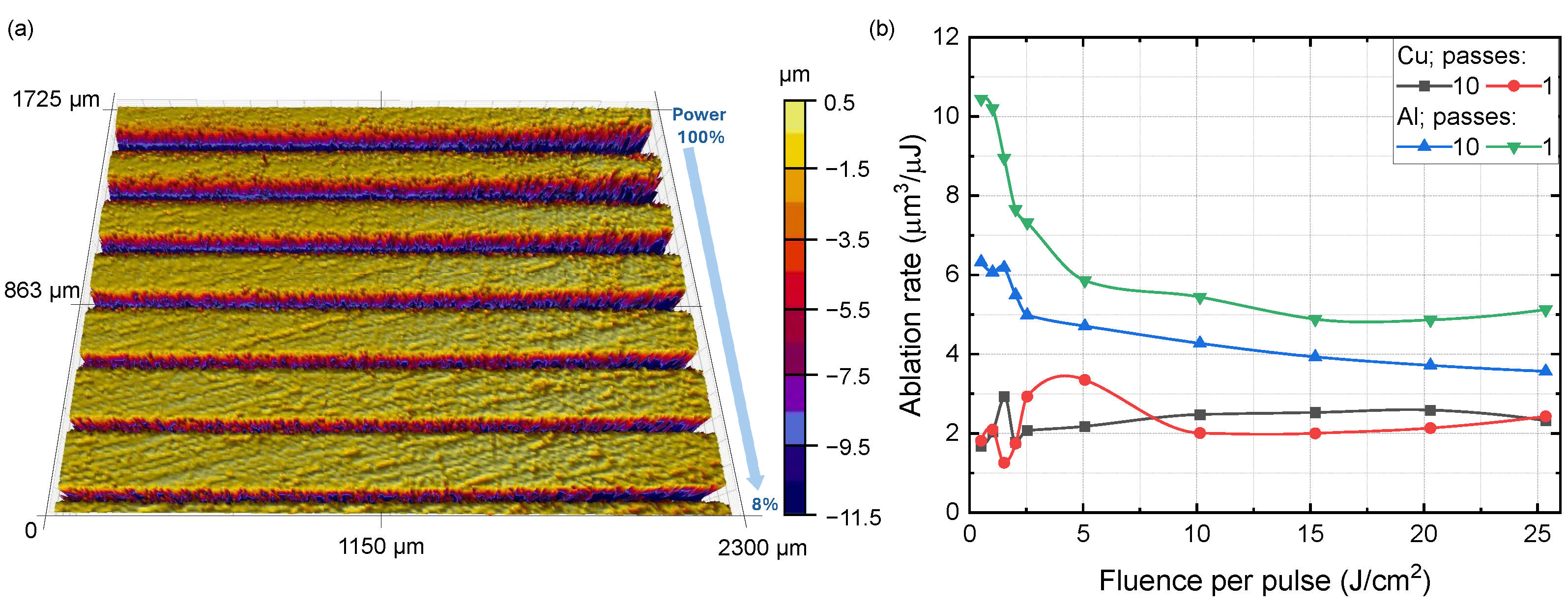

4.1. Cu and Al Ablation at High Scan Speed

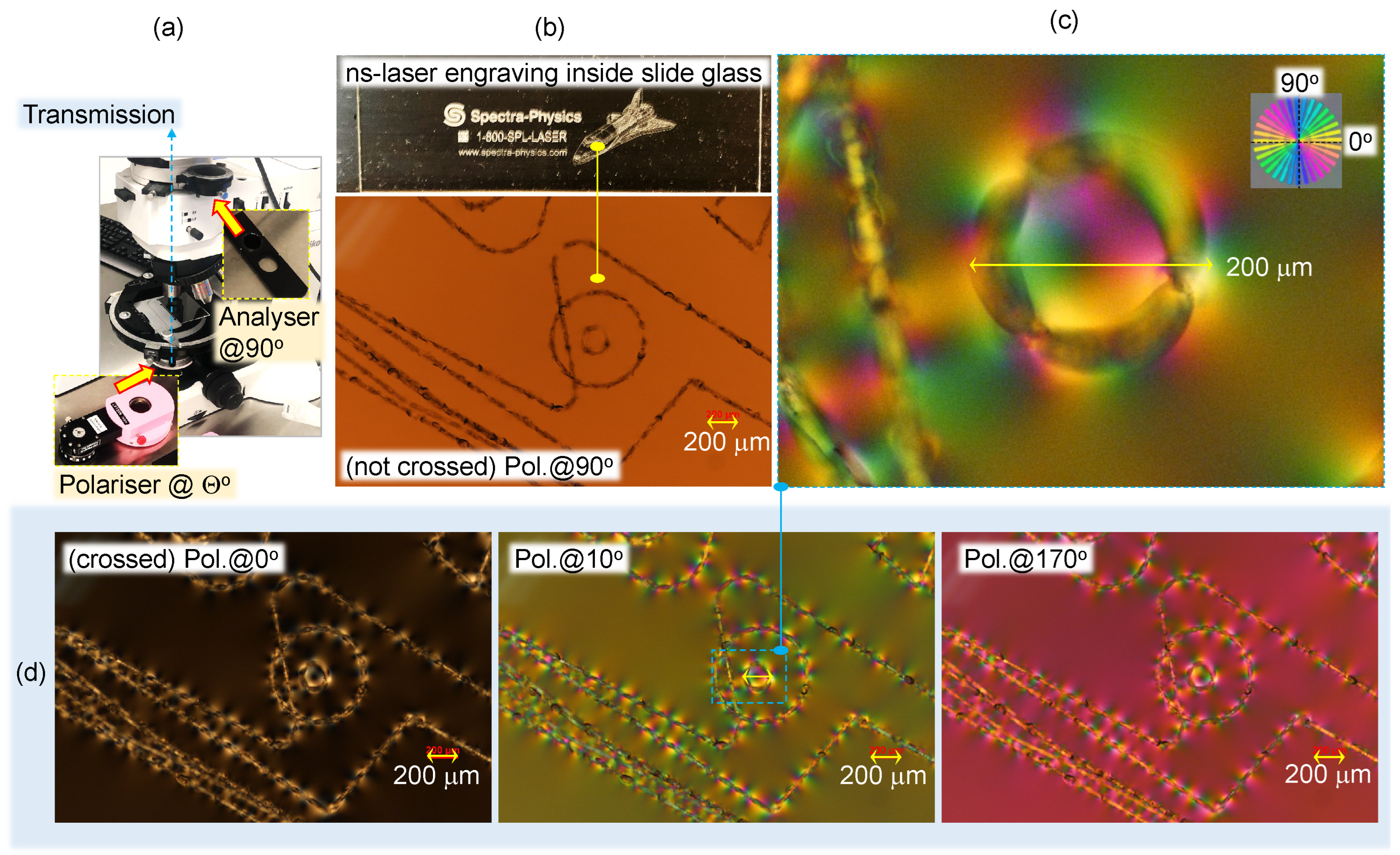

4.2. Silica Ablation and Defect Accumulation

4.3. X-ray Emission

5. Discussion

6. Conclusions and Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. Tunneling Ionization

Appendix B. Permittivity of Conductive Materials

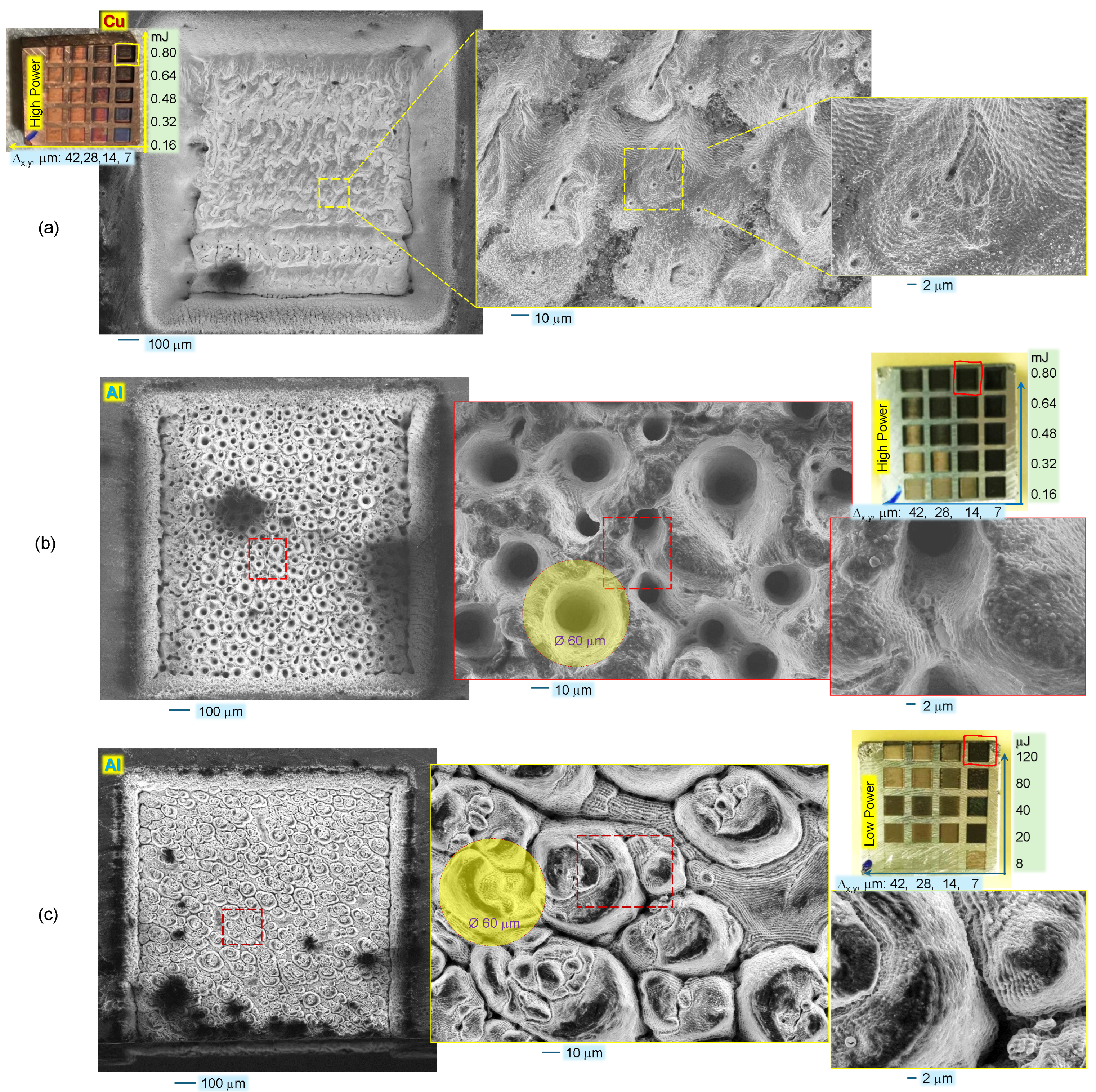

Appendix C. Ablated Textures on Metals

Appendix D. Polarisation Analysis

References

- Ng, S.H.; Han, M.; Hyde, L.; Durandet, Y.; Katkus, T.; Zaccaria, R.P.; Juodkazis, S. High Intensity Laser Applications: Space Prospective. In Proceedings of the 2021 Photonics & Electromagnetics Research Symposium (PIERS), Hangzhou, China, 21–25 November 2021; pp. 2670–2677. [Google Scholar]

- Mack, C.A. Will stochastics be the ultimate limiter for nanopatterning? In Proceedings of the Novel Patterning Technologies for Semiconductors, San Jose, CA, USA, 25–28 February 2019; Volume 10958, p. 1095803. [Google Scholar]

- Malinauskas, M.; Žukauskas, A.; Hasegawa, S.; Hayasaki, Y.; Mizeikis, V.; Buividas, R.; Juodkazis, S. Ultrafast laser processing of materials: From science to industry. Light Sci. Appl. 2016, 5, e16133. [Google Scholar] [CrossRef] [PubMed]

- Jain, K.; Dunn, T.J.; Farmiga, N.; Zemel, M.; Weisbecker, C. Large-area high-throughput high-resolution lithography systems for flat-panel displays and microelectronic modules. In Proceedings of the Emerging Lithographic Technologies II, Santa Clara, CA, USA, 23–25 February 1998; Volume 3331, pp. 197–206. [Google Scholar]

- McKee, D.C.; Bandera, C. Multistage foveal target detection system. In Proceedings of the Signal Processing, Sensor Fusion, and Target Recognition VII, Orlando, FL, USA, 13–15 April 1998; Volume 3374, pp. 194–203. [Google Scholar]

- Jia, W.; Leung, Y.S.; Mao, H.; Xu, H.; Zhou, C.; Chen, Y. Hybrid-Light-Source Stereolithography for Fabricating Macro-Objects With Micro-Textures. J. Manuf. Sci. Eng. 2021, 144, 031003. [Google Scholar] [CrossRef]

- Maksimovic, J.; Hu, J.; Ng, S.H.; Katkus, T.; Seniutinas, G.; Rivera, T.P.; Stuiber, M.; Nishijima, Y.; John, S.; Juodkazis, S. Beyond Lambertian light trapping for large-area silicon solar cells: Fabrication methods. Opto-Electron. Adv. 2022, 5, 210086. [Google Scholar] [CrossRef]

- Hilfiker, J.N.; Singh, B.; Synowicki, R.A.; Bungay, C.L. Optical characterization in the vacuum ultraviolet with variable angle spectroscopic ellipsometry: 157 nm and below. Proc. SPIE Int. Soc. Opt. Eng. 2000, 3998, 390–398. [Google Scholar]

- Kitayama, T.; Itoga, K.; Watanabe, Y.; Uzawa, S. Proposal for a 50 nm proximity x-ray lithography system and extension to 35 nm by resist material selection. J. Vac. Sci. Technol. B Microelectron. Nanometer Struct. Process. Meas. Phenom. 2000, 18, 2950–2954. [Google Scholar] [CrossRef]

- Rothschild, M.; Bloomstein, T.M.; Efremow, N.; Fedynyshyn, T.H.; Fritze, M.; Pottebaum, I.; Switkes, M. Nanopatterning with UV Optical Lithography. MRS Bull. 2005, 30, 942–946. [Google Scholar] [CrossRef]

- Kozawa, T.; Tagawa, S. Radiation Chemistry in Chemically Amplified Resists. Jpn. J. Appl. Phys. 2010, 49, 030001. [Google Scholar] [CrossRef]

- Hua, J.G.; Ren, H.; Huang, J.; Luan, M.L.; Chen, Q.D.; Juodkazis, S.; Sun, H.B. Laser-Induced Cavitation-Assisted True 3D Nano-Sculpturing of Hard Materials. Small 2023, 19, 2207968. [Google Scholar] [CrossRef] [PubMed]

- Žemaitis, A.; Gaidys, M.; Brikas, M.; Gečys, P.; Račiukaitis, G.; Gedvilas, M. Advanced laser scanning for highly-efficient ablation and ultrafast surface structuring: Experiment and model. Sci. Rep. 2018, 8, 17376. [Google Scholar] [CrossRef]

- Buividas, R.; Mikutis, M.; Juodkazis, S. Surface and bulk structuring of materials by ripples with long and short laser pulses: Recent advances. Prog. Quantum Electron. 2014, 38, 119–156. [Google Scholar] [CrossRef]

- Wang, L.; Chen, Q.D.; Cao, X.W.; Buividas, R.; Wang, X.; Juodkazis, S.; Sun, H.B. Plasmonic nano-printing: Large-area nanoscale energy deposition for efficient surface texturing. Light Sci. Appl. 2017, 6, e17112. [Google Scholar] [CrossRef] [PubMed]

- Maksimovic, J.; Mu, H.; Han, M.; Smith, D.; Katkus, T.; Anand, V.; Nishijima, Y.; Ng, S.H.; Juodkazis, S. Si-Cr Nano-Alloys Fabricated by Direct Femtosecond Laser Writing. Materials 2023, 16, 1917. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Jiang, Q.; Long, M.; Han, R.; Cao, K.; Zhang, S.; Feng, D.; Jia, T.; Sun, Z.; Qiu, J.; et al. Femtosecond laser-induced periodic structures: Mechanisms, techniques, and applications. Opto-Electron. Sci. 2022, 1, 220005. [Google Scholar] [CrossRef]

- Martinez-Calderon, M.; Groussin, B.; Bjelland, V.; Chevallay, E.; Fedosseev, V.N.; Himmerlich, M.; Lorenz, P.; Manjavacas, A.; Marsh, B.A.; Neupert, H.; et al. Hot electron enhanced photoemission from laser fabricated plasmonic photocathodes. Nanophotonics 2024, 13, 1975–1983. [Google Scholar] [CrossRef]

- Roques-Carmes, C.; Kooi, S.; Yang, Y.; Massuda, A.; Keathley, P.; Zaidi, A.; Yang, Y.; Joannopoulos, J.; Berggren, K.; Kaminer, I.; et al. Towards integrated tunable all-silicon free-electron light sources. Nat. Commun. 2019, 10, 3176. [Google Scholar] [CrossRef]

- Kerse, C.; Kalaycıoğlu, H.; Elahi, P.; Çetin, B.; Kesim, D.K.; Akçaalan, O.; Yavaş, S.; Aşık, M.D.; Öktem, B.; Hoogland, H.; et al. Ablation-cooled material removal with ultrafast bursts of pulses. Nature 2016, 537, 84–88. [Google Scholar] [CrossRef] [PubMed]

- Khurgin, J. Energy and Power Requirements for Alteration of the Refractive Index. Light Sci. Appl. 2024, 18, 2300836. [Google Scholar] [CrossRef]

- Lin, Z.; Ji, L.; Wang, W. Precision machining of single crystal diamond cutting tool via picosecond laser irradiation. Int. J. Refract. Met. Hard Mater. 2023, 114, 106226. [Google Scholar] [CrossRef]

- Marlow, F.; Josten, S.; Leiting, S. Electronics with stainless steel: The work functions. J. Appl. Phys. 2023, 133, 085104. [Google Scholar] [CrossRef]

- Neuenschwander, B.; Remund, S.; Nussbaum, C.; Kling, R.; Fritsch, K.; Franke, C.; Ballukonis, D.; Hochner, U. Michromachining of dielectrics and semiconductors with external pulse compression below 100 fs, 2024. In Proceedings of the LPM2024, San Sebastian, Spain, 11–14 June 2024. [Google Scholar]

- Gamaly, E.G.; Rode, A.V.; Luther-Davies, B. Ablation of solids by femtosecond lasers: Ablation mechanism and ablation thresholds for metals and dielectrics. Phys. Plasmas 2002, 18, 949–957. [Google Scholar] [CrossRef]

- Juodkazis, S.; Okuno, H.; Kujime, N.; Matsuo, S.; Misawa, H. Hole Drilling in Stainless Steel and Silicon by Femtosecond Pulses at Low Pressure. Appl. Phys. A 2004, 79, 1555–1559. [Google Scholar] [CrossRef]

- Jonušauskas, L.; Gailevičius, D.; Rekštytė, S.; Baldacchini, T.; Juodkazis, S.; Malinauskas, M. Mesoscale laser 3D printing. Opt. Express 2019, 27, 15205–15221. [Google Scholar] [CrossRef] [PubMed]

- Bonse, J.; Baudach, S.; Krüger, J.; Kautek, W.; Lenzner, M. Femtosecond laser ablation of silicon–modification thresholds and morphology. Appl. Phys. A 2002, 74, 19–25. [Google Scholar] [CrossRef]

- Gamaly, E.E.; Juodkazis, S.; Nishimura, K.; Misawa, H.; Luther-Davies, B.; Hallo, L.; Nicolai, P.; Tikhonchuk, V. Laser-matter interaction in a bulk of a transparent solid: Confined micro-explosion and void formation. Phys. Rev. B 2006, 73, 214101. [Google Scholar] [CrossRef]

- Groussin, B.; Martinez-Calderon, M.; Beldarrain, O.; Rodriguez, A.; Olaizola, S.M.; Marsh, B.A.; Granados, E. Efficient Composite Colorization of Copper by Spatially Controlled Oxidation with Deep-UV Ultrafast Lasers. Adv. Opt. Mater. 2024, 12, 2302071. [Google Scholar] [CrossRef]

- Gamaly, E.G.; Madsen, N.R.; Duering, M.; Rode, A.V.; Kolev, V.Z.; Luther-Davies, B. Ablation of metals with picosecond laser pulses: Evidence of long-lived nonequilibrium conditions at the surface. Phys. Rev. B 2005, 71, 174405. [Google Scholar] [CrossRef]

- Liu, J.M. Simple technique for measurements of pulsed Gaussian-beam spot sizes. Opt. Lett. 1982, 7, 196–198. [Google Scholar] [CrossRef] [PubMed]

- Vanagas, E.; Kudryashov, I.; Tuzhilin, D.; Juodkazis, S.; Matsuo, S.; Misawa, H. Surface nanostructuring of borosilicate glass by femtosecond nJ energy pulses. Appl. Phys. Lett. 2003, 82, 2901–2903. [Google Scholar] [CrossRef]

- Vanagas, E.; Kawai, J.; Tuzilin, D.; Kudryashov, I.; Mizuyama, A.; Nakamura, K.G.; Kondo, K.I.; Koshihara, S.Y.; Takesada, M.; Matsuda, K.; et al. Glass cutting by femtosecond pulsed irradiation. J. Microlith. Microfab. Microsyst. 2004, 3, 358–363. [Google Scholar] [CrossRef]

- Gaidys, M.; Selskis, A.; Gečys, P.; Gedvilas, M. Stainless steel colouring using burst and biburst mode ultrafast laser irradiation. Opt. Laser Technol. 2024, 174, 110561. [Google Scholar] [CrossRef]

- Kretkowski, M.; Jabłoński, R.; Shimodaira, Y. Development of an XYZ Digital Camera with Embedded Color Calibration System for Accurate Color Acquisition. IEICE Trans. Inf. Syst. 2010, E93.D, 651–653. [Google Scholar] [CrossRef]

- Kretkowski, M.; Shimodaira, Y.; Jabłoński, R. Color calibration method providing uniform distribution of color difference throughout the whole vision gamut. J. Autom. Mob. Robot. Intell. Syst. 2013, 3, 213–216. [Google Scholar]

- Jia, R.; Xiang, S.; Wang, Y.; Chen, H.; Xiao, M. Electrically Triggered Color-Changing Materials: Mechanisms, Performances, and Applications. Adv. Opt. Mater. 2024, 12, 2302222. [Google Scholar] [CrossRef]

- Tian, B.; Wang, Z.; Smith, A.T.; Bai, Y.; Li, J.; Zhang, N.; Xue, Z.; Sun, L. Stress-induced color manipulation of mechanoluminescent elastomer for visualized mechanics sensing. Nano Energy 2021, 83, 105860. [Google Scholar] [CrossRef]

- Cangueiro, L.; Ramos-de Campos, J.A.; Bruneel, D. Prediction of Thermal Damage upon Ultrafast Laser Ablation of Metals. Molecules 2021, 26, 6327. [Google Scholar] [CrossRef] [PubMed]

- Garasz, K.; Kocik, M.; Barbucha, R.; Tański, M.; Petrov, T.; Mohamed-Seghir, M. Optimisation of femtosecond laser micromachining of copper with AI algorithms. J. Achiev. Mater. Manuf. Eng. 2023, 121, 267–274. [Google Scholar]

- Greffet, J.J.; Nieto-Vesperinas, M. Field theory for generalized bidirectional reflectivity: Derivation of Helmholtz’s reciprocity principle and Kirchhoff’s law. J. Opt. Soc. Am. A 1998, 15, 2735–2744. [Google Scholar] [CrossRef]

- Greffet, J.J.; Carminati, R.; Joulain, K.; Mulet, J.P.; Mainguy, S.; Chen, Y. Coherent emission of light by thermal sources. Nature 2002, 416, 61–64. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Seniutinas, G.; Balcytis, A.; Kasalynas, I.; Jakstas, V.; Janonis, V.; Venckevicius, R.; Buividas, R.; Appadoo, D.; Valusis, G.; et al. Laser structuring for control of coupling between THz light and phonon modes. arXiv 2016, arXiv:1605.04493. [Google Scholar]

- Nishijima, Y.; Balčytis, A.; Naganuma, S.; Seniutinas, G.; Juodkazis, S. Kirchhoff’s metasurfaces towards efficient photo-thermal energy conversion. Sci. Rep. 2019, 9, 8284. [Google Scholar] [CrossRef]

- Gibbon, P. Introduction to Plasma Physics. In Proceedings of the CAS-CERN Accelerator School: Plasma Wake Acceleration, Geneva, Switzerland, 23–29 November 2014; Volume CERN-2016-001, pp. 51–65. [Google Scholar]

- Gibbon, P.; Förster, E. Short-pulse laser-plasma interactions. Plasma Phys. Control. Fusion 1996, 38, 769–793. [Google Scholar] [CrossRef]

- Gibbon, P. Short Pulse Laser Interactions with Matter: An Introduction; World Scientific: Singapore, 2005. [Google Scholar]

- Auguste, T.; Monot, P.; Lompre, L.; Mainfray, G.; Manus, C. Multiply charged ions produced in noble gases by a 1 ps laser pulse at λ = 1053 nm. J. Phys. B At. Mol. Opt. Phys. 1992, 25, 4181–4194. [Google Scholar] [CrossRef]

- Gibbon, P. Physics of High Intensity Laser Plasma Interactions. In Proceedings of the Varenna Summer School on Laser-Plasma Acceleration, Varenna, Italy, 20–25 June 2011. [Google Scholar]

- Normand, D.; Lompre, L.; Comaggia, C. Laser-induced molecular alignment probed by a double-pulse experiment. J. Phys. B At. Mol. Opt. Phys. 1992, 25, L497–L503. [Google Scholar] [CrossRef]

- Collett, E. Field Guide to Polarisation; SPIE Press: Bellingham, WA, USA, 2005. [Google Scholar]

- Zhou, L.; Li, X.Y.; Zhu, W.J.; Wang, J.X.; Tang, C.J. The effects of pulse duration on ablation pressure driven by laser radiation. J. Appl. Phys. 2015, 117, 125904. [Google Scholar] [CrossRef]

- Vanagas, E.; Ye, J.Y.; Li, M.; Miwa, M.; Juodkazis, S.; Misawa, H. Analysis of stress induced by a three-dimensional recording in glass. Appl. Phys. A 2005, 81, 725–727. [Google Scholar] [CrossRef]

| Material | Passes | Pulse Energy (J) | Ablation Rate (10−12 m3/J = m3/μJ) |

|---|---|---|---|

| Cu | 10 | 16 | 1.67 |

| 10 | 800 | 2.32 | |

| 1 | 16 | 1.81 | |

| 1 | 800 | 2.43 | |

| Al | 10 | 16 | 6.33 |

| 10 | 800 | 3.57 | |

| 1 | 16 | 10.44 | |

| 1 | 800 | 5.13 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, N.; Buividas, R.; Huang, H.-H.; Stonytė, D.; Palanisamy, S.; Katkus, T.; Kretkowski, M.; Stoddart, P.R.; Juodkazis, S. Laser Machining at High ∼PW/cm2 Intensity and High Throughput. Photonics 2024, 11, 598. https://doi.org/10.3390/photonics11070598

Zheng N, Buividas R, Huang H-H, Stonytė D, Palanisamy S, Katkus T, Kretkowski M, Stoddart PR, Juodkazis S. Laser Machining at High ∼PW/cm2 Intensity and High Throughput. Photonics. 2024; 11(7):598. https://doi.org/10.3390/photonics11070598

Chicago/Turabian StyleZheng, Nan, Ričardas Buividas, Hsin-Hui Huang, Dominyka Stonytė, Suresh Palanisamy, Tomas Katkus, Maciej Kretkowski, Paul R. Stoddart, and Saulius Juodkazis. 2024. "Laser Machining at High ∼PW/cm2 Intensity and High Throughput" Photonics 11, no. 7: 598. https://doi.org/10.3390/photonics11070598

APA StyleZheng, N., Buividas, R., Huang, H.-H., Stonytė, D., Palanisamy, S., Katkus, T., Kretkowski, M., Stoddart, P. R., & Juodkazis, S. (2024). Laser Machining at High ∼PW/cm2 Intensity and High Throughput. Photonics, 11(7), 598. https://doi.org/10.3390/photonics11070598