1. Introduction

Chinese steamed bread (CSB) is a popular food in China and many Asian countries [

1]. CSB is a fermented wheat flour product that is produced in a similar manner to many Western breads [

2,

3]. The steaming step imparts a white and smooth surface in contrast to a crust formed during baking at high temperatures [

2,

3]. It originated in and is a staple of northern China [

4,

5]. The two major types of Chinese streamed bread are the northern-type steamed bread (NTSB) and southern-type steamed bread (STSB) [

6]. The texture and eating quality of the northern style is described as cohesive, dense, firm, chewy, and elastic, with an even distribution of small cells in the crumb [

2,

3,

5]. The southern-style texture is known for its open and soft texture with a very white, shiny, and smooth appearance [

2,

3,

6]. Another difference is that northern-style steamed bread has less sugar than the southern-style [

4]. Because of its simple formula, changing the type of flour may change the quality of northern-style steamed bread.

Steamed bread accounts for approximately 40% of China’s wheat usage, and its market has spread to North America and Europe [

2,

7]. Taiwan’s Department of Statistics points out that the annual output value of baked and steamed food is about 6.2 billion NT dollars [

8]. Therefore, the incorporation of whole wheat flour (WWF) or bran would increase dietary fiber levels and provide health benefits to a wide population [

9].

WWF refers to flour that uses 100% of the wheat kernel, including all bran, germ, and endosperm materials [

10]. Whole wheat is a good source of dietary fiber, minerals, vitamins, and antioxidants [

11,

12]. The consumption of whole grain products is associated with a decreased risk developing of obesity, type 2 diabetes, cardiovascular disease, and cancer [

11]. However, the finished product quality and sensory challenges associated with the incorporation of WWF into a baked good influence public acceptance [

5,

11].

The presence of the bran and germ results in darker product color, reduced product volume, and firmer texture for products containing WWF [

9]. These effects have been studied in a wide variety of finished products such as bread, noodles, crackers, pasta, flatbread, and tortillas [

2,

13]. Information on how WWF and bran characteristics such as particle size affect dough properties and finished quality of CSB is limited and needs further investigation [

5,

7,

12,

13].

Using WWF to replace refined flour is not always simple. Whole wheat flour comprised of coarse bran produced CSB with better texture and crumb structure and equivalent specific volume, skin color, smoothness, and shape compared to a fine bran WWF [

14]. Xu et al. [

12] reported that decreasing WWF particle size decreased specific volume and resulted in firmer crumbs for both STSB and NTSB. In contrast, Wang et al. [

2] found that coarse WWF produced Chinese STSB with smaller specific volume, firmer texture, less open crumb grain, thicker cell walls, and a more compact structure compared to a finer WWF.

The effects of bran particle size on water absorption and dough rheology are also varied. It has been reported that water absorption for fine bran WWF was greater [

12,

14] and lesser [

2,

13] compared to coarse bran WWF. Zhang and Moore [

15] found that bran particle size did not affect Farinograph dough water absorption, although the same authors reported coarse bran to have higher water retention capacity than finely ground bran [

15]. Reduced bran particle size was found to both decrease dough mixing time [

2,

12,

13,

15] and increase it [

16] compared to coarse bran WWF. In addition, fine bran WWF has been reported to result in both a decrease in dough stability [

15] and an increase in stability [

2,

13,

14,

16] compared to coarse bran WWF. Mixolab starch hot gel stability and retrogradation were found to increase with a reduction in WWF particle size [

2,

12,

13]. A reduction in WWF particle size was also found to increase dough strength [

2,

15].

These effects on volume, rheology, and texture may be explained by studies that have indicated that the presence of bran in dough not only affects gluten structure [

9,

17], but also affects gas cells in the dough [

9,

18,

19]. Therefore, the bran fraction is considered to be an important factor affecting the structure and properties of bread [

19,

20,

21].

Another factor affecting the baking quality of WWF bread is the variability inherent in wheat bran. The addition of bran is challenging because it does not have a consistent chemical composition and quality [

15]. Wheat bran composition can vary due to wheat class, variety, growing environment, grain shape and size, the thickness of bran layers, and the milling technique used [

7,

11,

15]. Roller milling systems can be used to produce recombined WWF [

22]. The endosperm is separated from the bran and germ allowing for the endosperm to be gradually reduced and later recombined with bran or with components that represent the entire wheat kernel [

10,

22]. Roller mills are more flexible than other milling systems such as hammer mills and stone mills due to the ability to separate out the bran and germ for additional treatment such as particle size reduction, hydration, fermentation, and heat treatment [

5,

7,

10,

22]. Roller mills produce less heat than a stone mill during the whole wheat flour milling process due to the use of cooling systems for the rollers, which results in less altering of the starch, protein, and lipid fractions [

5,

22].

In this study, three different classes of wheat [hard white (HW), hard red winter (HRW) and hard red spring (HRS)] and four different particle size distributions of bran [D(50) values of 53 μm, 74 μm, 105 μm, and 125 μm] were blended at a fixed ratio (85% refined flour + 15% bran) to create reconstituted WWF and make reconstituted WWF NTSB. The purpose of this study was to investigate the effects of reconstituted WWF particle size on flour characteristics, dough rheology, and NTSB quality. The results show that larger particle sizes produce NTSB with more desirable quality attributes than smaller particle sizes.

2. Materials and Methods

2.1. Materials

Wheat from three U.S. wheat classes (HW, HRW, and HRS) was used in this study. Their protein contents (dry basis) were 15.1% (HW), 13.8% (HRW) and 17.1% (HRS). The three wheat samples were tempered in plastic buckets at room temperature to a final moisture level of 14.5% and milled on a Miag Multomat experimental mill (Bühler Inc., Plymouth, MN, USA). The refined flours (HWf, HRWf, and HRSf) were the controls in this study. Bran from each respective wheat sample was milled by Prater Industries (Bolingbrook, IL, USA) on a laboratory scale air classifier mill to four particle size distribution targets with D(50) values of 53 μm, 74 μm, 105 μm, and 125 μm. Other materials included instant dry yeast (Lesaffre Yeast Corp., Milwaukee, WI, USA), sugar, salt, and shortening (Crisco, J.M. Smucker Co., Orrville, OH, USA).

2.2. Preparation of Reconstituted Whole Wheat Flours (WWF)

After milling, control flours (HWf, HRWf, and HRSf) were mixed with bran from each particle size distribution target at a ratio of 85% refined control flour to 15% bran (w/w) to create reconstituted whole wheat flour (WWF). The final sample set included: HW (HWb53, HWb74, HWb105, and HWb125), HRW (HRWb53, HRWb74, HRWb105, and HRWb125), and HRS (HRSb53, HRSb74, HRSb105, and HRSb125). This study utilized reconstituted whole wheat flours to control variability stemming from attempting to combine different ratios of bran and shorts from the wheat classes studied.

2.3. Flour Composition and Quality Analyses

All samples were analyzed for moisture, protein, ash and damaged starch contents according to AACC Approved Methods (44-15A; 08-01; 46-30; 76-33.01, respectively) [

23]. Because the SD-matic (Chopin Technologies, Villeneuve-la-Garenne, France), an amperometric method, has not been evaluated for measurement of starch damage in WWF, an enzyme-based starch damage assay kit (Megazyme, Chicago, IL, USA) was also used to quantify starch damage using AACC Method 76-31.01 [

23]. The amperometric method (AACC 76-33) uses the absorption kinetics of iodine, as measured by an amperometric probe, to express the damaged starch content. The other method (AACC 76-31) is based on enzymatic hydrolysis under given temperature, pH, and enzyme conditions. In that method, α-amylase acts on the flour sample to break down the starch into maltosaccharides and dextrins, and amyloglucosidase breaks these sugars down to glucose. Starch damage is calculated according to the amount of reducing sugars produced.

Wet gluten content (AACC 38-12.01) is commonly used to indicate quality differences, especially among flours with similar protein contents [

24], and is particularly valuable in discriminating durum semolina quality [

25,

26]. Control flours presented with wet gluten values (14% mb) on the order of HRS (34.7 ± 0.0) > HW (32.8 ± 0.1) > HRW (26.5 ± 0.3), which closely tracks with their respective protein contents. However, screen flooding was encountered for the WWFs with smaller bran particle size distributions and thus WWF wet gluten contents were not collected. SRC profiles were recorded as an alternative to wet gluten because SRC profiles, and especially the gluten performance index (GPI) calculated from those profiles, have been more definitively linked to end product quality of refined and WWFs by various authors [

27,

28,

29,

30,

31].

To evaluate the flour quality characteristics (polymer swelling, water absorption, stability, starch gelatinization, retrogradation, and extensibility), Solvent Retention Capacity (SRC) (AACC Method 56-11.02), Farinograph (AACC Method 54-21.01) (C.W. Brabender, South Hackensack, NJ, USA), Mixolab (AACC Method 54-60.01) (Chopin Technologies, Villeneuve-la-Garenne, France) and Kieffer rig extensibility (Texture Technologies, Hamilton, MA, USA) tests were conducted [

23]. The Kieffer rig extensibility test was partially modified according to the method described by Londono et al. [

32]. Dough samples were prepared as appropriate for full formula steamed bread production. After dough sheeting, the dough was flattened with a rolling pin and placed on a grooved base with a Teflon coating. A flat-top piece was applied to the dough on the grooved base and pushed down firmly by tightening a clamp until the two pieces came together to separate the dough into strips. The mold and clamp apparatus was then placed in a closed plastic bag to allow the dough to relax for 45 min (30 °C, 85% RH). After the relaxation period, the clamp and flat top piece were removed and the dough strips were removed for extensibility measurement on the TA.XTPlus (Texture Technologies, Hamilton, MA, USA). The test parameters were pretest speed, 2.0 mm/s; test speed, 3.3 mm/s; post-test speed, 10 mm/s; trigger force, 5 g; and data acquisition rate, 200 PPS.

2.4. Steamed Bread Preparation

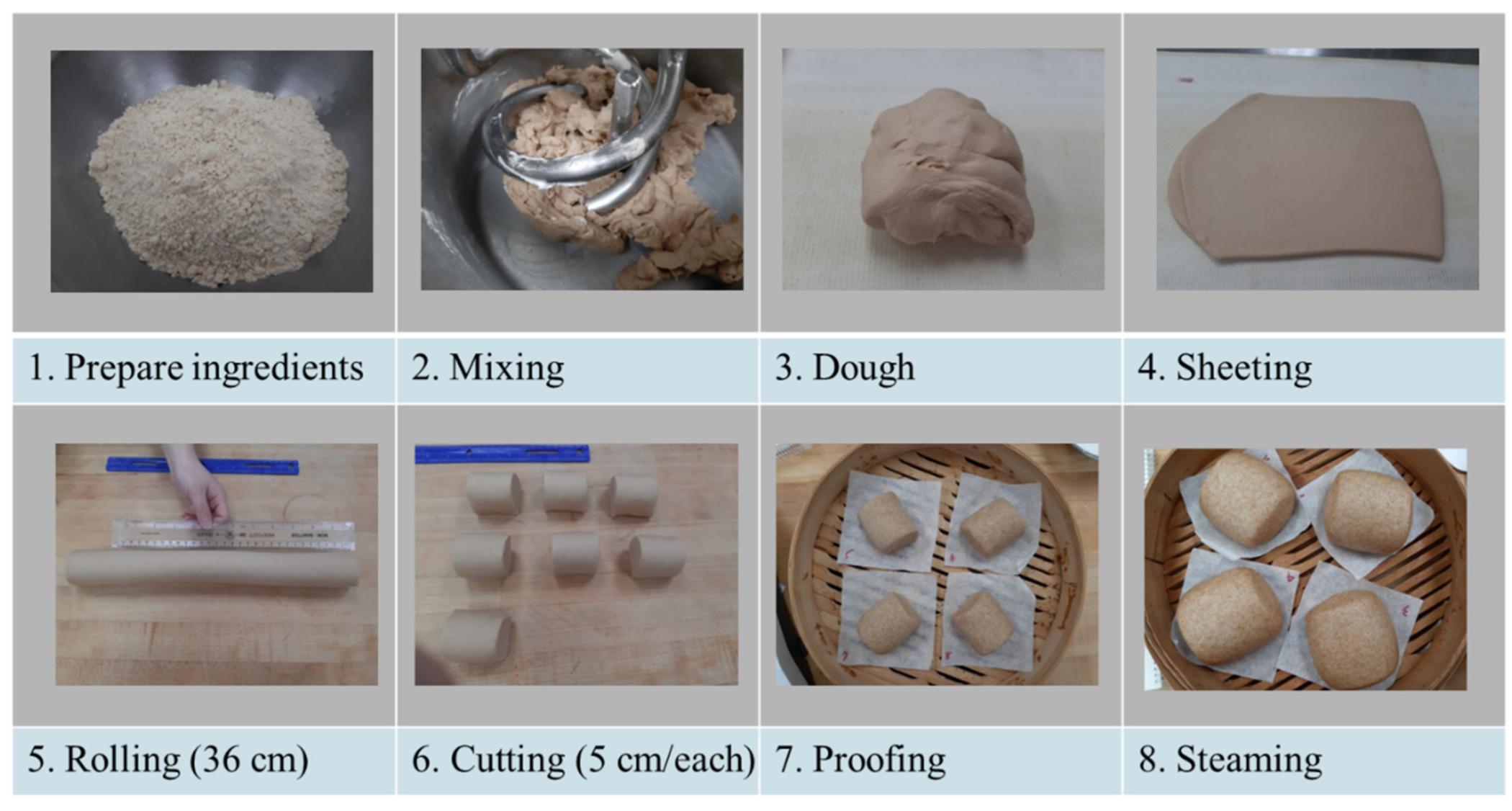

The steamed-bread making process is outlined in

Figure 1. The formula included: 400 g flour, 8 g instant dry yeast, 180–200 g water [optimized based on Farinograph water absorption (WA)], 32 g sugar, 1.2 g salt, and 16 g shortening. The yeast, sugar, and salt were each dissolved separately in water. The mixtures were then added to the flour and mixed in a Hobart mixer (Model A-120, Hobart Manufacturing Co., Troy, OH, USA) equipped with a special double spiral head at speed 1 for 1 min. The shortening was then added and mixed into the dough at speed 1 for another 1.5 min. The final dough was rested in a plastic bag for 10 min before sheeting until the surface was smooth (10–12 passes) using an Oshikiri sheeter/molder (Model WFS, Oshikiri Machinery Ltd., Kanagawa, Japan). The dough sheet was rolled into a cylinder by hand to 36 cm and cut into 6 equal parts (5 cm/piece). One piece of dough (25 g) was placed in a 45 mL plastic centrifuge tube before proofing. Initial dough volume was 21–22 mL. The dough pieces were then proofed (30 °C, 85% RH) in a proofing cabinet (Model LRPR-2, LBC Bakery Equipment, Everett, WA, USA) until the volume of dough in the centrifuge tube reached 40–45 mL. The remaining 5 pieces of dough were steamed for 15 min using a convection oven (Model SCCWE 62G, Rational AG, Landsberg am Lech, Germany).

2.5. Quality Evaluation of Steamed Bread

All steamed bread samples were evaluated for specific volume, exterior color, and texture. The specific volume of steamed bread was determined using a laser volume analyzer (BVM-L370, TexVol Instruments Inc., Viken, Sweden) and dividing the measured volume by the weight of the bread piece. The exterior L, a, b color was determined using a chroma meter (CR-410, Konica Minolta Sensing Inc., Tokyo, Japan). The texture profile analysis (TPA) of the steamed bread was determined using the TA.XTPlus Texture Analyzer equipped with a 35 mm acrylic cylindrical probe. Steamed bread was sliced horizontally, and a flat piece of 15 mm thickness was compressed to 50% of its original height in a two-compression cycle. The test conditions were pretest speed, 2 mm/s; test speed, 1 mm/s; post-test speed, 1 mm/s; and trigger force, 5 g.

2.6. Statistical Analysis

All measurements were performed at least in duplicate. A one-way Analysis of Variance (ANOVA) was performed using SAS statistical analysis software. Duncan’s test was used for the comparison of means. The value p < 0.05 was used to determine significant differences between mean values. The results of the study were presented as the average ± standard deviation.

4. Conclusions

Other research has shown that smaller bran particle sizes can adversely affect bread quality. This study presents similar findings, with larger bran particle size distributions (105 μm and 125 μm) being more suitable for producing whole-wheat steamed bread with a larger specific volume, brighter color, and softer texture. HRS appeared to be the most suitable wheat class for whole wheat steamed bread across the majority of the instrumentally measured product characteristics, although this would need to be confirmed with a sensory study.

From a flour quality and dough rheology standpoint, none of the tests performed in this study offered sufficient predictive potential related to final product quality. The SRC GPI offered some promise in predicting steamed bread volume, with values approaching ~0.80 leading to better specific volumes. The most promising rheological method appeared to be dough extensibility and resistance to extension, with R/E values approaching ~1.50 being more conducive to optimal specific volume and texture (hardness) of whole wheat steamed bread for a given wheat class. However, this needs to be investigated with a larger sample set encompassing a wider range of flour quality characteristics.

Future work should focus on investigating large bran particle sizes across a wider range of samples to identify optimal wheat quality, flour quality, and dough rheology parameters for CSB, as well as new methodology that is optimized for WWF.