Abstract

High-efficiency multijunction laser power converters are demonstrated for the first time at high power for optical inputs around 1070 nm. The InP-based photovoltaic power-converting III–V heterostructures are designed with eight lattice-matched InGaAsP subcells (PT8-1070 nm). Conversion efficiencies of 55% were obtained at 18 W of output power. Endurance testing was performed for over 1000 h of continuous operation with an average output power of 13.2 W at an input wavelength of 1064 nm. An average steady-state efficiency of 54.4% at an ambient temperature of ~20 °C was obtained for that duration. The results demonstrate that 1 cm2 optical power converter devices can produce electrical outputs of 20 W at maximum power voltages around Vmpp ~6 V, thus retaining an optimal load near Rmpp at ~2 ohms. Efficiencies between 57.9% and 59.0% were also obtained for smaller 0.029 cm2 chips for input intensities between 35 and 69 W/cm2. This is an important development for power beaming applications: the unprecedented combination of power and conversion efficiency capabilities is expected to enable deployments for key wavelengths between 1040 and 1080 nm.

1. Introduction

High-performance semiconductor optoelectronic devices have advanced continuously in the past few decades. On the emitter side, in the field of high-power lasers, many interesting semiconductor diode solutions are readily available today, covering various wavelength ranges. Furthermore, high-power fiber lasers [1,2,3,4,5], such as ytterbium fiber lasers, are commonly used industrially for applications such as material processing, laser manufacturing for electrification applications, metal welding, and many others. On the receiver side, photovoltaic optical power converters (OPCs) have been developed primarily for the wavelength ranges of 800–850 nm [6,7,8,9,10,11,12,13,14,15,16,17,18,19,20,21,22,23,24,25,26,27,28,29,30,31,32,33,34,35,36], 940–990 nm [37,38], and 1450–1550 nm [39,40,41,42,43,44]. There is also exciting potential for other wavelengths [45,46,47,48,49,50,51,52,53,54,55,56,57,58,59,60,61,62]. These OPC devices efficiently convert laser light into useable electrical power and are often referred to as laser power converters (LPCs). Many of the initial OPC developments have been focused on wavelengths around 808 nm, benefiting from the availability of laser diodes and the maturity of GaAs-based devices. The 940–990 nm spectral range has also become interesting because of laser diode reliability and cost considerations. The long-wavelength 1450–1550 nm spectral range is predominantly strategic due to its low attenuation in the case of long-distance power-over-fiber applications. Ongoing research related to photovoltaic devices suggests other potential device developments [63,64,65,66,67,68,69,70,71,72,73,74,75,76,77,78,79,80,81,82,83], new optical wireless power transmission applications [84,85,86,87,88,89,90,91,92,93,94,95,96], new OPC opportunities [97,98,99,100,101,102], and interesting system design strategies and achievements [103,104,105,106,107,108,109,110,111,112,113,114,115,116].

Nonetheless, it has become clear that high-power fiber lasers represent an interesting prospect for power beaming applications, especially given their unique high quality beam propagation properties. Moreover, most power beaming applications typically require such high-power capabilities. In fiber lasers, the active gain medium is based on optical fiber doped with lanthanide elements (often called rare-earth elements), typically operating around the visible to mid-infrared spectral range. The prevalent ytterbium-doped fiber lasers emit at ~1070 nm, whereas the OPC developments around this wavelength have been limited [50,51,52,53,55,60]. No multijunction devices have been developed yet to convert efficient, high-power laser beams around these key wavelengths.

In the current work, we therefore reveal the first commercial multijunction OPCs for the 1040–1080 nm spectral range. The initial results are presented for Broadcom’s new eight-junction InGaAsP/InP concept samples for power beaming applications, called PT8-1070 nm OPCs, intended for operation using high-power 1070 nm laser diodes or fiber lasers.

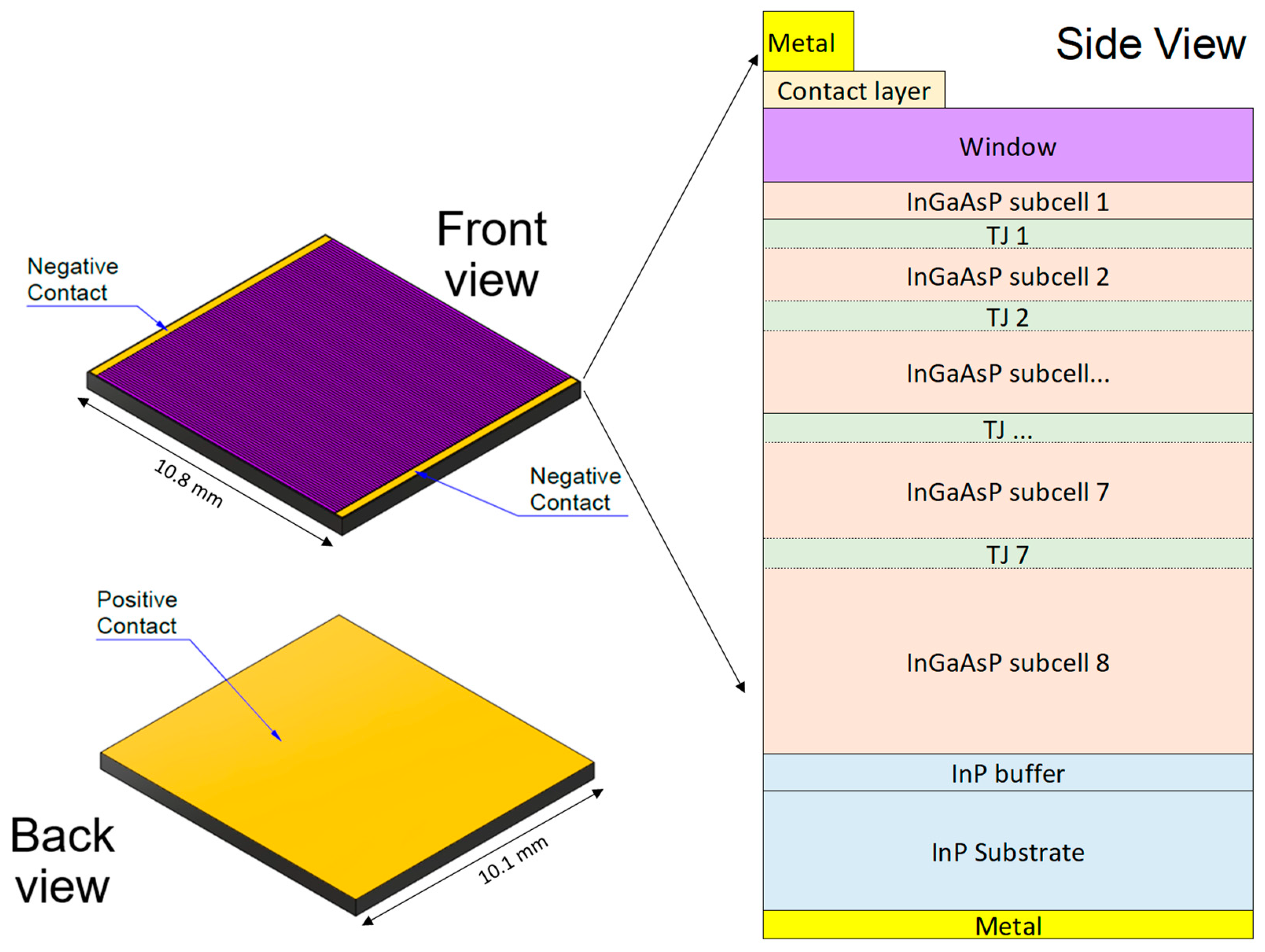

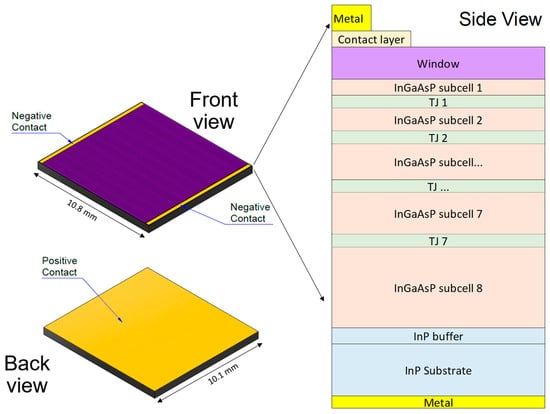

Relatively large chip areas are necessary for high-power applications; therefore, a new 10 mm × 10 mm product was developed. It is illustrated in Figure 1. The geometry is similar to high-power chips at 808 nm or 975 nm [29,31,32,37,89,90], including two narrow cathode busbars on opposite edges of the front side and a blanket back side metal for the anode. The device details are described in the section below.

Figure 1.

Schematic of Broadcom’s AFBR-POC506A6, a 10 mm × 10 mm PT8-1070 nm Vertical Epitaxial HeteroStructure Architecture (VEHSA design) device prepared with 8 InGaAsP subcells. The right side depicts the cross-section of the heterostructure (not to scale).

2. Materials and Methods

InGaAsP subcells lattice-matched to InP are expected to contribute between ~0.85 and ~0.9 V of output voltage each, for example, based on previous single junction measurements [70,74]. For the present development, a PT8 design was selected: a vertical multijunction with eight subcells. This design was selected to achieve an output voltage capable of maintaining an optimal load greater than 1 ohm in operation. The schematic of the 10 mm × 10 mm PT8-1070 nm heterostructure is depicted in Figure 1. It is based on the previously described Vertical Epitaxial HeteroStructure Architecture (VEHSA design) [14,15], here adapted for the lattice-matched InGaAsP/InP material system.

The Beer–Lambert law is utilized to determine the required absorber thicknesses of the individual subcells. Each subcell needs to be absorbing ~1/8 of the incident light. Such a PT8 design is expected to provide output voltages capable of high-power operation. The PT8 arrangement was selected to ensure that sufficient output voltage can be maintained over the industrial temperature range (−40 °C and 85 °C).

For the GaAs-based system, we have previously demonstrated that the output voltage scales linearly up to PT30 devices with 30 subcells [37]. For InP-based InGaAs absorbers, multijunctions with 10 subcells have also been commercialized [42,101,111]. Here, InP-based 8-junction InGaAsP OPCs is the focus of the present study.

The new photovoltaic vertical multijunction structure is built for operation with the optical input from a powerful laser source emitting in a spectral range peaking around 1070 nm. It is designed with eight thin (optically transparent) photovoltaic semiconductor subcells interconnected with tunnel junctions. The tunnel junctions are labelled TJi in Figure 1. Each individual subcell comprises an n-type emitter and a p-type base. The key aspects of the design strategy include selecting the absorber material composition such that its bandgap is at a target value with respect to the incident wavelength and then applying the previously described Beer–Lambert formalism to define the thicknesses of each subcells. For this study, we targeted an absorber bandgap between 40 and 50 nm below the incident wavelength. Such a spectral offset should allow satisfactory device performance over the entire operating temperature range of interest. The TJs are made to be as transparent as possible to the input beam, here utilizing InGaAlAsP alloys lattice-matched to InP. The optimization of TJs in InP-based material has been studied previously [14,42,67,79] and is not discussed here.

The epitaxial layers were grown using commercial Aixtron Metal Organic Chemical Vapor Deposition (MOCVD) reactors on 100 mm diameter InP substrates. Common commercial n-type and p-type dopant sources were used, as is customary for industrial devices. The total thickness of all the absorbing emitter and base layers from the different subcells is such that the impinging optical beam is almost completely absorbed. Here, for the InP material system, and InP window is used, and it is transparent to the incident light. An interesting design variation (not used here) consists of reducing the absorber thicknesses of the subcells and using the light reflected from the back side of the device. Indeed, the InP substrate is also transparent to the input light and to the InGaAsP luminescence, therefore allowing the reflected light [27] to be recycled [33,34,35,36] from the back side of the device. As described previously [14,15,37], to realize the required photocurrent matching condition, the structure usually has increasing subcell thicknesses from the top subcell (thinnest) toward the bottom subcell (thickest), as illustrated in Figure 1.

The device fabrication included standard blanket back-metallization (Zn-based alloy contacts) [63], front ohmic contacts (such as Pd/Ge/Ti/Pd/Ag/Au or In), and antireflection coatings (ARCs). The ARC is targeted to reduce the reflectivity (R) of the incident beam to R < 2% for the spectral range of interest.

For testing and characterization purposes, fiber-coupled semiconductor laser diodes were used in this study. It should be expected that testing with fiber lasers would give similar results as long as the beam profile is designed to have a comparable level of uniformity. Moreover, fiber lasers typically have a narrower spectral width compared to laser diodes, but both are relatively narrow compared to the spectral width of the device.

One of the test lasers has a maximum output power of ~24.5 W at a wavelength of 1064 nm. It has a numerical aperture of NA ~0.22, using a multi-mode fiber core diameter of 400 μm. Another fiber-coupled laser diode was also used with a maximum output power of ~10 W at 1067 nm. It was equipped with an integrated co-linear red aiming beam. The aiming beam is advantageous for obtaining good reproducibility in the alignment of the infrared probe beam with the test samples. For the I–V measurements, the tip of the fiber-coupled laser was positioned to form a circular spot contained within the clear aperture of the sample. The inscribed spot is achieved by positioning the output ferrule at ~25 mm above the surface of the sample.

The I–V characteristics were acquired using a Keithley 2601B, Keithley Instruments, Cleveland, OH, USA source-meter for output currents up to 1 amp and with a Keithley 2461 for higher currents. The data were obtained at a temperature of ~20 °C. Chip heating was minimized during the bare chip characterization measurements by using short scans, of the order of a few seconds, thereby called the cold-start method. For continuous, long-duration, steady-state measurements, bare chips were mounted on AlN carriers with silver epoxy. The heat extraction from the carriers was further obtained by mounting them on 200 g aluminum heatsinks. A thin layer of thermal interface material with a conductivity of 8.5 W/mK was employed for heat management purposes. An air flow of >~10 m3/h was used to maintain the heatsink near the ambient temperature. The output for the device was measured across a fixed power resistor using a data logger from DataQ Instruments, Akron, OH, USA.

3. Results

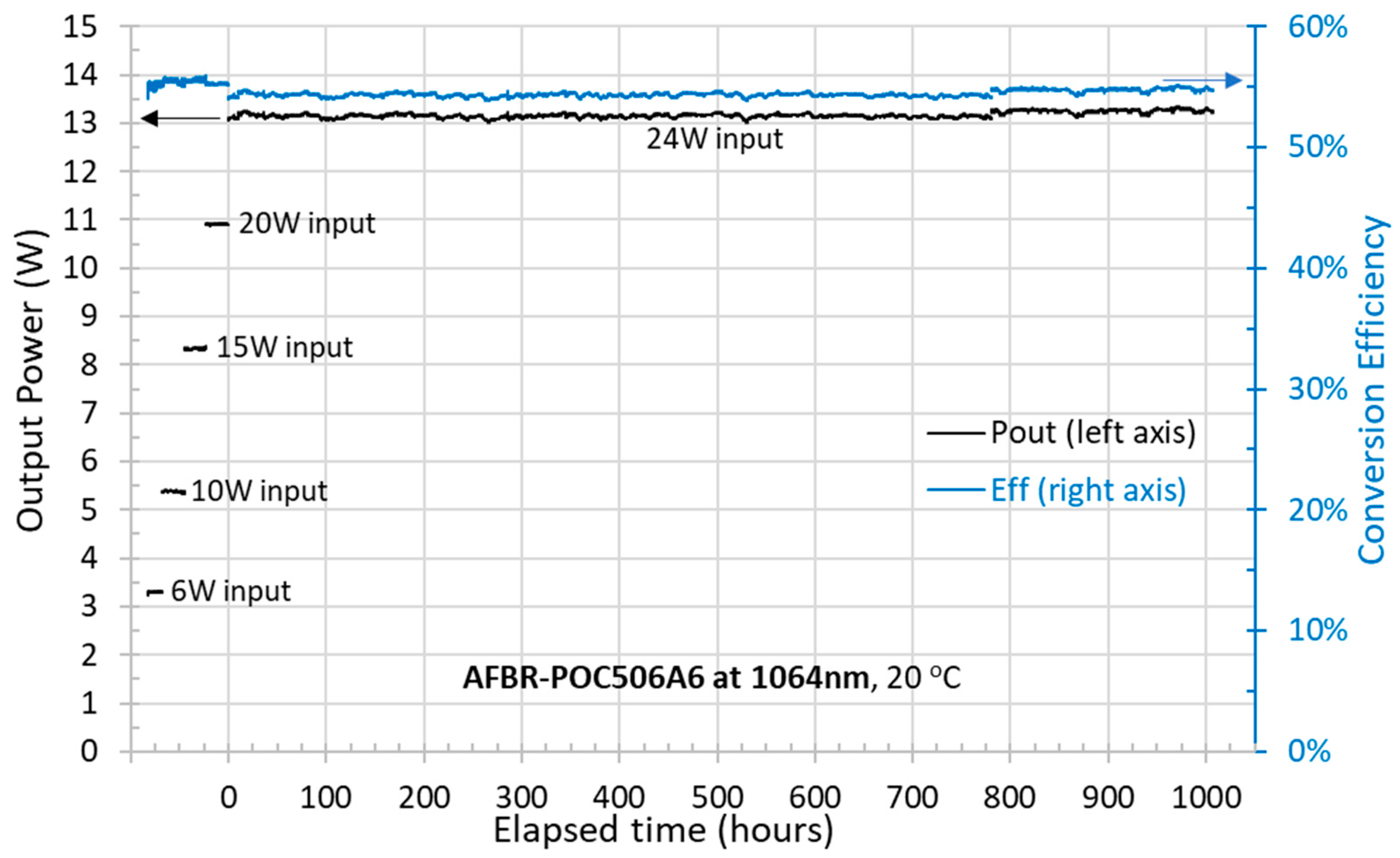

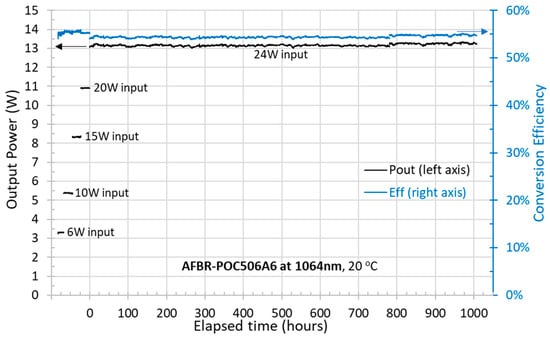

The results measured with the newly developed 10 mm × 10 mm PT8-1070 nm are shown in Figure 2, Figure 3 and Figure 4. Figure 2 shows the steady-state output characteristics of a chip-on-carrier (CoC) sample measured continuously for over 1000 h. As described above, the CoC was prepared by mounting the chip on an AlN carrier with silver epoxy and using an industrial wirebonding process.

Figure 2.

Steady-state output characteristics of the 10 mm × 10 mm PT8-1070 nm measured for over 1000 h. Various optical input powers (as indicated) were used between −100 h and 0 h, and a fixed optical input power of 24 W was maintained for the following 1000 h. The input wavelength is 1064 nm, the output power measured across a 2.75-ohm power resistor (from 0 to 1000 h) is indicated on the left vertical axis (black curve), and the corresponding conversion efficiency is shown on the right vertical axis (blue curve).

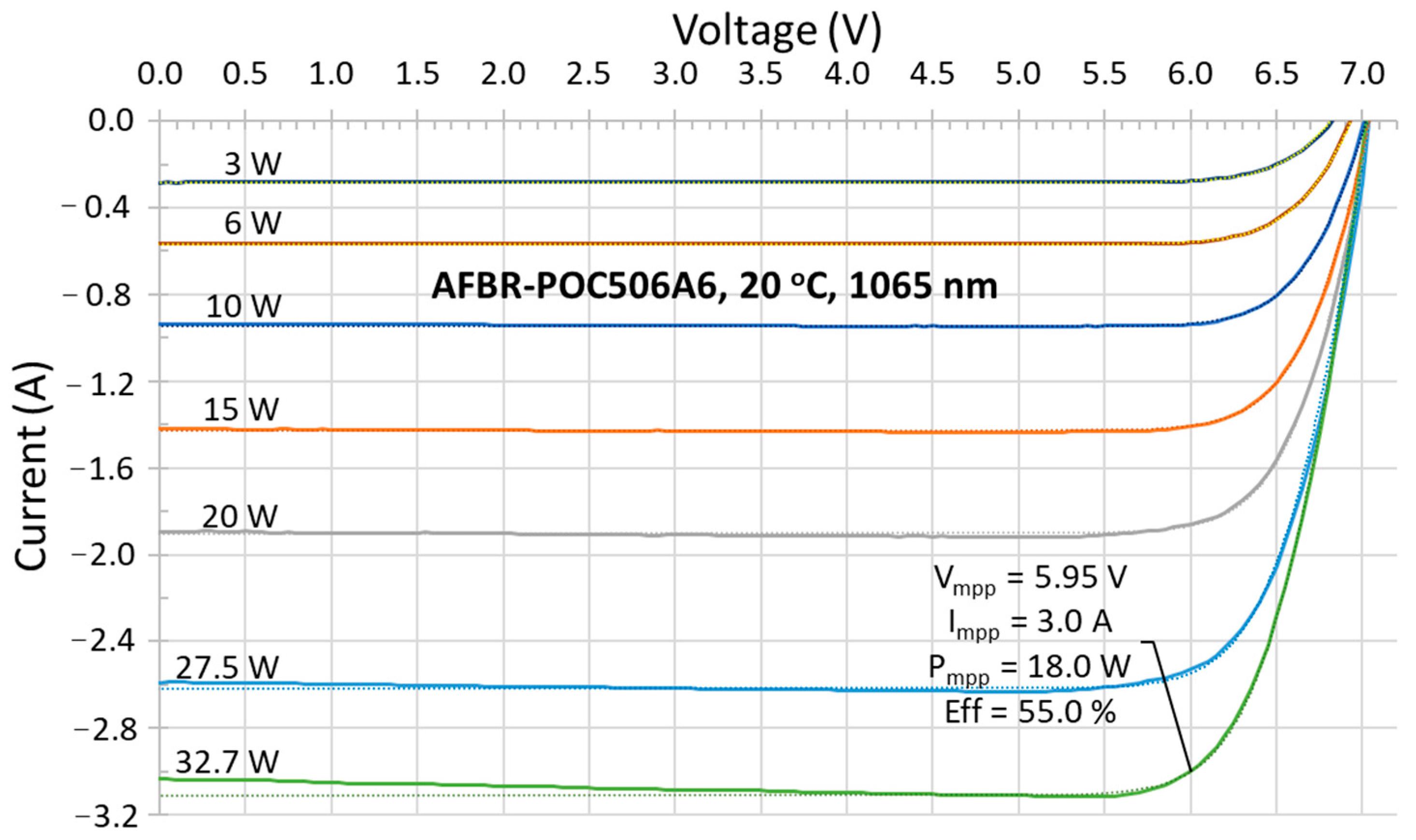

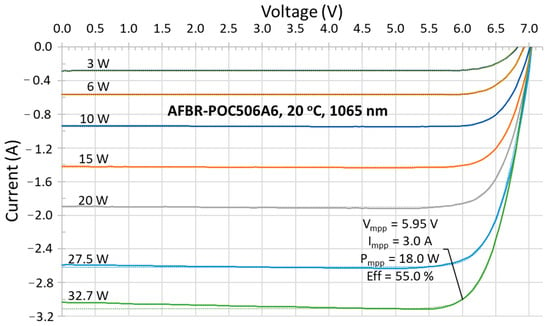

Figure 3.

Measured I–V properties (solid curves) at 20 °C for a 10 mm × 10 mm PT8-1070 nm OPC operating with laser power peaking between 1064 nm and 1067 nm for input powers between 3 W (upper dark-blue curve) and 32.7 W (lower green curve). At 32.7 W of input power, and efficiency of Eff = 55.0% is obtained with a Voc of 7.02 V. The output power (Pmpp) reaches 18 W with Vmpp = 5.95 V and Impp = 3.0 A. The diode equation fit (model) to the illuminated I–V curves is also shown with the overlapping dotted curves for each optical input power.

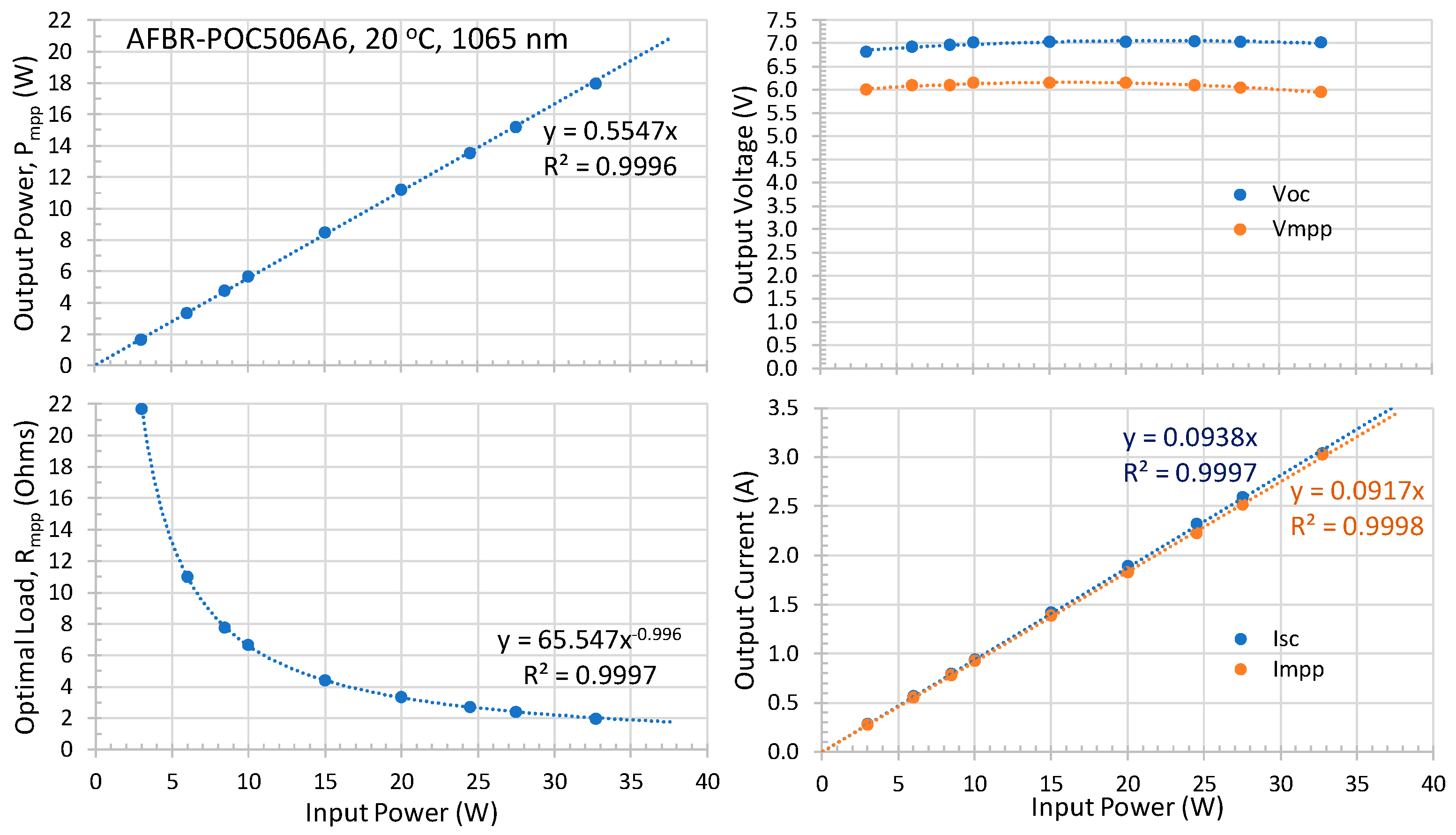

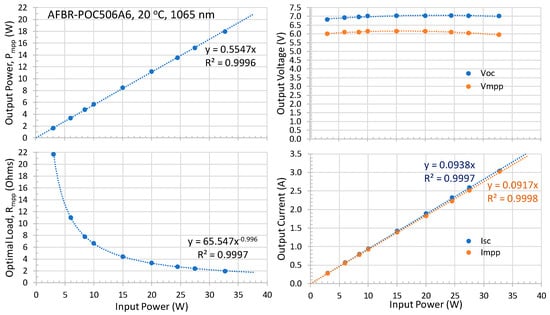

Figure 4.

The optical input power dependence of a 10 mm × 10 mm PT8-1070 nm OPC operating at 20 °C with laser power peaking between 1064 nm and 1067 nm. The electrical output power, Pmpp, is shown in the top-left; the output voltage, open-circuit voltage (Voc), and maximum power point voltage (Vmpp) are shown in the top-right; the optimal load, Rmpp, is shown in the bottom-left, and the output current, short-circuit current (Isc), and maximum power point current (Impp) are shown in the bottom-right. The values of the corresponding regressions are indicated in the plots.

Between −100 h and 0 h, various optical input powers were used, progressively stepping up the optical input power from 6 W to 24 W, as indicated in Figure 2. Fixed power resistor loads were used as follows: 11 ohms for a 6 W optical input, 6.8 ohms for a 10 W optical input, 4.4 ohms for a 15 W optical input, 3.36 ohms for a 19.8 W optical input, and 2.75 ohms for a 24.2 W optical input. The loads were selected to correspond to the optimal load (Rmpp), as evaluated from the I–V curves of Figure 3 or from the fit derived in Figure 4.

In Figure 2, the test with the fixed optical input power of 24.2 W ran continuously for 1000 h. The input wavelength of 1064 nm was delivered using an ST connector secured with a custom adapter to position the output tip of the fibered laser approximately 24 mm above the center of the sample. The OPC’s output power (measured across the 2.75-ohm power resistor) is indicated on the left vertical axis (black curve), and the corresponding conversion efficiency is shown on the right vertical axis (blue curve). Clearly, the output is stable over time. No observable performance degradation was observed for the 1000 h duration. The small fluctuations in the output power are attributable to minor drifts in the ambient temperature during the days of the ~6-week period.

Figure 3 shows the measured I–V curves for various optical input powers between Pin = 3 W and Pin = 32.7 W. At 32.7 W of laser power, an efficiency of Eff = 55.0% is obtained with a Voc of 7.02 V. The output power (Pmpp) reaches 18 W with Vmpp = 5.95 V and Impp = 3.0 A. Diode equation fits, based on a previously described model [76], are also shown together with the measured illuminated I–V curves: the overlapping dotted curves in Figure 3. As can be deduced from Figure 3, closely correlated fits are obtained. The fit is based on an 8J ideal diode equation with all the subcells having an ideality factor of n = 1.038. An overall series resistance of 0.12 ohm is extracted for the 15 W curve.

It is foreseen that these OPCs can operate at higher optical powers, but due to the limited laser power available in our setup, the experimental scope of the present study is restricted to optical input powers below 33 W.

The important characteristics of the I–V curves of Figure 3 are analyzed in more detail in Figure 4. The input power dependence of key parameters is plotted. The top-left plot of Figure 4 shows that the output power Pmpp has a measured slope efficiency of Eff ~55.5% with negligible deviations from a linear regression for optical input powers up to 33 W.

As mentioned above, the input power was limited by the maximum laser power available. The two lasers described above had to be used simultaneously to reach ~33 W via the dual beam method [29]. Provided adequate heatsinking is available for the device, we expect it would be possible to use higher optical input powers without damaging the photovoltaic laser power converter. In the high power range, it is also important to fill the chip aperture as much as possible in order to distribute the heat load and to avoid spiky optical and heat profiles.

The output voltage is shown in the top-right panel of Figure 4. The open-circuit voltage (Voc) reaches a maximum value of 7.040 V, while the maximum power point voltage (Vmpp) is then 6.15 V. It corresponds to an average voltage of 0.880 V per subcell, yielding a bandgap voltage offset value of Woc~0.234 V, where Woc = (Eg/q) − Voc, with Eg being the bandgap energy (here InGaAsP lattice-matched to InP) and q the electronic charge.

The optimal load Rmpp is shown in the bottom-left panel of Figure 4. The corresponding fit is derived from the measured data and provides the necessary load information for fixed load measurements at various optical input powers, as in Figure 2.

The output current is shown in the bottom-right panel of Figure 4. The short-circuit current (Isc) yields a responsivity of 93.8 mA/W. Taking into account the eight junctions of the PT8, for a wavelength of ~1065 nm, this corresponds to an EQEIsc of 87.4% (the external quantum efficiency measured at the short-circuit current point). The maximum power point current (Impp) is measured to have a responsivity of 91.7 mA/W, corresponding to an EQEmpp of 85.4% (the external quantum efficiency measured at the maximum power point).

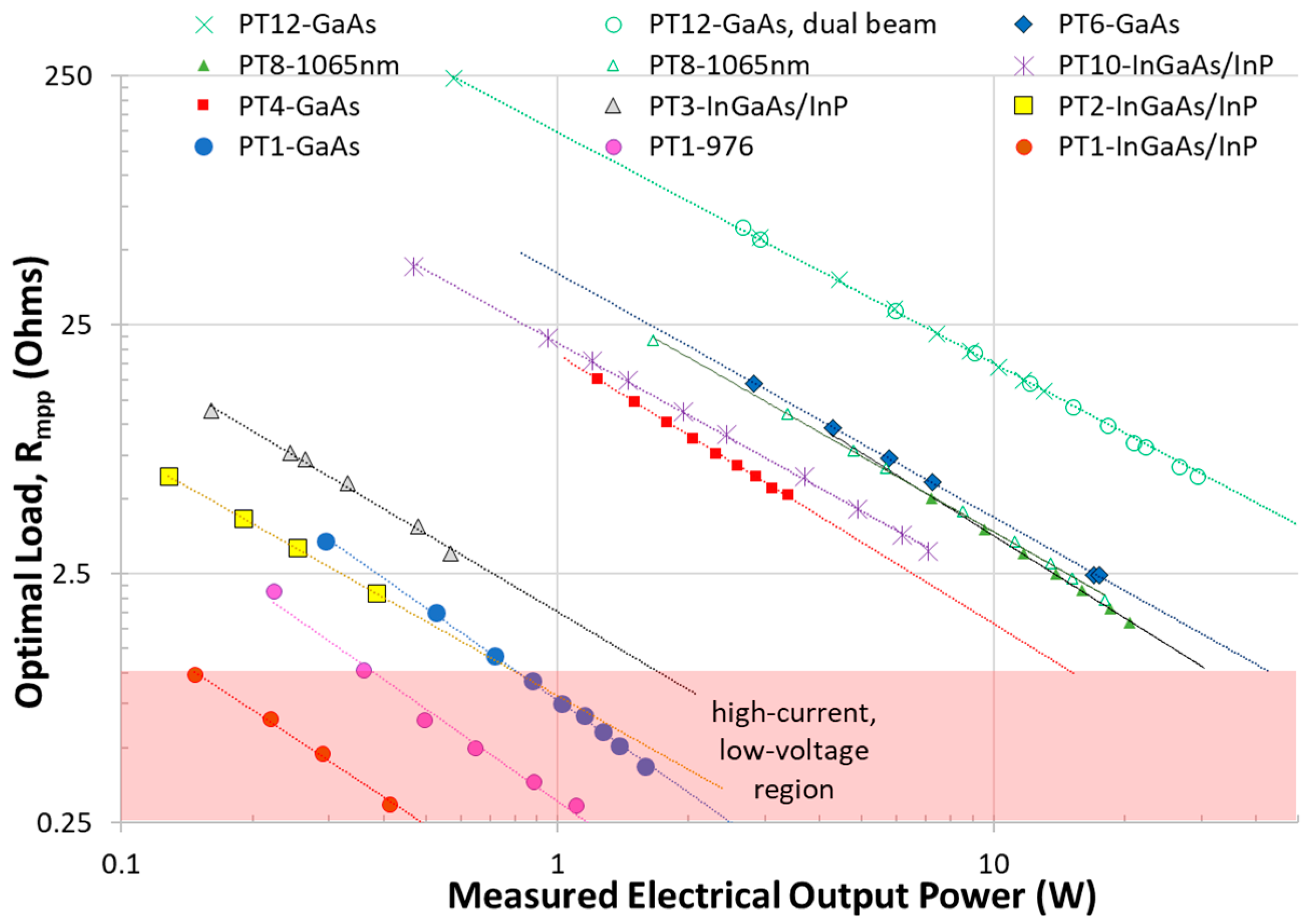

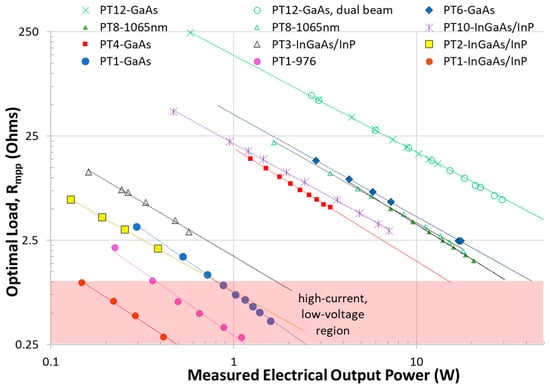

Figure 5 shows the Optimal Load Chart obtained with several previously characterized OPC designs. The plot is updated with the new 10 mm × 10 mm PT8-1070 nm OPC results from two samples from the present study (open and solid green triangles). It shows the measured optimal load (Rmpp = Vmpp/Impp) as a function of the electrical output power (Pmpp = Vmpp × Impp), and it further demonstrates that multijunction OPCs uniquely allow efficient high-power conversion for various wavelengths of operation [37].

Figure 5.

The measured optimal load (Rmpp = Vmpp/Impp) as a function of the output power obtained with various OPC designs, demonstrating that multijunction OPCs allow efficient high-power conversion for various wavelengths of operation. This Optimal Load Chart is updated with the 10 mm × 10 mm PT8-1070 nm OPC results from two samples (open and solid green triangles). The lines are the corresponding regressions. Updated from Fafard, S. and Masson, D.P. Photonics 2022, 9, 438. Copyright 2022 Author(s), licensed under a Creative Commons Attribution (CC BY) license [37].

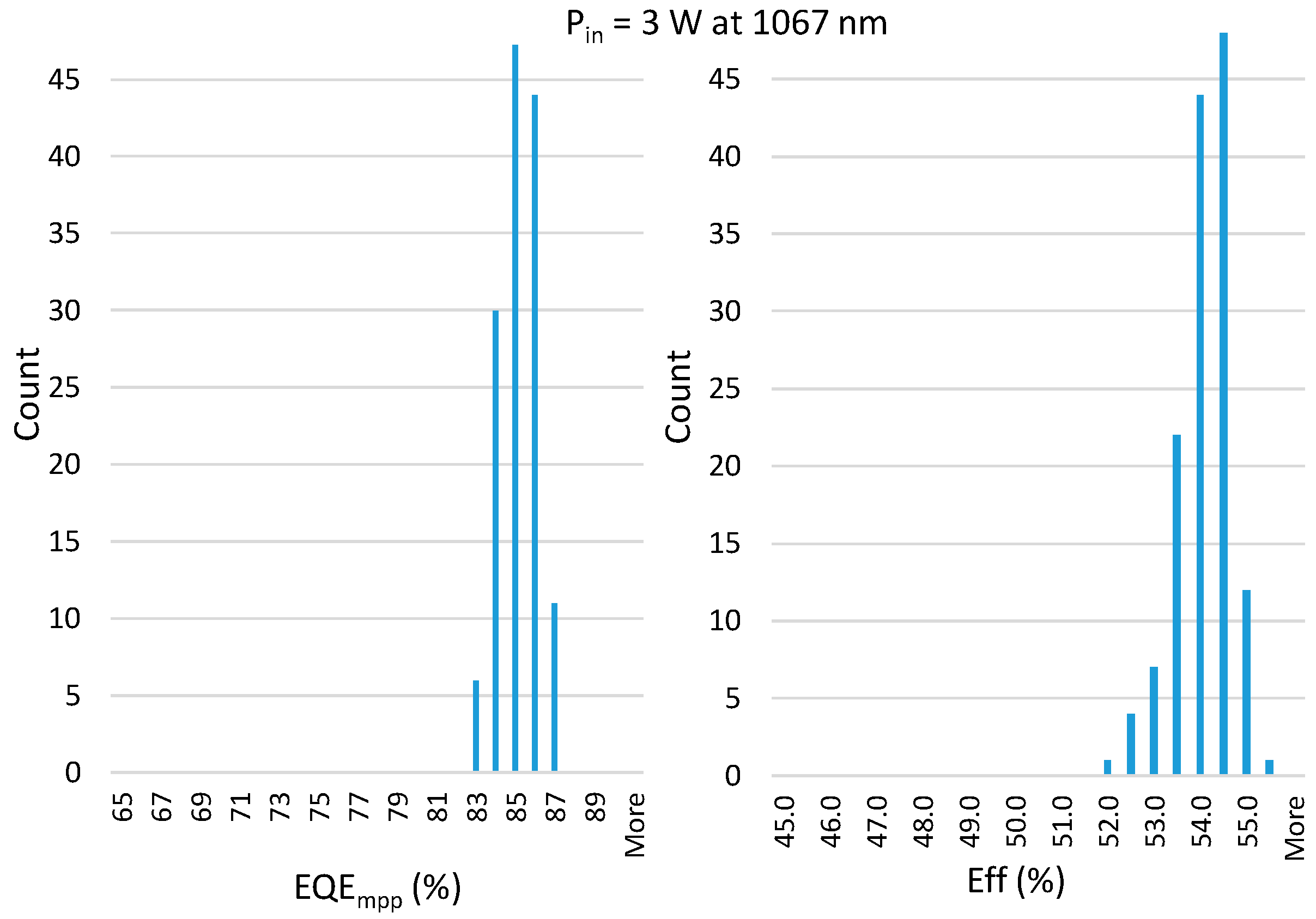

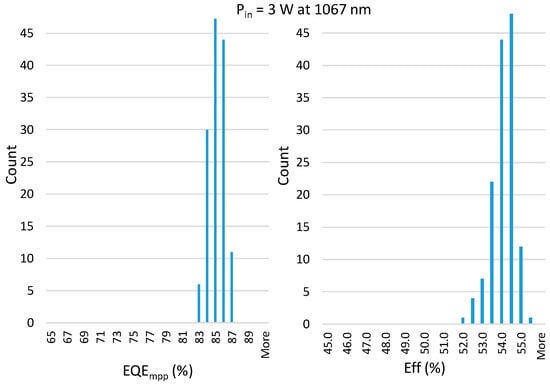

Based on the high-performance of the OPCs, as evident from Figure 2, Figure 3, Figure 4 and Figure 5, Broadcom is now in the process of commercializing the 10 mm × 10 mm PT8-1070 nm design under the product name AFBR-POC506A6. To that effect, Figure 6 shows histograms for a pilot manufacturing lot of concept samples. The test results were obtained with bare chip probing with a 3 W optical input at 1067 nm. For such bare chip probing, the back side of the chip is in electrical contact with a metal chuck, and four-wire needle probing is performed between the front busbars and the back side. This procedure keeps the chips in pristine shape for future uses, and the direct mechanical thermal interface for such chip-on-chuck testing is typically sufficient for 3 W optical probing using the cold-start approach described above. Key relevant statistics are shown in Figure 6 for 139 known-good-die chips tested with the chuck set at 20 °C.

Figure 6.

Histograms for a manufacturing lot of concept samples of Broadcom’s AFBR-POC506A6 PT8-1070 nm OPCs, for 10 mm × 10 mm chips at 20 °C. The external quantum efficiency at the maximum power point, EQEmpp, is shown on the left, and the conversion efficiency is shown on the right for bare chip probing with a 3 W optical input at 1067 nm.

The histogram for the external quantum efficiency based on the maximum point current (Impp) is shown on the left of Figure 6: EQEmpp. A tight distribution is obtained with a mean EQEmpp of 84.7% and a standard deviation of 1.0%abs.

The conversion efficiency (Eff = Pmpp/Pin) is shown on the right of Figure 6. A mean efficiency of Eff = 53.8% is obtained with a standard deviation of 0.6%abs. The above testing was performed at a low irradiance of 3 W/cm2. The efficiency will further increase for operations at higher input power on mounted chips.

To operate at higher powers, the chips must be mounted on carriers, for example, as was the case for Figure 2, Figure 3, Figure 4 and Figure 5. The maximum irradiance in Figure 3 and Figure 5 was 33 W/cm2.

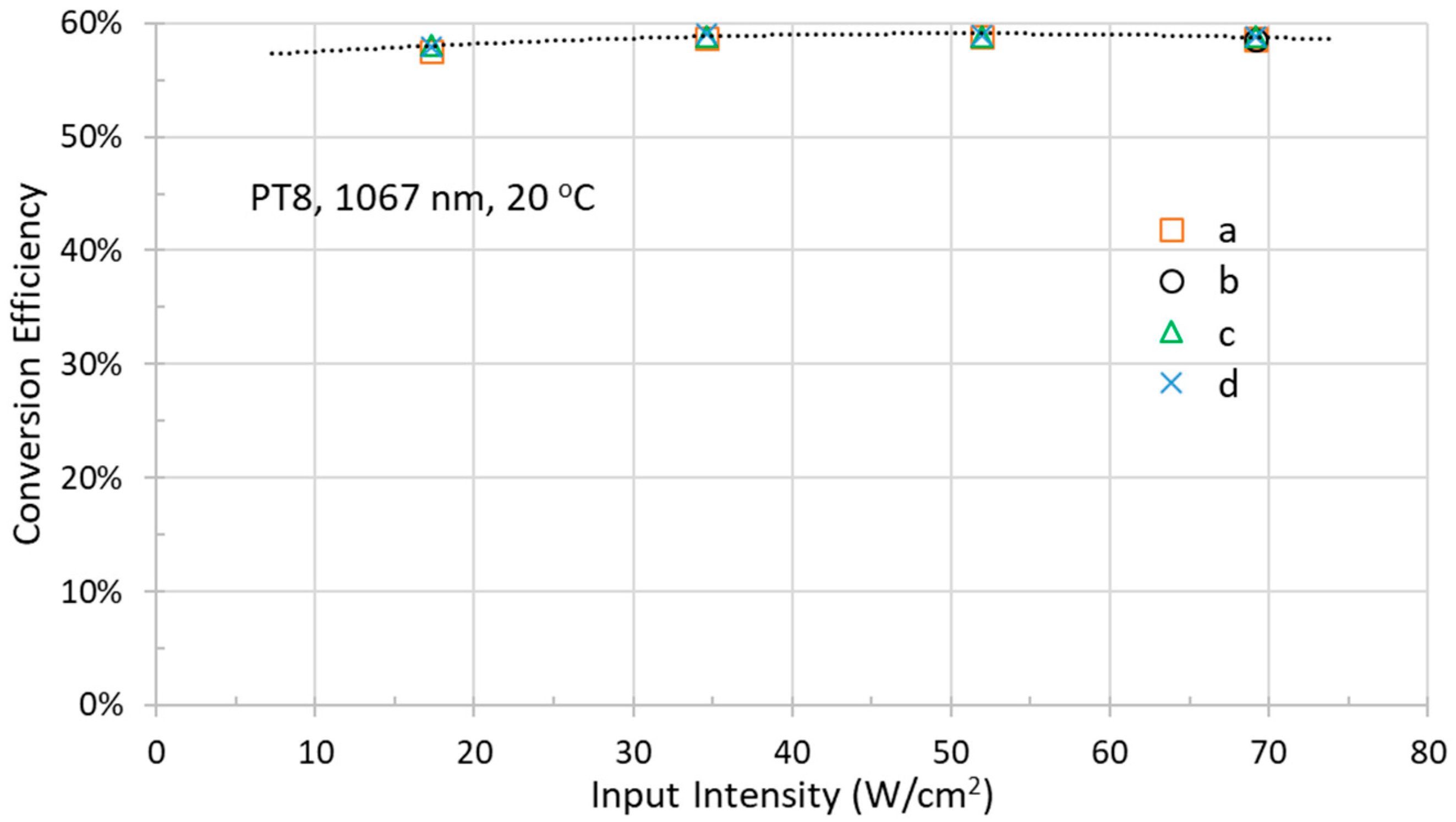

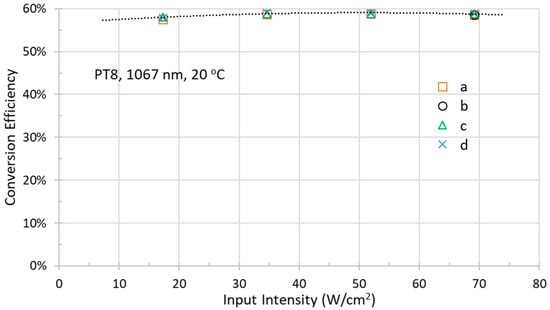

To measure the performance at higher irradiance, smaller chips can also be evaluated. To that effect, the wafer layout also incorporated 0.029 cm2 test chips. Figure 7 shows the optical input irradiance dependence of the conversion efficiency, up to ~70 W/cm2. Four 0.029 cm2 PT8-1070 nm OPCs from the same pilot batch are shown. At a 20 °C, with an optical input wavelength of 1067 nm, efficiencies between 57.9% and 59.0% are obtained for input intensities between 35 and 69 W/cm2.

Figure 7.

The optical input irradiance dependence of the conversion efficiency for 0.029 cm2 PT8-1070 nm OPCs at 1067 nm at 20 °C. The results for samples a, b, c, and d are shown.

It is interesting to note that in the solar field, 100 × AM1.5, commonly called 100 suns, corresponds roughly to 10 W/cm2, whereas the present study covered average irradiance up to 33 W/cm2 for the 10 mm chips and up to almost 70 W/cm2 for the smaller chips. It would therefore roughly correspond to an irradiance between the solar equivalent of 330 and 700 suns. The results reveal that the laser light can be concentrated at least to such levels as long as the thermal management is sufficient. The more concentrated irradiance in Figure 7 produced higher conversion efficiencies, mainly because of the higher output voltage obtained under these conditions.

4. Discussion

Laser power beaming applications at high power require large area photovoltaic devices designed to produce high output voltages and therefore support large currents with minimal resistive losses. The InP-based lattice-matched 8J heterostructure design, with the 1 cm2 form-factor of Figure 1, allows single units to be built that are expected to support up to 20 W of usable electrical power. The chips can also be arranged in arrays to scale up the output power.

In most practical cases, it is often advantageous to operate the laser power converter devices in an under-filled illumination mode [29]. For example, the laser beam typically has a round geometry and a relatively spiky profile; therefore, partial illumination is normally unavoidable. The results of Figure 2 demonstrate that the newly developed PT8-1070 nm can operate under these conditions with stable efficient output for 1000 h without observable performance degradations. We demonstrated continuous operation with 13.2 W of output power averaged over 1000 h with a mean conversion efficiency of 54.4% measured through a load of 2.75 ohms. Such an unprecedented combination of power capability and conversion efficiency is expected to enable the deployment of power beaming solutions in the 1040–1080 nm spectral range.

This study also demonstrated 18 W electrical output power at 55% conversion efficiency in Figure 3, Figure 4 and Figure 5. To reach output power of over 20 W, it is important to engineer the thermal management strategy adequately to avoid excess heating. For example, sufficient spatially concentrated currents can lead to sudden runaway conditions. Therefore, high thermal conduction in the chip assembly process is critical to avoid chip damage within a concentrated beam operation. It should be expected that this consideration is particularly relevant for the case of high-power fiber lasers, which often have a spikier Gaussian beam profile.

This study exemplified the use of silver epoxy for the assembly process on AlN carriers. The new PT8-1070 nm OPC chips would also be compatible with a solder assembly process, but in either case, it also is important that the assembly process does not leave voids under the chips.

Figure 4 demonstrates a linear output power with input power over the range studied. The relation of the optimal load with the input power was derived. An operational output voltage of ~6 V was revealed. An EQEmpp of 85.4% was obtained at 1065 nm.

Figure 5 demonstrates that new PT8-1070 nm OPCs have an optimal load characteristic comparable to GaAs-based PT6 but also feature the advantage of efficient operation at strategic wavelengths around 1070 nm. Overall, this makes these OPC devices suitable for operations at high input powers for key wavelengths for power beaming applications.

5. Conclusions

In conclusion, the high-efficiency capabilities of multijunction laser power converters were demonstrated at high power for an optical input around 1070 nm. The vertical multijunction VEHSA strategy has once again been proven very effective at trading photocurrent in favor of increasing the operating voltage for a new spectral range: an important development for power beaming applications. Conversion efficiencies of Eff ~ 55% were measured at electrical outputs 18 W for an input wavelength of ~1065 nm. These new lattice-matched InP-based PT8-1070 nm devices are giving a Vmpp of 5.95 V and an EQEmpp of 85.4%, as measured for a pilot lot of concept samples.

Endurance testing was performed for over 1000 h of continuous operation with an average output power of 13.2 W at an input wavelength of 1064 nm, giving an average steady-state efficiency of 54.4%. Efficiencies between 57.9% and 59.0% were demonstrated for smaller 0.029 cm2 chips for input intensities between 35 and 69 W/cm2.

Author Contributions

Conceptualization, S.F. and D.M.; methodology, S.F. and D.M.; software, S.F. and D.M.; validation, S.F. and D.M.; formal analysis, S.F. and D.M.; investigation, S.F. and D.M.; data curation, S.F. and D.M.; writing—original draft preparation S.F.; writing—review and editing S.F. and D.M.; visualization, S.F.; project administration, S.F. and D.M.; funding acquisition, S.F. and D.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The data that support the findings of this study are available from the corresponding author upon reasonable request.

Conflicts of Interest

The authors declare no particular conflicts of interest, but it should be noted that the authors are employed by Broadcom, a company that manufactures and sells semiconductor components, including power converter devices.

References

- Shcherbakov, E.A.; Fomin, V.V.; Abramov, A.A.; Ferin, A.A.; Mochalov, D.V.; Gapontsev, V.P. Industrial grade 100 kW power CW fiber laser. In Advanced Solid State Lasers; Optica Publishing Group: Washington, DC, USA, 2013; p. ATh4A–2. [Google Scholar]

- Varshney, A.K.; Singhal, G.; Nayak, J. High power lasers for directed energy applications: Developments and challenges. Infrared Phys. Technol. 2024, 136, 105064. [Google Scholar] [CrossRef]

- Platonov, N.; Yagodkin, R.; De La Cruz, J.; Arambula, C.; Fitts, J.; Sergeev, V. 5 kW single-mode narrow-linewidth ytterbium fiber amplifier with M2-value< 1.1 in all fiber format and direct diode pumping. In Fiber Lasers XXII: Technology and Systems; SPIE: Bellingham, WA, USA, 2025; Volume 13342. [Google Scholar]

- Kawahito, Y.; Wang, H.; Katayama, S.; Sumimori, D. Ultra high power (100 kW) fiber laser welding of steel. Opt. Lett. 2018, 43, 4667–4670. [Google Scholar] [CrossRef] [PubMed]

- Fathi, H.; Närhi, M.; Gumenyuk, R. Towards ultimate high-power scaling: Coherent beam combining of fiber lasers. Photonics 2021, 8, 566. [Google Scholar] [CrossRef]

- Olsen, L.C.; Huber, D.A.; Dunham, G.; Addis, F.W. High efficiency monochromatic GaAs solar cells. In Proceedings of the Conference Record of the IEEE Photovoltaic Specialists Conference, Las Vegas, NV, USA, 7–11 October 1991; Volume 1, pp. 419–424. [Google Scholar]

- Fahrenbruch, A.L.; Lopez-Otero, A.; Werthen, J.G.; Wu, T.C. GaAs- and InAlGaAs-based concentrator-type cells for conversion of power transmitted by optical fibers. In Proceedings of the Conference Record of the IEEE Photovoltaic Specialists Conference, Washington, DC, USA, 13–17 May 1996; pp. 117–120. [Google Scholar]

- Fave, A.; Kaminski, A.; Gavand, M.; Mayet, L.; Laugier, A. GaAs converter for high power laser diode. In Proceedings of the Conference Record of the IEEE Photovoltaic Specialists Conference, Washington, DC, USA, 13–17 May 1996; pp. 101–104. [Google Scholar]

- Peña, R.; Algora, C.; Anton, I. GaAs multiple photovoltaic converters with an efficiency of 45% for monochromatic illumination. In Proceedings of the 3rd World Conference on Photovoltaic Energy Conversion, Osaka, Japan, 11–18 May 2003; pp. 228–231. [Google Scholar]

- Krut, U.D.; Sudharsanan, R.; Isshiki, T.; King, R.; Karam, N.H. A 53% high efficiency GaAs vertically integrated multi-junction laser power converter. In Proceedings of the 65th DRC Device Research Conference, South Bend, IN, USA, 18–20 June 2007; pp. 123–124, art. no. 4373680.. [Google Scholar]

- Oliva, E.; Dimroth, F.; Bett, A.W. GaAs converters for high power densities of laser illumination. Prog. Photovolt. Res. Appl. 2008, 16, 289–295. [Google Scholar] [CrossRef]

- Bett, A.W.; Dimroth, F.; Lockenhoff, R.; Oliva, E.; Schubert, J. III-V solar cells under monochromatic illumination. In Proceedings of the Conference Record of the IEEE Photovoltaic Specialists Conference, San Diego, CA, USA, 11–16 May 2008. art. no. 4922910. [Google Scholar]

- Schubert, J.; Oliva, E.; Dimroth, F.; Guter, W.; Loeckenhoff, R.; Bett, A.W. High-voltage GaAs photovoltaic laser power converters. IEEE Trans. Electron Devices 2009, 56, 170–175. [Google Scholar] [CrossRef]

- Masson, D.; Proulx, F.; Fafard, S. Pushing the limits of concentrated photovoltaic solar cell tunnel junctions in novel high-efficiency GaAs phototransducers based on a vertical epitaxial heterostructure architecture. Prog. Photovolt. Res. Appl. 2015, 23, 1687–1696. [Google Scholar] [CrossRef]

- Fafard, S.; Masson, D.P. Transducer to Convert Optical Energy to Electrical Energy. U.S. Patent 9,673,343, 6 June 2017. [Google Scholar]

- Zhao, Y.; Sun, Y.; He, Y.; Yu, S.; Dong, J. Design and fabrication of six-volt vertically-stacked GaAs photovoltaic power converter. Sci. Rep. 2016, 6, 38044. [Google Scholar] [CrossRef] [PubMed]

- Fafard, S.; York, M.C.A.; Proulx, F.; Valdivia, C.E.; Wilkins, M.M.; Arès, R.; Aimez, V.; Hinzer, K.; Masson, D.P. Ultrahigh efficiencies in vertical epitaxial heterostructure architectures. Appl. Phys. Lett. 2016, 108, 071101. [Google Scholar] [CrossRef]

- Fafard, S.; Proulx, F.; York, M.C.A.; Richard, L.S.; Provost, P.O.; Arès, R.; Aimez, V.; Masson, D.P. High-photovoltage GaAs vertical epitaxial monolithic heterostructures with 20 thin p/n junctions and a conversion efficiency of 60%. Appl. Phys. Lett. 2016, 109, 131107. [Google Scholar] [CrossRef]

- Khvostikov, V.P.; Kalyuzhnyy, N.A.; Mintairov, S.A.; Sorokina, S.V.; Potapovich, N.S.; Emelyanov, V.M.; Timoshina, N.K.; Andreev, V.M. Photovoltaic laser-power converter based on AlGaAs/GaAs heterostructures. Semiconductors 2016, 50, 1220–1224. [Google Scholar] [CrossRef]

- Sun, Y.-R.; Dong, J.-R.; He, Y.; Zhao, Y.-M.; Yu, S.-Z.; Xue, J.-P.; Xue, C.; Wang, J.; Lu, Y.-Q.; Ding, Y.-W. A six-junction GaAs laser power converter with different sizes of active aperture. Optoelectron. Lett. 2017, 13, 21–24. [Google Scholar] [CrossRef]

- York, M.C.A.; Fafard, S. High efficiency phototransducers based on a novel vertical epitaxial heterostructure architecture (VEHSA) with thin p/n junctions. J. Phys. D Appl. Phys. 2017, 50, 173003. [Google Scholar] [CrossRef][Green Version]

- Huang, J.; Sun, Y.; Zhao, Y.; Yu, S.; Dong, J.; Xue, J.; Xue, C.; Wang, J.; Lu, Y.; Ding, Y. Four-junction AlGaAs/GaAs laser power converter. J. Semicond. 2018, 39, 044003. [Google Scholar] [CrossRef]

- Khvostikov, V.P.; Sorokina, S.V.; Potapovich, N.S.; Khvostikova, O.A.; Timoshina, N.K.; Shvarts, M.Z. Modification of Photovoltaic Laser-Power (λ = 808 nm) Converters Grown by LPE. Semiconductors 2018, 52, 366–370. [Google Scholar] [CrossRef]

- Huang, J.; Sun, Y.; Zhao, Y.; Yu, S.; Li, K.; Dong, J.; Xue, J.; Xue, C.; Ye, Y. Characterizations of high-voltage vertically-stacked GaAs laser power converter. J. Semicond. 2018, 39, 094006. [Google Scholar] [CrossRef]

- Panchak, A.N.; Pokrovskiy, P.V.; Malevskiy, D.A.; Larionov, V.R.; Shvarts, M.Z. High-Efficiency Conversion of High-Power-Density Laser Radiation. Tech. Phys. Lett. 2019, 45, 24–26. [Google Scholar] [CrossRef]

- Zhao, Y.; Liang, P.; Ren, H.; Han, P. Enhanced efficiency in 808 nm GaAs laser power converters via gradient doping. AIP Adv. 2019, 9, 105206. [Google Scholar] [CrossRef]

- Helmers, H.; Lopez, E.; Höhn, O.; Lackner, D.; Schön, J.; Schauerte, M.; Schachtner, M.; Dimroth, F.; Bett, A.W. 68.9% Efficient GaAs-Based Photonic Power Conversion Enabled by Photon Recycling and Optical Resonance. Phys. Status Solidi (RRL) Rapid Res. Lett. 2021, 15, 2100113. [Google Scholar] [CrossRef]

- Fafard, S.; Masson, D.P. 74.7% Efficient GaAs-Based Laser Power Converters at 808 nm at 150 K. Photonics 2022, 9, 579. [Google Scholar] [CrossRef]

- Fafard, S.; Masson, D. Vertical Multi-Junction Laser Power Converters with 61% Efficiency at 30 W Output Power and with Tolerance to Beam Non-Uniformity, Partial Illumination, and Beam Displacement. Photonics 2023, 10, 940. [Google Scholar] [CrossRef]

- García, I.; Hinojosa, M.; Delgado, M.; Algora, C. Photovoltaic laser power converters producing 21 W/cm2 at a conversion efficiency of 66.5%. Cell Rep. Phys. Sci. 2024, 5, 102263. [Google Scholar] [CrossRef]

- Helmers, H.; Oliva, E.; Schachtner, M.; Mikolasch, G.; Ruiz-Preciado, L.A.; Franke, A.; Bartsch, J. Overcoming optical-electrical grid design trade-offs for cm2-sized high-power GaAs photonic power converters by plating technology. Prog. Photovolt. Res. Appl. 2024, 32, 636–642. [Google Scholar] [CrossRef]

- Gou, Y.; Mou, Z.; Wang, H.; Chen, Y.; Wang, J.; Yang, H.; Deng, G. High-performance laser power converters with resistance to thermal annealing. Opt. Express 2024, 32, 8335–8342. [Google Scholar] [CrossRef] [PubMed]

- Proulx, F.; York, M.C.A.; Provost, P.O.; Arès, R.; Aimez, V.; Masson, D.P.; Fafard, S. Measurement of strong photon recycling in ultra-thin GaAs n/p junctions monolithically integrated in high-photovoltage vertical epitaxial heterostructure architec-tures with conversion efficiencies exceeding 60%. Phys. Status Solidi RRL 2017, 11, 1600385. [Google Scholar] [CrossRef]

- Wilkins, M.; Valdivia, C.E.; Gabr, A.M.; Masson, D.; Fafard, S.; Hinzer, K. Luminescent coupling in planar opto-electronic de-vices. J. Appl. Phys. 2015, 118, 143102. [Google Scholar] [CrossRef]

- Lopez, E.; Höhn, O.; Schauerte, M.; Lackner, D.; Schachtner, M.; Reichmuth, S.K.; Helmers, H. Experimental coupling process efficiency and benefits of back surface reflectors in photovoltaic multi-junction photonic power converters. Prog. Photovolt. Res. Appl. 2021, 29, 461–470. [Google Scholar] [CrossRef]

- Xia, D.; Krich, J.J. Efficiency increase in multijunction monochromatic photovoltaic devices due to luminescent coupling. J. Appl. Phys. 2020, 128, 013101. [Google Scholar] [CrossRef]

- Fafard, S.; Masson, D.P. Perspective on photovoltaic optical power converters. J. Appl. Phys. 2021, 130, 160901. [Google Scholar] [CrossRef]

- Keller, G. GaAs multi-junction laser power converters at AZUR SPACE: Current status and development activities. In Proceedings of the 1st Optical Wireless and Fiber Power Transmission Conference, Yokohama, Japan, 23–25 April 2019; pp. 11–12. [Google Scholar]

- Jarvis, S.D.; Mukherjee, J.; Perren, M.; Sweeney, S.J. Development and characterisation of laser power converters for optical power transfer applications. IET Optoelectron. 2014, 8, 64–70. [Google Scholar] [CrossRef]

- Wang, A.C.; Sun, Y.R.; Yu, S.Z.; Yin, J.J.; Zhang, W.; Wang, J.S.; Fu, Q.X.; Han, Y.H.; Qin, J.; Dong, J.R. Characteristics of 1520 nm InGaAs multijunction laser power converters. Appl. Phys. Lett. 2021, 119, 243902. [Google Scholar] [CrossRef]

- Sweeney, S.J. Optical wireless power at eye-safe wavelengths: Challenges and opportunities. In Proceedings of the 3rd Optical Wireless and Fiber Power Transmission Conference (OWPT2021), Yokohama, Japan, 19–22 April 2021. [Google Scholar]

- Fafard, S.; Masson, D.P. High-Efficiency and High-Power Multijunction InGaAs/InP Photovoltaic Laser Power Converters for 1470 nm. Photonics 2022, 9, 438. [Google Scholar] [CrossRef]

- Helmers, H.; Hohn, O.; Tibbits, T.; Schauerte, M.; Amin, H.M.N.; Lackner, D. Unlocking 1550 nm laser power conversion by InGaAs single- and multiple-junction PV cells. In Proceedings of the 2022 IEEE 49th Photovoltaics Specialists Conference (PVSC), Philadelphia, PA, USA, 5–10 June 2022. [Google Scholar]

- Prajzler, V.; Zikmund, M. Power over fiber system using high-power laser source operating at 1470 nm with maximum power 2.0 W for powering to distance up to 5855 m. Opt. Fiber Technol. 2024, 88, 104033. [Google Scholar] [CrossRef]

- Law, H.D.; Ng, W.W.; Nakano, K.; Dapkus, P.D.; Stone, D.R. High Efficiency InGaAsP Photovoltaic Power Converter. IEEE Electron Device Lett. 1981, 2, 26–27. [Google Scholar] [CrossRef]

- Green, M.A.; Zhao, J.; Wang, A.; Wenham, S.R. 45% Efficient Silicon Photovoltaic Cell Under Monochromatic Light. IEEE Electron Device Lett. 1992, 13, 317–318. [Google Scholar] [CrossRef]

- Wojtczuk, S.J. Long-wavelength laser power converters for optical fibers. In Proceedings of the Conference Record of the Twenty Sixth IEEE Photovoltaic Specialists Conference, Anaheim, CA, USA, 29 September–3 October 1997; pp. 971–974. [Google Scholar]

- Andreev, V.; Khvostikov, V.; Kalinovsky, V.; Lantratov, V.; Grilikhes, V.; Rumyantsev, V.; Shvarts, M.; Fokanov, V.; Pavlov, A. High current density GaAs and GaSb photovoltaic cells for laser power beaming. In Proceedings of the 3rd World Conference on Photovoltaic Energy Conversation, Osaka, Japan, 11–18 May 2003; Volume 1, pp. 761–764. [Google Scholar]

- Jomen, R.; Tanaka, F.; Akiba, T.; Ikeda, M.; Kiryu, K.; Matsushita, M.; Maenaka, H.; Dai, P.; Lu, S.; Uchida, S. Conversion efficiencies of single-junction III–V solar cells based on InGaP, GaAs, InGaAsP, and InGaAs for laser wireless power transmission. Jpn. J. Appl. Phys. 2018, 57, 08RD12. [Google Scholar] [CrossRef]

- Kalyuzhnyy, N.A.; Emelyanov, V.M.; Mintairov, S.A.; Shvarts, M.Z. InGaAs metamorphic laser (λ=1064 nm) power converters with over 44% efficiency. AIP Conf. Proc. 2018, 2012, 110002. [Google Scholar]

- Kim, Y.; Shin, H.-B.; Lee, W.-H.; Jung, S.H.; Kim, C.Z.; Kim, H.; Lee, Y.T.; Kang, H.K. 1080 nm InGaAs laser power converters grown by MOCVD using InAlGaAs metamorphic buffer layers. Sol. Energy Mater. Sol. Cells 2019, 200, 109984. [Google Scholar] [CrossRef]

- Khvostikov, V.P.; Kalyuzhnyy, N.A.; Mintairov, S.A.; Potapovich, N.S.; Sorokina, S.V.; Shvarts, M.Z. Module of Laser-Radiation (λ = 1064 nm) Photovoltaic Converters. Semiconductors 2019, 53, 1110–1113. [Google Scholar] [CrossRef]

- Yin, J.; Sun, Y.; Yu, S.; Zhao, Y.; Li, R.; Dong, J. 1064 nm InGaAsP multi-junction laser power converters. J. Semicond. 2020, 41, 062303. [Google Scholar] [CrossRef]

- Helmers, H.; Franke, A.; Lackner, D.; Hohn, O.; Predan, F.; Dimroth, F. 51% Efficient Photonic Power Converters for O-Band Wavelengths around 1310 nm. In Proceedings of the Conference Record of the IEEE Photovoltaic Specialists Conference, Calgary, AB, Canada, 15–21 June 2020; pp. 2471–2474. [Google Scholar]

- Kalyuzhnyy, N.A.; Emelyanov, V.M.; Evstropov, V.V.; Mintairov, S.A.; Mintairov, M.A.; Nahimovich, M.V.; Salii, R.A.; Shvarts, M.Z. Optimization of photoelectric parameters of InGaAs metamorphic laser (λ=1064 nm) power converters with over 50% efficiency. Sol. Energy Mater. Sol. Cells 2020, 217, 110710. [Google Scholar] [CrossRef]

- Komuro, Y.; Honda, S.; Kurooka, K.; Warigaya, R.; Tanaka, F.; Uchida, S. A 43.0% efficient GaInP photonic power converter with a distributed Bragg reflector under high-power 638 nm laser irradiation of 17 Wcm−2. Appl. Phys. Express 2021, 14, 052002. [Google Scholar] [CrossRef]

- Nouri, N.; Valdivia, C.E.; Beattie, M.N.; Zamiri, M.S.; Krich, J.J.; Hinzer, K. Ultrathin monochromatic photonic power converters with nanostructured back mirror for light trapping of 1310-nm laser illumination. In Physics, Simulation, and Photonic Engineering of Photovoltaic Devices X; SPIE: Bellingham, WA, USA, 2021; Volume 11681, p. 116810X. [Google Scholar]

- Lozano, J.F.; Seoane, N.; Almonacid, F.; Fernández, E.F.; García-Loureiro, A. Laser Power Converter Architectures Based on 3C-SiC with Efficiencies > 80%. Sol. RRL 2022, 6, 2101077. [Google Scholar] [CrossRef]

- Wong, Y.L.; Shibui, S.; Koga, M.; Hayashi, S.; Uchida, S. Optical Wireless Power Transmission Using a GaInP Power Converter Cell under High-Power 635 nm Laser Irradiation of 53.5 W/cm2. Energies 2022, 15, 3690. [Google Scholar] [CrossRef]

- Gou, Y.; Wang, H.; Wang, J.; Zhang, Y.; Niu, R.; Chen, X.; Wang, B.; Xiao, Y.; Zhang, Z.; Liu, W.; et al. 1064 nm InGaAs metamorphic laser power converts with over 44% efficiency. Opt. Express 2022, 30, 42178–42185. [Google Scholar] [CrossRef] [PubMed]

- Sanmartín, P.; Fernández, F.E.; García-Loureiro, A.; Montes-Romero, J.; Cano, A.; Martín, P.; Rey-Stolle, I.; García, I.; Almonacid, F. Design and Characterization of a 53.5% Efficient Gallium Indium Phosphide-Based Optical Photovoltaic Converter under 637 nm Laser Irradiation at 10 W cm−2. Solar RRL 2024, 8, 2400278. [Google Scholar] [CrossRef]

- Pan, H.; Wang, J.; Chen, X.; Chen, Y.; Mou, Z.; Yang, H.; Deng, G.; Gou, Y. InGaAs/GaAs metamorphic buffer for laser power converter applications. Opt. Express 2024, 32, 48105–48113. [Google Scholar] [CrossRef]

- Hwang, S.; Shim, J.; Eo, Y. Ohmic Contacts of Pd/Zn/M(= Pd or Pt)/Au to p-Type InP. J. Korean Phys. Soc. 2005, 46, 751. [Google Scholar]

- Höhn, O.; Walker, A.W.; Bett, A.W.; Helmers, H. Optimal laser wavelength for efficient laser power converter operation over temperature. Appl. Phys. Lett. 2016, 108, 241104. [Google Scholar] [CrossRef]

- Čičić, S.; Tomić, S. Automated design of multi junction solar cells by genetic approach: Reaching the> 50% efficiency target. Sol. Energy Mater. Sol. Cells 2018, 181, 30–37. [Google Scholar] [CrossRef]

- France, R.M.; Buencuerpo, J.; Bradsby, M.; Geisz, J.F.; Sun, Y.; Dhingra, P.; Lee, M.L.; Steiner, M.A. Graded buffer Bragg reflectors with high reflectivity and transparency for metamorphic optoelectronics. J. Appl. Phys. 2021, 129, 173102. [Google Scholar] [CrossRef]

- Beattie, M.N.; Valdivia, C.E.; Wilkins, M.M.; Zamiri, M.; Kaller, K.L.C.; Tam, M.C.; Kim, H.S.; Krich, J.J.; Wasilewski, Z.R.; Hinzer, K. High current density tunnel diodes for multi-junction photovoltaic devices on InP substrates. Appl. Phys. Lett. 2021, 118, 062101. [Google Scholar] [CrossRef]

- Lin, M.; Sha, W.E.I.; Zhong, W.; Xu, D. Intrinsic losses in photovoltaic laser power converters. Appl. Phys. Lett. 2021, 118, 104103. [Google Scholar] [CrossRef]

- Zhao, Y.; Li, S.; Ren, H.; Li, S.; Han, P. Energy band adjustment of 808 nm GaAs laser power converters via gradient doping. J. Semicond. 2021, 42, 032701. [Google Scholar] [CrossRef]

- Wulf, J.; Oliva, E.; Mikolasch, G.; Bartsch, J.; Dimroth, F.; Helmers, H. Thin film GaAs solar cell enabled by direct rear side plating and patterned epitaxial lift-off. In Proceedings of the 2021 IEEE 48th Photovoltaic Specialists Conference (PVSC), Fort Lauderdale, FL, USA, 20–25 June 2021; p. 1931. [Google Scholar]

- Schauerte, M.; Höhn, O.; Wierzkowski, T.; Keller, G.; Helmers, H. 4-Junction GaAs Based Thin Film Photonic Power Converter with Back Surface Reflector for Medical Applications. In Proceedings of the 2021 IEEE 48th Photovoltaic Specialists Conference (PVSC), Fort Lauderdale, FL, USA, 20–25 June 2021; pp. 1954–1959. [Google Scholar]

- France, R.M.; Hinojosa, M.; Ahrenkiel, S.P.; Young, M.R.; Johnston, S.W.; Guthrey, H.L.; Geisz, J.F. Improvement of front-junction GaInP by point-defect injection and annealing. In Proceedings of the 2021 IEEE 48th Photovoltaic Specialists Conference (PVSC), Fort Lauderdale, FL, USA, 20–25 June 2021; p. 2522. [Google Scholar]

- Geisz, J.F.; Buencuerpo, J.; McMahon, W.E.; Klein, T.R.; Tamboli, A.C.; Warren, E.L. Fabrication, Measurement, and Modeling of GaInP/GaAs Three-Terminal Cells and Strings. In Proceedings of the 2021 IEEE 48th Photovoltaic Specialists Conference (PVSC), Fort Lauderdale, FL, USA, 20–25 June 2021; pp. 0154–0157. [Google Scholar]

- Yamaguchi, M.; Dimroth, F.; Geisz, J.F.; Ekins-Daukes, N.J. Multi-junction solar cells paving the way for super high-efficiency. J. Appl. Phys. 2021, 129, 240901. [Google Scholar] [CrossRef]

- Wang, A.-C.; Yin, J.-J.; Yu, S.-Z.; Sun, Y.-R. Multiple tunnel diode peaks in I–V curves of a multijunction laser power converter. Appl. Phys. Lett. 2022, 121, 233901. [Google Scholar] [CrossRef]

- Fafard, S.; Masson, D. Onset of Quantum-Confined Stark Effects in Multijunction Photovoltaic Laser Power Converters Designed with Thin Subcells. Photonics 2023, 10, 1243. [Google Scholar] [CrossRef]

- Khvostikov, V.P.; Sorokina, S.V.; Khvostikova, O.A.; Nakhimovich, M.V.; Shvarts, Z. Ge-Based Photovoltaic Laser-Power Converters. IEEE J. Photovoltaics 2023, 13, 254–259. [Google Scholar] [CrossRef]

- Wang, A.-C.; Yin, J.-J.; Yu, S.-Z.; Sun, Y.-R.; Dong, J.-R. Origins of the short circuit current of a current mismatched multijunction photovoltaic cell considering subcell reverse breakdown. Opt. Express 2023, 31, 14482–14494. [Google Scholar] [CrossRef]

- Gou, Y.; Zhu, L.; Mou, Z.; Chen, Y.; Cheng, Y.; Wang, J.; Yang, H.; Deng, G. InP-based tunnel junctions for ultra-high concentration photovoltaics. Opt. Express 2023, 32, 408–414. [Google Scholar] [CrossRef]

- Zhang, Y.; Guan, C.; Chu, W.; Zhou, Y.; Zhou, R.; Yao, Y. Optimal I–V Curve Scan Time for a GaAs Laser Power Converter. Photonics 2023, 10, 762. [Google Scholar] [CrossRef]

- Shi, L.; Sun, C.; Liu, Y.; Wu, Y.; Wu, Z.; Guo, H.; Wan, R.; Zhang, B.; Zhang, Y. Effect of cell structures on electrical degradation of GaAs laser power convertors after 1 MeV electron irradiation and structure-optimization for improving radiation resistance. Sol. Energy Mater. Sol. Cells 2024, 278, 113206. [Google Scholar] [CrossRef]

- Shi, L.; Sun, C.; Liu, Y.; Liu, K.; Zhang, W.; Wu, Y.; Guo, H.; Sun, Q. A novel method of determining bias lights for spectral response measurement of GaAs multi-junction laser power converters and its applications. Sol. Energy Mater. Sol. Cells 2023, 266, 112661. [Google Scholar] [CrossRef]

- Schachtner, M.; Beattie, M.N.; Reichmuth, S.K.; Wekkeli, A.; Siefer, G.; Helmers, H. Measuring the device-level EQE of multi-junction photonic power converters. Prog. Photovolt. Res. Appl. 2024, 32, 827–836. [Google Scholar] [CrossRef]

- Mukherjee, J.; Jarvis, S.; Perren, M.; Sweeney, S.J. Efficiency limits of laser power converters for optical power transfer applications. J. Phys. D Appl. Phys. 2013, 46, 264006. [Google Scholar] [CrossRef]

- Shan, T.; Qi, X. Design and optimization of GaAs photovoltaic converter for laser power beaming. Infrared Phys. Technol. 2015, 71, 144–150. [Google Scholar] [CrossRef]

- Jaffe, P. Practical power beaming gets real. In IEEE Spectrum 21 May 2022; Jaffe, P., Jenkins, P., Nugent, T., Eds.; PowerLight Tech. Inc.: Kent, WA, USA, 2019; Available online: https://youtu.be/Xb9THqrXd4I (accessed on 6 April 2025).

- Algora, C.; García, I.; Delgado, M.; Peña, R.; Vázquez, C.; Hinojosa, M.; Rey-Stolle, I. Beaming power: Photovoltaic laser power converters for power-by-light. Joule 2022, 6, 340. [Google Scholar] [CrossRef]

- Gou, Y.; Wang, H.; Wang, J.; Niu, R.; Chen, X.; Wang, B.; Xiao, Y.; Zhang, Z.; Liu, W.; Yang, H.; et al. High-performance laser power converts for direct-energy applications. Opt. Express 2022, 30, 31509–31517. [Google Scholar] [CrossRef] [PubMed]

- Gou, Y.; Wang, H.; Wang, J.; Chen, Y.; Mou, Z.; Chen, Y.; Yang, H.; Deng, G. High-performance laser power converters for wireless information transmission applications. Opt. Express 2023, 31, 34937–34945. [Google Scholar] [CrossRef]

- Chen, Y.; Mou, Z.; Wang, J.; Zhu, L.; Gou, Y.; Sun, Z. 808 nm laser power converters for simultaneous wireless information and power transfer. IEEE J. Photovolt. 2024, 14, 890–900. [Google Scholar] [CrossRef]

- Jaffe, P.; Nugent, T.; Ii, B.S.; Szazynski, M. Power Beaming: History, Theory, and Practice; World Scientific: Singapore, 2024; Volume 5. [Google Scholar]

- Fujita, K. Laser Power Transmission on the Moon Using Multibeams of Single-Mode Fiber Lasers as Wireless System and Optical Fibers as Wired System. J. Evol. Space Act. 2024, 2, 174. [Google Scholar]

- Zheng, Y.; Zhang, G.; Huan, Z.; Zhang, Y.; Yuan, G.; Li, Q.; Ding, G.; Lv, Z.; Ni, W.; Shao, Y.; et al. Wireless laser power transmission: Recent progress and future challenges. Space Sol. Power Wirel. Transm. 2024, 1, 17–26. [Google Scholar] [CrossRef]

- Meng, X.-L.; Li, X.-Y.; Kong, D.-H.; Mallick, T.K.; Liu, C.-L. Enhanced heat transfer characteristics using dimples in the receiving end of laser wireless power transmission system. Appl. Therm. Eng. 2024, 252, 123619. [Google Scholar] [CrossRef]

- Thakar, B.; McNabb, J.T.; Robertson, B.E.; Mavris, D. Trade Studies for Evaluating Lunar Surface Power Architectures. In Proceedings of the AIAA SCITECH 2025 Forum, Orlando, FL, USA, 6–10 January 2025; p. 2192. [Google Scholar]

- Nugent, T., Jr.; Summers, J.; Gort, J.; Weinthal, W. Low-latency enhanced light curtain for safe laser power beaming. Opt. Power Deliv. 2025, 13359, 6–10. [Google Scholar]

- Kimovec, R.; Helmers, H.; Bett, A.W.; Topič, M. Comprehensive electrical loss analysis of monolithic interconnected multi-segment laser power converters. Prog. Photovolt. Res. Appl. 2019, 27, 199. [Google Scholar] [CrossRef]

- Wagner, L.; Reichmuth, S.K.; Philipps, S.P.; Oliva, E.; Bett, A.W.; Helmers, H. Integrated series/parallel connection for photo-voltaic laser power converters with optimized current matching. Prog. Photovolt. Res. Appl. 2020, 29, 172. [Google Scholar] [CrossRef]

- Panchak, A.; Khvostikov, V.; Pokrovskiy, P. AlGaAs gradient waveguides for vertical p/n junction GaAs laser power con-verters. Opt. Laser Technol. 2021, 136, 106735. [Google Scholar] [CrossRef]

- Fernández, E.F.; García-Loureiro, A.; Seoane, N.; Almonacid, F. Band-gap material selection for remote high-power laser transmission. Sol. Energy Mat. Sol. Cells 2022, 235, 111483. [Google Scholar] [CrossRef]

- Fafard, S.; Masson, D. 67.5% Efficient InP-Based Laser Power Converters at 1470 nm at 77 K. Photonics 2024, 11, 130. [Google Scholar] [CrossRef]

- Kim, B.; Kim, M.; Li, B.D.; Hool, R.D.; Lee, M.L. Cryogenic GaAs laser power converters. Sol. Energy Mater. Sol. Cells 2025, 281, 113321. [Google Scholar] [CrossRef]

- He, T.; Yang, S.-H.; Muñoz, M.Á.; Zhang, H.-Y.; Zhao, C.-M.; Zhang, Y.-C.; Xu, P. High-power high-efficiency laser power transmission at 100 m using optimized multi-cell GaAs converter. Chin. Phys. Lett. 2014, 31, 104203. [Google Scholar] [CrossRef]

- Wilkins, M.M.; Ishigaki, M.; Provost, P.-O.; Masson, D.; Fafard, S.; Valdivia, C.E.; DeDe, E.M.; Hinzer, K. Ripple-free boost-mode power supply using photonic power conversion. IEEE Trans. Power Electron. 2018, 34, 1054–1064. [Google Scholar] [CrossRef]

- Li, L.; Ji, H.-M.; Luo, S.; Xu, P.; Gao, Q.; Lv, H.; Liu, W. Fabrication and Characterization of a High-Power Assembly With a 20-Junction Monolithically Stacked Laser Power Converter. IEEE J. Photovoltaics 2018, 8, 1355–1362. [Google Scholar]

- Matsuura, M.; Nomoto, H.; Mamiya, H.; Higuchi, T.; Masson, D.; Fafard, S. Over 40-W Electric Power and Optical Data Transmission Using an Optical Fiber. IEEE Trans. Power Electron. 2020, 36, 4532–4539. [Google Scholar] [CrossRef]

- Helmers, H.; Armbruster, C.; von Ravenstein, M.; Derix, D.; Schoner, C. 6-W Optical Power Link with Integrated Optical Data Transmission. IEEE Trans. Power Electron. 2020, 35, 7904–7909. [Google Scholar] [CrossRef]

- Shindo, N.; Kobatake, T.; Masson, D.; Fafard, S.; Matsuura, M. Optically Powered and Controlled Drones Using Optical Fibers for Airborne Base Stations. Photonics 2022, 9, 882. [Google Scholar] [CrossRef]

- Zhou, Y.; Guan, C.; Lv, H.; Zhang, Y.; Zhou, R.; Chu, W.; Lv, P.; Qin, H.; Li, S.; Li, X. Design and research of laser power converter (LPC) for passive optical fiber audio transmission system terminal. Photonics 2023, 10, 1257. [Google Scholar] [CrossRef]

- Putra, E.P.; Theivindran, R.; Hasnul, H.; Lee, H.J.; Ker, P.J.; Jamaludin, Z.; Awang, R.; Yusof, F.A.M. Technology update on patent and development trend of power over fiber: A critical review and future prospects. J. Photon-Energy 2023, 13, 011001. [Google Scholar] [CrossRef]

- Fafard, S.; Masson, D. Demonstration of Power-over-Fiber with Watts of Output Power Capabilities over Kilometers or at Cryogenic Temperatures. Photonics 2024, 11, 596. [Google Scholar] [CrossRef]

- Souza, D.; Carneiro, L.; Souto, V.D.P.; Sodré, A.C. Radio-and Power-over-Fiber Integration for 6G Networks: Challenges and Future Prospects. IEEE Access 2024, 13, 5321–5341. [Google Scholar] [CrossRef]

- He, T.; Pan, G.; Zheng, G.; Xu, Z.; Lv, Z.; Wu, Q.; Wan, L.; Huang, H.; Shi, T. Experimentation and analysis of intra-cavity beam-splitting method to enhance the uniformity of light in the powersphere. Photonics 2024, 11, 128. [Google Scholar] [CrossRef]

- Vázquez, C.; Altuna, R.; López-Cardona, J.D.; Pérez, R. Power over fiber in radio access networks: 5G and beyond. J. Opt. Commun. Netw. 2024, 16, D119–D128. [Google Scholar] [CrossRef]

- Arroyave, M.; Behera, B.; Cavanna, F.; Feld, A.; Guo, F.; Heindel, A.; Jung, C.; Koch, K.; Silverio, D.L.; Caicedo, D.M.; et al. Characterization and novel application of power over fiber for electronics in a harsh environment. J. Instrum. 2024, 19, P10019. [Google Scholar] [CrossRef]

- Pellico, W.; Arroyave, M.A.; Behera, B.; Cavanna, F.; Guo, F.; Heindel, A.; Jung, C.K.; Silverio, D.L.; Caicedo, D.M.; McGrew, C.; et al. Power over fiber development for HEP detectors. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2024, 1069, 169880. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).