Surface Curvature Sensor Based on Intracavity Sensing of Fiber Ring Laser

Abstract

1. Introduction

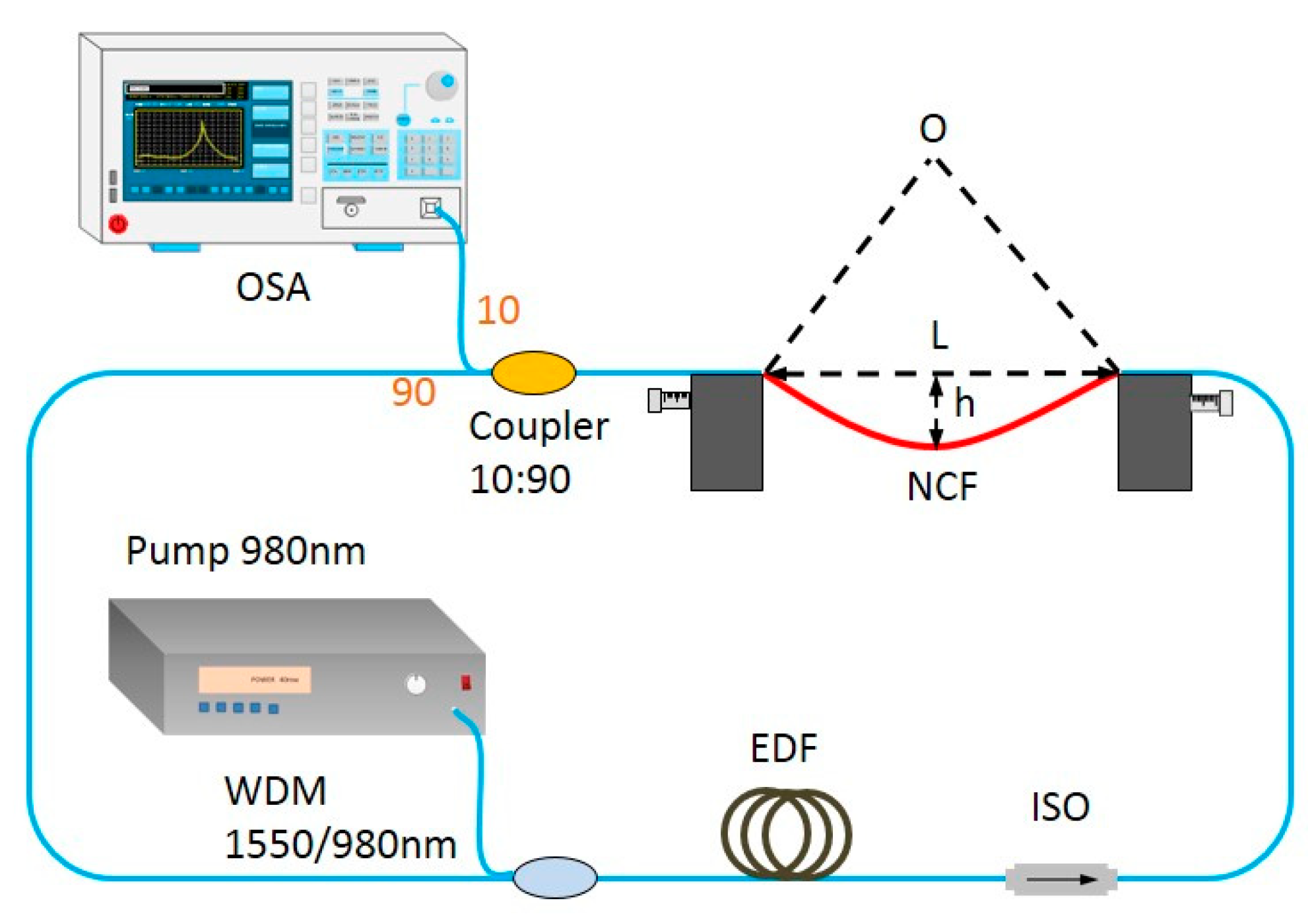

2. Experimental Setup and Theory of Operation

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhou, W.; Zhou, Y.; Dong, X.; Shao, L.Y.; Cheng, J.; Albert, J. Fiber-Optic Curvature Sensor Based on Cladding-Mode Bragg Grating Excited by Fiber Multimode Interferometer. IEEE Photonics J. 2012, 4, 1051–1057. [Google Scholar] [CrossRef]

- Wu, Z.; Shum, P.P.; Shao, X.; Zhang, H.; Zhang, N.; Huang, T.; Humbert, G.; Auguste, J.L.; Gerome, F.; Blondy, J.M.; et al. Temperature-and strain-insensitive curvature sensor based on ring-core modes in dual-concentric-core fiber. Opt. Lett. 2016, 41, 380–383. [Google Scholar] [CrossRef] [PubMed]

- Silva, S.; Biswas, P.; Bandyopadhyay, S.; Jorge, P.A.; Marques, M.B.; Frazao, O. Fiber-Optic Cavity Ring Down Using an Added-Signal for Curvature Sensing. IEEE Photonics Technol. Lett. 2015, 27, 2079–2082. [Google Scholar] [CrossRef]

- Gong, H.; Xiong, M.; Qian, Z.; Zhao, C.-L.; Dong, X. Simultaneous Measurement of Curvature and Temperature Based on Mach–Zehnder Interferometer Comprising Core-Offset and Spherical-Shape Structures. IEEE Photonics J. 2016, 8, 1–9. [Google Scholar] [CrossRef]

- Dass, S.; Jha, R. Micrometer Wire Assisted Inline Mach-Zehnder Interferometric Curvature Sensor. IEEE Photonics Technol. Lett. 2016, 28, 31–34. [Google Scholar] [CrossRef]

- Zhang, Y.X.; Zhou, A.; Qin, B.Y.; Xu, Q.; Liu, Z.H.; Yang, J.; Yuan, L.B. Simultaneous Measurement of Temperature and Curvature Based on Hollow Annular Core Fiber. IEEE Photonics Technol. Lett. 2014, 26, 1128–1131. [Google Scholar] [CrossRef]

- Fu, H.W.; Zhao, N.; Shao, M.; Li, H.D.; Gao, H.; Liu, Q.P.; Yong, Z.; Liu, Y.G.; Qiao, X.G. High-Sensitivity Mach-Zehnder Interferometric Curvature Fiber Sensor Based on Thin-Core Fiber. IEEE Sens. J. 2015, 15, 520–525. [Google Scholar]

- Gong, Y.; Zhao, T.; Rao, Y.J.; Wu, Y. All-Fiber Curvature Sensor Based on Multimode Interference. IEEE Photonics Technol. Lett. 2011, 23, 679–681. [Google Scholar] [CrossRef]

- Silva, S.; Pachon, E.G.P.; Franco, M.A.R.; Jorge, P.; Santos, J.L.; Malcata, F.X.; Cordeiro, C.M.B.; Frazao, O. Curvature and Temperature Discrimination Using Multimode Interference Fiber Optic Structures-A Proof of Concept. J. Lightwave Technol. 2012, 30, 3569–3575. [Google Scholar] [CrossRef]

- Cano-Contreras, M.; Guzman-Chavez, A.D.; Mata-Chavez, R.I.; Vargas-Rodriguez, E.; Jauregui-Vazquez, D.; Claudio-Gonzalez, D.; Estudillo-Ayala, J.M.; Rojas-Laguna, R.; Huerta-Mascotte, E. All-Fiber Curvature Sensor Based on an Abrupt Tapered Fiber and a Fabry-Perot Interferometer. IEEE Photonics Technol. Lett. 2014, 26, 2213–2216. [Google Scholar] [CrossRef]

- Van Newkirk, A.; Antonio-Lopez, J.E.; Velazquez-Benitez, A.; Albert, J.; Amezcua-Correa, R.; Schulzgen, A. Bending sensor combining multicore fiber with a mode-selective photonic lantern. Opt. Lett. 2015, 40, 5188–5191. [Google Scholar] [CrossRef] [PubMed]

- Salceda-Delgado, G.; Van Newkirk, A.; Antonio-Lopez, J.E.; Martinez-Rios, A.; Schulzgen, A.; Correa, R.A. Compact fiber-optic curvature sensor based on super-mode interference in a seven-core fiber. Opt. Lett. 2015, 40, 1468–1471. [Google Scholar] [CrossRef]

- Leal-Junior, A.G.; Frizera, A.; Pontes, M.J. Analytical model for a polymer optical fiber under dynamic bending. Opt. Laser Technol. 2017, 93, 92–98. [Google Scholar] [CrossRef]

- Leal-Junior, A.G.; Frizera, A.; Pontes, M.J. Sensitive zone parameters and curvature radius evaluation for polymer optical fiber curvature sensors. Opt. Laser Technol. 2018, 100, 272–281. [Google Scholar] [CrossRef]

- Leal-Junior, A.G.; Avellar, L.M.; Diaz, C.A.; Frizera, A.; Marques, C.; Pontes, M.J. Fabry–Perot Curvature Sensor With Cavities Based on UV-Curable Resins: Design, Analysis, and Data Integration Approach. IEEE Sens. J. 2019, 19, 9798–9805. [Google Scholar] [CrossRef]

- Leal-Junior, A.G.; Frizera-Neto, A.; Pontes, M.J.; Botelho, T.R. Hysteresis compensation technique applied to polymer optical fiber curvature sensor for lower limb exoskeletons. Meas. Sci. Technol. 2017, 28, 125103. [Google Scholar] [CrossRef]

- Leal-Junior, A.G.; Frizera, A.; Marques, C.; Pontes, M.J. Viscoelastic features based compensation technique for polymer optical fiber curvature sensors. Opt. Laser Technol. 2018, 105, 35–40. [Google Scholar] [CrossRef]

- Leal-Junior, A.G.; Frizera, A.; Avellar, L.M.; Pontes, M.J. Design considerations, analysis, and application of a low-cost, fully portable, wearable polymer optical fiber curvature sensor. Appl. Opt. 2018, 57, 6927–6936. [Google Scholar] [CrossRef]

- Xiong, H.; Xu, B.; Wang, D.N. Temperature Insensitive Optical Fiber Laser Bend Sensor With a Low Detection Limit. IEEE Photonics Technol. Lett. 2015, 27, 2599–2602. [Google Scholar] [CrossRef]

- Bai, X.; Fan, D.; Wang, S.; Pu, S.; Zeng, X. Strain Sensor Based on Fiber Ring Cavity Laser With Photonic Crystal Fiber In-Line Mach–Zehnder Interferometer. IEEE Photonics J. 2014, 6, 1–8. [Google Scholar]

- Shi, J.; Wang, Y.; Xu, D.; Su, G.; Zhang, H.; Feng, J.; Yan, C.; Fu, S.; Yao, J. Remote Magnetic Field Sensor Based on Intracavity Absorption of Evanescent Field. IEEE Photonics J. 2016, 8, 1–7. [Google Scholar] [CrossRef]

- Liu, Z.B.; Tan, Z.W.; Yin, B.; Bai, Y.L.; Jian, S.S. Refractive index sensing characterization of a singlemode-claddingless-singlemode fiber structure based fiber ring cavity laser. Opt. Express 2014, 22, 5037–5042. [Google Scholar] [CrossRef] [PubMed]

- Shi, J.; Wang, Y.Y.; Xu, D.G.; Zhang, H.W.; Su, G.H.; Duan, L.C.; Yan, C.; Yan, D.X.; Fu, S.J.; Yao, J.Q. Temperature Sensor Based on Fiber Ring Laser With Sagnac Loop. IEEE Photonics Technol. Lett. 2016, 28, 794–797. [Google Scholar] [CrossRef]

- Zhang, H.W.; Lu, Y.; Duan, L.C.; Zhao, Z.Q.; Shi, W.; Yao, J.Q. Intracavity absorption multiplexed sensor network based on dense wavelength division multiplexing filter. Opt. Express 2014, 22, 24545–24550. [Google Scholar] [CrossRef] [PubMed]

- Mohammed, W.S.; Mehta, A.; Johnson, E.G. Wavelength tunable fiber lens based on multimode interference. J. Lightwave Technol. 2004, 22, 469–477. [Google Scholar] [CrossRef]

- Schermer, R.T.; Cole, J.H. Improved bend loss formula verified for optical fiber by simulation and experiment. IEEE J. Quantum Electron. 2007, 43, 899–909. [Google Scholar] [CrossRef]

- Liu, Y.G.; Dong, X.Y.; Shum, P.; Yuan, S.Z.; Kai, G.Y.; Dong, X.Y. Stable room-temperature multi-wavelength lasing realization in ordinary erbium-doped fiber loop lasers. Opt. Express 2006, 14, 9293–9298. [Google Scholar] [CrossRef] [PubMed]

- Hofmann, P.; Mafi, A.; Jollivet, C.; Tiess, T.; Peyghambarian, N.; Schulzgen, A. Detailed Investigation of Mode-Field Adapters Utilizing Multimode-Interference in Graded Index Fibers. J. Lightwave Technol. 2012, 30, 2289–2297. [Google Scholar] [CrossRef]

- Ma, L.; Qi, Y.H.; Kang, Z.X.; Jian, S.S. All-Fiber Strain and Curvature Sensor Based on No-Core Fiber. IEEE Sens. J. 2014, 14, 1514–1517. [Google Scholar] [CrossRef]

- White, I.M.; Fan, X.D. On the performance quantification of resonant refractive index sensors. Opt. Express 2008, 16, 1020–1028. [Google Scholar] [CrossRef] [PubMed]

- Ma, Y.; Zhao, M.; Su, C.; Sun, J.; Li, X.; Yu, Z.; Zhang, L.; Geng, T. Vector curvature sensor based on asymmetrically polished long-period fiber grating. Measurement 2022, 194, 110997. [Google Scholar] [CrossRef]

- Guo, Y.; Zhang, Y. A New Bamboo-Shaped Sensor for Curvature Measurement With Microstructured Fiber. IEEE Photonics Technol. Lett. 2021, 33, 619–622. [Google Scholar] [CrossRef]

- Zhao, R.; Shu, X.; Xu, Z. Compact fiber curvature and temperature sensor inscribed by femtosecond laser through the coating. J. Lightwave Technol. 2021, 39, 3981–3990. [Google Scholar]

- Xu, S.; Chen, H.; Feng, W. Fiber-optic curvature and temperature sensor based on the lateral-offset spliced SMF-FCF-SMF interference structure. Opt. Laser Technol. 2021, 141, 107174. [Google Scholar] [CrossRef]

| Sensor | Highest Sensitivity (nm/m−1) | Temperature Cross-Sensitivity (pm/°C) | Detection Limit (m−1) | Ref. |

|---|---|---|---|---|

| Long-period fiber grating | 30.85 | 76 | N.A. | [31] |

| Microstructured fiber | 1.118 | >40 | N.A. | [32] |

| In-fiber Mach–Zehnder interferometer | 2.491 | 9.72 | N.A. | [33] |

| Four-core fiber Mach–Zehnder interferometer | −18.75 | 74 | 0.042 | [34] |

| SNCS fiber + FRL | −3.185 | −3.3 | 0.08 | This work |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yi, L.; Xue, Z.; Ding, Y.; Wang, M.; Guo, Z.; Shi, J. Surface Curvature Sensor Based on Intracavity Sensing of Fiber Ring Laser. Photonics 2022, 9, 781. https://doi.org/10.3390/photonics9100781

Yi L, Xue Z, Ding Y, Wang M, Guo Z, Shi J. Surface Curvature Sensor Based on Intracavity Sensing of Fiber Ring Laser. Photonics. 2022; 9(10):781. https://doi.org/10.3390/photonics9100781

Chicago/Turabian StyleYi, Liang, Zhifei Xue, Yiyun Ding, Min Wang, Zekang Guo, and Jia Shi. 2022. "Surface Curvature Sensor Based on Intracavity Sensing of Fiber Ring Laser" Photonics 9, no. 10: 781. https://doi.org/10.3390/photonics9100781

APA StyleYi, L., Xue, Z., Ding, Y., Wang, M., Guo, Z., & Shi, J. (2022). Surface Curvature Sensor Based on Intracavity Sensing of Fiber Ring Laser. Photonics, 9(10), 781. https://doi.org/10.3390/photonics9100781