Analysis of the Temperature Distribution in a Refrigerated Truck Body Depending on the Box Loading Patterns

Abstract

:1. Introduction

2. Materials and Methods

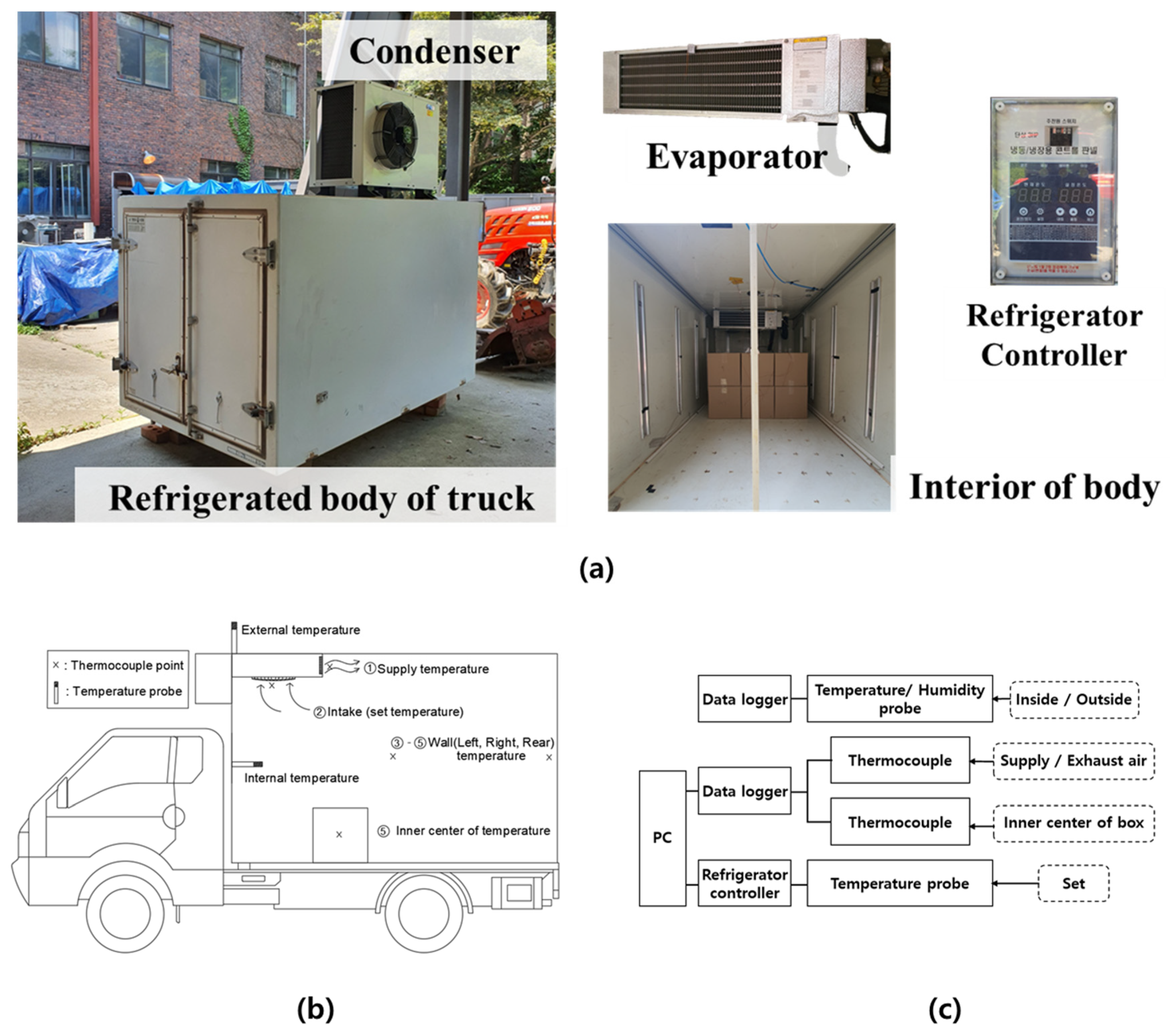

2.1. Refrigerated Body Set Up

2.2. Experimental Procedure

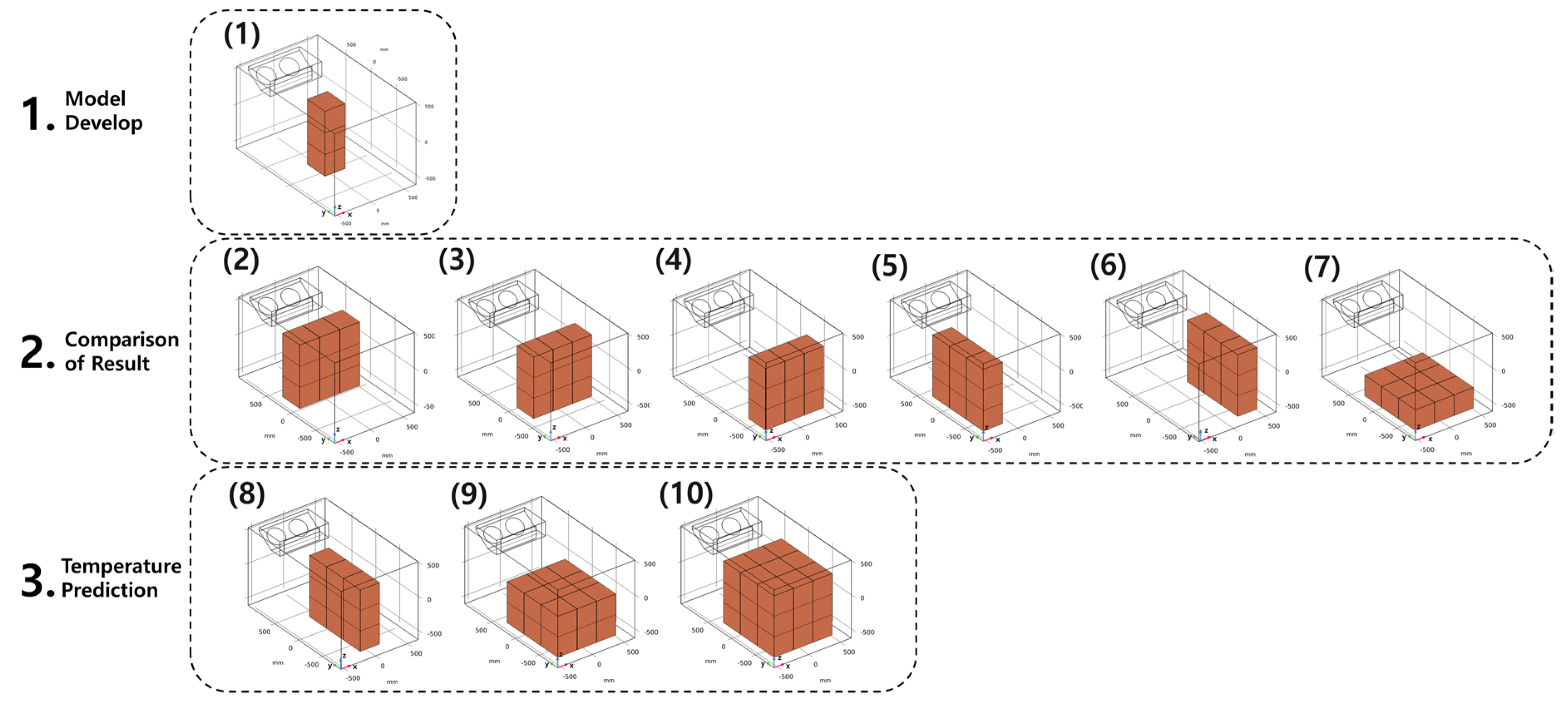

2.3. Box Loading Patterns

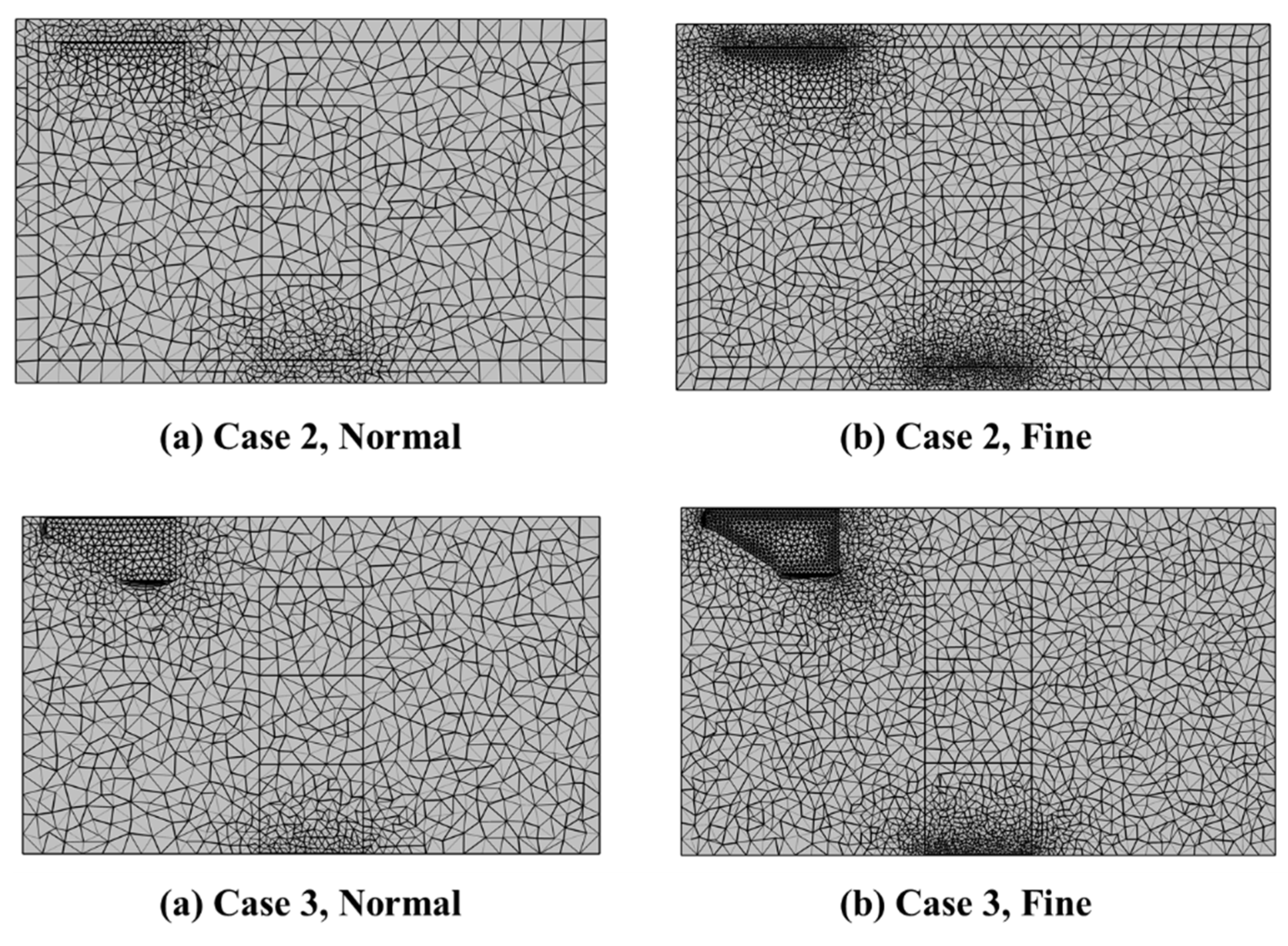

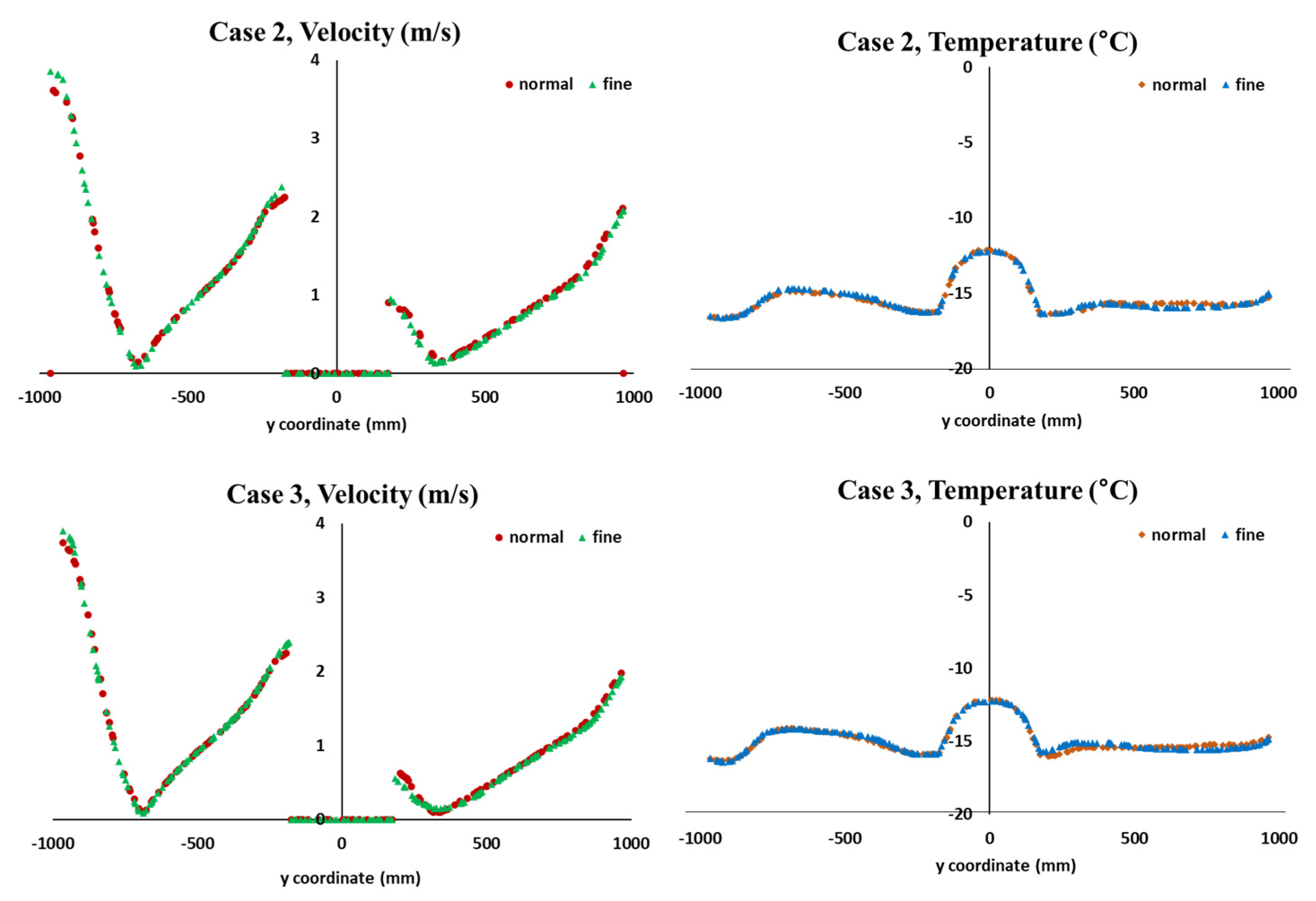

2.4. Numerical Analysis

2.4.1. Geometry

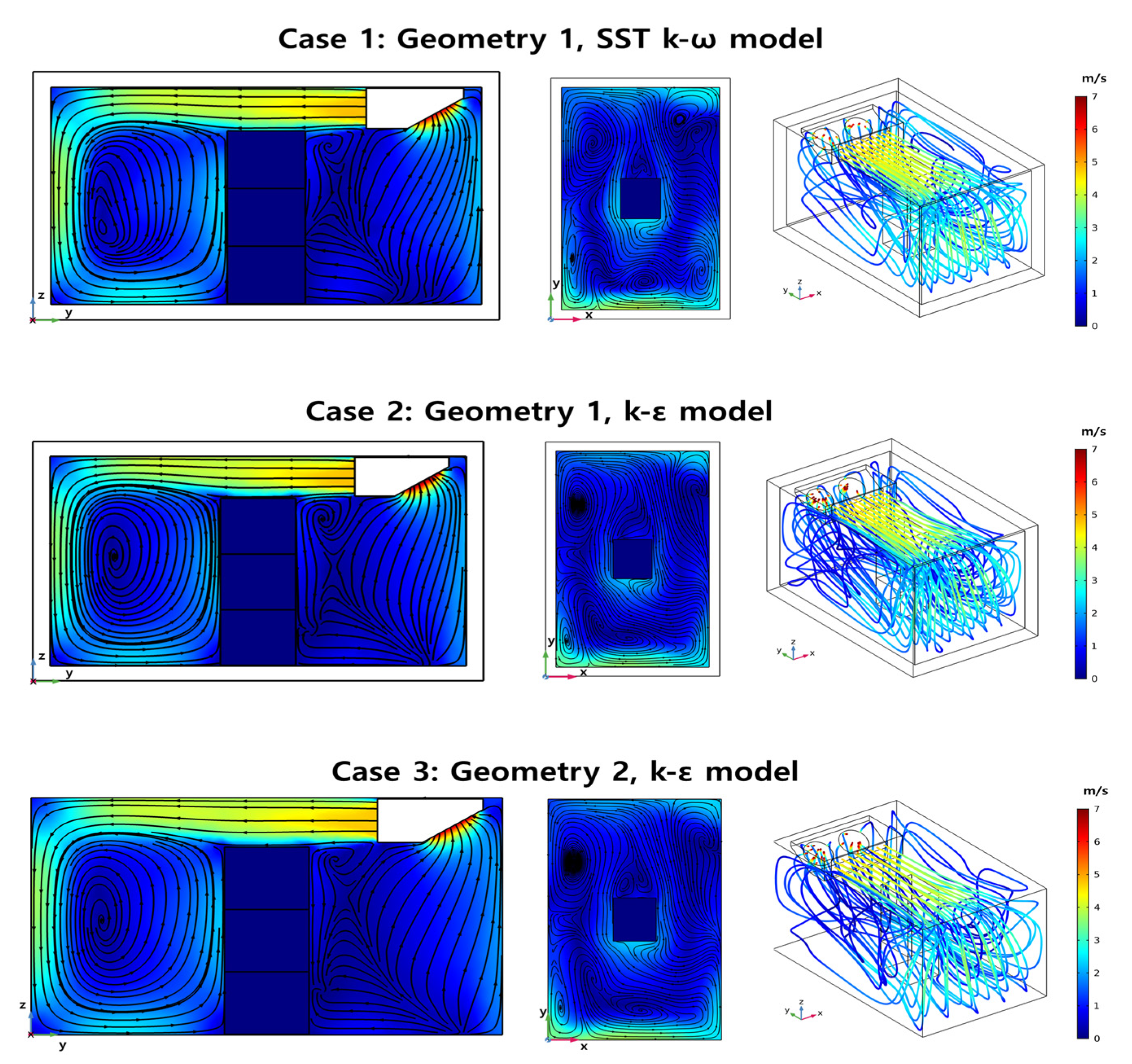

2.4.2. Fluid Dynamics Model

2.4.3. Heat Transfer Model

2.4.4. Boundary Conditions

2.5. Error Calculation

3. Results and Discussion

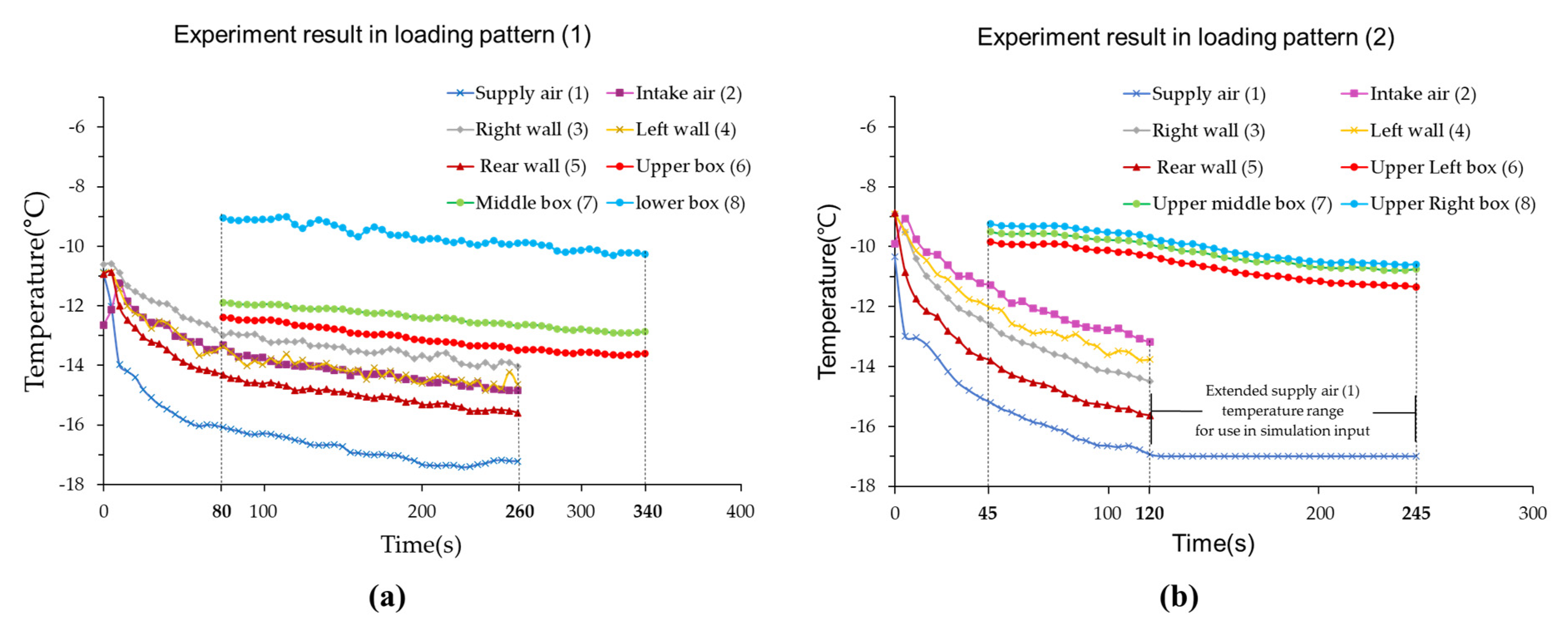

3.1. Experimental Results for Loading Pattern (1)

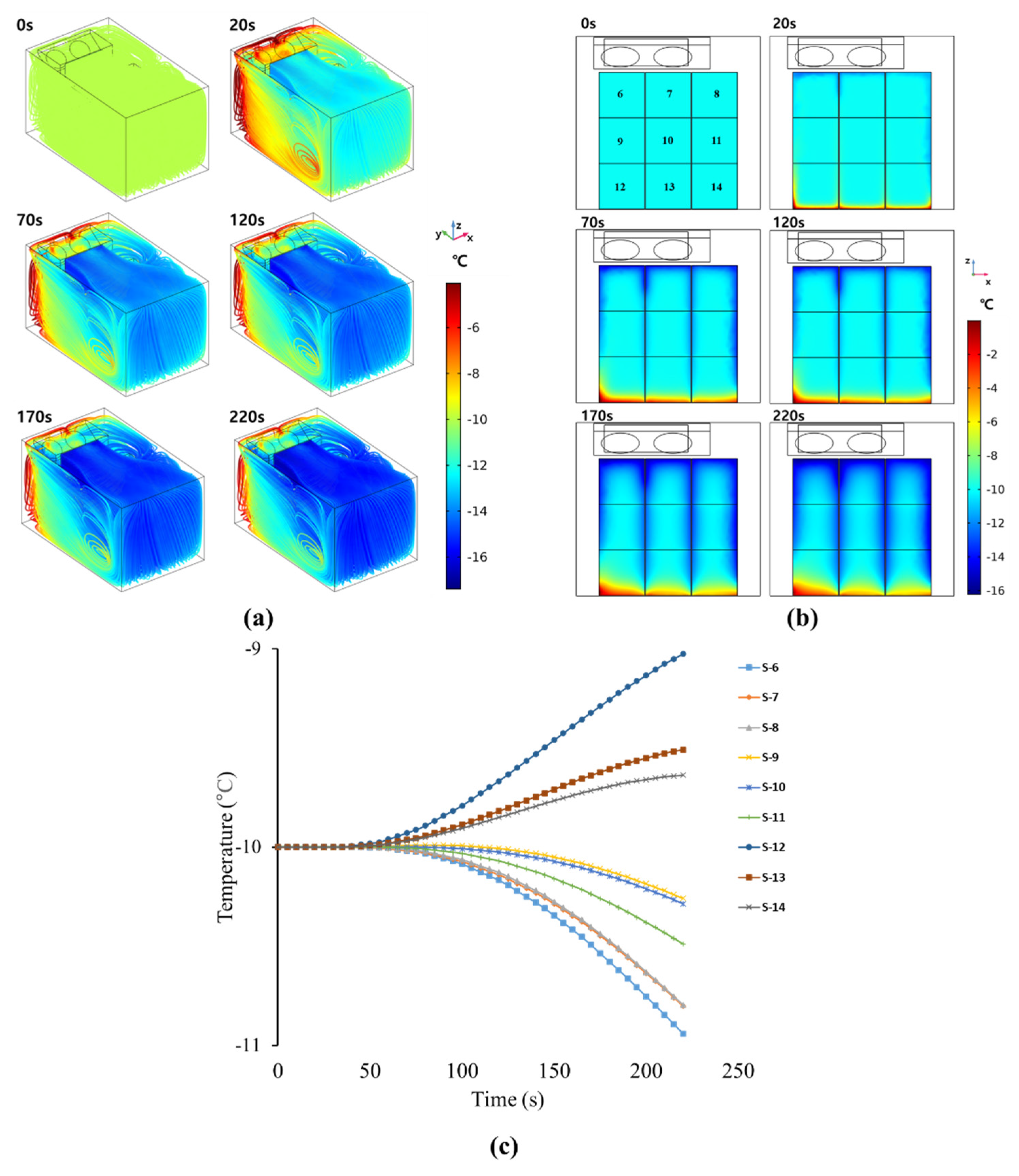

3.2. Numerical Analysis Results for Loading Pattern (1)

3.2.1. Air Velocity Field

3.2.2. Temperature Field

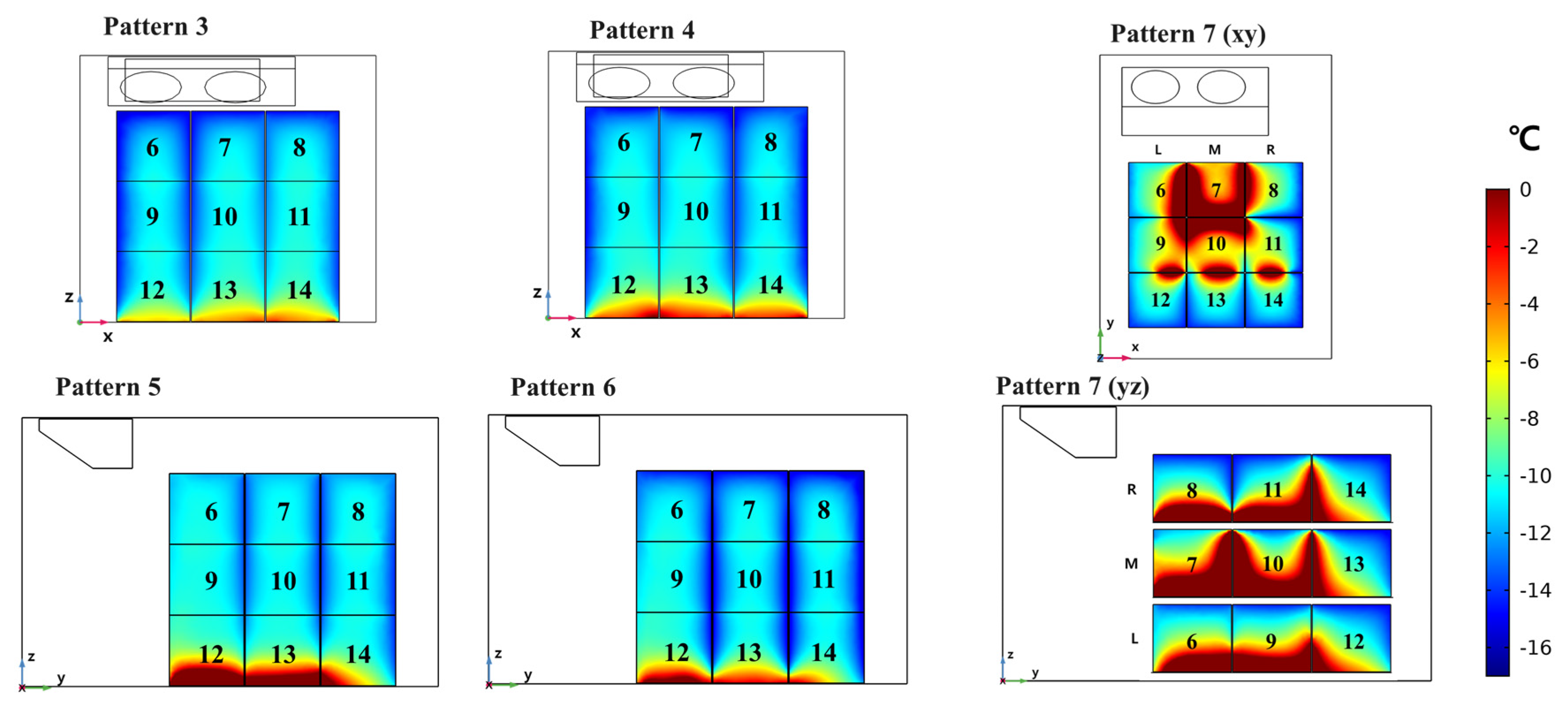

3.3. Comparison between Experimental and Simulated Results for Loading Patterns (2) to (7)

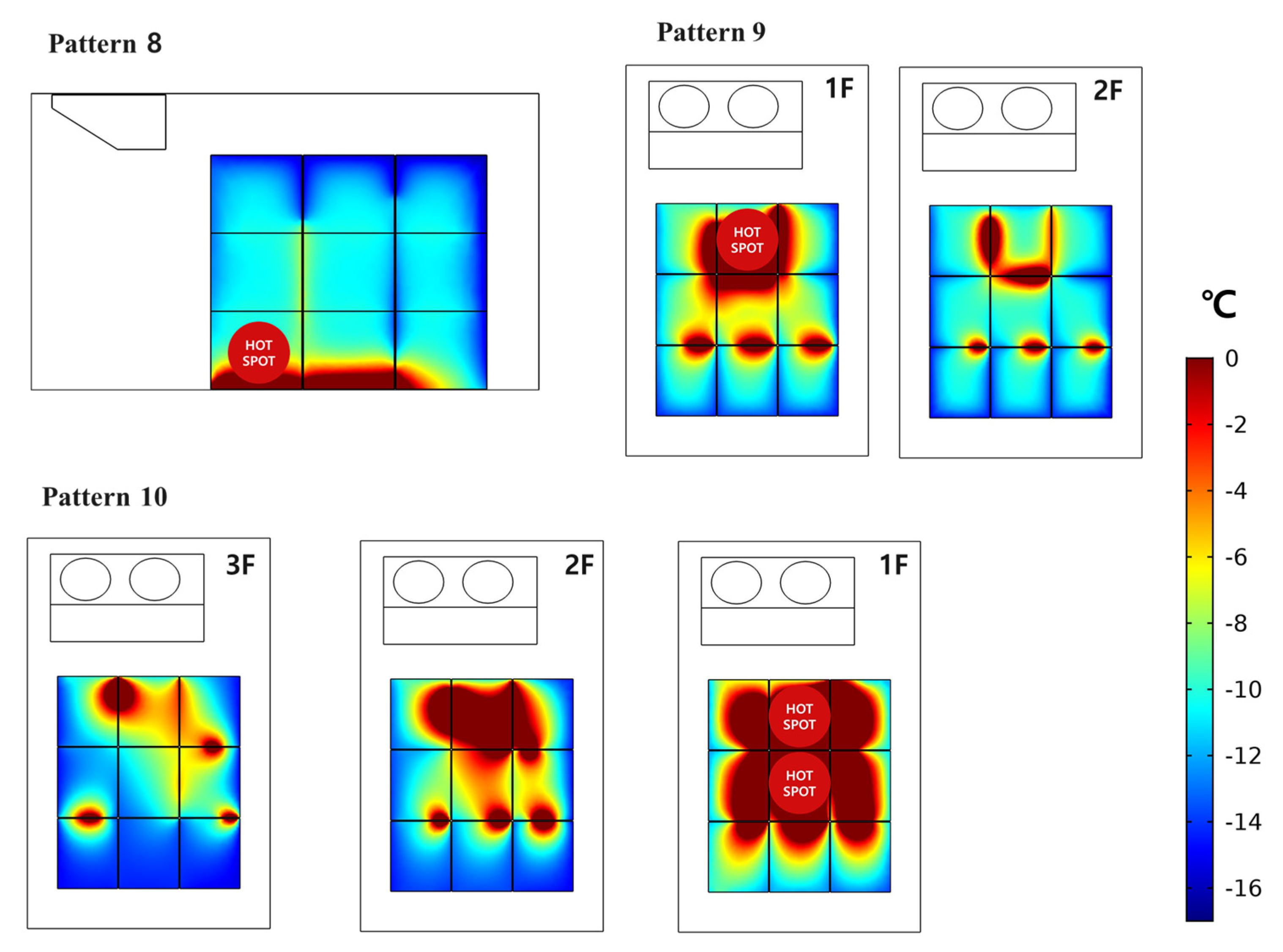

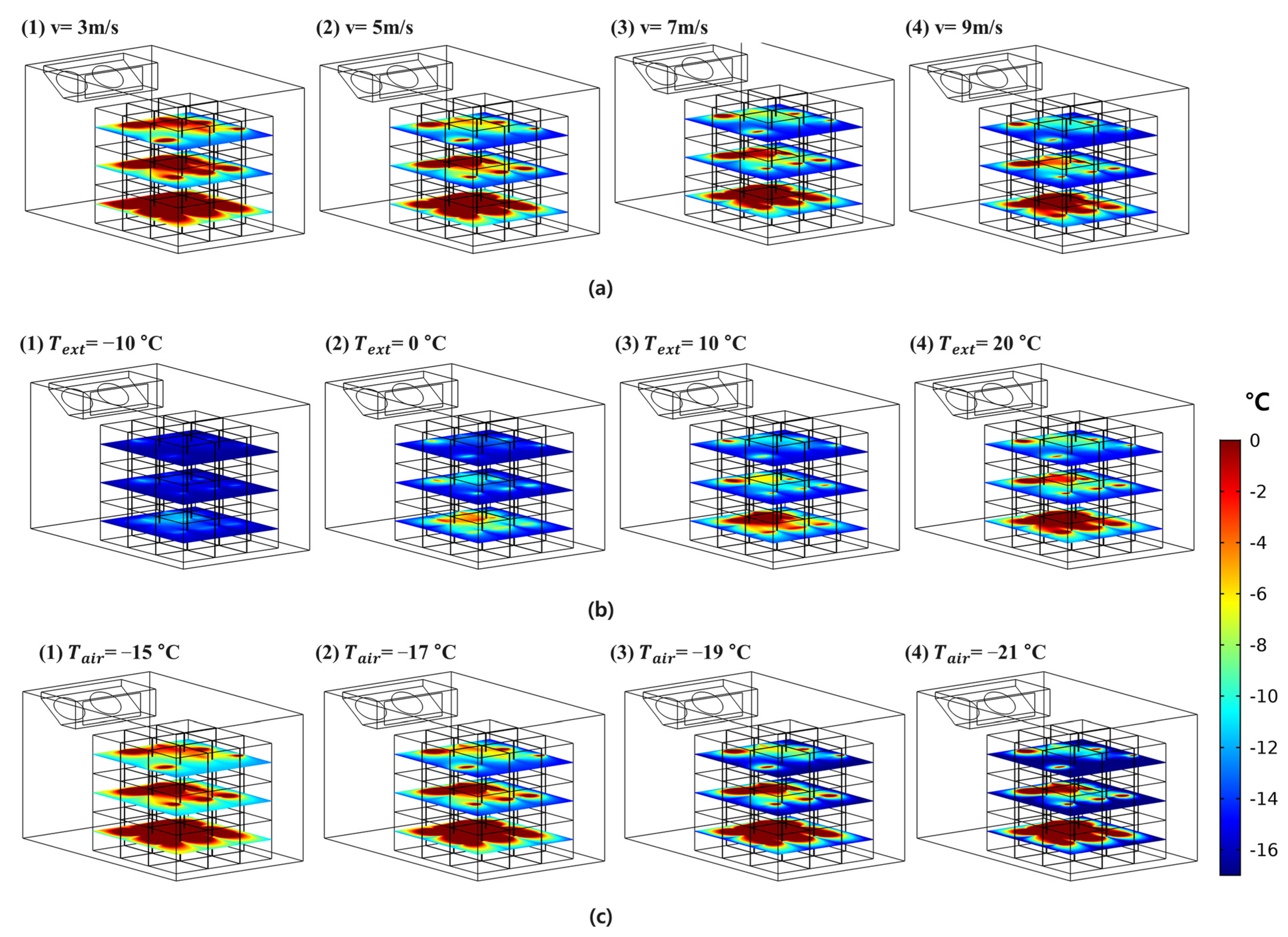

3.4. Prediction of Hot Spots during Cooling for Loading Patterns (8) to (10) Using the Developed Model

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wu, J.Y.; Hsiao, H.I. Food quality and safety risk diagnosis in the food cold chain through failure mode and effect analysis. Food Control. 2021, 120, 107501. [Google Scholar] [CrossRef]

- Dai, D.; Wu, X.; Si, F. Complexity analysis of cold chain transportation in a vaccine supply chain considering activity inspection and time-delay. Adv. Differ. Equ. 2021, 2021, 1–18. [Google Scholar] [CrossRef]

- Wang, S. Developing value added service of cold chain logistics between China and Korea. J. Korea Trade 2018, 22, 247–264. [Google Scholar] [CrossRef]

- Han, J.W.; Zuo, M.; Zhu, W.Y.; Zuo, J.H.; Lü, E.L.; Yang, X.T. A comprehensive review of cold chain logistics for fresh agricultural products: Current status, challenges, and future trends. Trends Food Sci. Technol. 2021, 109, 536–551. [Google Scholar] [CrossRef]

- Castelein, B.; Geerlings, H.; Van Duin, R. The reefer container market and academic research: A review study. J. Clean. Prod. 2020, 256, 120654. [Google Scholar] [CrossRef]

- Croquer, S.; Benchikh Lehocine, A.E.; Poncet, S. Numerical modelling of heat and mass transfer in a refrigerated truck trailer. In Proceedings of the 25th IIR International Congress of Refrigeration, Montréal, QC, Canada, 24–30 August 2019. [Google Scholar]

- Artuso, P.; Rossetti, A.; Minetto, S.; Marinetti, S.; Moro, L.; Col, D. Del Dynamic modeling and thermal performance analysis of a refrigerated truck body during operation. Int. J. Refrig. 2019, 99, 288–299. [Google Scholar] [CrossRef]

- Jedermann, R.; Palafox-Albarrán, J.; Barreiro, P.; Ruiz-García, L.; Ignacio Robla, J.; Lang, W. Interpolation of spatial temperature profiles by sensor networks. In Proceedings of the Sensors, Limerick, Ireland, 28–21 October 2011; pp. 778–781. [Google Scholar]

- Ruiz-Garcia, L.; Barreiro, P.; Robla, J.I.; Lunadei, L. Testing zigBee motes for monitoring refrigerated vegetable transportation under real conditions. Sensors 2010, 10, 4968–4982. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mercier, S.; Villeneuve, S.; Mondor, M.; Uysal, I. Time–Temperature Management Along the Food Cold Chain: A Review of Recent Developments. Compr. Rev. Food Sci. Food Saf. 2017, 16, 647–667. [Google Scholar] [CrossRef]

- Badia-Melis, R.; Mc Carthy, U.; Ruiz-Garcia, L.; Garcia-Hierro, J.; Robla Villalba, J.I. New trends in cold chain monitoring applications–A review. Food Control. 2018, 86, 170–182. [Google Scholar] [CrossRef]

- Yildiz, T. CFD characteristics of refrigerated trailers and improvement of airflow for preserving perishable foods. Logistics 2019, 3, 11. [Google Scholar] [CrossRef] [Green Version]

- Tanner, D.J.; Amos, N.D. Temperature variability during shipment of fresh produce. In Proceedings of the International Postharvest Unlimited Conference, Leuven, Belgium, 11–14 June 2002; Volume 599, pp. 193–203. [Google Scholar]

- Emenike, C.C.; Eyk, N.P.V.; Hoffman, A.J. Improving cold chain logistics through RFID temperature sensing and predictive modelling. In Proceedings of the 2016 IEEE 19th International Conference on Intelligent Transportation Systems (ITSC), Rio de Janeiro, Brazil, 1–4 November 2016; pp. 2331–2338. [Google Scholar]

- Mercier, S.; Uysal, I. Neural network models for predicting perishable food temperatures along the supply chain. Biosyst. Eng. 2018, 171, 91–100. [Google Scholar] [CrossRef]

- Jedermann, R.; Lang, W. Semi-passive RFID and beyond: Steps towards automated quality tracing in the food chain. Int. J. Radio Freq. Identif. Technol. Appl. 2007, 1, 247–259. [Google Scholar] [CrossRef]

- Amador, C.; Emond, J.P.; Nunes, M.C.d.N. Application of RFID technologies in the temperature mapping of the pineapple supply chain. Sens. Instrum. Food Qual. Saf. 2009, 3, 26–33. [Google Scholar] [CrossRef]

- Tsironi, T.; Giannoglou, M.; Platakou, E.; Taoukis, P. Evaluation of Time Temperature Integrators for shelf-life monitoring of frozen seafood under real cold chain conditions. Food Packag. Shelf Life 2016, 10, 46–53. [Google Scholar] [CrossRef]

- Vivaldi, F.; Melai, B.; Bonini, A.; Poma, N.; Salvo, P.; Kirchhain, A.; Tintori, S.; Bigongiari, A.; Bertuccelli, F.; Isola, G.; et al. A temperature-sensitive RFID tag for the identification of cold chain failures. Sens. Actuators A Phys. 2020, 313, 112182. [Google Scholar] [CrossRef]

- Abad, E.; Palacio, F.; Nuin, M.; de Zárate, A.G.; Juarros, A.; Gómez, J.M.; Marco, S. RFID smart tag for traceability and cold chain monitoring of foods: Demonstration in an intercontinental fresh fish logistic chain. J. Food Eng. 2009, 93, 394–399. [Google Scholar] [CrossRef]

- Shan, Q.; Liu, Y.; Prossec, G.; Brown, D. Wireless intelligent sensor networks for refrigerated vehicle. In Proceedings of the IEEE 6th Circuits and Systems Symposium on Emerging Technologies: Frontiers of Mobile and Wireless Communication, Shanghai, China, 31 May–2 June 2004; pp. 525–528. [Google Scholar]

- Montanari, R. Cold chain tracking: A managerial perspective. Trends Food Sci. Technol. 2008, 19, 425–431. [Google Scholar] [CrossRef]

- Jedermann, R.; Ruiz-Garcia, L.; Lang, W. Spatial temperature profiling by semi-passive RFID loggers for perishable food transportation. Comput. Electron. Agric. 2009, 65, 145–154. [Google Scholar] [CrossRef] [Green Version]

- Do Nascimento Nunes, M.C.; Nicometo, M.; Emond, J.P.; Melis, R.B.; Uysal, I. Improvement in fresh fruit and vegetable logistics quality: Berry logistics field studies. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2014, 372, 20130307. [Google Scholar] [CrossRef] [Green Version]

- Li, F.; Chen, Z. Brief analysis of application of RFID in pharmaceutical cold-chain temperature monitoring system. In Proceedings of the International Conference on transportation, mechanical, and electrical engineering (TMEE), Changchun, China, 16–18 December 2011; pp. 2418–2420. [Google Scholar]

- Raab, V.; Petersen, B.; Kreyenschmidt, J. Temperature monitoring in meat supply chains. Br. Food J. 2011, 113, 1267–1289. [Google Scholar] [CrossRef]

- Mercier, S.; Marcos, B.; Uysal, I. Identification of the best temperature measurement position inside a food pallet for the prediction of its temperature distribution. Int. J. Refrig. 2017, 76, 147–159. [Google Scholar] [CrossRef]

- Kayansayan, N.; Alptekin, E.; Ezan, M.A. Thermal analysis of airflow inside a refrigerated container. Int. J. Refrig. 2017, 84, 76–91. [Google Scholar] [CrossRef]

- Margeirsson, B.; Pálsson, H.; Gospavic, R.; Popov, V.; Jónsson, M.Ó.; Arason, S. Numerical modelling of temperature fluctuations of chilled and superchilled cod fillets packaged in expanded polystyrene boxes stored on pallets under dynamic temperature conditions. J. Food Eng. 2012, 113, 87–99. [Google Scholar] [CrossRef]

- Hoang, M.H.; Laguerre, O.; Moureh, J.; Flick, D. Heat transfer modelling in a ventilated cavity loaded with food product: Application to a refrigerated vehicle. J. Food Eng. 2012, 113, 389–398. [Google Scholar] [CrossRef]

- Defraeye, T.; Cronjé, P.; Berry, T.; Opara, U.L.; East, A.; Hertog, M.; Verboven, P.; Nicolai, B. Towards integrated performance evaluation of future packaging for fresh produce in the cold chain. Trends Food Sci. Technol. 2015, 44, 201–225. [Google Scholar] [CrossRef]

- Han, J.-W.; Zhu, W.-Y.; Ji, Z.-T. Comparison of veracity and application of different CFD turbulence models for refrigerated transport. Artif. Intell. Agric. 2019, 3, 11–17. [Google Scholar] [CrossRef]

- Menter, F.R. Two-equation eddy-viscosity turbulence models for engineering applications. AIAA J. 1994, 32, 1598–1605. [Google Scholar] [CrossRef] [Green Version]

- Han, J.W.; Zhao, C.J.; Yang, X.T.; Qian, J.P.; Xing, B. Computational fluid dynamics simulation to determine combined mode to conserve energy in refrigerated vehicles. J. Food Process. Eng. 2016, 39, 186–195. [Google Scholar] [CrossRef]

- Wilcox, D.C. Turbulence Modelling for CFD; DCW Industries: La Canada, CA, USA, 1998. [Google Scholar]

| Point | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

|---|---|---|---|---|---|---|---|---|

| Temperature (°C) | −17.21 | −14.83 | −14.03 | −14.63 | −15.59 | −13.59 | −12.87 | −10.26 |

| Simulation | Point | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Case | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | |

| Temperature (°C) | 1 | −17.00 | −15.18 | −13.47 | −14.03 | −16.55 | −12.69 | −12.08 | −10.07 |

| 2 | −17.00 | −15.24 | −12.85 | −14.74 | −16.60 | −12.77 | −12.15 | −10.01 | |

| 3 | −17.05 | −14.42 | −11.62 | −13.61 | −16.30 | −12.86 | −12.16 | −9.99 | |

| Case | Point | ||||||

|---|---|---|---|---|---|---|---|

| 2 | 3 | 4 | 5 | 6 | 7 | 8 | |

| 1 | 0.724 | 0.754 | 1.082 | 0.980 | 0.758 | 0.570 | 0.303 |

| 2 | 0.718 | 1.242 | 0.515 | 0.998 | 0.714 | 0.531 | 0.316 |

| 3 | 0.700 | 2.173 | 1.030 | 1.027 | 0.653 | 0.512 | 0.334 |

| Case | Loading Pattern | |

|---|---|---|

| 1 | 2 | |

| 1 | 13 min 41 s | 1 h 10 min 17 s |

| 2 | 9 min 42 s | 22 min 35 s |

| 3 | 9 min 3 s | 21 min 24 s |

| Experiment | Pattern | Point | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | ||

| Average Temperature (°C) ± Stdev | 2 | −11.56 | −11.36 | −11.13 | −10.69 | −10.37 | −10.89 | −8.26 | −8.34 | −9.25 |

| ±0.31 | ±0.44 | ±0.39 | ±0.37 | ±0.49 | ±0.38 | ±0.29 | ±0.27 | ±0.21 | ||

| 3 | −12.17 | −11.99 | −11.63 | −11.57 | −11.11 | −11.55 | −10.06 | −9.87 | −10.71 | |

| ±0.2 | ±0.29 | ±0.28 | ±0.28 | ±0.39 | ±0.3 | ±0.22 | ±0.27 | ±0.28 | ||

| 4 | −12.52 | −12.31 | −11.95 | −11.72 | −11.18 | −11.50 | −9.05 | −8.66 | −10.00 | |

| ±0.13 | ±0.2 | ±0.2 | ±0.19 | ±0.29 | ±0.27 | ±0.19 | ±0.23 | ±0.24 | ||

| 5 | −10.45 | −10.69 | −11.31 | −10.25 | −10.43 | −11.01 | −7.66 | −8.28 | −8.96 | |

| ±0.06 | ±0.04 | ±0.05 | ±0.08 | ±0.05 | ±0.07 | ±0.13 | ±0.07 | ±0.1 | ||

| 6 | −9.81 | −10.16 | −10.69 | −10.11 | −10.20 | −10.69 | −8.70 | −8.98 | −9.63 | |

| ±0.45 | ±0.5 | ±0.38 | ±0.42 | ±0.44 | ±0.4 | ±0.19 | ±0.24 | ±0.2 | ||

| 7 | −7.38 | −6.61 | −7.59 | −7.18 | −5.99 | −7.76 | −9.00 | −8.96 | −9.79 | |

| ±0.02 | ±0.05 | ±0.03 | ±0.03 | ±0.03 | ±0.01 | ±0.06 | ±0.07 | ±0.03 | ||

| Simulation | Pattern | Point | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | ||

| Predicted Temperature (°C) ± Error * | 2 | −10.94 | −10.80 | −10.80 | −10.26 | −10.29 | −10.49 | −9.03 | −9.51 | −9.64 |

| 0.62 | 0.56 | 0.33 | 0.43 | 0.09 | 0.41 | −0.77 | −1.17 | −0.39 | ||

| 3 | −11.00 | −10.75 | −10.54 | −10.68 | −10.42 | −10.18 | −9.98 | −9.40 | −9.38 | |

| 1.17 | 1.24 | 1.09 | 0.89 | 0.69 | 1.37 | 0.08 | 0.48 | 1.33 | ||

| 4 | −10.77 | −10.74 | −10.85 | −10.44 | −10.37 | −10.65 | −9.47 | −9.30 | −9.61 | |

| 1.76 | 1.57 | 1.10 | 1.28 | 0.80 | 0.85 | −0.42 | −0.64 | 0.39 | ||

| 5 | −10.62 | −10.57 | −10.64 | −10.35 | −10.65 | −10.65 | −9.27 | −9.62 | −10.19 | |

| −0.18 | 0.12 | 0.67 | −0.10 | −0.22 | 0.36 | −1.61 | −1.33 | −1.23 | ||

| 6 | −10.77 | −10.74 | −10.85 | −10.44 | −10.37 | −10.65 | −9.47 | −9.30 | −9.61 | |

| −0.96 | −0.58 | −0.16 | −0.32 | −0.17 | 0.04 | −0.77 | −0.31 | 0.02 | ||

| 7 | −7.27 | −5.37 | −7.73 | −7.77 | −6.40 | −8.03 | −9.58 | −9.52 | −9.69 | |

| 0.11 | 1.24 | −0.14 | −0.59 | −0.41 | −0.27 | −0.59 | −0.56 | 0.10 | ||

| Pattern | Method | Point | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | |||

| Temperature Rank * | 2 | Experiment | 1 | 2 | 3 | 5 | 6 | 4 | 9 | 8 | 7 |

| Simulation | 1 | 2 | 3 | 6 | 5 | 4 | 9 | 8 | 7 | ||

| 3 | Experiment | 1 | 2 | 3 | 4 | 6 | 5 | 8 | 9 | 7 | |

| Simulation | 1 | 2 | 4 | 3 | 5 | 6 | 7 | 8 | 9 | ||

| 4 | Experiment | 1 | 2 | 3 | 4 | 6 | 5 | 8 | 9 | 7 | |

| Simulation | 2 | 3 | 1 | 5 | 6 | 4 | 8 | 9 | 7 | ||

| 5 | Experiment | 4 | 3 | 1 | 6 | 5 | 2 | 9 | 8 | 7 | |

| Simulation | 4 | 5 | 3 | 6 | 2 | 1 | 9 | 8 | 7 | ||

| 6 | Experiment | 6 | 4 | 2 | 5 | 3 | 1 | 9 | 8 | 7 | |

| Simulation | 2 | 3 | 1 | 5 | 6 | 4 | 8 | 9 | 7 | ||

| 7 | Experiment | 6 | 8 | 5 | 7 | 9 | 4 | 2 | 3 | 1 | |

| Simulation | 7 | 9 | 6 | 5 | 8 | 4 | 2 | 3 | 1 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

So, J.-H.; Joe, S.-Y.; Hwang, S.-H.; Jun, S.; Lee, S.-H. Analysis of the Temperature Distribution in a Refrigerated Truck Body Depending on the Box Loading Patterns. Foods 2021, 10, 2560. https://doi.org/10.3390/foods10112560

So J-H, Joe S-Y, Hwang S-H, Jun S, Lee S-H. Analysis of the Temperature Distribution in a Refrigerated Truck Body Depending on the Box Loading Patterns. Foods. 2021; 10(11):2560. https://doi.org/10.3390/foods10112560

Chicago/Turabian StyleSo, Jun-Hwi, Sung-Yong Joe, Seon-Ho Hwang, Soojin Jun, and Seung-Hyun Lee. 2021. "Analysis of the Temperature Distribution in a Refrigerated Truck Body Depending on the Box Loading Patterns" Foods 10, no. 11: 2560. https://doi.org/10.3390/foods10112560

APA StyleSo, J.-H., Joe, S.-Y., Hwang, S.-H., Jun, S., & Lee, S.-H. (2021). Analysis of the Temperature Distribution in a Refrigerated Truck Body Depending on the Box Loading Patterns. Foods, 10(11), 2560. https://doi.org/10.3390/foods10112560