Cocoa Coproducts-Based and Walnut Oil Gelled Emulsion as Animal Fat Replacer and Healthy Bioactive Source in Beef Burgers

Abstract

:1. Introduction

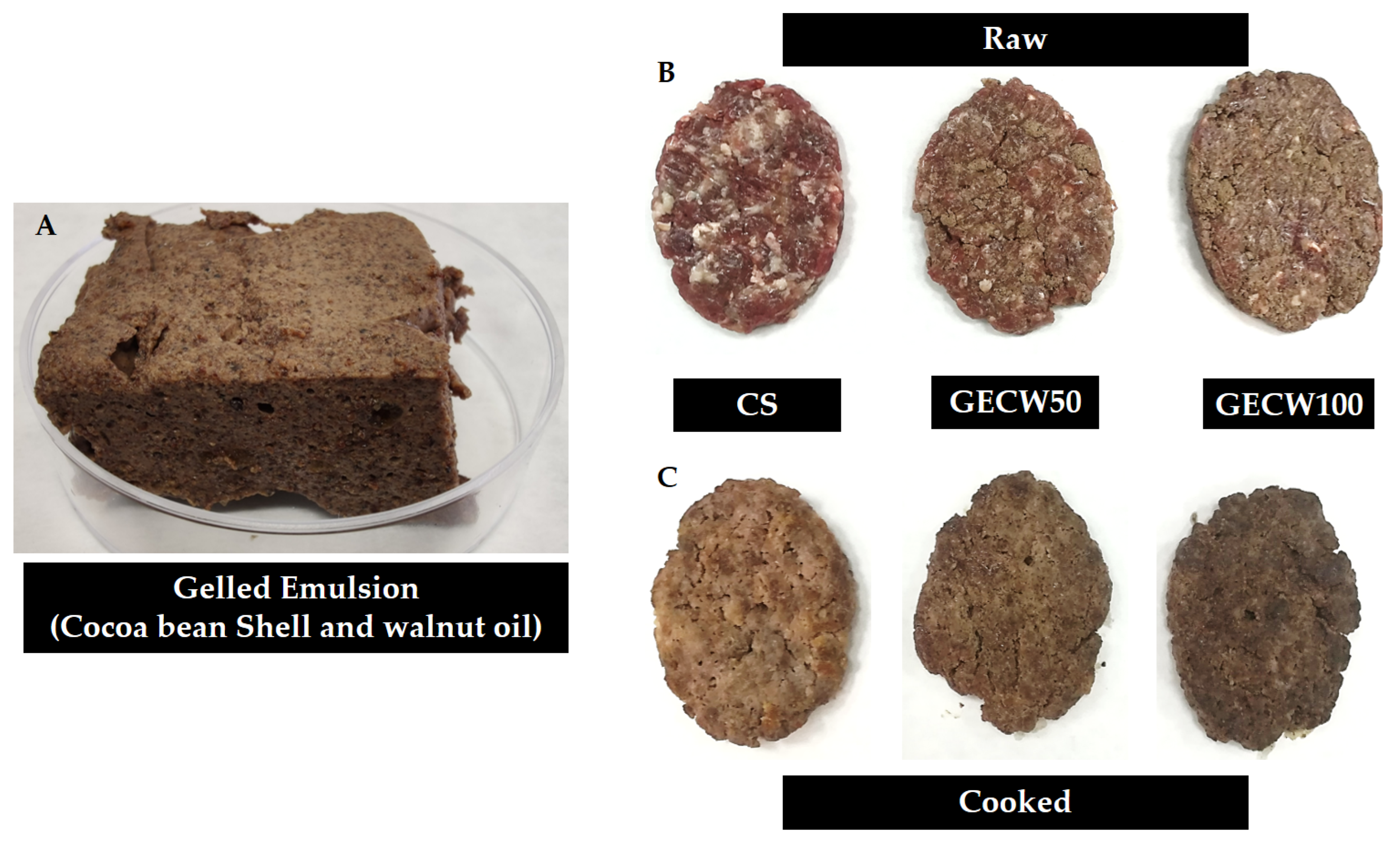

2. Materials and Methods

2.1. Gelled Emulsion Elaboration

2.1.1. Materials

2.1.2. Elaboration of Oil-in-Water-Gelled Emulsion

2.2. Preparation and Reformulation of Beef Burgers

2.3. Chemical Composition of Beef Burgers

2.4. Fatty Acid Profile and Health Indices of Beef Burgers

2.4.1. Fatty Acid Profile

2.4.2. Health Indices

2.5. Physic-Chemical Properties of Beef Burgers

2.5.1. Colour Parameters

2.5.2. pH

2.5.3. Texture

2.6. Cooking Characteristics of Beef Burgers

2.7. Polyphenolic Profile of Beef Burgers

2.7.1. Extract Preparation

2.7.2. High-Performance Liquid Chromatography Analysis

2.8. Methylxanthines Analysis

2.9. Lipid Oxidation of Beef Burgers

2.10. Sensory Analysis of Beef Burgers

2.11. Statistical Analysis

3. Results

3.1. Chemical Composition

3.2. Fatty Acid Profile and Health Indices

3.3. Physic-Chemical Properties

3.4. Physic-Chemical Properties

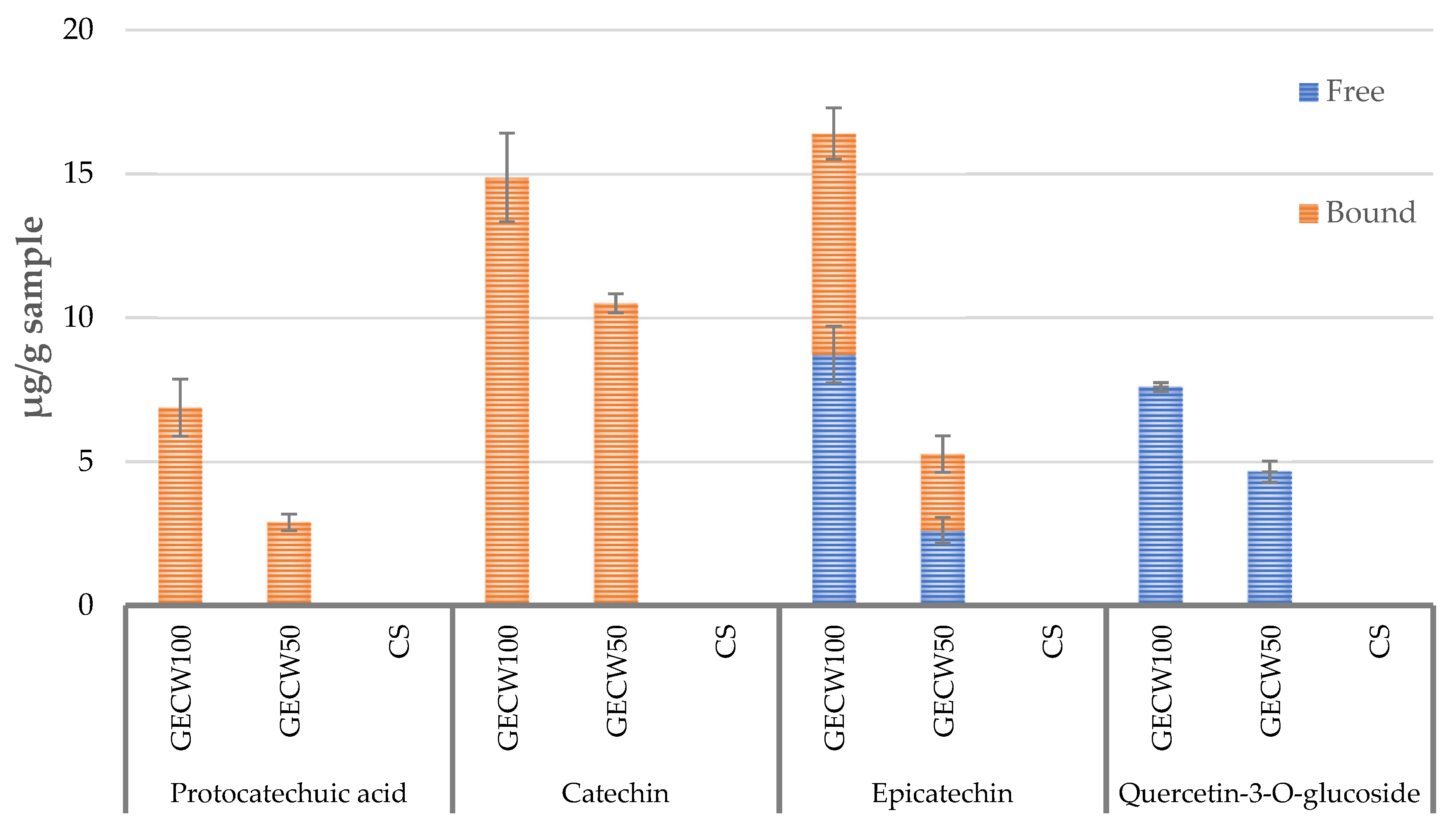

3.5. Polyphenol and Methylxanthines Content

3.6. Lipid Oxidation

3.7. Sensorial Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- de Souza Paglarini, C.; de Figueiredo Furtado, G.; Raissa Honório, A.; Mokarzel, L.; da Silva Vidal, V.A.; Badan Ribeiro, A.P.; Lopes Cunha, R.; Rodrigues Pollonio, M.A. Functional emulsion gels as pork back fat replacers in Bologna sausage. Food Struct. 2019, 20, 100105. [Google Scholar] [CrossRef]

- Jandásek, J. Seasoning in the production of frankfurters and sausages. Maso Int. J. Food Sci. Technol. 2014, 1, 53–62. [Google Scholar]

- Islam, A.; Amin, M.N.; Siddiqui, S.A.; Hossain, P.; Sultana, F.; Kabir, R. Trans fatty acids and lipid profile: A serious risk factor to cardiovascular disease, cancer and diabetes. Diabetes Metab. Syndr. 2019, 13, 1643–1647. [Google Scholar] [CrossRef] [PubMed]

- Granato, D.; Barba, F.J.; Kovačević, D.B.; Lorenzo, J.M.; Cruz, A.G.; Putnik, P. Functional foods: Product development, technological trends, efficacy testing, and safety. Ann. Rev. Food Sci. Technol. 2020, 11, 93–118. [Google Scholar] [CrossRef] [Green Version]

- Chen, Y.; Jia, X.; Sun, F.; Jiang, S.; Liu, H.; Liu, Q.; Kong, B. Using a stable pre-emulsified canola oil system that includes porcine plasma protein hydrolysates and oxidized tannic acid to partially replace pork fat in frankfurters. Meat Sci. 2020, 160, 107968. [Google Scholar] [CrossRef] [PubMed]

- Domínguez, R.; Bohrer, B.; Munekata, P.E.S.; Pateiro, M.; Lorenzo, J.M. Recent discoveries in the field of lipid bio-based ingredients for meat processing. Molecules 2021, 26, 190. [Google Scholar] [CrossRef]

- Öztürk-Kerimoğlu, B.; Kavuşan, H.S.; Gürel, D.B.; Çağındı, Ö.; Serdaroğlu, M. Cold-set or hot-set emulsion gels consisted of a healthy oil blend to replace beef fat in heat-treated fermented sausages. Meat Sci. 2021, 176, 10846. [Google Scholar] [CrossRef]

- Botella-Martínez, C.; Viuda-Martos, M.; Pérez-Álvarez, J.A.; Fernández-López, J. Total and partial fat replacement by gelled 29 emulsion (hemp oil and buckwheat flour) and its impact on the chemical, technological and sensory properties of frankfurters. Foods 2021, 10, 1681. [Google Scholar] [CrossRef]

- Barros, J.C.; Munekata, P.E.S.; de Carvalho, F.A.L.; Domínguez, R.; Trindade, M.A.; Pateiro, M.; Lorenzo, J.M. Healthy beef burgers: Effect of animal fat replacement by algal and wheat germ oil emulsions. Meat Sci. 2021, 173, 108396. [Google Scholar] [CrossRef]

- Nacak, B.; Kerimoğlu, B.; Yıldız, D.; Çağındı, Ö.; Serdaroğlu, M. Peanut and linseed oil emulsion gels as potential fat 40 replacer in emulsified sausages. Meat Sci. 2021, 176, 108464. [Google Scholar] [CrossRef]

- Pintado, T.; Herrero, A.M.; Jiménez-Colmenero, F.; Pasqualin Cavalheiro, C.; Ruiz-Capillas, C. Chia and oat emulsion gels as new animal fat replacers and healthy bioactive sources in fresh sausage formulation. Meat Sci. 2018, 135, 6–13. [Google Scholar] [CrossRef] [PubMed]

- Herrero, A.M.; Ruiz-Capillas, C.; Pintado, T.; Carmona, P.; Jiménez-Colmenero, F. Elucidation of lipid structural characteristics of chia oil emulsion gels by Raman spectroscopy and their relationship with technological properties. Food Hydrocol. 2018, 77, 212–219. [Google Scholar] [CrossRef]

- Xu, Q.; Qi, B.; Han, L.; Wang, D.; Zhang, S.; Jiang, L.; Xie, F.; Li, Y. Study on the gel properties, interactions, and pH stability of pea protein isolate emulsion gels as influenced by inulin. LWT Food Sci. Technol. 2021, 137, 110421. [Google Scholar] [CrossRef]

- Hernández-Hernández, C.; Morales-Sillero, A.; Fernández-Bolaños, J.; Bermúdez-Oria, A.; Morales, A.A.; Rodríguez-Gutiérrez, G. Cocoa bean husk: Industrial source of antioxidant phenolic extract. J. Sci. Food Agric. 2019, 99, 325–333. [Google Scholar] [CrossRef] [PubMed]

- Botella-Martínez, C.; Lucas-Gonzalez, R.; Ballester-Costa, C.; Pérez-Álvarez, J.Á.; Fernández-López, J.; Delgado-Ospina, J.; Chaves-López, C.; Viuda-Martos, M. Ghanaian cocoa (Theobroma cacao L.) bean shells coproducts: Effect of particle size on chemical composition, bioactive compound content and antioxidant activity. Agronomy 2021, 11, 401. [Google Scholar] [CrossRef]

- American Meat Science Association (AMSA). Research Guidelines for Cookery, Sensory Evaluation and Instrumental Tenderness Measurements of Fresh Meat; American Meat Science Association: Chicago, IL, USA, 1995; pp. 1–48. [Google Scholar]

- Association of Official Analytical Chemists (AOAC). Official Methods of Analysis of AOAC International, 19th ed.; Association of Official Analytical Chemists: Gaithersburg, MD, USA, 2012. [Google Scholar]

- Folch, J.; Lees, M.; Stanley, G.S. A simple method for the isolation and purification of total lipides from animal tissues. J. Biol. Chem. 1957, 226, 497–509. [Google Scholar] [CrossRef]

- Golay, P.A.; Moulin, J. Determination of labeled fatty acids content in milk products, infant formula, and adult/pediatric nutritional formula by capillary gas chromatography: Collaborative study, Final Action 2012.13. J. AOAC Int. 2016, 99, 210–222. [Google Scholar] [CrossRef] [Green Version]

- Pellegrini, M.; Lucas-Gonzales, R.; Ricci, A.; Fontecha, J.; Fernández-López, J.; Pérez-Álvarez, J.A.; Viuda-Martos, M. Chemical, 34 fatty acid, polyphenolic profile, techno-functional and antioxidant properties of flours obtained from quinoa (Chenopodium quinoa Willd) seeds. Ind. Crop Prod. 2018, 111, 38–46. [Google Scholar] [CrossRef]

- Ulbricht, T.L.V.; Southgate, D.A.T. Coronary heart disease: Seven dietary factors. Lancet 1991, 338, 985–992. [Google Scholar] [CrossRef]

- Fernández, M.; Ordóñez, J.A.; Cambero, I.; Santos, C.; Pin, C.; de la Hoz, L. Fatty acid compositions of selected varieties of Spanish dry ham related to their nutritional implications. Food Chem. 2007, 101, 107–112. [Google Scholar] [CrossRef]

- Hunt, M.C.; Acton, J.C.; Benedict, R.C.; Calkins, C.R.; Cornforth, D.P.; Jeremiah, L.E.; Olson, D.G.; Salm, C.P.; Sawell, J.W.; Shivas, S.D. Guidelines for Meat Color Evaluation; American Meat Science Association and National Live Stock and Meat Board: Chicago, IL, USA, 1991; pp. 1–12. [Google Scholar]

- Sánchez-Zapata, E.; Fuentes-Zaragoza, E.; Navarro-Rodríguez de Vera, C.; Sayas, E.; Sendra, E.; Fernández-López, J.; Pérez-Alvarez, J.A. Effects of tuna pâté thickness and background on CIEL*a*b* color parameters and reflectance spectra. Food Control 2011, 22, 1226–1232. [Google Scholar] [CrossRef]

- Bourne, M.C. Texture profile analysis. Food Technol. 1978, 32, 62–65. [Google Scholar]

- Genskowsky, E.; Puente, L.A.; Pérez-Álvarez, J.A.; Fernández-López, J.; Muñoz, L.A.; Viuda-Martos, M. Determination of polyphenolic profile, antioxidant activity and antibacterial properties of maqui [Aristotelia chilensis (Molina) Stuntz] a Chilean blackberry. J. Sci. Food Agric. 2016, 96, 4235–4242. [Google Scholar] [CrossRef]

- Mpofu, A.; Sapirstein, H.D.; Beta, T. Genotype and environmental variation in phenolic content, phenolic acid composition, and antioxidant activity of hard spring wheat. J. Agric. Food Chem. 2006, 54, 1265–1270. [Google Scholar] [CrossRef] [PubMed]

- Grillo, G.; Boffa, L.; Binello, A.; Mantegna, S.; Cravotto, G.; Chemat, F.; Dizhbite, T.; Lauberte, L.; Telysheva, G. Cocoa bean shell waste valorisation; extraction from lab to pilot-scale cavitational reactors. Food Res. Int. 2019, 115, 200–208. [Google Scholar] [CrossRef]

- Rosmini, M.R.; Perlo, F.; Perez-Alvarez, J.A.; Pagan-Moreno, M.J.; Gago-Gago, M.A.; Lopez-Santoveña, F.; Aranda-Catala, V. TBA test by extractive method applied to pate. Meat Sci. 1996, 42, 103–110. [Google Scholar] [CrossRef]

- Serdaroğlu, M.; Nacak, B.; Karabiylkoglu, M. Effects of beef fat replacement with gelled emulsion prepared with olive oil on quality parameters of chicken patties. Korean J. Food Sci. Anim. Resour. 2017, 37, 376–384. [Google Scholar]

- Alejandre, M.; Astiasarán, I.; Ansorena, D.; Barbut, S. Using canola oil hydrogels and organogels to reduce saturated animal fat in meat batters. Food Res. Int. 2019, 122, 129–136. [Google Scholar] [CrossRef]

- Lucas-Gonzalez, R.; Roldán-Verdu, A.; Sayas-Barberá, E.; Fernández-López, J.; Pérez-Álvarez, J.A.; Viuda-Martos, M. Assessment of emulsion gels formulated with chestnut (Castanea sativa M.) flour and chia (Salvia hispanica L.) oil as partial fat replacers in pork burger formulation. J. Sci. Food Agric. 2020, 100, 1265–1273. [Google Scholar] [CrossRef]

- Cittadini, A.; Munekata, P.E.S.; Pateiro, M.; Sarriés, M.V.; Domínguez, R.; Lorenzo, J.M. Physicochemical composition and nutritional properties of foal burgers enhanced with healthy oil emulsion hydrogels. Int. J. Food Sci. Technol. 2021, in press. [Google Scholar] [CrossRef]

- Vargas-Ramella, M.; Munekata, P.E.S.; Pateiro, M.; Franco, D.; Campagnol, P.C.B.; Tomasevic, I.; Domínguez, R.; Lorenzo, J.M. Physicochemical composition and nutritional properties of deer burger enhanced with healthier oils. Foods 2020, 9, 571. [Google Scholar] [CrossRef]

- Heck, R.T.; Jordana Lima da Rosa, J.; Guidetti Vendruscolo, R.; Cichoski, A.J.; Dillenburg Meinhart, A.; Lorini, A.; Trindade Paim, B.; Galli, V.; Sasso Robalo, S.; Alves Dos Santos, B.; et al. Lipid oxidation and sensory characterization of Omega-3 rich buffalo burgers enriched with chlorogenic acids from the mate (Ilex paraguariensis) tree harvesting residues. Meat Sci. 2021, 179, 108534. [Google Scholar] [CrossRef]

- Heck, R.T.; Saldaña, E.; Lorenzo, J.M.; Pereira Correa, L.; Bittencourt Fagundes, M.; Cichoski, A.J.; Ragagnin de Menezes, C.; Wagner, R.; Campagnol, P.C.B. Hydrogelled emulsion from chia and linseed oils: A promising strategy to produce low-fat burgers with a healthier lipid profile. Meat Sci. 2019, 156, 174–182. [Google Scholar] [CrossRef]

- Food and Agriculture Organization of the United Nations. Fat and fatty acid requirements for adults. In Fats and Fatty Acids in Human Nutrition; FAO: Rome, Italy, 2010; Volume 91. [Google Scholar]

- Lu, F.; Kuhnle, G.K.; Cheng, Q. Vegetable oil as fat replacer inhibits formation of heterocyclic amines and polycyclic aromatic hydrocarbons in reduced fat pork patties. Food Control 2017, 81, 113–125. [Google Scholar] [CrossRef]

- Kim, T.K.; Hwang, K.E.; Sung, J.M.; Park, J.D.; Kim, M.H.; Jeon, K.H.; Kim, Y.B.; Cho, Y.S. Replacement of pork back fat with pre-emulsion of wheat (Triticum aestivum L.) sprout and collagen and its optimization for reduced-fat patties. J. Food Process. Preserv. 2018, 42, e13576. [Google Scholar] [CrossRef]

- Heck, R.T.; Freitas Ferreira, D.; Bittencourt Fagundes, M.; Alves Dos Santos, B.; Cichoski, A.J.; Saldaña, E.; Lorenzo, J.M.; de Menezes, C.R.; Wagner, R.; Barin, J.; et al. Jabuticaba peel extract obtained by microwave hydro-diffusion and gravity extraction: A green strategy to improve the oxidative and sensory stability of beef burgers produced with healthier oils. Meat Sci. 2020, 170, 108230. [Google Scholar] [CrossRef]

- Pintado, T.; Ruiz-Capillas, C.; Jiménez-Colmenero, F.; Carmona, P.; Herrero, A.M. Oil-in-water emulsion gels stabilized with chia (Salvia hispanica L.) and cold gelling agents: Technological and infrared spectroscopic characterization. Food Chem. 2015, 185, 470–478. [Google Scholar] [CrossRef] [PubMed]

- Martínez, J.A.; Melgosa, M.; Pérez, M.; Hita, E.; Negueruela, A.I. Visual and instrumental color evaluation in red wines. Food Sci. Technol. Int. 2001, 7, 439–444. [Google Scholar] [CrossRef]

- Třešňák, K. Barvy a barevné modely. Svět Tisku 1999, 6, 58–60. [Google Scholar]

- Freire, M.; Cofrades, S.; Serrano-Casas, V.; Pintado, T.; Jimenez, M.J.; Jimenez-Colmenero, F. Gelled double emulsions as delivery systems for hydroxytyrosol and n-3 fatty acids in healthy pork patties. J. Food Sci. Technol. 2017, 54, 3959–3968. [Google Scholar] [CrossRef]

- de Oliveira Fagundes, D.T.; Lorenzo, J.M.; dos Santos, B.; Fagundes, M.; Heck, R.; Cichoski, A.; Wagner, R.; Campagnol, P.C.B. Pork skin and canola oil as strategy to confer technological and nutritional advantages to burgers. Czech J. Food Sci. 2017, 35, 352–359. [Google Scholar]

- Barros, J.C.; Munekata PE, S.; De Carvalho FA, L.; Pateiro, M.; Barba, F.J.; Domínguez, R.; Trindade, M.A.; Lorenzo, J.M. Use of tiger nut (Cyperus esculentus L.) oil emulsion as animal fat replacement in beef burgers. Foods 2020, 9, 44. [Google Scholar] [CrossRef] [Green Version]

- Domínguez, R.; Gómez, M.; Fonseca, S.; Lorenzo, J.M. Influence of thermal treatment on formation of volatile compounds, cooking loss and lipid oxidation in foal meat. LWT Food Sci. Technol. 2014, 58, 439–445. [Google Scholar] [CrossRef]

- Vaskoska, R.; Ha, M.; Naqvi, Z.B.; White, J.D.; Warner, R.D. Muscle, ageing and temperature influence the changes in texture, cooking loss and shrinkage of cooked beef. Foods 2020, 9, 1289. [Google Scholar] [CrossRef]

- Serdaroglu, M.; Degirmencioglu, O. Effects of fat level 5%, 10%, 20% and corn flour 0%, 2%, 4% on some properties of Turkish type meatballs koefte. Meat Sci. 2004, 68, 291–296. [Google Scholar] [CrossRef] [PubMed]

- Jokíc, S.; Gagíc, T.; Knez, Z.; Šubaríc, D.; Škerget, M. Separation of active compounds from food by-product (cocoa shell) using subcritical water extraction. Molecules 2018, 23, 1408. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Papillo, V.A.; Locatelli, M.; Travaglia, F.; Bordiga, M.; Garino, C.; Coïsson, J.D.; Arlorio, M. Cocoa hulls polyphenols stabilized by microencapsulation as functional ingredient for bakery applications. Food Res. Int. 2019, 115, 511–518. [Google Scholar] [CrossRef] [PubMed]

- Santana, A.L.; Macedo, G.A. Health and technological aspects of methylxanthines and polyphenols from guarana: A review. J. Funct. Foods 2018, 47, 457–468. [Google Scholar] [CrossRef]

- Zhang, Y.; Holman, B.W.B.; Ponnampalam, E.N.; Kerr, M.G.; Bailes, K.L.; Kilgannon, A.K.; Collins, D.; Hopkins, D.L. Understanding beef flavour and overall liking traits using two different methods for determination of thiobarbituric acid reactive substance (TBARS). Meat Sci. 2019, 149, 114–119. [Google Scholar] [CrossRef]

- Longato, E.; Meineri, G.; Peiretti, P.G.; Gai, F.; Viuda-Martos, M.; Pérez-Álvarez, J.A.; Amarowicz, R.; Fernández-López, J. Effects of hazelnut skin addition on the cooking, antioxidant and sensory properties of chicken burgers. J. Food Sci. Technol. 2019, 56, 3329–3336. [Google Scholar] [CrossRef]

- Gómez-Estaca, J.; Pintado, T.; Jiménez-Colmenero, F.; Cofrades, S. The effect of household storage and cooking practices on quality attributes of pork burgers formulated with PUFA- and curcumin-loaded oleogels as healthy fat substitutes. LWT Food Sci. Technol. 2020, 119, 108909. [Google Scholar] [CrossRef]

| Treatments (%) | |||

|---|---|---|---|

| CS | GECW50 | GECW100 | |

| Beef | 70 | 70 | 70 |

| Pork backfat | 30 | 15 | 0 |

| Water | 5 | 5 | 5 |

| Salt | 1.5 | 1.5 | 1.5 |

| White pepper | 0.05 | 0.05 | 0.05 |

| GECW | 0 | 15 | 30 |

| Raw | Cooked | |||||

|---|---|---|---|---|---|---|

| CS | GECW50 | GECW100 | CS | GECW50 | GECW100 | |

| Moisture | 61.90 ± 0.14 c | 66.76 ± 0.09 b | 68.20 ± 0.09 a | 55.60 ± 0.31 c | 57.14 ± 0.06 b | 60.01 ± 0.08 a |

| Protein | 19.75 ± 1.41 a | 17.92 ± 1.09 b | 14.16 ± 1.36 c | 26.11 ± 0.15 a | 23.16 ± 0.39 b | 19.90 ± 0.50 c |

| Fat | 15.93 ± 0.09 a | 12.63 ± 0.24 b | 11.38 ± 0.10 c | 12.30 ± 0.11 b | 16.48 ± 0.11 a | 16.31 ± 1.10 a |

| Ash | 1.94 ± 0.04 b | 2.21 ± 0.16 a | 2.25 ± 0.04 a | 2.22 ± 0.03 b | 2.43 ± 0.05 a | 2.50 ± 0.09 a |

| Fatty Acid Profile | ||||||

|---|---|---|---|---|---|---|

| Raw | Cooked | |||||

| CS | GECW50 | GECW100 | CS | GECW50 | GECW100 | |

| C10:0 | 0.06 ± 0.01 a | 0.04 ± 0.01 a | 0.02 ± 0.00 b | 0.06 ± 0.00 a | 0.03 ± 0.00 b | 0.02 ± 0.00 b |

| C12:0 | 0.06 ± 0.01 a | 0.04 ± 0.01 ab | 0.03 ± 0.00 b | 0.06 ± 0.00 a | 0.04 ± 0.00 b | 0.03 ± 0.00 b |

| C14:0 | 1.30 ± 0.11 a | 0.91 ± 0.07 b | 0.98 ± 0.08 b | 1.55 ± 0.06 a | 0.92 ± 0.08 b | 0.90 ± 0.04 b |

| C14:1 | 0.14 ± 0.04 ab | 0.12 ± 0.02 b | 0.22 ± 0.05 a | 0.26 ± 0.02 a | 0.15 ± 0.04 b | 0.19 ± 0.02 b |

| C15:0 | 0.09 ± 0.02 b | 0.09 ± 0.01 b | 0.19 ± 0.03 a | 0.17 ± 0.01 a | 0.11 ± 0.02 b | 0.18 ± 0.01 a |

| C15:1 | 0.14 ± 0.03 b | 0.22 ± 0.03 a | 0.08 ± 0.01 c | 0.30 ± 0.02 a | 0.17 ± 0.01 b | 0.07 ± 0.00 c |

| C16:0 | 22.45 ± 1.25 a | 17.01 ± 1.04 b | 14.98 ± 1.25 | 24.22 ± 1.04 a | 16.42 ± 0.87 b | 14.40 ± 0.63 c |

| C16:1 | 3.53 ± 0.49 a | 2.18 ± 0.38 b | 1.44 ± 0.54 c | 3.63 ± 0.84 a | 2.18 ± 0.24 b | 1.34 ± 0.09 c |

| C17:0 | 0.28 ± 0.06 ab | 0.24 ± 0.07 b | 0.36 ± 0.04 a | 0.43 ± 0.01 a | 0.26 ± 0.02 c | 0.35 ± 0.04 b |

| C17:1 | 0.32 ± 0.07 a | 0.22 ± 0.05 b | 0.22 ± 0.03 b | 0.38 ± 0.05 a | 0.23 ± 0.04 b | 0.23 ± 0.04 b |

| C18:0 | 9.77 ± 0.96 a | 7.92 ± 0.87 b | 7.93 ± 0.87 b | 11.95 ± 0.94 a | 7.63 ± 0.97 c | 7.75 ± 0.98 b |

| C18:1n-9 | 48.99 ± 1.79 a | 34.69 ± 1.42 b | 23.48 ± 1.22 c | 45.35 ± 2.07 a | 33.42 ± 1.19 b | 22.89 ± 1.20 c |

| C18:2n-6 | 9.67 ± 1.08 c | 28.65 ± 1.37 b | 40.42 ± 2.04 a | 8.42 ± 1.28 c | 30.55 ± 1.04 b | 41.46 ± 2.08 a |

| C18:3n-3 | 0.62 ± 0.02 c | 5.40 ± 0.89 b | 8.48 ± 0.68 a | 0.77 ± 0.03 c | 5.82 ± 0.44 b | 8.67 ± 0.79 a |

| C20:0 | 0.17 ± 0.01 a | 0.15 ± 0.04 a | 0.12 ± 0.05 a | 0.16 ± 0.01 a | 0.14 ± 0.04 a | 0.12 ± 0.04 a |

| C20:1 | 0.88 ± 0.04 a | 0.54 ± 0.06 b | 0.17 ± 0.03 c | 0.66 ± 0.04 a | 0.48 ± 0.07 b | 0.17 ± 0.03 c |

| C20:2n-11 | 0.48 ± 0.03 a | 0.25 ± 0.08 b | 0.04 ± 0.00 c | 0.34 ± 0.04 a | 0.23 ± 0.04 b | 0.05 ± 0.00 c |

| C20:3n-8 | 0.14 ± 0.01 a | 0.12 ± 0.03 a | 0.08 ± 0.01 b | 0.19 ± 0.03 a | 0.11 ± 0.02 b | 0.10 ± 0.01 b |

| C20:3n-11 | 0.38 ± 0.02 a | 0.33 ± 0.07 a | 0.12 ± 0.02 b | 0.54 ± 0.02 a | 0.30 ± 0.02 b | 0.24 ± 0.04 b |

| C24:0 | 0.07 ± 0.01 a | 0.08 ± 0.02 a | 0.05 ± 0.01 a | 0.13 ± 0.02 a | 0.07 ± 0.00 b | 0.07 ± 0.01 b |

| ΣSFA | 34.38 ± 1.23 a | 26.58 ± 1.37 b | 24.75 ± 1.80 b | 38.85 ± 1.63 a | 25.70 ± 1.73 b | 23.90 ± 1.85 b |

| ΣMUFA | 54.17 ± 1.57 a | 38.07 ± 1.49 b | 25.77 ± 1.73 c | 50.75 ± 1.42 a | 36.76 ± 1.55 b | 25.01 ± 1.09 c |

| ΣPUFA | 11.38 ± 0.96 c | 35.03 ± 1.11 b | 49.02 ± 1.48 a | 10.35 ± 0.74 c | 37.19 ± 1.89 b | 50.63 ± 2.24 a |

| Health Indices | ||||||

| Raw | Cooked | |||||

| CS | GECW50 | GECW100 | CS | GECW50 | GECW100 | |

| ΣPUFA/ΣSFA | 0.33 ± 0.08 c | 1.33 ± 0.21 b | 1.98 ± 0.18 a | 0.27 ± 0.07 c | 1.44 ± 0.03 b | 2.12 ± 0.04 a |

| Σn-3 | 0.99 ± 0.06 c | 5.78 ± 0.84 b | 8.60 ± 0.94 a | 1.32 ± 0.09 c | 6.15 ± 0.88 b | 8.91 ± 0.73 a |

| Σn-6 | 10.38 ± 0.57 c | 29.20 ± 1.22 b | 40.42 ± 1.74 a | 9.03 ± 0.78 c | 31.00 ± 1.22 b | 41.71 ± 1.74 a |

| Σn-6/Σn-3 | 10.48 ± 0.34 a | 5.05 ± 0.73 b | 4.07 ± 0.61 c | 6.84 ± 0.88 a | 5.04 ± 0.63 b | 4.68 ± 0.57 b |

| h/H | 2.54 ± 0.14 c | 3.89 ± 0.12 b | 4.54 ± 0.75 a | 2.16 ± 0.24 | 4.07 ± 0.83 | 4.80 ± 0.72 a |

| AI | 0.42 ± 0.04 a | 0.28 ± 0.08 b | 0.25 ± 0.06 b | 0.50 ± 0.07 a | 0.27 ± 0.04 b | 0.24 ± 0.05 b |

| TI | 0.94 ± 0.07 a | 0.50 ± 0.04 b | 0.40 ± 0.06 b | 1.11 ± 0.04 a | 0.47 ± 0.07 b | 0.38 ± 0.04 b |

| Raw | Cooked | |||||

|---|---|---|---|---|---|---|

| CS | GECW50 | GECW100 | CS | GECW50 | GECW100 | |

| pH | 5.82 ± 0.01 a | 5.72 ± 0.02 b | 5.64 ± 0.02 c | 5.90 ± 0.02 a | 5.78 ± 0.04 b | 5.68 ± 0.11 c |

| L* | 38.54 ± 4.03 b | 42.29 ± 2.07 a | 42.43 ± 1.66 a | 44.06 ± 3.27 a | 39.57 ± 4.06 b | 39.01 ± 4.50 b |

| a* | 7.96 ± 2.30 a | 7.33 ± 0.88 a | 7.56 ± 0.67 a | 4.86 ± 0.81 a | 5.54 ± 0.66 a | 5.47 ± 0.51 a |

| b* | 9.29 ± 1.62 b | 11.16 ± 0.90 a | 10.86 ± 0.95 a | 11.37 ± 1.32 a | 9.56 ± 1.51 b | 9.24 ± 1.18 b |

| C* | 12.30 ± 2.49 b | 13.36 ± 1.13 a | 13.25 ± 0.99 a | 12.40 ± 1.21 a | 11.07 ± 1.45 b | 10.77 ± 0.99 b |

| h* | 50.08 ± 6.54 b | 56.77 ± 2.43 a | 55.12 ± 2.55 a | 66.67 ± 4.52 a | 59.57 ± 4.44 b | 59.05 ± 4.56 b |

| ΔE | --- | 4.57 ± 1.72 a | 4.36 ± 1.71 a | --- | 5.50 ± 3.59 a | 5.94 ± 4.14 a |

| CS | GECW50 | GECW100 | |

|---|---|---|---|

| Cooking loss (%) | 28.04 ± 0.79 a | 25.44 ± 0.25 b | 22.62 ± 1.41 c |

| Shrinkage (%) | 19.77 ± 0.91 a | 17.99 ± 1.16 b | 17.27 ± 1.03 b |

| Thickness increase (%) | 12.48 ± 0.81 a | 10.44 ± 0.33 b | 7.14 ± 0.12 c |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Botella-Martinez, C.; Lucas-González, R.; Lorenzo, J.M.; Santos, E.M.; Rosmini, M.; Sepúlveda, N.; Teixeira, A.; Sayas-Barberá, E.; Pérez-Alvarez, J.A.; Fernandez-Lopez, J.; et al. Cocoa Coproducts-Based and Walnut Oil Gelled Emulsion as Animal Fat Replacer and Healthy Bioactive Source in Beef Burgers. Foods 2021, 10, 2706. https://doi.org/10.3390/foods10112706

Botella-Martinez C, Lucas-González R, Lorenzo JM, Santos EM, Rosmini M, Sepúlveda N, Teixeira A, Sayas-Barberá E, Pérez-Alvarez JA, Fernandez-Lopez J, et al. Cocoa Coproducts-Based and Walnut Oil Gelled Emulsion as Animal Fat Replacer and Healthy Bioactive Source in Beef Burgers. Foods. 2021; 10(11):2706. https://doi.org/10.3390/foods10112706

Chicago/Turabian StyleBotella-Martinez, Carmen, Raquel Lucas-González, José M. Lorenzo, Eva María Santos, Marcelo Rosmini, Néstor Sepúlveda, Alfredo Teixeira, Estrella Sayas-Barberá, Jose A. Pérez-Alvarez, Juana Fernandez-Lopez, and et al. 2021. "Cocoa Coproducts-Based and Walnut Oil Gelled Emulsion as Animal Fat Replacer and Healthy Bioactive Source in Beef Burgers" Foods 10, no. 11: 2706. https://doi.org/10.3390/foods10112706

APA StyleBotella-Martinez, C., Lucas-González, R., Lorenzo, J. M., Santos, E. M., Rosmini, M., Sepúlveda, N., Teixeira, A., Sayas-Barberá, E., Pérez-Alvarez, J. A., Fernandez-Lopez, J., & Viuda-Martos, M. (2021). Cocoa Coproducts-Based and Walnut Oil Gelled Emulsion as Animal Fat Replacer and Healthy Bioactive Source in Beef Burgers. Foods, 10(11), 2706. https://doi.org/10.3390/foods10112706