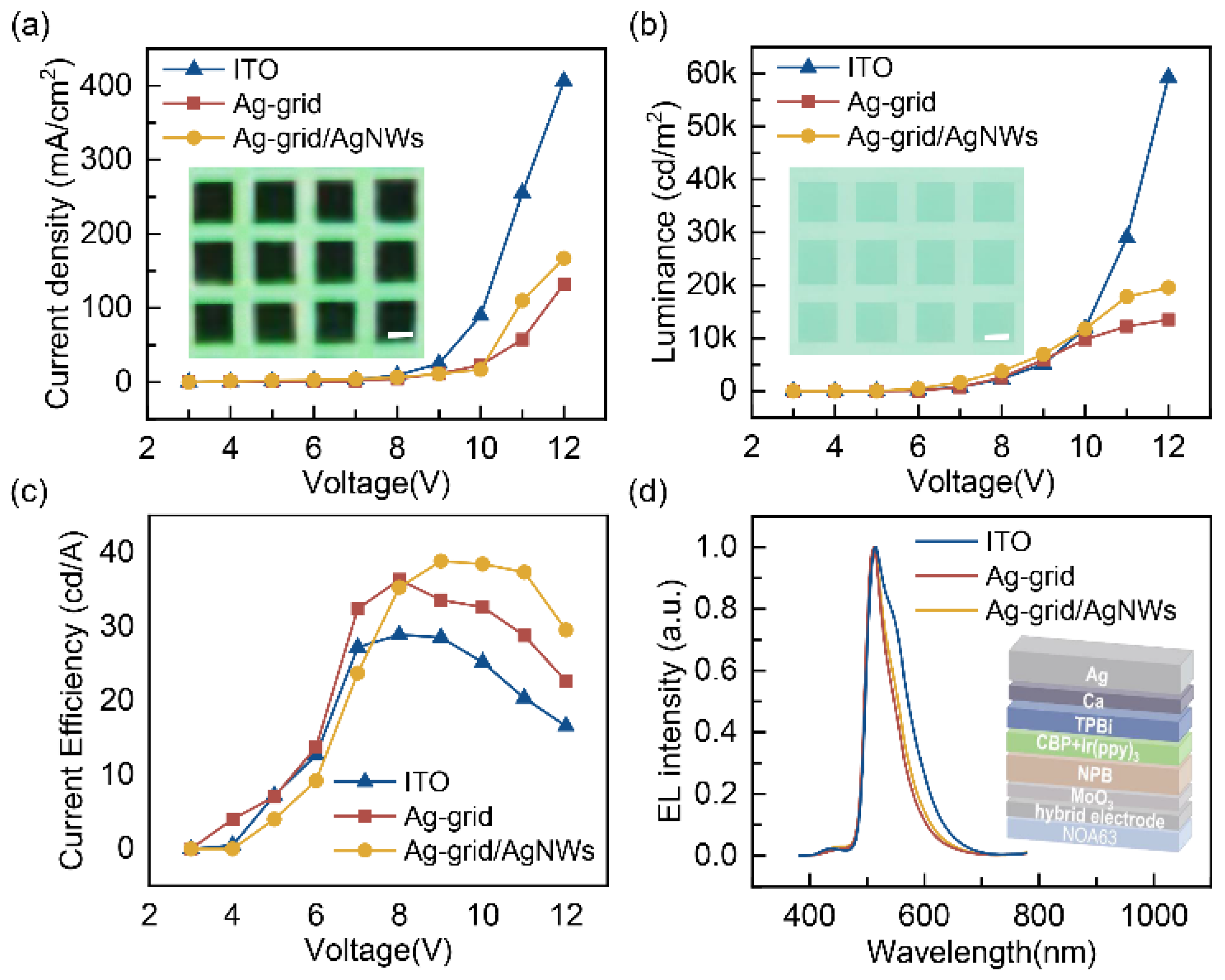

Ag-Grid and Ag-Nanowires Hybrid Transparent Electrodes to Improve Performance of Flexible Organic Light-Emitting Devices

Abstract

1. Introduction

2. Experiments

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sannicolo, T.; Lagrange, M.; Cabos, A.; Celle, C.; Simonato, J.P.; Bellet, D. Metallic Nanowire-Based Transparent Electrodes for Next Generation Flexible Devices: A Review. Small 2016, 12, 6052–6075. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.; Chang, M.; Meng, L.; Wan, X.; Gao, H.; Zhang, Y.; Zhao, K.; Sun, Z.; Li, C.; Liu, S.; et al. Flexible organic photovoltaics based on water-processed silver nanowire electrodes. Nat. Electron. 2019, 2, 513–520. [Google Scholar] [CrossRef]

- Liu, Q.; Liu, Z.; Li, C.; Xie, K.; Zhu, P.; Shao, B.; Zhang, J.; Yang, J.; Zhang, J.; Wang, Q.; et al. Highly Transparent and Flexible Iontronic Pressure Sensors Based on an Opaque to Transparent Transition. Adv. Sci. 2020, 7, 2000348. [Google Scholar] [CrossRef] [PubMed]

- Helander, M.G.; Wang, Z.B.; Qiu, J.; Greiner, M.T.; Puzzo, D.P.; Liu, Z.W.; Lu, Z.H. Chlorinated Indium Tin Oxide Electrodes with High Work Function for Organic Device Compatibility. Science 2011, 332, 944–947. [Google Scholar] [CrossRef] [PubMed]

- Azani, M.-R.; Hassanpour, A.; Torres, T. Benefits, Problems, and Solutions of Silver Nanowire Transparent Conductive Electrodes in Indium Tin Oxide (ITO)-Free Flexible Solar Cells. Adv. Energy Mater. 2020, 10, 2002536. [Google Scholar] [CrossRef]

- Kwon, O.E.; Shin, J.W.; Oh, H.; Kang, C.M.; Cho, H.; Kwon, B.H.; Byun, C.W.; Yang, J.H.; Lee, K.M.; Han, J.H.; et al. A prototype active-matrix OLED using graphene anode for flexible display application. J. Inf. Disp. 2020, 21, 49–56. [Google Scholar] [CrossRef]

- Hao, T.; Ji, H.; Xu, D.; Liu, D.; Ren, Z.; Liu, W.; Zhang, Y.; Sun, J.; Zhao, J.; Zhang, L.; et al. Capillary Force-Induced Graphene Spontaneous Transfer and Encapsulation of Silver Nanowires for Highly-Stable Transparent Electrodes. ACS Appl. Mater. Interfaces 2024, 16, 40199–40209. [Google Scholar] [CrossRef]

- Snarski, L.; Biran, I.; Bendikov, T.; Pinkas, I.; Iron, M.A.; Kaplan-Ashiri, I.; Weissman, H.; Rybtchinski, B. Highly Conductive Robust Carbon Nanotube Networks for Strong Buckypapers and Transparent Electrodes. Adv. Funct. Mater. 2024, 34, 2309742. [Google Scholar] [CrossRef]

- Suh, B.L.; Kang, G.; Yoon, S.M.; Cho, S.; Moon, M.-W.; Sung, Y.-M.; Kim, M.-S.; Hur, K. Dimensional Control of Highly Anisotropic and Transparent Conductive Coordination Polymers for Solution-Processable Large-Scale 2D Sheets. Adv. Mater. 2023, 35, 2206980. [Google Scholar] [CrossRef]

- Tseng, C.-P.; Liu, F.; Zhang, X.; Huang, P.-C.; Campbell, I.; Li, Y.; Atkinson, J.T.; Terlier, T.; Ajo-Franklin, C.M.; Silberg, J.J.; et al. Solution-Deposited and Patternable Conductive Polymer Thin-Film Electrodes for Microbial Bioelectronics. Adv. Mater. 2022, 34, 2109442. [Google Scholar] [CrossRef]

- Kang, H.; Jung, S.; Jeong, S.; Kim, G.; Lee, K. Polymer-metal hybrid transparent electrodes for flexible electronics. Nat. Commun. 2015, 6, 6503. [Google Scholar] [CrossRef]

- Lu, Y.; Chen, M.; Jiang, L.; Cao, J.-j.; Li, H.; Lee, S.C.; Huang, Y. Oxygen vacancy engineering of photocatalytic nanomaterials for enrichment, activation, and efficient removal of nitrogen oxides with high selectivity: A review. Environ. Chem. Lett. 2022, 20, 3905–3925. [Google Scholar] [CrossRef]

- Hu, H.; Wang, S.; Wang, S.; Liu, G.; Cao, T.; Long, Y. Aligned Silver Nanowires Enabled Highly Stretchable and Transparent Electrodes with Unusual Conductive Property. Adv. Funct. Mater. 2019, 29, 1902922. [Google Scholar] [CrossRef]

- Atkinson, J.; Goldthorpe, I.A. Near-infrared properties of silver nanowire networks. Nanotechnology 2020, 31, 365201. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; Yang, S.; Huang, J.; Gu, Y.; Huang, W.; Liu, S.; Lin, Z.; Zeng, Z.; Hu, Y.; Chen, Z.; et al. Flexible, Transparent and Conductive Metal Mesh Films with Ultra-High FoM for Stretchable Heating and Electromagnetic Interference Shielding. Nano-Micro Lett. 2024, 16, 92. [Google Scholar] [CrossRef] [PubMed]

- Kamijo, T.; de Winter, S.; Panditha, P.; Meulenkamp, E. Printed Copper Grid Transparent Conducting Electrodes for Organic Light-Emitting Diodes. ACS Appl. Electron. Mater. 2022, 4, 698–706. [Google Scholar] [CrossRef]

- Li, L.; Zhang, B.; Zou, B.; Xie, R.; Zhang, T.; Li, S.; Zheng, B.; Wu, J.; Weng, J.; Zhang, W.; et al. Fabrication of Flexible Transparent Electrode with Enhanced Conductivity from Hierarchical Metal Grids. ACS Appl. Mater. Interfaces 2017, 9, 39110–39115. [Google Scholar] [CrossRef]

- Feng, Y.; Song, J.; Han, G.; Zhou, B.; Liu, C.; Shen, C. Transparent and Stretchable Electromagnetic Interference Shielding Film with Fence-like Aligned Silver Nanowire Conductive Network. Small Methods 2023, 7, 2201490. [Google Scholar] [CrossRef]

- Qiao, J.; Huang, J.; Zhao, L.; Yuan, D.; Wang, P.; Xu, S. Line-Shaped Laser Lithography for Efficiently Fabricating Flexible Transparent Electrodes with Hierarchical Metal Grids across λ/10 to Microscale. Adv. Mater. Technol. 2023, 8, 2201209. [Google Scholar] [CrossRef]

- Yi, F.S.; Bi, Y.G.; Zhang, X.L.; Yin, D.; Liu, Y.F.; Feng, J.; Sun, H.B. Highly Flexible and Mechanically Robust Ultrathin Au Grid as Electrodes for Flexible Organic Light-Emitting Devices. IEEE Trans. Nanotechnol. 2019, 18, 776–780. [Google Scholar] [CrossRef]

- Cho, E.C.; Xie, J.; Wurm, P.A.; Xia, Y. Understanding the Role of Surface Charges in Cellular Adsorption versus Internalization by Selectively Removing Gold Nanoparticles on the Cell Surface with a I2/KI Etchant. Nano Lett. 2009, 9, 1080–1084. [Google Scholar] [CrossRef] [PubMed]

- Haacke, G. New figure of merit for transparent conductors. J. Appl. Phys. 1976, 47, 4086–4089. [Google Scholar] [CrossRef]

- Bi, Y.G.; Yi, F.S.; Ji, J.H.; Ma, C.; Wang, W.Q.; Feng, J.; Sun, H.B. Ultrathin Au Electrodes Based on a Hybrid Nucleation Layer for Flexible Organic Light-Emitting Devices. IEEE Trans. Nanotechnol. 2018, 17, 1077–1081. [Google Scholar] [CrossRef]

- Wang, M.; Lin, J.; Hsiao, Y.-C.; Liu, X.; Hu, B. Investigating underlying mechanism in spectral narrowing phenomenon induced by microcavity in organic light emitting diodes. Nat. Commun. 2019, 10, 1614. [Google Scholar] [CrossRef] [PubMed]

| Line Width–Gap Width | T (%) | Rs (Ω/sq) | FOM (×10−3/Ω) |

|---|---|---|---|

| 15 μm–30 μm a | 70.77 | 14.06 | 2.24 |

| 15 μm–40 μm a | 71.66 | 22.19 | 1.61 |

| 15 μm–50 μm a | 73.42 | 38.04 | 1.19 |

| 15 μm–60 μm a | 74.66 | 43.11 | 1.24 |

| 15 μm–70 μm a | 78.51 | 67.04 | 1.32 |

| 10 μm–50 μm a | 78.99 | 46.20 | 2.04 |

| 10 μm–60 μm a | 79.57 | 56.17 | 1.81 |

| 15 μm–30 μm b | 67.99 | 9.00 | 2.34 |

| 15 μm–40 μm b | 68.92 | 15.01 | 1.61 |

| 15 μm–50 μm b | 69.01 | 16.21 | 1.51 |

| 15 μm–60 μm b | 72.18 | 17.14 | 2.23 |

| 15 μm–70 μm b | 72.49 | 24.18 | 1.65 |

| 10 μm–50 μm b | 73.29 | 19.88 | 2.24 |

| 10 μm–60 μm b | 74.06 | 22.15 | 2.24 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, H.; Bi, Y.; Wang, S.; Wang, C.; Wang, H.; Ye, G.; Feng, J. Ag-Grid and Ag-Nanowires Hybrid Transparent Electrodes to Improve Performance of Flexible Organic Light-Emitting Devices. Photonics 2025, 12, 272. https://doi.org/10.3390/photonics12030272

Yang H, Bi Y, Wang S, Wang C, Wang H, Ye G, Feng J. Ag-Grid and Ag-Nanowires Hybrid Transparent Electrodes to Improve Performance of Flexible Organic Light-Emitting Devices. Photonics. 2025; 12(3):272. https://doi.org/10.3390/photonics12030272

Chicago/Turabian StyleYang, Hao, Yangang Bi, Shirong Wang, Congfang Wang, Haipeng Wang, Gaoda Ye, and Jing Feng. 2025. "Ag-Grid and Ag-Nanowires Hybrid Transparent Electrodes to Improve Performance of Flexible Organic Light-Emitting Devices" Photonics 12, no. 3: 272. https://doi.org/10.3390/photonics12030272

APA StyleYang, H., Bi, Y., Wang, S., Wang, C., Wang, H., Ye, G., & Feng, J. (2025). Ag-Grid and Ag-Nanowires Hybrid Transparent Electrodes to Improve Performance of Flexible Organic Light-Emitting Devices. Photonics, 12(3), 272. https://doi.org/10.3390/photonics12030272