Recent Progress Using Graphene Oxide and Its Composites for Supercapacitor Applications: A Review

Abstract

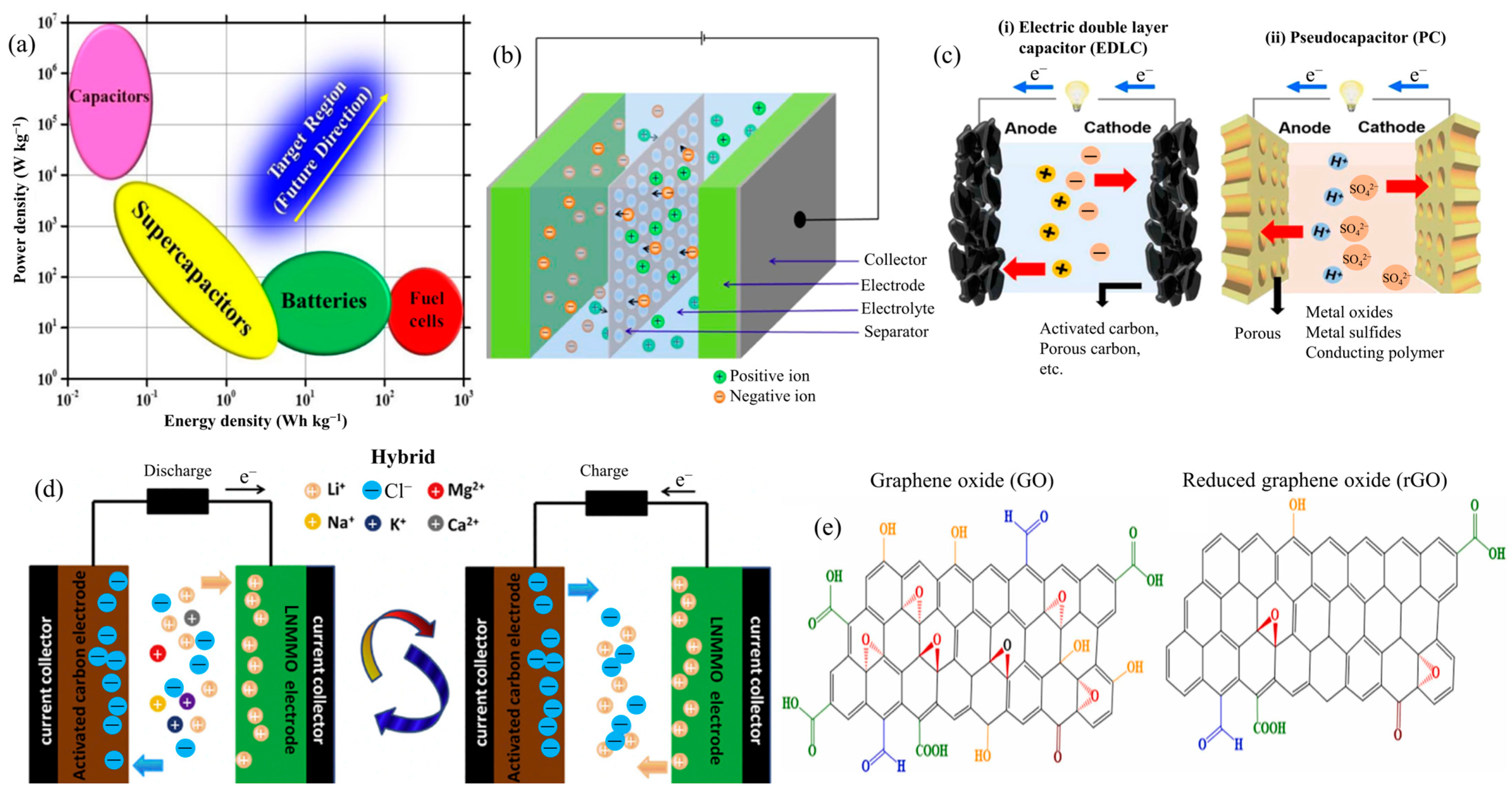

1. Introduction

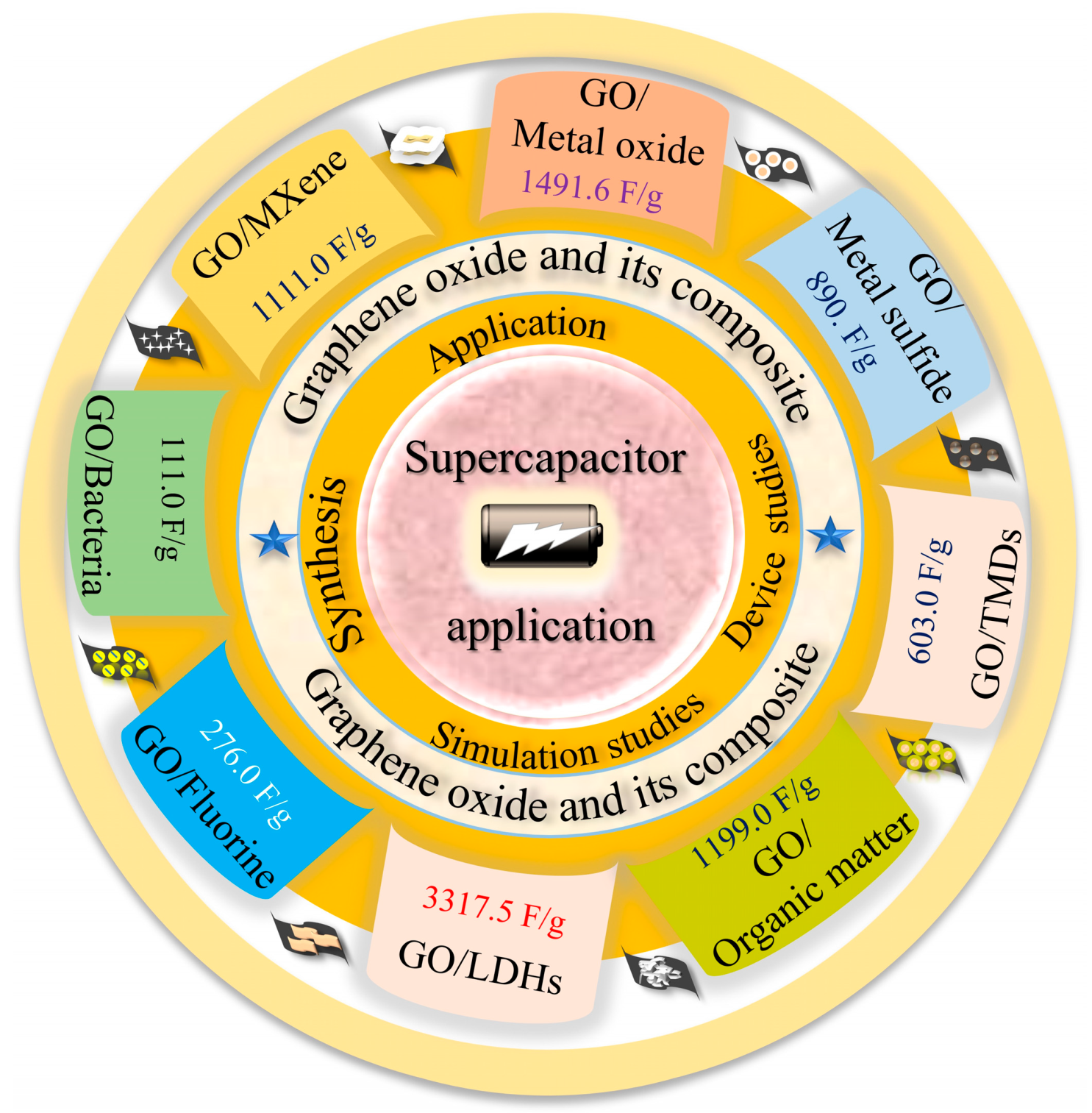

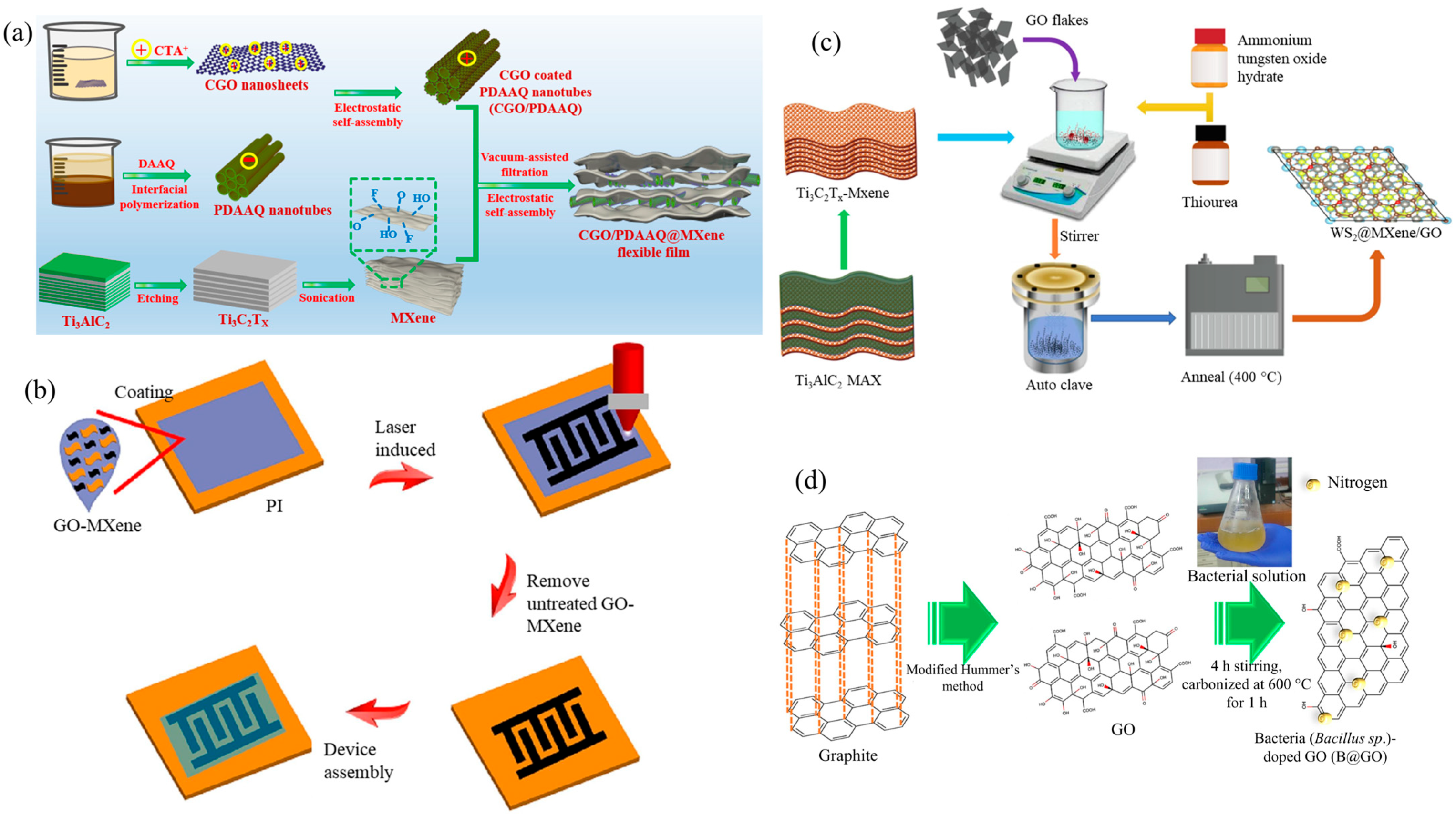

2. Synthesis

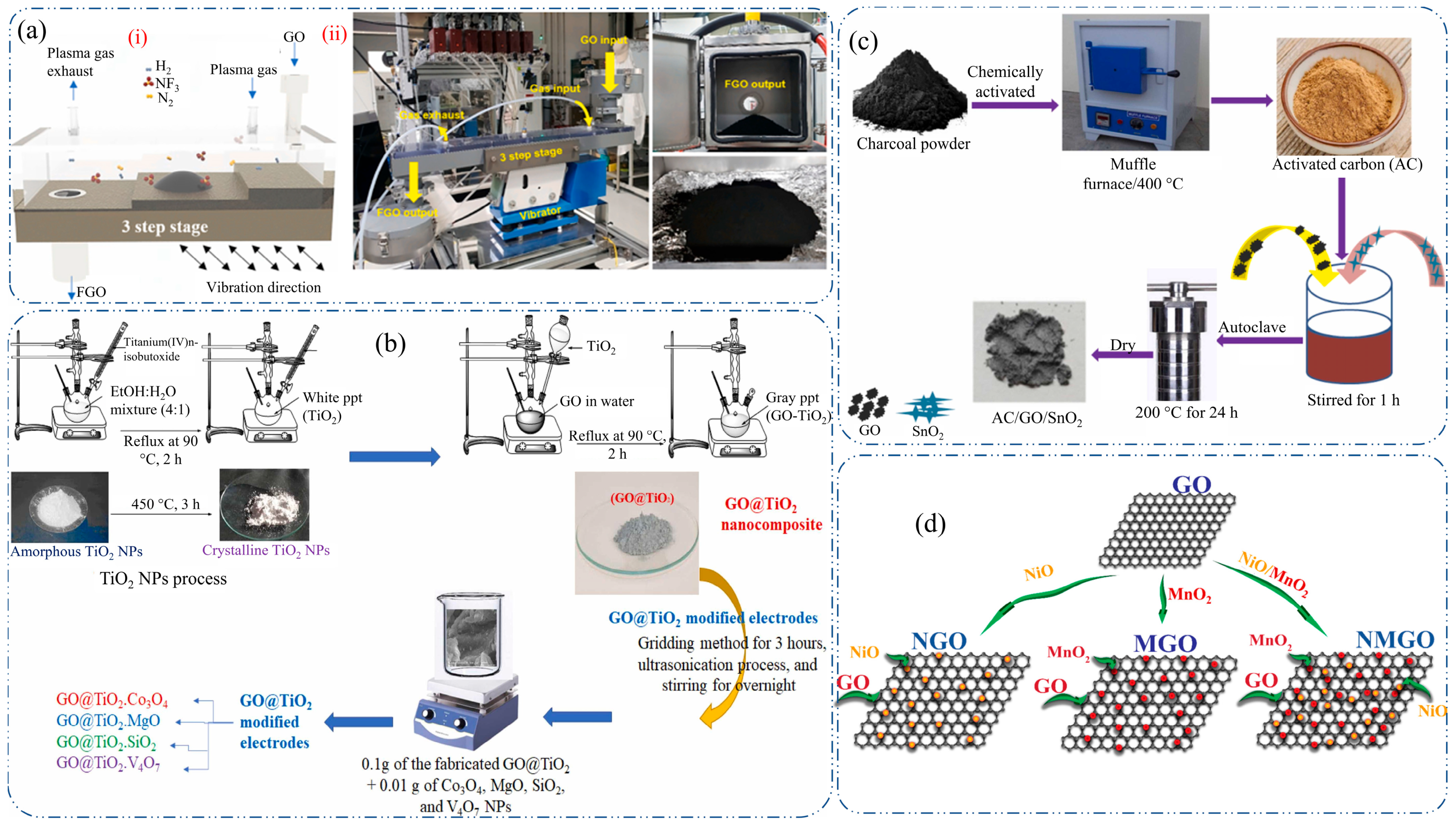

2.1. Fluorine-Functionalized GO

2.2. GO-Metal Oxides

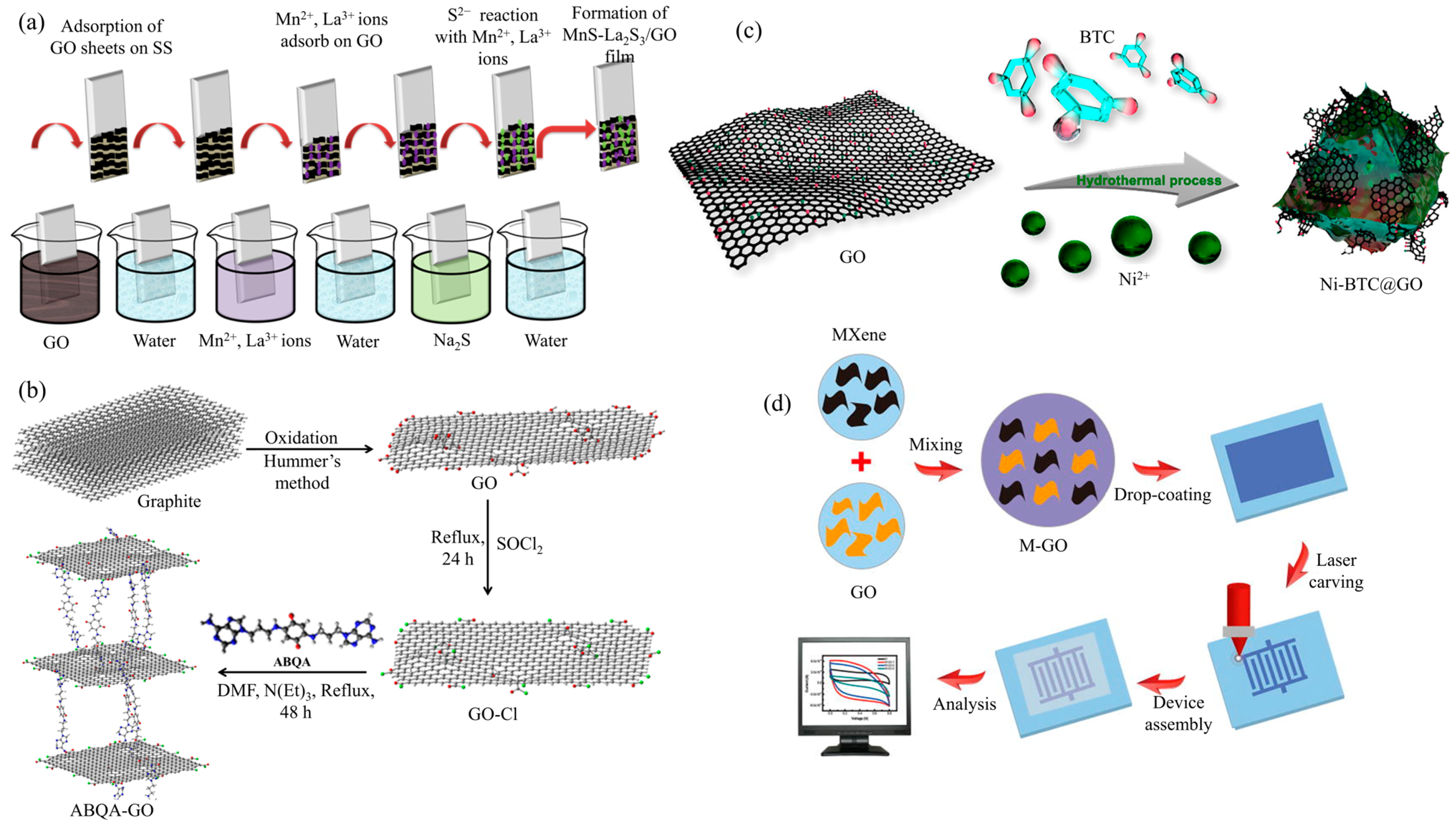

2.3. GO-Metal Sulfide

2.4. GO-Transition Metal Chalcogenide

2.5. GO-Layered Double Hydroxide

2.6. GO-Organic Material

2.7. GO-MXene

2.8. GO-Bacteria

2.9. Discussion

3. GO and Its Composites in Supercapacitor Application

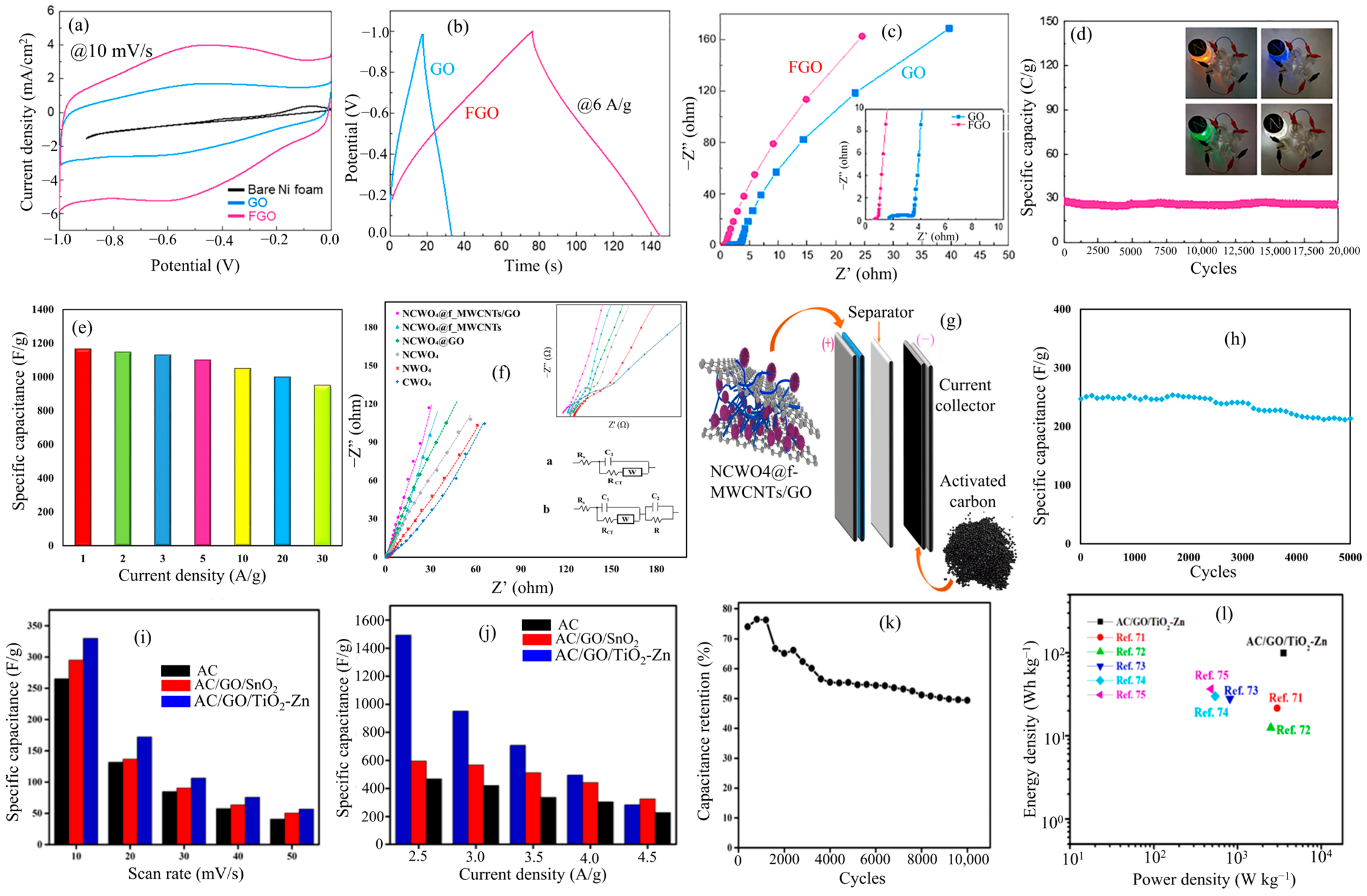

3.1. Fluorine-Functionalized GO

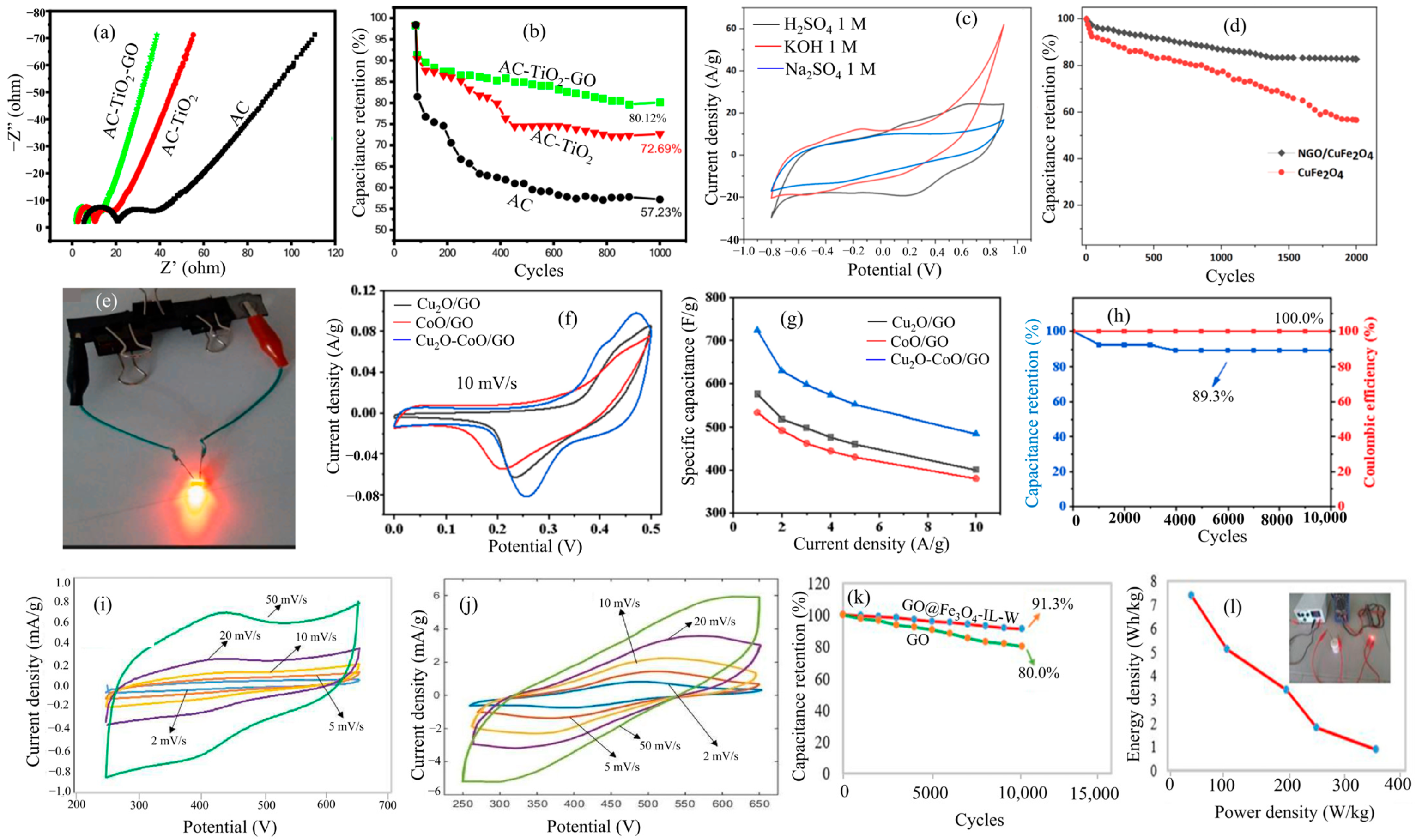

3.2. GO-Metal Oxides

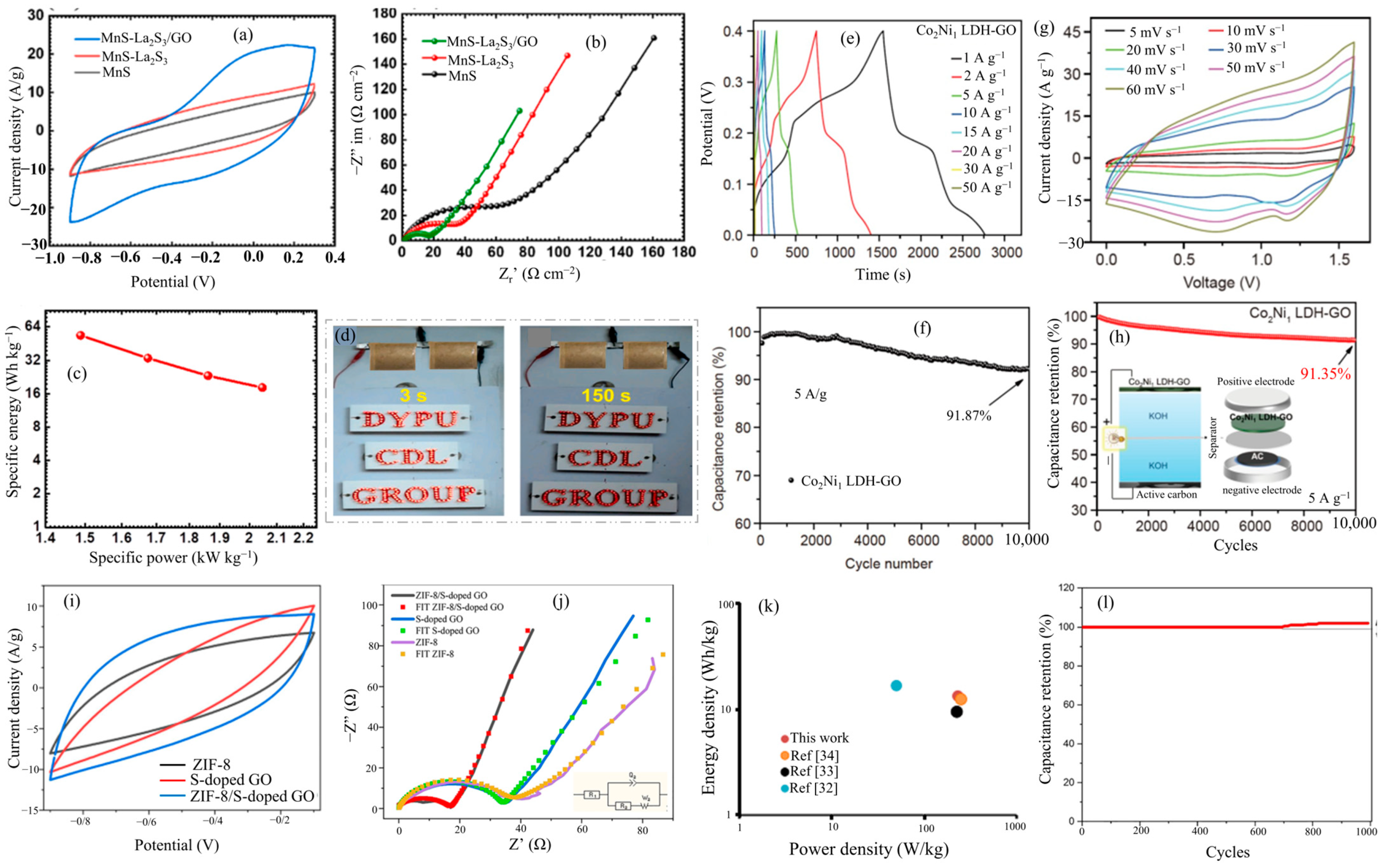

3.3. GO-Metal Sulfide

3.4. GO-Transition Metal Chalcogenides

3.5. GO-Layered Double Hydroxides

3.6. GO-Organic Materials

3.7. GO-MXene

3.8. GO-Bacteria

3.9. Discussion

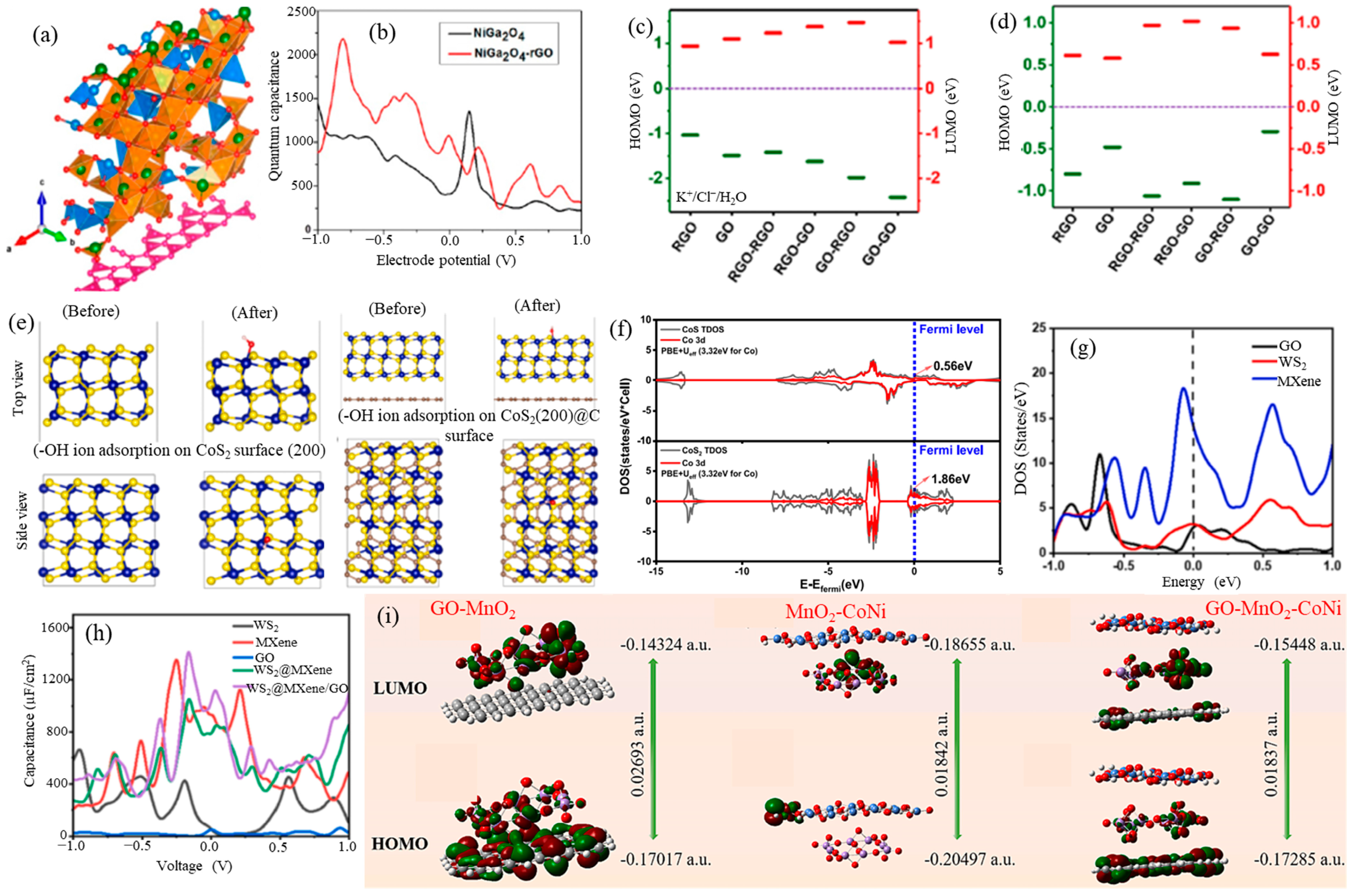

4. Simulation Studies

5. Conclusions and Future Perspectives

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, J.; Guo, Z.; Li, F.; Yang, H.; Che, H.; Zhang, Z.; Wang, Y.; Zhang, X.; Li, S.; Mu, J. Rational design of ternary NiCo2Alx-LDH coupled with PANI coated Nitrogen-doped carbon capsule for High-Performance asymmetric supercapacitors. J. Electroanal. Chem. 2023, 931, 117189. [Google Scholar] [CrossRef]

- Nasrin, K.; Arunkumar, M.; Koushik Kumar, N.; Sudharshan, V.; Rajasekar, S.; Mukhilan, D.; Arshad, M.; Sathish, M. A rationally designed hetero-assembly of 2D/2D Nitrogen-doped MXene/Graphene via supercritical fluid processing for high energy durable supercapacitors. Chem. Eng. J. 2023, 474, 145505. [Google Scholar] [CrossRef]

- Li, M.; Zhou, S.; Cheng, L.; Mo, F.; Chen, L.; Yu, S.; Wei, J. 3D Printed Supercapacitor: Techniques, Materials, Designs, and Applications. Adv. Funct. Mater. 2023, 33, 2208034. [Google Scholar] [CrossRef]

- Park, H.W.; Roh, K.C. Recent advances in and perspectives on pseudocapacitive materials for Supercapacitors—A review. J. Power Sources 2023, 557, 232558. [Google Scholar] [CrossRef]

- Balasankar, A.; Arthiya, S.E.; Ramasundaram, S.; Sumathi, P.; Arokiyaraj, S.; Oh, T.; Aruchamy, K.; Sriram, G.; Kurkuri, M.D. Recent Advances in the Preparation and Performance of Porous Titanium-Based Anode Materials for Sodium-Ion Batteries. Energies 2022, 15, 9495. [Google Scholar] [CrossRef]

- Mouraliraman, D.; Thiagarajan, A.; Deepa, S.; Sriram, G.; Aruchamy, K.; Oh, T.H.; Shin, D. 3D printed lithium-ion batteries: An in-depth examination of the advancements in flexibility and stand-alone capability. J. Energy Storage 2024, 81, 110395. [Google Scholar] [CrossRef]

- Nishchith, B.S.; Kalegowda, Y.; Ashoka, S.; Shreenivasa, L.; Sriram, G.; Kurkuri, M.D.; Ajeya, K.V.; Jung, H.-Y. Electrochemical kinetic study and performance evaluation of surface-modified mesoporous sodium carbonophosphates nanostructures for pseudocapacitor applications. J. Alloys Compd. 2023, 939, 168711. [Google Scholar] [CrossRef]

- Anwar, M.I.; Asad, M.; Ma, L.; Zhang, W.; Abbas, A.; Khan, M.Y.; Zeeshan, M.; Khatoon, A.; Gao, R.; Manzoor, S.; et al. Nitrogenous MOFs and their composites as high-performance electrode material for supercapacitors: Recent advances and perspectives. Coord. Chem. Rev. 2023, 478, 214967. [Google Scholar] [CrossRef]

- Conway, B.E. Transition from “Supercapacitor” to “Battery” Behavior in Electrochemical Energy Storage. J. Electrochem. Soc. 1991, 138, 1539. [Google Scholar] [CrossRef]

- Jiang, Y.; Liu, J. Definitions of Pseudocapacitive Materials: A Brief Review. Energy Environ. Mater. 2019, 2, 30–37. [Google Scholar] [CrossRef]

- Bhat, V.S.; Kanagavalli, P.; Sriram, G.; John, N.S.; Veerapandian, M.; Kurkuri, M.; Hegde, G. Low cost, catalyst free, high performance supercapacitors based on porous nano carbon derived from agriculture waste. J. Energy Storage 2020, 32, 101829. [Google Scholar] [CrossRef]

- Shaheen Shah, S.; Abu Nayem, S.M.; Sultana, N.; Saleh Ahammad, A.J.; Abdul Aziz, M. Preparation of Sulfur-doped Carbon for Supercapacitor Applications: A Review. ChemSusChem 2022, 15, e202101282. [Google Scholar] [CrossRef] [PubMed]

- Tong, Y.; Yang, J.; Li, J.; Cong, Z.; Wei, L.; Liu, M.; Zhai, S.; Wang, K.; An, Q. Lignin-derived electrode materials for supercapacitor applications: Progress and perspectives. J. Mater. Chem. A 2023, 11, 1061–1082. [Google Scholar] [CrossRef]

- Zhao, X.; Li, G.; Feng, M.; Wang, Y. Semi-continuous electrochemical extraction of lithium from brine using CF-NMMO/AC asymmetric hybrid capacitors. Electrochim. Acta 2020, 331, 135285. [Google Scholar] [CrossRef]

- Tamang, S.; Rai, S.; Bhujel, R.; Bhattacharyya, N.K.; Swain, B.P.; Biswas, J. A concise review on GO, rGO and metal oxide/rGO composites: Fabrication and their supercapacitor and catalytic applications. J. Alloys Compd. 2023, 947, 169588. [Google Scholar] [CrossRef]

- Iqbal, M.Z.; Zakar, S.; Haider, S.S. Role of aqueous electrolytes on the performance of electrochemical energy storage device. J. Electrochem. Soc. 2020, 858, 113793. [Google Scholar] [CrossRef]

- Zhong, C.; Deng, Y.; Hu, W.; Qiao, J.; Zhang, L.; Zhang, J. A review of electrolyte materials and compositions for electrochemical supercapacitors. Chem. Soc. Rev. 2015, 44, 7484–7539. [Google Scholar] [CrossRef] [PubMed]

- Cheng, B.; Li, X.; Li, H.; Zhang, W.; Han, R.; Zhang, Y.; Xiang, J. Morphology-controllable synthesis of bimetallic oxide Bi2Fe4O9 as novel electrode materials for high-performance supercapacitors. J. Energy Storage 2024, 79, 110137. [Google Scholar] [CrossRef]

- Zhang, Y.; Jing, X.; Yan, X.-H.; Gao, H.-L.; Gao, K.-Z.; Cao, Y.; Hu, S.; Zhang, Y.-Y. Rational design of NiMn-based electrode materials for high-performance supercapacitors. Coord. Chem. Rev. 2024, 499, 215494. [Google Scholar] [CrossRef]

- Zeng, J.; Wei, L.; Guo, X. Bio-inspired high-performance solid-state supercapacitors with the electrolyte, separator, binder and electrodes entirely from kelp. J. Mater. Chem. A 2017, 5, 25282–25292. [Google Scholar] [CrossRef]

- Xiong, C.; Zhang, Y.; Ni, Y. Recent progress on development of electrolyte and aerogel electrodes applied in supercapacitors. J. Power Sources 2023, 560, 232698. [Google Scholar] [CrossRef]

- Zhang, L.; Hu, X.; Wang, Z.; Sun, F.; Dorrell, D.G. A review of supercapacitor modeling, estimation, and applications: A control/management perspective. Renew. Sustain. Energy Rev. 2018, 81, 1868–1878. [Google Scholar] [CrossRef]

- Şahin, M.E.; Blaabjerg, F.; Sangwongwanich, A. A Comprehensive Review on Supercapacitor Applications and Developments. Energies 2022, 15, 674. [Google Scholar] [CrossRef]

- Poonam; Sharma, K.; Arora, A.; Tripathi, S.K. Review of supercapacitors: Materials and devices. J. Energy Storage 2019, 21, 801–825. [Google Scholar] [CrossRef]

- Noori, A.; El-Kady, M.F.; Rahmanifar, M.S.; Kaner, R.B.; Mousavi, M.F. Towards establishing standard performance metrics for batteries, supercapacitors and beyond. Chem. Soc. Rev. 2019, 48, 1272–1341. [Google Scholar] [CrossRef] [PubMed]

- Boulanger, N.; Talyzin, A.V.; Xiong, S.; Hultberg, M.; Grimm, A. High surface area activated carbon prepared from wood-based spent mushroom substrate for supercapacitors and water treatment. Colloids Surf. A 2024, 680, 132684. [Google Scholar] [CrossRef]

- Gao, R.; Guo, W.; Zhang, Y.; Zhang, Q.; Li, Y.; Wang, J. Enhancement of gelatinization on electrochemical performance of corn starch-based porous carbon as electrode material in supercapacitors. Diam. Relat. Mater. 2024, 141, 110598. [Google Scholar] [CrossRef]

- Yang, K.; Fan, Q.; Zhang, Y.; Ren, G.; Huang, X.; Fu, P. Hierarchical porous carbon aerogels as a versatile electrode material for high-stability supercapacitors. RSC Adv. 2024, 14, 1123–1133. [Google Scholar] [CrossRef] [PubMed]

- Zhang, R.; Zhang, Z.; Xu, P.; Xu, J.; Gao, Y.; Gao, G. Cellulose nanofiber hydrogel with high conductivity electrolytes for high voltage flexible supercapacitors. Carbohydr. Polym. 2024, 326, 121654. [Google Scholar] [CrossRef] [PubMed]

- Yang, S.; Wang, Z.; Xie, Y.; Gao, X.; Yao, F.; Bai, H.; Zhang, X.; Zhang, H.; Yue, H. Polyaniline nanowire arrays on biomass-derived carbon nanotubes with typha longbracteata for high-performance symmetric supercapacitors. Diam. Relat. Mater. 2024, 141, 110608. [Google Scholar] [CrossRef]

- Liu, J.; Yang, G.; Lu, K.; Ye, C.; Ma, Y.; Ye, J. One-step process to obtain manganese-assisted laser-induced multi-layer graphene-like carbon supercapacitor. Electrochim. Acta 2024, 474, 143505. [Google Scholar] [CrossRef]

- Varghese, S.M.; Mohan, V.V.; Suresh, S.; Bhoje Gowd, E.; Rakhi, R.B. Synergistically modified Ti3C2Tx MXene conducting polymer nanocomposites as efficient electrode materials for supercapacitors. J. Alloys Compd. 2024, 973, 172923. [Google Scholar] [CrossRef]

- Wang, W.; Yang, C.; Han, D.; Yu, S.; Qi, W.; Ling, R.; Liu, G. Ni3S2/Ni2O3 heterojunction anchored on N-doped carbon nanosheet aerogels for dual-ion hybrid supercapacitors. J. Colloid Interface Sci. 2024, 654, 709–718. [Google Scholar] [CrossRef] [PubMed]

- Zheng, W.; Fan, L.; Meng, Z.; Zhou, J.; Ye, D.; Xu, W.; Xu, J. Flexible quasi-solid-state supercapacitors for anti-freezing power sources based on polypyrrole@cation-grafted bacterial cellulose. Carbohydr. Polym. 2024, 324, 121502. [Google Scholar] [CrossRef] [PubMed]

- Wan, L.; Chen, J.; Zhang, Y.; Du, C.; Xie, M.; Hu, S. High-mass-loading cobalt iron phosphide@nickel vanadium layered double hydroxide heterogeneous nanosheet arrays for hybrid supercapacitors. J. Colloid Interface Sci. 2024, 654, 539–549. [Google Scholar] [CrossRef]

- Wu, M.-S.; Hong, L.-R. Cyclic voltammetric formation of hollow porous γ-MnO2 microspheres as stable electrodes for high-performance supercapacitors. J. Energy Storage 2024, 75, 109721. [Google Scholar] [CrossRef]

- Cao, X.-M.; Liu, D.; Sun, Z.-J.; Zhang, Q. In situ construction of core–shell structured cobalt oxide@nickel–cobalt-layered double hydroxide nanorods with abundant oxygen vacancies towards boosting electrochemical energy storage. Inorg. Chem. Front. 2024, 11, 789–798. [Google Scholar] [CrossRef]

- Sriram, G.; Kurkuri, M.; Oh, T.H. Recent Trends in Highly Porous Structured Carbon Electrodes for Supercapacitor Applications: A Review. Energies 2023, 16, 4641. [Google Scholar] [CrossRef]

- Anwer, A.H.; Zubair, M.M.; Mashkoor, F.; Benamor, A.; Hasan, I.; Shoeb, M.; Jeong, C. Enhancing the electrochemical performance of hybrid supercapacitors with in-situ grown ultrasound-mediated heterostructure bi-metallic and dual-linker MOF nanoarchitecture by harnessing charge storage mechanisms. J. Alloys Compd. 2024, 970, 172512. [Google Scholar] [CrossRef]

- Xu, M.; Zhu, X.; Lai, Y.; Xia, A.; Huang, Y.; Zhu, X.; Liao, Q. Production of hierarchical porous bio-carbon based on deep eutectic solvent fractionated lignin nanoparticles for high-performance supercapacitor. Appl. Energy 2024, 353, 122095. [Google Scholar] [CrossRef]

- Navaneeth, P.; Jayakanthan, S.; Kumar, M.S.; Kumar, A.; Pradeep, A.; Suneesh, P.V.; Babu, T.S. High surface area cobalt aluminium layered double hydroxide printed electrodes for flexible supercapacitor and on-chip electrochemical bacterial lysing. Electrochim. Acta 2024, 476, 143744. [Google Scholar] [CrossRef]

- Shinde, S.K.; Karade, S.S.; Truong, N.T.N.; Veer, S.S.; Shaikh, S.F.; Al-Enizi, A.M.; Jagadale, A.D.; Yadav, H.M.; Tamboli, M.S.; Park, C.; et al. Highly stable and thin layer of conducting PANI decorative on porous 3D nanoflakes like-NiCo2O4/CF nanomaterials for efficient Hybrid Supercapacitors application. J. Energy Storage 2024, 78, 109960. [Google Scholar] [CrossRef]

- Li, X.; Ren, J.; Sridhar, D.; Xu, B.B.; Algadi, H.; El-Bahy, Z.M.; Ma, Y.; Li, T.; Guo, Z. Progress of layered double hydroxide-based materials for supercapacitors. Mater. Chem. Front. 2023, 7, 1520–1561. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, H.; Li, L. Applications and challenges of porous carbon with different dimensions in supercapacitors-a mini review. Front. Energy Res. 2022, 10, 951701. [Google Scholar] [CrossRef]

- Singal, S.; Yadav, A.; Sharma, R.K. A high-performance asymmetric supercapacitor based on morphologically tuned CoB anode and heterostructured graphitic carbon nitride/MoSe2 cathode. J. Energy Storage 2024, 80, 110300. [Google Scholar] [CrossRef]

- He, M.; Wu, L.; Yu, A.; Li, X.; Guan, S.; Han, Q.; Wang, H.; Zhou, B.; Melvin, G.J.H.; Wang, M.; et al. Surface functionalization of vertical graphene significantly enhances the energy storage capability for symmetric supercapacitors. Carbon 2024, 216, 118511. [Google Scholar] [CrossRef]

- Huang, Z.; Zhang, Z.; Qi, X.; Ren, X.; Xu, G.; Wan, P.; Sun, X.; Zhang, H. Wall-like hierarchical metal oxide nanosheet arrays grown on carbon cloth for excellent supercapacitor electrodes. Nanoscale 2016, 8, 13273–13279. [Google Scholar] [CrossRef] [PubMed]

- Cai, D.; Wang, D.; Liu, B.; Wang, Y.; Liu, Y.; Wang, L.; Li, H.; Huang, H.; Li, Q.; Wang, T. Comparison of the Electrochemical Performance of NiMoO4 Nanorods and Hierarchical Nanospheres for Supercapacitor Applications. ACS Appl. Mater. Interfaces 2013, 5, 12905–12910. [Google Scholar] [CrossRef] [PubMed]

- Korkmaz, S.; Kariper, İ.A. Graphene and graphene oxide based aerogels: Synthesis, characteristics and supercapacitor applications. J. Energy Storage 2020, 27, 101038. [Google Scholar] [CrossRef]

- Ghosh, R.; Siddiqui, M.S.; Kalita, H. Fabrication of highly conductive graphene paper for supercapacitors with a one-step hydrothermal method. Carbon Trends 2024, 14, 100317. [Google Scholar] [CrossRef]

- Pandey, M.; Deshmukh, K.; Raman, A.; Asok, A.; Appukuttan, S.; Suman, G.R. Prospects of MXene and graphene for energy storage and conversion. Renew. Sustain. Energy Rev. 2024, 189, 114030. [Google Scholar] [CrossRef]

- Nwankwo, M.C.; Ezealigo, B.; Nwanya, A.C.; Nkele, A.C.; Agbogu, A.; Chime, U.; Asogwa, P.U.; Ezekoye, B.A.; Ekwealor, A.B.C.; Osuji, R.U.; et al. Syntheses and characterizations of GO/Mn3O4 nanocomposite film electrode materials for supercapacitor applications. Inorg. Chem. Commun. 2020, 119, 107983. [Google Scholar] [CrossRef]

- Chen, J.; Li, Y.; Huang, L.; Jia, N.; Li, C.; Shi, G. Size Fractionation of Graphene Oxide Sheets via Filtration through Track-Etched Membranes. Adv. Mater. 2015, 27, 3654–3660. [Google Scholar] [CrossRef]

- Gund, G.S.; Dubal, D.P.; Patil, B.H.; Shinde, S.S.; Lokhande, C.D. Enhanced activity of chemically synthesized hybrid graphene oxide/Mn3O4 composite for high performance supercapacitors. Electrochim. Acta 2013, 92, 205–215. [Google Scholar] [CrossRef]

- Du, W.; Lv, Y.; Lu, H.; Chen, Z.; Wright, D.S.; Zhang, C. Surface modification by graphene oxide: An efficient strategy to improve the performance of activated carbon based supercapacitors. Chin. Chem. Lett. 2017, 28, 2285–2289. [Google Scholar] [CrossRef]

- Iqbal, M.F.; Yousef, A.K.M.; Hassan, A.; Hussain, S.; Ashiq, M.N.; Ul Mahmood, H.; Razaq, A. Significantly improved electrochemical characteristics of nickel sulfide nanoplates using graphene oxide thin film for supercapacitor applications. J. Energy Storage 2021, 33, 102091. [Google Scholar] [CrossRef]

- Chen, X.; Paul, R.; Dai, L. Carbon-based supercapacitors for efficient energy storage. Natl. Sci. Rev. 2017, 4, 453–489. [Google Scholar] [CrossRef]

- Dalvand, S.; Khoushab, Z.; Mousavi-Khoshdel, S.M.; Ghafuri, H.; Esmaili Zand, H.R.; Omidvar, M. Graphene oxide@Fe3o4@Tungstate modified ionic liquid as a novel electrode material for high-performance supercapacitor. Int. J. Hydrogen Energy 2023, 48, 10098–10107. [Google Scholar] [CrossRef]

- Kuila, T.; Mishra, A.K.; Khanra, P.; Kim, N.H.; Lee, J.H. Recent advances in the efficient reduction of graphene oxide and its application as energy storage electrode materials. Nanoscale 2013, 5, 52–71. [Google Scholar] [CrossRef]

- Naser, S.A.E.; Badmus, K.O.; Khotseng, L. Synthesis, Properties, and Applications of Metal Organic Frameworks Supported on Graphene Oxide. Coatings 2023, 13, 1456. [Google Scholar] [CrossRef]

- Abdillah, O.B.; Rus, Y.B.; Ulfa, M.; Dedi; Iskandar, F. Recent progress on reduced graphene oxide and polypyrrole composites for high performance supercapacitors: A review. J. Energy Storage 2023, 74, 109300. [Google Scholar] [CrossRef]

- Mousavi, S.M.; Hashemi, S.A.; Kalashgrani, M.Y.; Gholami, A.; Binazadeh, M.; Chiang, W.-H.; Rahman, M.M. Recent advances in energy storage with graphene oxide for supercapacitor technology. Sustain. Energy Fuels 2023, 7, 5176–5197. [Google Scholar] [CrossRef]

- Sahoo, P.K.; Kumar, N.; Jena, A.; Mishra, S.; Lee, C.-P.; Lee, S.-Y.; Park, S.-J. Recent progress in graphene and its derived hybrid materials for high-performance supercapacitor electrode applications. RSC Adv. 2024, 14, 1284–1303. [Google Scholar] [CrossRef]

- Luo, Z.; Quan, J.; Ding, T.; Xu, B.; Li, W.; Mao, Q.; Ma, W.; Li, M.; Xiang, H.; Zhu, M. Recent advances in iron oxide/graphene composites for flexible supercapacitors. J. Alloys Compd. 2024, 980, 173614. [Google Scholar] [CrossRef]

- Nargatti, K.I.; Ahankari, S.S.; Dizon, J.R.C.; Subramaniam, R.T. Environmentally Friendly Water-Based Reduced Graphene Oxide/Cellulose Nanofiber Ink for Supercapacitor Electrode Applications. ACS Omega 2024, 9, 11730–11737. [Google Scholar] [CrossRef]

- Ndagijimana, P.; Rong, H.; Ndokoye, P.; Mwizerwa, J.P.; Nkinahamira, F.; Luo, S.; Guo, D.; Cui, B. A review on activated carbon/ graphene composite-based materials: Synthesis and applications. J. Clean. Prod. 2023, 417, 138006. [Google Scholar] [CrossRef]

- Shruti, M.S.; Khilari, S.; Samuel, E.J.J.; Han, H.; Nayak, A.K. Recent trends in graphene assisted vanadium based nanocomposites for supercapacitor applications. J. Energy Storage 2023, 63, 107006. [Google Scholar] [CrossRef]

- Philip, A.; Ruban Kumar, A. Recent advancements and developments employing 2D-materials in enhancing the performance of electrochemical supercapacitors: A review. Renew. Sustain. Energy Rev. 2023, 182, 113423. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhou, C.-G.; Yan, X.-H.; Cao, Y.; Gao, H.-L.; Luo, H.-W.; Gao, K.-Z.; Xue, S.-C.; Jing, X. Recent advances and perspectives on graphene-based gels for superior flexible all-solid-state supercapacitors. J. Power Sources 2023, 565, 232916. [Google Scholar] [CrossRef]

- Sahoo, B.B.; Pandey, V.S.; Dogonchi, A.S.; Thatoi, D.N.; Nayak, N.; Nayak, M.K. Synthesis, characterization and electrochemical aspects of graphene based advanced supercapacitor electrodes. Fuel 2023, 345, 128174. [Google Scholar] [CrossRef]

- Yang, H.; Zheng, H.; Duan, Y.; Xu, T.; Xie, H.; Du, H.; Si, C. Nanocellulose-graphene composites: Preparation and applications in flexible electronics. Int. J. Biol. Macromol. 2023, 253, 126903. [Google Scholar] [CrossRef] [PubMed]

- Ray, P.K.; Mohanty, R.; Parida, K. Recent advancements of NiCo LDH and graphene based nanohybrids for supercapacitor application. J. Energy Storage 2023, 72, 108335. [Google Scholar] [CrossRef]

- Kumar, R.; Sahoo, S.; Joanni, E.; Singh, R.K.; Yadav, R.M. Graphene-metal oxide hybrid materials with 2D and 3D morphologies for advanced supercapacitor electrodes: Status, challenges and prospects. Mater. Today Nano 2023, 24, 100399. [Google Scholar] [CrossRef]

- Ahmad, F.; Zahid, M.; Jamil, H.; Khan, M.A.; Atiq, S.; Bibi, M.; Shahbaz, K.; Adnan, M.; Danish, M.; Rasheed, F.; et al. Advances in graphene-based electrode materials for high-performance supercapacitors: A review. J. Energy Storage 2023, 72, 108731. [Google Scholar] [CrossRef]

- Chaudhuri, H.; Yun, Y.-S. A critical review on the properties and energy storage applications of graphene oxide/layered double hydroxides and graphene oxide/MXenes. J. Power Sources 2023, 564, 232870. [Google Scholar] [CrossRef]

- Na, W.; Jun, J.; Park, J.W.; Lee, G.; Jang, J. Highly porous carbon nanofibers co-doped with fluorine and nitrogen for outstanding supercapacitor performance. J. Mater. Chem. A 2017, 5, 17379–17387. [Google Scholar] [CrossRef]

- Sim, Y.; Surendran, S.; Cha, H.; Choi, H.; Je, M.; Yoo, S.; Chan Seok, D.; Ho Jung, Y.; Jeon, C.; Jin Kim, D.; et al. Fluorine-doped graphene oxide prepared by direct plasma treatment for supercapacitor application. Chem. Eng. J. 2022, 428, 132086. [Google Scholar] [CrossRef]

- El-Shafai, N.M.; Ramadan, M.S.; Alkhamis, K.M.; Aljohani, M.M.; El-Metwaly, N.M.; El-Mehasseb, I.M. A unique engineering building of nanoelectrodes based on titanium and metal oxides nanoparticles captured on graphene oxide surface for supercapacitors and energy storage. J. Alloys Compd. 2023, 939, 168685. [Google Scholar] [CrossRef]

- Veeresh, S.; Ganesha, H.; Nagaraju, Y.S.; Vijeth, H.; Devendrappa, H. Activated carbon incorporated graphene oxide with SnO2 and TiO2-Zn nanocomposite for supercapacitor application. J. Alloys Compd. 2023, 952, 169907. [Google Scholar] [CrossRef]

- Abdallah, F.; Arthur, E.K.; Mensah-Darkwa, K.; Gikunoo, E.; Baffour, S.A.; Agamah, B.A.; Nartey, M.A.; Agyemang, F.O. Electrochemical performance of corncob-derived activated carbon-graphene oxide and TiO2 ternary composite electrode for supercapacitor applications. J. Energy Storage 2023, 68, 107776. [Google Scholar] [CrossRef]

- Wang, Q.; Zhang, Y.; Xiao, J.; Jiang, H.; Hu, T.; Meng, C. Copper oxide/cuprous oxide/hierarchical porous biomass-derived carbon hybrid composites for high-performance supercapacitor electrode. J. Alloys Compd. 2019, 782, 1103–1113. [Google Scholar] [CrossRef]

- El-Shafai, N.M.; Alamrani, N.A.; Al-bonayan, A.M.; Abu-Melha, S.; El-Metwaly, N.M.; El-Mehasseb, I. Building electrons clouds of redesigned copper oxide nanorods captured on the graphene oxide surface for supercapacitors and energy storage. Surf. Interfaces 2023, 38, 102757. [Google Scholar] [CrossRef]

- Arshad, N.; Usman, M.; Adnan, M.; Ahsan, M.T.; Rehman, M.R.; Javed, S.; Ali, Z.; Akram, M.A.; Demopoulos, G.P.; Mahmood, A. Nanoengineering of NiO/MnO2/GO Ternary Composite for Use in High-Energy Storage Asymmetric Supercapacitor and Oxygen Evolution Reaction (OER). Nanomaterials 2023, 13, 99. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Deng, Q.; Li, M.; Jiang, K.; Zhang, J.; Hu, Z.; Chu, J. Copper ferrites@reduced graphene oxide anode materials for advanced lithium storage applications. Sci. Rep. 2017, 7, 8903. [Google Scholar] [CrossRef] [PubMed]

- Lashkenari, M.S.; Ghasemi, A.K.; Khalid, M.; Shahgaldi, S. Facile synthesis of N-doped graphene oxide decorated with copper ferrite as an electrode material for supercapacitor with enhanced capacitance. Electrochim. Acta 2023, 465, 142959. [Google Scholar] [CrossRef]

- Nithya, V.D.; Sabari Arul, N. Progress and development of Fe3O4 electrodes for supercapacitors. J. Mater. Chem. A 2016, 4, 10767–10778. [Google Scholar] [CrossRef]

- Sumboja, A.; Liu, J.; Zheng, W.G.; Zong, Y.; Zhang, H.; Liu, Z. Electrochemical energy storage devices for wearable technology: A rationale for materials selection and cell design. Chem. Soc. Rev. 2018, 47, 5919–5945. [Google Scholar] [CrossRef] [PubMed]

- Emmanuel Hounkanrin, S.R.J.; Guo, Z.; Luo, J. Microwave-synthesized Bismuth oxide-graphene oxide composite as an electrode for supercapacitors. Int. J. Electrochem. Sci. 2023, 18, 100086. [Google Scholar] [CrossRef]

- Dhanabalan, K.; Bhosale, M.; Murugan, N.; Aruchamy, K.; Sriram, G.; Sadhasivam, T.; Oh, T.H. A versatile heterostructure junction of NiO–C-MoOx (X= 2 & 3) composite electrocatalysts for hydrogen evolution reaction. J. Solid State Chem. 2024, 335, 124702. [Google Scholar]

- Abdolahi, B.; Gholivand, M.B.; Shamsipur, M.; Taherpour, A.; Mirzaei, M.; Daramroudi, A.H. Ni0.5Co0.5WO4@f-MWCNTs/GO nanocomposite with improved supercapattery activity as the electrode for asymmetric supercapacitor device. J. Energy Storage 2023, 73, 109181. [Google Scholar] [CrossRef]

- Foroutan, N.; Lashkenari, M.S.; Alizadeh, E.; Sedighi, M. Synthesis of manganese ferrite/graphene oxide nanocomposite and investigation of its supercapacitor behaviors. Int. J. Hydrogen Energy 2023, 48, 25859–25868. [Google Scholar] [CrossRef]

- Pang, N.; Wang, M.; Wang, X.; Xiong, D.; Xu, S.; Lu, X.; Wang, L.; Jiang, L.; Chu, P.K. Graphene-oxide-modified MnO2 composite electrode for high-performance flexible quasi-solid-state zinc-ion batteries. Mater. Sci. Eng. B 2024, 299, 116981. [Google Scholar] [CrossRef]

- Mao, X.; Zou, Y.; Xu, F.; Sun, L.; Chu, H.; Zhang, H.; Zhang, J.; Xiang, C. Three-Dimensional Self-Supporting Ti3C2 with MoS2 and Cu2O Nanocrystals for High-Performance Flexible Supercapacitors. ACS Appl. Mater. Interfaces 2021, 13, 22664–22675. [Google Scholar] [CrossRef] [PubMed]

- Basu, P.; Mahesh, R.; Harish, S.; Joseph, S.; Sagayaraj, P. One-pot hydrothermal preparation of Cu2O-CuO/rGO nanocomposites with enhanced electrochemical performance for supercapacitor applications. Appl. Surf. Sci. 2018, 449, 474–484. [Google Scholar]

- Yu, Z.; Wang, S.; Xiao, Z.; Xu, F.; Xiang, C.; Sun, L.; Zou, Y. Graphene-supported Cu2O-CoO heterojunctions for high performance supercapacitors. J. Energy Storage 2024, 77, 110009. [Google Scholar] [CrossRef]

- Shembade, U.V.; Gurav, S.R.; Gaikwad, M.A.; Wategaonkar, S.B.; Ghatage, S.R.; Sonkawade, R.G.; Kim, J.H.; Moholkar, A.V. Hydrothermal synthesis of graphene oxide interspersed in non-uniform tungsten oxide nanorod and its performance towards highly efficient hybrid supercapacitor. Ceram. Int. 2024, 50, 340–350. [Google Scholar] [CrossRef]

- Verma, S.; Verma, B. Synergistic optimization of nanostructured graphene oxide based ternary composite for boosting the performance of supercapacitor electrode material via response surface methodology. Colloids Surf. A 2024, 682, 132893. [Google Scholar] [CrossRef]

- Chandraraj, S.S.; Xavier, J.R. Facile synthesis of graphene based mixed metal sulphide nanocomposite for energy storage applications. Surf. Interfaces 2023, 36, 102515. [Google Scholar] [CrossRef]

- Rao, S.S.; Kanaka Durga, I.; Naresh, B.; Jin-Soo, B.; Krishna, T.N.V.; In-Ho, C.; Ahn, J.-W.; Kim, H.-J. One-Pot Hydrothermal Synthesis of Novel Cu-MnS with PVP Cabbage-Like Nanostructures for High-Performance Supercapacitors. Energies 2018, 11, 1590. [Google Scholar] [CrossRef]

- Mane, V.J.; Lokhande, A.C.; Nikam, R.P.; Padalkar, N.S.; Lokhande, V.C.; Dhawale, D.S.; Lokhande, C.D. MnS-La2S3/GO composite electrodes for high-performance flexible symmetric supercapacitor. Appl. Surf. Sci. Adv. 2023, 15, 100399. [Google Scholar] [CrossRef]

- Biradar, M.R.; Rao, C.R.K.; Bhosale, S.V.; Bhosale, S.V. Bio-inspired adenine-benzoquinone-adenine pillar grafted graphene oxide materials with excellent cycle stability for high energy and power density supercapacitor applications. J. Energy Storage 2023, 58, 106399. [Google Scholar] [CrossRef]

- Chen, T.; Shen, T.; Wang, Y.; Yu, Z.; Zhang, W.; Zhang, Y.; Ouyang, Z.; Cai, Q.; Ji, Y.; Wang, S. In Situ Synthesis of Ni-BTC Metal–Organic Framework@Graphene Oxide Composites for High-Performance Supercapacitor Electrodes. ACS Omega 2023, 8, 10888–10898. [Google Scholar] [CrossRef] [PubMed]

- Fu, X.-Y.; Ma, C.-J.; Shu, R.-Y.; Zhang, Y.-Y.; Jiang, H.-B. Electrostatic self-assembled MXene–graphene oxide composite electrodes for planar supercapacitors. Appl. Phys. Lett. 2023, 122, 113901. [Google Scholar] [CrossRef]

- Yasoda, K.Y.; Baji, D.S.; Kumar, M.S.; Santhanagopalan, D.; Batabyal, S.K. Sustainable development of manganese sulfoselenide nanoparticles anchored graphene oxide nanocomposite for high-performance supercapacitor and lithium-ion battery applications. J. Alloys Compd. 2023, 930, 167282. [Google Scholar] [CrossRef]

- Sriram, G.; Thangarasu, S.; Selvakumar, K.; Kurkuri, M.; Dhineshbabu, N.R.; Oh, T.H. Effective removal of Rose Bengal using Ni-Co-Zn layered triple hydroxide: Studies on batch adsorption, mechanism, selectivity, co-ions, and reusability. Colloids Surf. A 2024, 685, 133199. [Google Scholar] [CrossRef]

- Zhao, W.; Liu, T.; Wu, N.; Zhou, B.; Yan, Y.; Ye, Y.; Gong, J.; Yang, S. Bimetallic electron-induced phase transformation of CoNi LDH-GO for high oxygen evolution and supercapacitor performance. Sci. China Mater. 2023, 66, 577–586. [Google Scholar] [CrossRef]

- Shi, J.; Du, N.; Zheng, W.; Li, X.; Dai, Y.; He, G. Ultrathin Ni-Co double hydroxide nanosheets with conformal graphene coating for highly active oxygen evolution reaction and lithium ion battery anode materials. Chem. Eng. J. 2017, 327, 9–17. [Google Scholar] [CrossRef]

- Sriram, G.; Uthappa, U.T.; Losic, D.; Kigga, M.; Jung, H.-Y.; Kurkuri, M.D. Mg–Al-Layered Double Hydroxide (LDH) Modified Diatoms for Highly Efficient Removal of Congo Red from Aqueous Solution. Appl. Sci. 2020, 10, 2285. [Google Scholar] [CrossRef]

- Sriram, G.; Bendre, A.; Altalhi, T.; Jung, H.-Y.; Hegde, G.; Kurkuri, M. Surface engineering of silica based materials with Ni–Fe layered double hydroxide for the efficient removal of methyl orange: Isotherms, kinetics, mechanism and high selectivity studies. Chemosphere 2022, 287, 131976. [Google Scholar] [CrossRef] [PubMed]

- Bao, E.; Ren, X.; Wang, Y.; Zhang, Z.; Luo, C.; Liu, X.; Xu, C.; Chen, H. Advanced hybrid supercapacitors assembled with CoNi LDH nanoflowers and nanosheets as high-performance cathode materials. J. Energy Storage 2024, 82, 110535. [Google Scholar] [CrossRef]

- Hummers, W.S., Jr.; Offeman, R.E. Preparation of Graphitic Oxide. J. Am. Chem. Soc. 1958, 80, 1339. [Google Scholar] [CrossRef]

- Nanaji, K.; Sarada, B.V.; Varadaraju, U.V.; Rao, T.N.; Anandan, S. A novel approach to synthesize porous graphene sheets by exploring KOH as pore inducing agent as well as a catalyst for supercapacitors with ultra-fast rate capability. Renew. Energy 2021, 172, 502–513. [Google Scholar] [CrossRef]

- Siddiqui, R.; Rani, M.; Ahmad Shah, A.; Razaq, A.; Iqbal, R.; Neffati, R.; Arshad, M. Fabrication of tricarboxylate-neodymium metal organic frameworks and its nanocomposite with graphene oxide by hydrothermal synthesis for a symmetric supercapacitor electrode material. Mater. Sci. Eng. B 2023, 295, 116530. [Google Scholar] [CrossRef]

- Khakpour, F.; Ghafouri Taleghani, H.; Soleimani Lashkenari, M. Metal–organic framework/sulfur-doped graphene oxide nanocomposite for high efficiency electrochemical double-layer capacitors. Appl. Organomet. Chem. 2023, 37, e6969. [Google Scholar] [CrossRef]

- Zhang, H.; Wei, Z.; Wu, J.; Cheng, F.; Ma, Y.; Liu, W.; Cheng, Y.; Lin, Y.; Liu, N.; Gao, Y.; et al. Interlayer-spacing-regulated MXene/rGO Foam for Multi-functional Zinc-ion Microcapacitors. Energy Storage Mater. 2022, 50, 444–453. [Google Scholar] [CrossRef]

- Sun, P.; Liu, J.; Liu, Q.; Yu, J.; Chen, R.; Zhu, J.; Sun, G.; Li, Y.; Liu, P.; Wang, J. An inkjet-printing ink based on porous NiS/N-MXene for high-performance asymmetric micro-supercapacitors and self-powered microelectronics. Chem. Eng. J. 2023, 474, 145466. [Google Scholar] [CrossRef]

- An, N.; Li, W.; Shao, Z.; Zhou, L.; He, Y.; Sun, D.; Dong, X.; Hu, Z. Graphene oxide coated polyaminoanthraquinone@MXene based flexible film electrode for high-performance supercapacitor. J. Energy Storage 2023, 57, 106180. [Google Scholar] [CrossRef]

- Fu, X.-Y.; Shu, R.-Y.; Ma, C.-J.; Zhang, Y.-Y.; Jiang, H.-B.; Yao, M.-N. Self-assembled MXene-graphene oxide composite enhanced laser-induced graphene based electrodes towards conformal supercapacitor applications. Appl. Surf. Sci. 2023, 631, 157549. [Google Scholar] [CrossRef]

- Hussain, S.; Vikraman, D.; Ali Sheikh, Z.; Taqi Mehran, M.; Shahzad, F.; Mujasam Batoo, K.; Kim, H.-S.; Kim, D.-K.; Ali, M.; Jung, J. WS2-embedded MXene/GO hybrid nanosheets as electrodes for asymmetric supercapacitors and hydrogen evolution reactions. Chem. Eng. J. 2023, 452, 139523. [Google Scholar] [CrossRef]

- Verma, S.; Verma, B. Synergistic interaction of bacteria with graphene oxide for high performance supercapacitor. Bioresour. Technol. Rep. 2023, 21, 101354. [Google Scholar] [CrossRef]

- Li, X.; Wu, H.; Guan, C.; Elshahawy, A.M.; Dong, Y.; Pennycook, S.J.; Wang, J. (Ni,Co)Se2/NiCo-LDH Core/Shell Structural Electrode with the Cactus-Like (Ni,Co)Se2 Core for Asymmetric Supercapacitors. Small 2019, 15, 1803895. [Google Scholar] [CrossRef] [PubMed]

- Sriram, G.; Bendre, A.; Mariappan, E.; Altalhi, T.; Kigga, M.; Ching, Y.C.; Jung, H.-Y.; Bhaduri, B.; Kurkuri, M. Recent trends in the application of metal-organic frameworks (MOFs) for the removal of toxic dyes and their removal mechanism—A review. Sustain. Mater. Technol. 2022, 31, e00378. [Google Scholar] [CrossRef]

- Feng, S.; Wang, X.; Wang, M.; Bai, C.; Cao, S.; Kong, D. Crumpled MXene Electrodes for Ultrastretchable and High-Area-Capacitance Supercapacitors. Nano Lett. 2021, 21, 7561–7568. [Google Scholar] [CrossRef] [PubMed]

- Wu, J.; Li, Q.; Shuck, C.E.; Maleski, K.; Alshareef, H.N.; Zhou, J.; Gogotsi, Y.; Huang, L. An aqueous 2.1 V pseudocapacitor with MXene and V-MnO2 electrodes. Nano Res. 2022, 15, 535–541. [Google Scholar] [CrossRef]

- Hashem, A.; Tabassum, B.; Fathi Abd_Allah, E. Bacillus subtilis: A plant-growth promoting rhizobacterium that also impacts biotic stress. Saudi J. Biol. Sci. 2019, 26, 1291–1297. [Google Scholar] [CrossRef] [PubMed]

- Wu, Q.; He, T.; Zhang, Y.; Zhang, J.; Wang, Z.; Liu, Y.; Zhao, L.; Wu, Y.; Ran, F. Cyclic stability of supercapacitors: Materials, energy storage mechanism, test methods, and device. J. Mater. Chem. A 2021, 9, 24094–24147. [Google Scholar] [CrossRef]

- Patra, A.; Namsheer, K.; Jose, J.R.; Sahoo, S.; Chakraborty, B.; Rout, C.S. Understanding the charge storage mechanism of supercapacitors: In situ/operando spectroscopic approaches and theoretical investigations. J. Mater. Chem. A 2021, 9, 25852–25891. [Google Scholar] [CrossRef]

- Ali, S.; Ahmad, T.; Tahir, M.Y.; Usman, M.; Chhattal, M.; Hussain, I.; Khan, S.; Hassan, A.M.; Assiri, M.A.; Rosaiah, P.; et al. The emergence of density functional theory for supercapacitors: Recent progress and advances. J. Energy Storage 2023, 73, 109100. [Google Scholar] [CrossRef]

- Becke, A.D. Perspective: Fifty years of density-functional theory in chemical physics. J. Chem. Phys. 2014, 140, 18A301. [Google Scholar] [CrossRef]

- Perdew, J.P.; Burke, K.; Ernzerhof, M. Generalized Gradient Approximation Made Simple. Phys. Rev. Lett. 1996, 77, 3865–3868. [Google Scholar] [CrossRef]

- Luryi, S. Quantum capacitance devices. Appl. Phys. Lett. 1988, 52, 501–503. [Google Scholar] [CrossRef]

- Karmakar, S.; Mistari, C.D.; Shajahan, A.S.; More, M.A.; Chakraborty, B.; Behera, D. Enhancement of Pseudocapacitive Behavior, Cyclic Performance, and Field Emission Characteristics of Reduced Graphene Oxide Reinforced NiGa2O4 Nanostructured Electrode: A First Principles Calculation to Correlate with Experimental Observation. J. Phys. Chem. C 2021, 125, 7898–7912. [Google Scholar] [CrossRef]

- Kolavada, H.; Gajjar, P.N.; Gupta, S.K. Unraveling quantum capacitance in supercapacitors: Energy storage applications. J. Energy Storage 2024, 81, 110354. [Google Scholar] [CrossRef]

- Ghosh, S.; Behera, S.K.; Mishra, A.; Casari, C.S.; Ostrikov, K.K. Quantum Capacitance of Two-Dimensional-Material-Based Supercapacitor Electrodes. Energy Fuels 2023, 37, 17836–17862. [Google Scholar] [CrossRef]

- Pathak, M.; Jose, J.R.; Chakraborty, B.; Rout, C.S. High performance supercapacitor electrodes based on spinel NiCo2O4@MWCNT composite with insights from density functional theory simulations. J. Chem. Phys. 2020, 152, 064706. [Google Scholar] [CrossRef] [PubMed]

- Islam, T.; Hasan, M.M.; Sarker, S.; Ahammad, A.J.S. Intrinsic Properties of GO/RGO Bilayer Electrodes Dictate Their Inter-/Intralayer Intractability to Modulate Their Capacitance Performance. ACS Omega 2023, 8, 14013–14024. [Google Scholar] [CrossRef] [PubMed]

- Reddy, P.A.K.; Han, H.; Kim, K.C.; Bae, S. Synthesis of ZIF-67-derived CoS2@graphitic carbon/reduced graphene oxide for supercapacitor application. Chem. Eng. J. 2023, 471, 144608. [Google Scholar] [CrossRef]

- Li, X.; Lin, Z.; Wang, C.; Wang, H.; Feng, S.; Li, T.; Ma, Y. Hierarchical graphene oxide/manganese dioxide/cobalt-nickel layered double hydroxide electrodes for high energy density asymmetric flexible supercapacitor. Chem. Eng. J. 2024, 484, 149430. [Google Scholar] [CrossRef]

- da Silva, D.A.C.; Paulista Neto, A.J.; Pascon, A.M.; Fileti, E.E.; Fonseca, L.R.C.; Zanin, H.G. Combined Density Functional Theory and Molecular Dynamics Simulations To Investigate the Effects of Quantum and Double-Layer Capacitances in Functionalized Graphene as the Electrode Material of Aqueous-Based Supercapacitors. J. Phys. Chem. C 2021, 125, 5518–5524. [Google Scholar] [CrossRef]

- Li, Z.; Hu, B.; Yu, R.; Tian, T.; Guo, Z.; Mu, J.; Zhang, X.; Wang, G.; Liu, X.; Liu, A. Hollow cobalt selenide nanospheres wrapped with reduced graphene oxide nanosheets as electrodes for hybrid supercapacitor. Appl. Surf. Sci. 2023, 608, 155237. [Google Scholar] [CrossRef]

- Yang, Y.; Qian, D.; Yang, J.; Xiong, Y.; Chen, Y.; He, Y.; Hu, Z. Graphene modification with chrysin molecules as a high performance electrode material for supercapacitor. Appl. Surf. Sci. 2023, 639, 158267. [Google Scholar] [CrossRef]

- Kumar, N.; Verma, S.; Kumar, P.; Khan, A.A.; Park, J.; Srivastava, V.C. Efficient one-pot two-step electrochemical synthesis of highly oxidized graphene oxide for enhanced energy and environmental applications: Structure elucidation through DFT simulations. Carbon 2024, 218, 118722. [Google Scholar] [CrossRef]

- Mohammadi, S.; Mahdi Homayounfard, A.; Morteza Mousavi–Khoshdel, S. Experimental and theoretical investigation of high-performance supercapacitor based on guanidine functionalized graphene oxide. Electrochem. Commun. 2024, 163, 107703. [Google Scholar] [CrossRef]

| EDLC | PC | Hybrid |

|---|---|---|

| Carbon-based materials are utilized as electrode materials. | Metal oxides and conducting polymers are utilized as electrode materials | Electrode materials are used as both carbon and metal oxides/conducting polymers. |

| The charge storage mechanism is via the non-Faradaic process (electrochemical double-layer formation). | The charge storage mechanism is via the Faradaic process (redox reactions). | The charge storage mechanism is via both Faradaic and non-Faradaic processes. |

| It has low energy density, good rate capability, cyclic stability, and low specific capacitance (Cs). | High energy density, high power density, low rate capability, and high Cs. | With high energy and power density and good cyclability, the system could have a low or high cost, which depends on the design of electrode materials and modest stability. |

| Electrode Materials | Methods | Advantages | Disadvantages | Morphology | Surface Area (m2 g−1) | Structure | Ref. |

|---|---|---|---|---|---|---|---|

| GO-Fluorine | |||||||

| FGO | Direct plasma reactive treatment | Achieving uniform coating of fluorine on GO and rich active sites, large-scale preparation, and operation under atmospheric pressure could be the best surface coating method for powdery materials. | High-cost process and methods may not be environmentally friendly due to the use of NF3 gas, which is toxic. Skilled labor is required to handle the reactor, possible corrosion in the reactor through NF3 gas, the plasma generates high electron temperature affects the sensitive material, maintenance of the reactor, low surface area of material, and high energy consumption. | Thin layers with large interspaces | 3.7 | - | [77] |

| GO-Metal oxides | |||||||

| GO@TiO2-NPs | Grinding | Low-cost, simple, easy to composite, rich active sites, no energy consumption, large-scale production, and environmentally friendly procedure. | High aggregation, particle sizes could be very high, poor quality, the interaction between nanoparticles and GO may be weak, morphological shape damages during grinding, possibly low surface area, and different techniques used to synthesize different nanoparticles consume the cost of the process and time. | Aggregation and spherical shape | - | High crystalline | [78] |

| AC-GO-SnO2 | Hydrothermal | Low-cost, simple, safe, environmentally friendly, doping, high-purity particles, highly active sites, easy to composite, low-temperature process, and well-structured morphologies. | Small-scale production, time-consuming process, moderate surface area, moderate energy consumption, and this method requires a vacuum or unvacuumed oven to synthesize particles. | Aggregated and spherical shape | - | Low crystalline | [79] |

| AC-TiO2-GO | Simple reaction | Cheap, easy-to-obtain composite using a binder, large-scale production, rich active sites, high hybrid structure, and no energy consumption. | Synthesizing AC, TiO2, and GO separately and then combining them may be a costly, time-consuming process; there is poor composite quality owing to dust particles during outdoor mixing; and it is not environmentally friendly since organic chemicals are added during particle mixing. | Micro-TiO2 and GO sheet hybrid AC (Fluffy) | 439.2 | High crystalline | [80] |

| GO-CuO/ZnO/TiO2 | Ultrasonication | Cheap, very simple process, easy to operate instrument, has no energy consumption, has highly active sites, time-saving and room-temperature process, applies to all common materials for composites, the composite surfaces may exhibit high surface functional groups, low particle aggregation, and homogeneity of particles. | Mechanical forces cause morphological damage to particles and produce heat while performing small-scale production, and long-term operation may affect the instrument; high-time consuming procedures; this technique may produce low bonding between particles, and synthesizing many nanoparticles using chemical procedures might be expensive and expensive. | Nanorods of CuO and ZnO and irregular shape TiO2 on GO sheet | - | High crystalline | [82] |

| NGO-CuFe2O4 | Hydrothermal | Cheap, simple, environmentally friendly, high-purity particles, easy to hybrid particles, rich active sites, doping, particles could be of high surface area, low-temperature process, well-structured morphologies, and particles produced by this method are nanometer in size. | Commonly used to prepare metal oxides, temperatures below 220 °C could be used for particle synthesis, particles cannot be produced if the autoclave is not tightly closed, small-scale production, time-consuming process, doping N on GO by thermal decomposition in the tubular furnace could be high energy consumption and expensive, and high-temperature thermal decomposition can affect the stability of the material. | CuFe2O4 nanocubes on GO sheet | - | High crystalline | [85] |

| GO/Fe3O4-IL@W | Simple reaction | Low-cost procedure, highly hybrid particles, high-purity particles, high structural stability, highly active sites, large-scale production, the composite surfaces may exhibit high surface functional groups, low-temperature process, and no energy consumption. | Synthesis of GO and its functionalization with Fe3O4-IL may be time-consuming and energy consumption due to the large number of organic compounds and processes involved, and GO-Fe3O4-IL reaction under inert conditions. | Fe3O4/IL/W presents an irregular spherical shape on the GO sheet | - | High crystalline | [58] |

| Bi2O3-GO | Microwave | Dust-free synthesis, nanoparticles can be synthesized, high-purity particles, a time-saving process, high yields, no chemicals or water were used, no solvents or water are needed to purify the product after synthesis, sugar used as a source for GO, and chemical-free GO is synthesis. | Energy consumption, expensive technique, maintenance cost, morphology can be damaged under high watts operation, limited penetration depth of the heat radiation into the reaction precursors/medium, and heat-sensitive material cannot be used for surface modification or functionalization. | Sheet morphology | - | High crystalline | [88] |

| NMGO | Ultrasonication | The process is inexpensive, produces highly hybrid particles, high-surface-area particle formation, uses only water as a medium for composite formation, consumes no energy, operates at room temperature, and saves time. It also facilitates the interaction between GO and nanoparticles, enhances composite structural stability, allows for the adsorption of high-density particles on GO surfaces, and does not require the use of solvents or organic media. | Specific morphology cannot be obtained; low-purity particles form on GO due to atmospheric dust contamination; sonication process under long-term operation and high amplitude may develop defects on the particle surface and break GO layers; instrument maintenance; and synthesis of GO, NiO, and MnO2 to prepare composite structure are expensive and time-consuming. | Nanoparticles on the GO sheet have no specific shape | 102.0 | Moderate crystalline | [83] |

| NCWO4/f-MWCNTs/GO | Ultrasonication | Only uses water to produce composites. For ideal composite preparation, first ultrasonicate f-MWCNTs and GO in water. After that, NCWO4 was added to the solution, and the particles had a substantial surface area. | Low-purity particles were observed. It could be an expensive process due to the synthesis of NCWO4 by hydrothermal and then ultrasonication used for composite f-MWCNTs and GO. Additionally, using commercial MWCNTs and their functionalization and commercial GO in this procedure seems to be expensive, and a 2 h continuous ultrasonication process may affect the instrument’s functionality. | Urchin-like structure of NCWO4 on the wire-like shape of f-MWCNTs and GO sheet composite | 172.2 | Low crystalline | [90] |

| MnFe2O4/GO | Modified Hummer’s method | Carbon-based materials can be synthesized by this technique, a low-temperature process, a time-saving procedure, highly layered GO sheets, high-purity GO sheets, highly dense composite particles, high-surface-area composites, high crystallinity composites, and high structural and morphological stability | The use of the coprecipitation technique to synthesize MnFe2O4 revealed low purity, moderately expensive procedures, and the need for an ice bath for GO/composite preparation; the precipitation process uses a high molarity ratio for the precursors, commercial graphite is used for the preparation of GO and its composites, vacuum drying is used for the composites, and a high amount of KMnO4 is used for the reaction of GO and its composites. | The MnFe2O4 has a fine spherical shape on the GO sheet | - | High crystalline | [91] |

| MnO2-GO/GF | Hydrothermal | The synthesis process is simple, involving only water as the medium for MnO2-GO formation on GF, an environmentally friendly procedure, a well-structured morphology, the possibility of high-surface-area composites, the use of major precursors for composite preparation, and the absence of any toxic solvents or liquids in the procedure. | The process is costly due to the utilization of commercial GF, a 12 h process, the lack of a detailed explanation for the synthesis procedure, the use of toxic chemicals for pretreating the GF, the production of low-purity particles or composites, the requirement for pretreated GF to dry under vacuum conditions, the absence of a purification procedure after synthesis, the potential expense of using a high-pressure reactor for the synthesis of GO, and potential maintenance issues. | Nanorod shape of MnO2/GO on GF | - | Low crystalline | [92] |

| Cu2O-CoO/GO | Hydrothermal | This process used only an 8 h reaction and may have high-surface-area composites, moderate energy consumption, high-purity composites, highly active sites, and synthesized GO that can directly be added to the precursor for composite preparation using hydrothermal. | The process was moderately expensive, revealed no significant morphology, and revealed low-purity particles. The addition of KOH to the precursor solution for alkaline titration may not be environmentally friendly, the interaction between GO and nanoparticles could be low, the resulting black gel product requires soaking in water for 24 h to purify it, this process is time-consuming, and the final composite particles require calcination in a tubular furnace under an N2 atmosphere. | No significant morphology; however, GO shows the sheet-layered structure | - | High crystalline | [95] |

| 10%GO/WO3 | Hydrothermal | Using H2O2 as a reducing agent in the synthesis could make fine particles, the reaction could directly add GO powder to make the composite, and a methodical process could find the best ratio of GO to WO3 for the composite formation. Fine-size particles were synthesized, along with high-purity particles, and it has a moderate energy consumption and a high hybrid particle formation. | It is a 12 h process, low-surface-area particles, annealing at 500 °C may damage the morphology, low-activity sites, a high GO ratio may affect the crystallinity of WO3, using commercial graphite flake for GO synthesis may be costly, and using HCl and H2O2 in the synthesis may be an environmentally unfriendly and time-consuming procedure. | Nanorods | 33.9 | High crystalline | [96] |

| GO/CNTs/CoFe2O4 | Simple reaction | The process is low-cost, simple, energy-free, and time-saving. It uses only water as a medium for composite formation under stirring, has rich active sites, is environmentally friendly, and does not use any solvents or organic chemicals. | The process may be costly because it involves synthesizing GO using a modified Hummer’s method, which necessitates the use of numerous chemicals, acids, solvents, and an ice bath setup. The solution-combustion method synthesizes CoFe2O4 but requires calcination at 800 °C. Further, commercial CNTs and graphite flakes are expensive. The preparation of composites in water with simple mixing may not be effective, the particles may not hybridize strongly, and the use of 10% HCl to wash the composites may damage their structure and morphology. | The spherical shape of CoFe2O4 and the tube shape of CNTs are present on GO sheets | - | High crystalline | [97] |

| GO-Metal sulfide | |||||||

| NiS/GO and CoS/GO | Hydrothermal | The process is environmentally friendly and time-saving, as it directly adds GO powder to the precursor solution for composite synthesis, eliminating the need for any additional pH adjustments or reducing agents. This technique can achieve a uniform particle size distribution and deposition. The particle interaction with the GO sheet could be strong, ensuring high stability and purity. | The particles on the GO sheets did not exhibit any notable morphology. They might have a low surface area, undergo a 12 h process, and have few active sites. The process involves the consumption of chemicals for GO, NiS, and CoS synthesis, as well as hydrothermal treatment at high temperatures, which can be somewhat expensive. | No significant shape of nanoparticles was observed on the GO sheet | - | High crystalline | [98] |

| MnS-La2S3/GO | SILAR | Thin film dip coating can be performed at low cost, simple, room temperature, time-saving, large-scale production, no energy consumption, highly active sites, high composite structures, only water used to remove the unbound anion/cations on the film surfaces, an environmentally friendly process, multiple dip coating can be performed, no drying process is required, and no chemical reaction is required to coat the film on the SS substrate. | It takes at least 100 SILAR cycles to obtain a perfect coating. There are concerns about the coating’s stability, difficulties regulating the film’s thickness, and the possibility of airborne dust particles contaminating thin film surfaces. Handling thin film devices by hand or in a closed pack is challenging due to their susceptibility to scratches or cracks. And dip-coating film on one side of the substrate is challenging. | Thin film/sheet morphology | - | Low crystalline | [100] |

| GO-Transition metal chalcogenide | |||||||

| GO-MnSSe | Simple reaction | Low-cost, simple, environmentally friendly process, no complicated technique or method used, room-temperature process, no energy consumption, mass production, no solvents or reducing agents used for the composite preparation, and low-temperature drying process. | The overnight process used 1 g of GO to prepare Go-MnSSe, low-activity sites, low purity, and potentially low-surface-area particles. The reaction under only water may not form particles on GO, leading to uneven particle formation on GO and no particle formation on GO for the composite GO-MnS. The composite preparation did not calculate a ratio, limiting the possibility of incorporating Mn into GO synthesis using a modified Hummer’s method. | The GO sheet contains fine spherical MnSSe nanoparticles | - | Low crystalline | [104] |

| GO-Layered double hydroxide | |||||||

| GO/Co2-Ni1 LDH | Reflux | The procedure is simple and involves high-surface-area particles, rich active sites, a low-temperature process, high hybrid formation, a sheet type of morphology, highly porous composites, and no energy consumption. | The process is not environmentally friendly, it takes a long time, the particles are not very pure, it uses high molarity ratios, it is moderately expensive because it synthesizes them through reflux in an oil bath, and the clay-like nature of the LDHs may damage the shape of the GO. | Sheets with a wrinkled structure | 84.6 | Low crystalline | [106] |

| GO-organic material | |||||||

| ABQA-GO | Organic reaction | It is simple to synthesize, ABQA and GO are strongly covalently bonded, it has inert atmosphere processes, the process is carried out at low temperatures, there are a lot of active sites and functional groups on the surface of the functionalized GO, and ABQA has a high redox property. | The process is time-consuming, not environmentally friendly, and costly due to the use of expensive organic chemicals and commercial graphite, as well as the use of toxic chemicals and the freeze-drying process. The product’s purity may be low, necessitating self-safety precautions before synthesis. The distillation process can be energy-consuming, and only synthesis can take place in fume exhaust hoods. And there are morphology stability issues. | Broken and wrinkled sheet structure | - | Low crystalline | [101] |

| Nd-MOF/GO | Hydrothermal | Easy to synthesize, environmentally friendly, low cost, high-purity particles, well-structured morphology, water and ethanol utilized for reaction, drying particle at less than 90 °C, low-energy consumption, and highly active sites. | The process involves the use of an ice bath before the hydrothermal reaction, treatment at elevated temperatures, and a prolonged duration. High temperatures could not be used to dry the particles; hybrid particles could not form properly, and the morphology was slightly damaged after the composite was mixed with GO. | Hexagonal-rod-shaped Nd-MOFs on the GO sheet | - | High crystalline | [113] |

| Ni-BTC@GO | Hydrothermal | Cheap, simple to synthesize, drying particles at less than 90 °C, rich active sites, low energy consumption, high-purity particles, high surface area and porous surfaces, and well-structured morphology particles. | It is a time-consuming technique owing to the 48 h hydrothermal process and the 24 h particle drying time. The organic solvents employed for washing the particles may affect their surfaces. Adjusting the dosage of GO in the composite preparation for comparison makes it a bit expensive. Higher doses of GO could affect the crystallinity of MOF, and the procedure is not environmentally friendly because of the usage of organic solvents for the reaction. | Sheet-structured GO on octahedral-shaped Ni-BTC MOF. | - | High crystalline | [102] |

| SGZ | Simple reaction | The process is cheap, simple, easy to synthesize, conducted at 40 °C, consumes no energy, has highly active sites, may have a high surface area, and uses only methanol for reaction and particle purification. | It is not an environmentally friendly procedure and also not an effective procedure for making composites due to the possibility of contamination, which leads to low purity. Sonication and mechanical stretching destroy the particle shape. Overall, processes such as GO fabrication, S doping on GO, and ZIF-8 MOF to make composite particles are quite expensive. GO affects the crystallinity of MOF. | Irregular shape | - | Low crystalline | [114] |

| GO-MXene | |||||||

| CGO/PDAAQ/MXene film electrode | Vacuum-assisted filtration | The composite structure exhibits high flexibility and high stability due to the electrostatic interaction between CGO/PDAAQ and MXene. The preparation of the composite film at room temperature and the conducting composite at water are both easy and simple processes. | The procedure is expensive due to the numerous processing stages involved, and the final product requires the use of a freeze-drier. It is not an environmentally friendly procedure for CGO/PDDAQ, and the whole synthesis study seems time-consuming. The pH of the solution should be 6–7 for MXene preparation, ice bath ultrasonication, and vacuum-assisted filtration to obtain the final composite may damage the morphology by the force of the vacuum. | Unsmooth nanotube-blended sheet morphology | - | Low crystalline | [117] |

| MXene/GO film electrode | Drop-coating and laser-induced graphene technology | Drop-coating is a simple method for achieving film uniformity. GO is used to prevent MXene aggregation. The polyamide substrate provides excellent film deformation-resisting properties, along with good stability and flexibility. The laser-induced graphene (LIG) process was able to demonstrate perfect patterning to obtain a graphene-structured film, a programmable fabrication process, a highly porous structure, and a fibrous structure. | A time-consuming procedure. Laser-induced technology may make it costly. The film drying process should be carried out in inert gas. High-power-watt lasers can damage morphology and contaminate film during drop coating. Self-precaution may be needed to process the patterning electrode. Electrode operation and patterning demand skilled researchers. | Fibrous with stacked structure film | - | - | [118] |

| WS2@MXene/GO | Hydrothermal | The procedure is environmentally friendly and easy to synthesize, the composite surface is rich in active sites, and it uses only water for the hydrothermal reaction, resulting in high purity and particle purification through a green process. | The impregnation process for GO with MXene (1 h) and the subsequent addition of sodium tungsten hydrate (2 h) before the reaction result in a moderately time-consuming procedure. The reaction process operates at a high temperature of 200 °C, has a small surface area, produces laboratory-scale samples, and lacks a well-organized morphological structure. This procedure could be moderately expensive due to the use of commercial GO and Ti2AlC2 powder. | GO sheets contain grain-shaped WS2@MXene particles | 12.9 | High crystalline | [119] |

| GO-Bacteria | |||||||

| B@GO | Simple reaction | The procedure is cheap, simple, environmentally friendly, and time-saving. | Using N2 gas under calcination may not be effective in dope N on GO. The stirring process for 4 h changes the shape and structure of the GO, resulting in low-quality particles and active sites. Cell culture and incubation of Gram-positive bacteria may be costly and have low-purity particles and active sites. The bacterial solution and the GO were not optimized. | Wrecked sheets | - | Semi-crystalline | [120] |

| Three-Electrode System | Two-Electrode System | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| CV | GCD | EIS | Cycles | ||||||||

| Electrodes | Cs | Rs and Rct | CS and CR | Device | Cs | ED | PD | CS and CR | EL | Ref. | |

| GO-Fluorine | |||||||||||

| FGO | 514.0 | 276.0 | 0.58; 0.71 | - | FGO//FGO (Symmetry) | - | 25.8 | 1280.0 | 20,000; 99.0% | 1.0 M KOH | [77] |

| GO-metal oxides | |||||||||||

| NCWO4/f-MWCNT/GO | - | 1166.6 | 0.67; 1.2 | 5000; 95.6% | NCWO4/f-MWCNT/GO//AC (Asymmetry) | 266.2 | 83.3 | 703.1 | 5000; 87.0% | 6.0 M KOH | [90] |

| AC/GO/TiO2-Zn | 329.9 | 1491.6 | 192.2; - | - | AC/GO/TiO2-Zn//AC/GO/TiO2-Zn (Symmetry) | - | 99.0 | 3572.0 | 10,000; 61.8% | 3.0 M KOH | [79] |

| Bi2O3/GO | - | 1029.0 | 0.91; - | 3000; 80% | - | - | - | - | - | 6.0 M KOH | [88] |

| MnFe2O4/GO | - | 298.0 | 2.16; 2.45 | 500; 92.0% | - | - | - | - | - | 6.0 M KOH | [91] |

| AC/TiO2/GO | 219.3 | 617.0 | 1.87; 2.68 | 1000; 80.1% | - | - | - | - | - | 2.0 M H2SO4 | [80] |

| NGO/CuFe2O4 | - | 374.2 | 6.85; 1.1 | 2000; 82% | NGO/CuFe2O4//AC (Asymmetry) | 89.1 | 35.7 | 883.0 | 500; 78.6% | 1.0 M H2SO4 | [85] |

| Cu2O-CoO/GO | - | 723.0 | 0.1; - | - | Cu2O-CoO/GO//GO (Asymmetry) | 125.0 | 44.1 | 794.0 | 10,000; 89.3% | 6.0 M KOH | [95] |

| GO/CNT/COF | 544.9 | 175.0 | 2.25; 11.34 | 8000; 84.7% | GO/CNT/COF//GO/CNT/COF (Symmetry) | - | 24.3 | 248.9 | - | 1.0 M H2SO4 | [97] |

| GO@ Fe3O4-IL@W | - | 332.4 | 5.47; 9.35 × 10−5 | 10,000;91.3% | - | - | 7.3 | 40.0 | 10,000; 91.3% | 1.0 M H2SO4 | [58] |

| NMGO | - | 402.0 | -; 34.0 | 14,000; 93% | NMGO//MWCNT (Asymmetry) | 90.0 | 28.0 | 750.0 | 6000; 88% | 1.0 M KOH or Na2SO4 | [83] |

| 10%GO/WO3 | 668.0 | 738.0 | 1.05; - | 7000; 88.0% | GO/WO3//GO (Asymmetry) | 213.0 | 25.0 | 1000.0 | 3000; 87% | 2.0 M KOH | [96] |

| GO-metal sulfides | |||||||||||

| MnS-La2S3/GO | - | 890.0 | - | 4000; 89.0% | MnS-La2S3/GO//MnS-La2S3/GO (Symmetry) | 151.0 | 54.2 | 1300.0 | 10,000; 92.5% | 1.0 M Na2SO4 or PVA-Na2SO4 | [100] |

| NiS/CoS/GO | - | 1114.0 | - | 8000; 80.0% | - | - | 674.1 | 8089.4 | - | 3.0 M KOH | [98] |

| GO-Transition metal chalcogenides | |||||||||||

| GO-MnSSe | 300.0 | 603.0 | - | 9000; 67.0% | - | - | - | - | - | 1.0 M KOH | [104] |

| GO-Layered double hydroxides | |||||||||||

| Co2Ni1-GO | - | 3317.5 | 0.88; 0.029 | 10,000; 91.8% | Co2Ni1-GO//AC (Asymmetry) | 328.7 | 94.7 | 750.0 | 10,000; 91.3% | 3.0 M KOH | [106] |

| GO-organic materials | |||||||||||

| SGZ | - | 261.0 | -; 14.7 | 1000; 102% | - | - | - | - | - | 6.0 M KOH | [114] |

| Nd-MOFs/GO | 677.6 | 633.5 | 0.8; - | 4000; 88.7% | - | - | - | - | - | 3.0 M KOH | [113] |

| Ni-BTC MOF/GO 2 | - | 1199.0 | 0.79; 7.0 | 5000; 84.4% | Ni-BTC MOF/GO 2//AC (Asymmetry) | - | 42.8 | 800.0 | 10,000; 70% | 3.0 M KOH | [102] |

| ABQA-GO/CP | 203.2 | 235.5 | - | - | ABQA-GO/CP//ABQA-GO/CP (Symmetry) | 134.1 | 32.8 | 1256.0 | 5000; 106% | 1.0 M H2SO4 | [101] |

| GO-MXene | |||||||||||

| LIG-C film | - | - | 182; - | 1000; 102.4% | LIG-C-based supercapacitor | - | - | - | 1000; 103% | H3PO4-PVA | [118] |

| MXene-GO film | - | - | 8.5; - | 1000; 92.6% | Planar supercapacitor | - | - | - | 1000; 94.8% | H3PO4-PVA | [103] |

| CGO/PDAAQ-MXene film | - | 346.0 | -; 1.15 | 5000; 83% | CGO/PDAAQ-MXene//rGO (Asymmetry) | 114.0 | 41.0 | 404.0 | 10,000; 70.3% | 1.0 M H2SO4 | [117] |

| WS2@MXene/GO | - | 1111.0 | 2.3; 0.41 | 5000; 97.1% | WS2@MXene/GO// AC (Asymmetry) | 320.0 | 95.0 | 1000.4 | 15,000; 93.1% | 1.0 M KOH | [119] |

| GO-Bacteria | |||||||||||

| BGO | - | 111.0 | -; 29.2 | 5000; 86.9% | - | - | - | - | - | 0.5 M Na2SO4 | [120] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sriram, G.; Arunpandian, M.; Dhanabalan, K.; Sarojamma, V.R.; David, S.; Kurkuri, M.D.; Oh, T.H. Recent Progress Using Graphene Oxide and Its Composites for Supercapacitor Applications: A Review. Inorganics 2024, 12, 145. https://doi.org/10.3390/inorganics12060145

Sriram G, Arunpandian M, Dhanabalan K, Sarojamma VR, David S, Kurkuri MD, Oh TH. Recent Progress Using Graphene Oxide and Its Composites for Supercapacitor Applications: A Review. Inorganics. 2024; 12(6):145. https://doi.org/10.3390/inorganics12060145

Chicago/Turabian StyleSriram, Ganesan, Muthuraj Arunpandian, Karmegam Dhanabalan, Vishwanath Rudregowda Sarojamma, Selvaraj David, Mahaveer D. Kurkuri, and Tae Hwan Oh. 2024. "Recent Progress Using Graphene Oxide and Its Composites for Supercapacitor Applications: A Review" Inorganics 12, no. 6: 145. https://doi.org/10.3390/inorganics12060145

APA StyleSriram, G., Arunpandian, M., Dhanabalan, K., Sarojamma, V. R., David, S., Kurkuri, M. D., & Oh, T. H. (2024). Recent Progress Using Graphene Oxide and Its Composites for Supercapacitor Applications: A Review. Inorganics, 12(6), 145. https://doi.org/10.3390/inorganics12060145